Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Good rotation balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controller

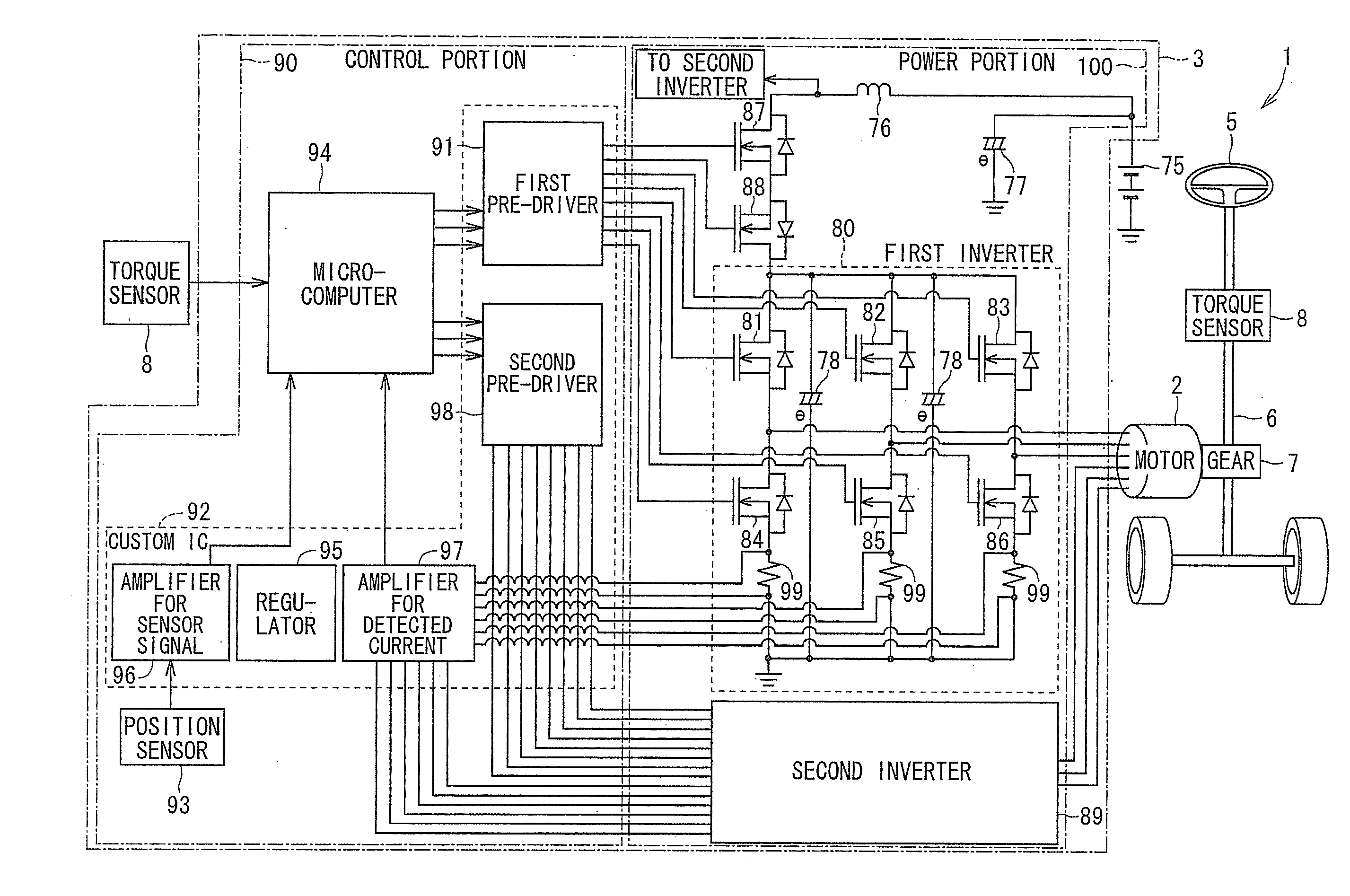

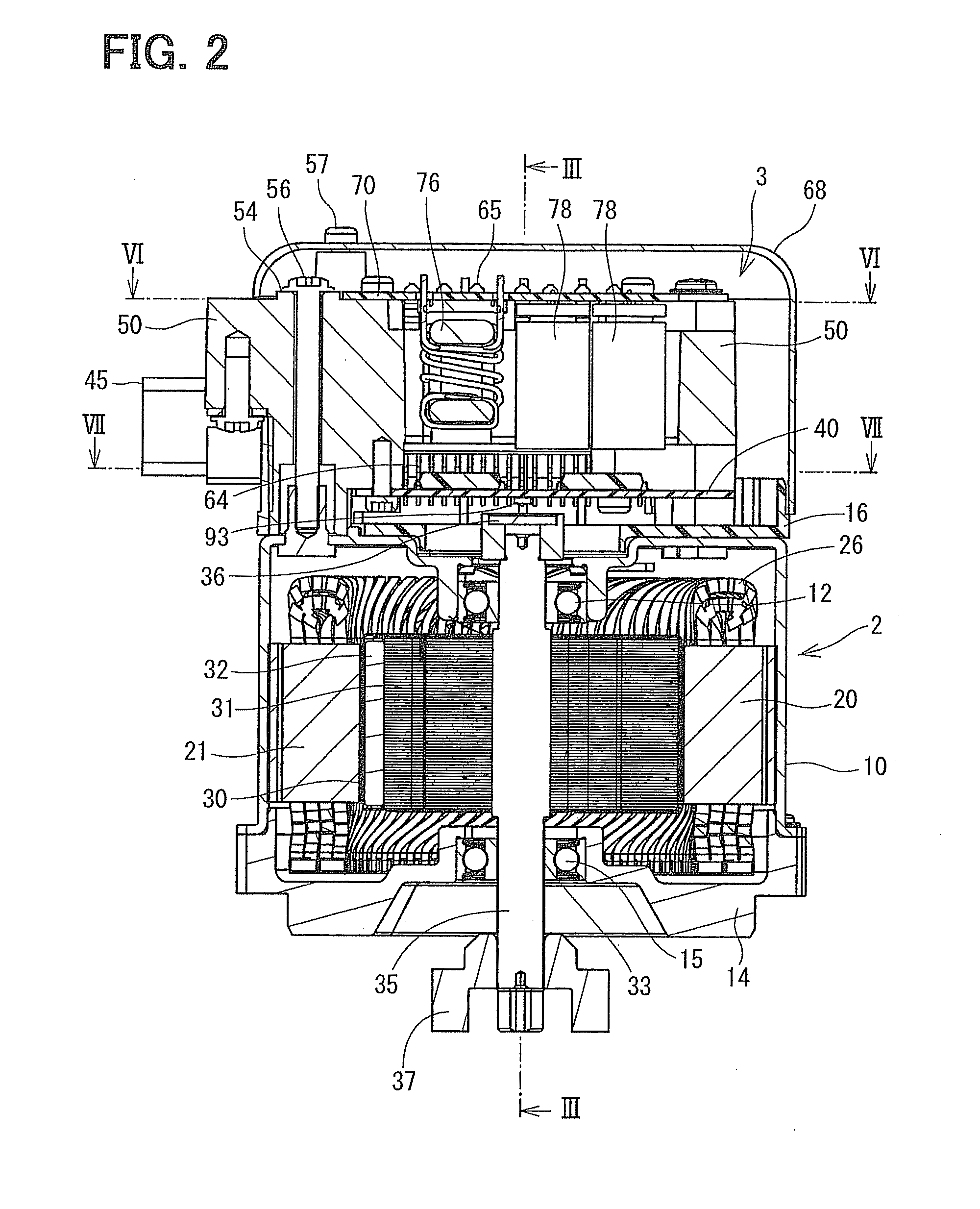

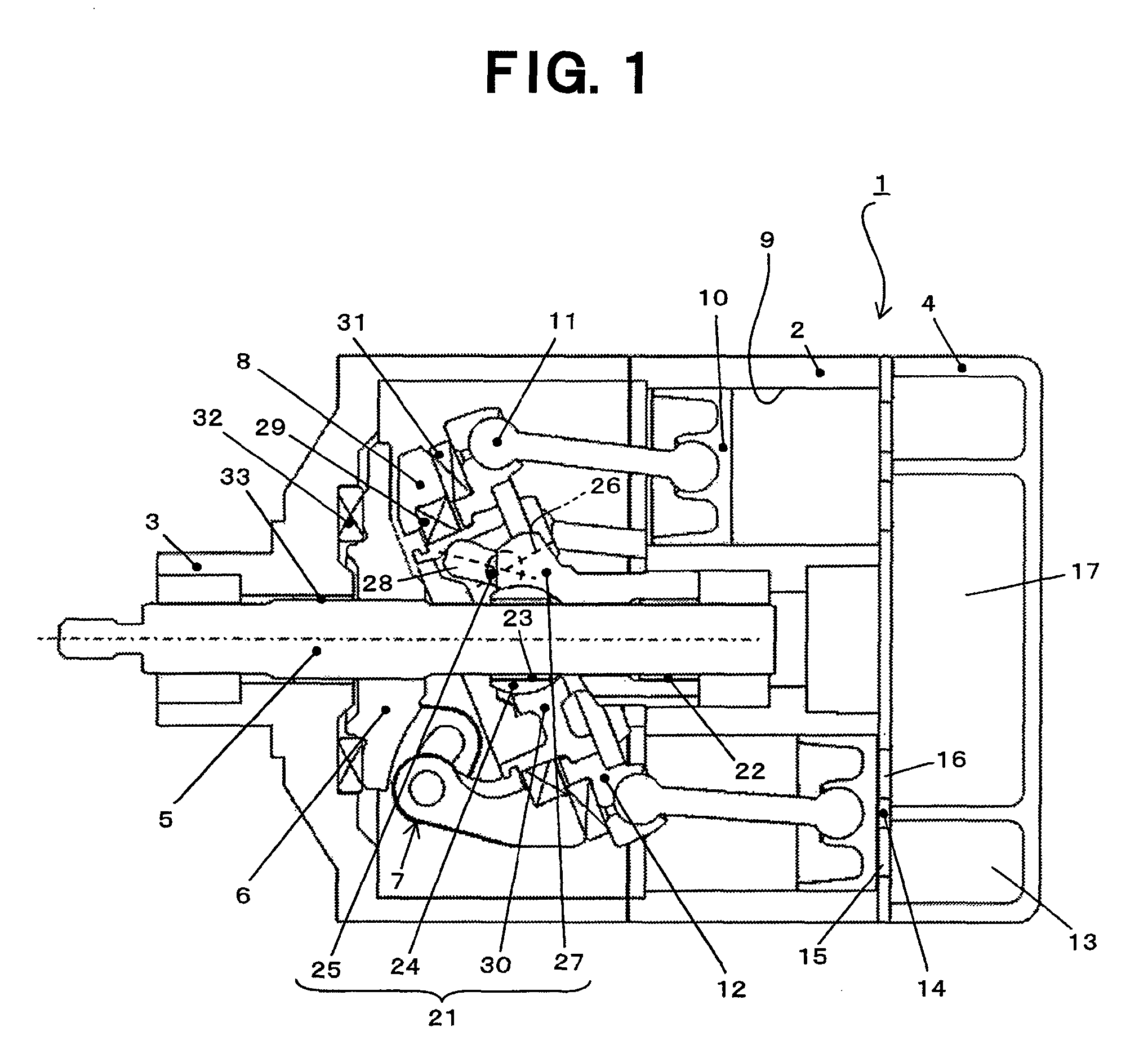

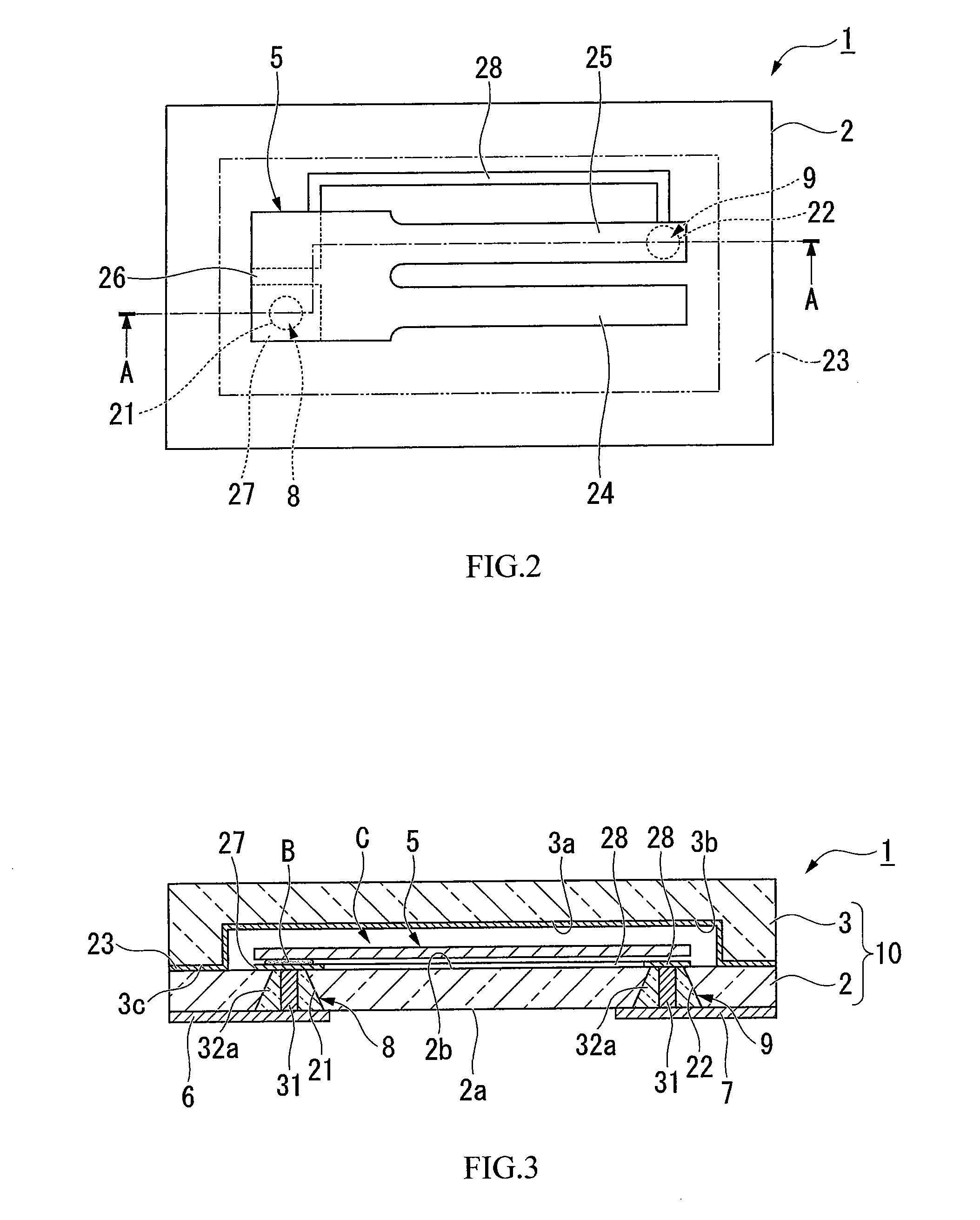

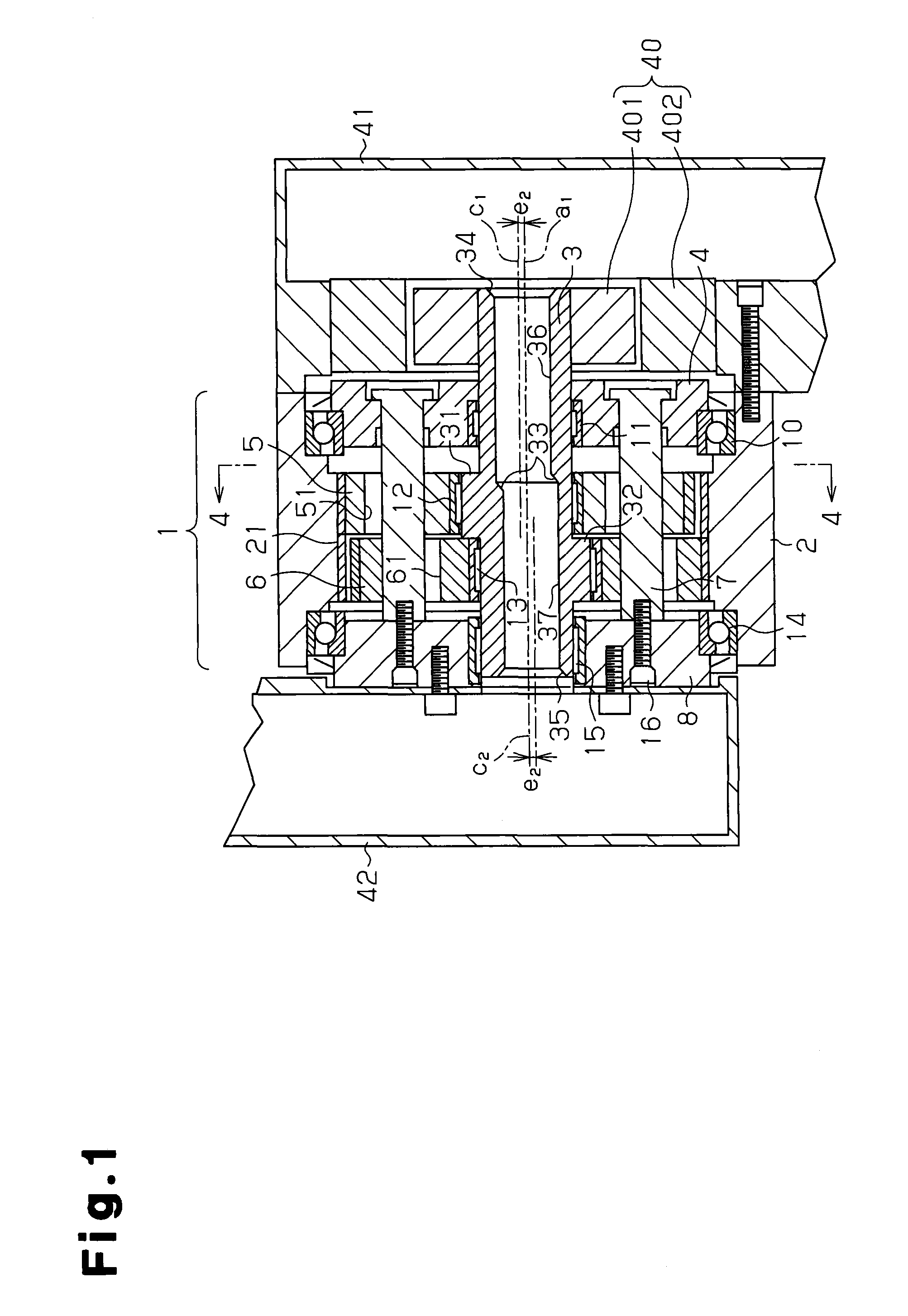

ActiveUS20120161689A1Improve balanceGood rotation balanceSynchronous motors startersAC motor controlMicrocomputerDriver circuit

Each of a first and a second inverter circuit supplies a driving current to an electric motor in a different power supply line. A custom IC has a first pre-driver circuit for outputting control signals to the first inverter circuit and a second pre-driver circuit for outputting control signals to the second inverter circuit. A micro-computer for outputting operation signals to the first and second pre-driver circuits is mounted to a control board on a center line. A distance between the center line and the first inverter circuit and a distance between the center line and the second inverter circuit is equal to each other. First and second output terminals of the micro-computer as well as first and second input and output terminals of the custom IC are symmetric with respect to the center line.

Owner:DENSO CORP

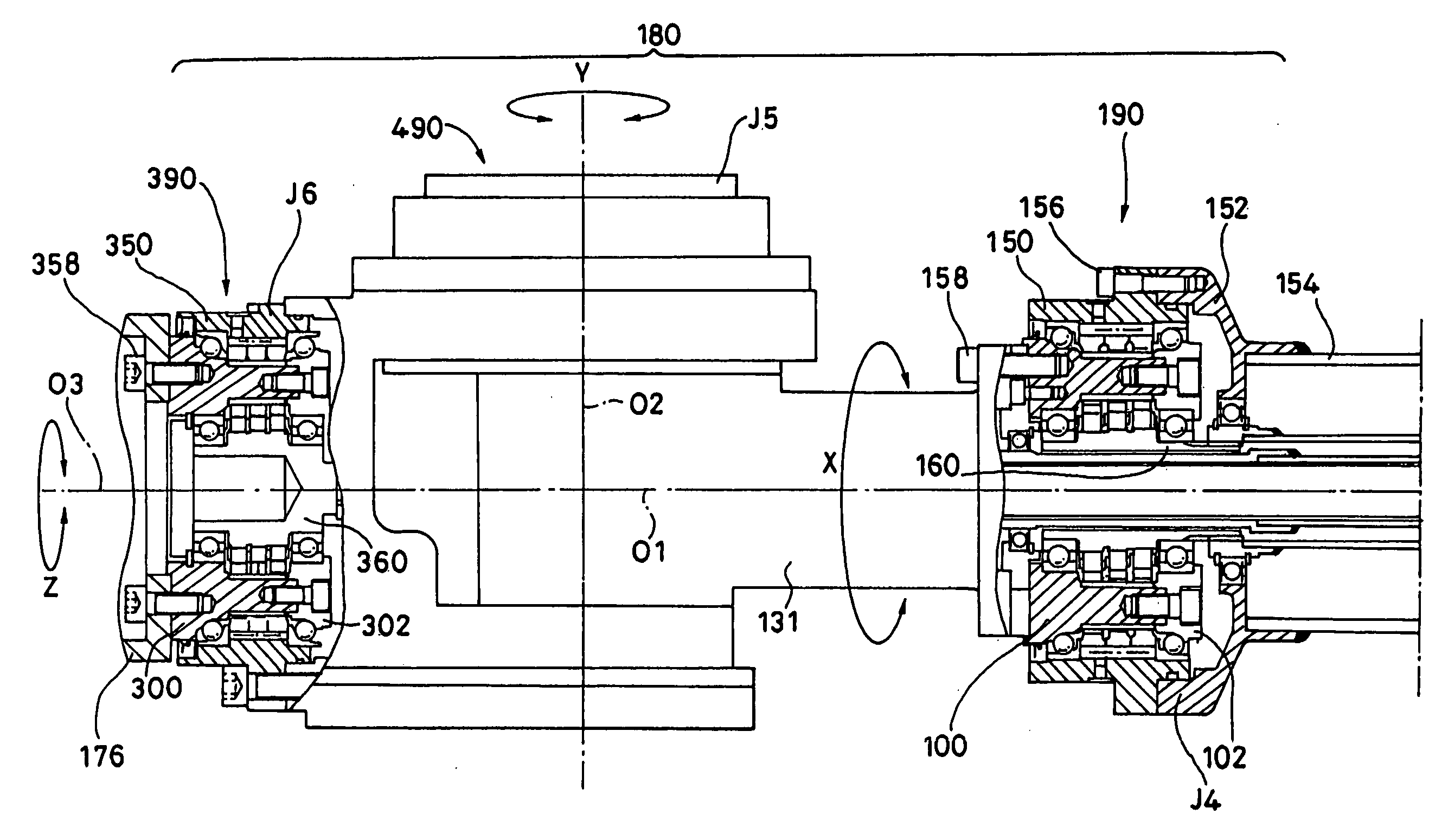

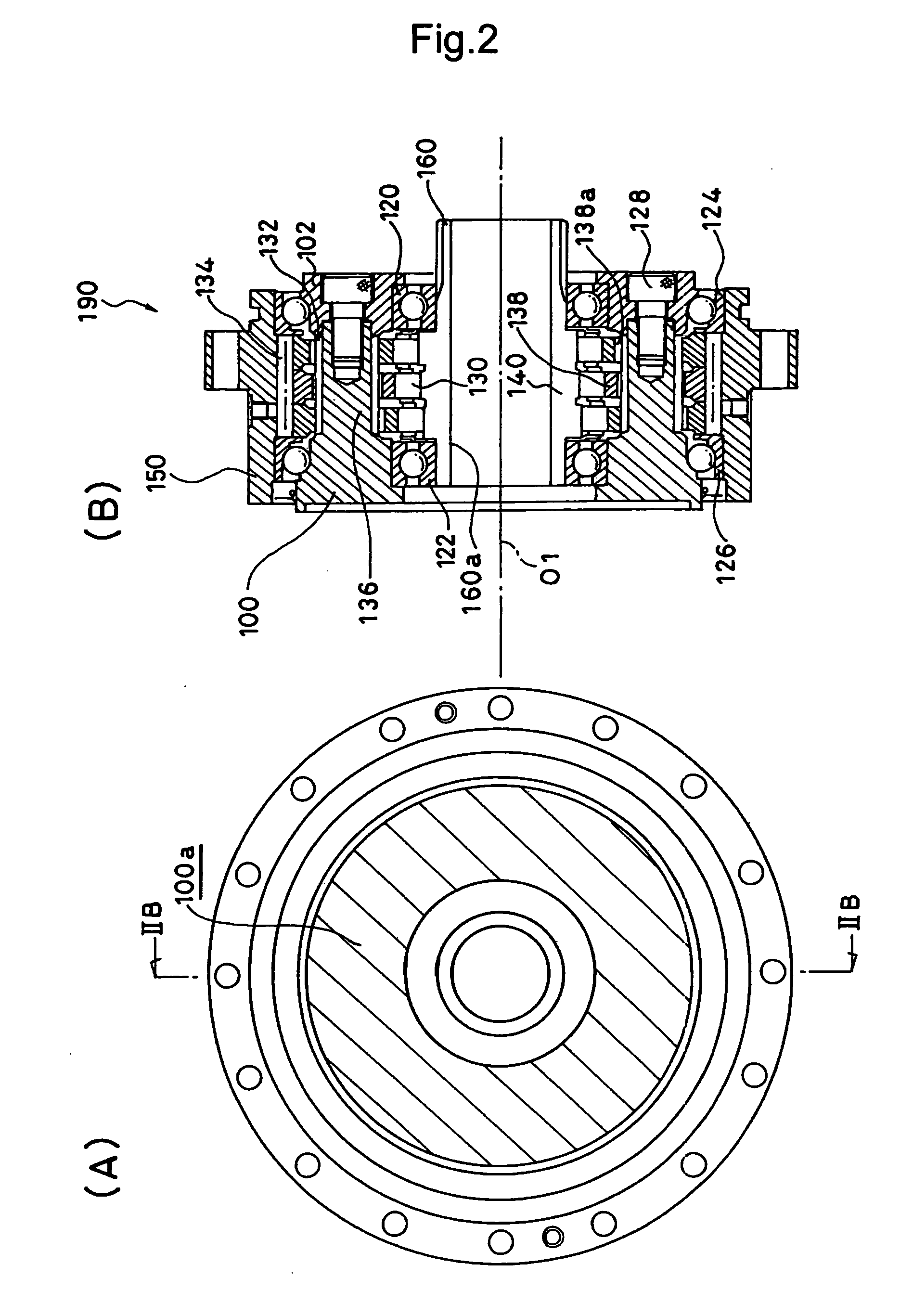

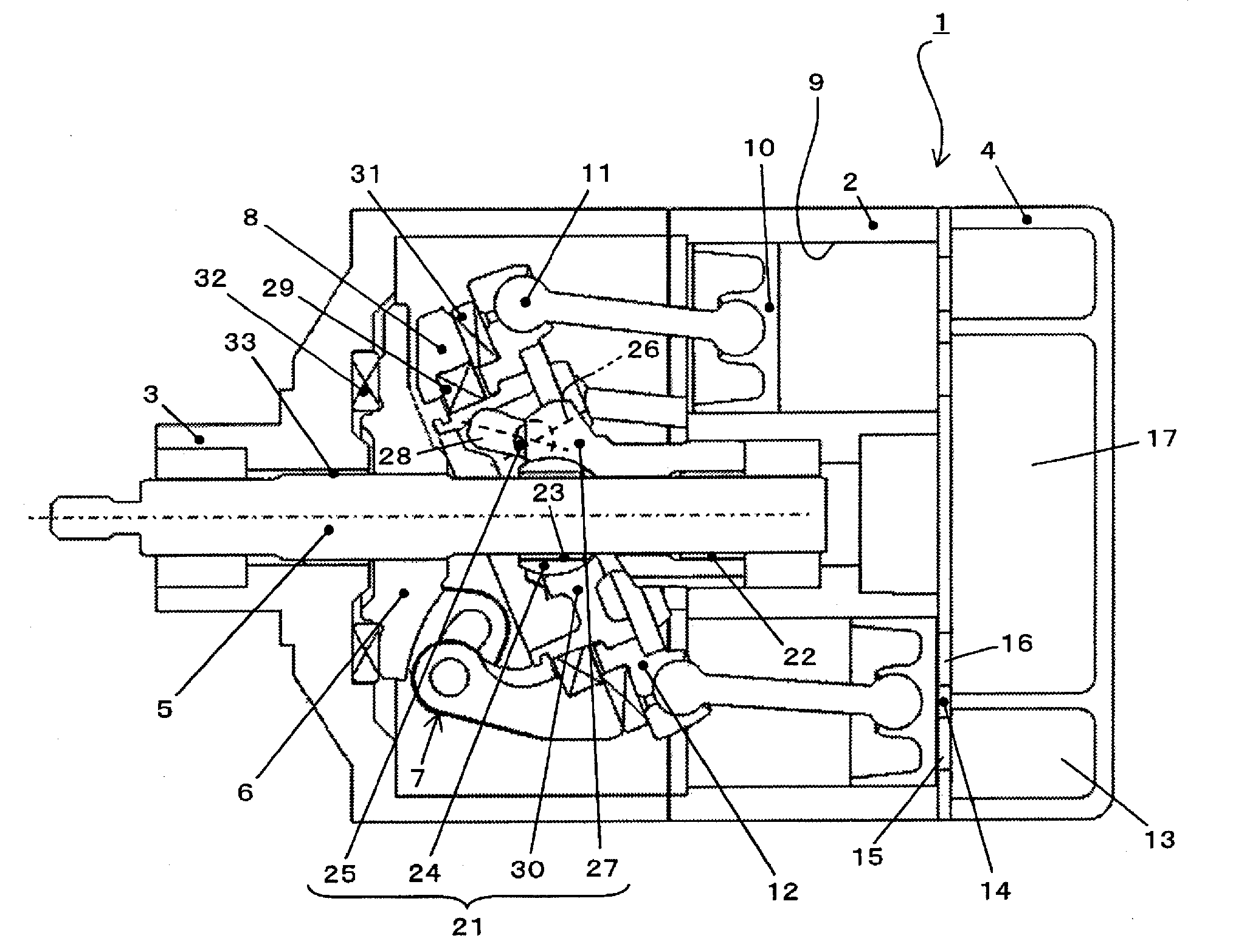

Power transmission device for driving robot wrist and power transmission device

InactiveUS20060213307A1Good rotation balanceHigh strengthProgramme-controlled manipulatorJointsGear wheelEngineering

The power transmission device includes an internal gear and an external gear that is inscribed in the internal gear and engages with the internal gear, and can transmit an input power to an attachment. The power transmission device further includes: an inner pin for bringing out a relative rotation component between the internal gear and the external gear; and an output flange connected to the inner pin. In this configuration, the inner pin and the output flange are integrally formed as one member, and a mounting hole for connecting the output flange to the attachment is formed in a surface of the output flange that is opposite to the inner pin.

Owner:SUMITOMO HEAVY IND LTD

Controller for an electric motor

ActiveUS8829746B2Improve balanceGood rotation balanceSynchronous motors startersAC motor controlMicrocomputerDriver circuit

Each of a first and a second inverter circuit supplies a driving current to an electric motor in a different power supply line. A custom IC has a first pre-driver circuit for outputting control signals to the first inverter circuit and a second pre-driver circuit for outputting control signals to the second inverter circuit. A micro-computer for outputting operation signals to the first and second pre-driver circuits is mounted to a control board on a center line. A distance between the center line and the first inverter circuit and a distance between the center line and the second inverter circuit is equal to each other. First and second output terminals of the micro-computer as well as first and second input and output terminals of the custom IC are symmetric with respect to the center line.

Owner:DENSO CORP

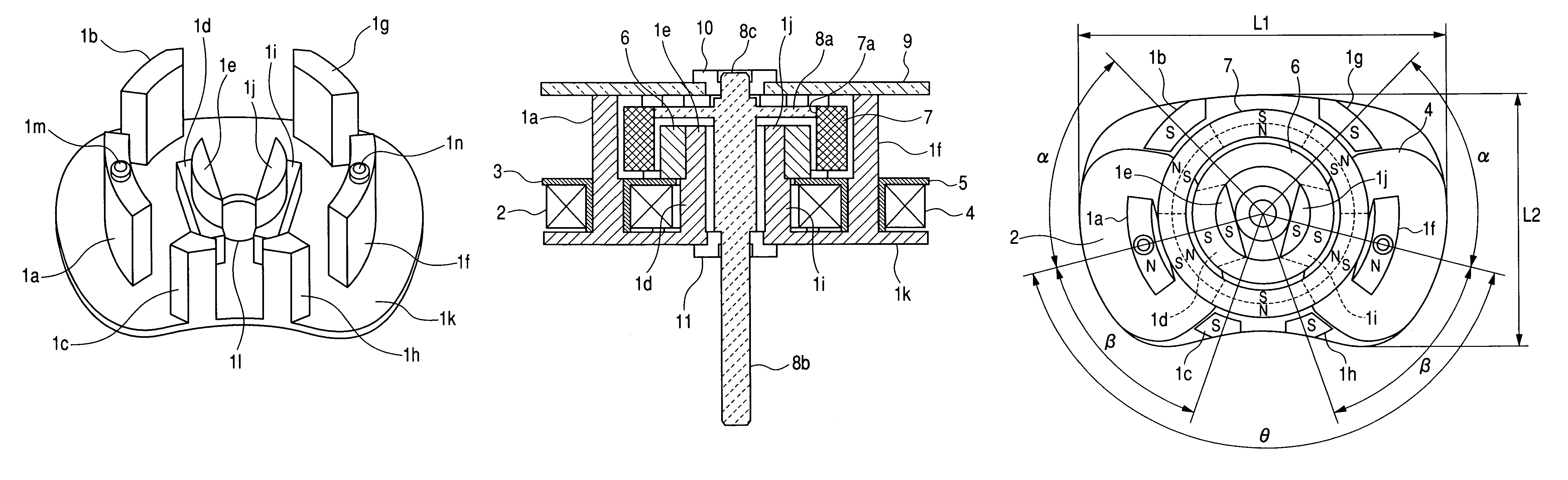

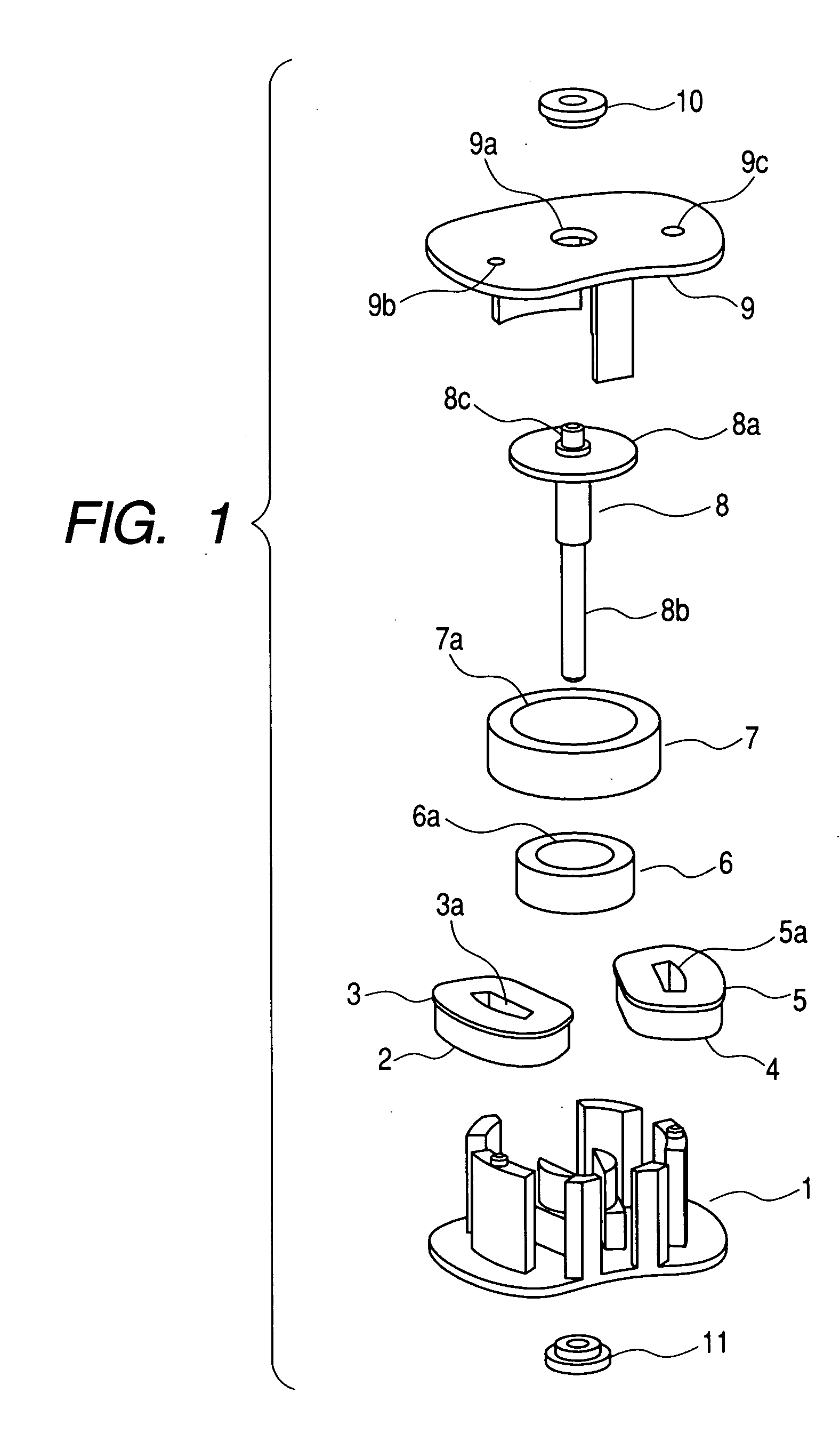

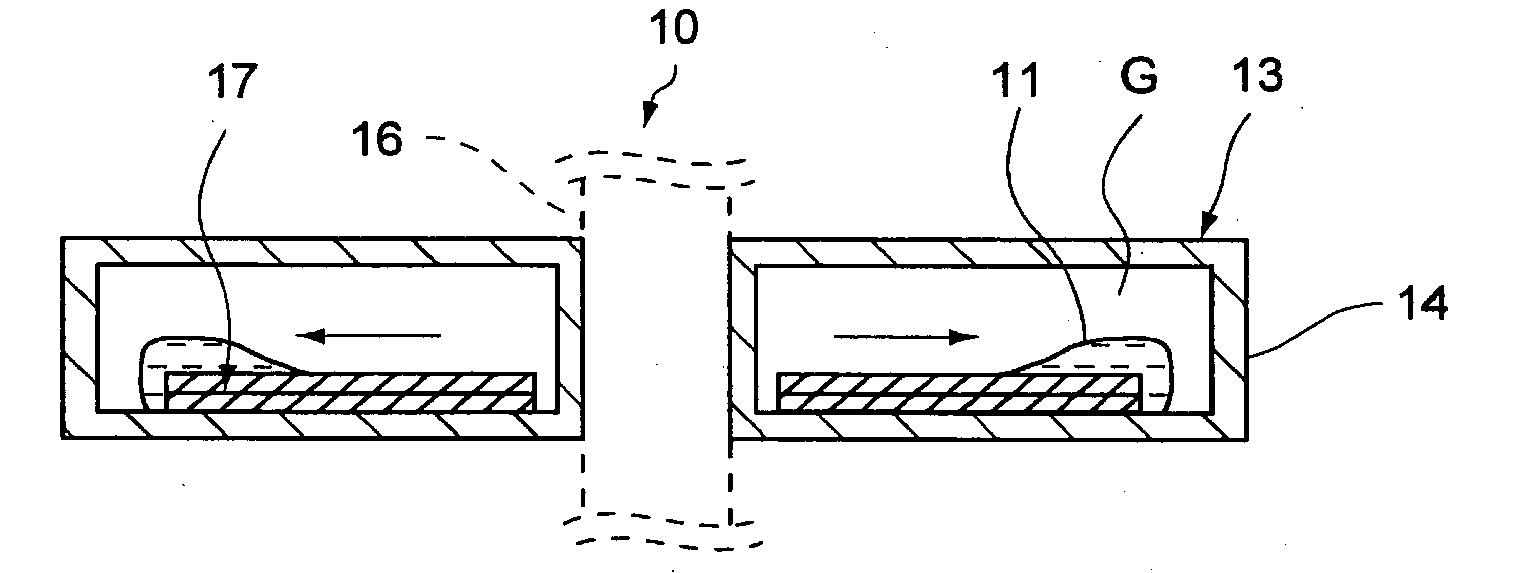

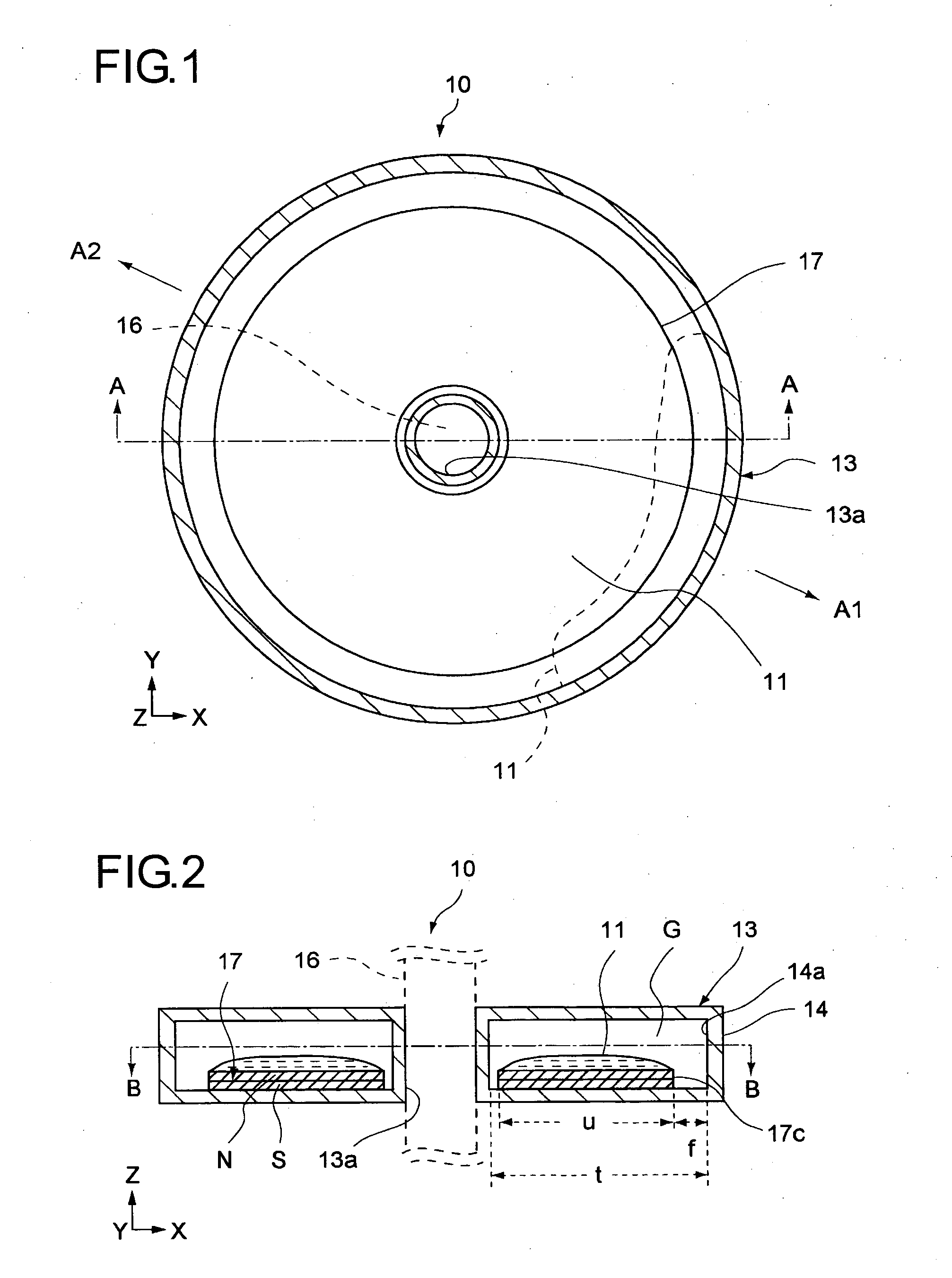

Motor and optical apparatus

InactiveUS7122920B2Increase productionHigh outputWindingsCamera focusing arrangementMagnetic polesMiniaturization

Provided are a motor and an optical apparatus each including: a rotatable rotor having a cylindrical magnet; a first coil; a first outer magnetic pole portion which is disposed at a center portion of the first coil and which is opposed to an outer circumferential surface of the magnet within a first predetermined angle range; a second outer magnetic pole portion which is adjacent to an outer circumference of the first coil and which is opposed to the outer circumferential surface of the magnet; a first inner magnetic pole portion which is adjacent to the outer circumference of the first coil and which is opposed to an inner circumferential surface of the magnet; a second coil; a third outer magnetic pole portion which is disposed at a center portion of the second coil and which is opposed to the outer circumferential surface of the magnet within a second predetermined angle range; a fourth outer magnetic pole portion which is adjacent to an outer circumference of the second coil and which is opposed to the outer circumferential surface of the magnet; and a second inner magnetic pole portion which is adjacent to the outer circumference of the second coil and which is opposed to the inner circumferential surface of the magnet. Accordingly, there are provided a motor and an optical apparatus which realize higher output without impairing miniaturization.

Owner:CANON KK

Driving apparatus and light amount adjustment apparatus

InactiveUS20060006968A1DownsizingIncrease productionMagnetic circuit stationary partsMaster clocksMagnetic polesCoil insertion

The invention provides a driving apparatus comprising: a magnet that is magnetized to at least two poles in a circumferential direction and fixed to a rotor axis formed with a soft magnetic material; first and second coils arranged in the same direction as the magnet with respect to the magnet-axis direction and arranged adjacent to an end surface of the magnet in the magnet-axis direction; the first magnetic pole portion excited by energizing the first coil; the second magnetic pole portion excited to a pole opposite to the first magnetic pole portion by energizing the second coil; and a yoke portion formed with a soft magnetic material for supporting the first and second magnetic pole portions. The first magnetic pole portion includes a first coil insertion portion that is inserted to an internal diameter portion of the first coil, and a first magnet facing portion that is arranged to face a magnetized outer circumferential portion of the magnet with a predetermined gap at a predetermined angle. The second magnetic pole portion includes a second coil insertion portion that is inserted to an internal diameter portion of the second coil, and a second magnet facing portion that is arranged to face a magnetized outer circumferential portion of the magnet with a predetermined gap at a predetermined angle.

Owner:CANON KK

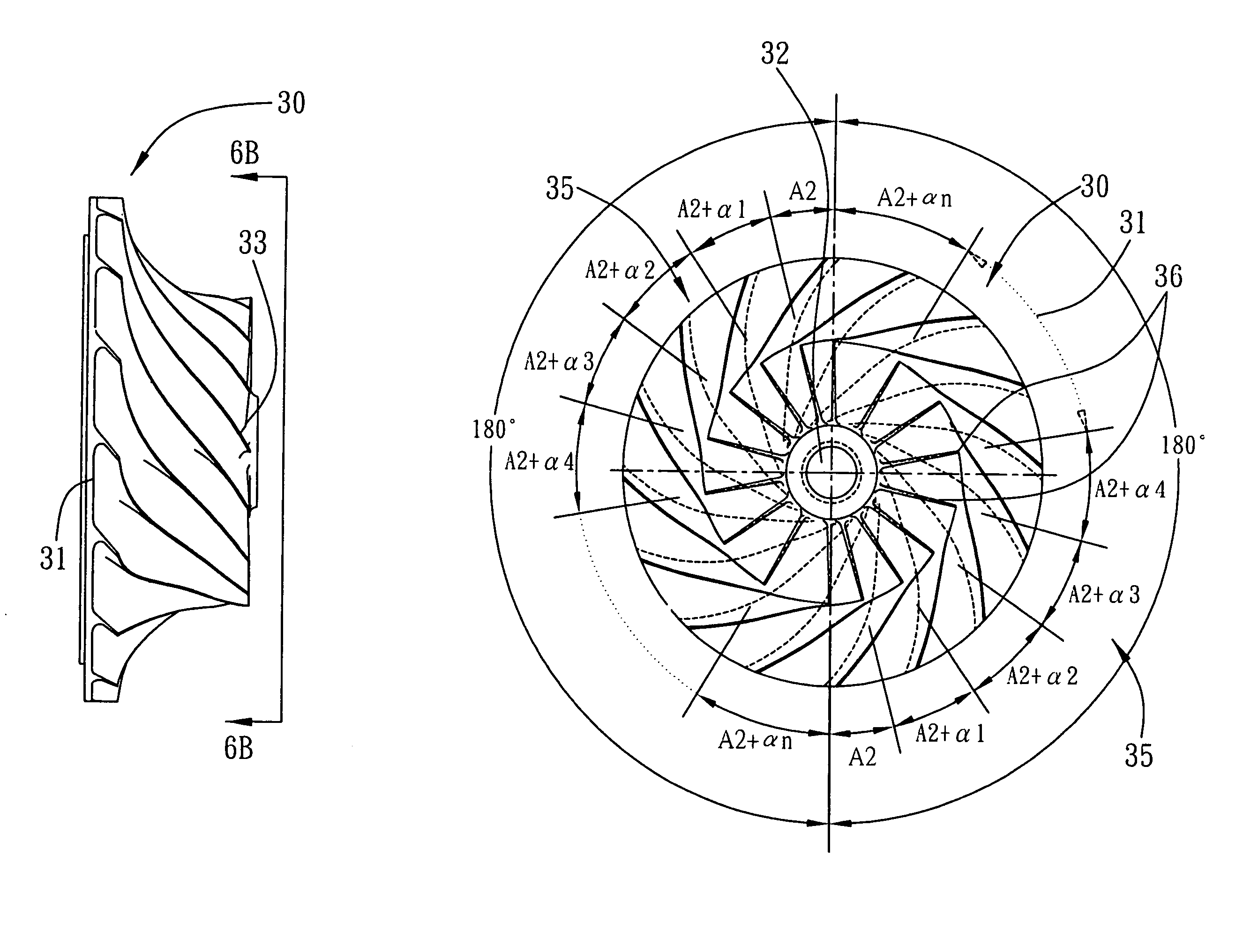

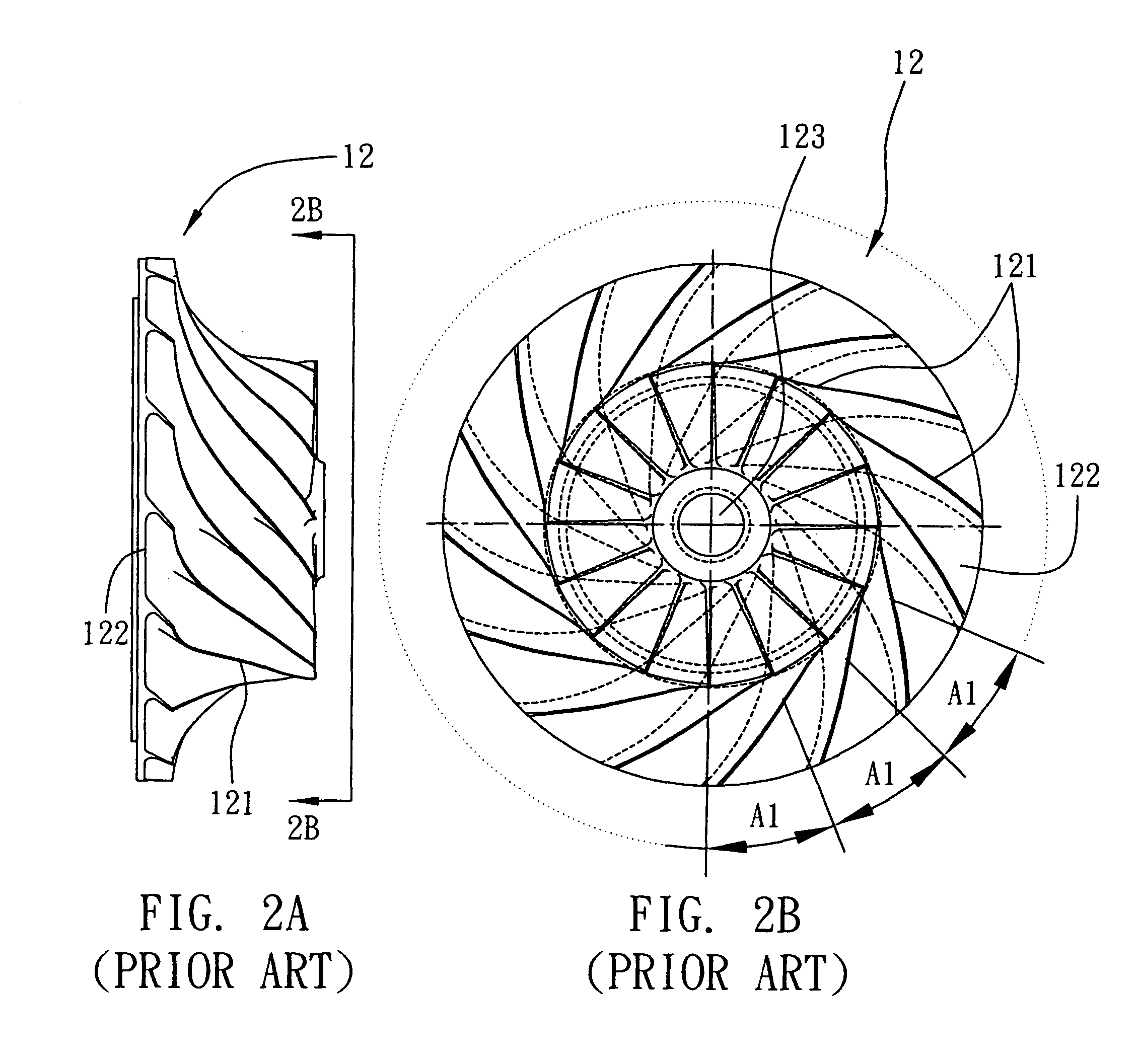

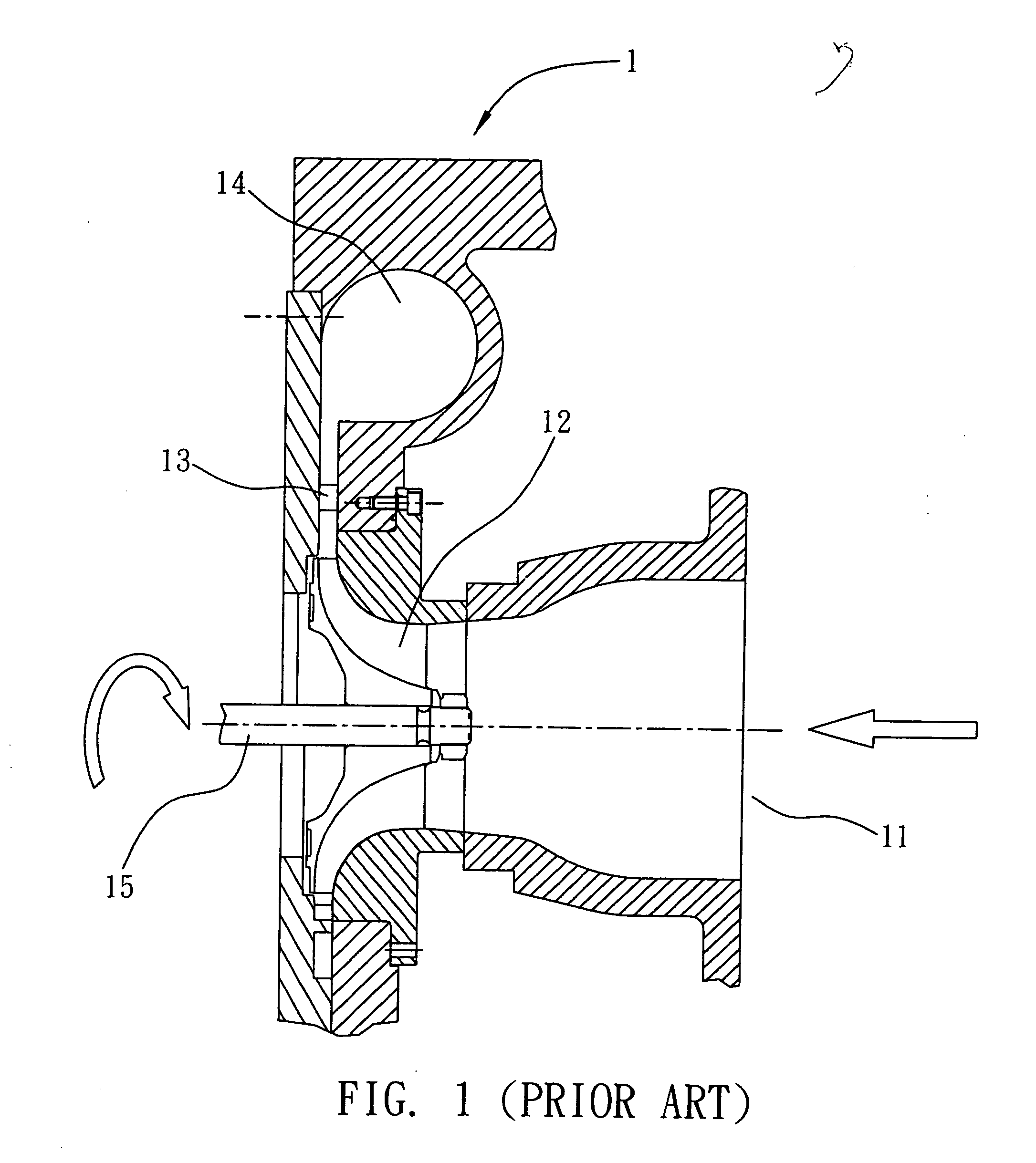

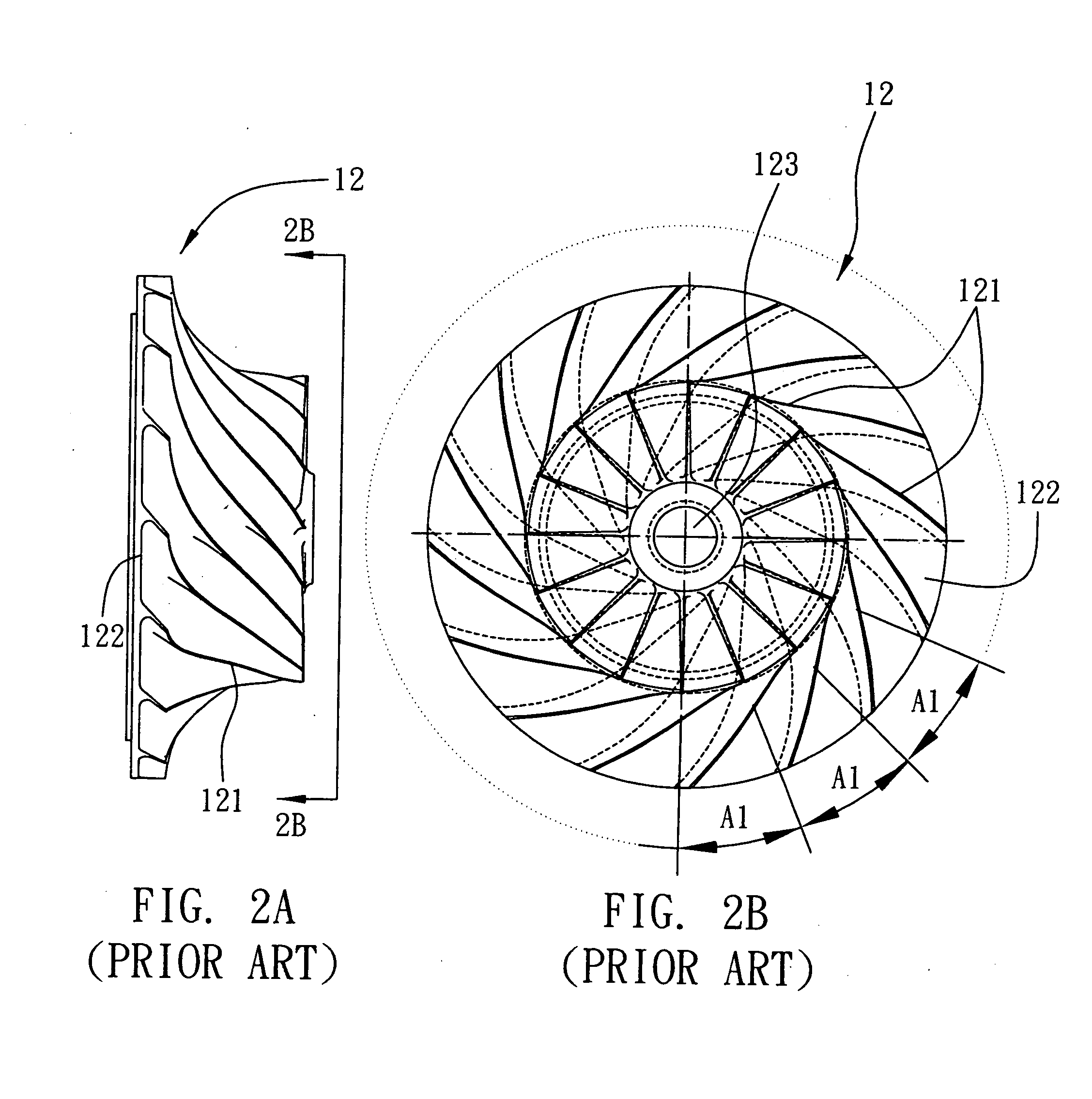

Centrifugal impeller

ActiveUS7789627B2Reduce running noiseReduce sound pressure levelPropellersPump componentsImpellerEngineering

A centrifugal impeller employed in a centrifugal machine, includes a main body, the main body generally being conical and defining a shaft bore in a center portion thereof; and a plurality of blade groups evenly arranged surrounding the shaft bore in sequence, each of the blade groups having a plurality of blades wherein neighboring blades having an interval angle, and the number and corresponding interval angles of the blades of different blade groups are identical. The present impeller structure can be employed to distribute the concentrated energy of the discrete tones noise of the blades, which is generated by the high-speed rotation impeller, and further to reduce the operating tones noise.

Owner:IND TECH RES INST

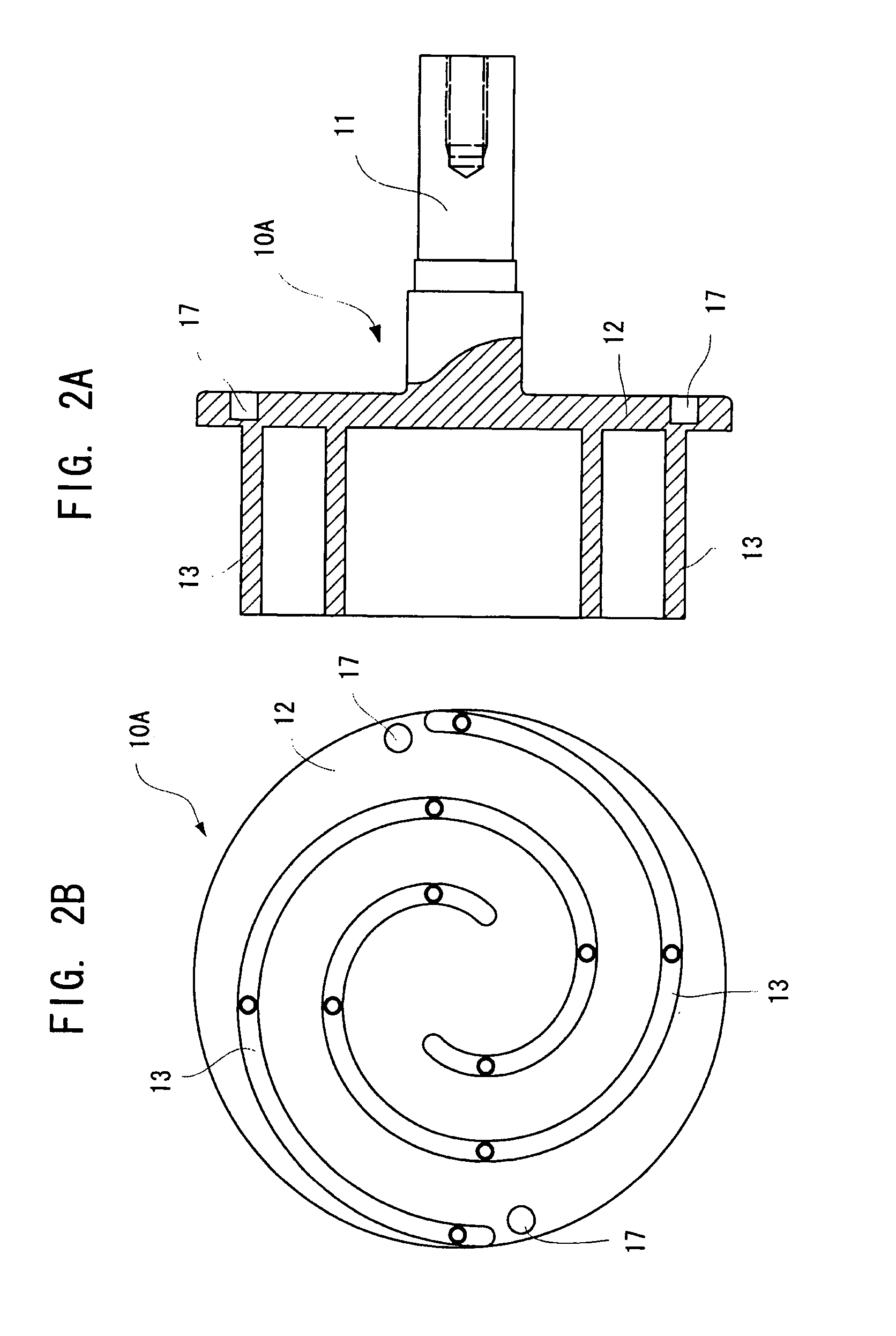

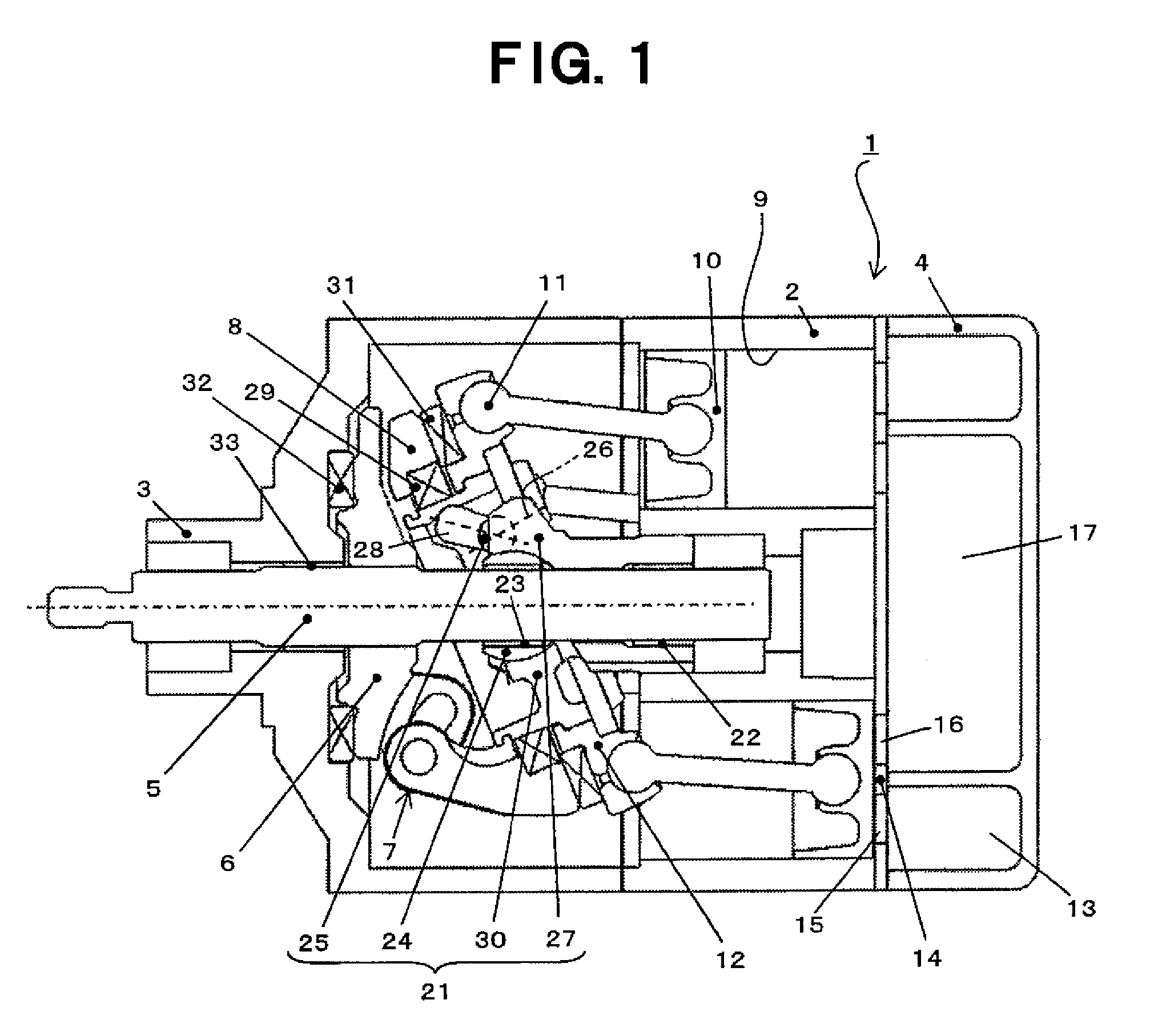

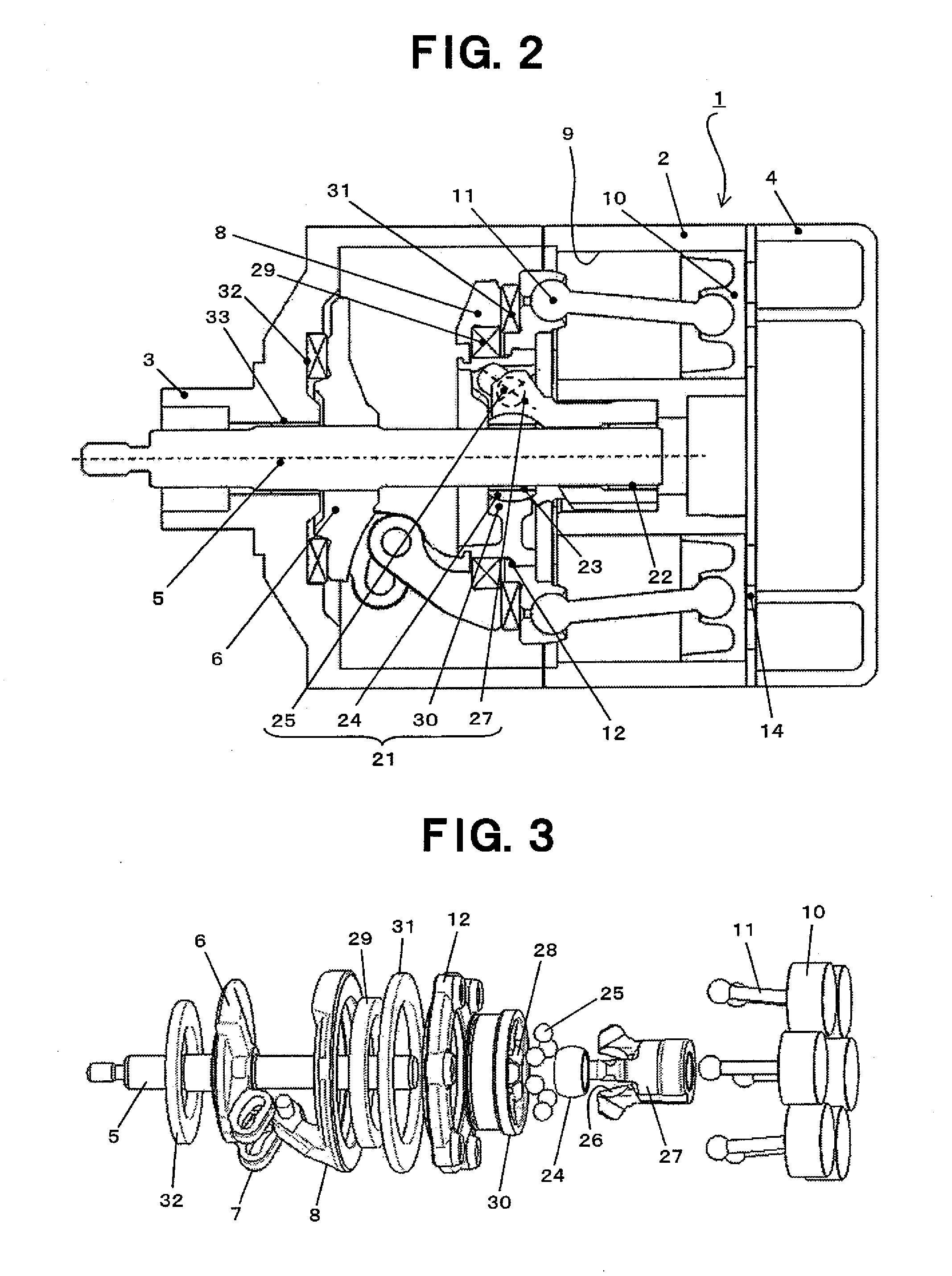

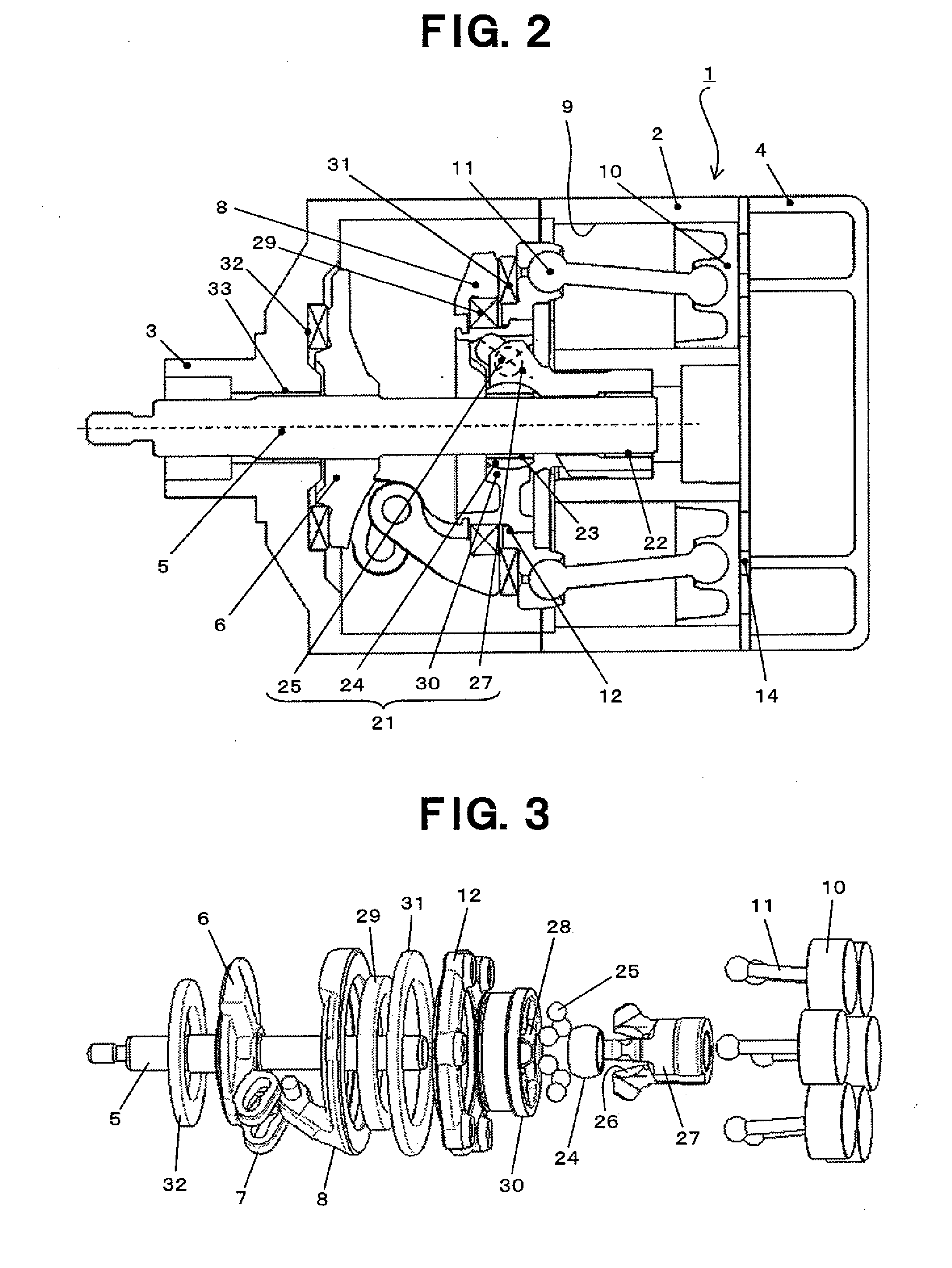

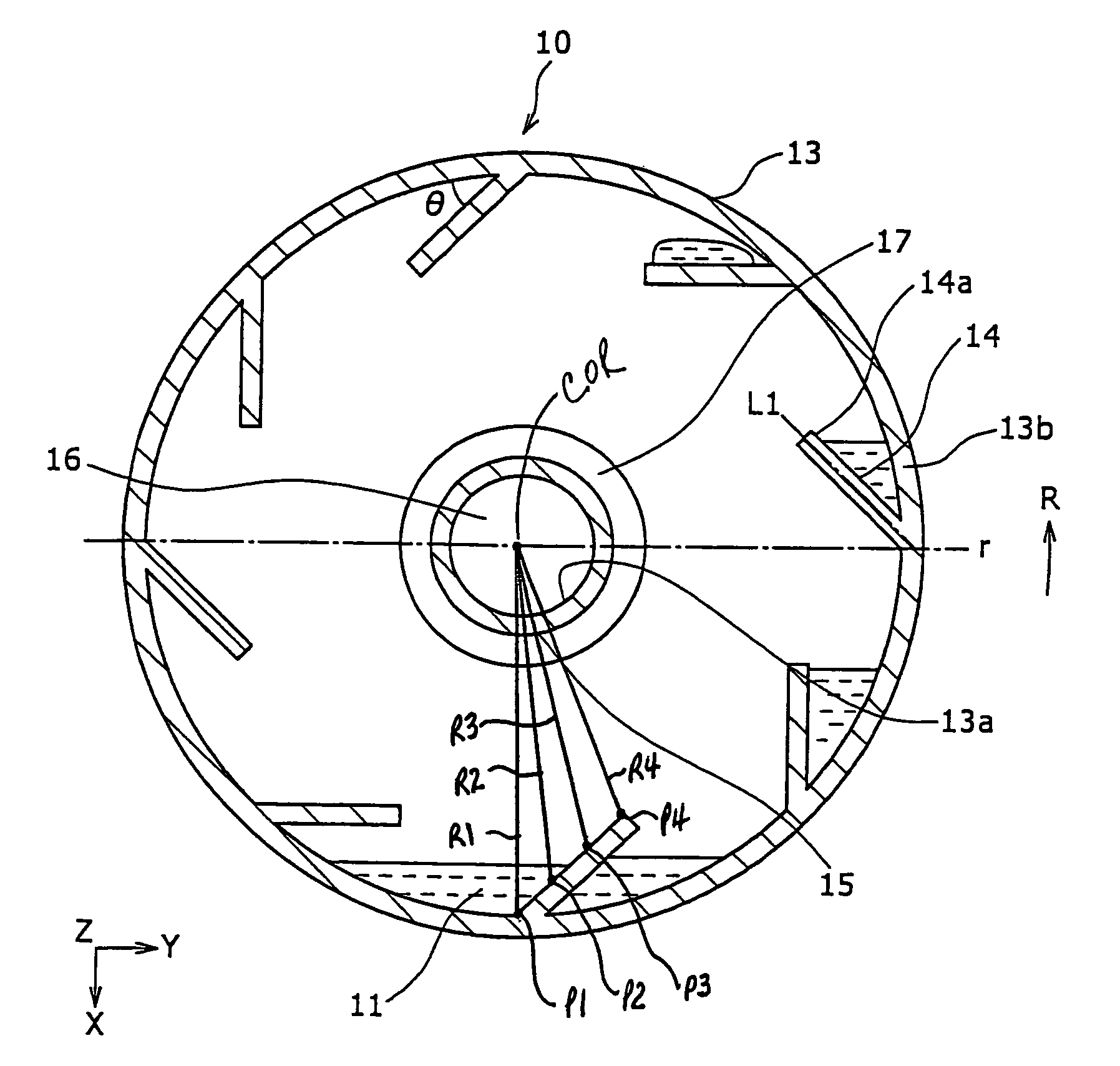

Scroll type fluid machine having a first scroll wrap unit with a scroll member and a scroll receiving member, and a second scroll wrap unit engaged with the first scroll wrap unit

ActiveUS7445437B1Good rotation balanceUseless spaceEngine of arcuate-engagement typeOscillating piston enginesEngineeringMechanical engineering

A scroll type fluid machine includes a housing, a first scroll unit arranged rotatably in the housing and a second scroll unit rotating with rotation of the first scroll unit and gyrating relative to the first scroll unit to vary volumes of compression spaces. The first scroll unit includes a first wrap group including two end plates with support shafts supported rotatably by the housing and scrolled wraps arranged uniformly. The second scroll unit includes a cylindrical outer peripheral ring portion held slidably between the end plates of the first scroll unit, a connection block portion located in a center portion and a second wrap group having plural scrolled wraps extending from the ring portion to the connection block portion to define insertion spaces into which the wraps of the first wrap group are inserted and, with the first wrap group, forming compression spaces.

Owner:SCROLL GIKEN

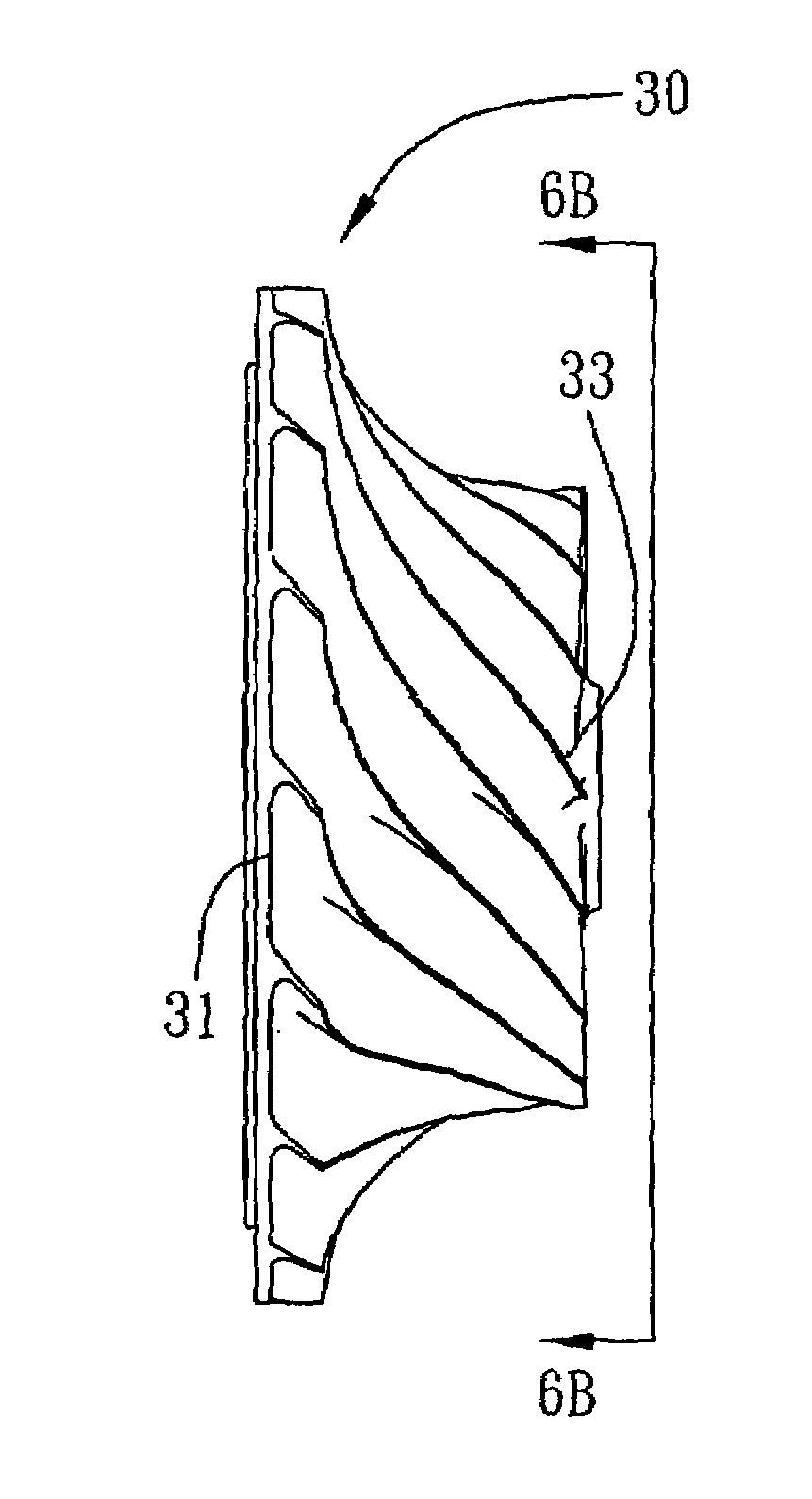

Centrifugal impeller

ActiveUS20070140832A1Effective distributionReduce sound pressure levelPropellersRotary propellersImpellerEngineering

A centrifugal impeller employed in a centrifugal machine, includes a main body, the main body generally being conical and defining a shaft bore in a center portion thereof; and a plurality of blade groups evenly arranged surrounding the shaft bore in sequence, each of the blade groups having a plurality of blades wherein neighboring blades having an interval angle, and the number and corresponding interval angles of the blades of different blade groups are identical. The present impeller structure can be employed to distribute the concentrated energy of the discrete tones noise of the blades, which is generated by the high-speed rotation impeller, and further to reduce the operating tones noise.

Owner:IND TECH RES INST

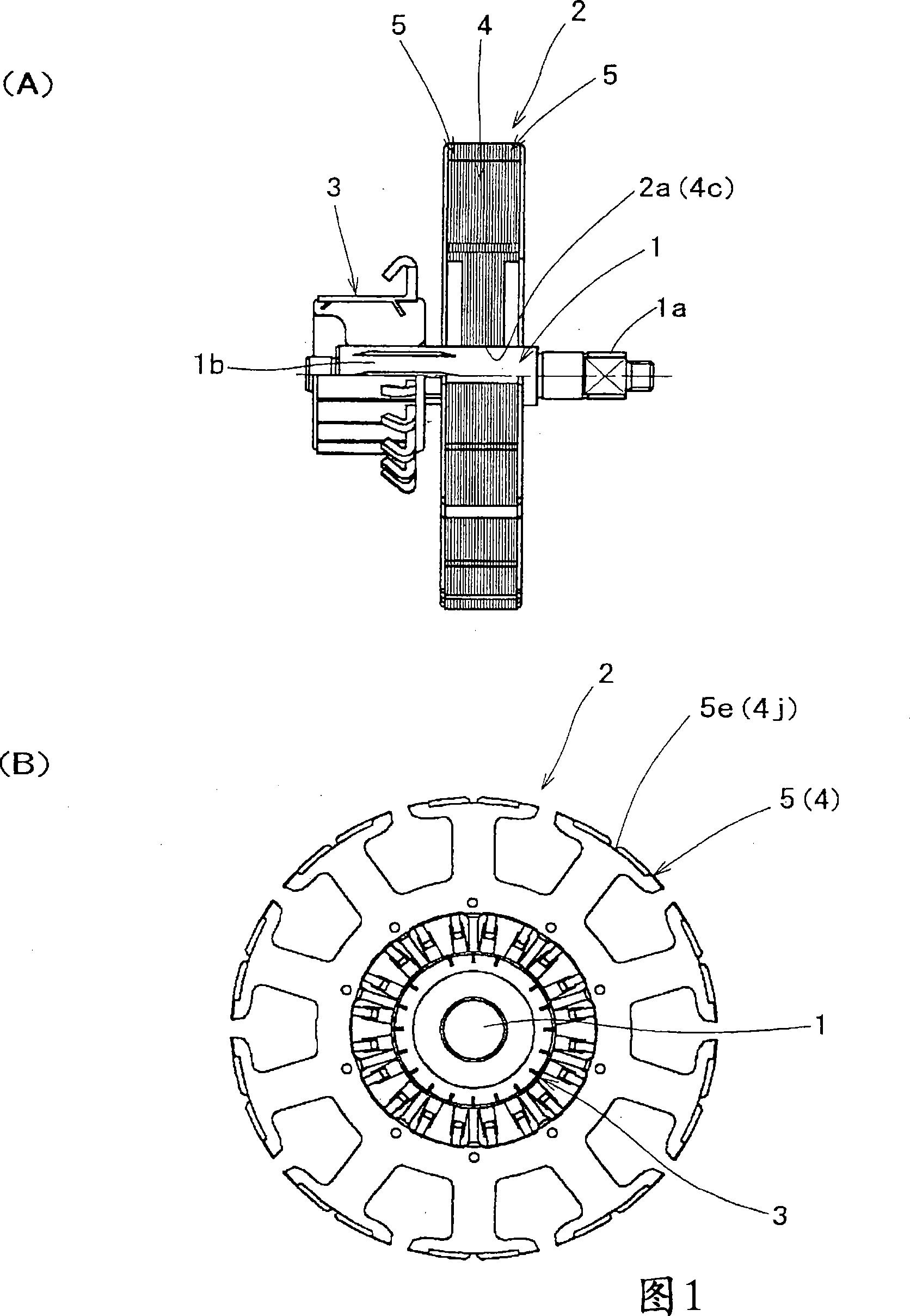

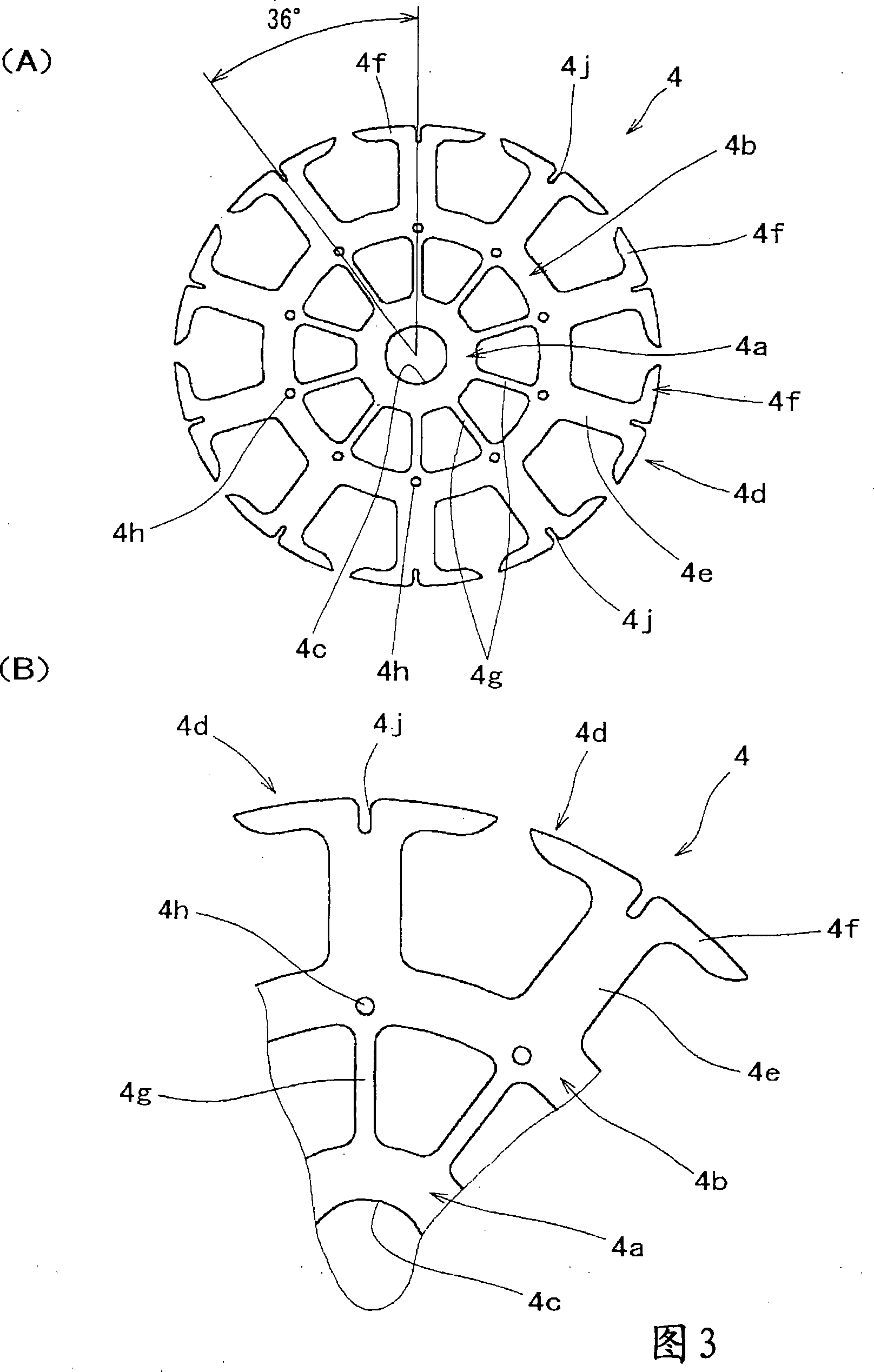

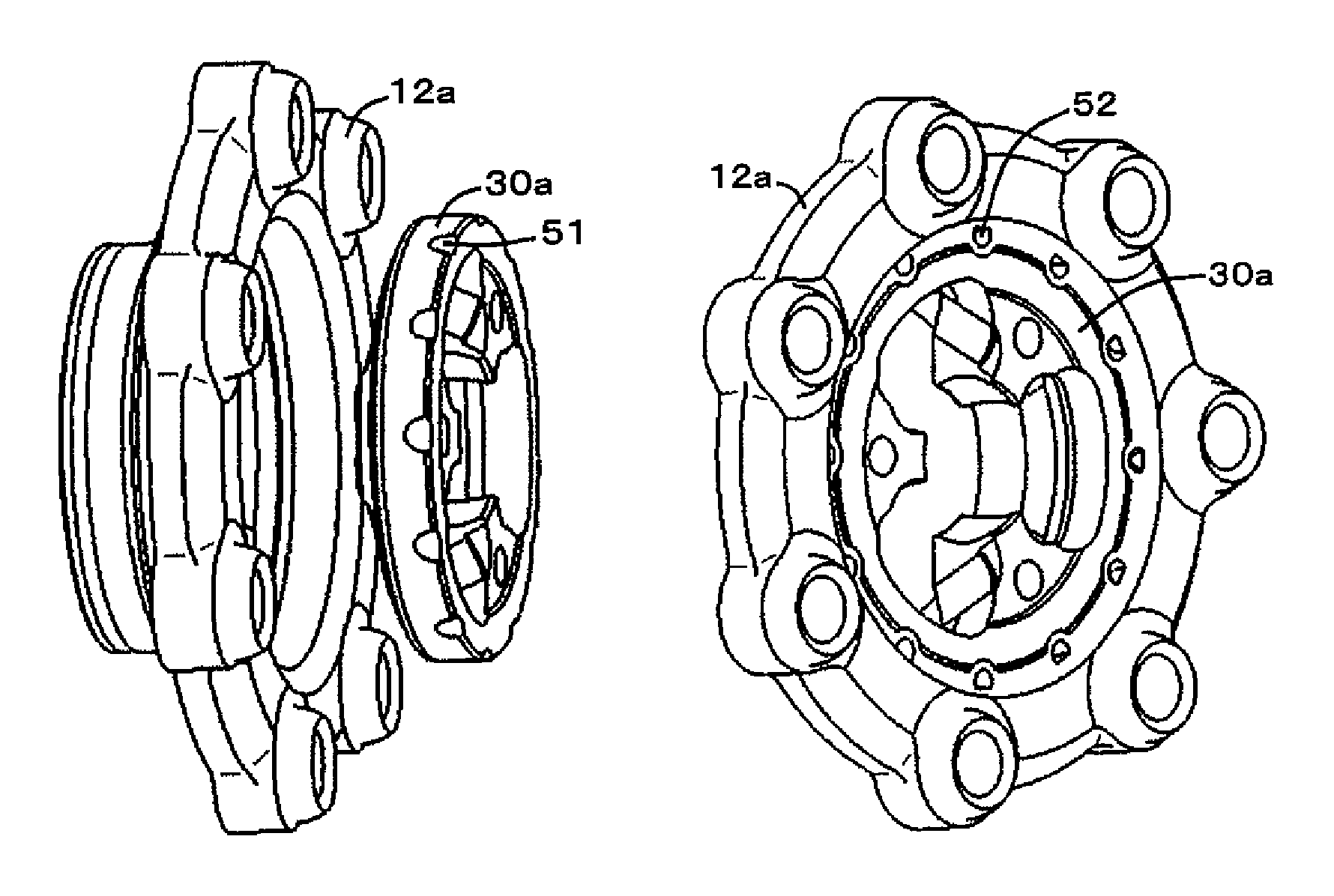

Armature of rotating electric machine and method of manufacturing the same

InactiveCN101189780AGood axis accuracyGood rotation balanceMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineEngineering

The present invention configures the armature of the rotating electrical machine into a structure with good rotational balance. Utilize the main and auxiliary core parts (4, 5) made of ring-shaped plates, stack multiple auxiliary core parts (5) on both sides of the multiple main core parts (4), and use the holes provided on each core part to The riveting parts (4h, 5f) are convexly riveted to these core members (4, 5) to integrate the core (2), and a perfectly round motor is pressed into the shaft hole (2a) formed in the core (2). In the stage before the shaft (1), a thinning and drawing process is performed in advance using a thinning and drawing punch (7).

Owner:MITSUBA CORP

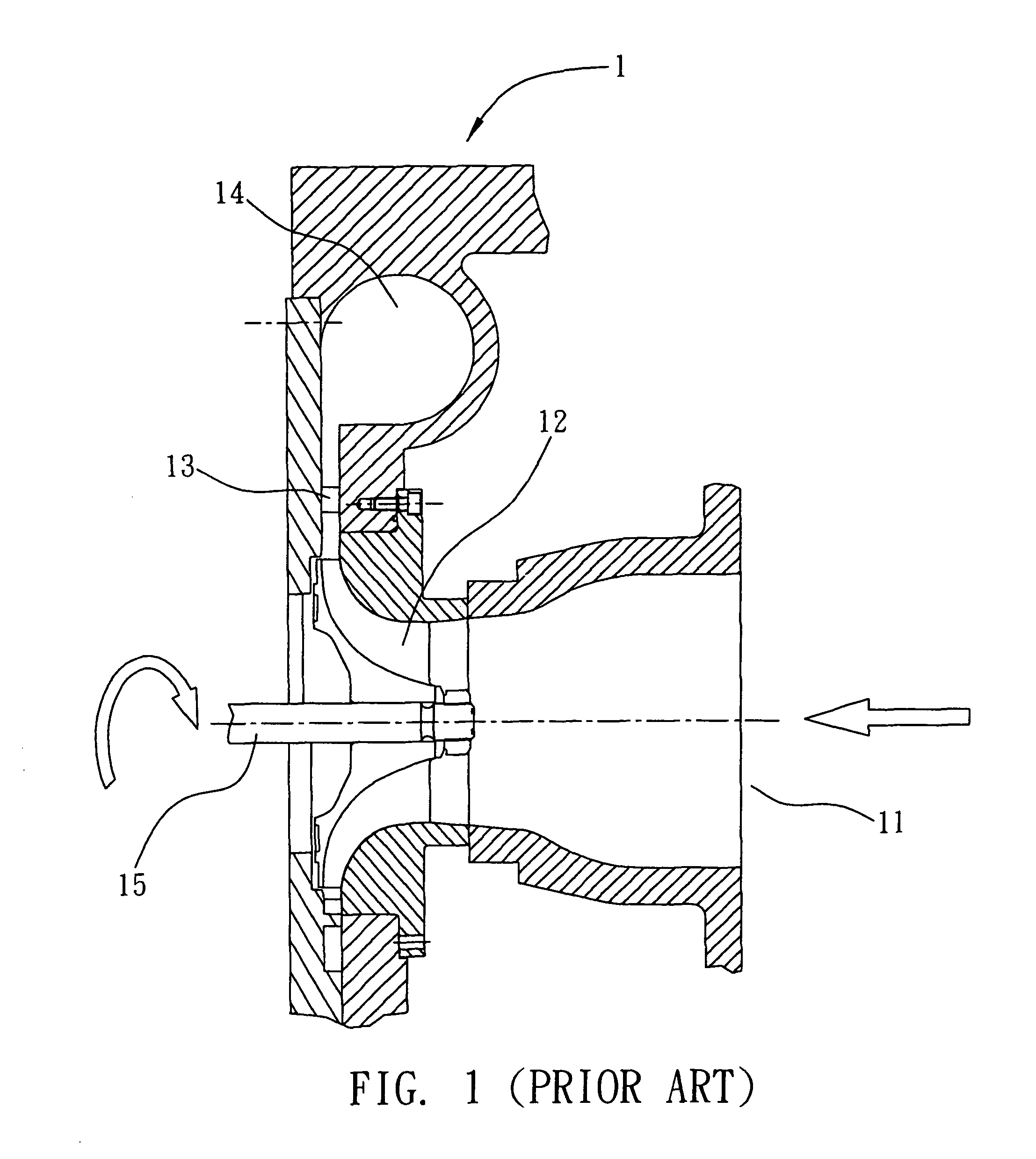

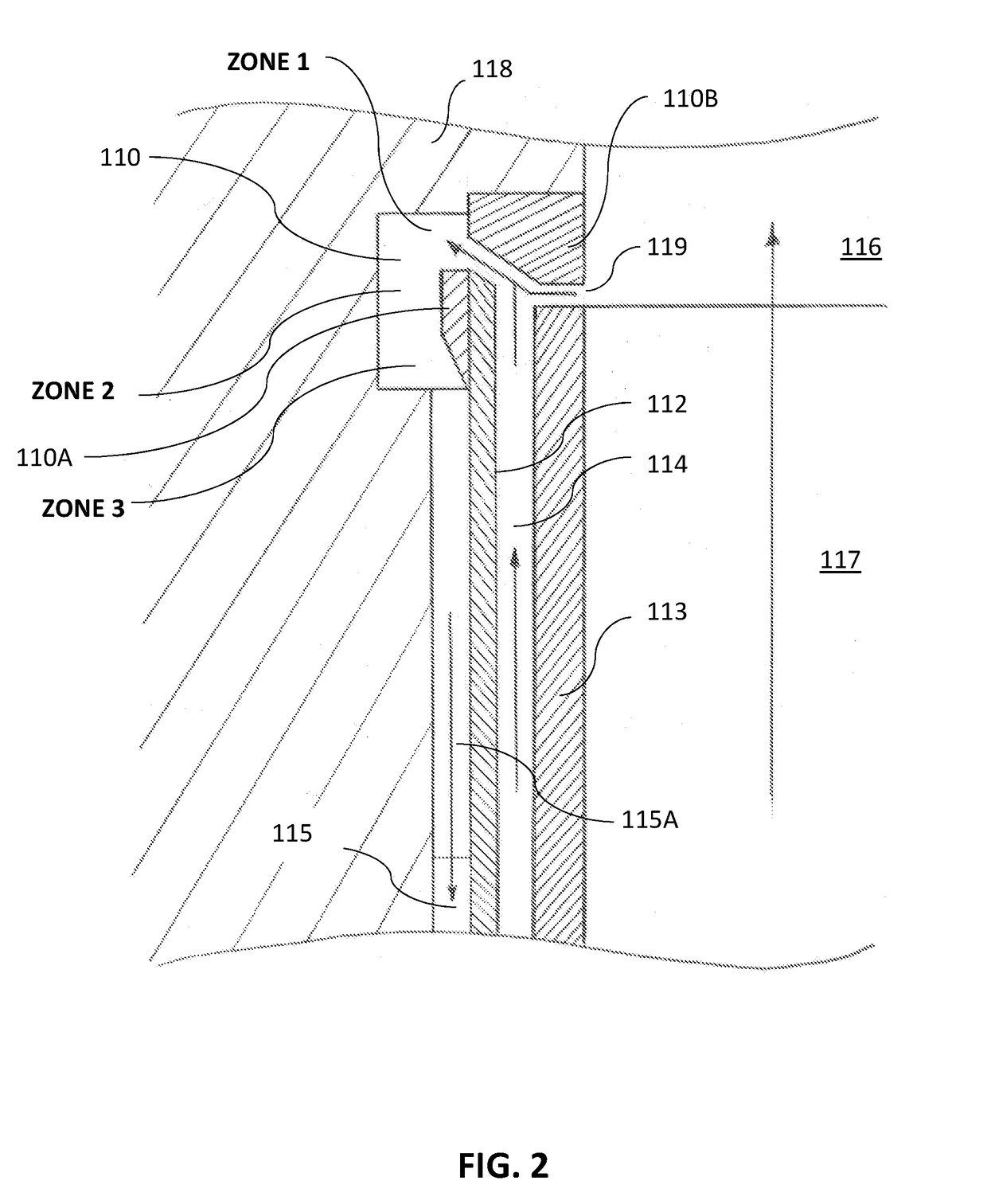

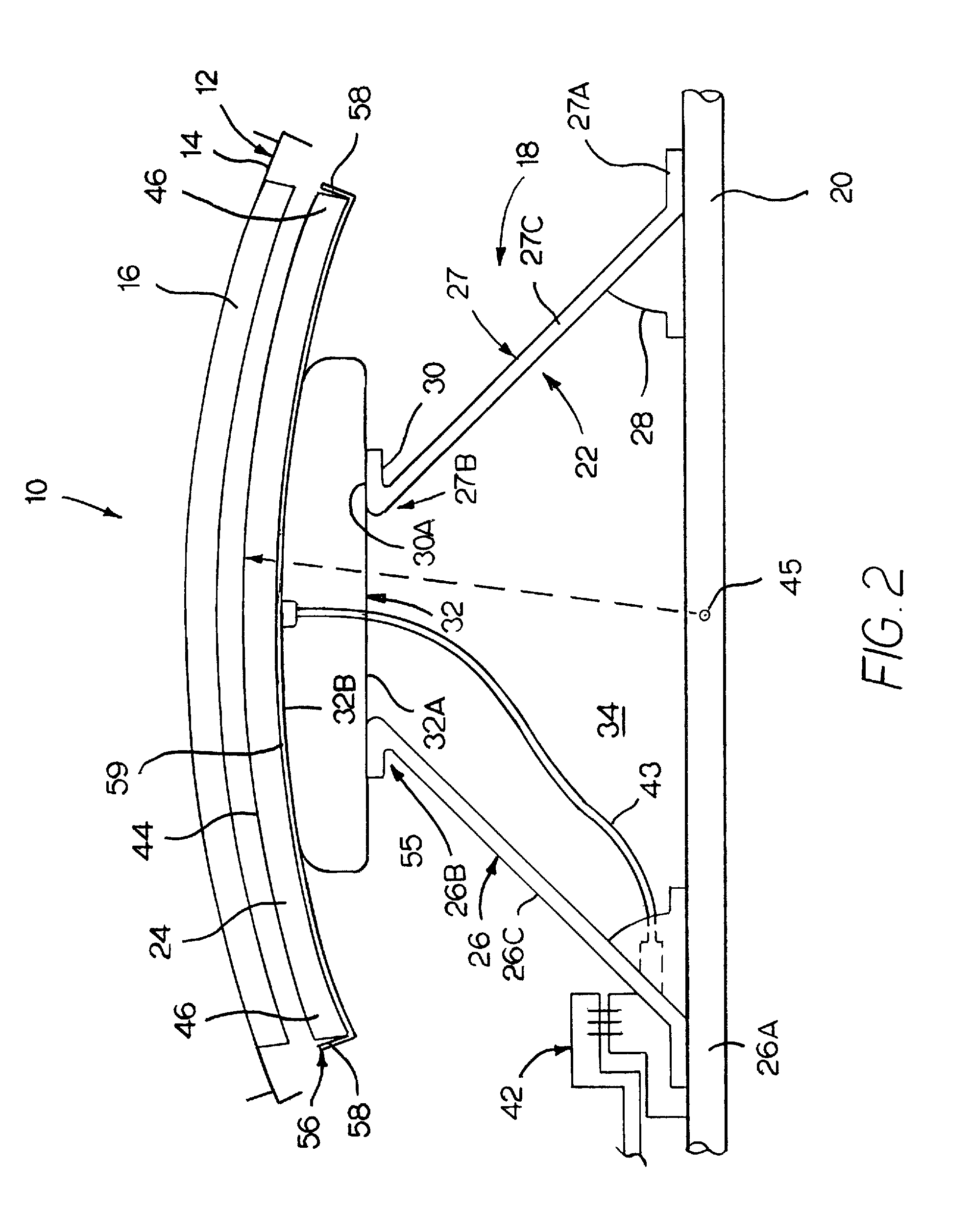

Methods and devices for reducing circumferential pressure imbalances in an impeller side cavity of rotary machines

ActiveUS20180291928A1Altering natureEncourage free circumferential flowPump componentsPumpsImpellerRotary machine

An improved rotary machine of the invention may include a rotor with an impeller mounted thereon. A side cavity may be formed between an impeller and the housing. The rotary machine may be further equipped with an annular subdividing disk for segmenting a fluid flow in the cavity into a first fluid flow between the disc and the impeller, and a second fluid flow on the other side of the disk between the disc and the housing. The rotary machine of the invention also features a peripheral annular space formed in the periphery of the housing in the cavity at a location adjacent to a peripheral region of the annular subdividing disk. Importantly, this peripheral annular space is void of restrictions to circumferential fluid flow therein so as to alter the second fluid flow in the cavity in order to reduce pressure variations and flow disturbances along the circumference of the rotary machine. This in turn improves rotational balance of the rotary machine.

Owner:TECH COMMLIZATION

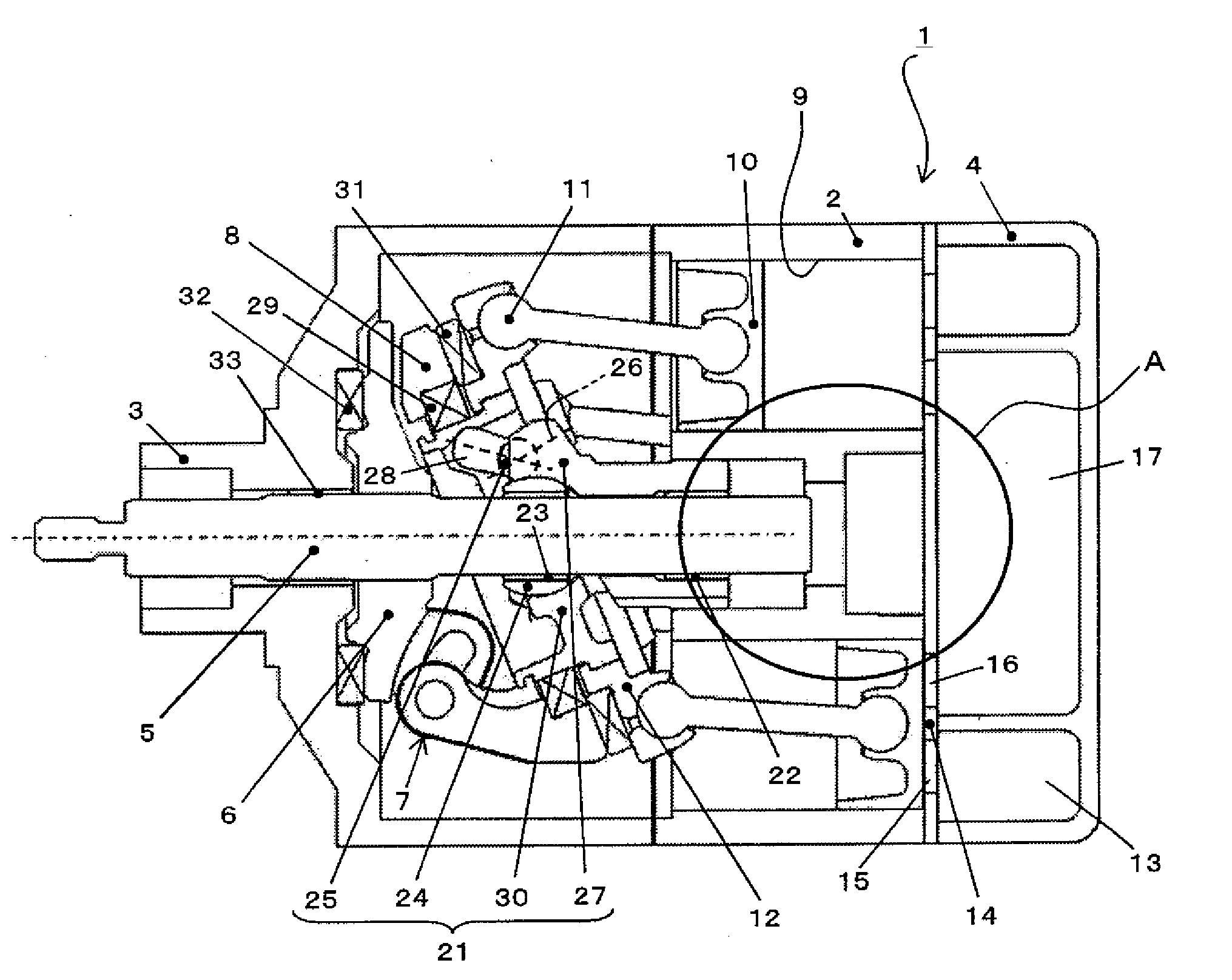

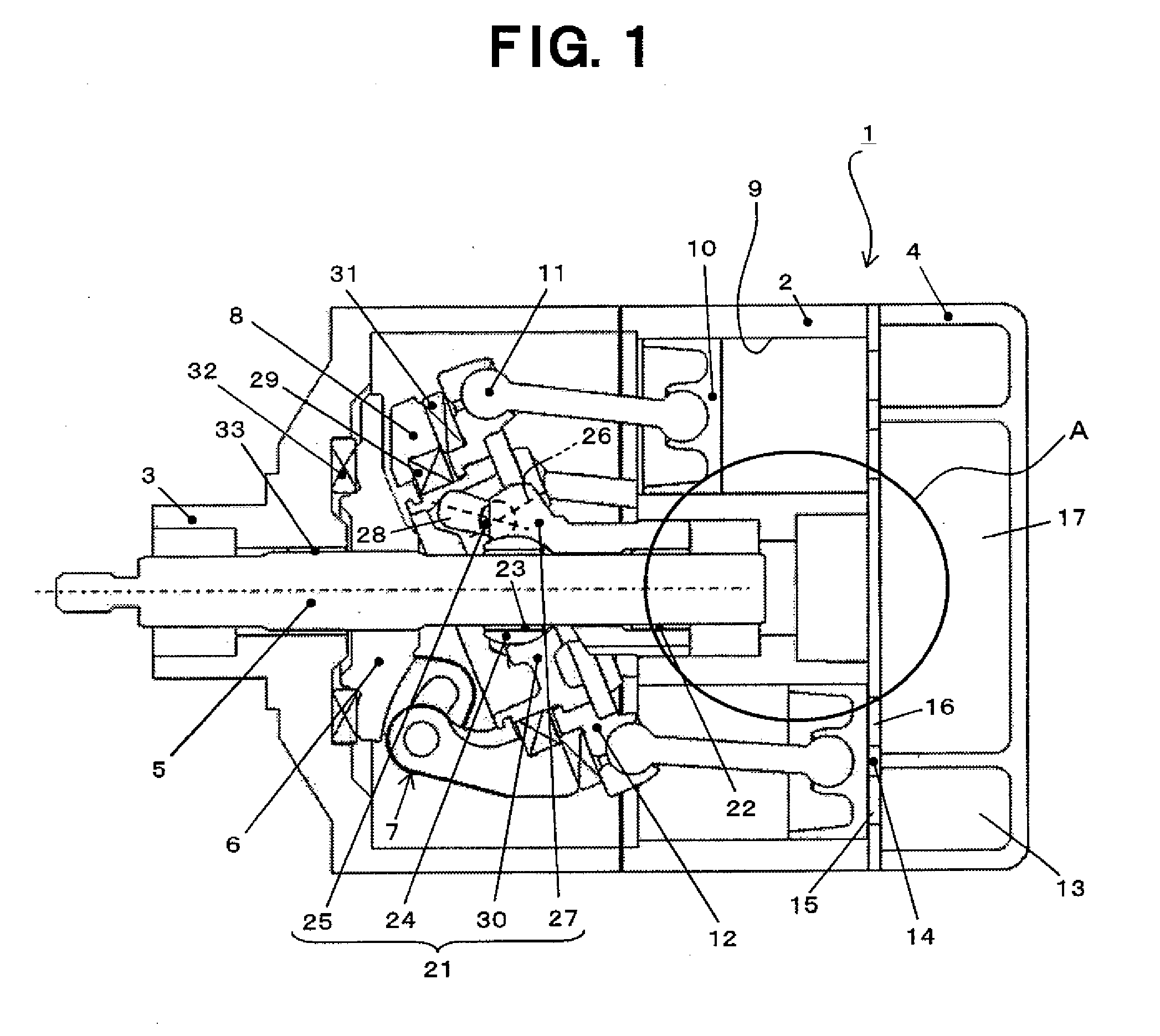

Wabble plate type variable displacement compressor

InactiveUS8549985B2Increased durabilityImprove performanceWobble plate gearingsMulti-stage pumpsUniversal jointSpherical form

A compressor reciprocates pistons via a wabble plate wabbled while being prevented from rotating. A wabble plate rotation preventing mechanism is constructed as a mechanism comprising an inner ring axially movable relative to a main shaft, an outer ring connected to the wobble plate, a plurality of balls placed between guide grooves of the inner and outer rings and performing power transmission, and a sleeve axially movably engaged with the inner ring, provided so as to be axially movable together with the inner ring, and functioning as a central member for wabbling of the wabble plate. A difference in shape is provided between the axial cross-sectional profile of a substantially concave spherical surface formed in the inner periphery of the outer ring and the axial cross-sectional profile of a substantially convex spherical surface formed on the outer periphery of the sleeve such that the closer to the axial opposite ends of the contact portion between both the surfaces the position is, the greater the clearance between the surfaces becomes. Seizure and abrasion in sliding sections in the wabble plate rotation preventing mechanism using a specified constant velocity universal joint are suppressed, and a wabble plate type variable displacement compressor exhibiting excellent durability and silent performance can be provided.

Owner:SANDEN CORP

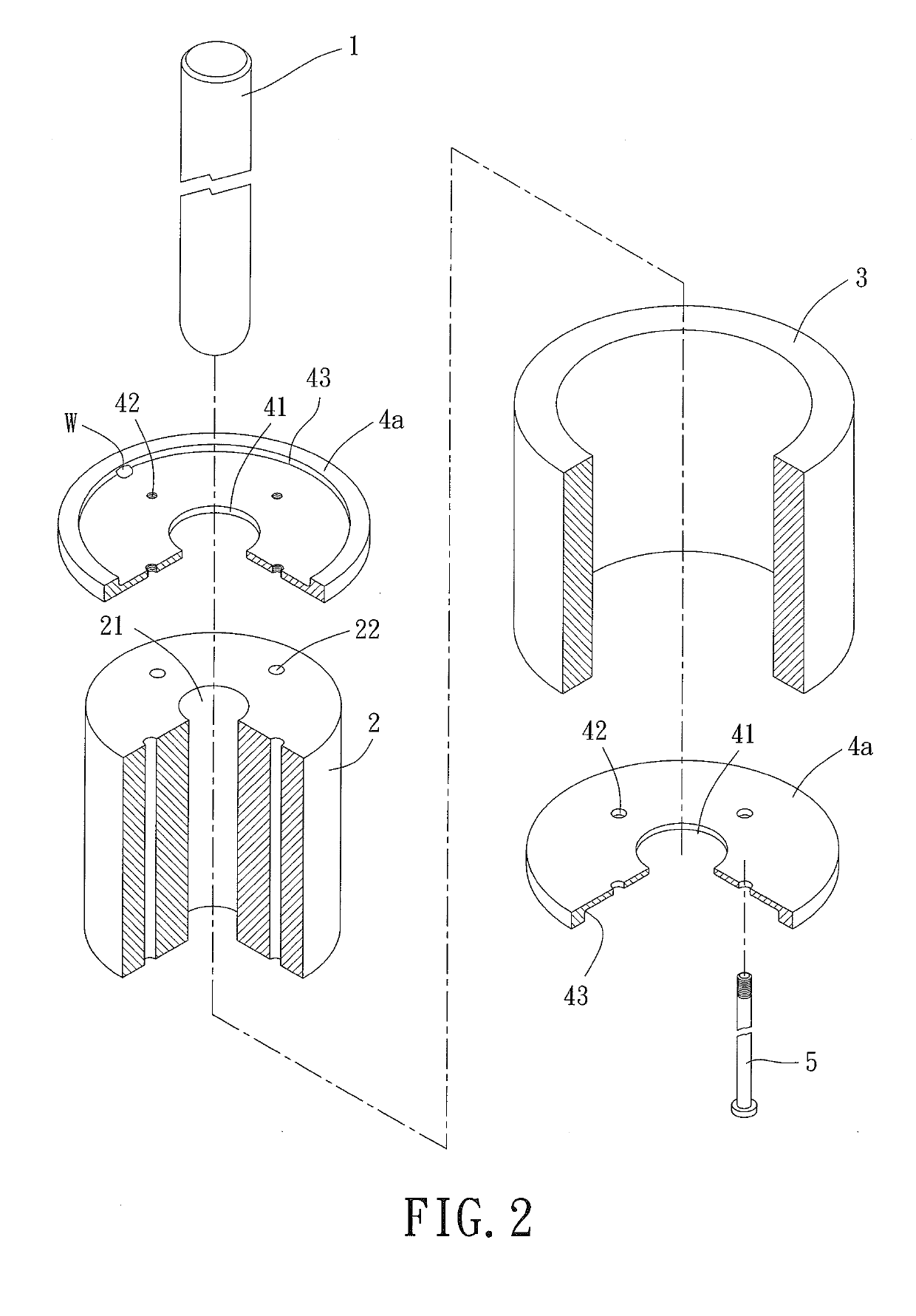

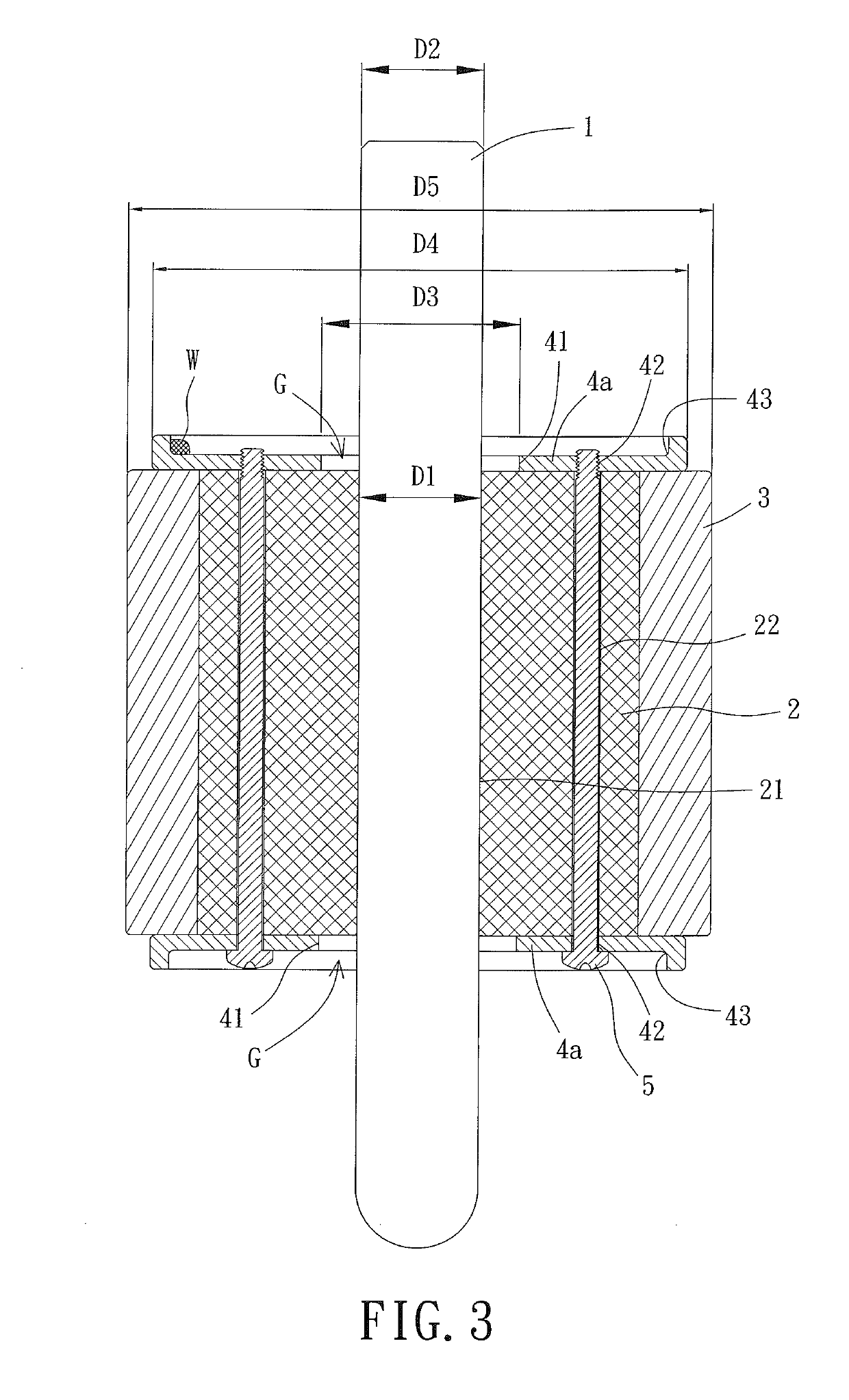

Tray assembly for spindle motor with aerodynamic bearing

InactiveUS20070216239A1Improve assembly yieldIncrease productionRecord information storageDC commutatorEngineeringMechanical engineering

A tray assembly for a spindle motor includes a tray and an aerodynamic rotational shaft. The tray includes an engaging hole in a center thereof. The aerodynamic rotational shaft includes an outer circumference with a smooth surface. An end of the aerodynamic rotational shaft is engaged in the engaging hole of the tray, with the outer circumference of the end of the aerodynamic rotational shaft engaged with an inner circumference of the engaging hole of the tray by forcibly fitting, allowing precise control and adjustment of an engaging relationship between the aerodynamic rotational shaft and the tray.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Motor and optical apparatus

InactiveUS20050218743A1Increase productionHigh outputWindingsCamera focusing arrangementMagnetic polesMiniaturization

Provided are a motor and an optical apparatus each including: a rotatable rotor having a cylindrical magnet; a first coil; a first outer magnetic pole portion which is disposed at a center portion of the first coil and which is opposed to an outer circumferential surface of the magnet within a first predetermined angle range; a second outer magnetic pole portion which is adjacent to an outer circumference of the first coil and which is opposed to the outer circumferential surface of the magnet; a first inner magnetic pole portion which is adjacent to the outer circumference of the first coil and which is opposed to an inner circumferential surface of the magnet; a second coil; a third outer magnetic pole portion which is disposed at a center portion of the second coil and which is opposed to the outer circumferential surface of the magnet within a second predetermined angle range; a fourth outer magnetic pole portion which is adjacent to an outer circumference of the second coil and which is opposed to the outer circumferential surface of the magnet; and a second inner magnetic pole portion which is adjacent to the outer circumference of the second coil and which is opposed to the inner circumferential surface of the magnet. Accordingly, there are provided a motor and an optical apparatus which realize higher output without impairing miniaturization.

Owner:CANON KK

Polishing method, manufacturing method of piezoelectric vibrating piece, piezoelectric vibrator, oscillator, electronic apparatus and radio-controlled timepiece

InactiveUS20120252319A1Well formedImprove parallelismImpedence networksLapping machinesResonanceEngineering

Provided is a polishing method which can enhance thickness accuracy of a wafer at the time of polishing the wafer. In a polishing method of a crystal wafer (tuning fork substrate) which is held on a carrier between an upper platen and a lower platen, an AT cut wafer for thickness measurement is arranged on the carrier, the AT cut wafer is polished together with the crystal wafer (tuning fork substrate), resonance frequency of the AT cut wafer is detected, and a thickness of the crystal wafer (tuning fork substrate) is controlled based on a detection result.

Owner:SII CRYSTAL TECH

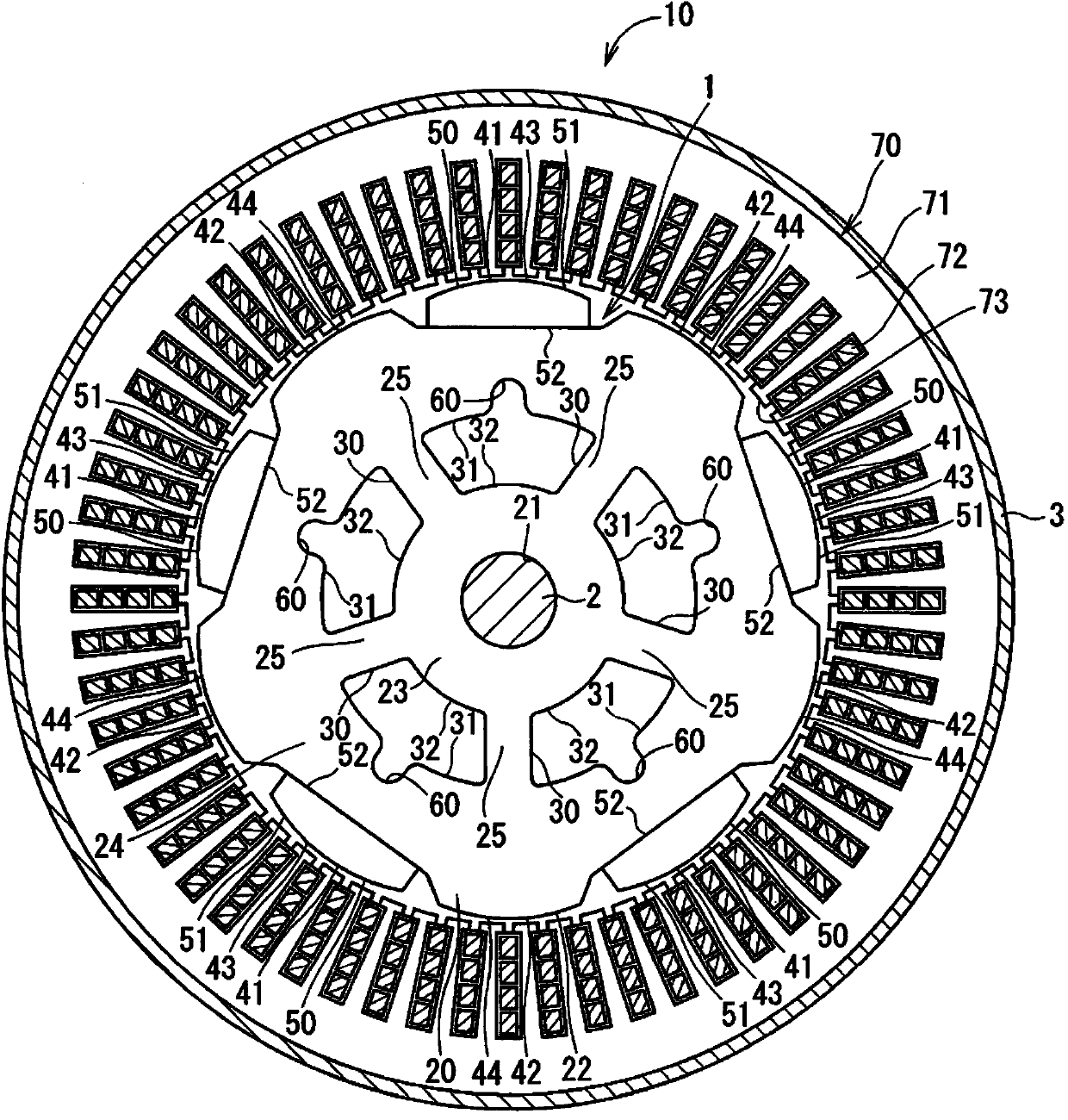

Rotor and rotating electric machine having the same

ActiveCN103795166AHigh outputExcellent magnetic propertiesMagnetic circuit rotating partsMechanical energy handlingElectric machineElectrical polarity

A rotor for a rotating electric machine has a core body (20) and a magnets (50,53). The core body has a through-hole (30), a first polar portion (41), and a second polar portion (42). The first polar portion and the second polar portion are alternately arranged in the circumference direction. The magnets are disposed on the core body at a position corresponding to the first polar portion or the second polar portion. The through-hole has an arc-shaped surface (31) having a first curvature radius (R1). The first polar portion has an arc-shaped surface (43) having a second curvature radius (R2). The second polar portion has an arc-shaped surface (44) having a third curvature radius (R3). The first curvature radius is larger than or equal to the second curvature radius (R1>=R2). The first curvature radius is larger than or equal to the third curvature radius (R1>=R3).

Owner:DENSO CORP

Wobble plate type variable displacement compressor

ActiveUS9046089B2Increased durabilityImprove performanceYielding couplingMulti-stage pumpsProduction rateUniversal joint

Disclosed is a wobble plate type variable displacement compressor that uses a constant velocity universal joint mechanism, which comprises an inner ring and an outer ring, balls that are held between guide grooves of the inner ring and the outer ring to transmit power, wherein a wobble plate is connected and fixed to the outer ring. In the compressor, the connecting structure for the outer ring and the wobble plate is formed by providing a plurality of concave portions arranged in a circumferential direction on one member, by plastically deforming the other member partially at locations corresponding to the concave portions such that it fits into the concave portions, and by fixing both members to each other in the axial direction and in the rotational direction by means of the plastic deformation. With this wobble plate type variable displacement compressor using the specified constant velocity universal joint mechanism, the structure for connecting the wobble plate and the outer ring in the wobble plate rotation preventing mechanism can be improved, thereby improving the productivity and reducing the cost and the weight.

Owner:SANDEN CORP

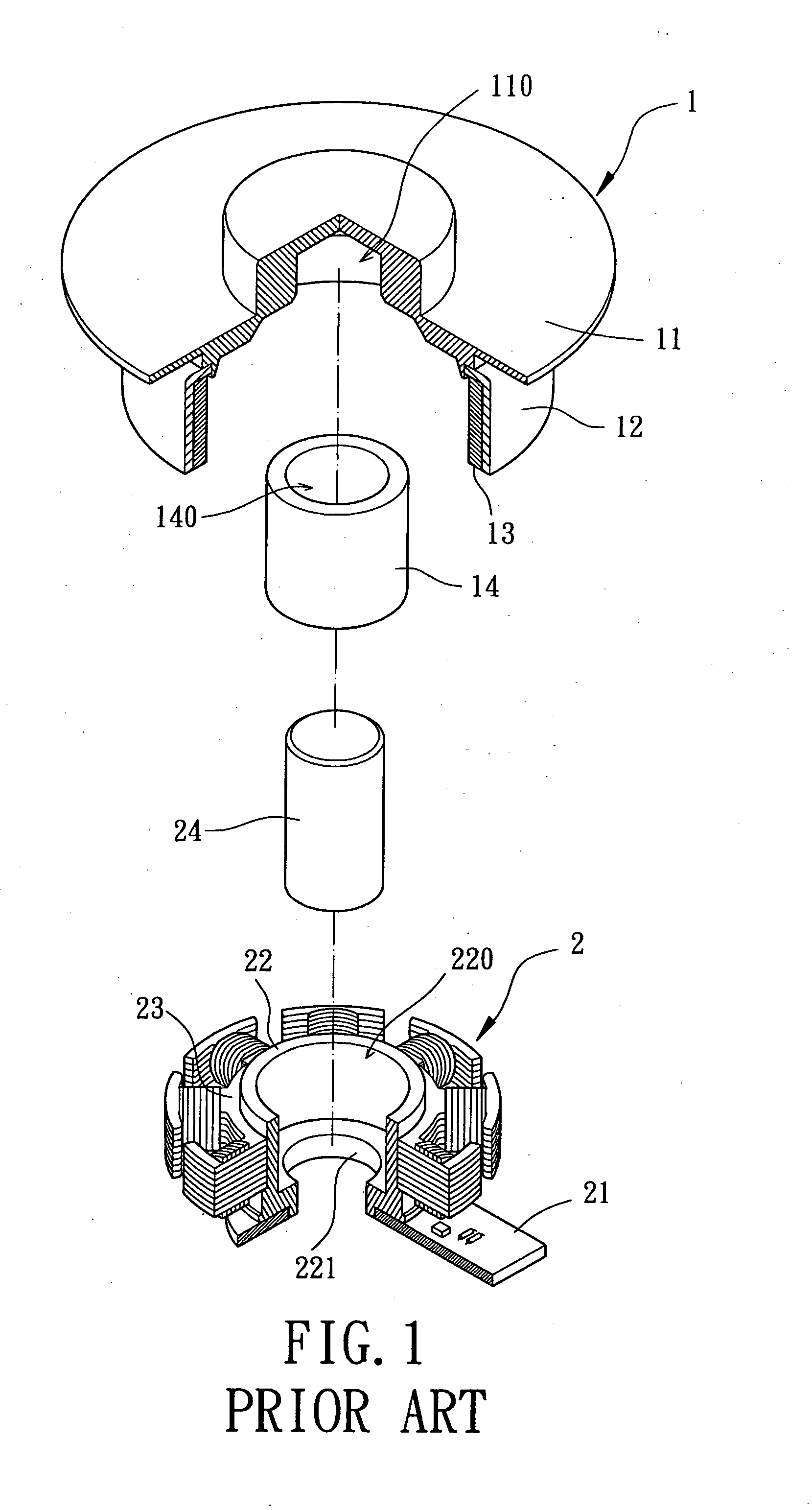

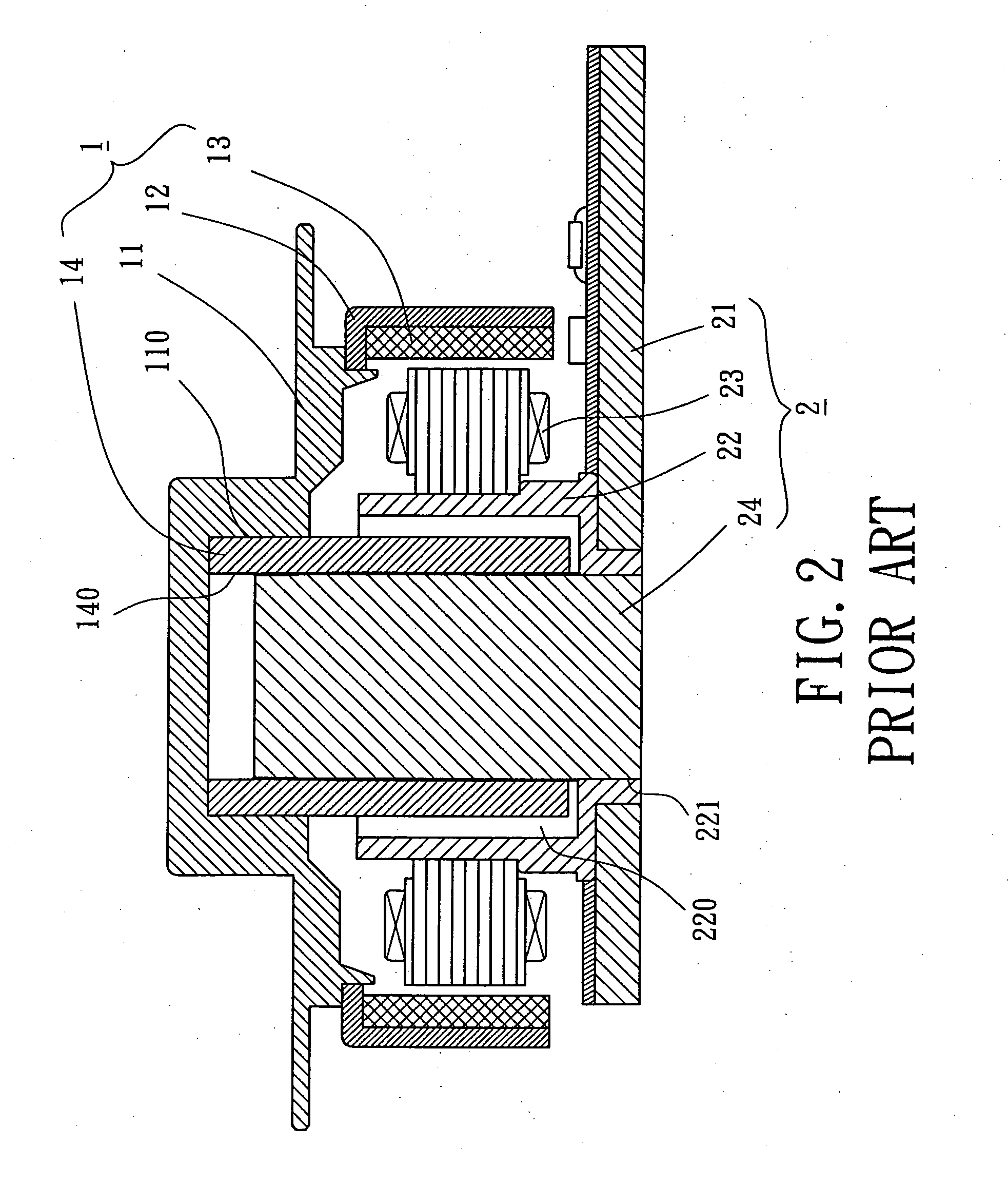

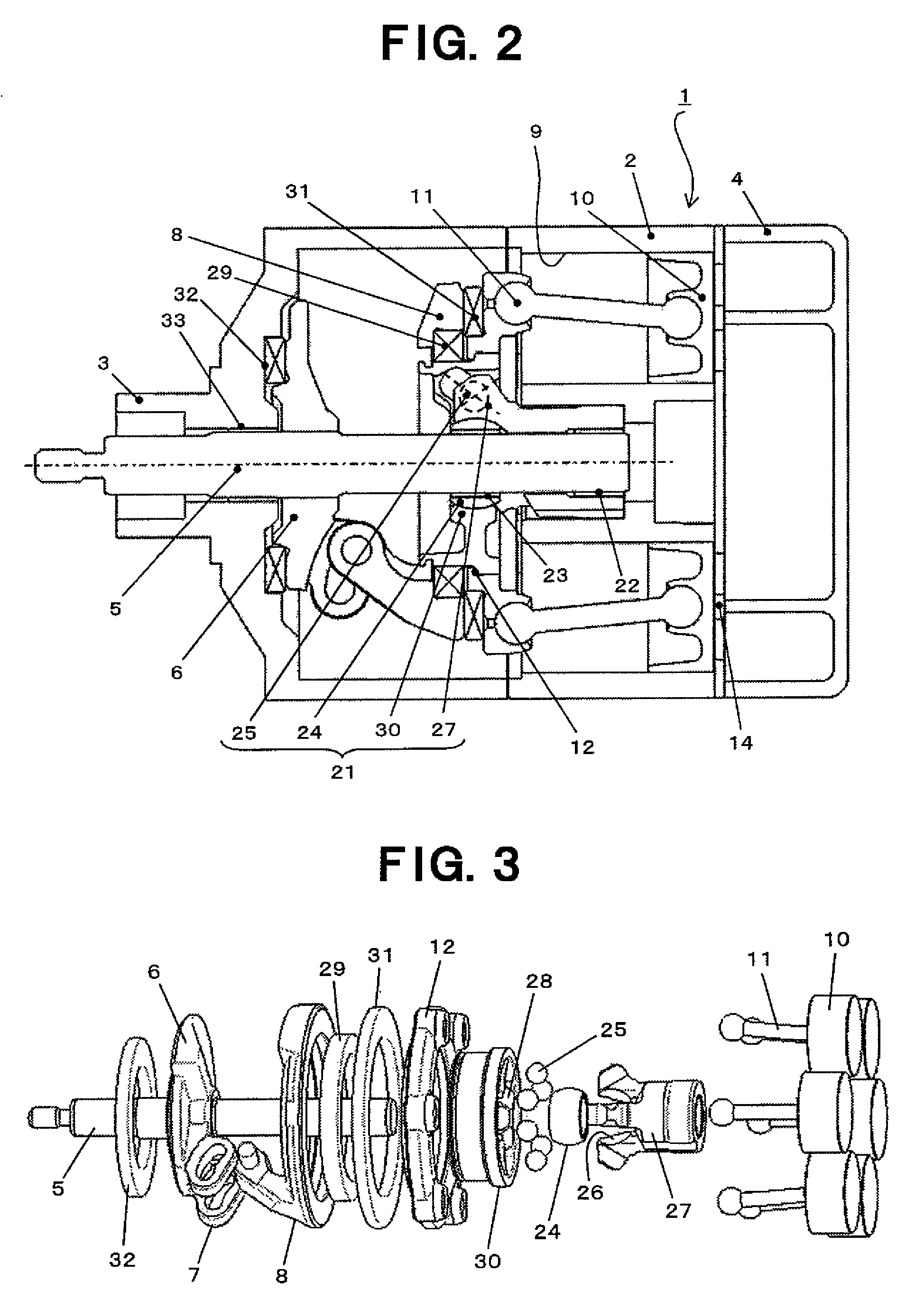

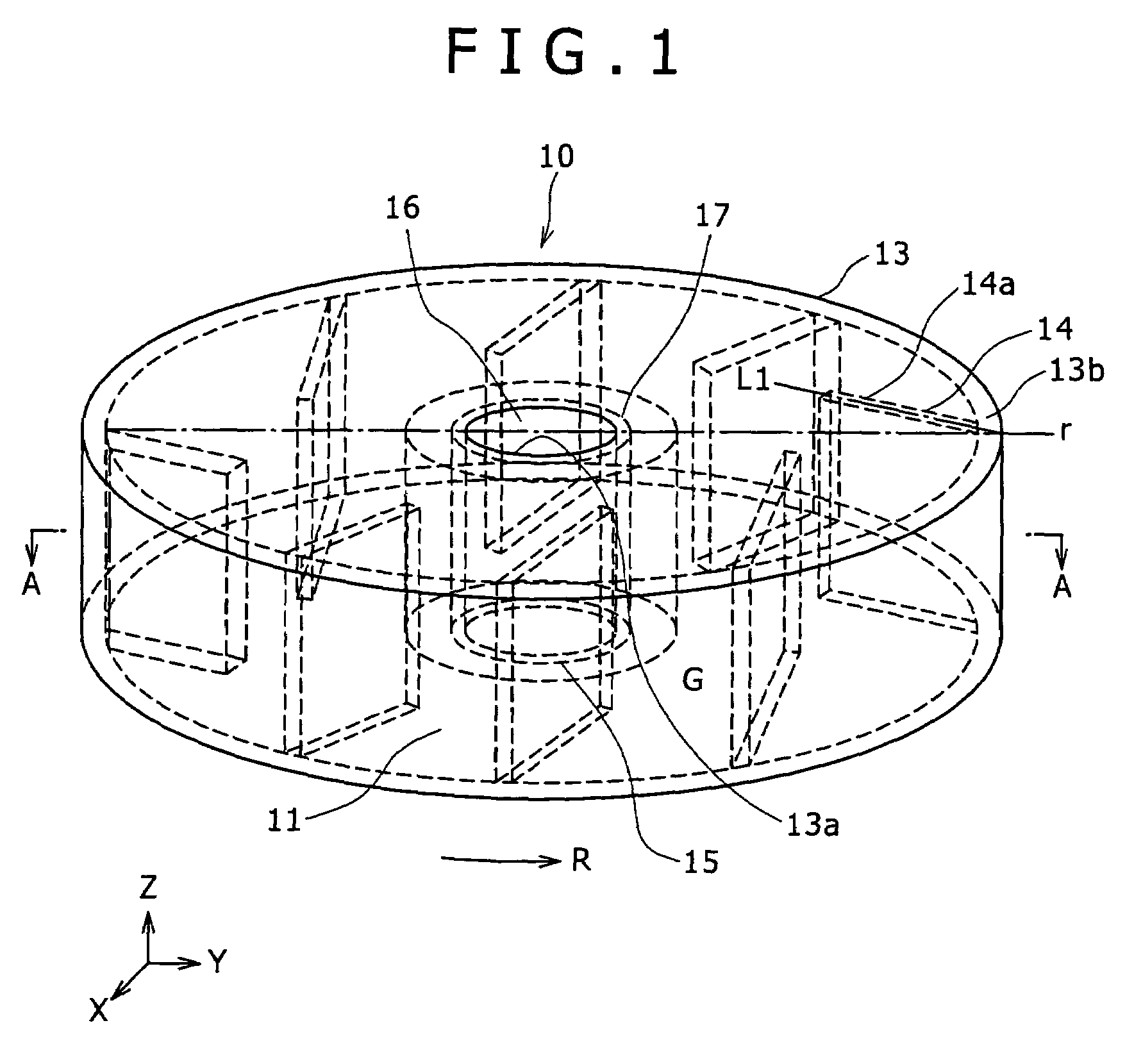

Automatic balancing apparatus and rotative apparatus using the same

InactiveUS20050235304A1Good rotation balanceAmount can be ensuredUndesired vibrations/sounds insulation/absorptionRotating bodies balancingEngineeringMagnet

An automatic balancing apparatus includes a balancer made of a magnetic fluid, a housing member rotatably provided and for housing the balancer, and a flat magnet disposed integrally rotatable within the housing member and to extend from a center of rotation to an outer circumferential side of the housing member. Accordingly, the automatic balancing apparatus can start rotating with the balancer held by the magnet irrespective of the attitude of the automatic balancing apparatus, whereby the balance of rotation can be improved in a stable manner.

Owner:SONY CORP

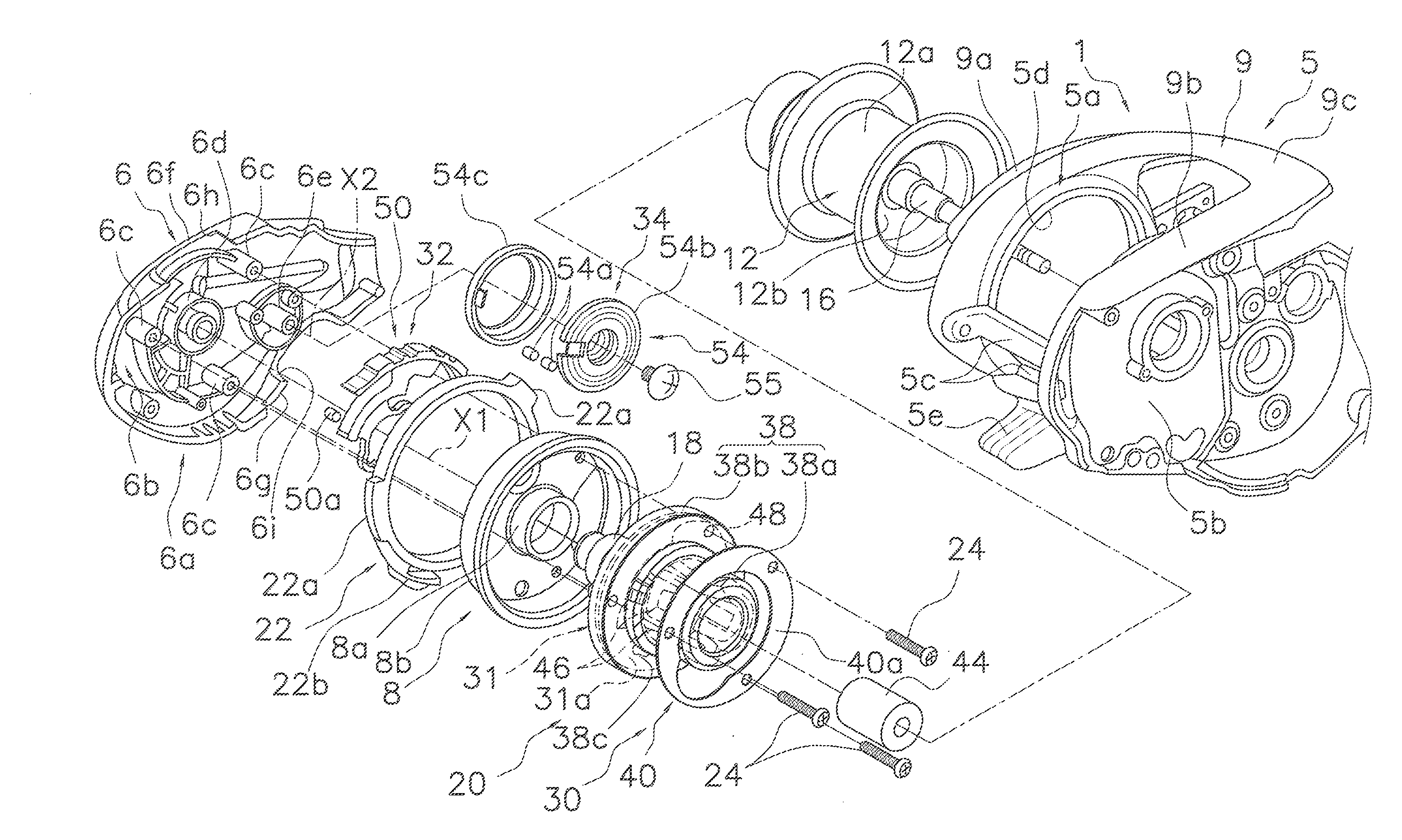

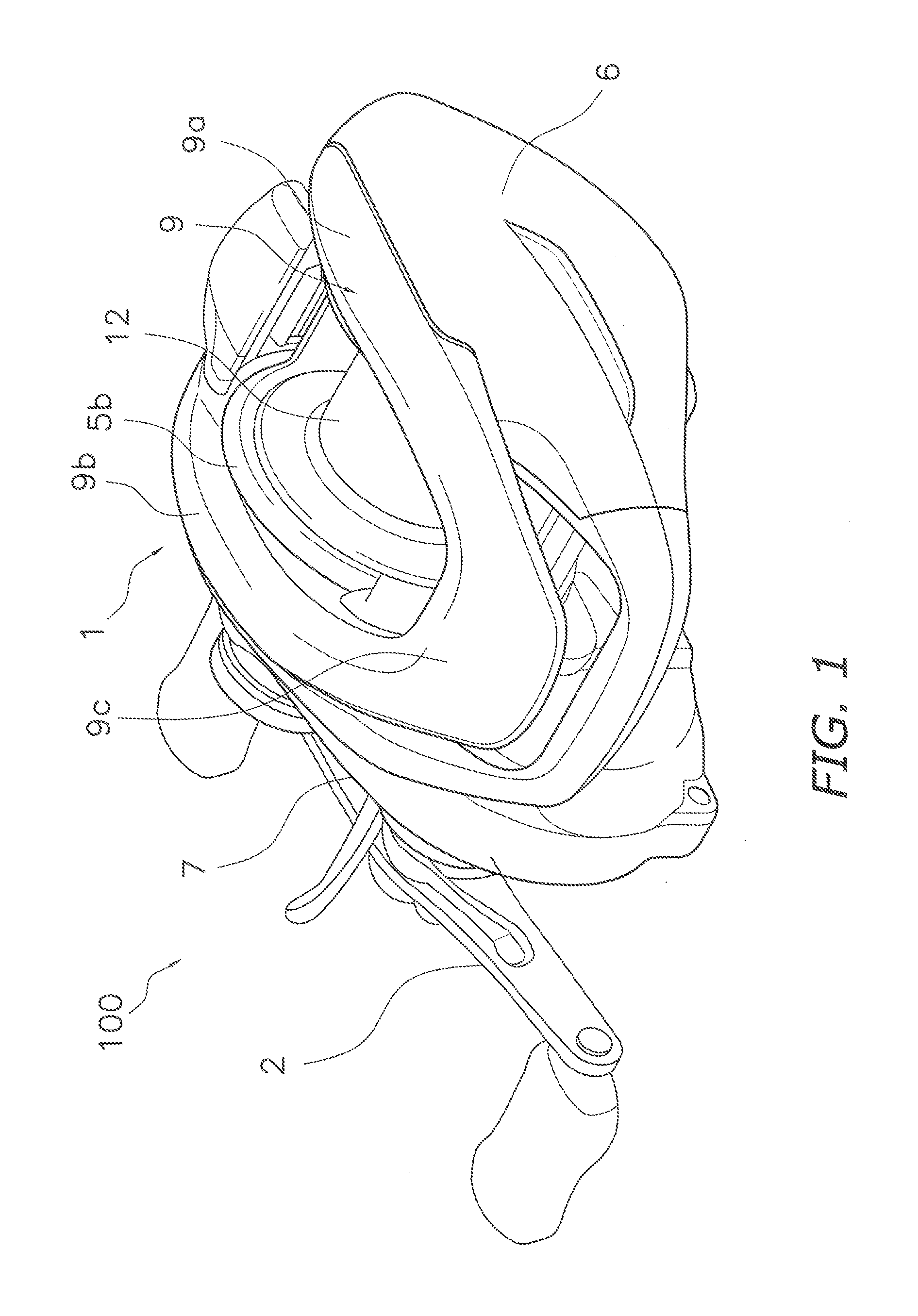

Dual-bearing reel

ActiveUS20160015015A1Effective shieldingImprove detection accuracyReelsEngineeringMechanical engineering

A dual-bearing reel includes a reel body, a spool rotatably held between side plates, and a brake unit configured to brake the spool. The brake unit includes a cover portion, a first regulator and a second regulator. The cover portion has a first circumferential part and a second circumferential part, and is mounted to the reel body. The first regulator and the second regulator are covered with the cover portion. The first circumferential part has a first opening exposing at least a part of the first regulator therethrough, whereas the second circumferential part has a second opening exposing at least a part of the second regulator therethrough. The reel body has a first restriction part covering the first opening.

Owner:SHIMANO INC

Wobble Plate Type Variable Displacement Compressor

InactiveUS20110070104A1Improve accuracyIncreased durabilityMulti-stage pumpsWobble plate gearingsUniversal jointTransmitted power

Disclosed is a wobble plate type variable displacement compressor that uses a constant velocity universal joint mechanism, which comprises an inner ring and an outer ring, balls that are held between guide grooves of the inner ring and the outer ring to transmit power, and a sleeve, which functions as a wobble central member of the wobble plate, which is rotatable relative to a main shaft and is movable in the axial direction, and which is engaged with the inner ring movably in the axial direction. In the compressor, an inner ring rotation preventing mechanism is constructed as a contoured interlock mechanism formed between the outer circumference of the inner ring and the inner circumference of a housing, and a swash plate minimum inclination angle regulating mechanism, which regulates the minimum inclination angle of the swash plate by abutting the axial ends of the inner ring side and the housing side of the contoured interlock mechanism to each other, is provided to the contoured interlock mechanism. The accuracy of the minimum inclination angle regulation can be improved, and the abrasion resistance of the inner ring rotation preventing mechanism can be improved in the wobble plate type variable displacement compressor using this specified constant velocity universal joint mechanism.

Owner:SANDEN CORP

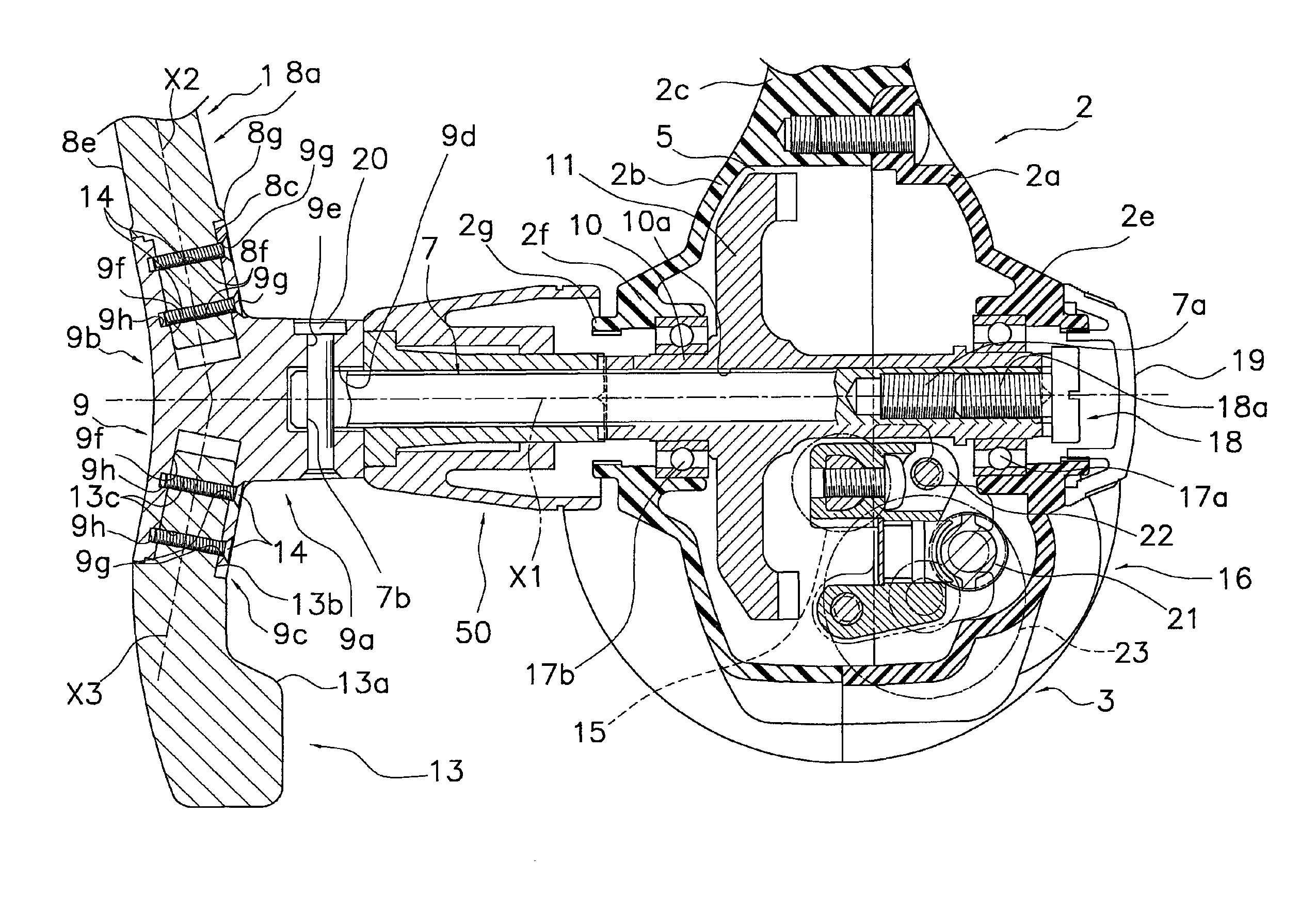

Chassis dynamometer

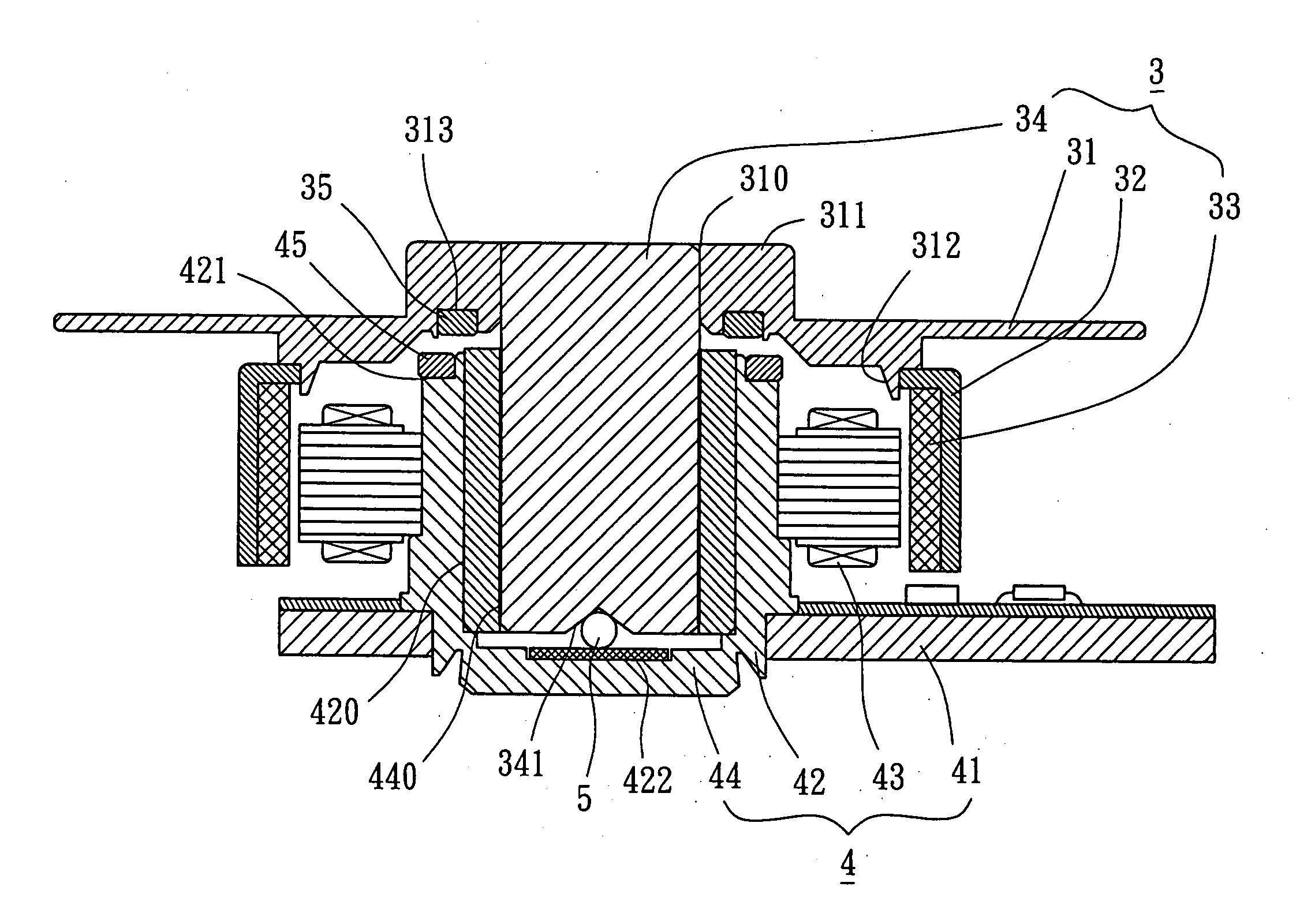

InactiveUS8037743B2Save spaceGood rotation balanceVehicle testingEngine testingTangential forceEngineering

A chassis dynamometer for a vehicle has a motor having a rotor, rollers configured to be operably connected to wheels of the vehicle, a flange portion extending inward in a radial direction from each of the rollers, and a rotor bracket for supporting the rotor of the motor. The flange portion and the rotor bracket are connected via a torque meter capable of measuring at least an outer peripheral tangential force of the roller.

Owner:A&D CO LTD +1

Fishing reel handle assembly

InactiveUS8011610B2Good rotation balanceGood adhesionControlling membersMechanical apparatusEngineeringFishing lure

Owner:SHIMANO COMPONENTS MALAYSIA

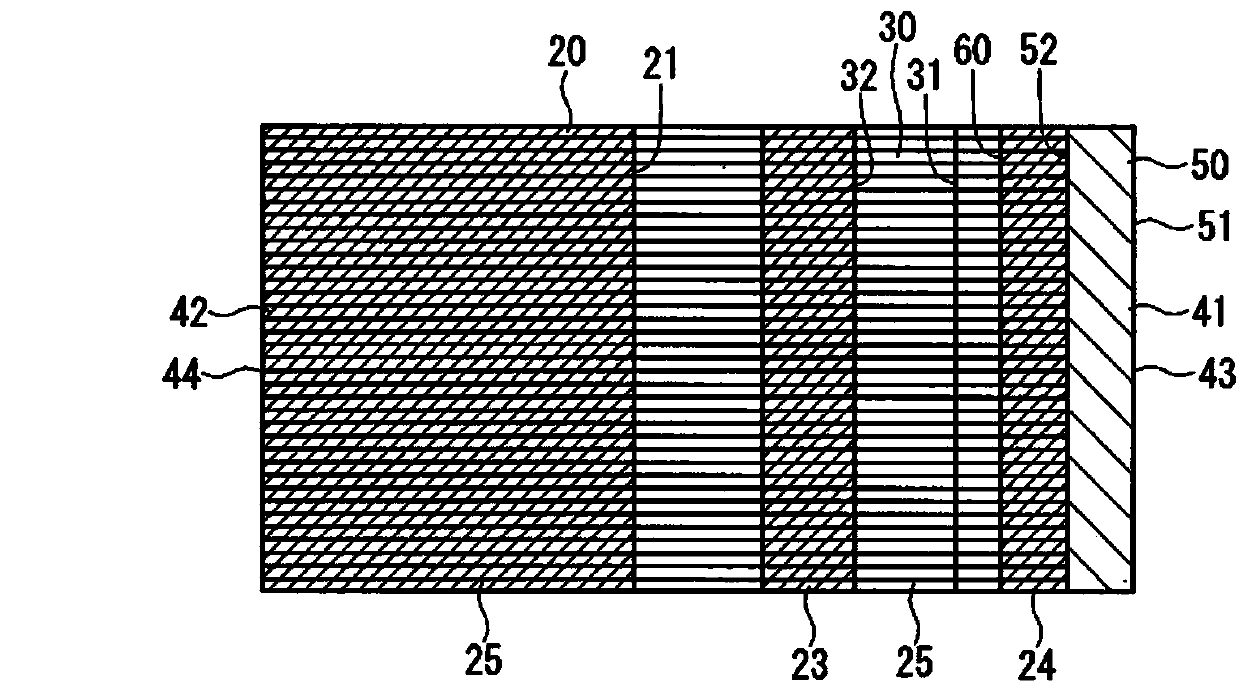

Laminated core for rotary electric machine

InactiveUS20160352165A1Less deformationRotation balance be improveMagnetic circuit rotating partsEngineeringDowel

A laminated core for a rotary electric machine includes a disc-shaped first laminated block, a disc-shaped second laminated block and an end steel sheet. The first and second laminated block are formed by a plurality of main steel sheets that have a protruding dowel crimping portion and that are laminated together. The second laminated block being front / back reversed with respect to the first laminated block around a reference line of the first laminated block. The end steel sheet has a first dowel insertion hole formed in a position corresponding to the dowel crimping portion of the first laminated block, and a second dowel insertion hole formed in a position symmetrical to the first dowel insertion hole with respect to the reference line of the first laminated block. The end steel sheet is arranged in a position between opposing surfaces of the first laminated block and the second laminated block.

Owner:TOYOTA JIDOSHA KK

Wobble Plate-Type Variable Displacement Compressor

InactiveUS20110088547A1Simple structureIncrease productivityYielding couplingWobble plate gearingsUniversal jointEngineering

Disclosed is a wobble plate type variable displacement compressor that uses a constant velocity universal joint mechanism, which comprises an inner ring and an outer ring, balls that are held between guide grooves of the inner ring and the outer ring to transmit power, wherein a wobble plate is connected and fixed to the outer ring. In the compressor, the wobble plate is provided with a cylindrical part which extends in the axial direction of a swash plate, and in the relative rotation structure between the swash plate, and the wobble plate and the outer ring, the swash plate is supported to be able to relatively rotate only in relation to the wobble plate via a bearing interposed at least between the cylindrical part and the inner diameter portion of the swash plate, without being supported to be able to rotate relative to the outer ring. With this wobble plate type variable displacement compressor using the specified constant velocity universal joint mechanism, the relative rotation structure between the wobble plate and the outer ring, and the swash plate, can be improved, workability and productivity can be improved, and the cost and weight can be reduced.

Owner:SANDEN CORP

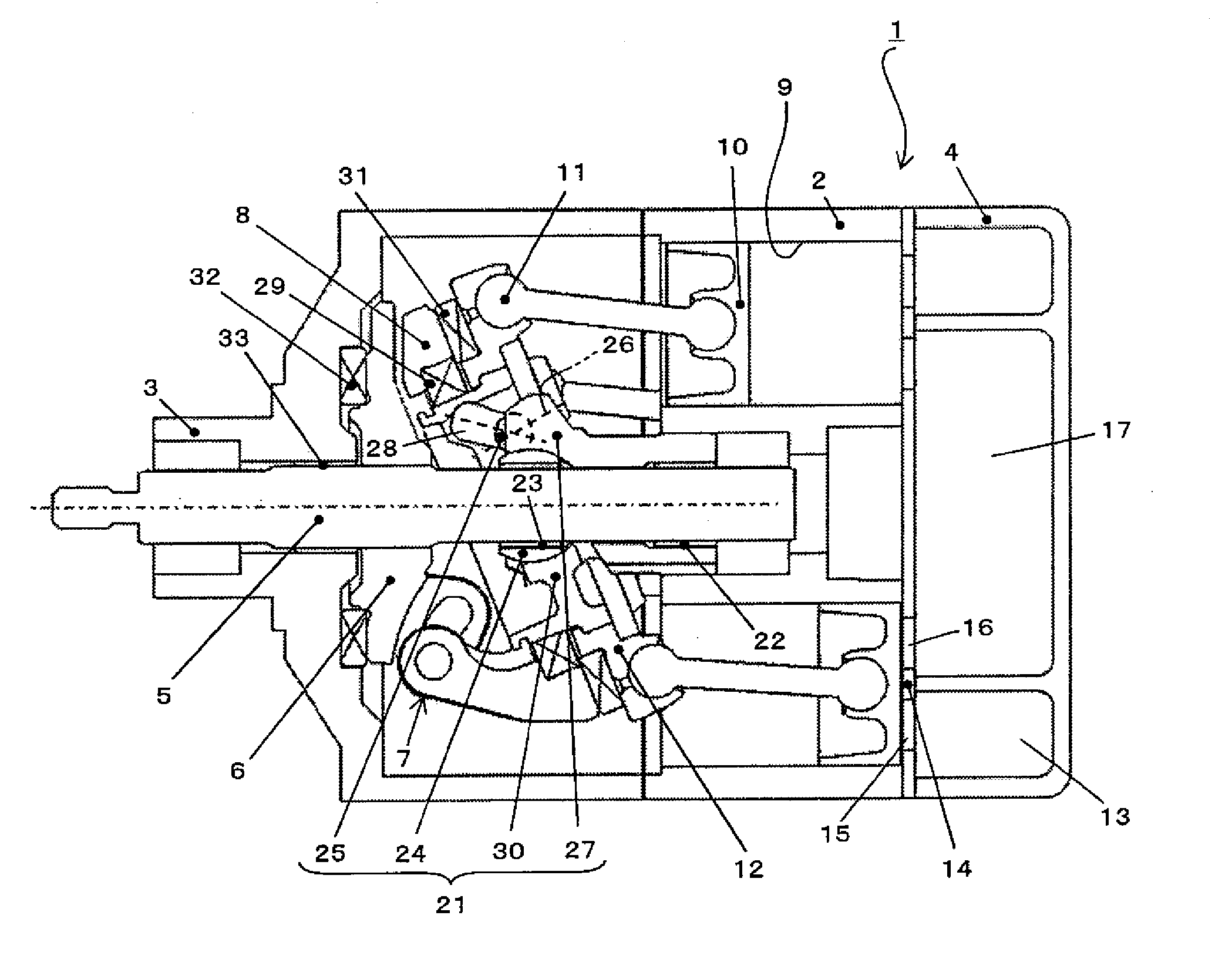

Eccentric rocking type reduction gear

A crankshaft has eccentric holes communicating with each other. The eccentric hole extends in the axial direction of the crankshaft from one end surface of the crankshaft and is disposed so as to be eccentric in the same direction as a cam section. The eccentric hole extends in the axial direction of the crankshaft from the other end surface of the crankshaft and is disposed so as to be eccentric in the direction of the eccentricity of a cam section. A centrifugal force due to the rotation of the crankshaft generates a force couple about an axis which is perpendicular to the axis of the crankshaft. The force couple is reduced by the eccentric holes. The cam sections are arranged around the axis of rotation with the phases shifted by 180 degrees from each other. As a result, a translational force acting in the direction perpendicular to the axis of the crankshaft is also reduced.

Owner:JTEKT CORP

Laminated core for rotary electric machine

A laminated core for a rotary electric machine includes a disc-shaped first laminated block, a disc-shaped second laminated block and an end steel sheet. The first and second laminated block are formed by a plurality of main steel sheets that have a protruding dowel crimping portion and that are laminated together. The second laminated block being front / back reversed with respect to the first laminated block around a reference line of the first laminated block. The end steel sheet has a first dowel insertion hole formed in a position corresponding to the dowel crimping portion of the first laminated block, and a second dowel insertion hole formed in a position symmetrical to the first dowel insertion hole with respect to the reference line of the first laminated block. The end steel sheet is arranged in a position between opposing surfaces of the first laminated block and the second laminated block.

Owner:TOYOTA JIDOSHA KK

Wabble plate type variable displacement compressor

ActiveUS20100092312A1Increased durabilityImprove performanceMulti-stage pumpsWobble plate gearingsStructural engineeringMachine

A wabble plate type variable displacement compressor comprises a rotation preventing mechanism of the wabble plate which includes (a) an inner ring provided movably in the axial direction although rotation is prevented, supporting a main shaft at the inner diameter portion to rotate relatively and to move relatively in the axial direction and having a plurality of guide grooves for guiding a plurality of balls provided for power transmission, (b) a sleeve functioning as a wabble central member of wabble movement of the wabble plate, provided on the main shaft to rotate relatively thereto and to move in the axial direction and engaging with the inner ring movably in the axial direction, (c) an outer ring having a plurality of guide grooves for guiding balls at positions opposing respective guide grooves in the inner ring, supported on the sleeve wabblingly, supporting the wabble plate fixedly on the outer circumference and supporting a swash plate rotatably via a bearing, and (d) a plurality of balls held by the guide grooves formed in the inner ring and the outer ring and being compressed between the guide grooves to transmit power. While play in a uniform motion joint provided as the wabble plate rotation preventing mechanism in the radial direction and the rotational direction is suppressed, uniform and continuous contact of the plurality of balls operating for power transmission can be realized, and a compact, easy-to-machine and inexpensive wabble plate type variable displacement compressor exhibiting good durability and silent performance can be provided.

Owner:SANDEN CORP

Rotor for a Motor

InactiveUS20190131835A1Increase engagementQuick alignmentMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMagnet

A rotor for a motor according to the invention is provided to solve the problem where the rotor of the conventional motor does not have an excellent vibration-reducing effect. The rotor for the motor includes a shaft, an elastic sleeve, a permanent magnet and two engaging units. The elastic sleeve is fit around the shaft. The permanent magnet is fit around the elastic sleeve. The elastic sleeve and the permanent magnet have two sides spaced from each other in an axial direction. The two engaging units are coupled with the elastic sleeve and the permanent magnet at the two sides, respectively. Each of the two engaging units includes a through-hole through which the shaft extends. The two engaging units are not in contact with the shaft.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

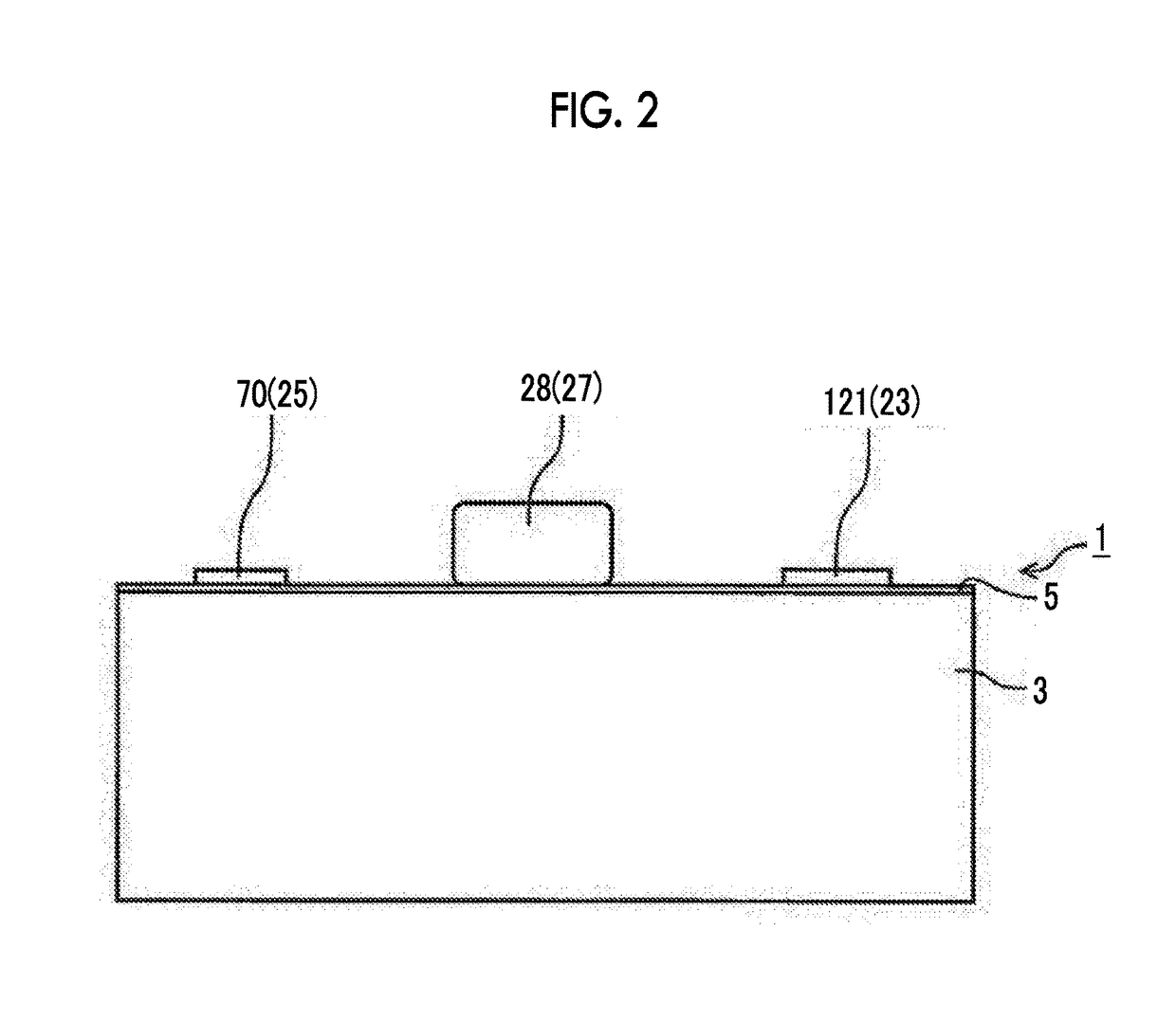

Automatic balancing device, rotational driving device and disk drive

InactiveUS7492549B2Good rotation balanceReliable returnUndesired vibrations/sounds insulation/absorptionRecord information storageCentre of rotationEngineering

Disclosed herein is an automatic balancing device including a balancer made of a magnetic fluid, a rotatable enclosure having an outer circumferential wall and accommodating the balancer, a magnet provided near at least the center of rotation of the enclosure so as to be rotatable integrally with the enclosure, and a platelike projection projecting from the outer circumferential wall toward the center of rotation of the enclosure, at least a part of the platelike projection extending in a direction different from a radial direction of the enclosure at the juncture between the platelike projection and the outer circumferential wall.

Owner:SONY CORP

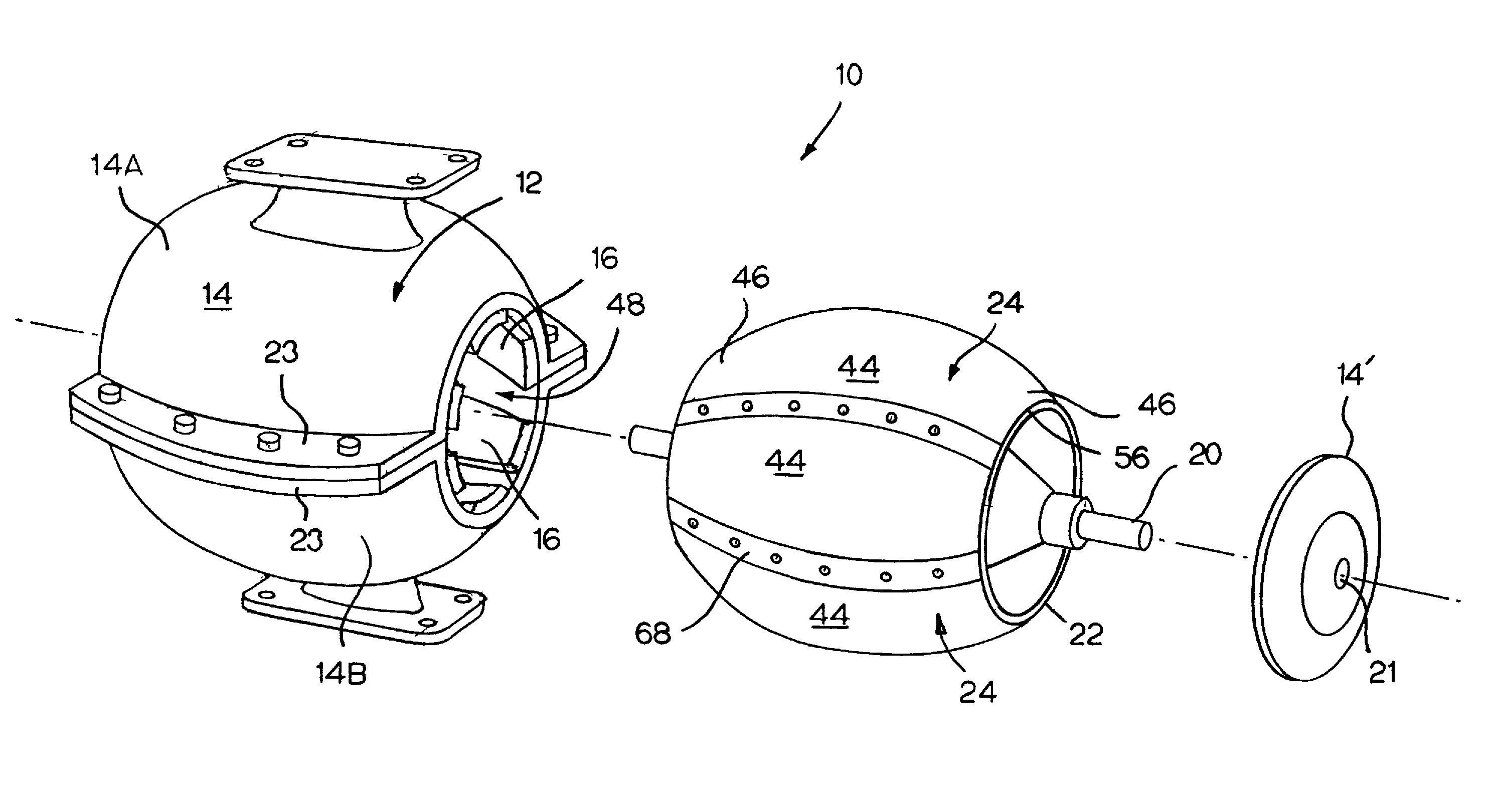

High torque electric motor/flywheel

InactiveUS7791233B1Easy to disassembleGood rotation balanceMagnetic circuit rotating partsDC commutatorRotational axisEngineering

A high-torque electric motor having a rotor supported by an elongated torque arm comprising a pair of frustoconical-shaped support members. The rotor has a spherical-shaped outer surface and a complementarily shaped stator cavity. The spherical magnetic elements and the conical support members cooperate to brace the rotor against deflection along its rotational axis.

Owner:ATTARD MICHAEL T

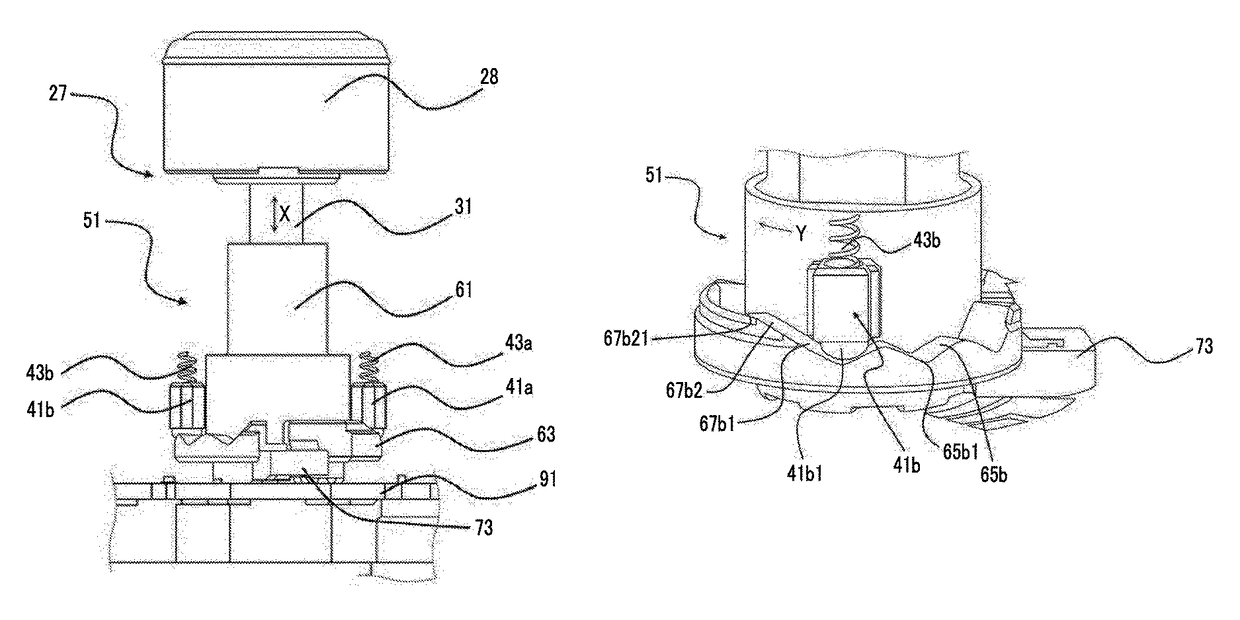

Rotary input operation device

ActiveUS9791884B2Reduce problem sizeSimple manufacturing processControlling membersLimiting/preventing/returning movement of partsSteep slopeCam

In a rotating operation body, a cam part has first cam faces for click feeling generation and second cam faces for return of the rotating operation body. The second cam faces are respectively formed continuously with the first cam faces, and an angle between each of the second cam faces and a direction in which elastic forces of engagement parts are generated is smaller than an angle of each of the first cam faces. That is, each of the second cam faces has a steeper slope than each of the first cam faces.

Owner:ALPS ALPINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com