Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Prevent pulsation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

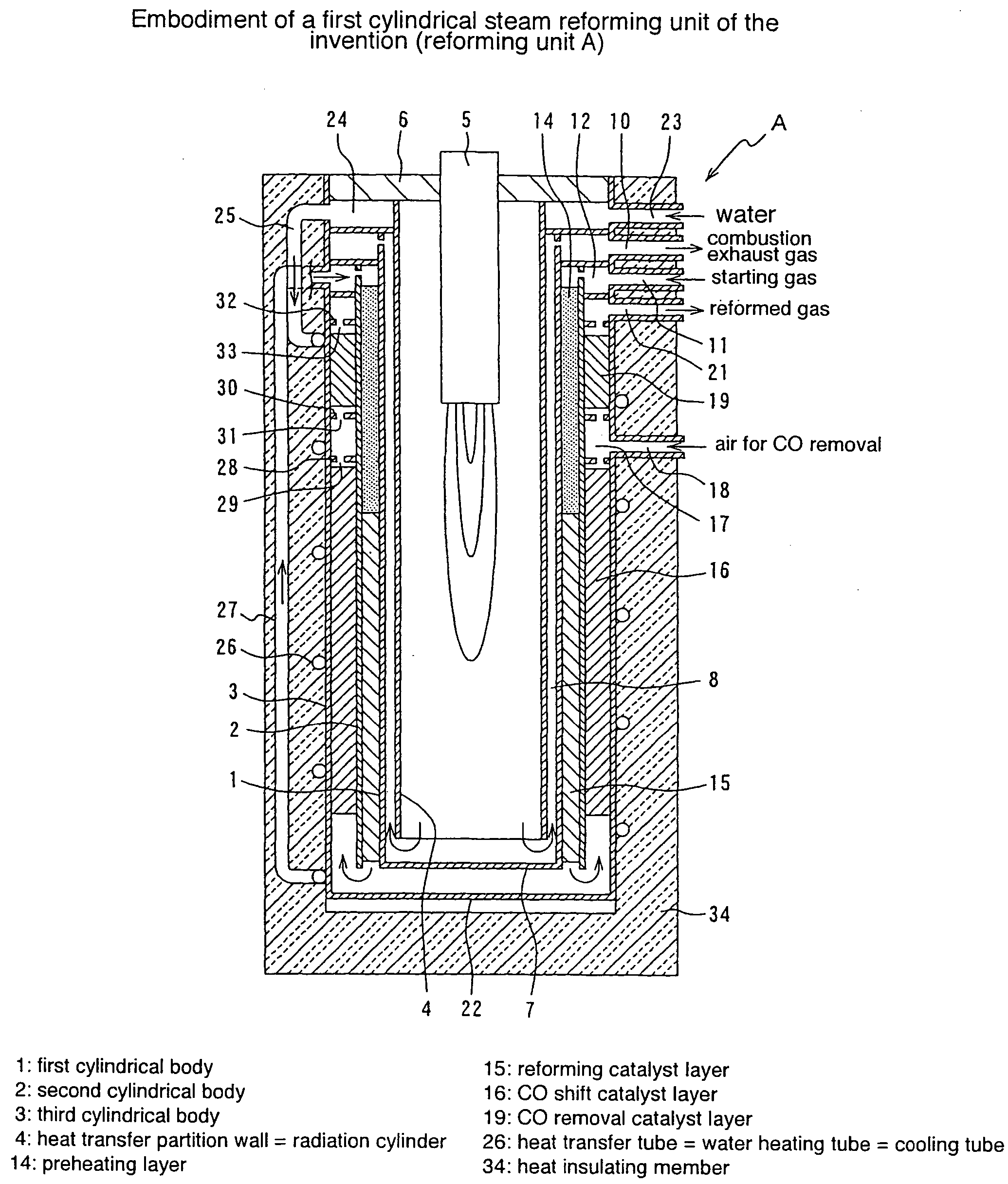

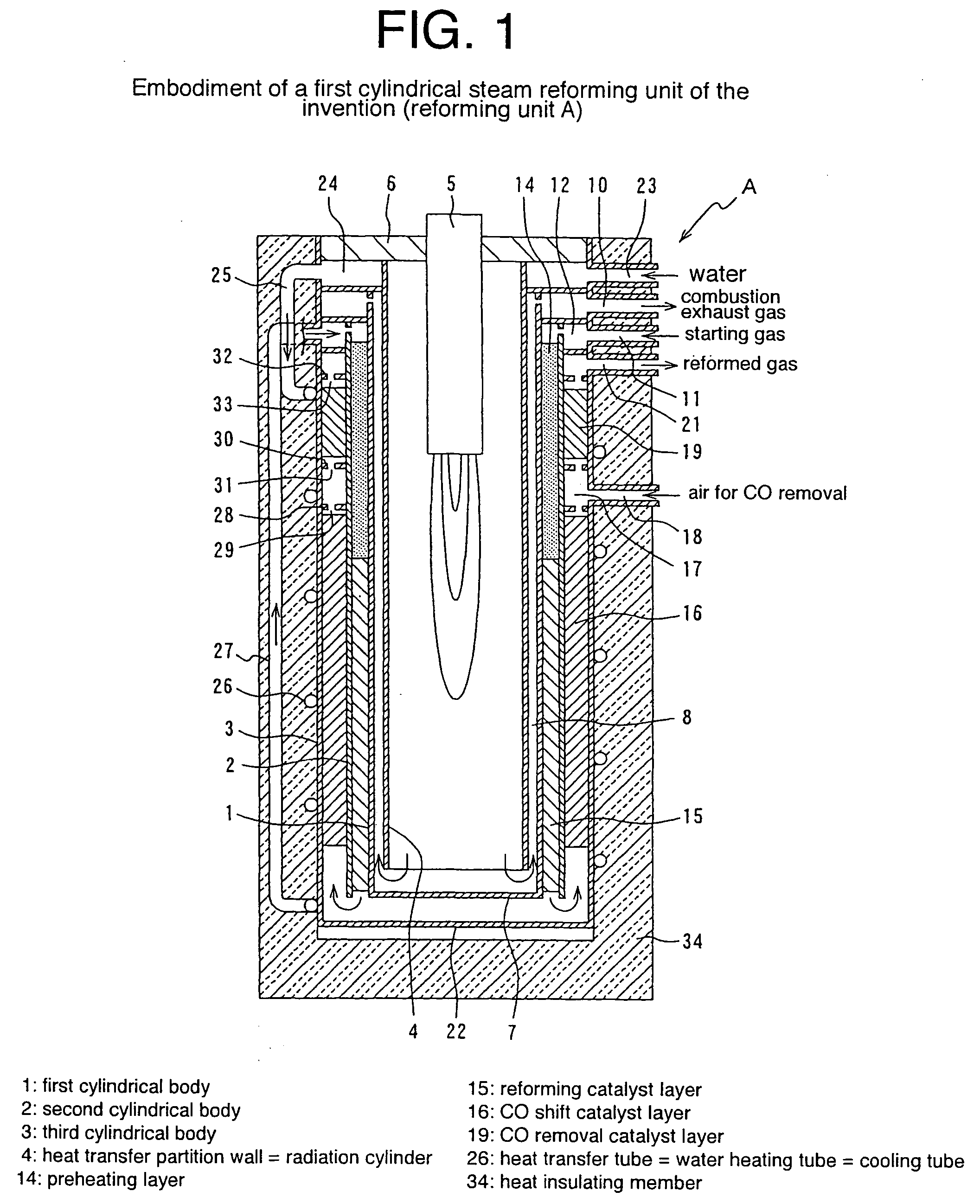

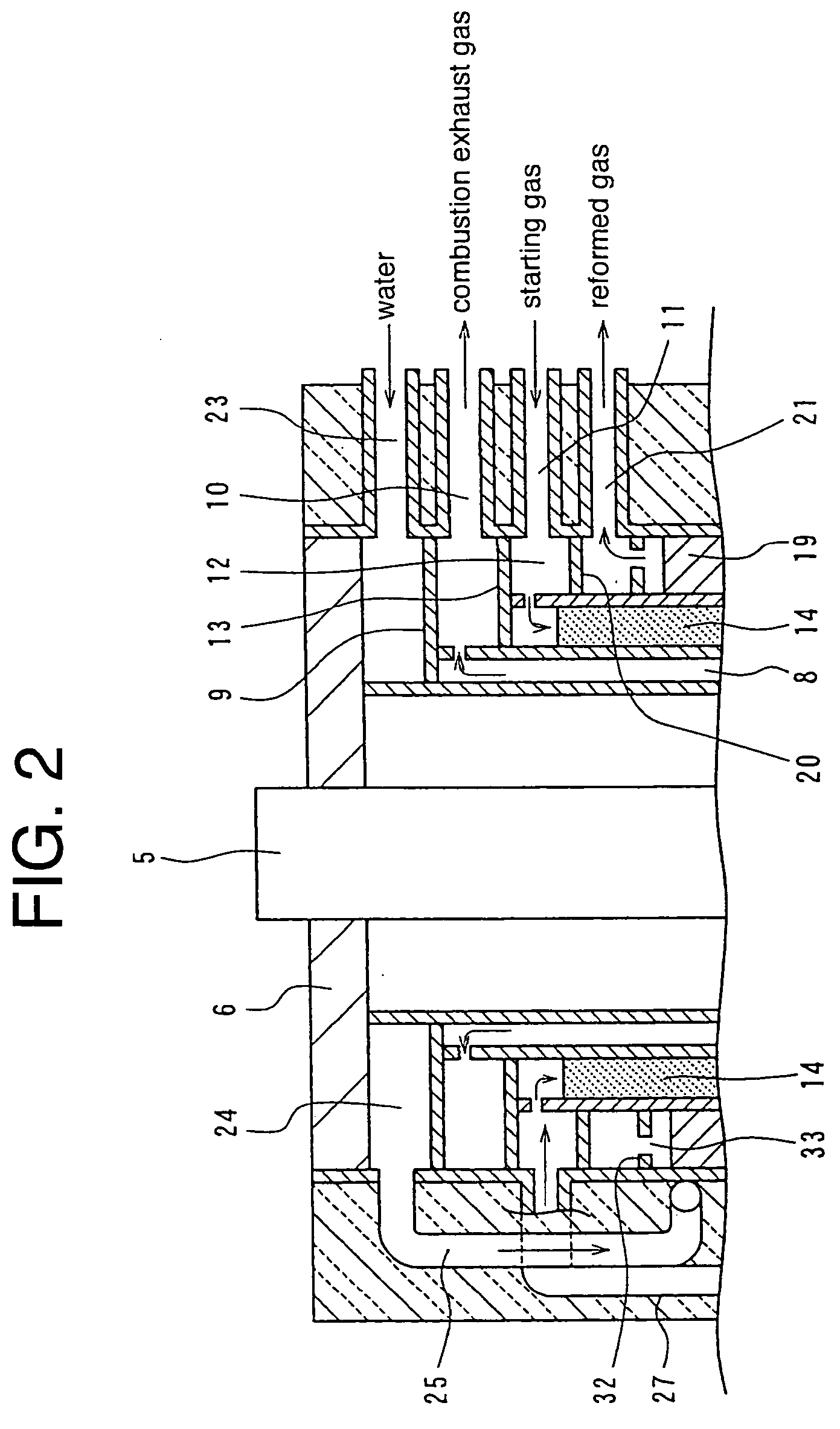

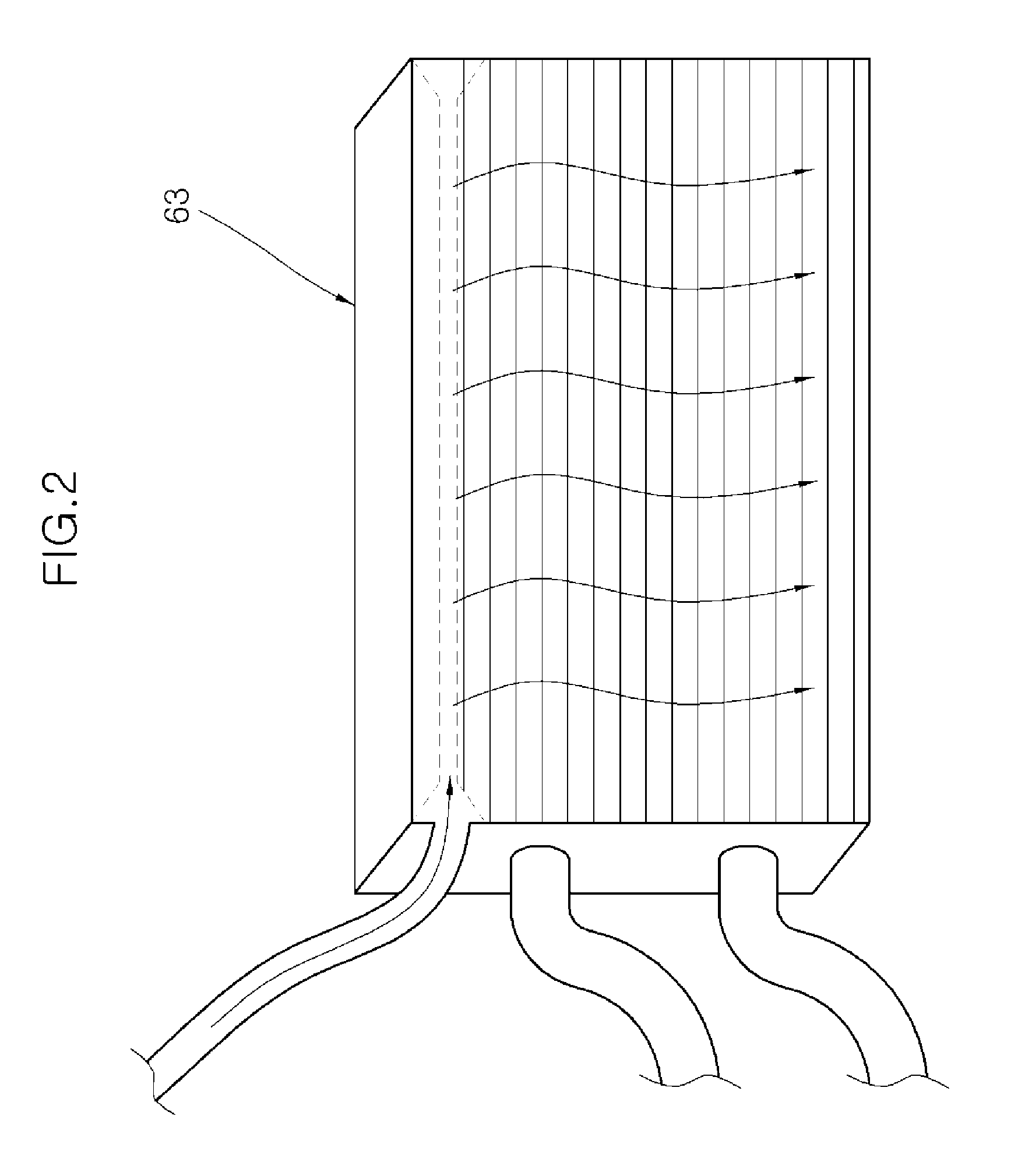

Cylindrical water vapor reforming unit

InactiveUS20040144029A1Small sizePass smoothlyHydrogen/synthetic gas productionChemical/physical/physico-chemical processesSteam reformingInsulation layer

A cylindrical steam reforming unit comprising a plurality of cylindrical bodies consisting of a first cylindrical body, a second cylindrical body and a third cylindrical body of successively increasing diameters disposed in a concentric spaced relation, a radiation cylinder disposed within and concentrically with the first cylindrical body, a burner disposed in the radial central portion of the radiation cylinder, and a reforming catalyst layer with a reforming catalyst filled in a gap between the first and second cylindrical bodies, wherein a CO shift catalyst layer and a CO removal catalyst layer are disposed in a gap between the second and third cylindrical bodies, the CO shift catalyst layer being formed in a gap with the direction of flow reversed at one axial end of the reforming catalyst layer and through a heat recovery layer of predetermined length. According to this reforming unit, without internally disposing a heat insulation layer, a cooling mechanism or the like, the reforming catalyst layer, CO shift catalyst layer, and CO removal catalyst layer can be integrated, achieving various useful effects, including size and weight reductions and the shortening of startup time.

Owner:TOKYO GAS CO LTD

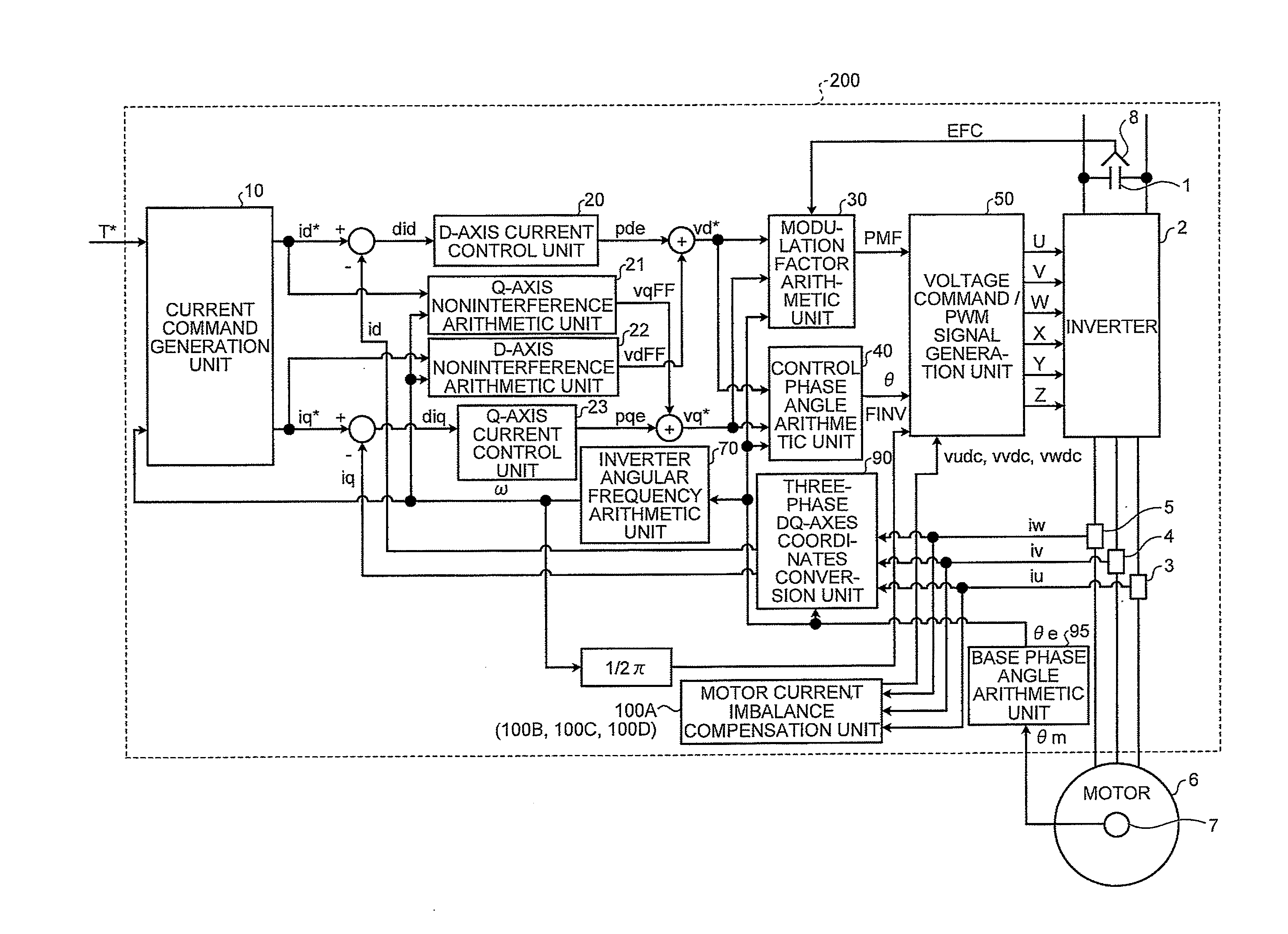

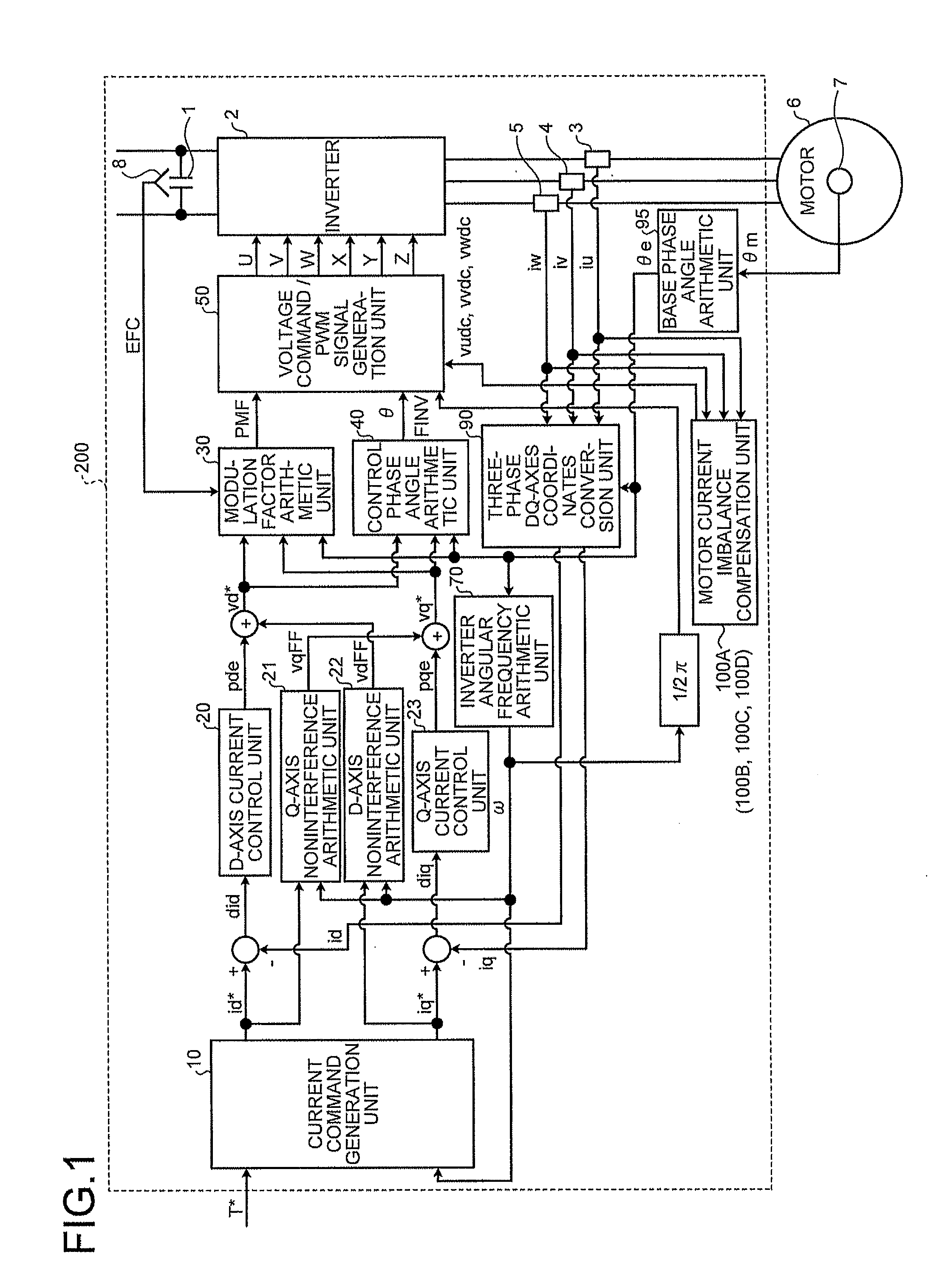

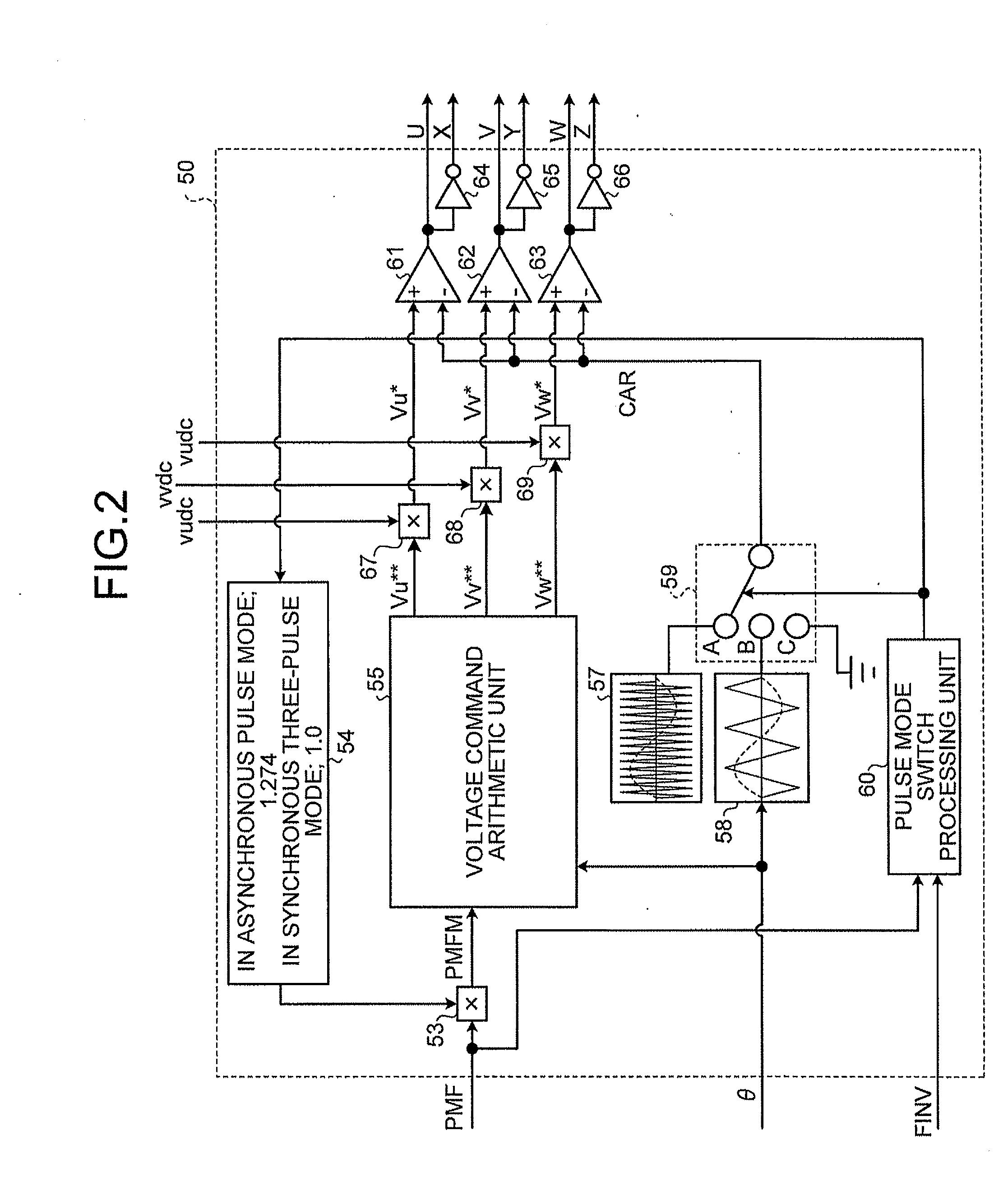

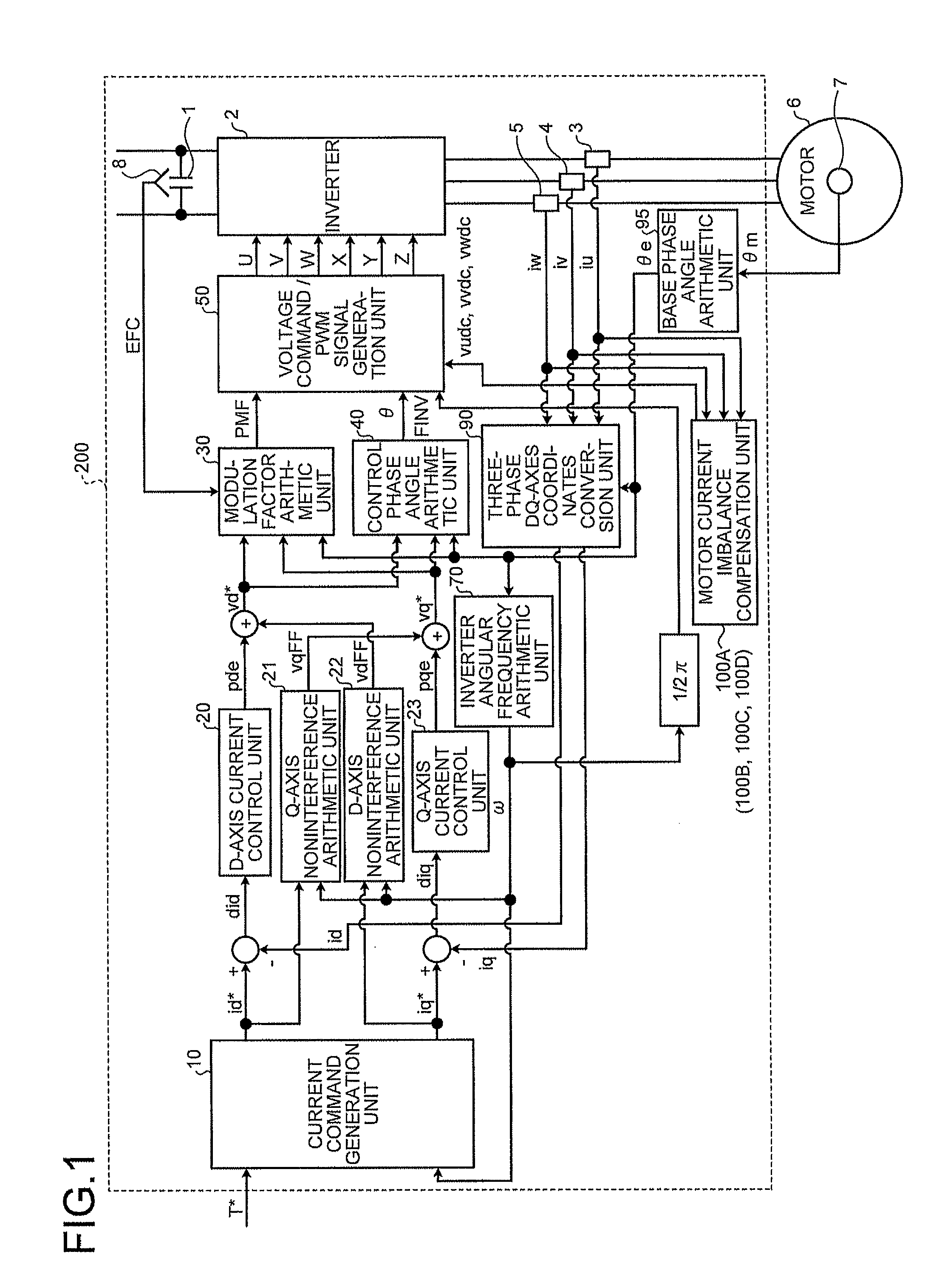

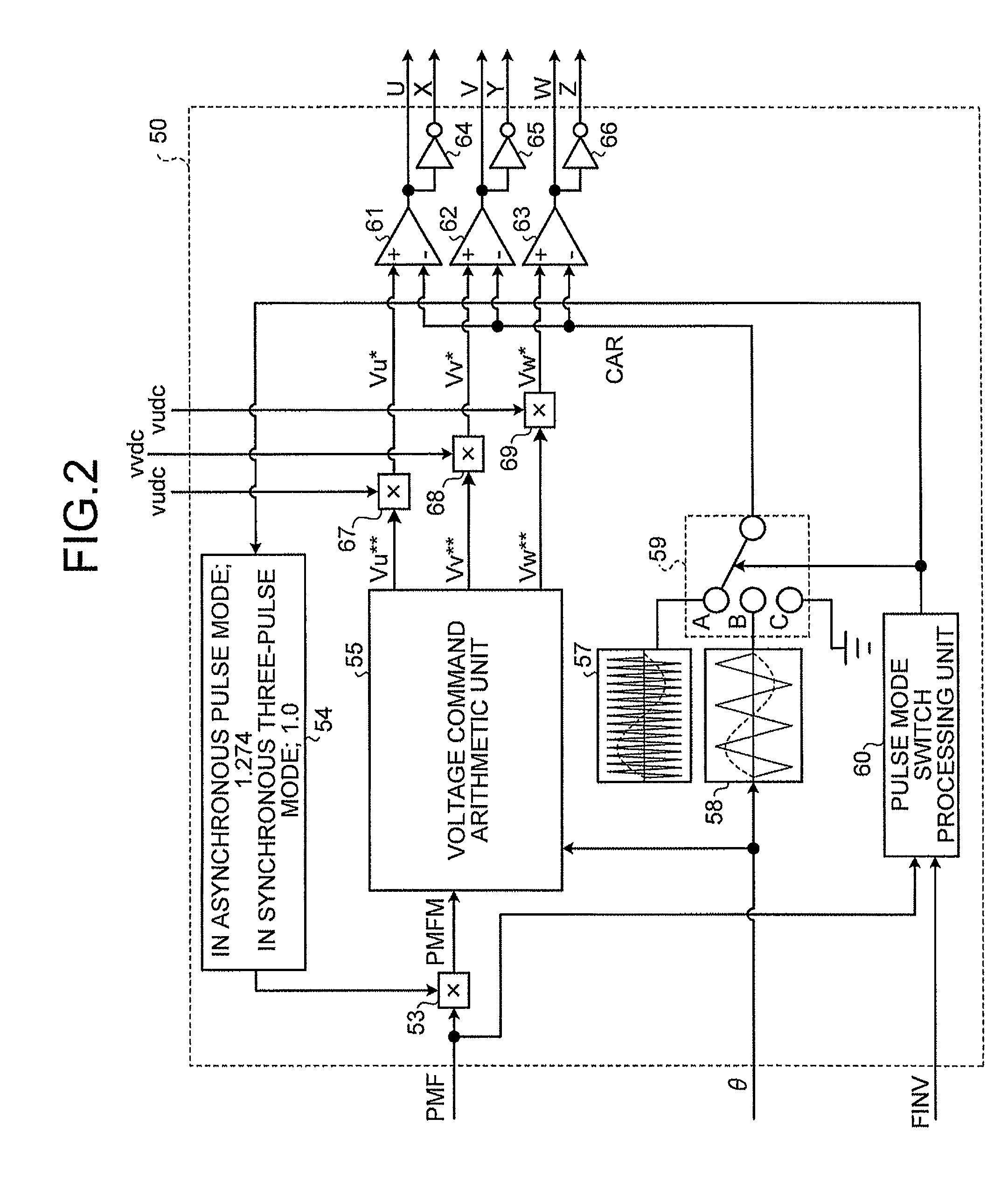

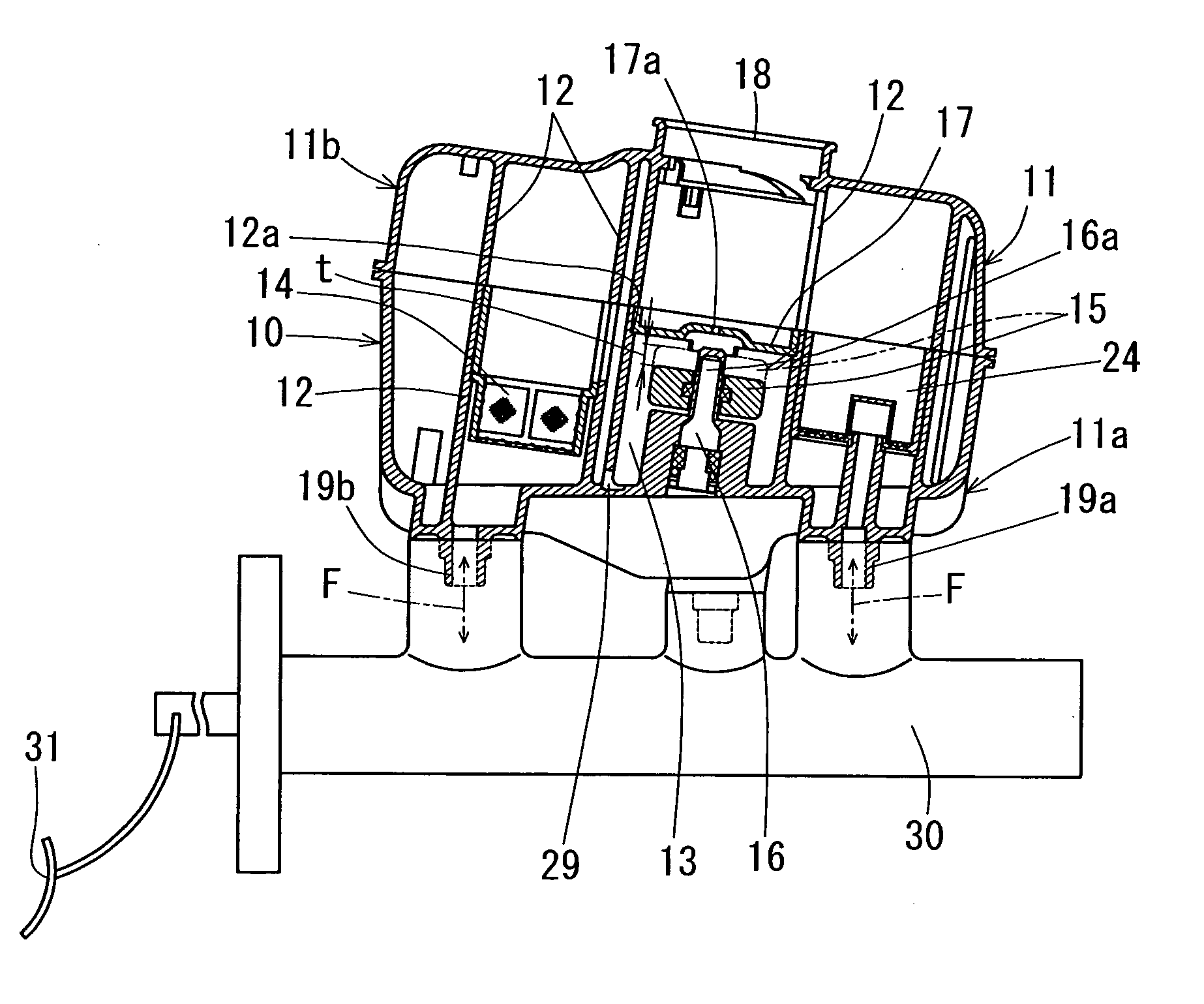

Control apparatus of alternating-current motor

ActiveUS20100259207A1Prevent torque pulsation and damageAvoid damageDC motor speed/torque controlAC motor controlPower inverterEngineering

A control apparatus of an alternating-current motor includes an inverter which is connected to a direct-current source and outputs three-phase alternating currents to the alternating-current motor, a current detector which detects a current of the alternating-current motor, a voltage command / PWM signal generation unit which calculates an output voltage command of the inverter based on a signal from the current detector and generates a pulse width modulation signal to control a switching element arranged in the inverter based on the output voltage command, and a motor current imbalance compensation unit which generates a motor current imbalance compensation amount based on the current detected by the current detector. The pulse width modulation signal is directly or indirectly adjusted at the voltage command / PWM signal generation unit based on the motor current imbalance compensation amount in accordance with a driving state of the inverter.

Owner:AUTO TECH GRP LLC

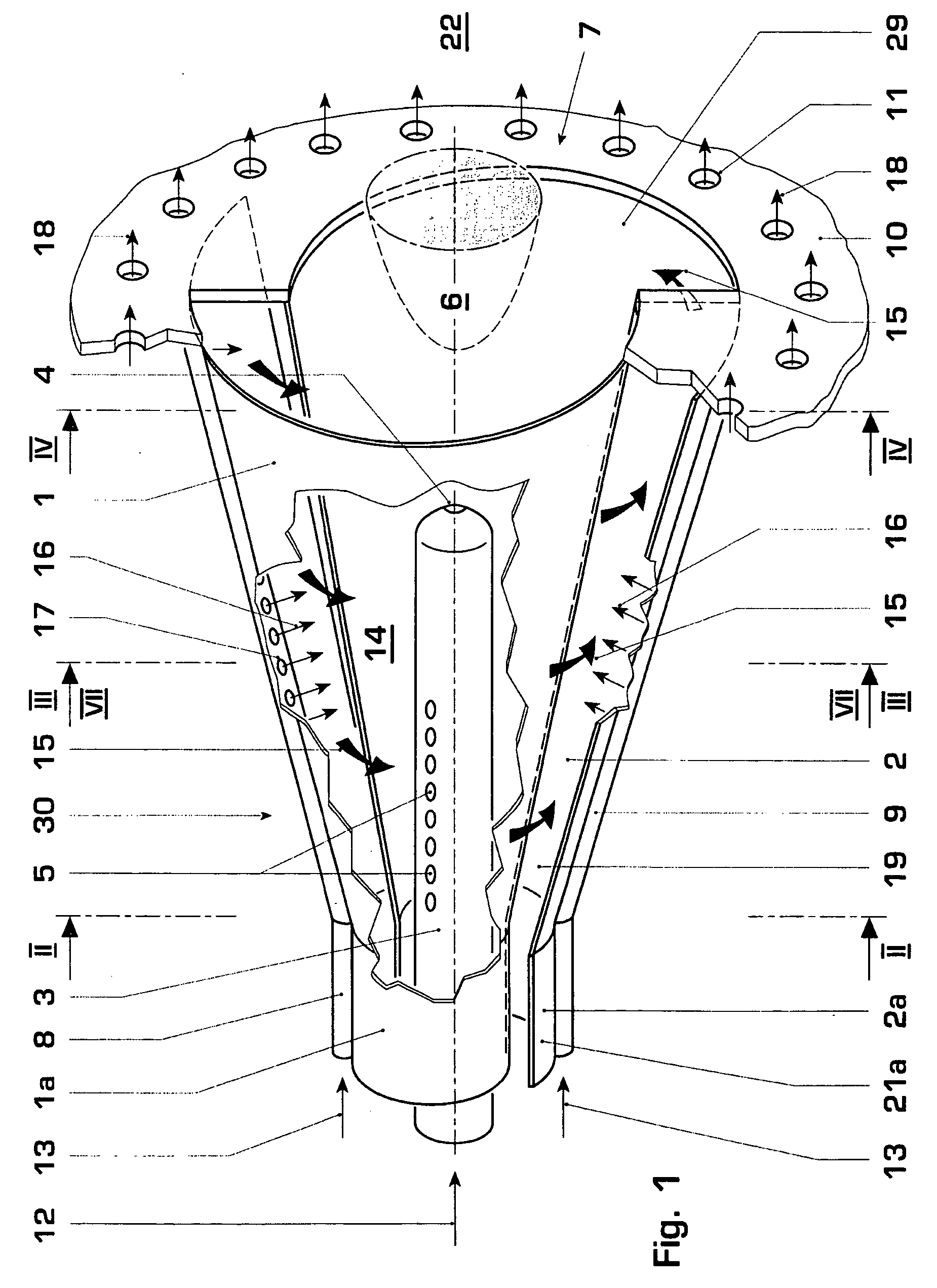

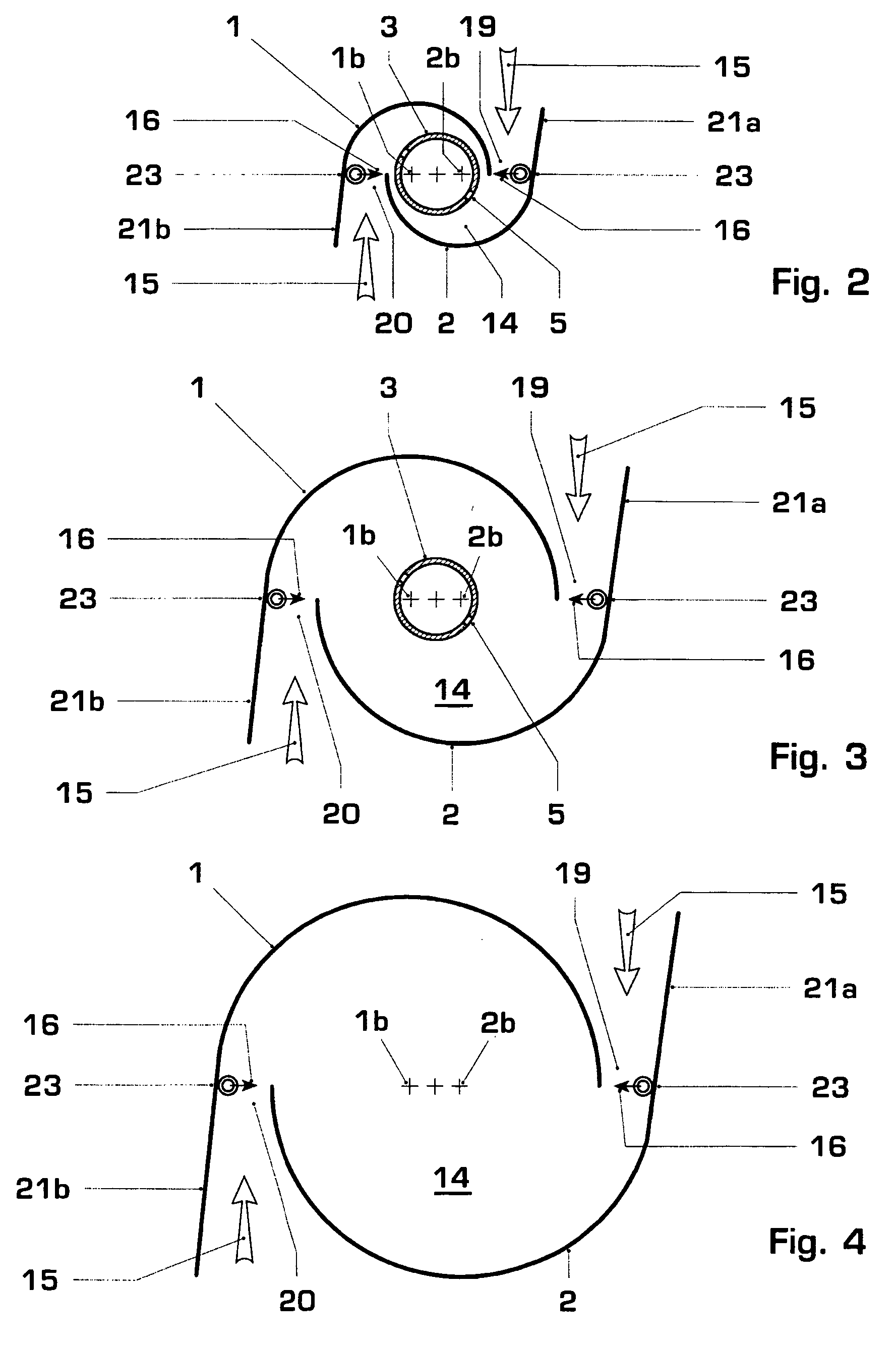

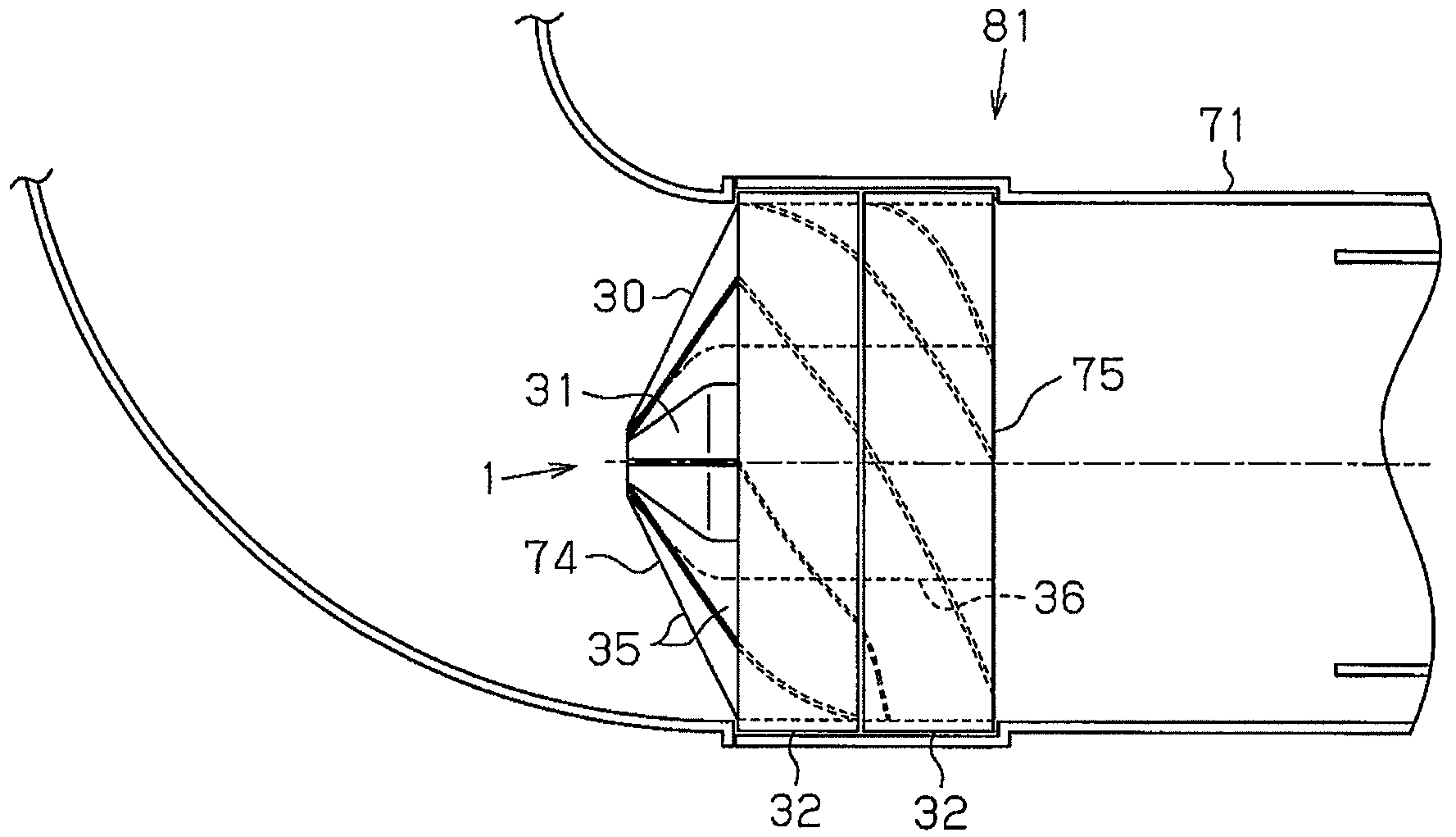

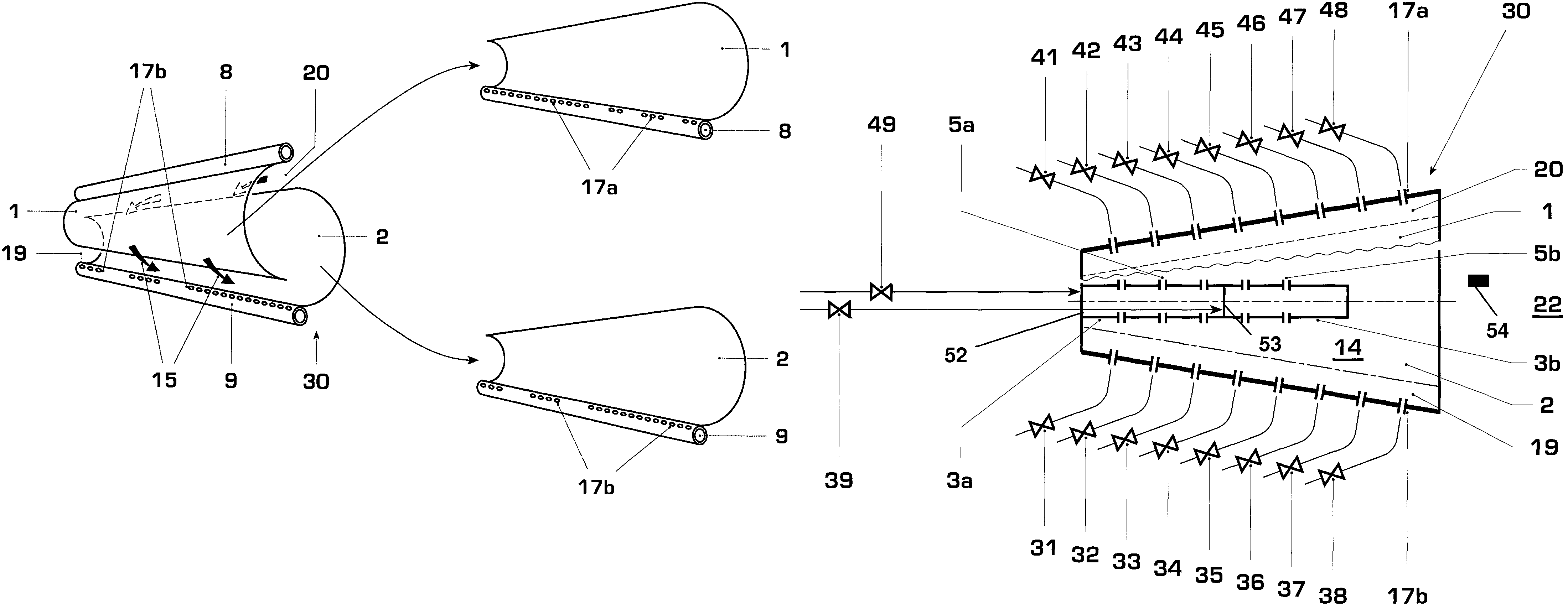

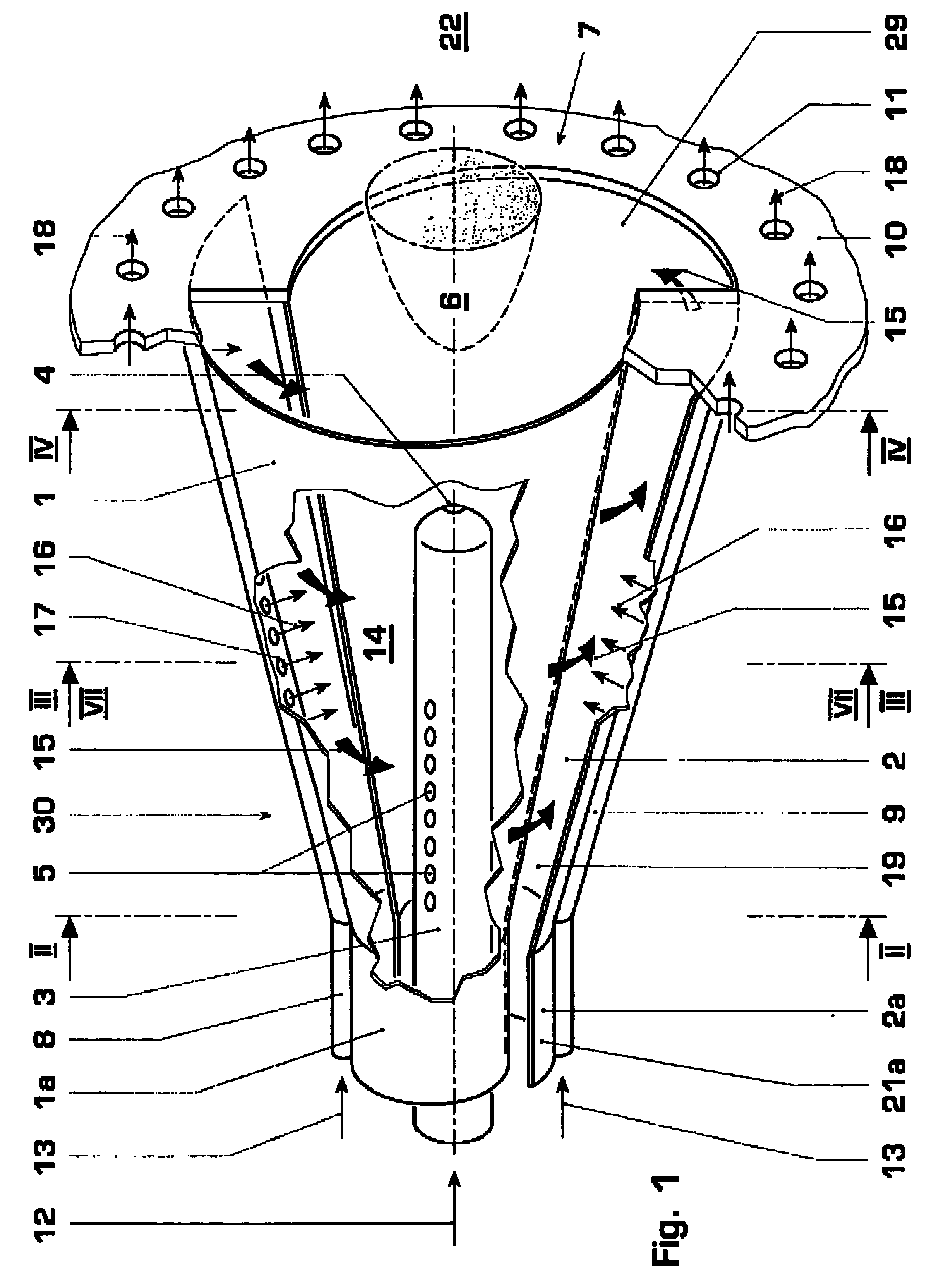

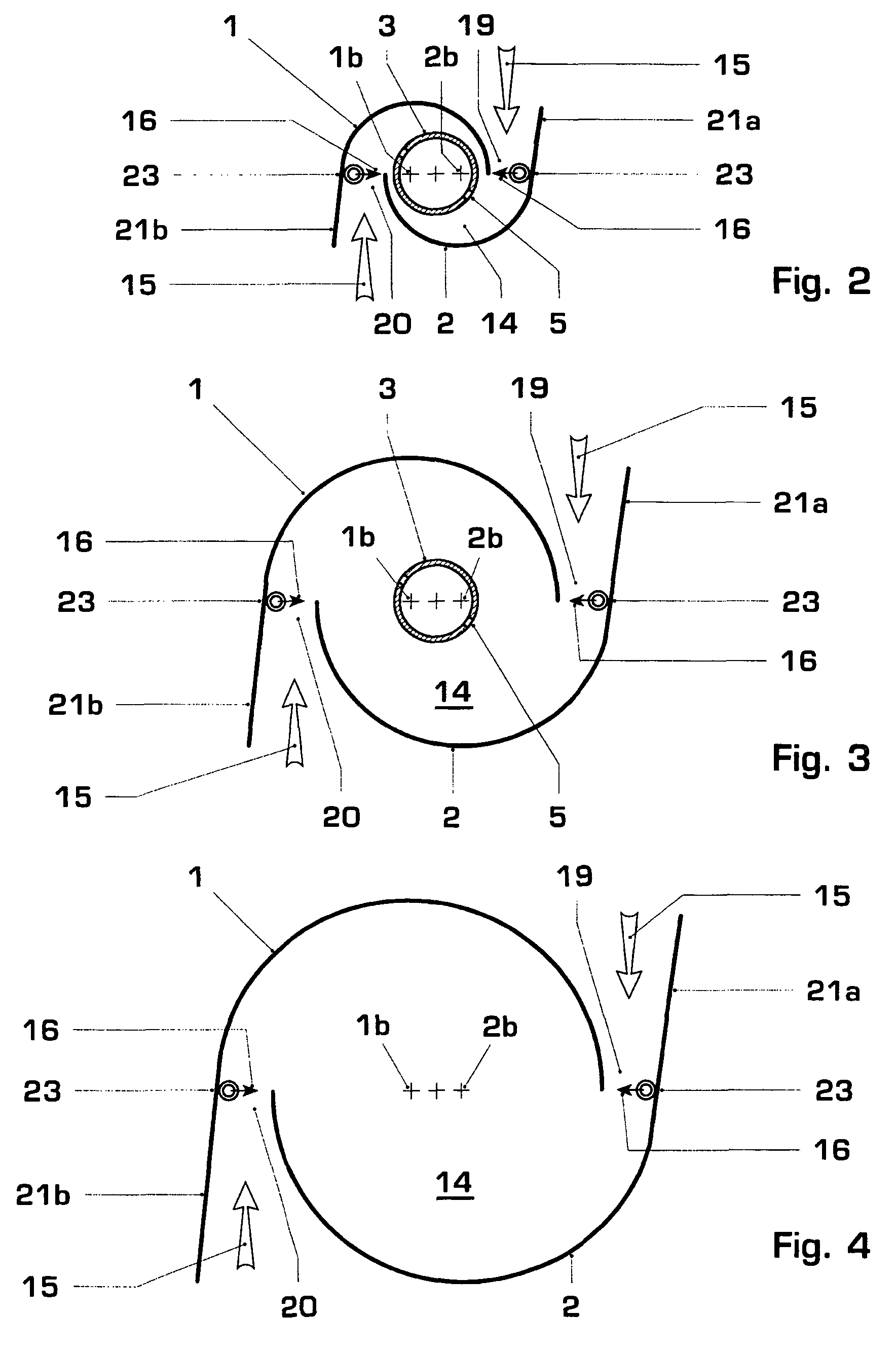

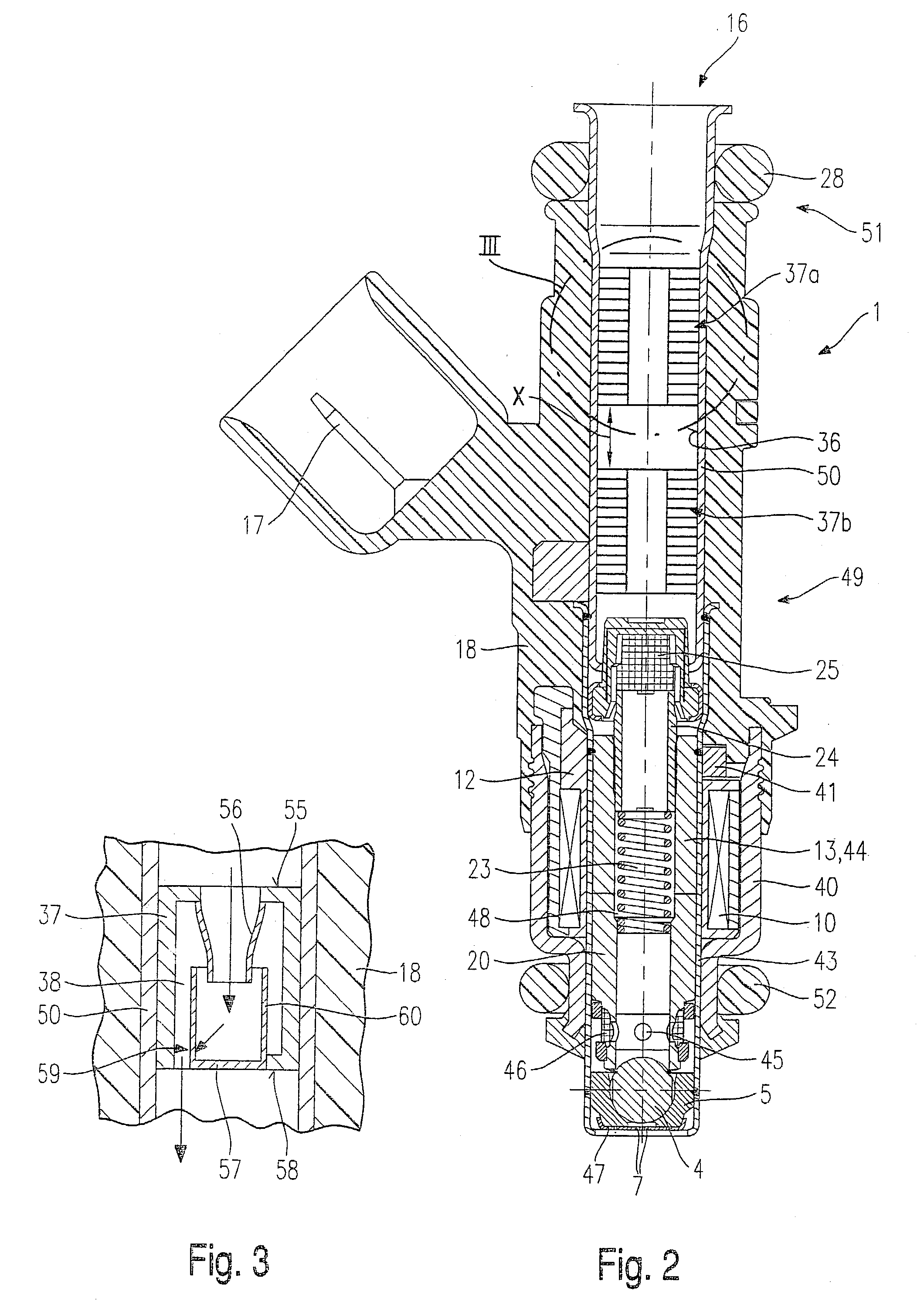

Premix burner

InactiveUS20060183069A1Wide range of operationsEasy injectionFuel supply regulationContinuous combustion chamberCombustionInjection device

A premix burner includes a vortex generator (30) for combustion air stream (15), devices (17, 17a, 17b, 31-38, 41-48) to inject fuel into the combustion air stream (15), and tangential air ducts (19, 20). The combustion air (15) enters the cone cavity (14) of the vortex generator (30) via the air ducts. The injection of the fuel into the combustion air is done asymmetrically by injection devices (17, 17a, 17b, 31-38, 41-48). At least one of the injection devices (5) is arranged on a fuel lance (3) that extends into the vortex chamber.

Owner:ANSALDO ENERGIA IP UK LTD

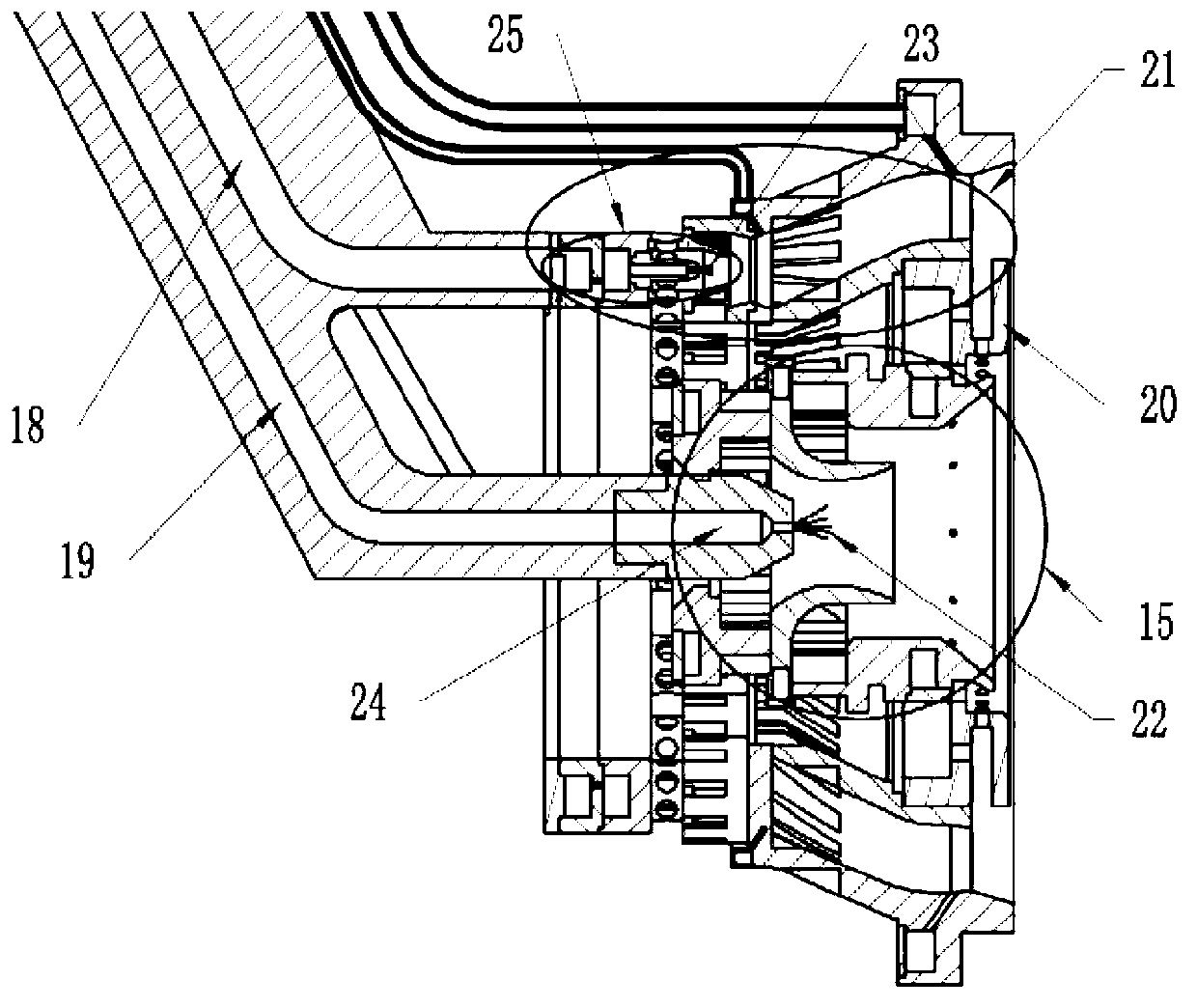

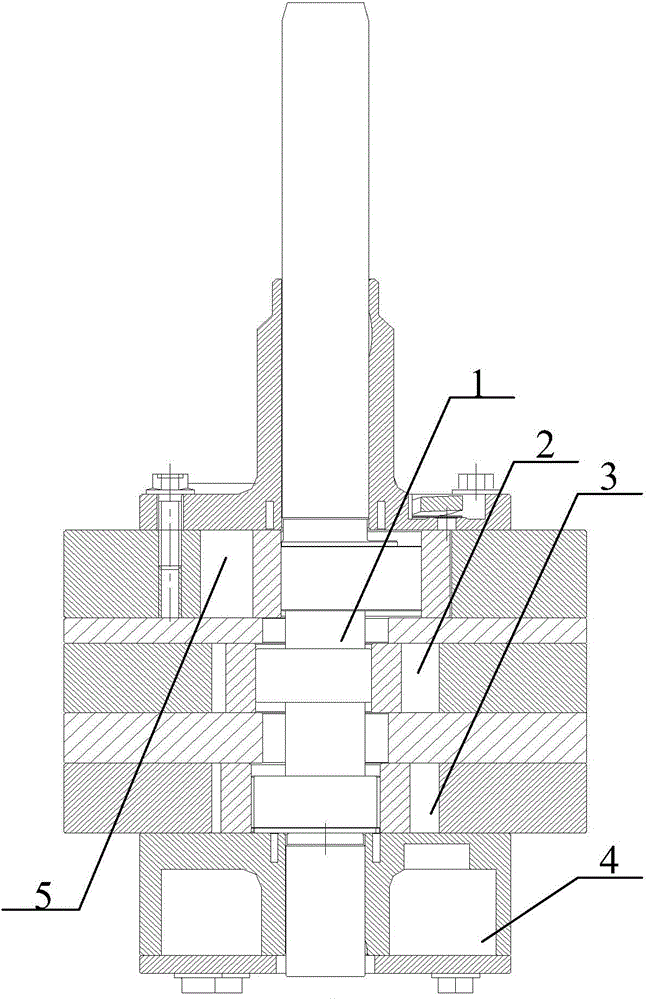

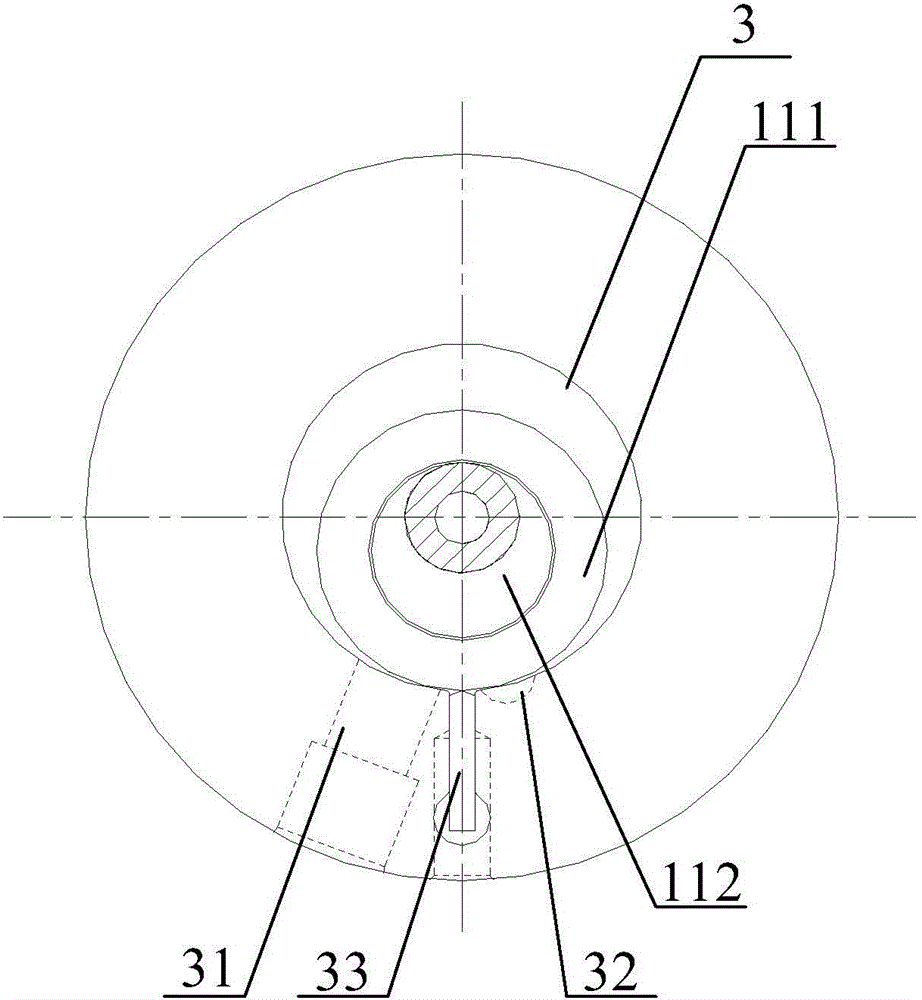

Combined moving type powder feeder

ActiveCN105297008AImprove reliabilityPrevent pulsationMetallic material coating processesImpellerMetallurgy

The invention discloses a combined moving type powder feeder. The combined moving type powder feeder comprises an impeller shaft, a barrel body, a powder bucket, a slide block and a turntable. When the combined moving type powder feeder works, the air tightness of the barrel body is kept, and powder fed into the powder bucket is scattered through a stirring rod, thus preventing the powder from forming an arched structure in the powder bucket; a spiral impeller at the bottom part of the impeller shaft can reversely rotate at the set speed to push the powder; the powder can enter a powder groove in the turntable through a powder falling tube and the power groove is gradually filled; the powder in the powder groove is leveled through the slide block; the turntable can rotate along with a main transmission shaft, so that the powder in the powder groove can be rotated to arrive at a powder inlet of a powder discharging tube and then is sucked off through the powder discharging tube, and the powder feeding process is finished. According to the combined moving type powder feeder, the rotating speed ratio K of the turntable plate to the impeller shaft can be accurately controlled, so that the uniformity of powder feeding quantity can be maintained. The combined moving type powder feeding manner that the spiral impeller is used for impelling and the turntable is used for sucking is adopted and particularly suitable for the powder with low flowablity or without flowablity; with the adoption of the aforementioned combined moving manner, the powder feeding quantity uniformity can be ensured, and the powder can be continuously adjustably fed.

Owner:WUHAN HIVALUE INTELASER LTD

Control apparatus of alternating-current motor

ActiveUS8344680B2Avoid damagePrevent pulsationSynchronous motors startersDC motor speed/torque controlCurrent meterPower inverter

A control apparatus of an alternating-current motor includes an inverter which is connected to a direct-current source and outputs three-phase alternating currents to the alternating-current motor, a current detector which detects a current of the alternating-current motor, a voltage command / PWM signal generation unit which calculates an output voltage command of the inverter based on a signal from the current detector and generates a pulse width modulation signal to control a switching element arranged in the inverter based on the output voltage command, and a motor current imbalance compensation unit which generates a motor current imbalance compensation amount based on the current detected by the current detector. The pulse width modulation signal is directly or indirectly adjusted at the voltage command / PWM signal generation unit based on the motor current imbalance compensation amount in accordance with a driving state of the inverter.

Owner:AUTO TECH GRP LLC

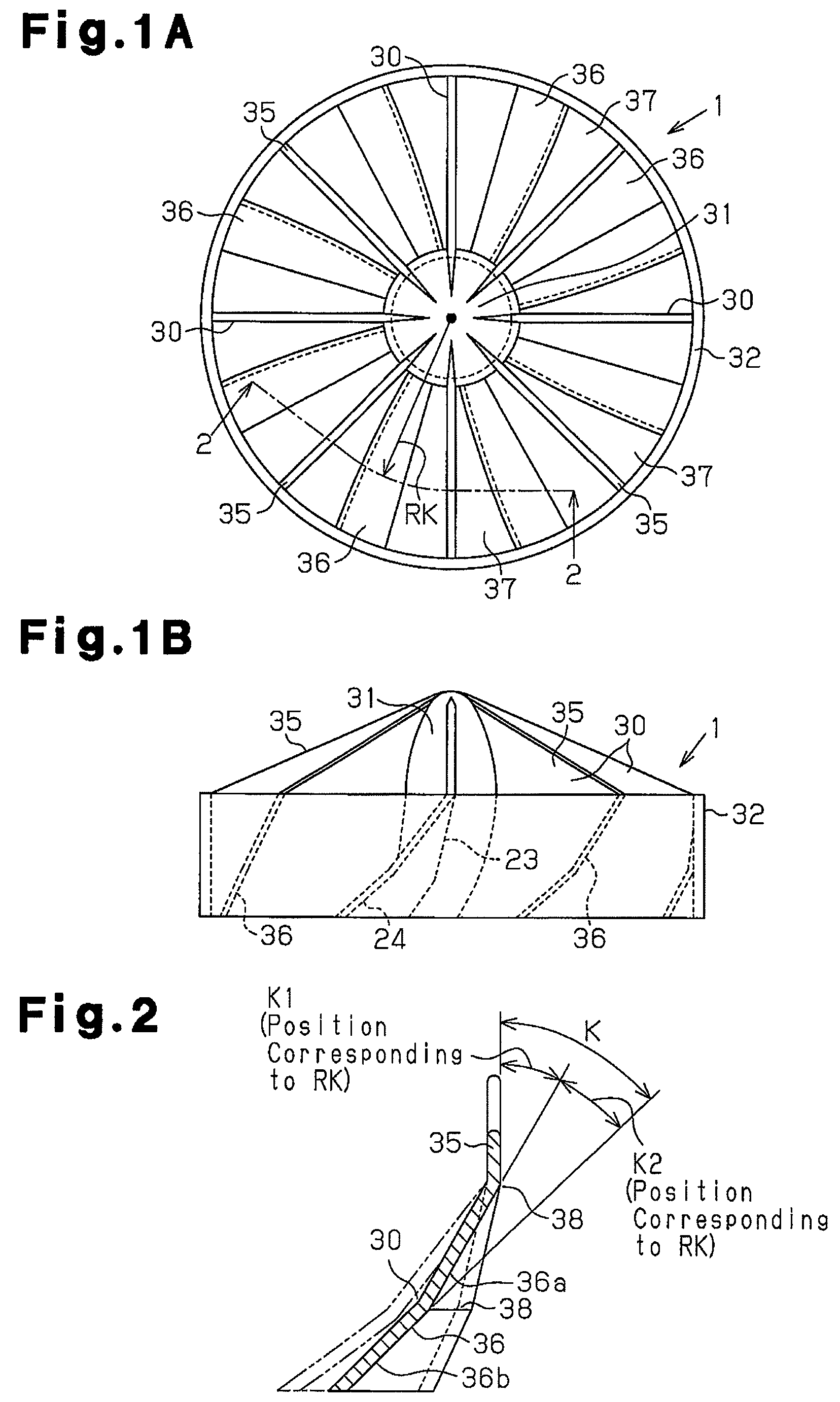

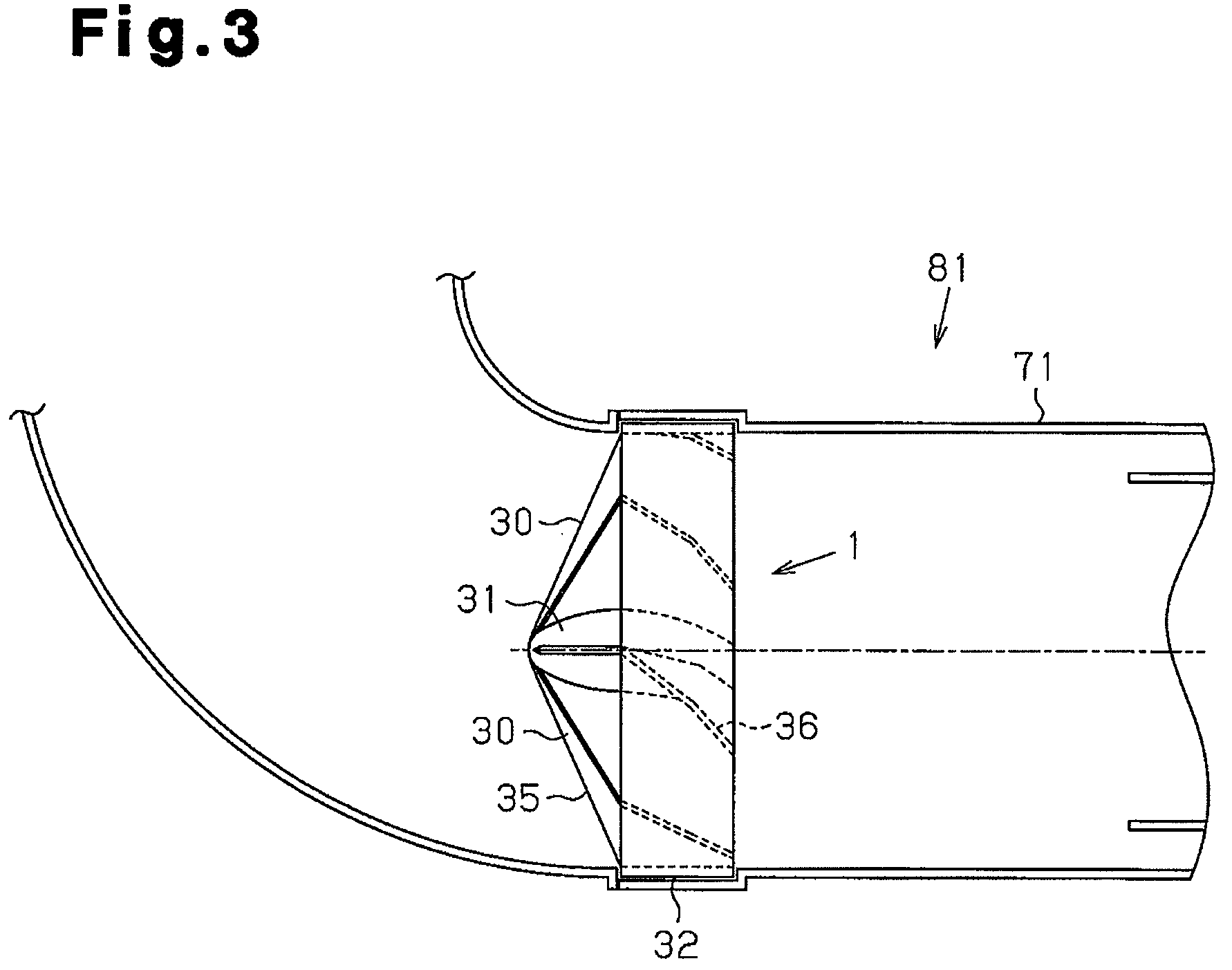

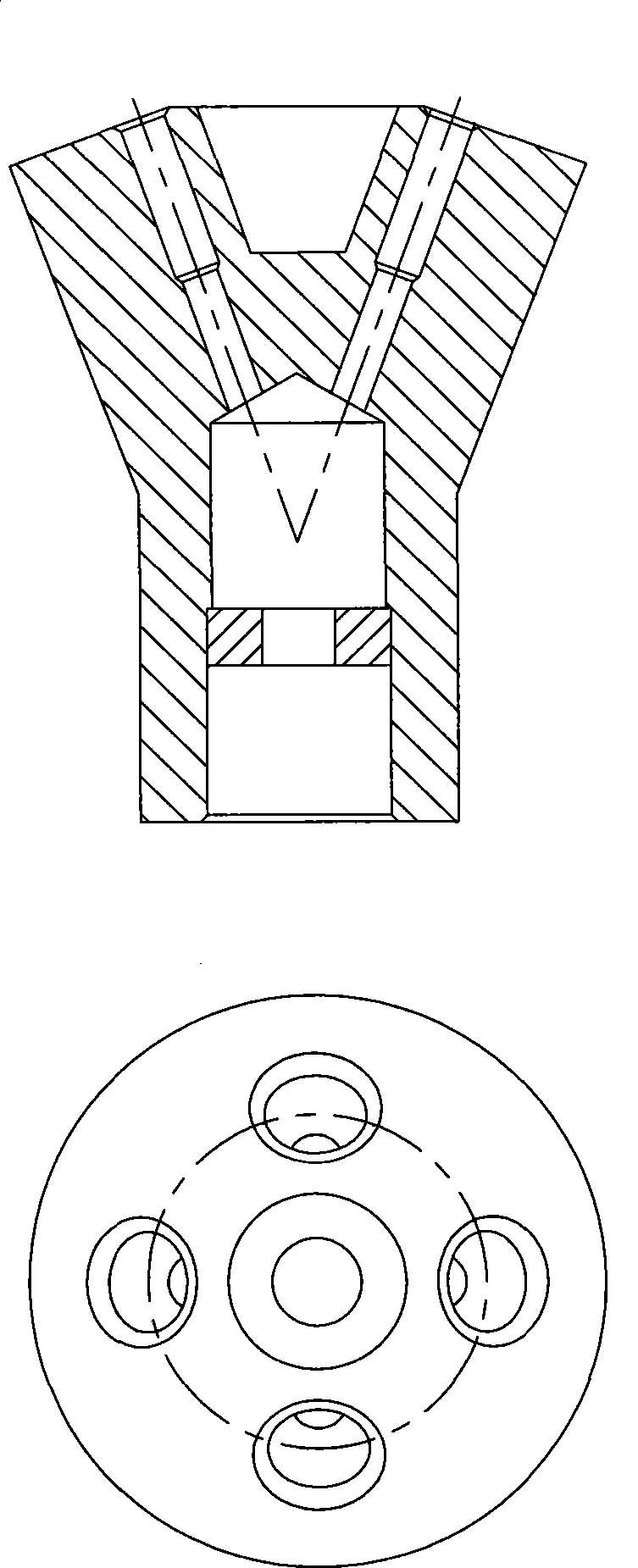

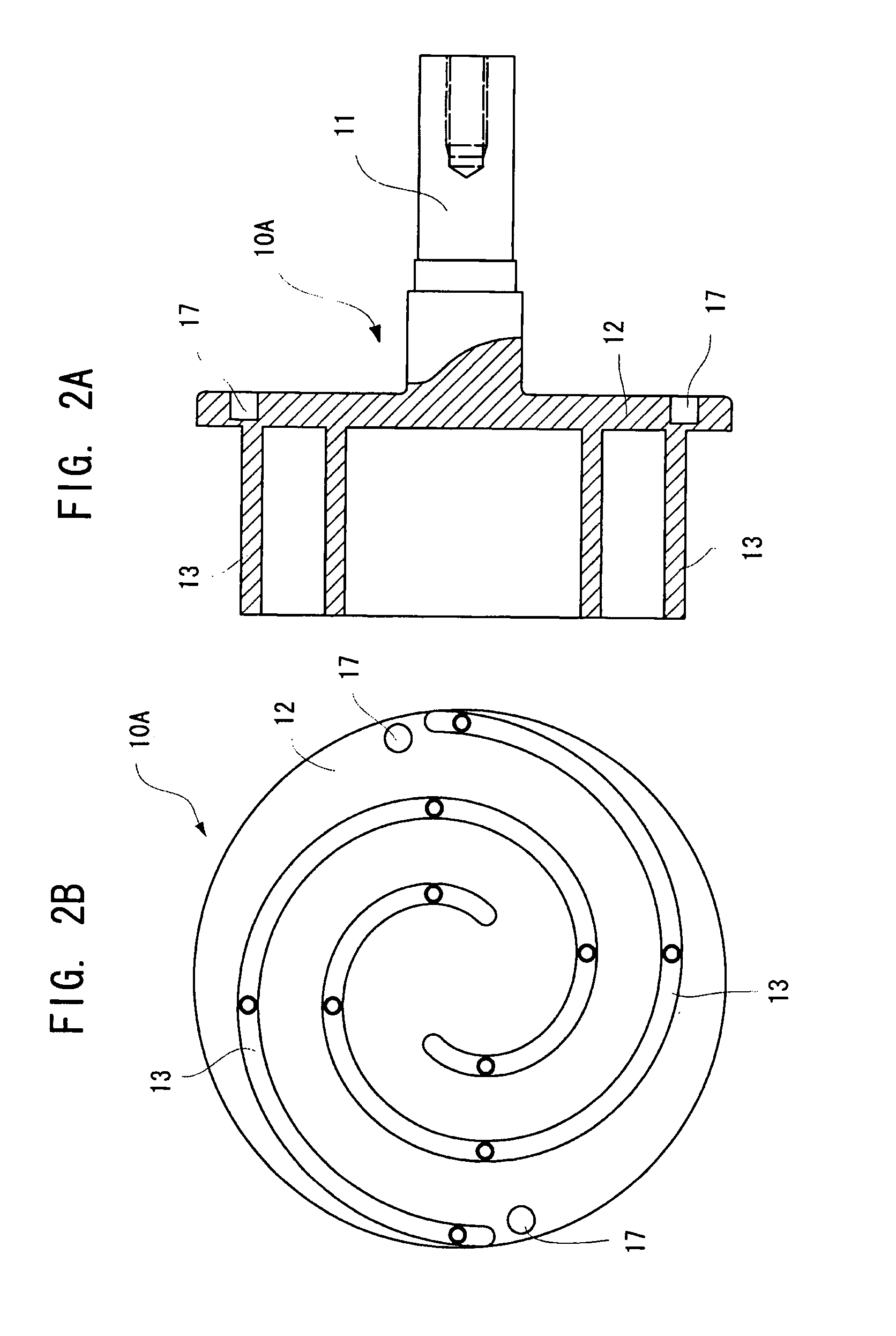

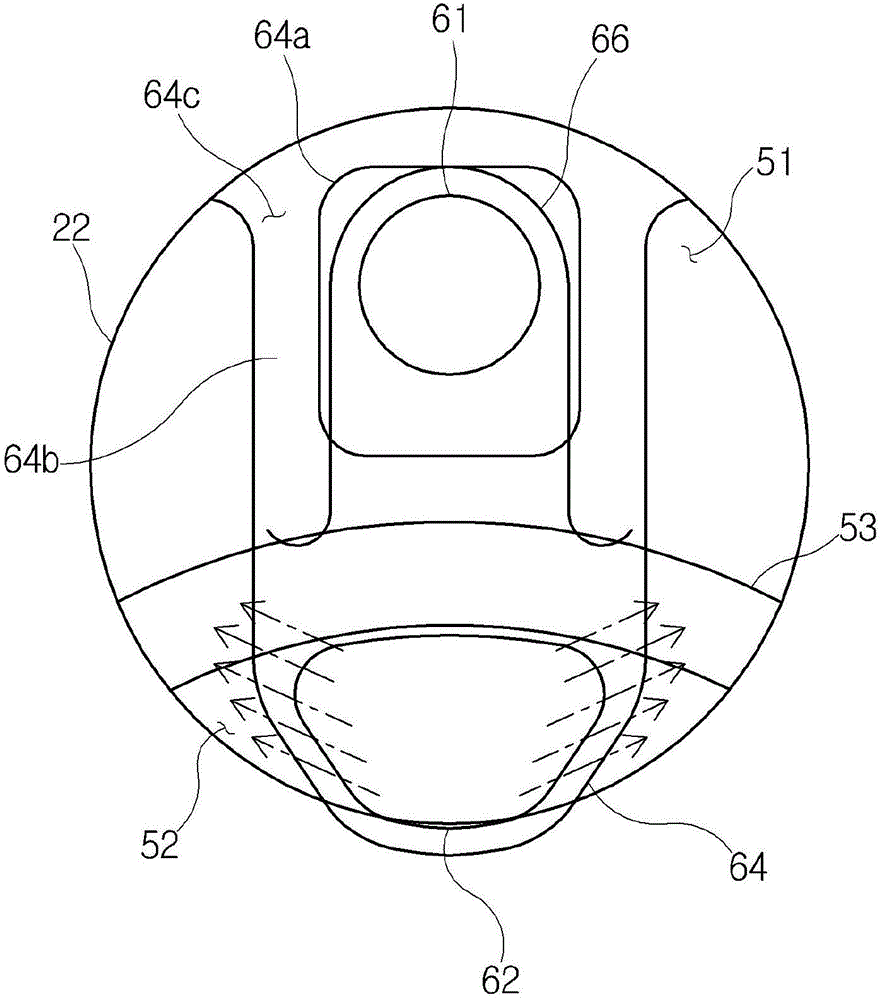

Swirl generator

ActiveUS7543561B2Effectively isolates dust particlesAvoid noiseDispersed particle filtrationCombustion enginesEngineeringNose cone

A swirl generator is arranged in a duct through which air is sent from the exterior to an air cleaner. The swirl generator has a plurality of guide vanes, which change the flow direction of an air flow. Each of the guide vanes has a guide fin that adjusts the air flow and a deflecting fin that applies swirl force to the air flow. The deflecting fin is configured by an upstream portion and a downstream portion, which are connected together at a predetermined angle. The upstream portion and the downstream portion each have a cross section extending linearly along a cylindrical plane coaxial with a nose cone.

Owner:TOYOTA BOSHOKU KK +1

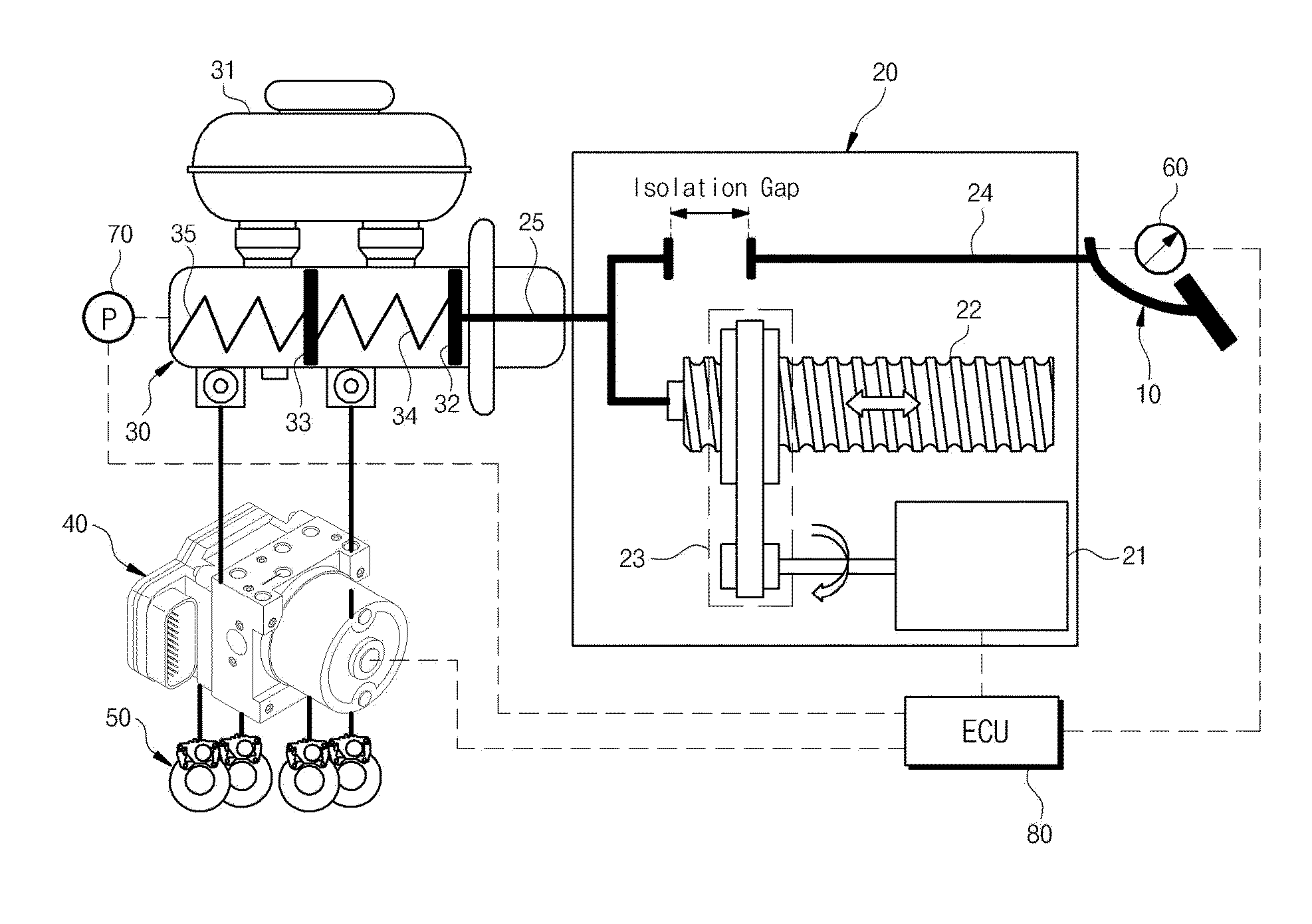

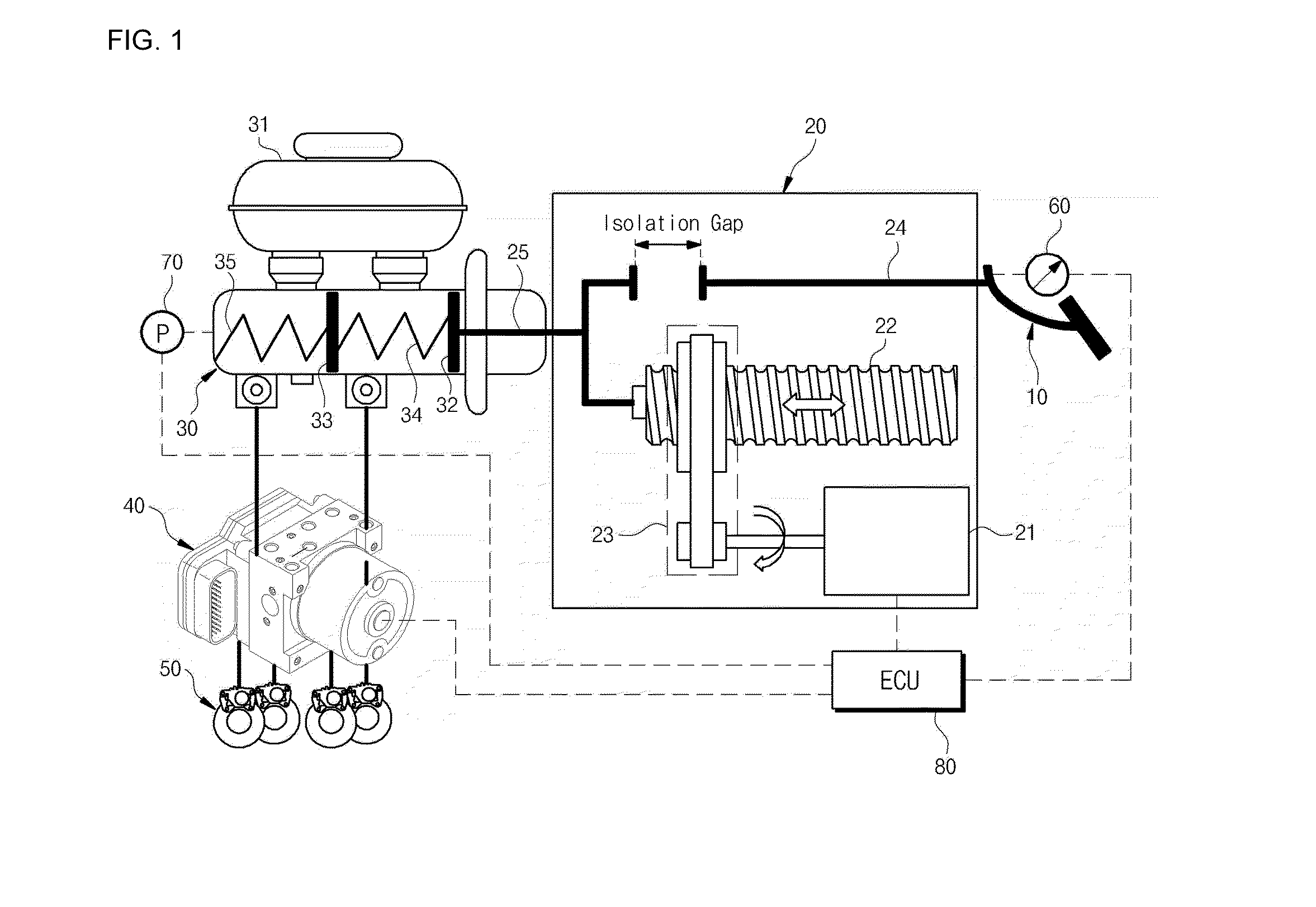

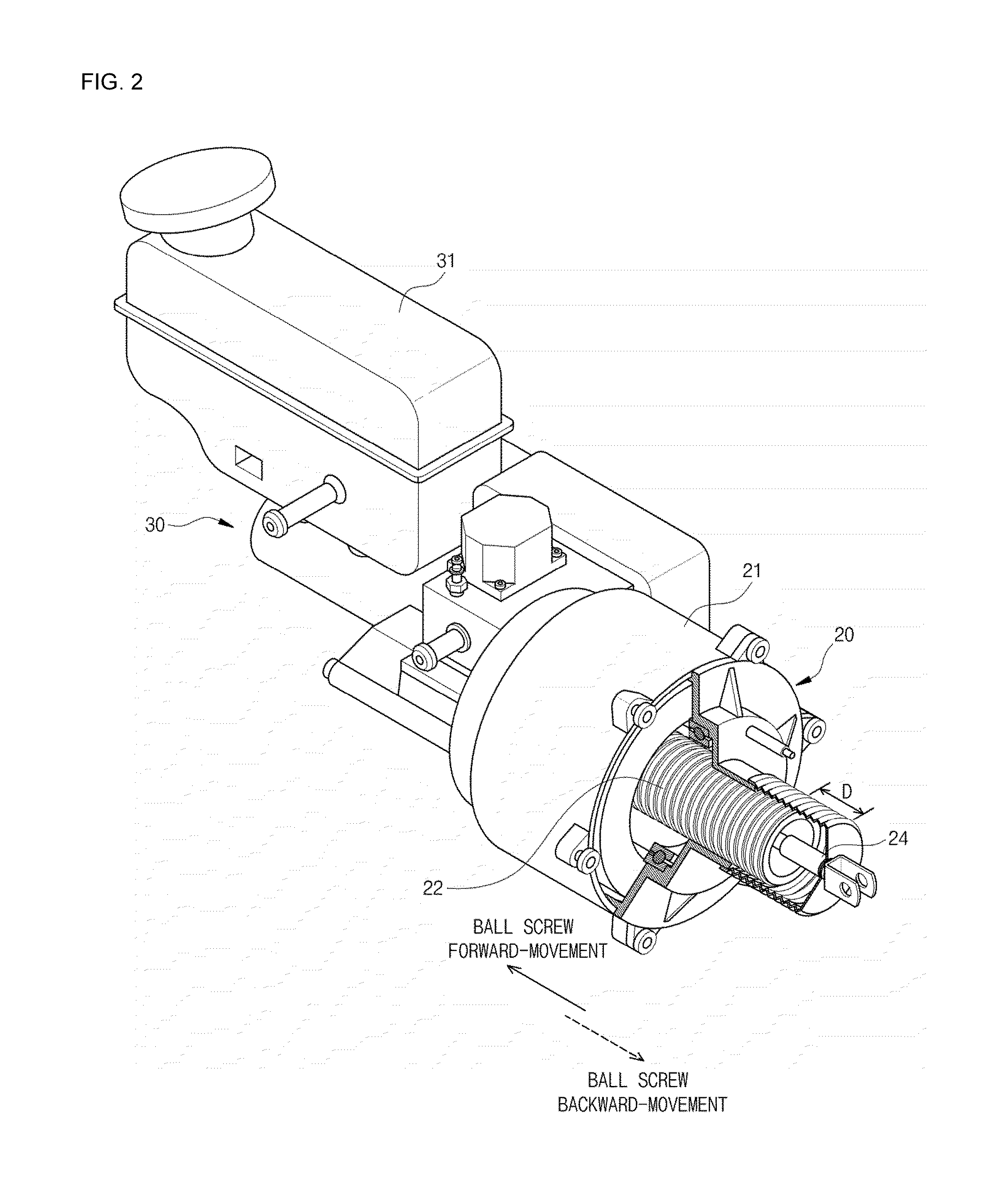

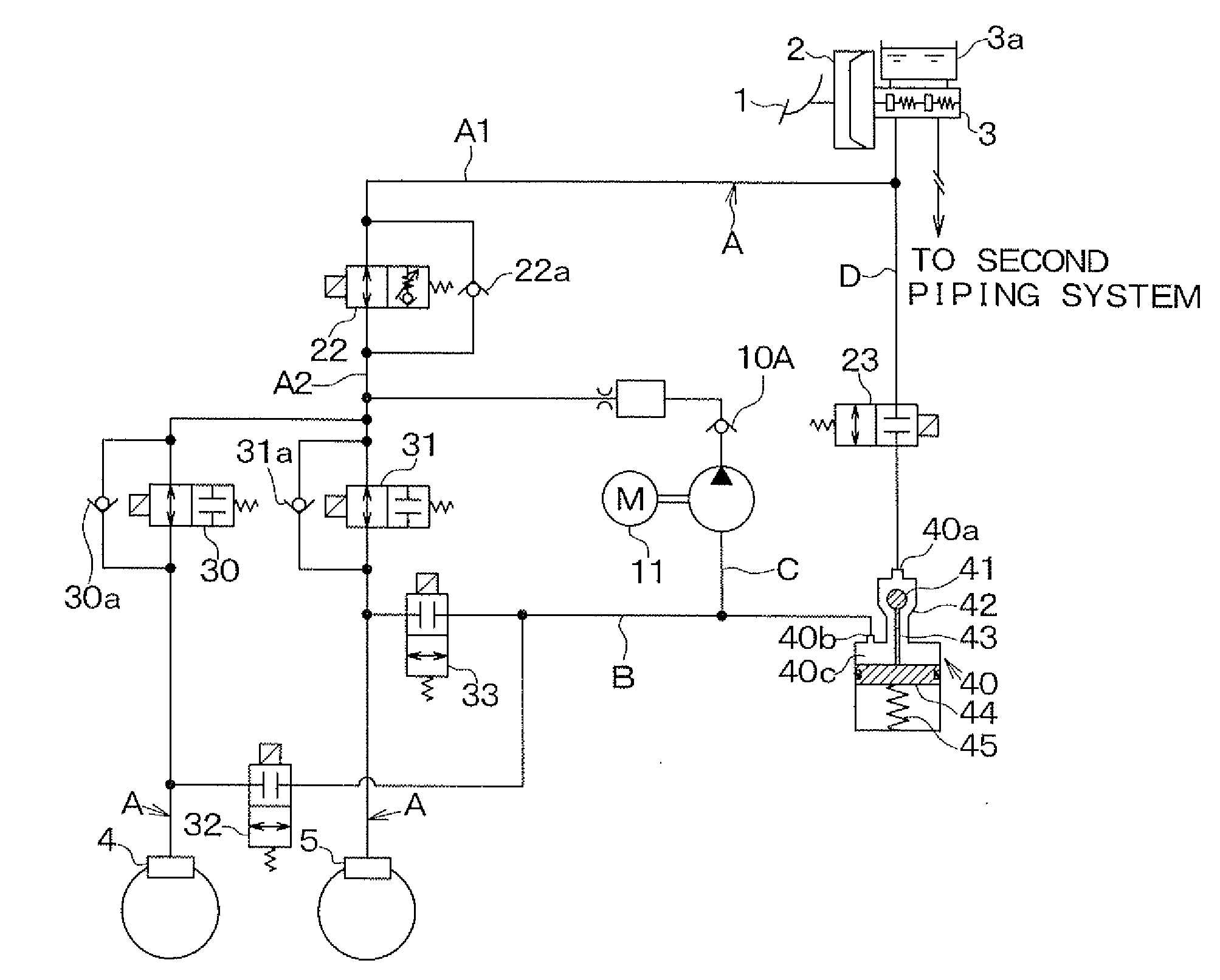

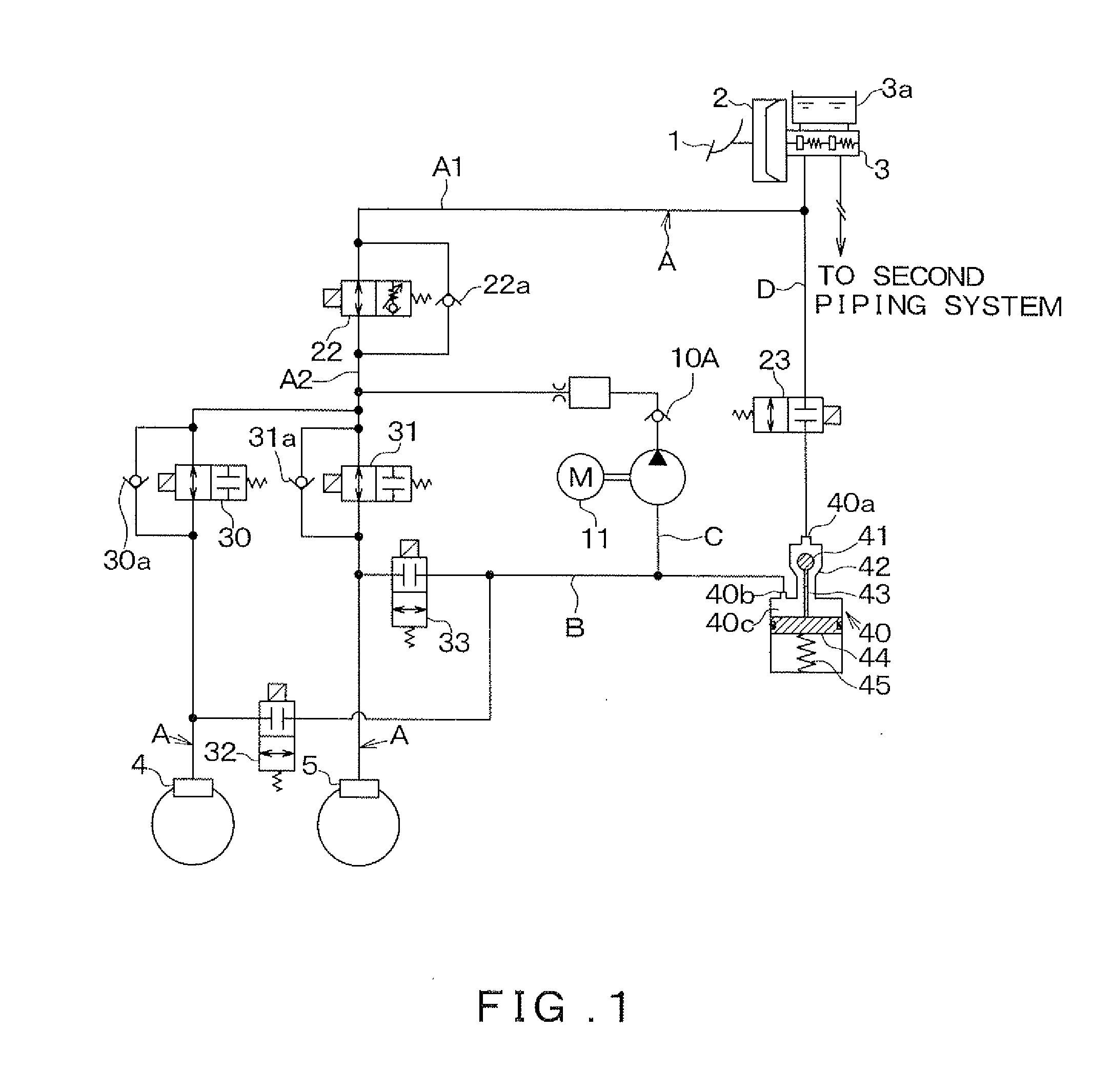

Electronic brake system and control method thereof

ActiveUS20150028664A1Improving ride comfortImprove driving stabilityFoot actuated initiationsFluid braking transmissionLinear motionMaster cylinder

Disclosed are an electronic brake system and a control method thereof. The electronic brake system includes a master cylinder including a piston, an output rod contacting the piston, an input rod configured to be moved forward by a driver's manipulation of a brake pedal and arranged coaxially to the master cylinder and spaced a predetermined isolation gap apart from the output rod, an electrically-driven booster including a motor, a ball screw to move the output rod, and a motion converting unit to move the ball screw forward and backward by converting rotational movement of the motor into linear movement, and an electronic control unit (ECU) to control operation of the motor based on the size of the isolation gap. When the ball screw is moved backward in an ABS mode, the ECU stops backward-movement of the ball screw before the output rod collides with the input rod.

Owner:HL MANDO CORP

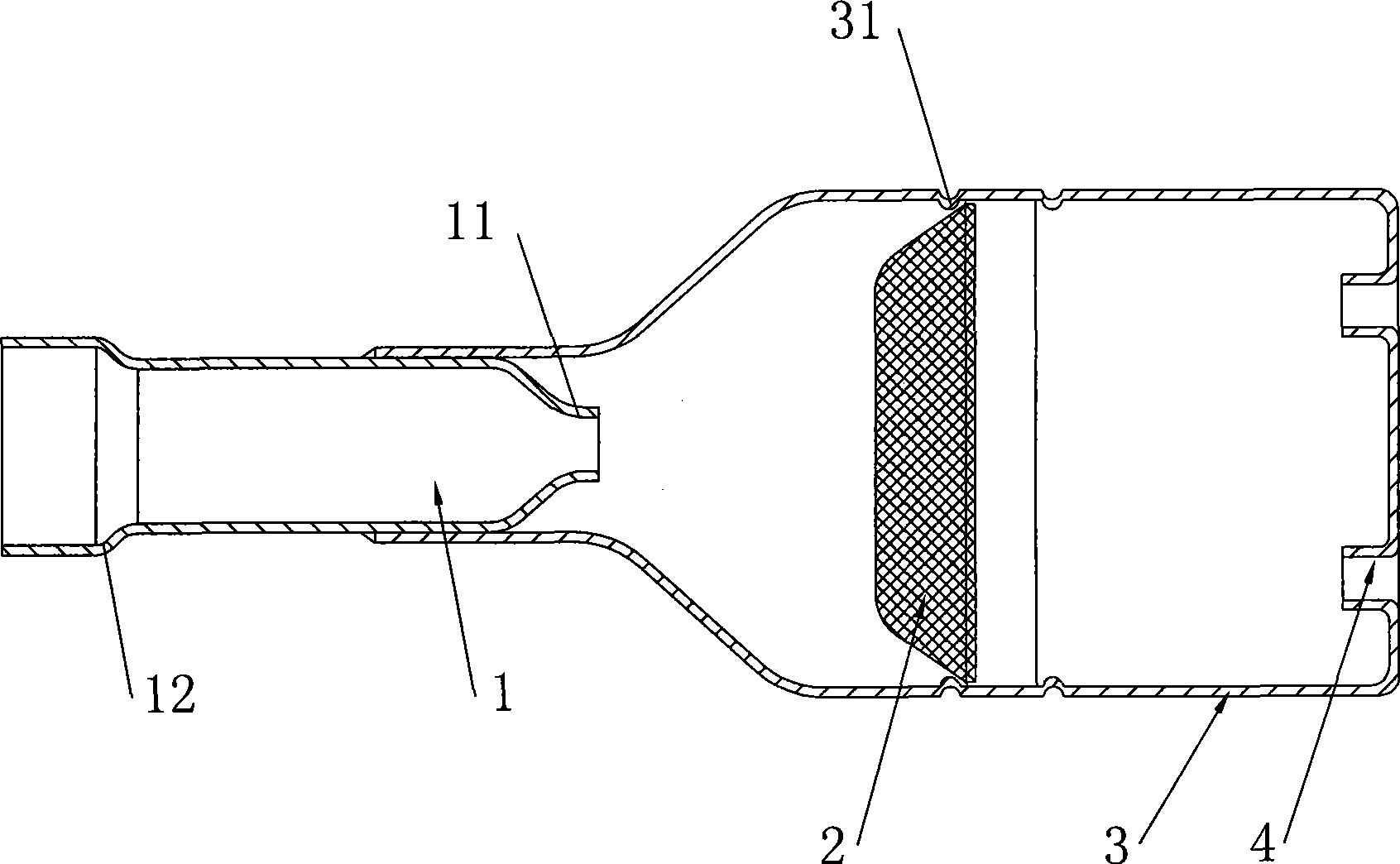

Refrigerant distributor used for air conditioner heat-exchanger

InactiveCN101430147AAvoid flow resistance loss and shock vibrationIncrease refrigerant flow rateFluid circulation arrangementEngineeringAir bubble

The invention relates to a refrigerant distributor used in an air-conditioning heat exchanger. The refrigerant distributor comprises a shell and an input tube welded on an input end of the shell, and a plurality of relief holes are arranged on an output end of the shell. The refrigerant distributor is characterized in that the orifice of the input tube which extends into the input end of the shell takes a tapered shape, the diameter of the orifice is less than that of the input end, and a filter screen is arranged in the cavity of the shell. The refrigerant distributor adopts a structure including a tapered jet-type input tube and the filter screen arranged in the cavity of the shell, which can avoid fluid resistance loss and impact vibration caused by abrupt change of cross section, greatly increase flow rate of the refrigerant, and reduce separation of gas and liquid phases, reduce effect of gravity so as to cause uniform refrigerant flow distribution, and also avoid requirement for a mounting angle; furthermore, the filter screen which is arranged in the cavity of the shell can filter off impurities and avoid blocking of capillary tubes, and can divide big air bubbles generated by flash evaporation into small bubbles, which prevents pulsation and impulsive sound of the refrigerant generated by air bubble cracking and greatly reduces the running noise. Therefore, the refrigerant distributor combines the advantages of built-in distributors and common tubby distributors very well.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

Premix burner

InactiveUS7780437B2Wide range of operationsEasy injectionFuel supply regulationContinuous combustion chamberCombustorInjection device

A premix burner includes a vortex generator (30) for combustion air stream (15), devices (17, 17a, 17b, 31-38, 41-48) to inject fuel into the combustion air stream (15), and tangential air ducts (19, 20). The combustion air (15) enters the cone cavity (14) of the vortex generator (30) via the air ducts. The injection of the fuel into the combustion air is done asymmetrically by injection devices (17, 17a, 17b, 31-38, 41-48). At least one of the injection devices (5) is arranged on a fuel lance (3) that extends into the vortex chamber.

Owner:ANSALDO ENERGIA IP UK LTD

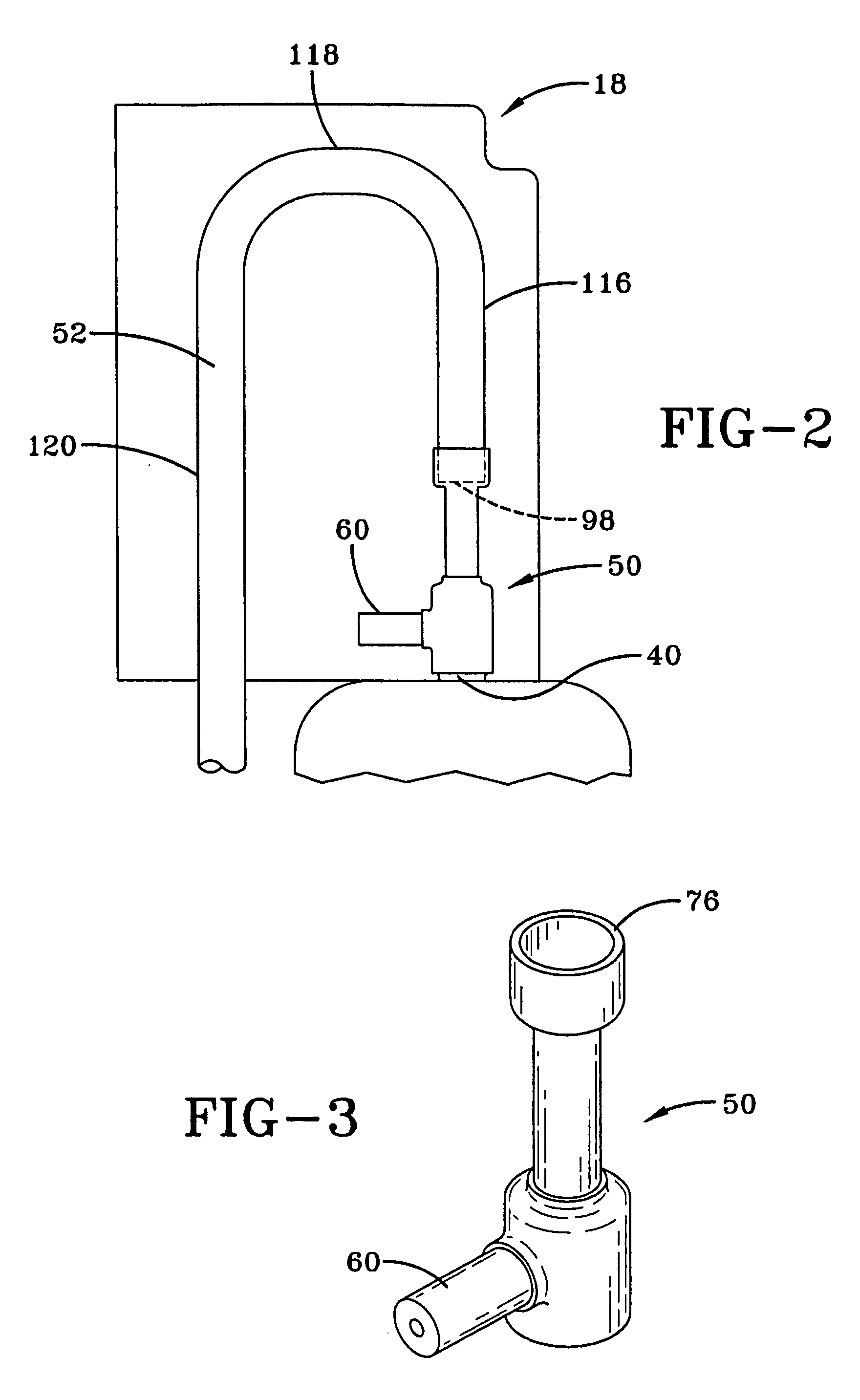

Apparatus and method for dispensing liquids

InactiveUS20050150910A1Improve reliabilityDecrease phenomenonSpray nozzlesLiquid transferring devicesNozzleCoolant

Owner:GEBRAUER

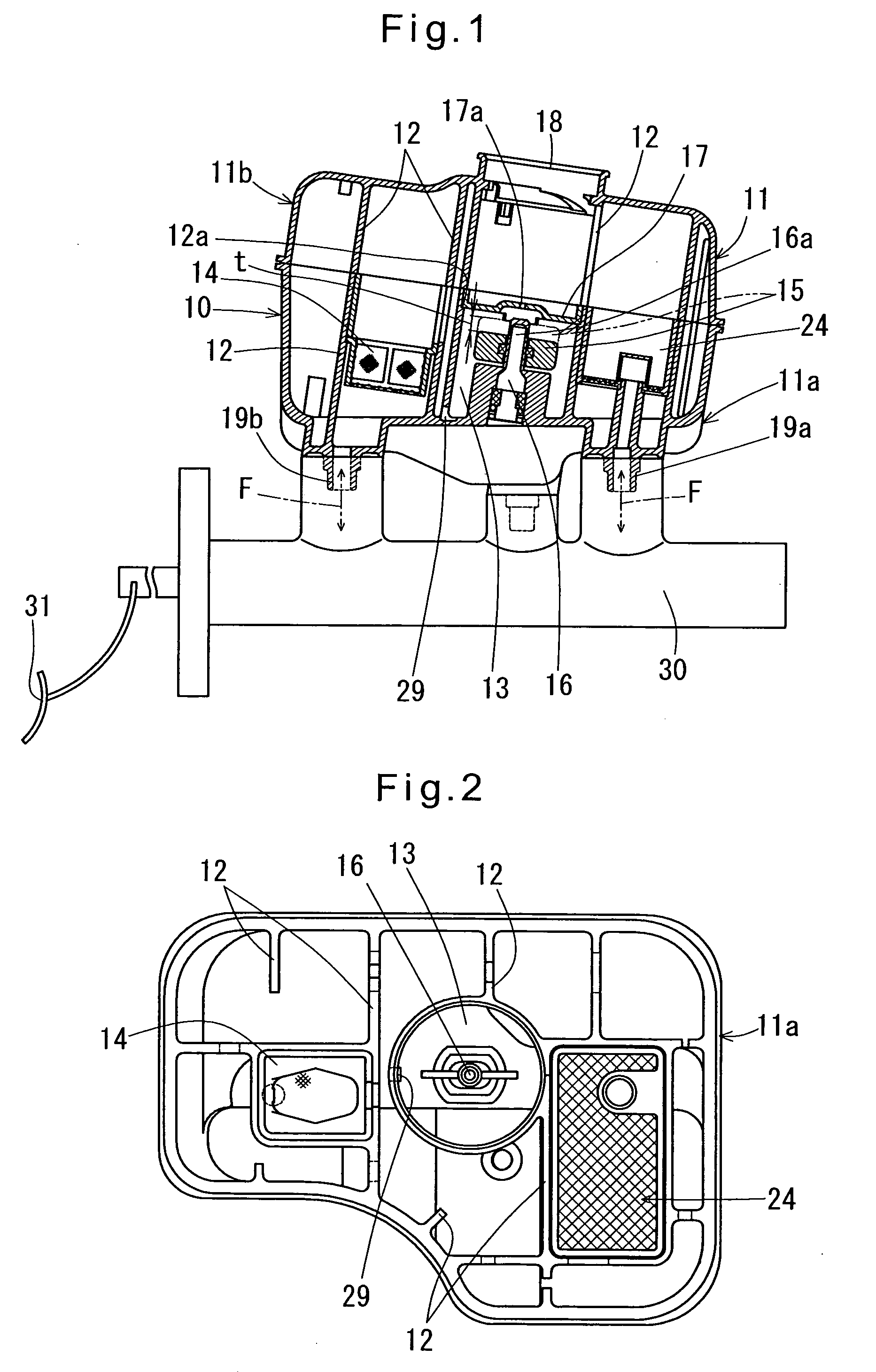

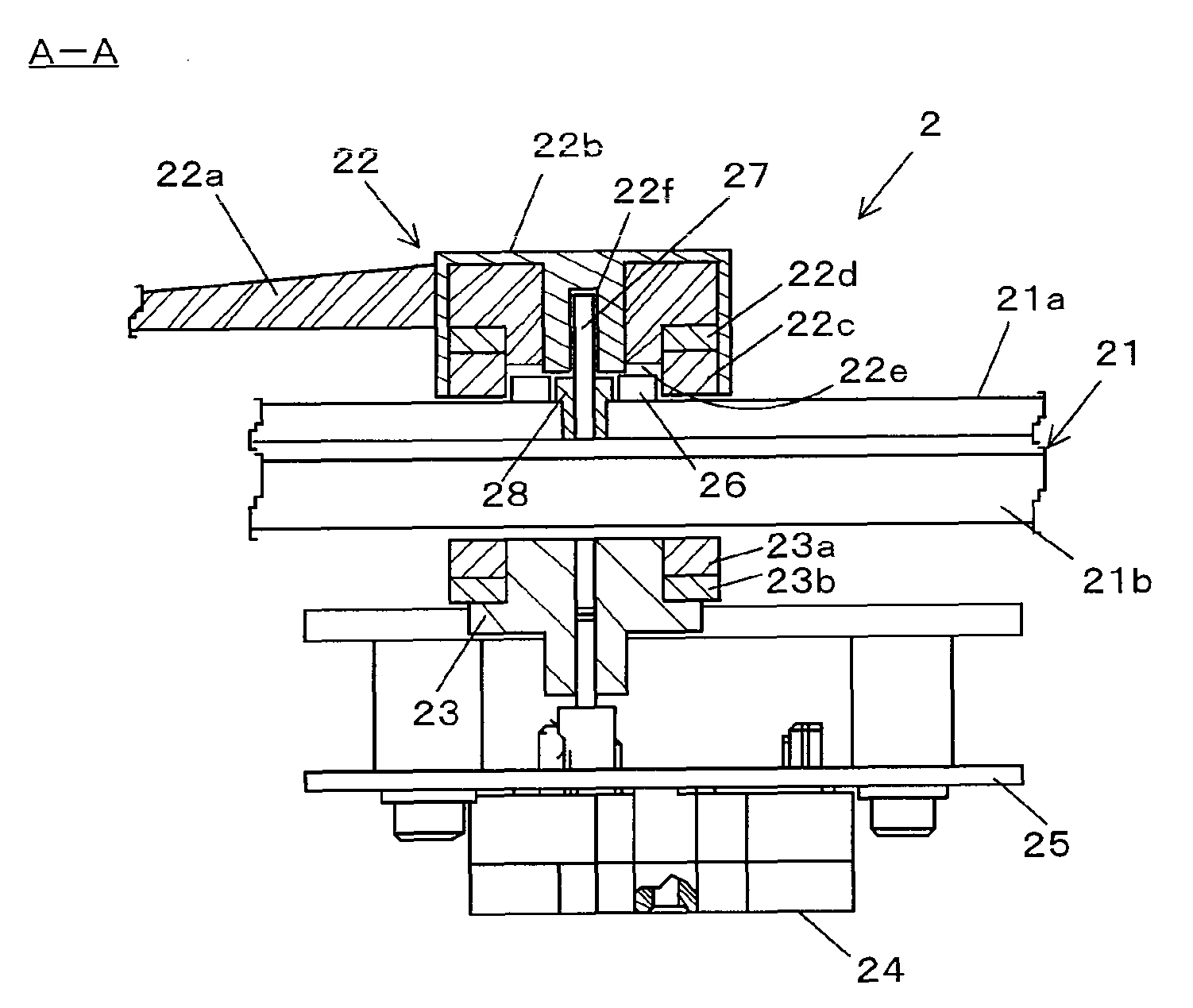

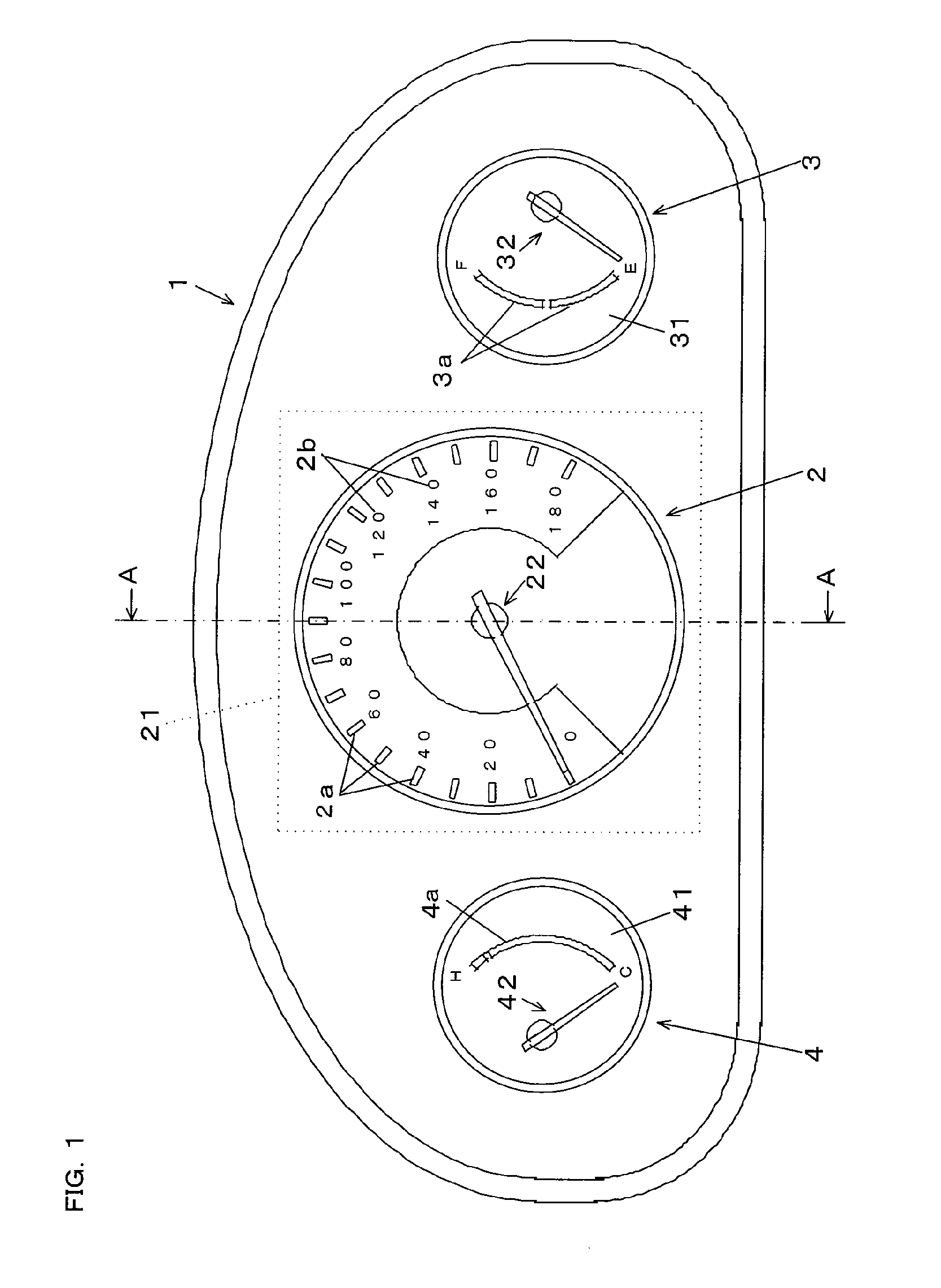

Indicator apparatus

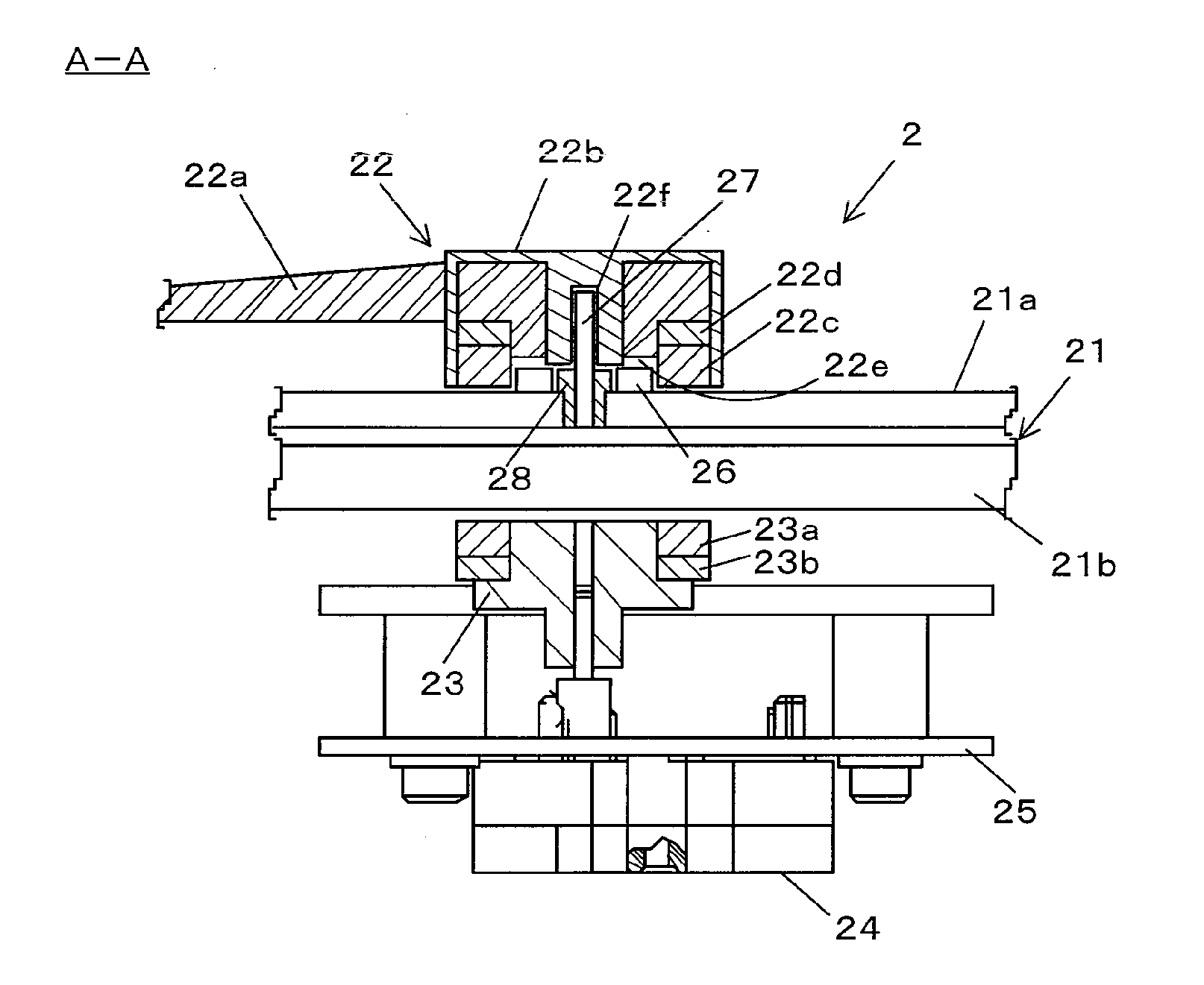

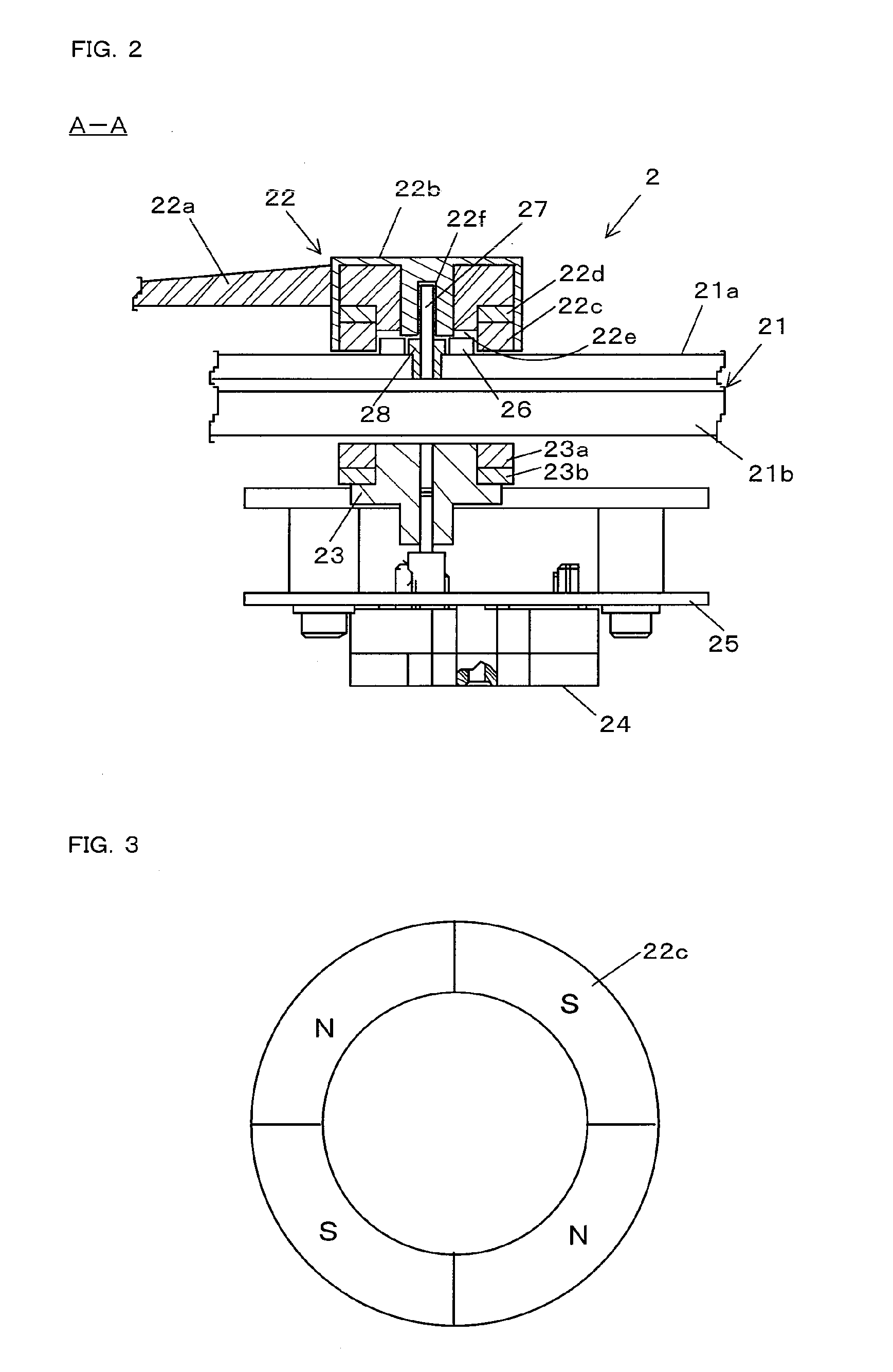

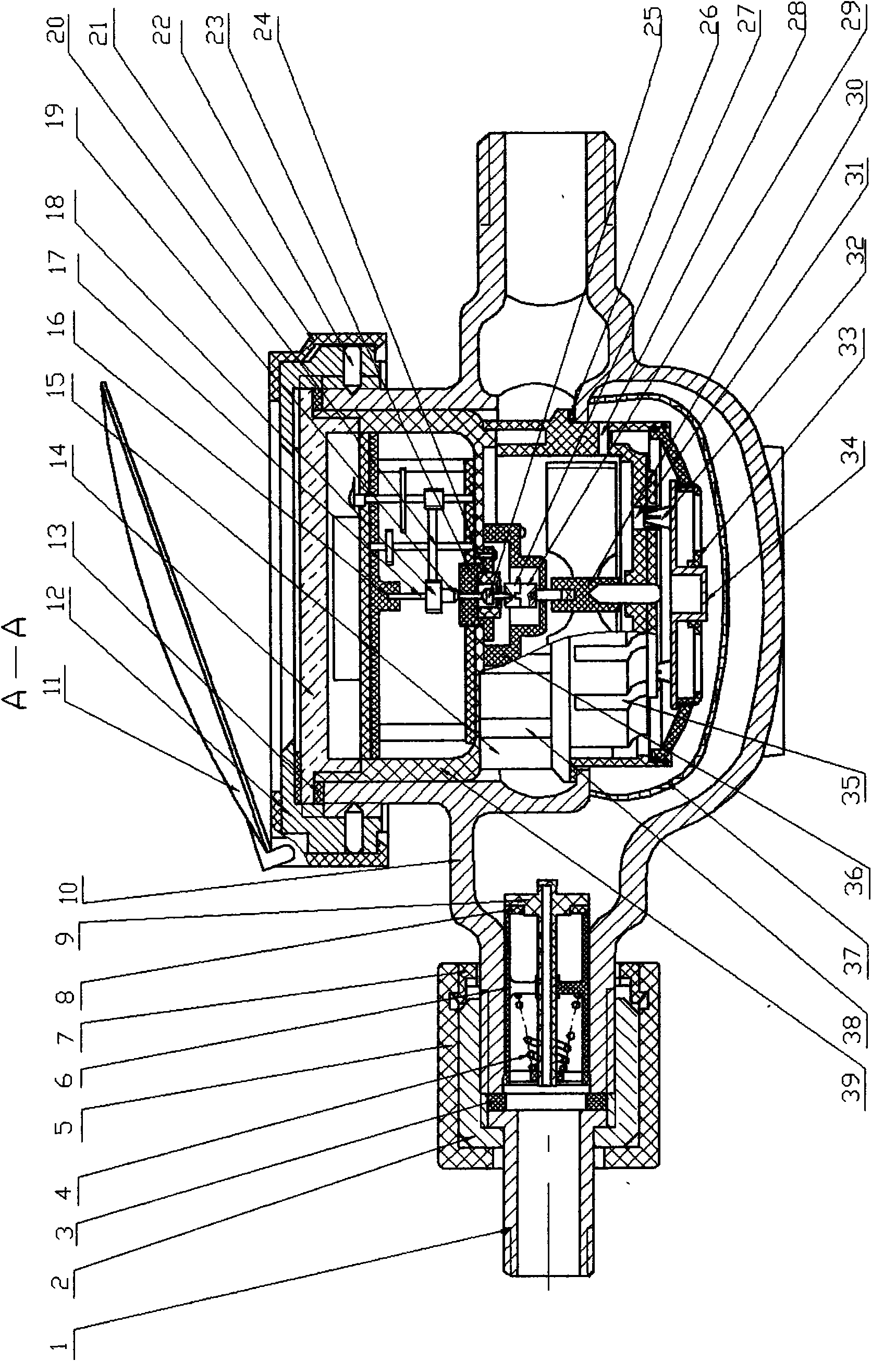

InactiveUS20100064961A1Prevent pulsationIndicator componentsMeasurement apparatus componentsComputer scienceMagnet

To provide an indicator apparatus in which a pointer is secured to a pointer drive means by attraction force of magnets and it is possible to prevent an overshoot and pulsation of the pointer with sufficient attraction force. The indicator apparatus has a display plate 21, a pointer 22 provided on a front-face side of the display plate 21, and a pointer drive means provided on a back-face side of the display plate 21 for rotating the pointer 22. The indicator apparatus includes first magnet 22c in a ring shape provided for the pointer 22 and a second magnet 23a provided for the pointer drive means to be opposite to the first magnet 22c, and the pointer 22 is rotated in association with rotation drive of the pointer drive means by attraction force of the first and second magnets 22c, 23a. A yoke 22d in a ring shape is located closer to a surface of the first magnet 22c that is not opposite to the second magnet 23a.

Owner:NIPPON SEIKI CO LTD

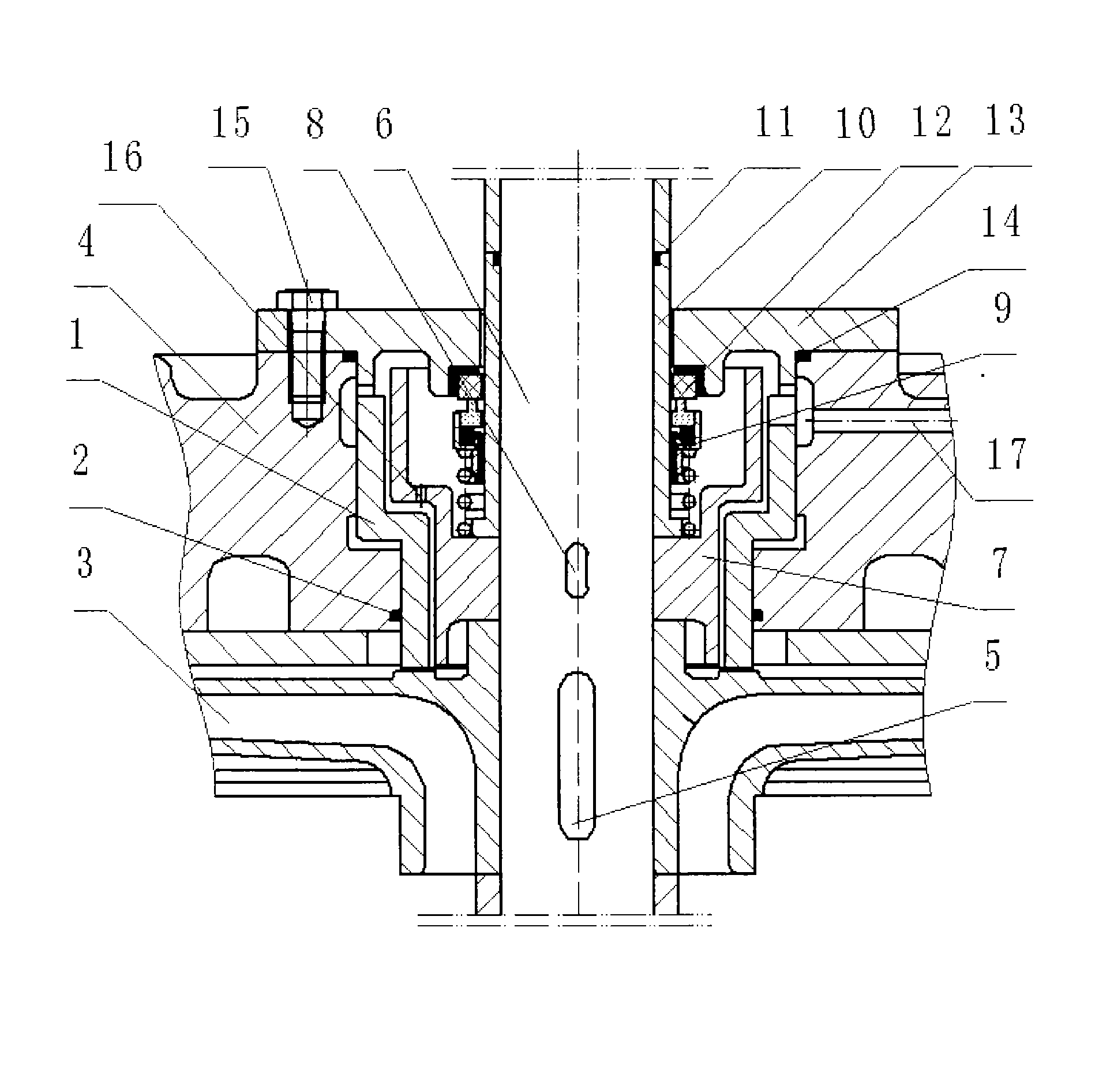

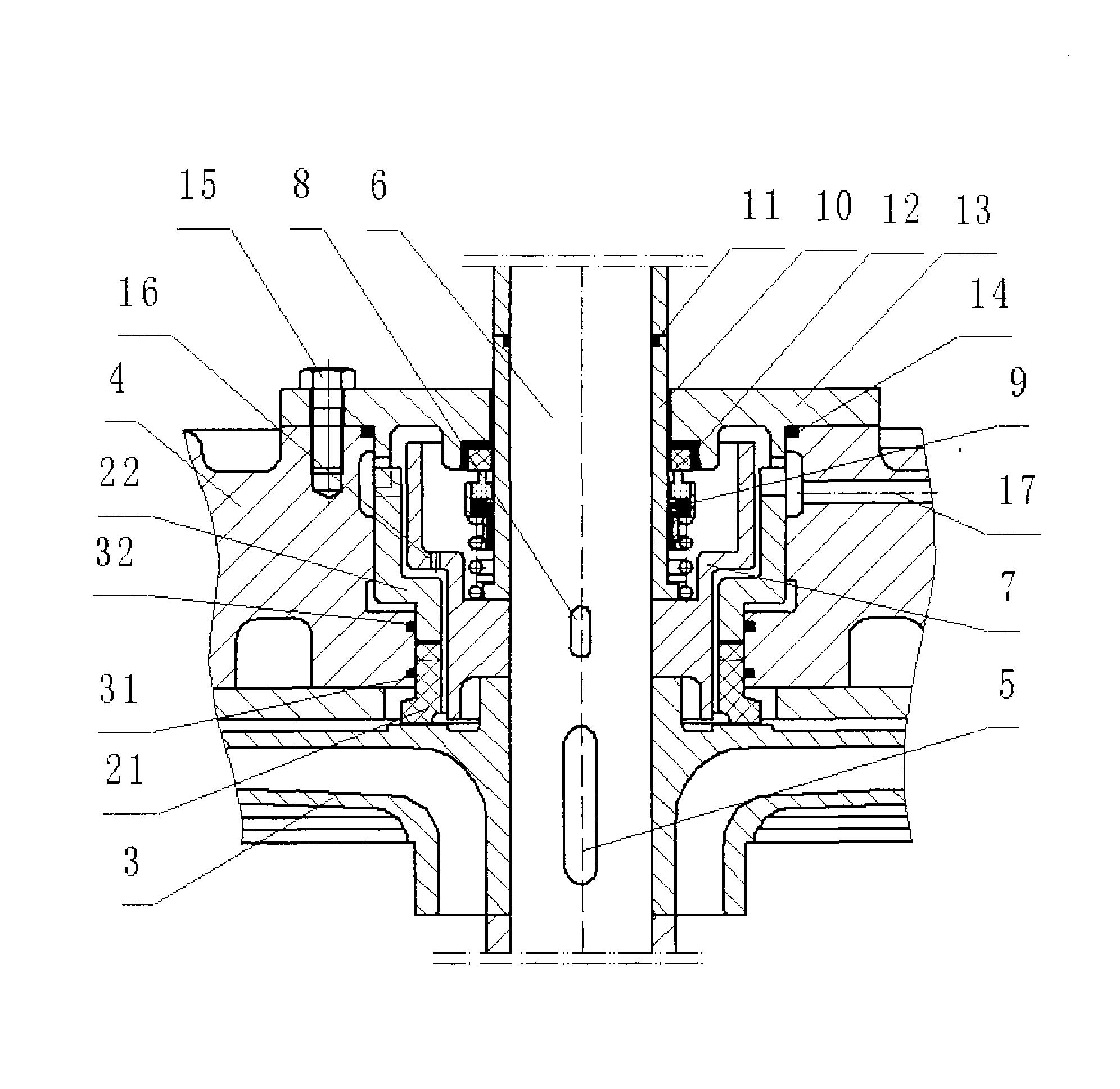

Anti-disassembly, anti-reversion, anti-pulsation, antirust and antidrip energy-saving water meter

InactiveCN101556175APrevent faucets from leakingPrevent being removedVolume/mass flow by mechanical effectsVolume meteringGear transmissionImpeller

The invention relates to an anti-disassembly, anti-reversion, anti-pulsation, antirust and antidrip energy-saving water meter belonging to a measuring instrument for preventing the running water from running away and from being stolen. A pipe connector protective sleeve sleeved on a nut for an inlet pipe connector of the water meter is buckled with a protective sleeve retaining ring to enable meter casings to be connected into a whole, a meter cover protective sleeve is buckled on a meter cover and is used for buckling and hooking the meter cover through an interlocking hook, and a positioning pin is inserted on the meter cover and connected into a whole with the meter casings so as to prevent the water meter from being disassembled and prevent the meter cover from dripping water; an anti-reversion and anti-pulsation structure formed by a check valve is arranged in an inlet of the water meter so as to avoid reversion and pulsation; the transmission between an impeller and a counting device is carried out through an ultra-thin gear transmission shaft and a lip-shaped sealing ring, and an antirust structure for a meter panel can prevent the water from entering in the counting device to cause the meter panel to rust; and symmetrical microflow holes, a recharging hole and a dead weight valve on an impeller case of the water meter and a flow regulation valve on a valve plate form an antidrip structure to avoid a dead angle to affect the accuracy in the rotating process of the impeller and water from dripping, therefore, the invention integrates the five precaution functions into a whole and plays the roles of fair water supply and water saving.

Owner:隋明祥

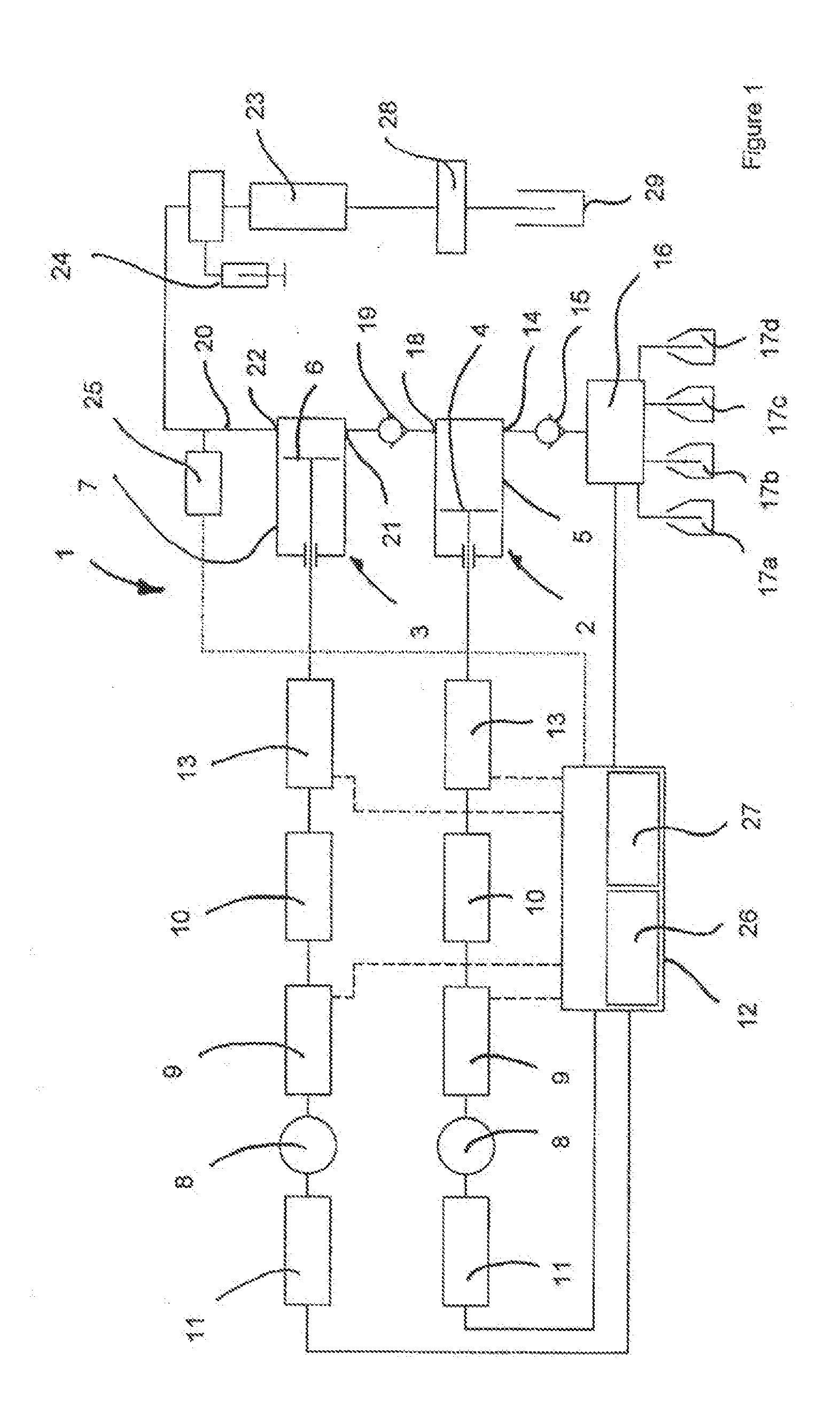

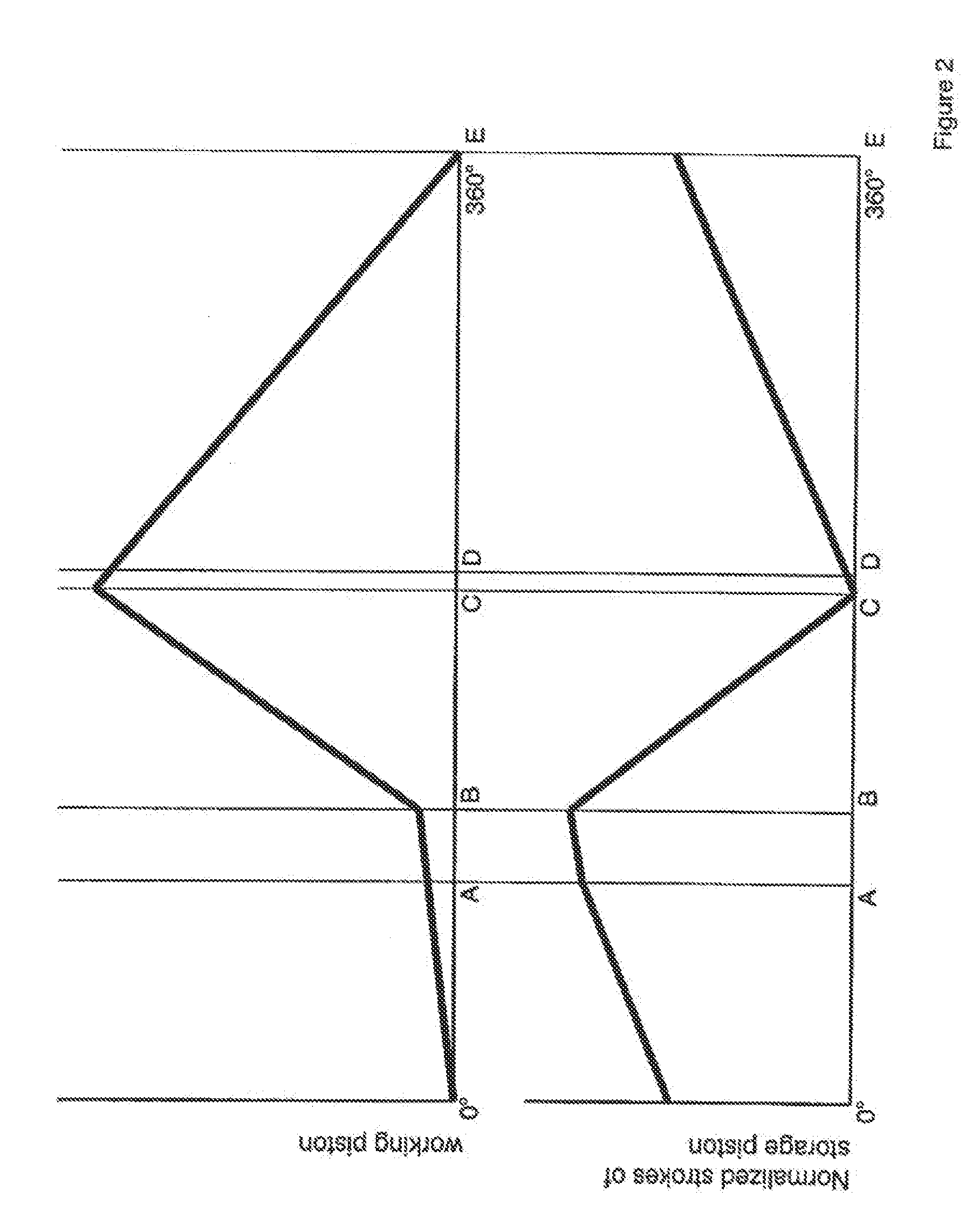

Piston Pump Having A Force Sensor And A Method For Controlling Said Pump

InactiveUS20100143155A1High delivery pressurePulsation be reduced and suppressedPump controlPump installationsMechanical forceEngineering

The present invention relates to a piston pump for generating a delivery flow, which is substantially free of pulsation, in particular to a dual piston pump, and to a method for controlling such a piston pump delivering a pumped medium from a low-pressure area into a high-pressure area, wherein measuring sensors detecting mechanical forces or moments transmitted by the structure of the pump or its associated drive unit are used instead of the pressure or flow sensors usually employed for this purpose.

Owner:FLUX INSTR

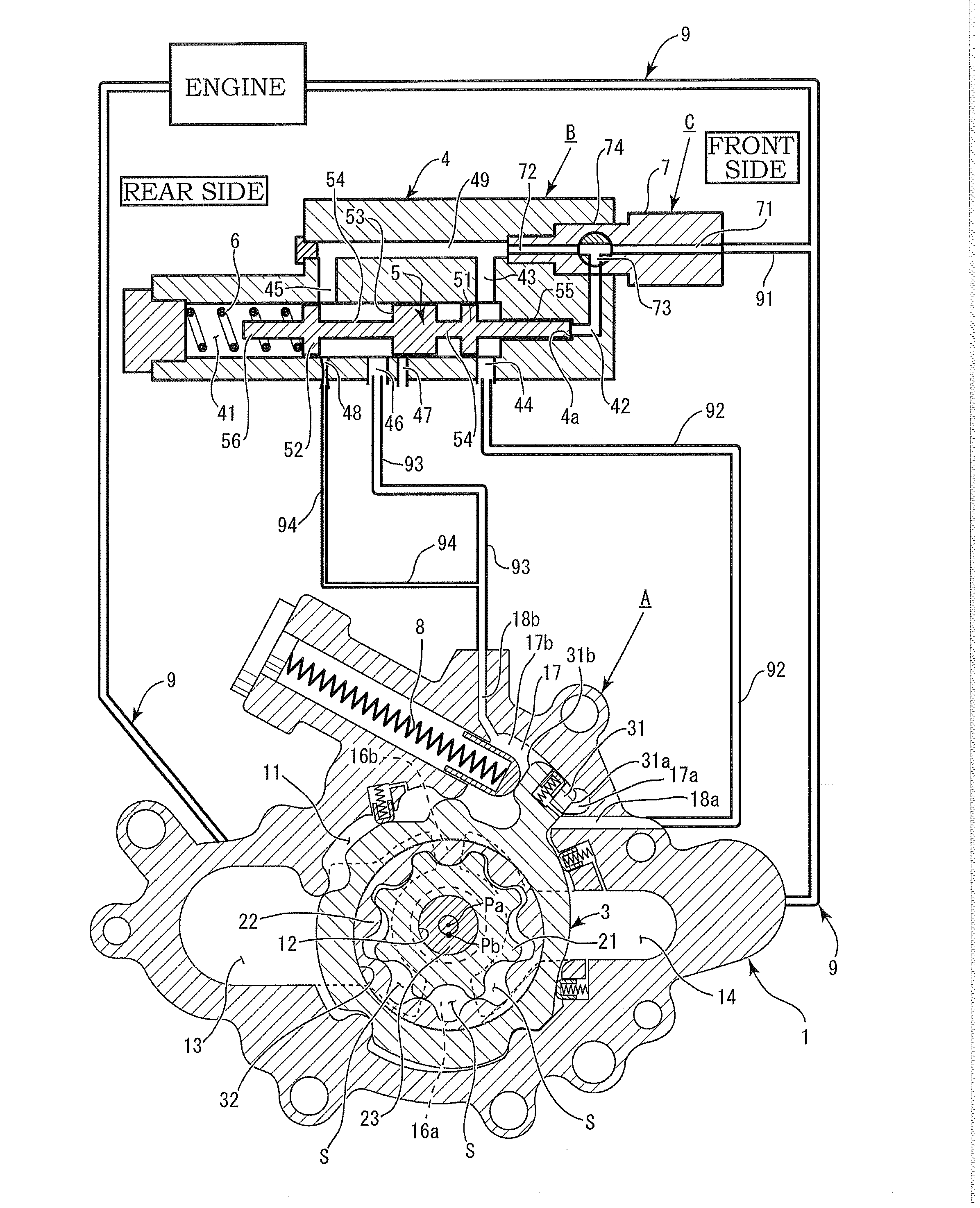

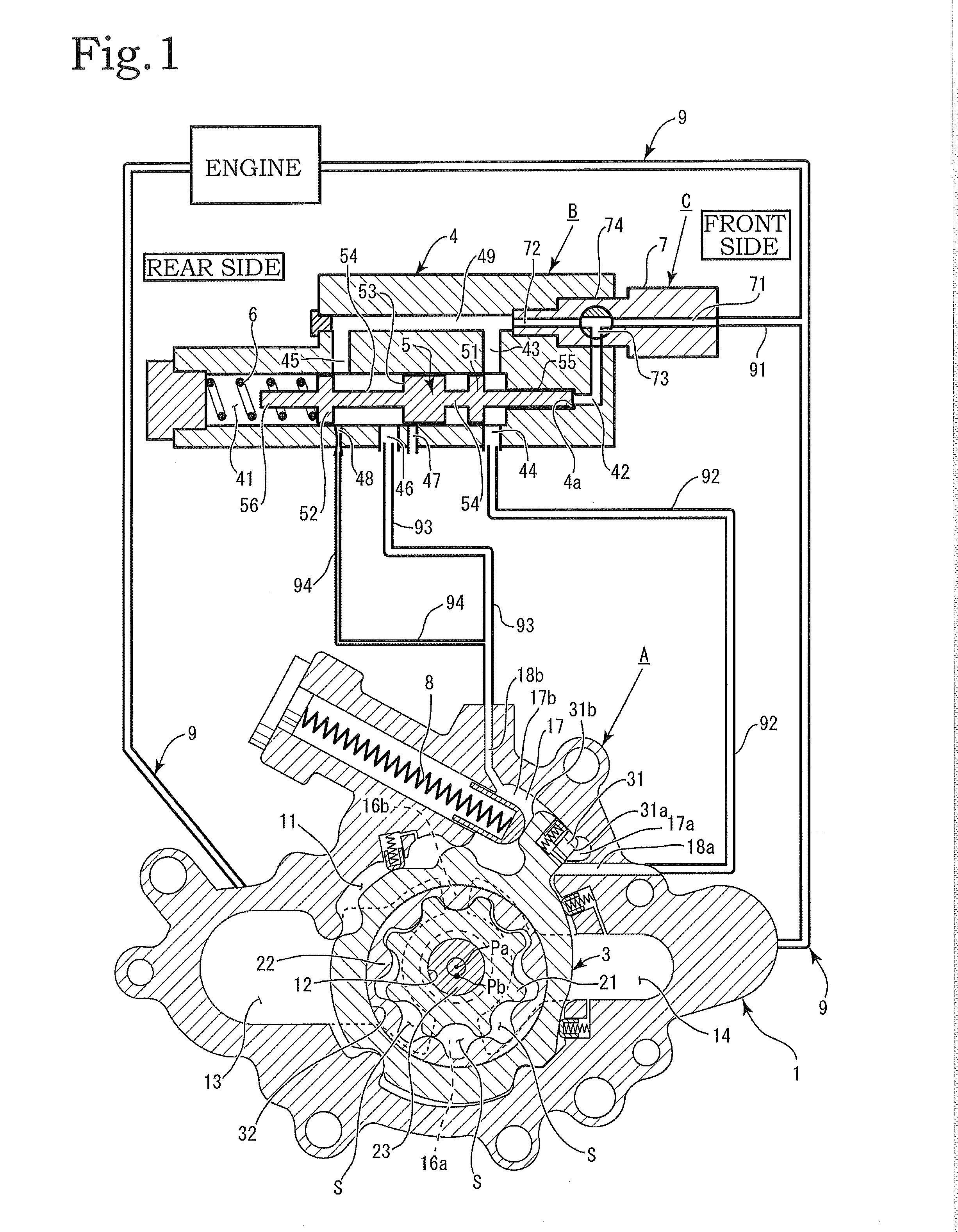

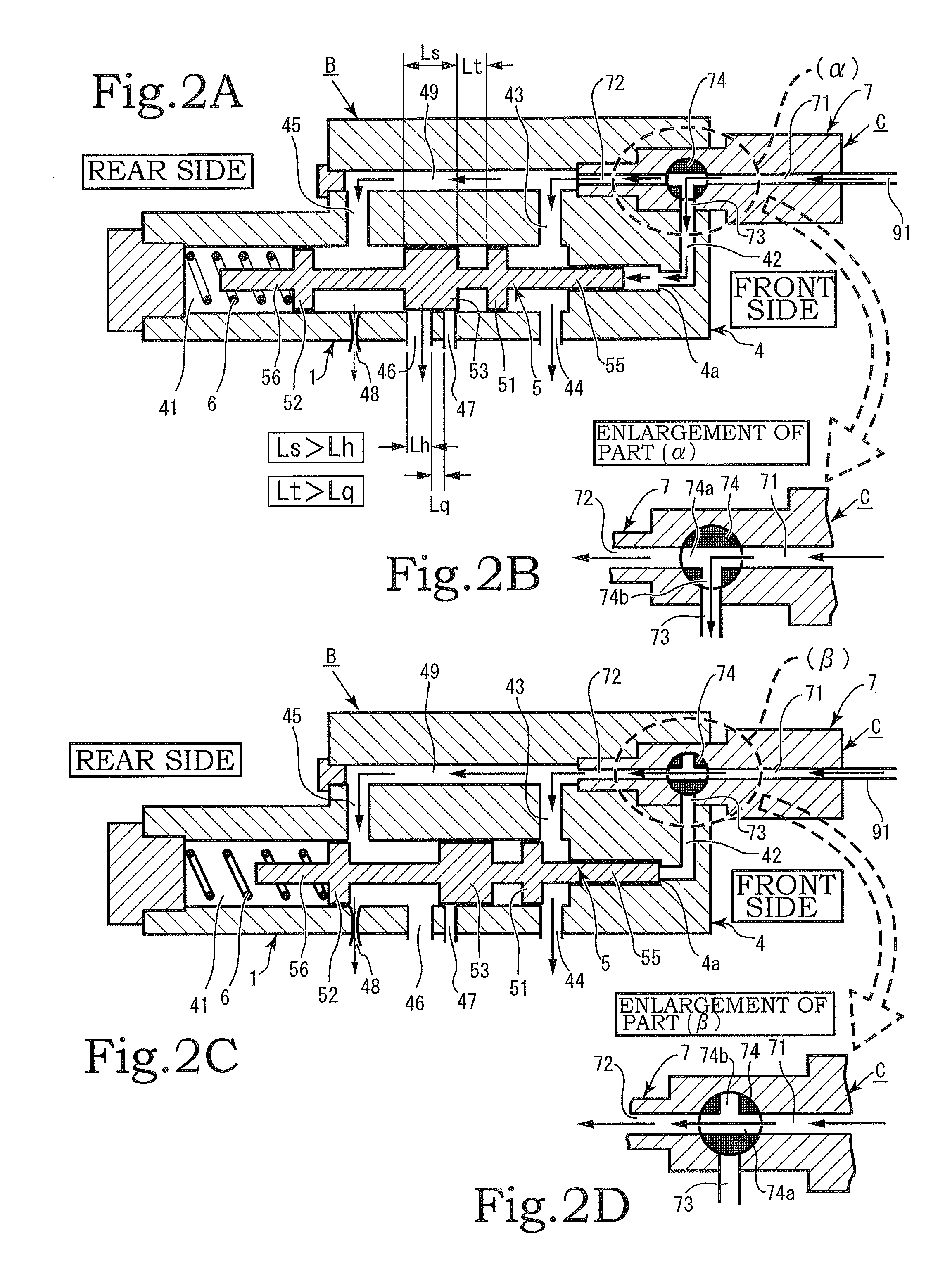

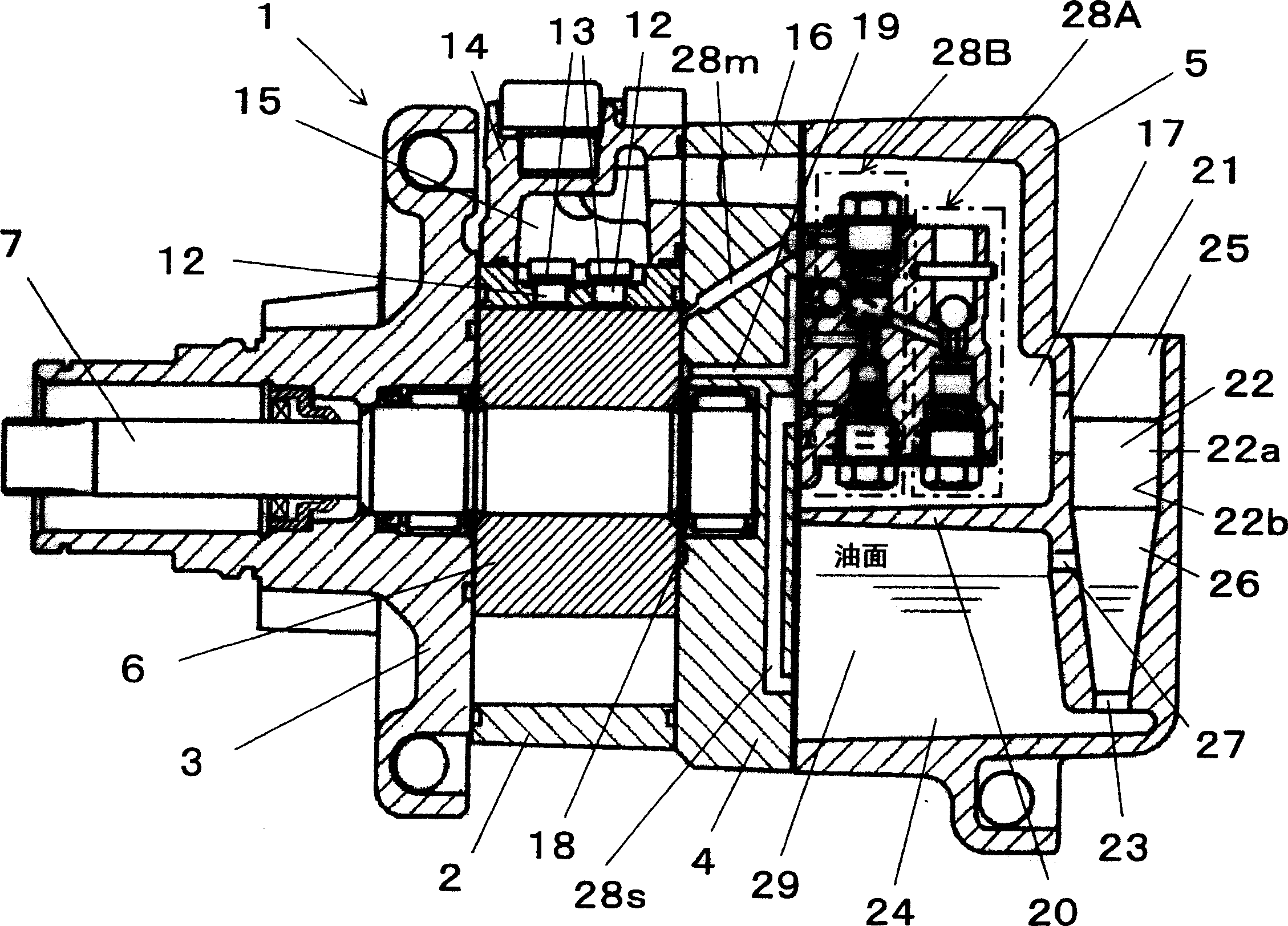

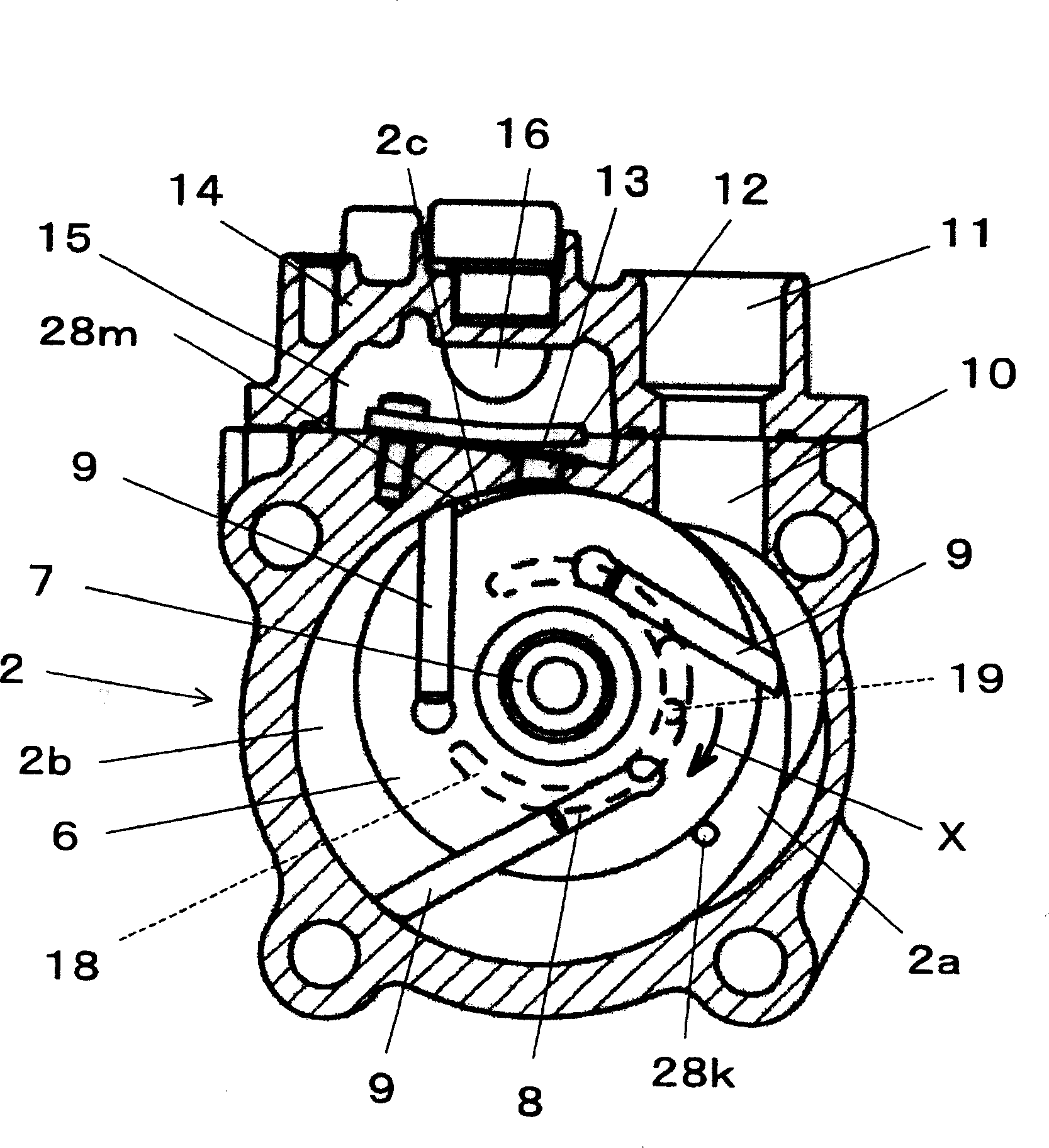

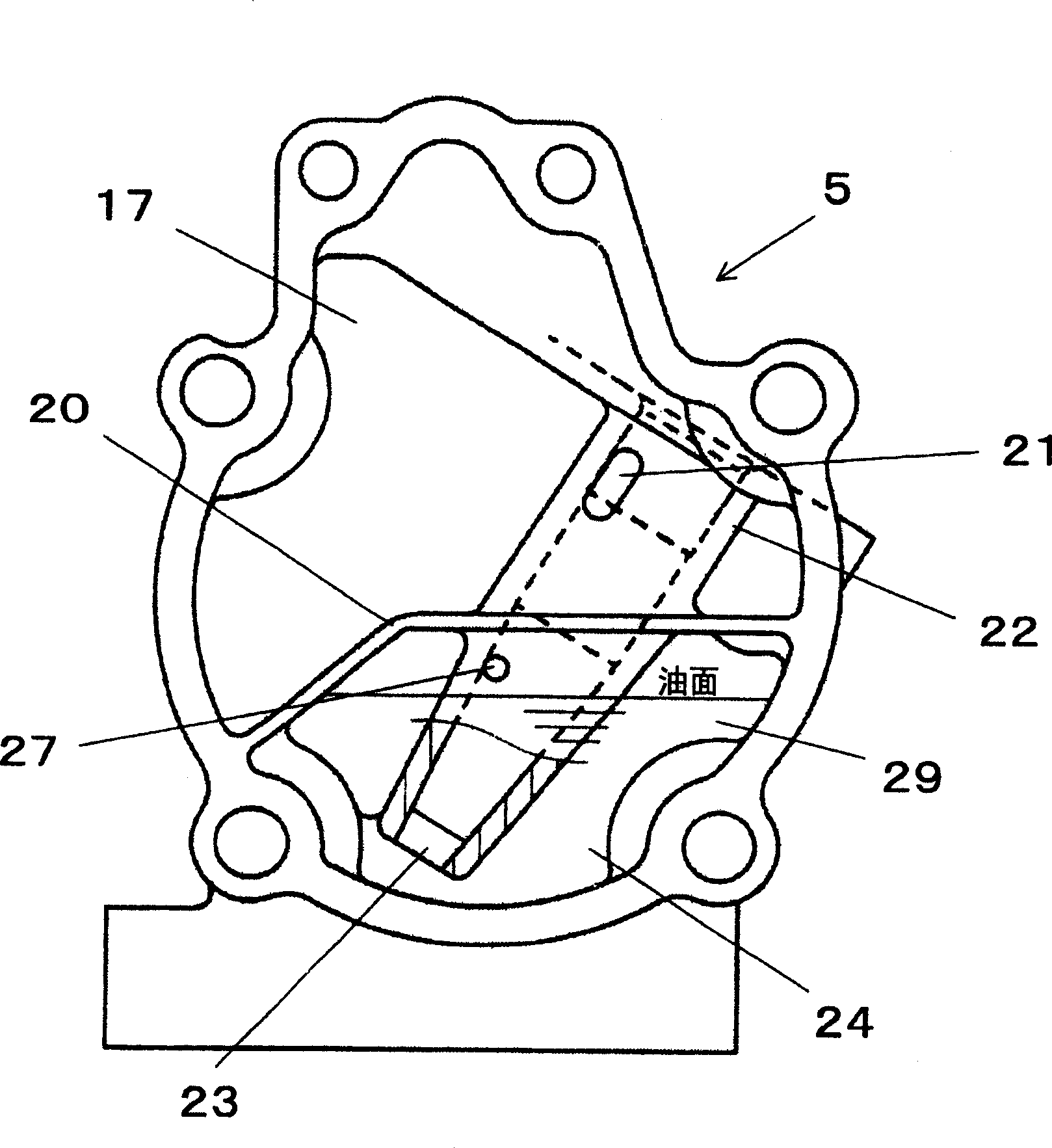

Rotary pump and brake device in which rotary pump is provided

InactiveUS20100060074A1Well formedIncrease braking powerEngine of arcuate-engagement typeEngine of intermeshing engagement typeInternal pressureRotary pump

In an inner wall surface of a casing, grooves are formed that correspond to end faces of an outer rotor and an inner rotor, and seal members are disposed within the grooves, the seal members presses against the end faces of the outer rotor and the inner rotor. Inclined portions are provided in sealing portions of resin members of seal members, the sealing portions covering a closed portion. With this configuration, an internal pressure in the closed portion causes the inclined portions to separate from an outer rotor and an inner rotor when a brake fluid pressure within the closed portion increases to the point that the brake fluid is excessively compressed, releasing the brake fluid that is inside the closed portion. It is therefore possible to prevent the brake fluid pressure from increasing excessively within the closed portion.

Owner:ADVICS CO LTD +1

Oil pump structure

InactiveUS20160090983A1Reduce noiseReduce vibrationOscillating piston enginesRotary piston pumpsSpool valveEngineering

An oil pump structure including: an oil pump having a first hydraulic control chamber and a second hydraulic control chamber; a hydraulic control valve having a valve operating oil passage, a first inflow passage, a second inflow passage, a first outflow passage, a second outflow passage and a drain flow passage; and an oil circuit, wherein the hydraulic control valve is connected to a branching flow passage of the oil circuit; a spool valve body of the hydraulic control valve has a front valve section, a rear valve section and an intermediate valve section, which are formed perpendicularly to the axial direction of a connecting shaft; an axial-direction dimension of the intermediate valve section is larger than an axial-direction dimension of the second outflow passage; the second outflow passage and the drain flow passage are both accommodated temporarily between the intermediate valve section and the front valve section due to movement of the spool valve body; and in the hydraulic control valve, a control hydraulic pressure is applied at all times to the first hydraulic control chamber, and the control hydraulic pressure is increased and decreased in the second hydraulic control chamber.

Owner:YAMADA SEISAKUSHO KK

Axial force balancing device of pump

The invention relates to an axial force balancing device of a pump, which is characterized in that an engine body at the rear end of an impeller is provided with one or a set of step type floating sealing sleeve(s). When in work, under the condition of changeable pressure at the two ends, the step type floating sealing sleeve(s) can automatically regulate the axial clearance with the impeller, thereby having the effects of reducing leakage flow rate and automatically balancing axial force; a rotating main shaft at the rear end of the impeller is provided with a step type balancing drum matched with the step type floating sealing sleeve(s); the step type balancing drum is not only matched with the function that the step type floating sealing sleeve(s) can automatically regulate the axial clearance with the impeller, but also preserves the function of the traditional balancing drum, and has the effect of labyrinth clearance seal. The axial force balancing device of the pump has compact structure and small axial dimension, is high in the generalized degree with the existing products and parts, can greatly reduce the volume loss and disk friction loss, improves the efficiency of the pump, and has the characteristics of simple structure, low manufacturing cost as well as safe and reliable use.

Owner:杨丽萍

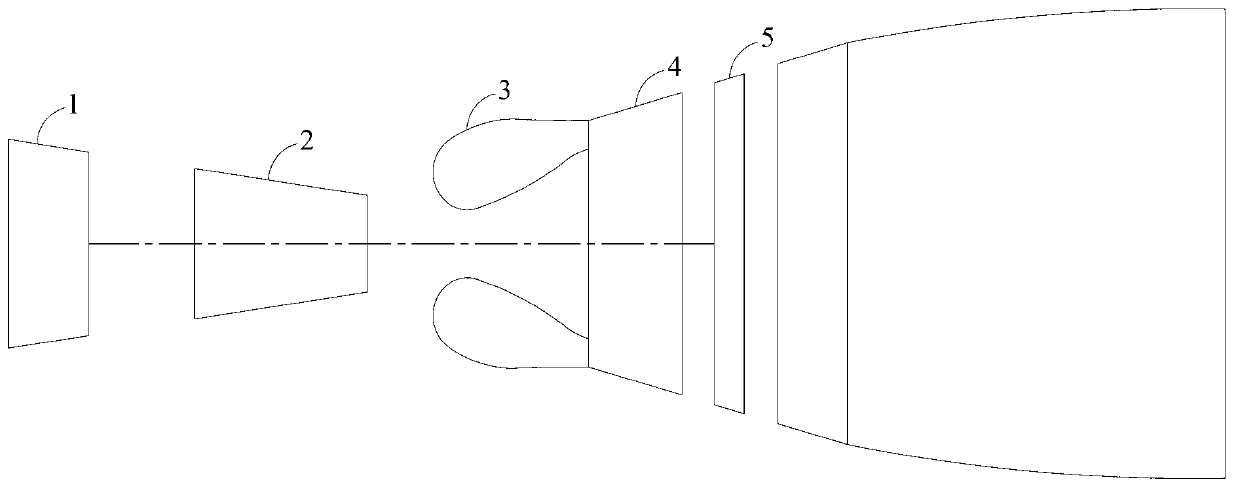

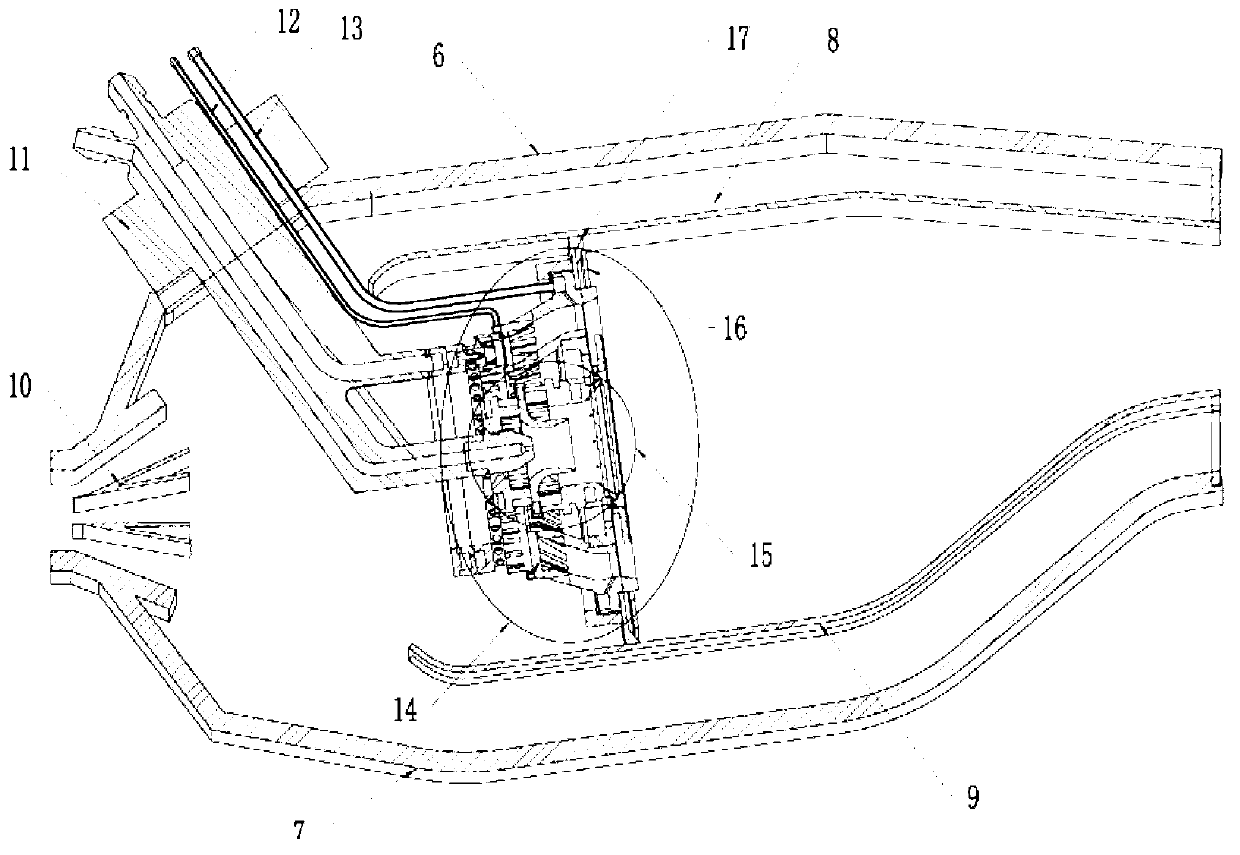

Low-pollution combustor for emission reduction through hydrogenation during aviation fuel combustion

ActiveCN103277813APromote oxidationPromote disseminationContinuous combustion chamberCombustion chamberHydrogen

The invention relates to a low-pollution combustor for emission reduction through hydrogenation during aviation fuel combustion. As a whole, the combustor adopts a premixed lean combustion mode, wherein the head portion of the combustor adopts the mode that a preliminary combustion stage center and a main combustion stage center are in staged combustion, and the overall structure of a flame tube is a single-ring cavity. A preliminary combustion stage adopts a diffusive combustion mode to guarantee stable combustion. A main combustion stage adopts a premixed combustion to lower pollutant discharge of large working conditions. The preliminary combustion stage and the main combustion stage can adopt a hydrogenation auxiliary combustion mode respectively or simultaneously, therefore, the efficiency and the stability of extremely lean combustion are guaranteed, the limit of the lean combustion is expanded, the temperature and the combustion pulsation in a combustion zone are reduced, and the purpose of reducing the pollutant discharge of nitric oxides NOx is achieved. According to the low-pollution combustor for the emission reduction through the hydrogenation during the aviation fuel combustion, hydrogenation assistance is conducted on the aviation fuel combustion, the pollutant discharge of NOx is lowered substantially through the extremely lean consumption, the fuel is mainly aviation fuel, the hydrogenation only plays a role in assisting combustion, the total consumption of hydrogen is low, and the requirement for the improvement of an engine and aircraft hardware is low. The low-pollution combustor has the advantage of fuel flexibility.

Owner:BEIHANG UNIV

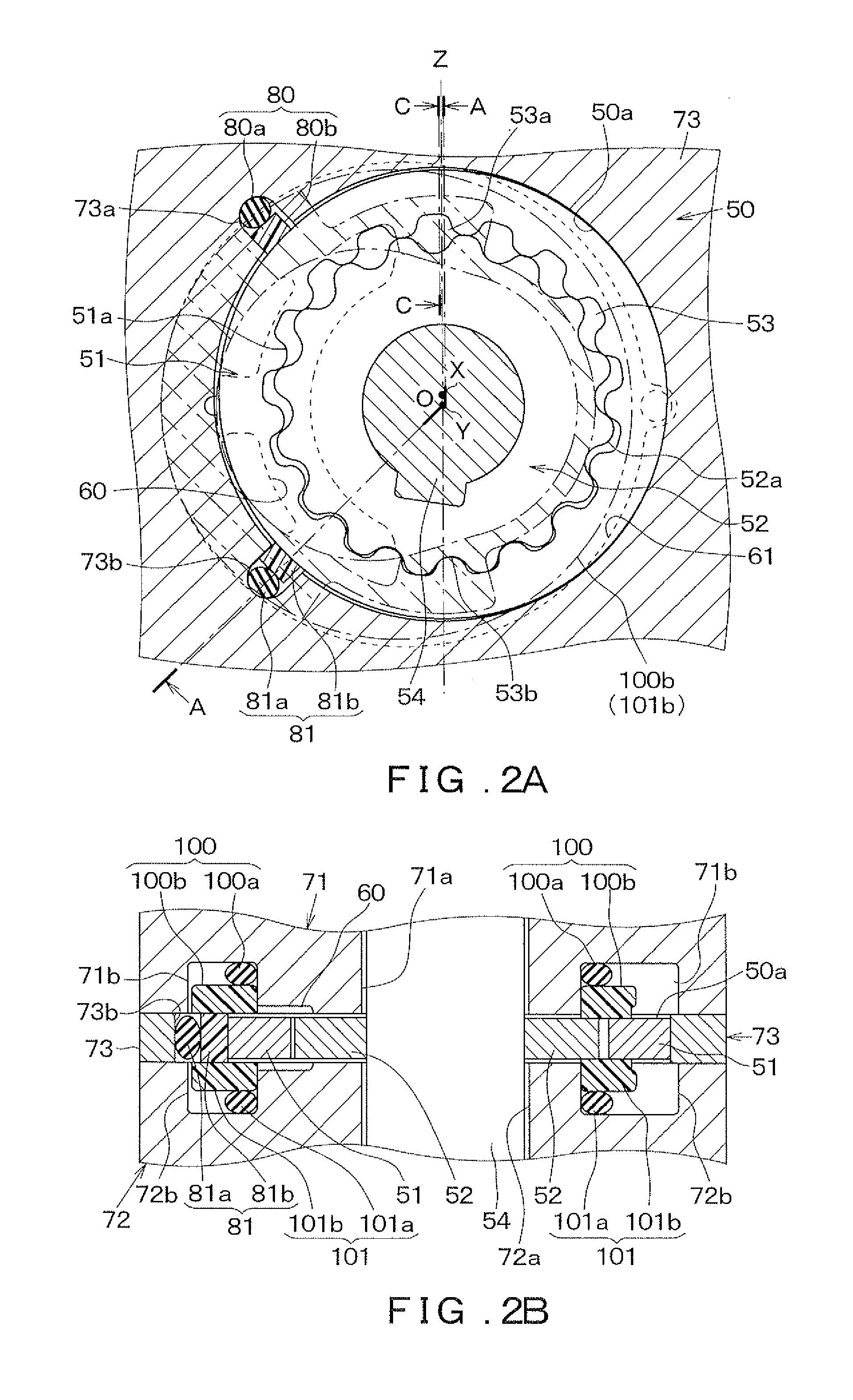

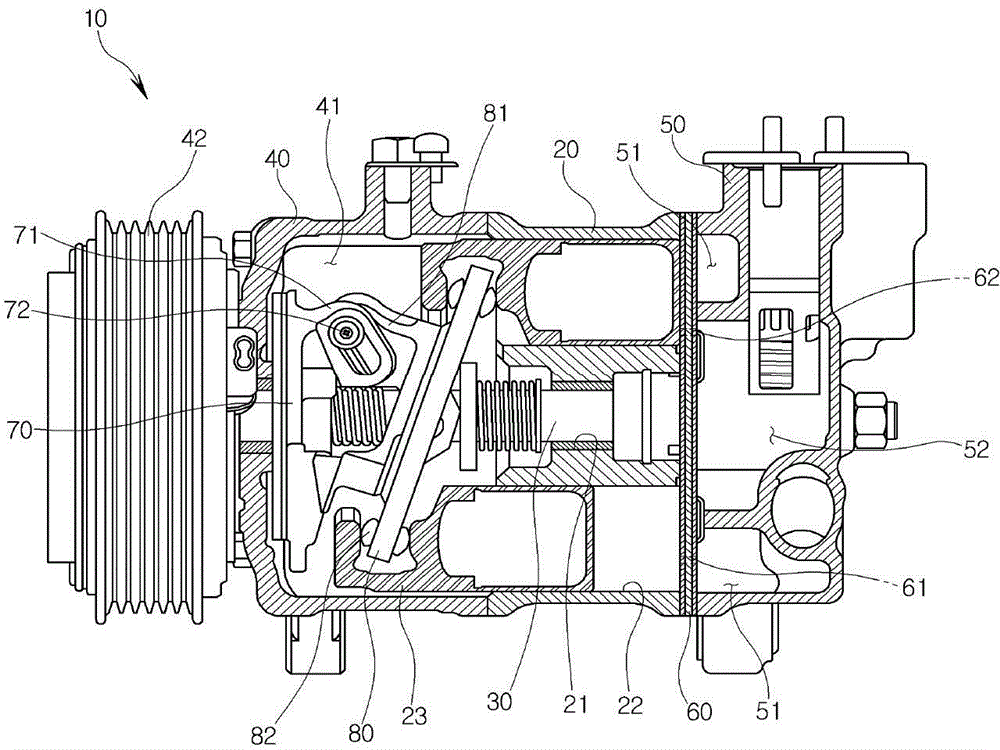

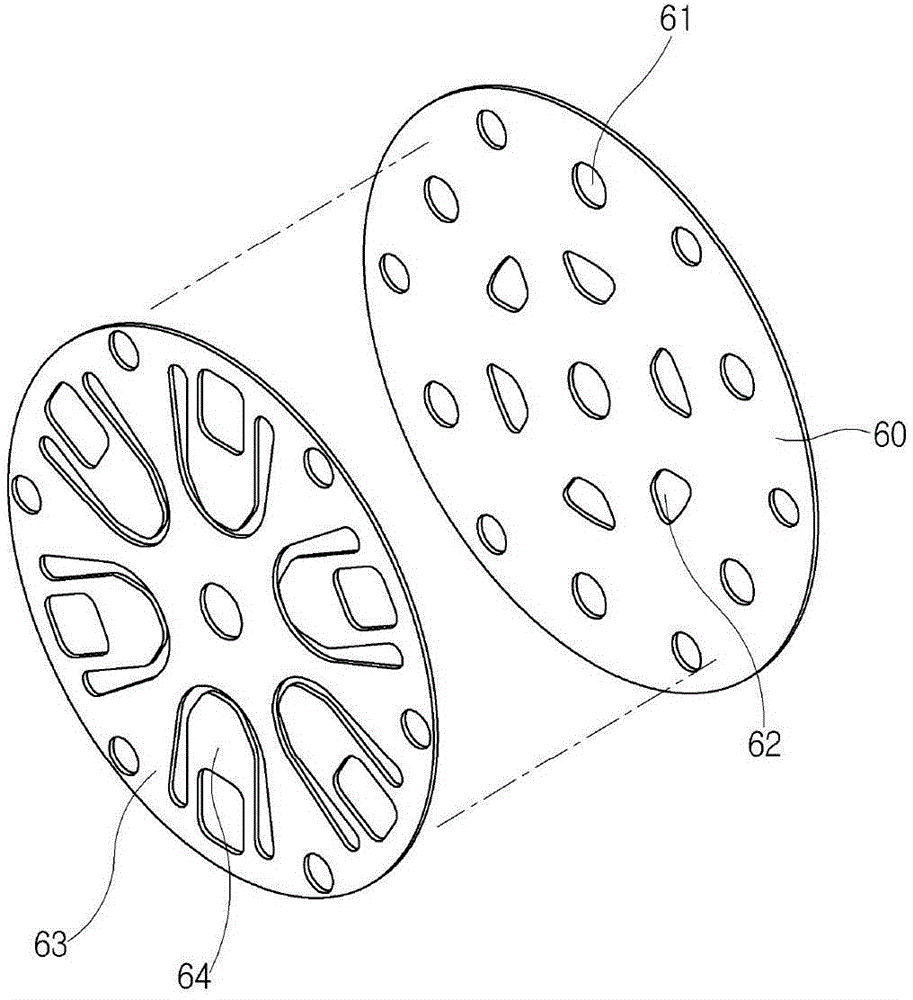

Scroll type fluid machine having a first scroll wrap unit with a scroll member and a scroll receiving member, and a second scroll wrap unit engaged with the first scroll wrap unit

ActiveUS7445437B1Good rotation balanceUseless spaceEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

A scroll type fluid machine includes a housing, a first scroll unit arranged rotatably in the housing and a second scroll unit rotating with rotation of the first scroll unit and gyrating relative to the first scroll unit to vary volumes of compression spaces. The first scroll unit includes a first wrap group including two end plates with support shafts supported rotatably by the housing and scrolled wraps arranged uniformly. The second scroll unit includes a cylindrical outer peripheral ring portion held slidably between the end plates of the first scroll unit, a connection block portion located in a center portion and a second wrap group having plural scrolled wraps extending from the ring portion to the connection block portion to define insertion spaces into which the wraps of the first wrap group are inserted and, with the first wrap group, forming compression spaces.

Owner:SCROLL GIKEN

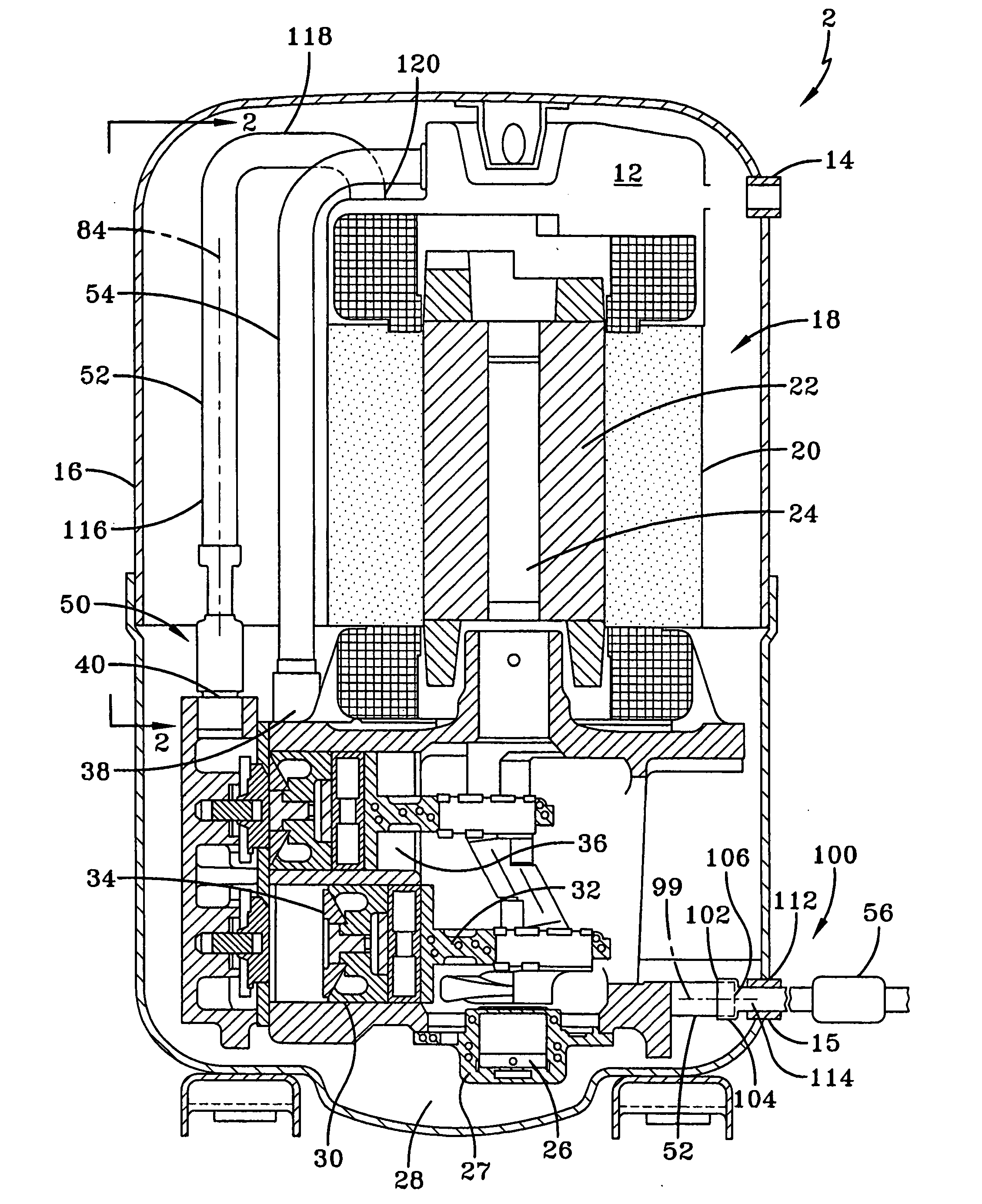

Muffler system for a compressor

InactiveUS20050276711A1Small sizeNot adversely affecting the compressor operating efficiencyPositive displacement pump componentsPump controlEngineeringExpansion chamber

A muffler system for a compressor includes an expansion chamber muffler for reducing pressure pulses at the compressor's fundamental pulsation frequency and a side-branch muffler for filtering high-frequency pressure pulses. The expansion muffler is positioned along the compressor discharge stream at a location that maximizes pulsation reduction at the compressor's fundamental pulsation frequency. The side-branch muffler is tuned to the frequency at which the pulsation reduction for the expansion muffler is at a minimum.

Owner:BRISTOL COMPRESSORS INT

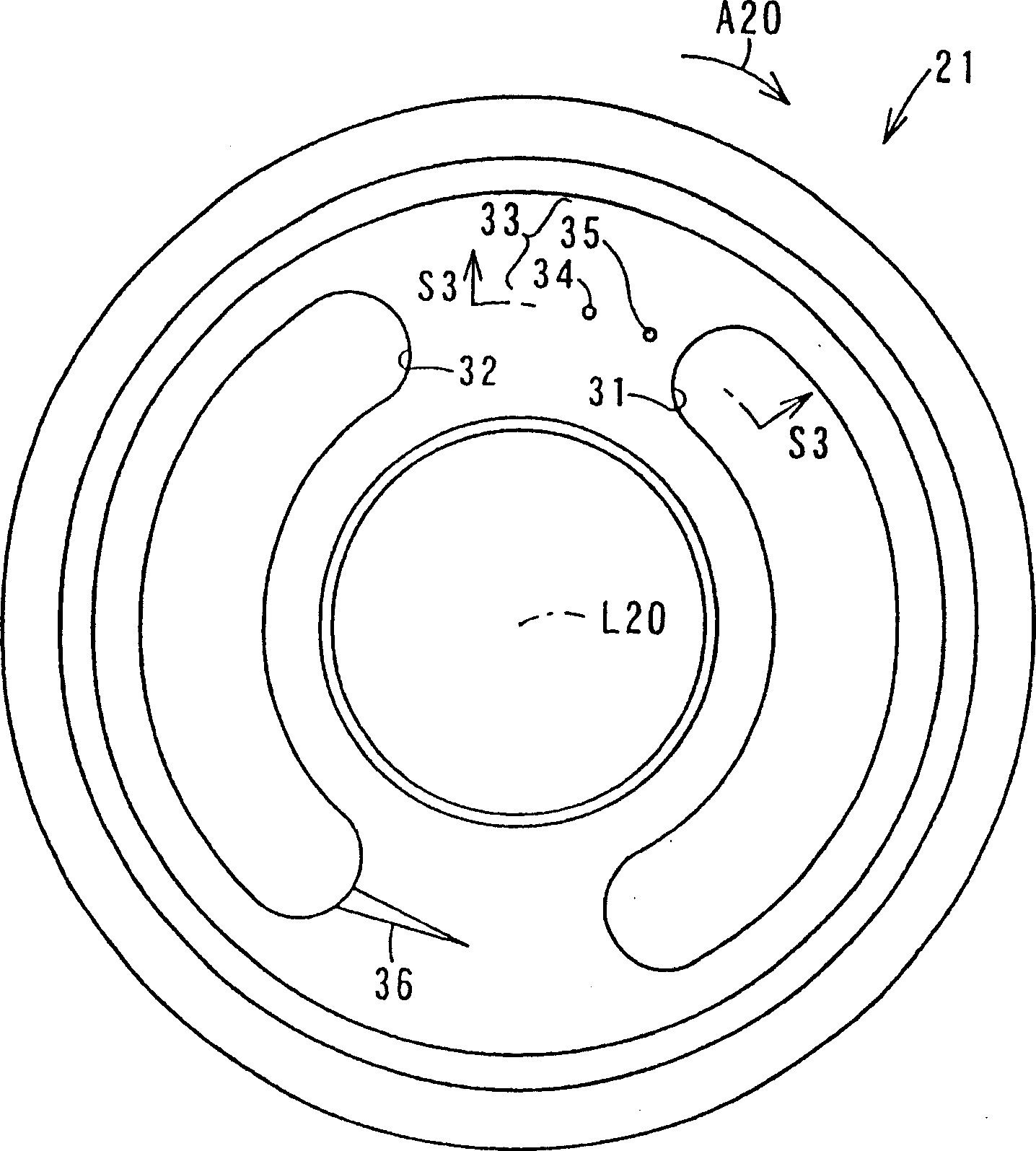

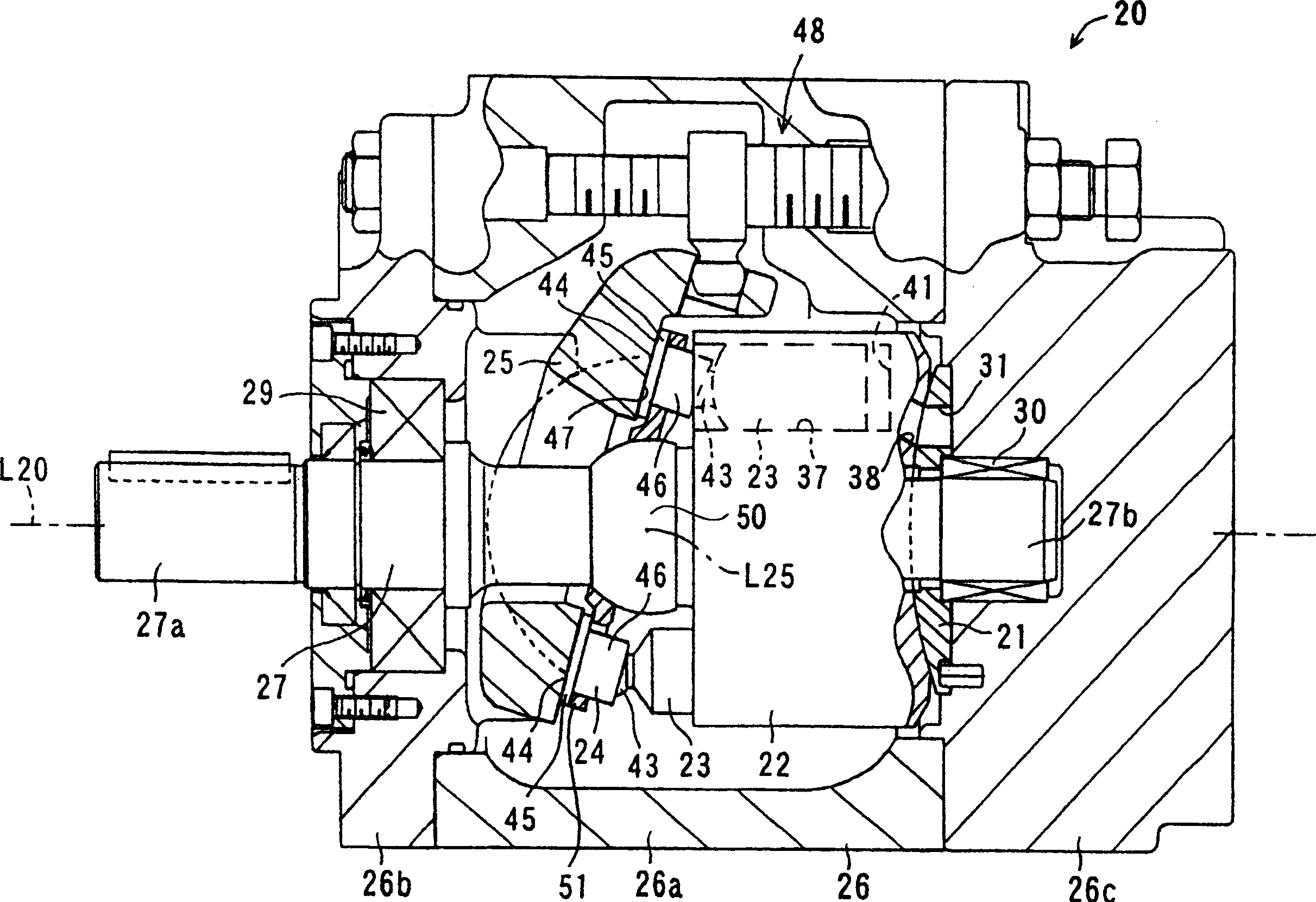

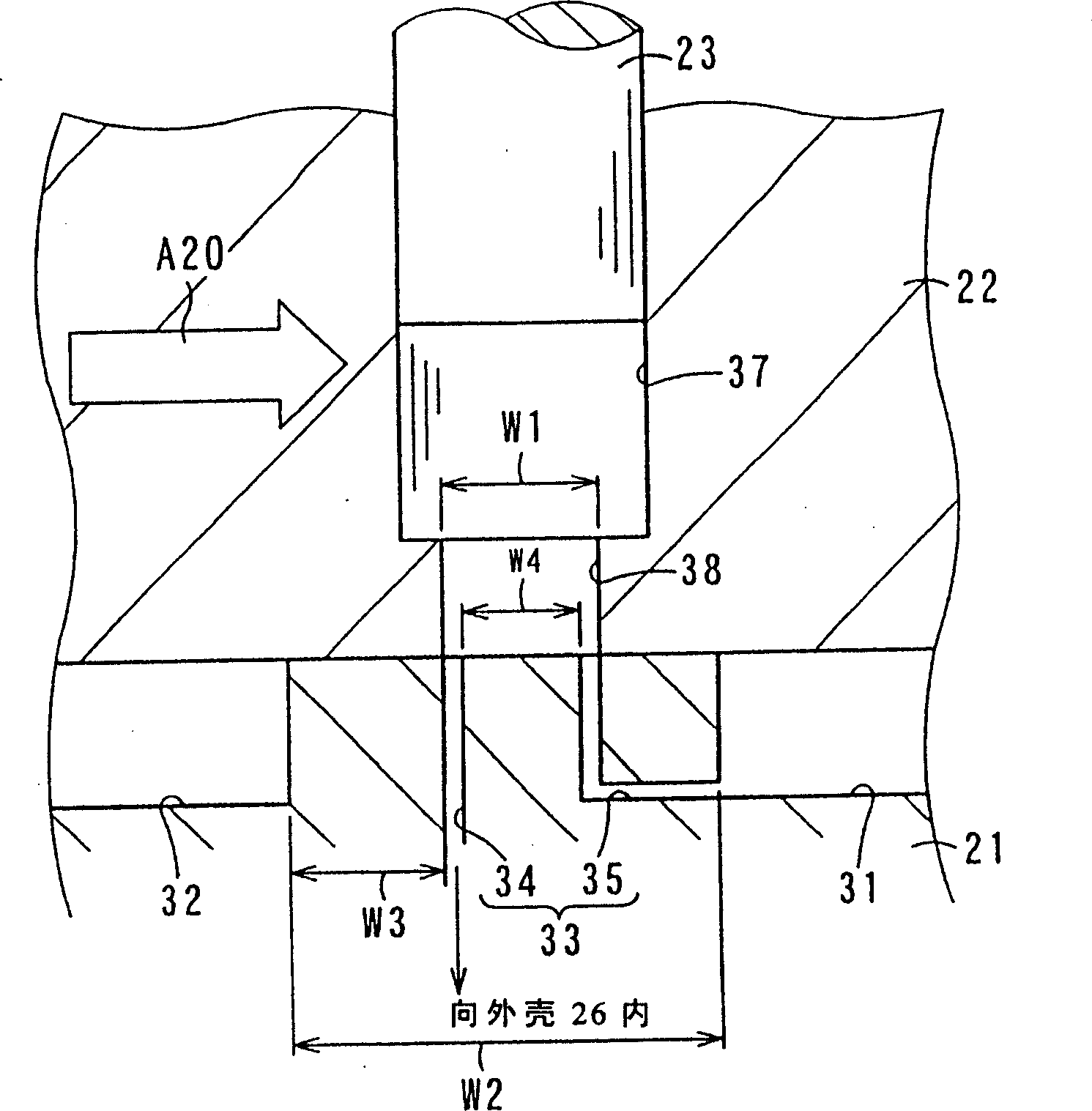

Valve plate and hydraulic apparatus with the same

ActiveCN1892032AReduce noiseAvoid damagePositive displacement pump componentsPisciculture and aquariaWorking fluidCavitation

Provided an efficient valve plate capable of keeping noise low and a hydraulic device provided with the same. A pressure release port 33 including a first and a second pressure release hole 34, 35 is formed on an upstream side of a rotary direction A20 of a cylinder block 22 in relation of an intake port 31 on the valve plate 21. The pressure release port 33 opens a cylinder port in multiple steps, and discharges working fluid in a piston chamber 37 before the piston chamber 37 is connected to the intake port 31. Consequently, jet is prevented from occurring when the piston chamber 37 is connected to the intake port 31, noise can be prevented and cavitation damage of the valve plate 21 can be prevented.

Owner:KAWASAKI HEAVY IND LTD

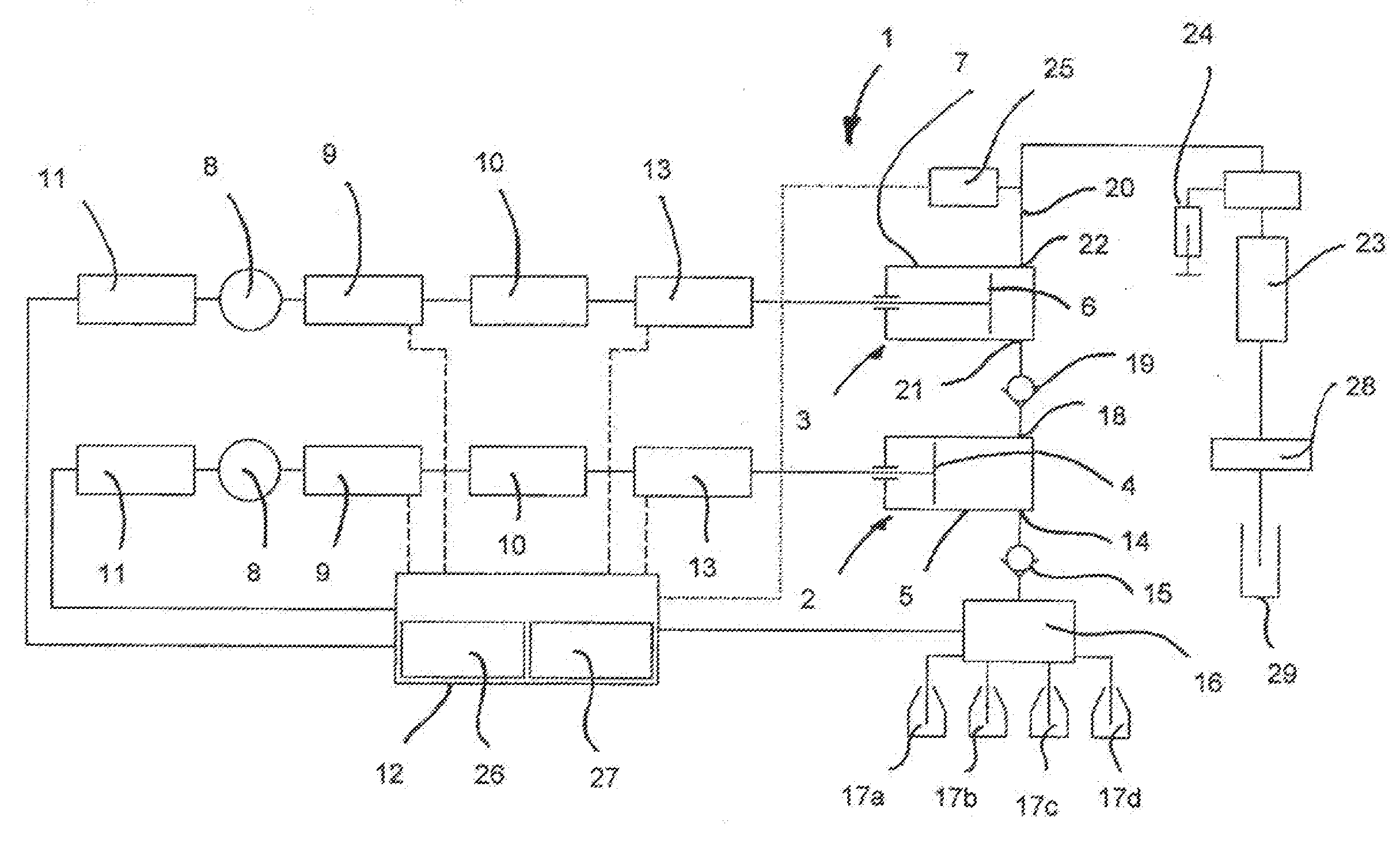

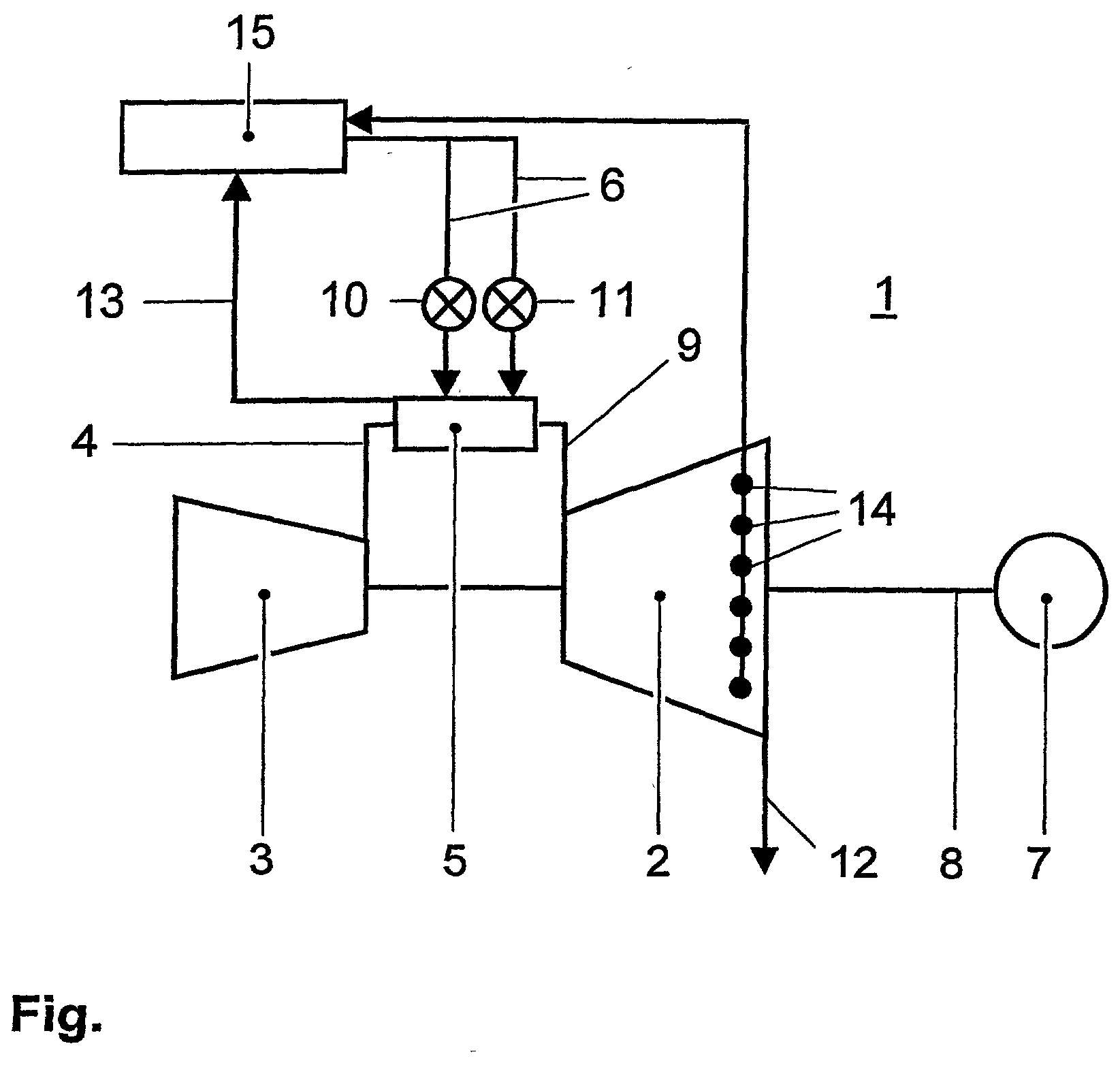

Method for running up a gas turbine plant

InactiveUS20020194851A1Short warm-up timeSignificant positive effectContinuous combustion chamberTurbine/propulsion engine ignitionCombustion chamberLow load

A method for running up a gas turbine plant (1) is disclosed. In the method, a fuel (6) is injected into the combustion chamber (5) via a plurality of pilot burners (10) and premix burners (11). During the start-up and in a lower load range, the combustion chamber (5) is operated in the pilot mode, and, at a specific time point, the combustion chamber (5) is changed over from the pilot mode to the premix mode. The changeover time point from the pilot mode to the premix mode depends on a variable changeover temperature (TSWO), and this changeover temperature (T-SWO) is determined from pulsations occurring in the flame of the combustion chamber (5).

Owner:ANSALDO ENERGIA IP UK LTD

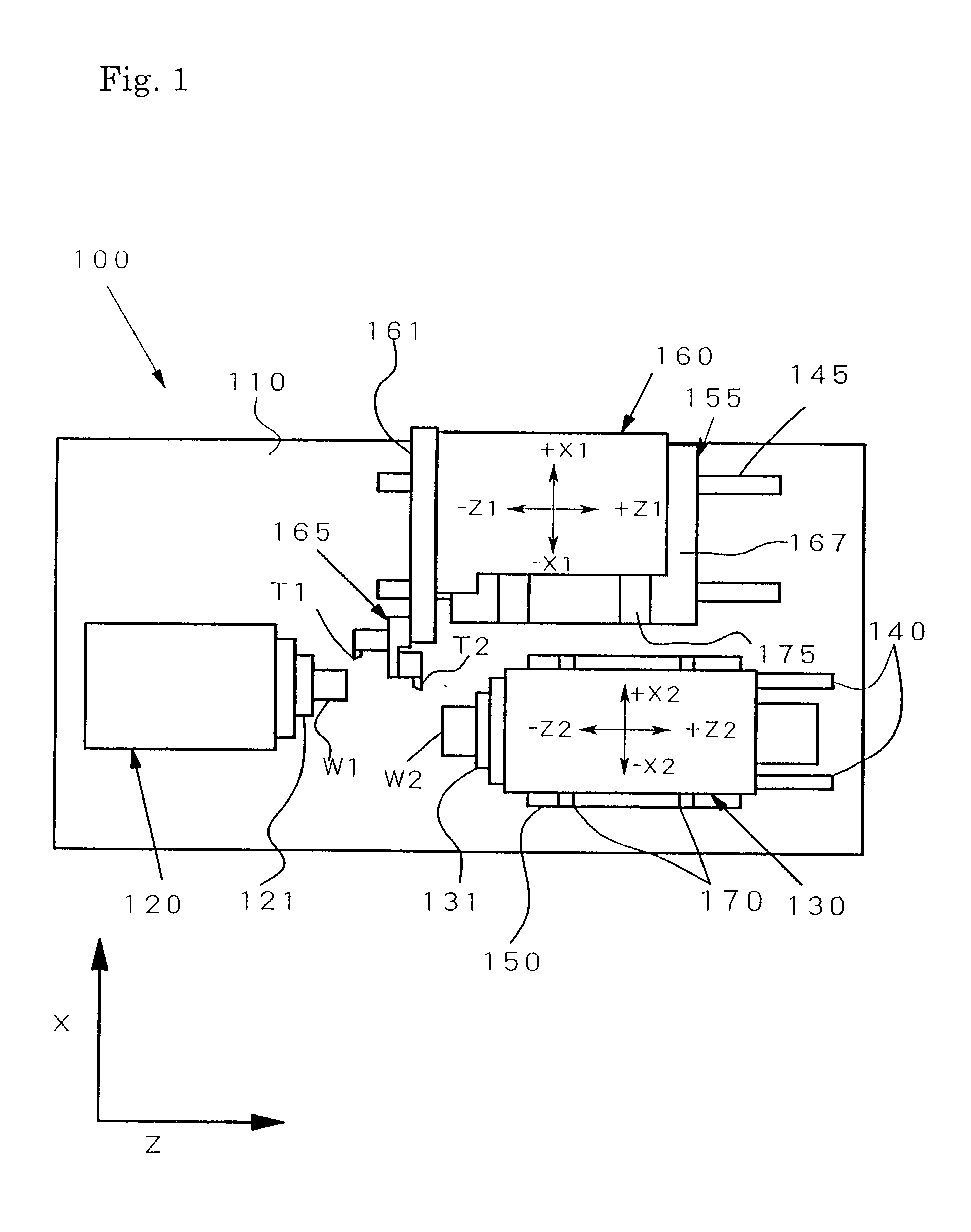

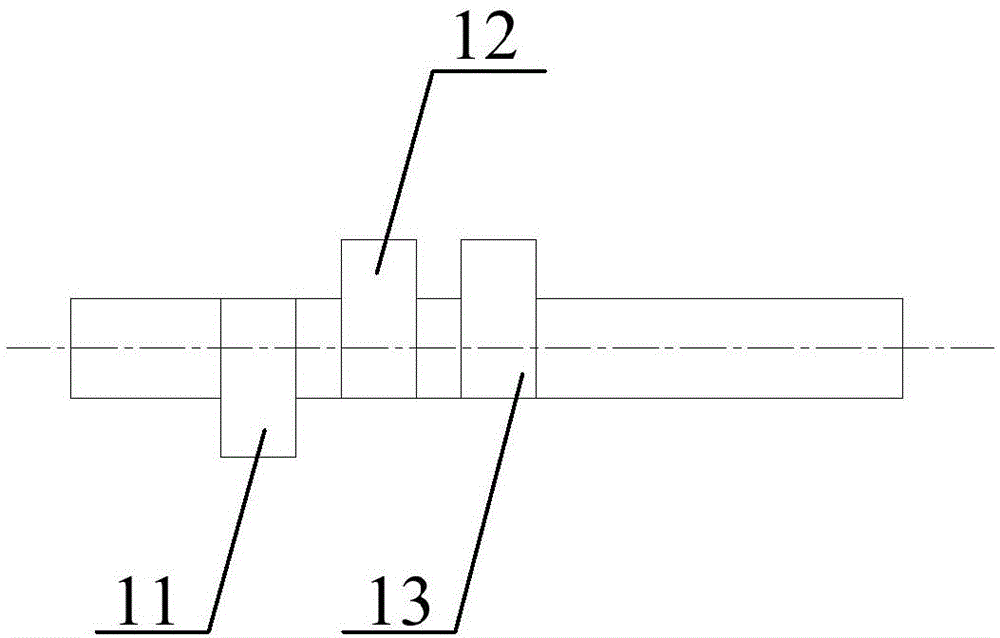

Numerically controlled lathe and method of machining work using this numerically controlled lathe

InactiveUS6971294B1Simple processReduce the overall diameterLathesAutomatic/semiautomatic turning machinesEngineeringIndustrial engineering

An NC lathe performs various processing at the same time to a plurality of works. The NC lathe includes a first spindle and a second spindle, and a tool rest having tools for processing works. The tool rest is freely movable in the direction of Z1-axis and X1-axis. The second spindle is freely movable in the direction of X2-axis and Z2-axis. An NC unit controls the movement in the direction of the X1-axis and the Z1-axis of the tool rest, and controls the movement in the direction of the X2-axis and the Z2-axis of the second headstock. The NC unit superposes the movement in the direction of the X2-axis on the movement of the X1-axis of the tool rest. Furthermore, the movement of the Z2-axis is superposed on the movement in the direction of the Z1-axis of the tool rest.

Owner:CITIZEN WATCH CO LTD

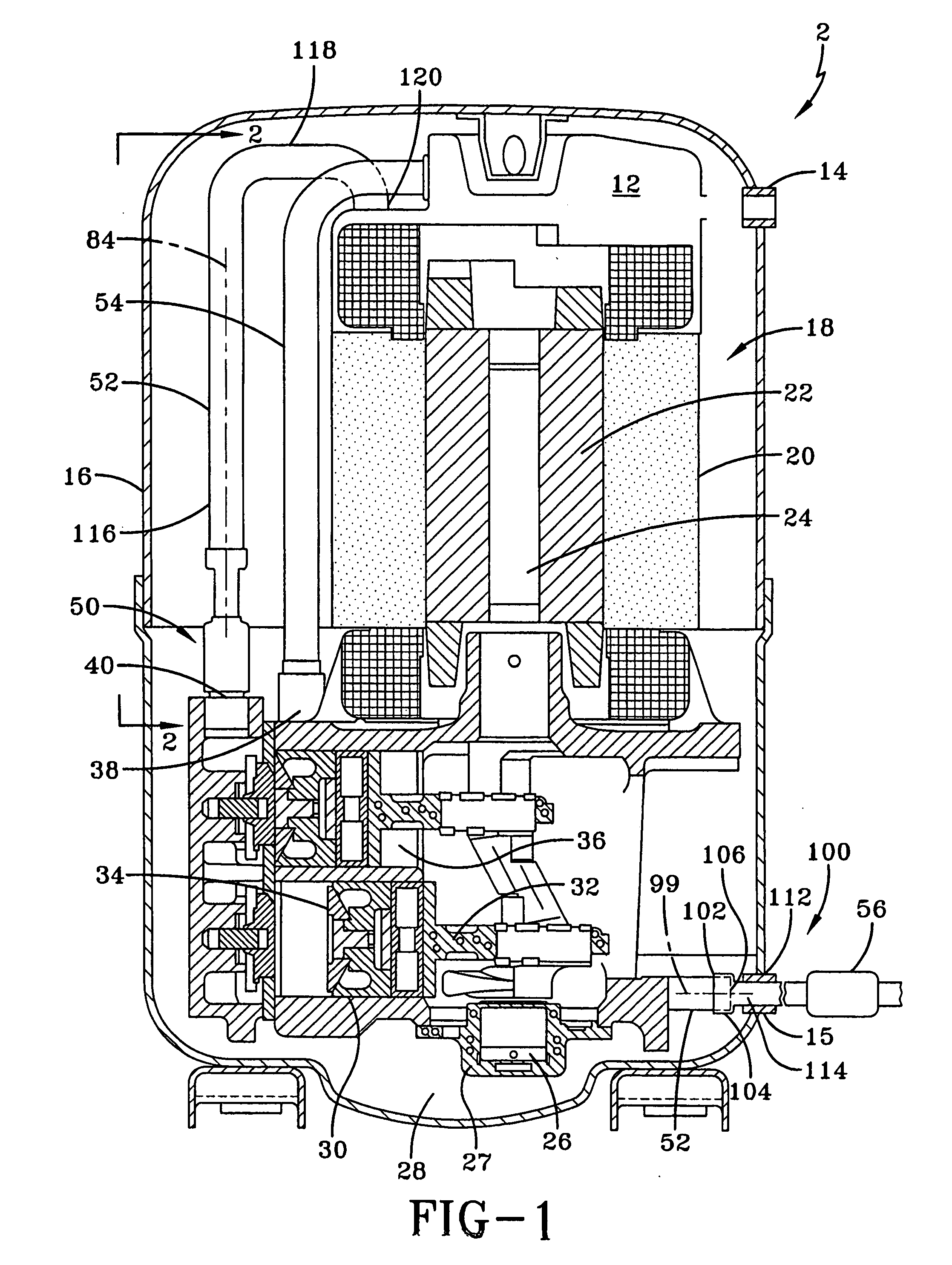

Double-stage compressor

ActiveCN104632623ASolve the problem of limited displacementSmooth suction and exhaust processRotary/oscillating piston combinations for elastic fluidsMachines/enginesGas compressorPhase difference

The invention discloses a double-stage compressor. The double-stage compressor comprises a low-pressure-stage air cylinder and a high-pressure-stage air cylinder, wherein the low-pressure-stage air cylinder comprises a first air cylinder and a second air cylinder, which are arranged in the axis direction of the compressor, the phase difference of the first air cylinder and the second air cylinder at an air inlet beginning time falls in a range of 120 to 240 degrees, and the phase difference of the high-pressure-stage air cylinder and one of the first air cylinder and the second air cylinder at the air inlet beginning time falls in a range of 120 to 240 degrees or -60 to 60 degrees. By adopting the double-stage compressor, not only can the problem that the gas displacement of the double-stage compressor is limited be effectively solved, but also the simultaneous occurrence of an air suction peak value of the two air cylinders in the low-pressure-stage air cylinder can be avoided; moreover, when the high-pressure-stage air cylinder stays nearby the air suction peak value position, the two air cylinders at the lower-pressure stage can successively reach an exhaust peak value position, so that the air suction process and the exhaust process of the compressor can be maintained smooth, and the severe fluctuation of the compressor in the suction and exhaust processes can be avoided.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

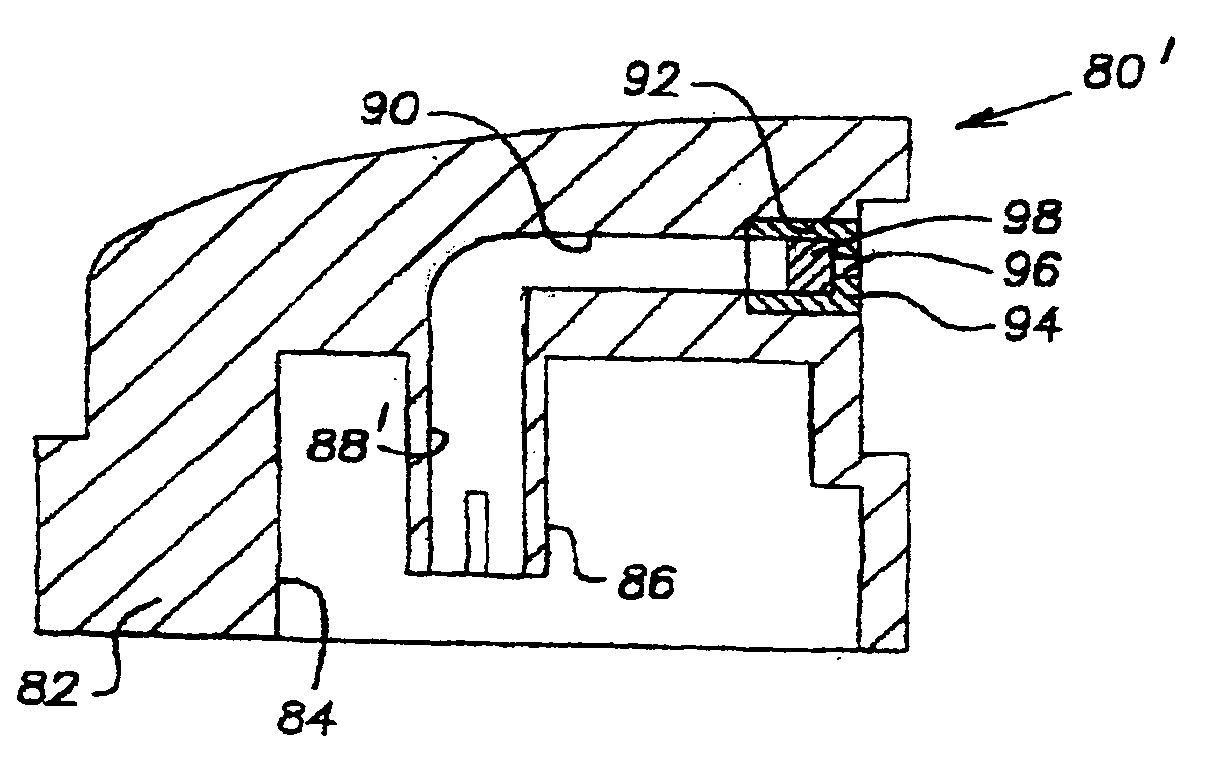

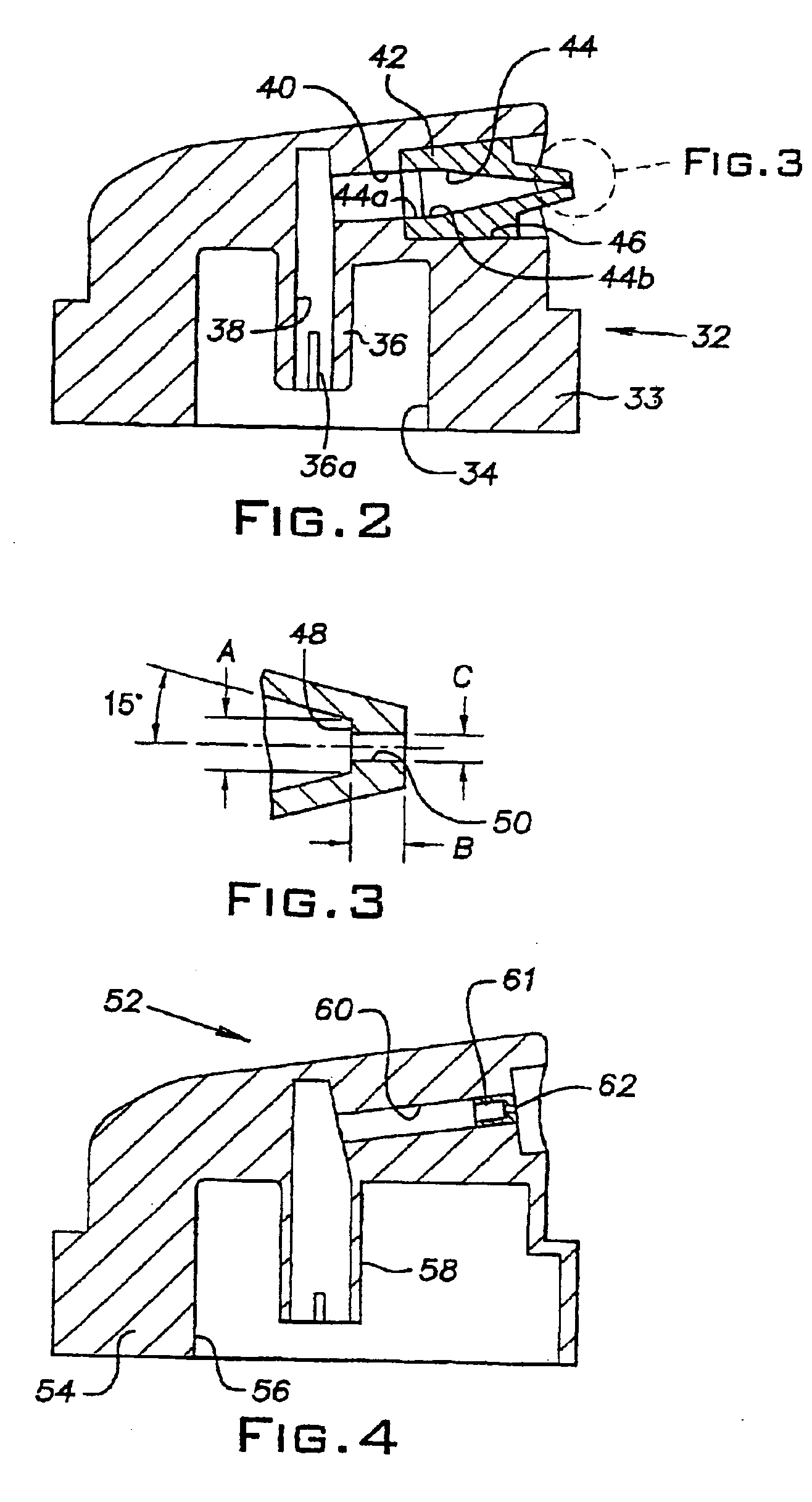

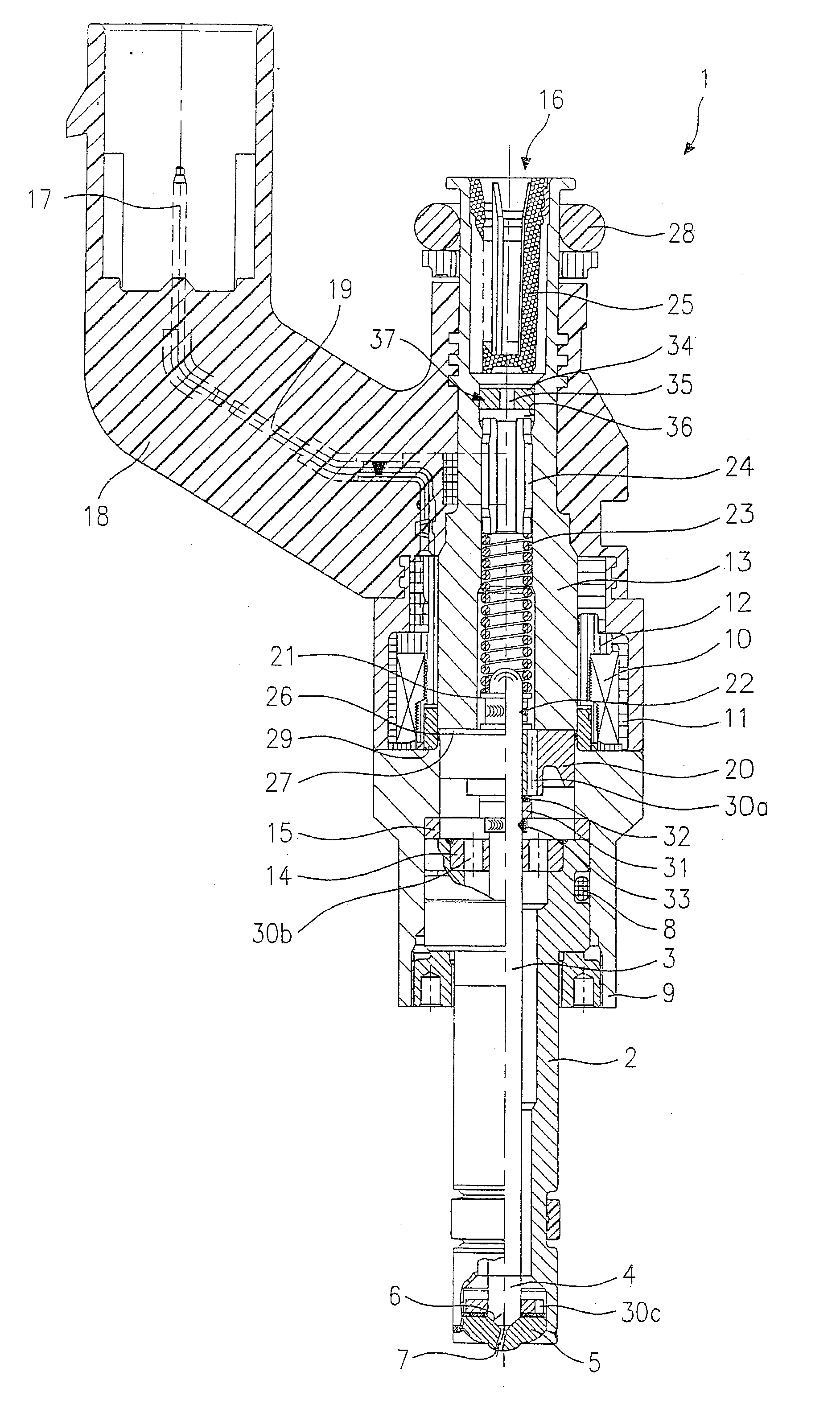

Fuel injection valve with a damping element

InactiveUS20030155448A1Prevent pulsationEffective dampingInternal combustion piston enginesSpray nozzlesEngineeringValve seat

A fuel injector (1) is provided with a magnetic coil (10) which cooperates with an armature (20) acted upon by a restoring spring (23), the armature forming an axially movable valve part with a valve needle (3). A valve-closure member (4) which forms a sealing seat with a valve-seat member (5) is provided at the valve needle (3). At least one damping element (37) is disposed in an opening (36) of the fuel injector (1) through which fuel flows.

Owner:ROBERT BOSCH GMBH

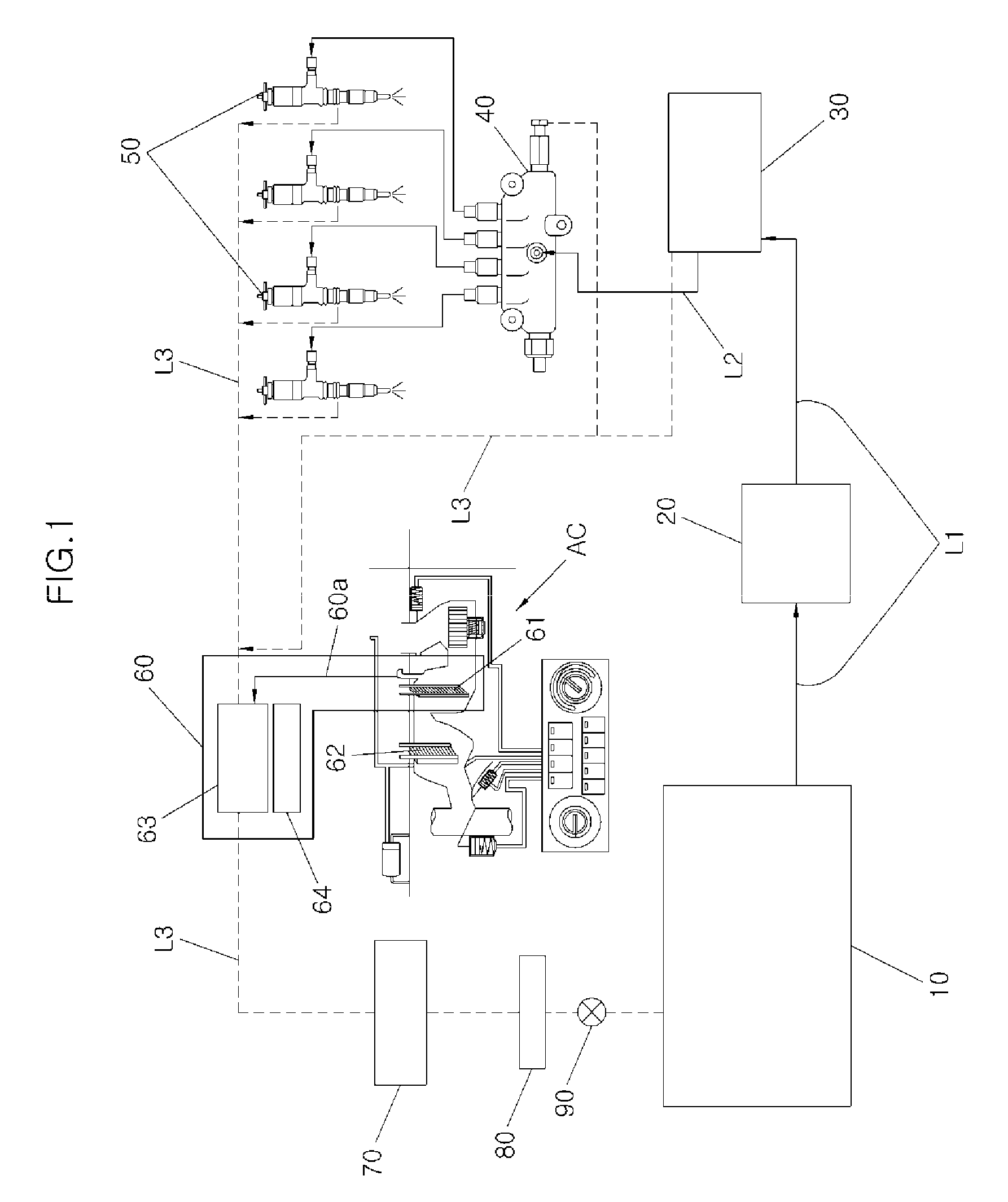

Reservoir tank for vehicle brake system

ActiveUS20060016484A1Limit distanceSmooth dischargeTelemotorsPipeline systemsEngineeringHydraulic fluid

A reservoir tank for a vehicle brake system has a tank body including upper and lower shells joined together along mating surfaces. A float and a fluid level sensor are mounted in a fluid level detecting chamber defined in the tank body. The float is fitted on a shaft of the fluid level sensor. A partition plate is fitted in the lower shell to restrict a flow of hydraulic fluid into and out of the fluid level detecting chamber. The partition plate is disposed near the top end of the shaft of the fluid level sensor to restrict the distance by which the float can move vertically. A filter, the fluid level sensor and the partition plate are all set in the lower shell. The filter and the partition plate having their top ends pressed against the bottom ends of partitioning walls of the upper shell. Thus, the filter and the partition wall are held in position in the tank body between the upper and lower shells. No separate retainer for the float is necessary because the partition plate serves also as a float retainer.

Owner:ADVICS CO LTD

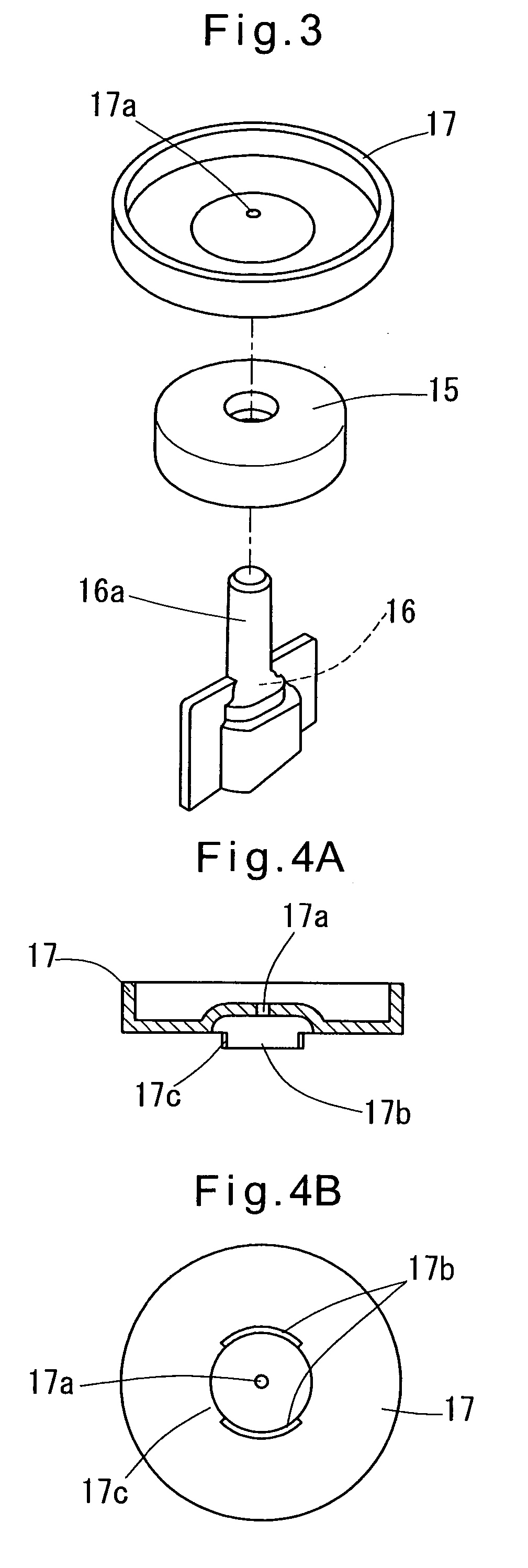

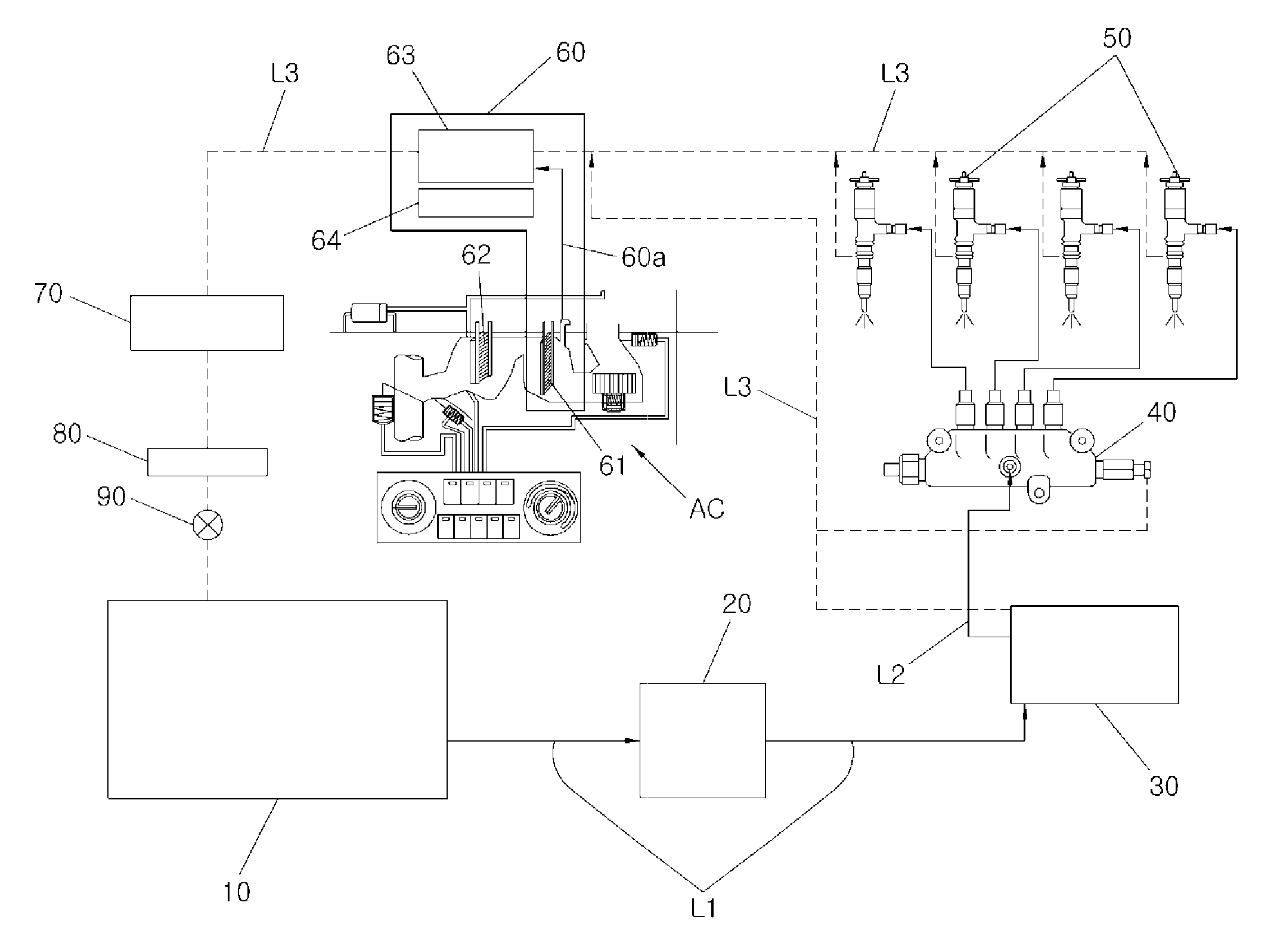

Fuel cooling system for dimethyl-ether fuel vehicle

InactiveUS20130032125A1Improve cooling effectPrevent pulsationInternal combustion piston enginesFuel supply apparatusCommon railFuel tank

A fuel cooling system for a dimethyl-ether fuel vehicle includes a fuel tank storing dimethyl-ether, a fuel supply line introducing the dimethyl-ether into an engine, a fuel supply pump, pressurizing the dimethyl-ether, and sending the pressurized dimethyl-ether to a fuel injection system, a common rail maintaining a pressure of the pressurized dimethyl-ether from the fuel supply pump, a fuel injection system injecting the pressurized dimethyl-ether supplied from the common rail, a fuel return line communicating with and diverging from the fuel injection system, the common rail and / or a downstream side of the fuel supply pump to collect remaining dimethyl-ether, a fuel cooling device disposed in the fuel return line, and a drain pipe to discharge condensed water generated from an evaporator disposed in an air conditioner, wherein discharged condensed water from the drain pipe is supplied to the fuel cooling device and cools the collected dimethyl-ether.

Owner:HYUNDAI MOTOR CO LTD

Indicator apparatus

InactiveUS8151725B2Prevent pulsationIndicator componentsMeasurement apparatus componentsComputer scienceMagnet

To provide an indicator apparatus in which a pointer is secured to a pointer drive means by attraction force of magnets and it is possible to prevent an overshoot and pulsation of the pointer with sufficient attraction force. The indicator apparatus has a display plate 21, a pointer 22 provided on a front-face side of the display plate 21, and a pointer drive means provided on a back-face side of the display plate 21 for rotating the pointer 22. The indicator apparatus includes first magnet 22c in a ring shape provided for the pointer 22 and a second magnet 23a provided for the pointer drive means to be opposite to the first magnet 22c, and the pointer 22 is rotated in association with rotation drive of the pointer drive means by attraction force of the first and second magnets 22c, 23a. A yoke 22d in a ring shape is located closer to a surface of the first magnet 22c that is not opposite to the second magnet 23a.

Owner:NIPPON SEIKI CO LTD

Compressor

ActiveCN1749570AEasy to operateAvoid abnormal noiseRotary piston pumpsRotary piston liquid enginesCompressed fluidResonance

The present invention provides one kind of sliding-vane rotary compressor. Inside the limited volume of high pressure compartment, the high pressure chamber is set to have volume greater than that of oil storing chamber to prevent resonance between the refrigerating circulation parts, such as the heat exchanger, and the relevant vehicle members and to avoid abnormal sound. The sliding-vane rotary compressor includes high pressure chamber for the compressed fluid to be exhausted into, oil storing chamber for the lubricant oil separated from the high pressure fluid to be stored in, and sliding vane back pressure controller to provide the sliding vane back pressure chamber with gaseous fluid or lubricant oil from the oil storing chamber optionally. By means of setting the sliding vane back pressure controller set inside the high pressure chamber, the present invention can ensure the volume of the high pressure chamber and the fluid supply from the high pressure chamber to the sliding vane back pressure controller.

Owner:PANASONIC CORP

Valve assembly for variable swash plate compressor

ActiveCN104454464AIncrease suction flowAccurate opening and closingPositive displacement pump componentsMulti-stage pumpsEngineeringRefrigerant

Owner:HANON SYST

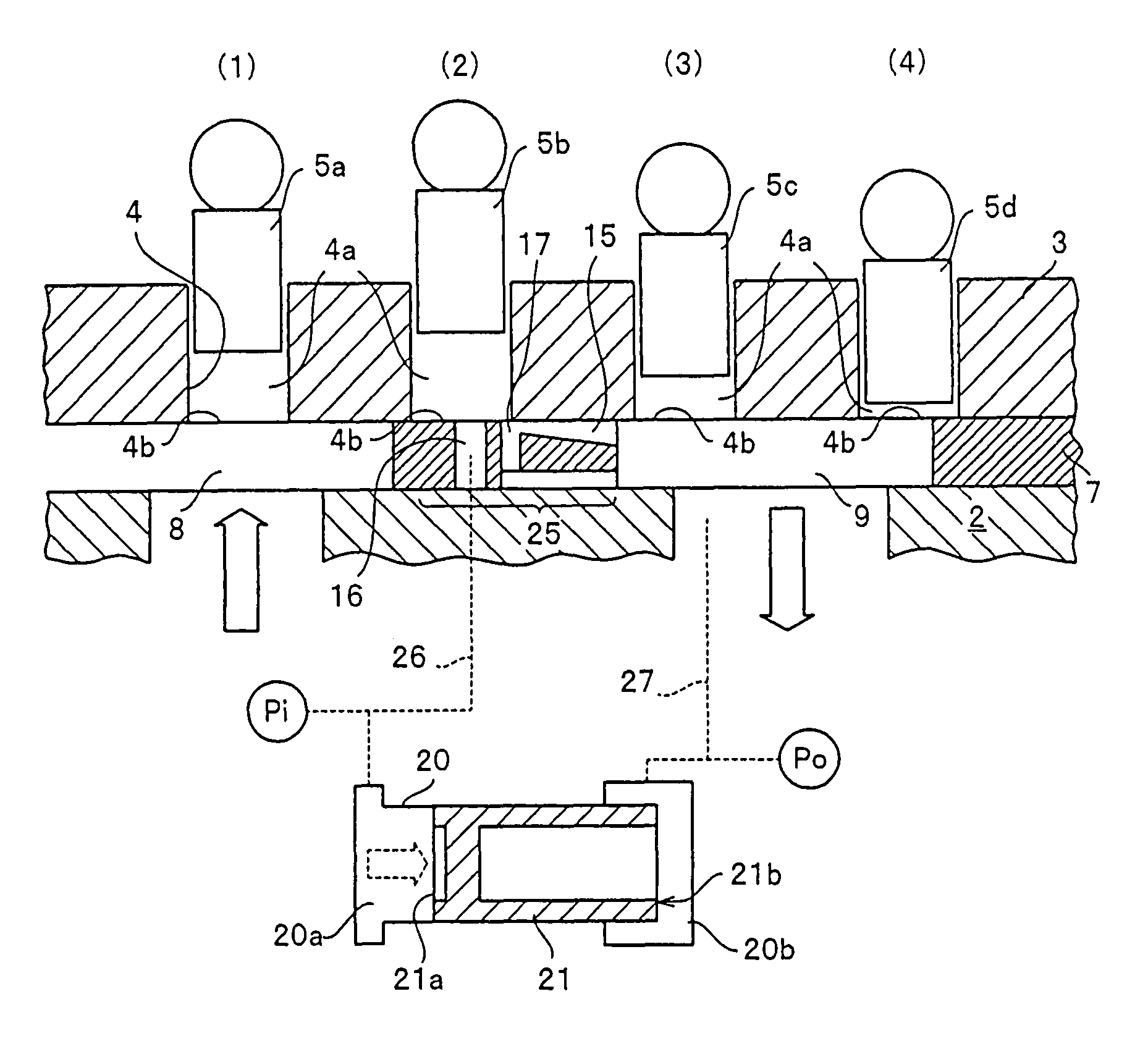

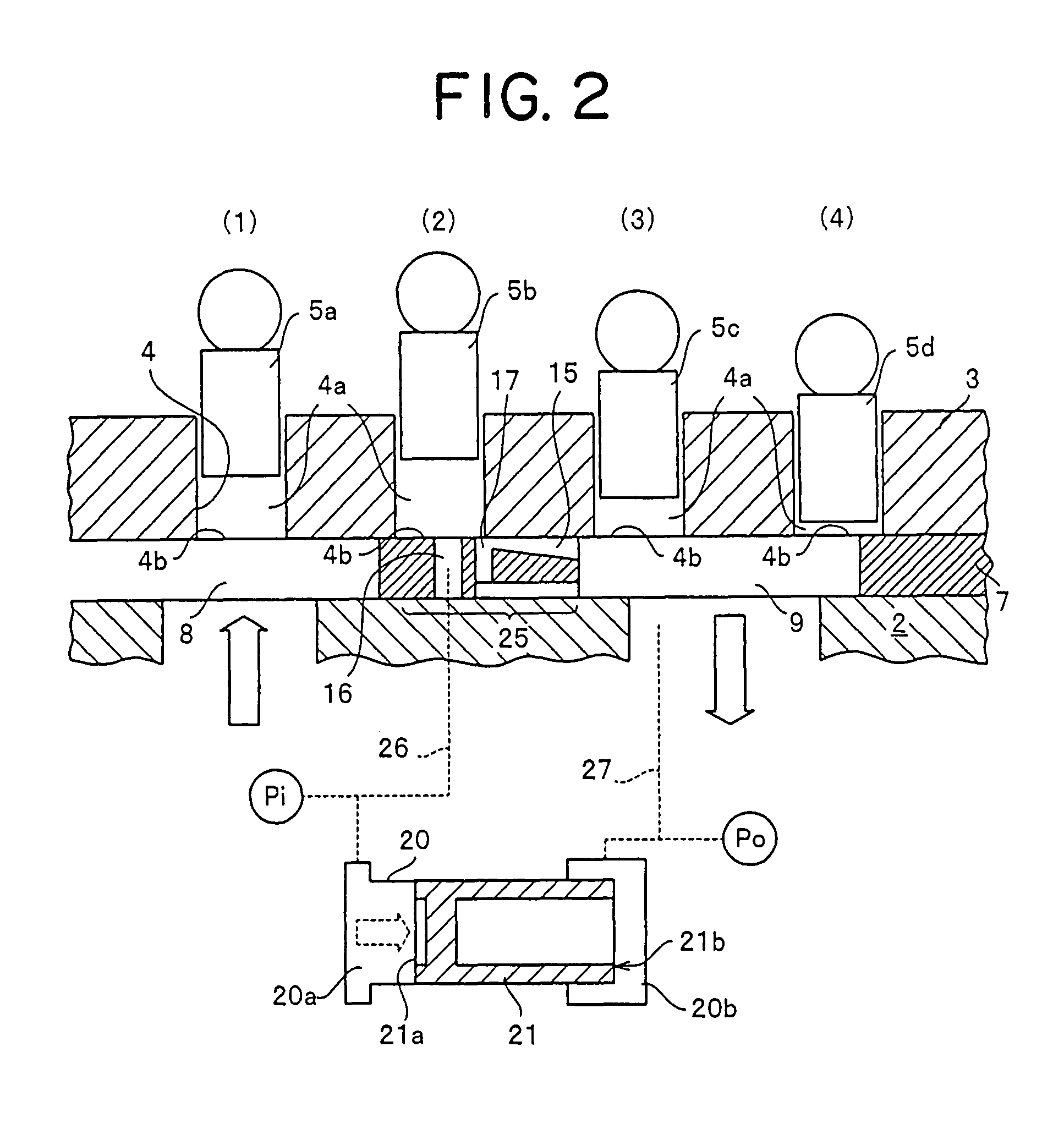

Hydraulic piston pump with a balance valve

InactiveUS8047120B2Prevent pulsationReduce generationPositive displacement pump componentsFluid-pressure actuatorsSystem pressureEngineering

In a hydraulic piston pump, a cylinder port can communicate with a discharge port after a system pressure and a chamber pressure in a cylinder bore becomes in an equilibrium condition. A through hole opening to a surface on which a cylinder block slides in a valve plate is allowed to communicate with a side of one end surface of a balance valve, and the system pressure of a discharge port side is supplied to the other end surface of the balance valve. In the balance valve, a balance piston which slides by a pressure difference between the chamber pressure of the cylinder bore and the system pressure is accommodated. Before the cylinder port communicates with an oil guiding groove, the chamber pressure can be equilibrated to the system pressure by an activation of the balance piston.

Owner:KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com