Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135 results about "Coil insertion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

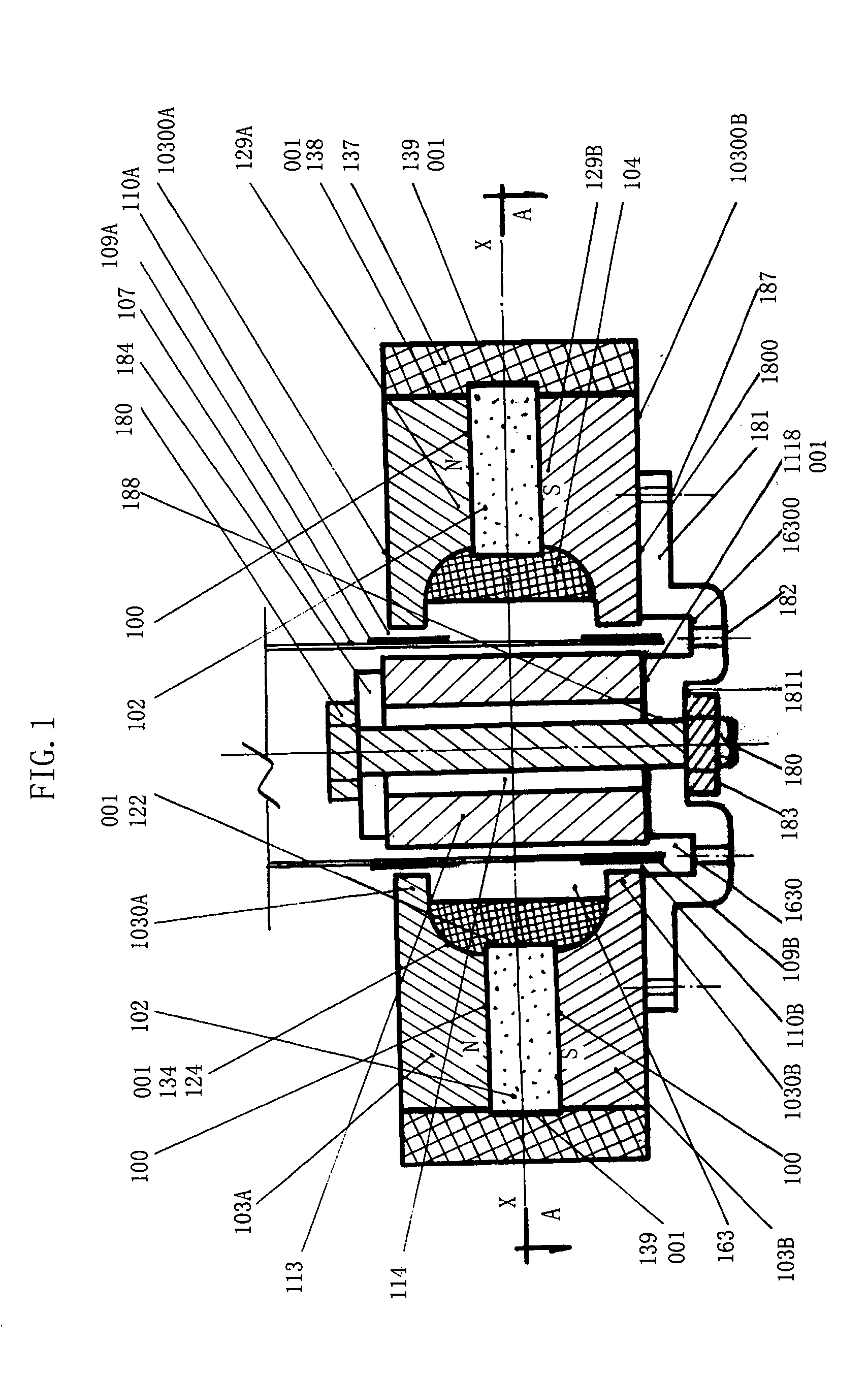

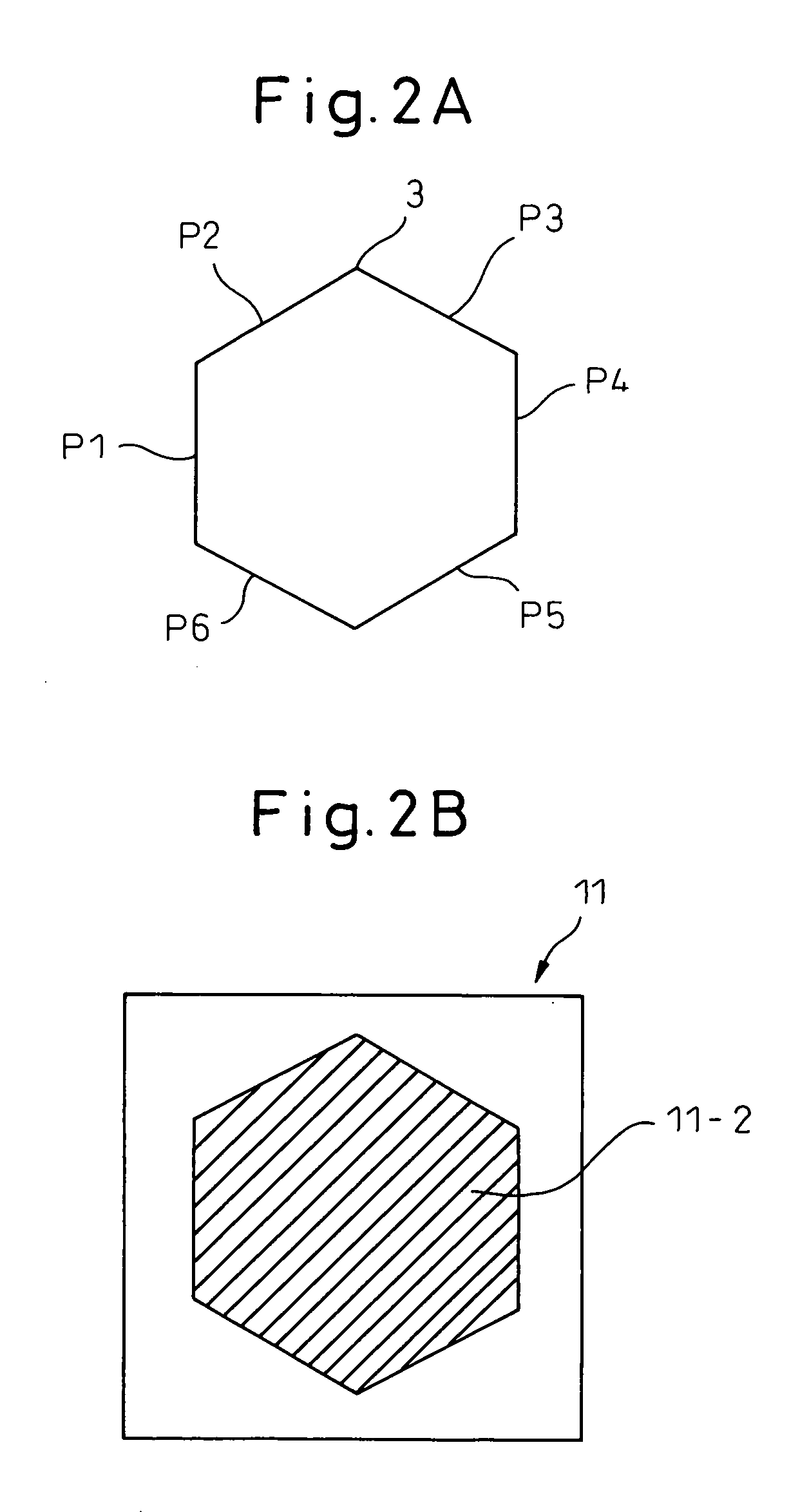

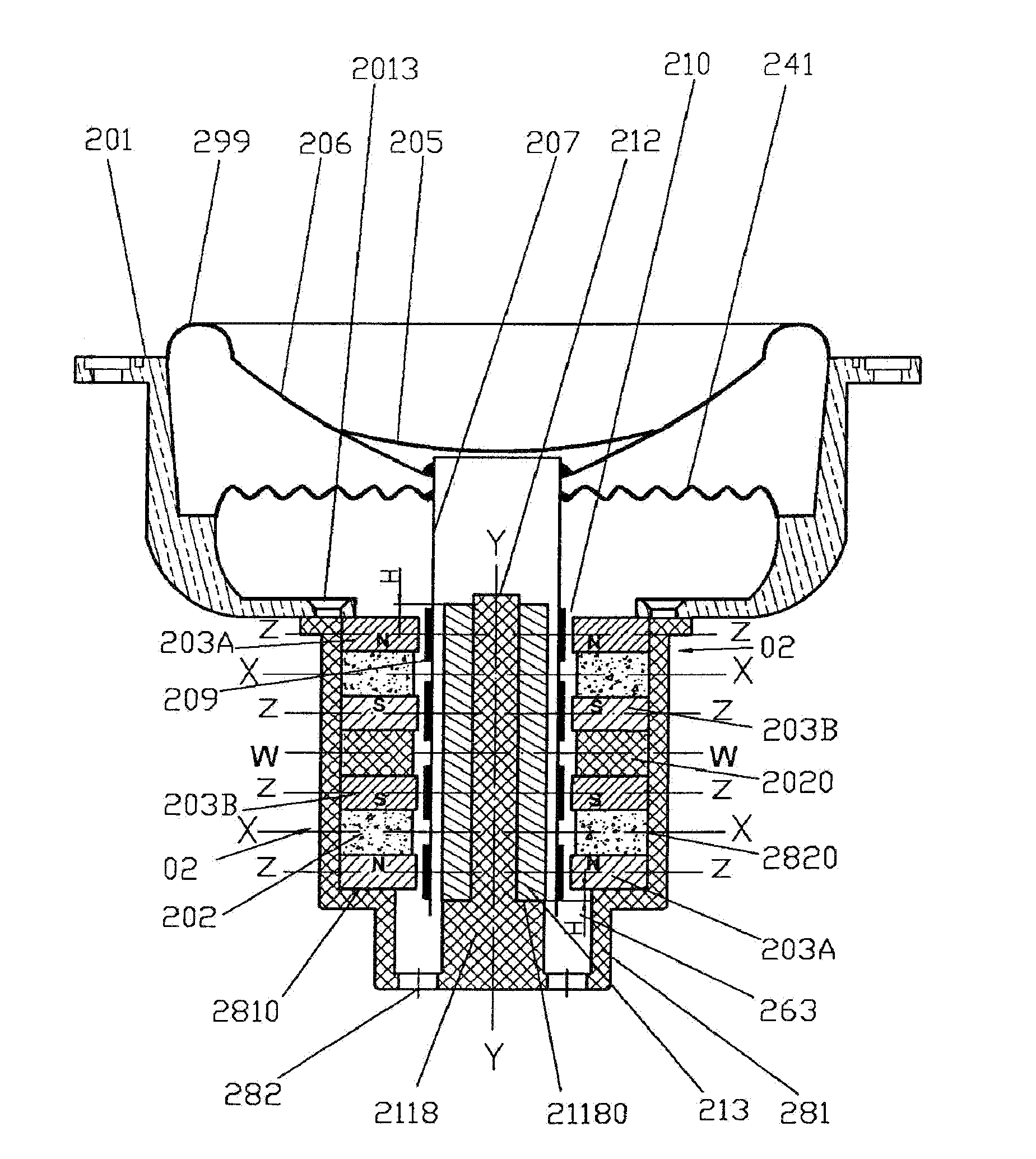

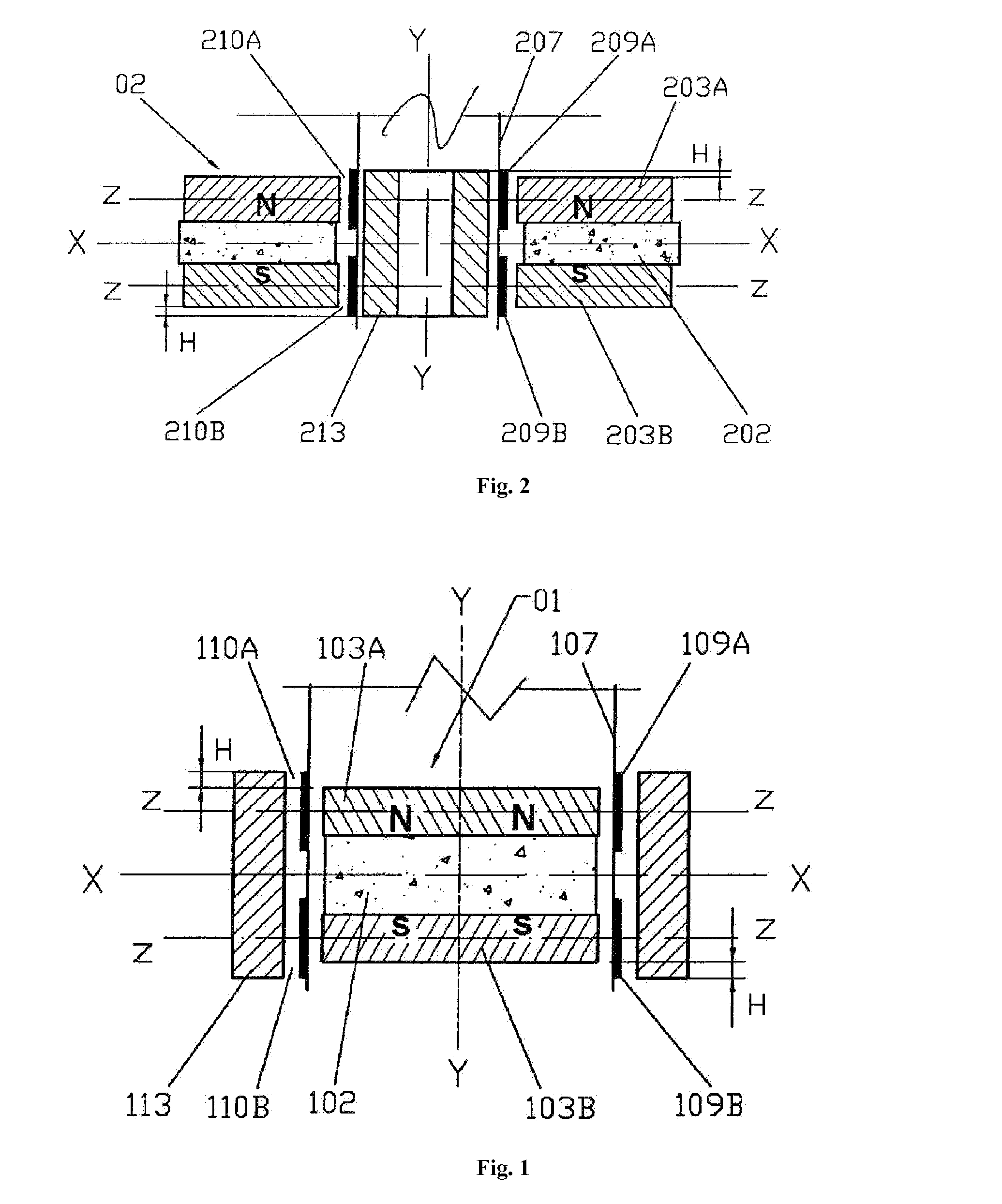

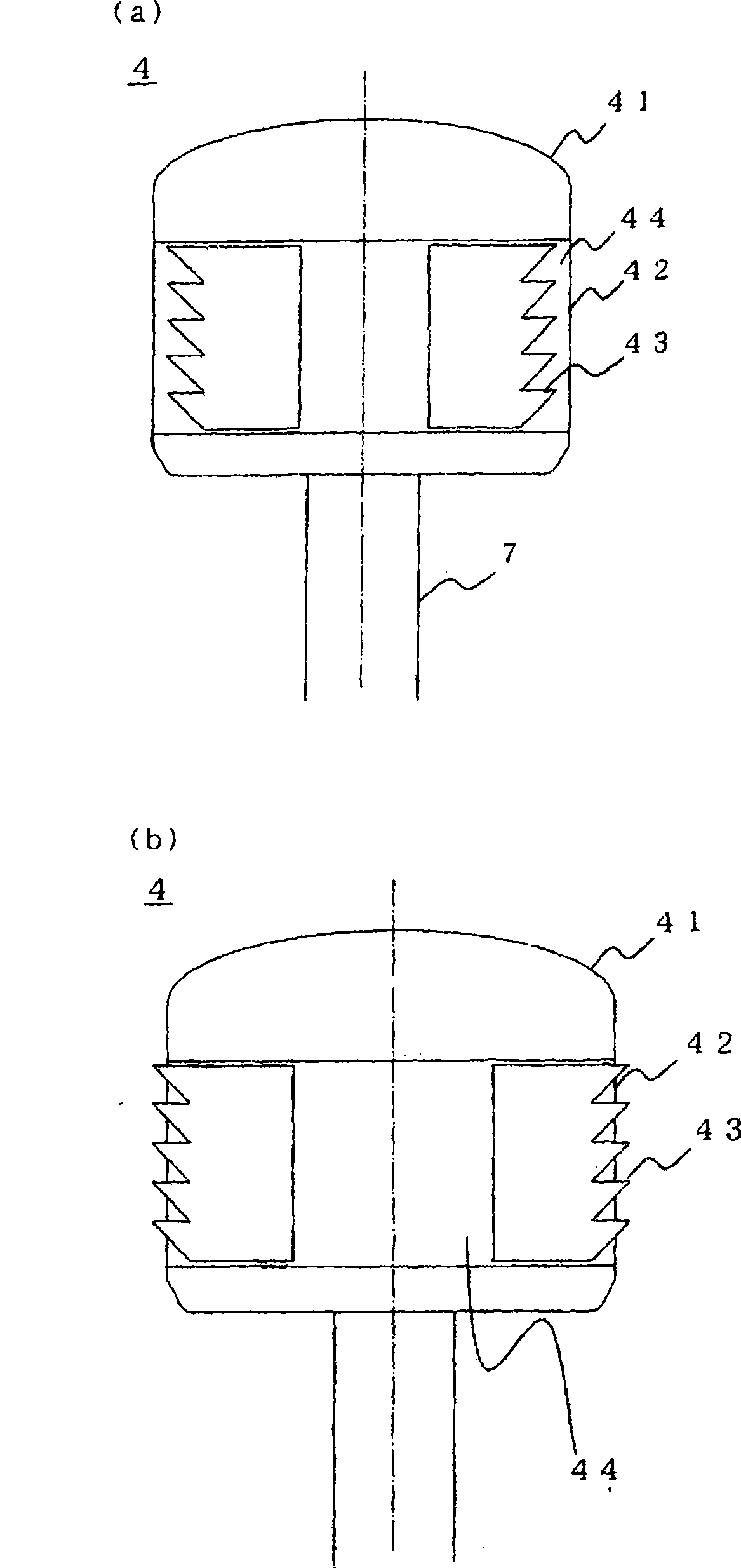

Transducer with dual coil and dual magnetic gap

InactiveUS20050099255A1Improve fidelitySmall volumeElectrical transducersDynamo-electric machinesDual coilTransducer

A transducer with dual coil and dual magnetic gap of which the upper and lower pole plates of are two inwardly concave plates or round plates. A set or more than1 a piece sets of axially magnetized permanent magnets are provided. Said permanent magnets are engaged with pole faces of said plates. Dual magnetic gap are formed between the vertical faces of said plates and the vertical faces of a coaxial mounted annular or cylindrical magnetic body. Coils are inserted into said magnetic gap, while wound direction of dual coil and the direction of current are decided to produce an electrodynamic force in the coils to the same direction. Said transducer possesses resistance load characteristics by setting the values of the inductance of the dual coil equal to each other in case that said transducer are provided with two magnetic paths and coil circuits completely symmetric in their magnetic characteristics.

Owner:ZHANG FAN

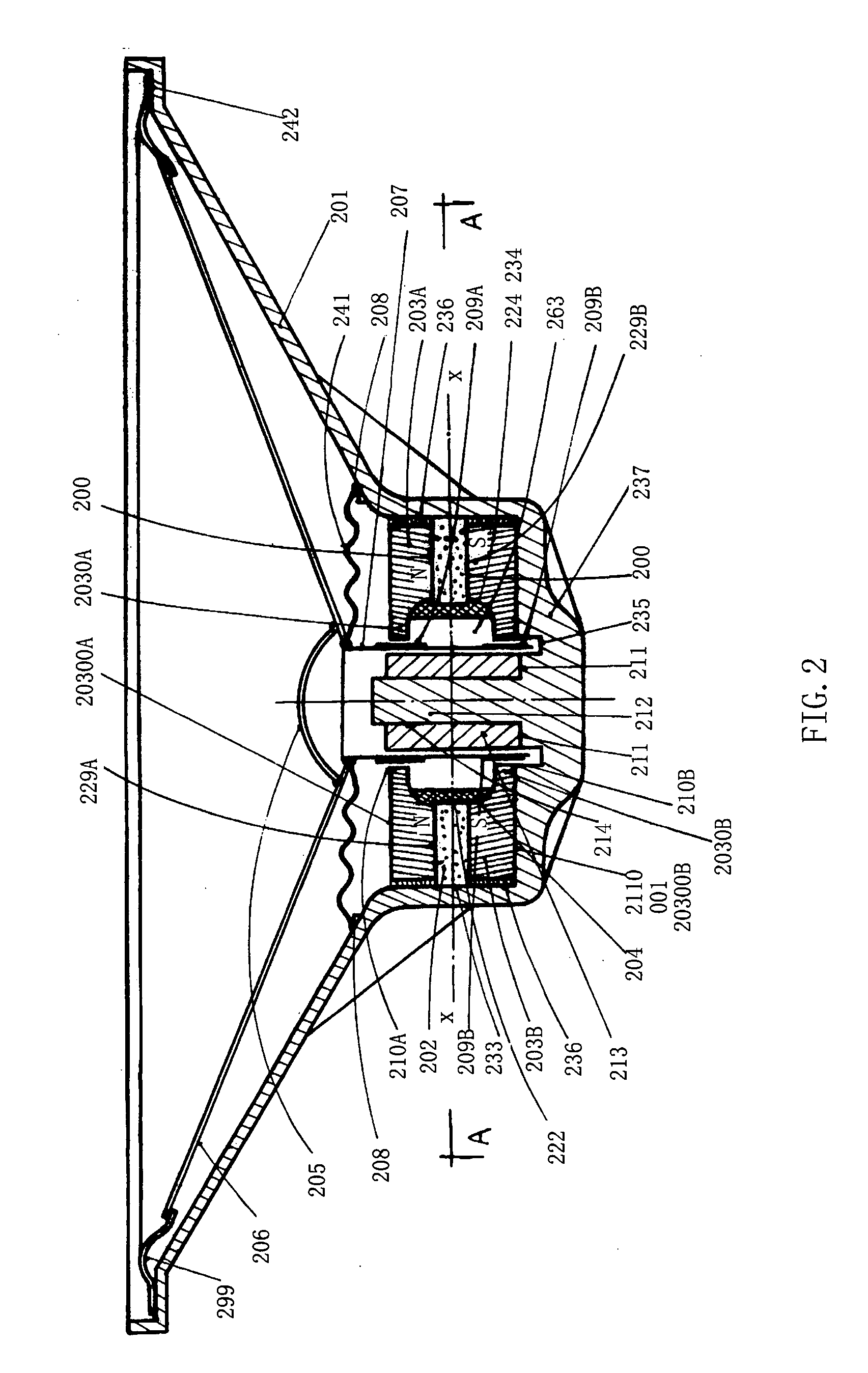

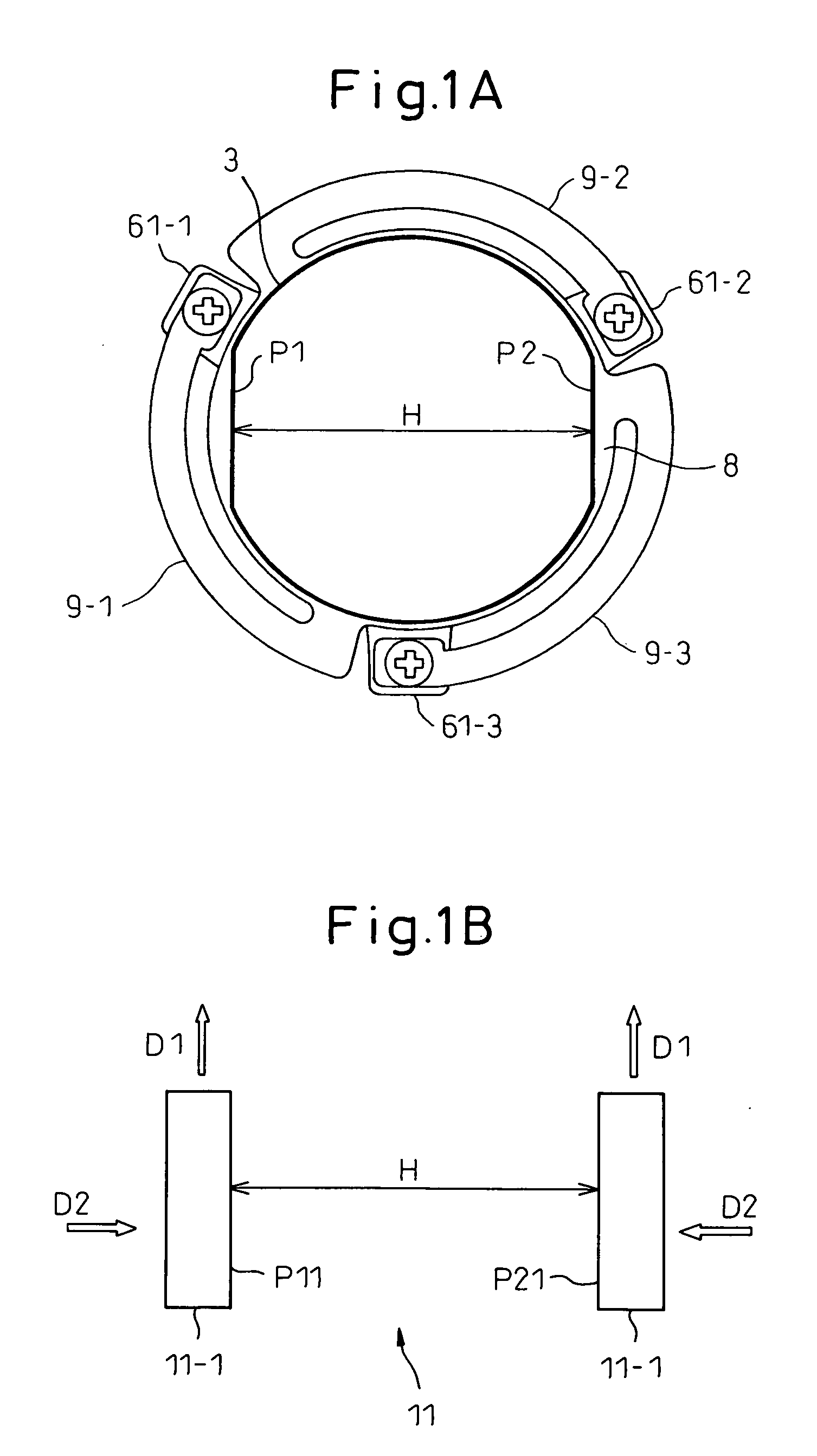

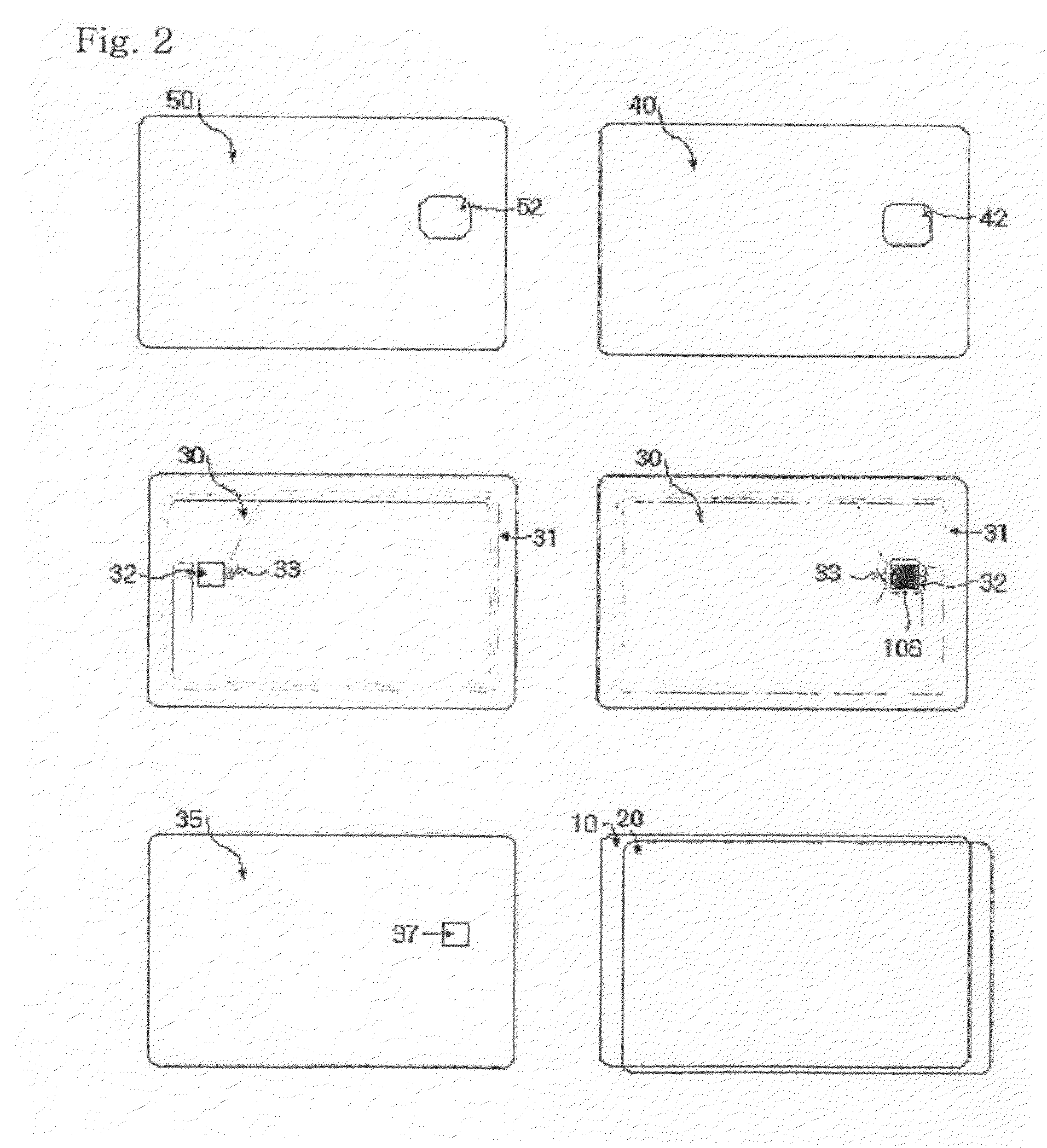

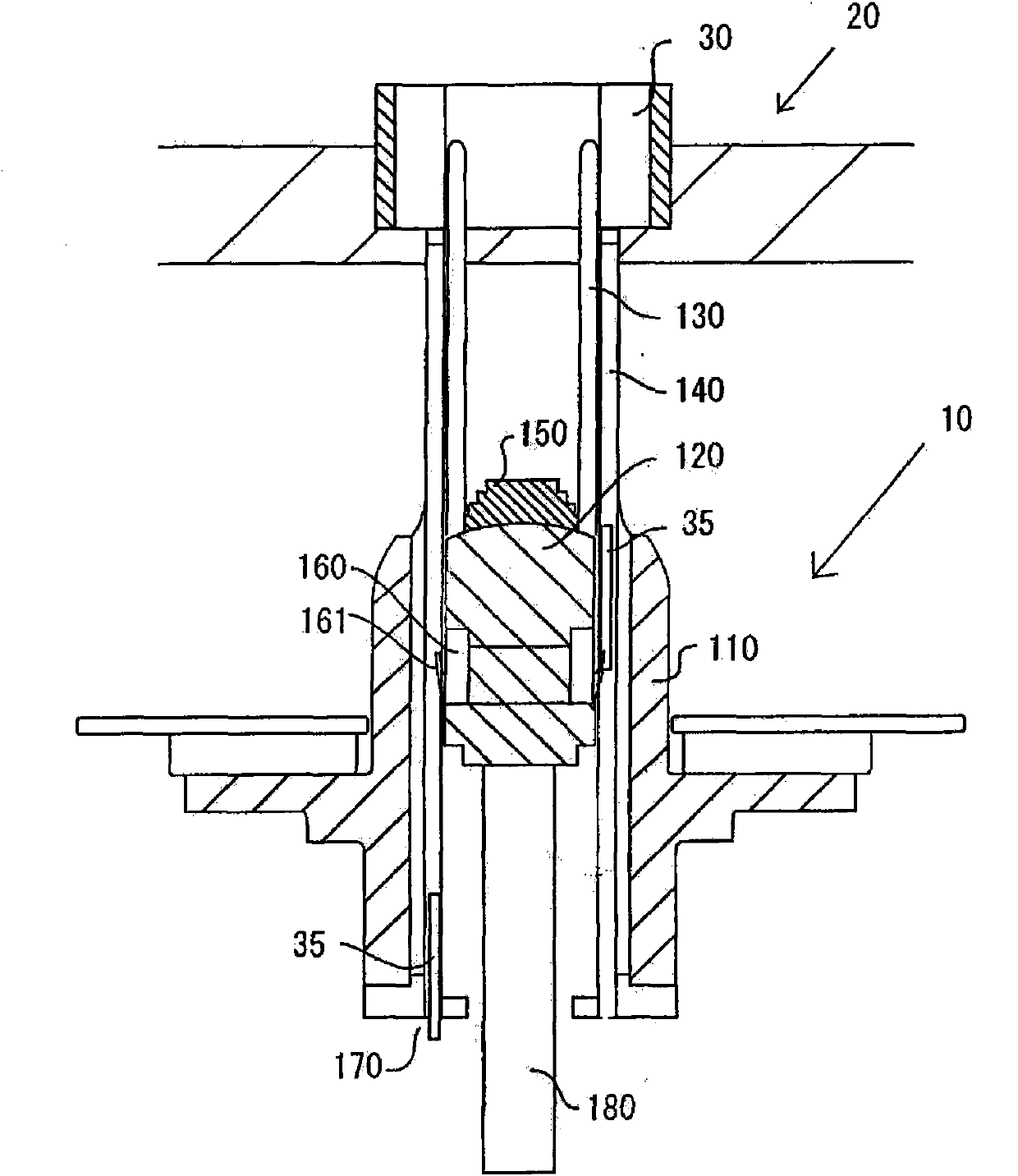

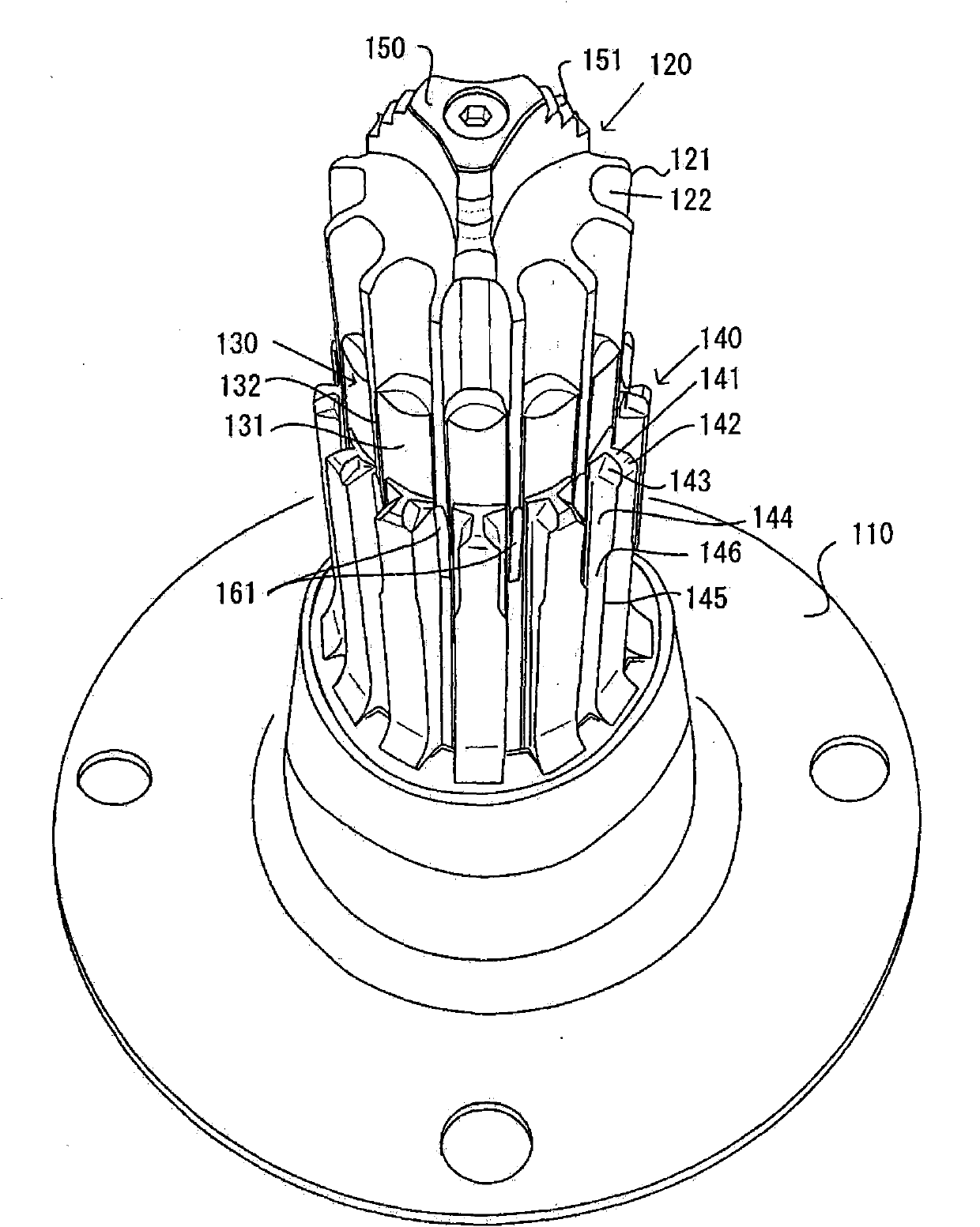

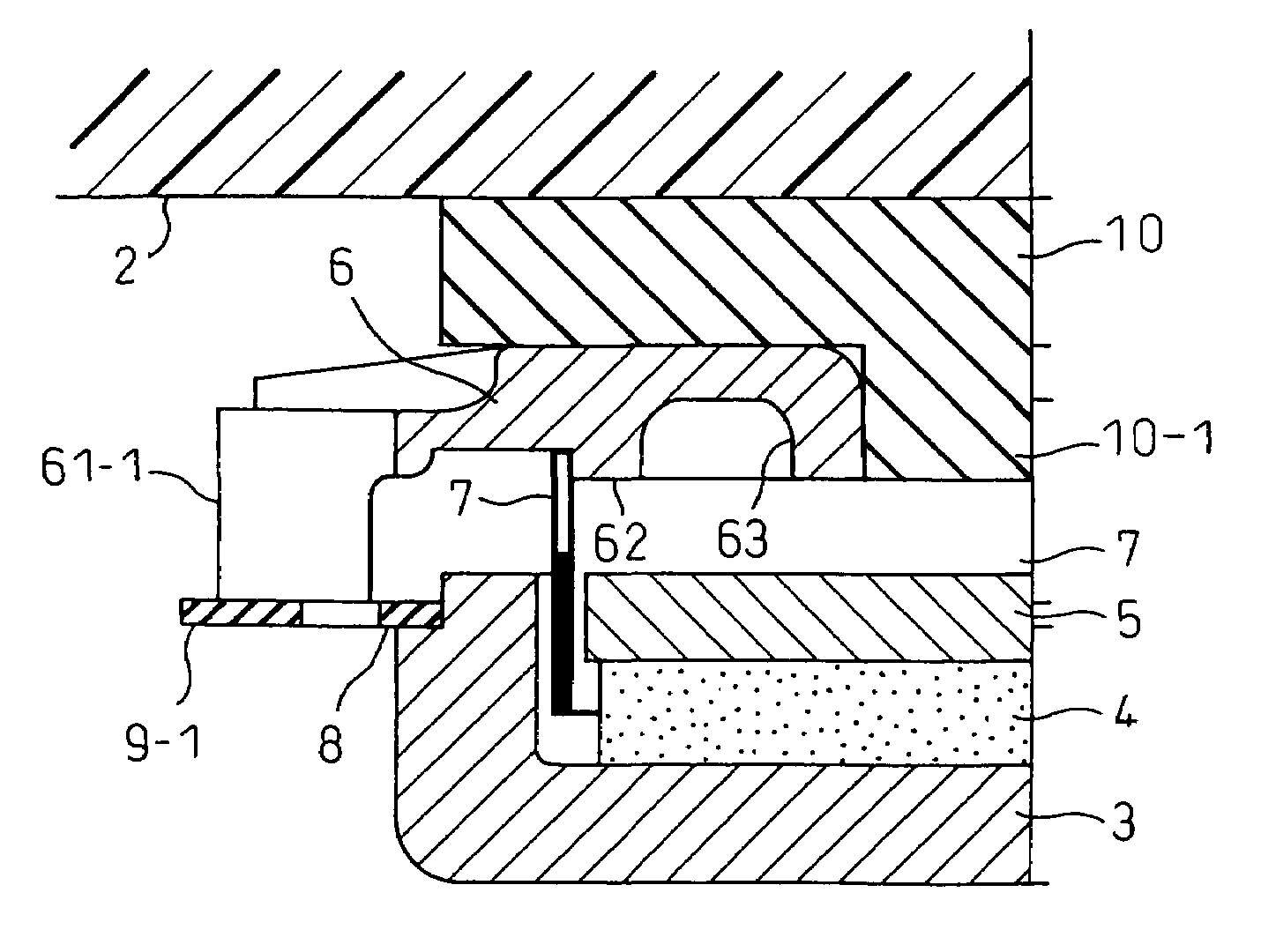

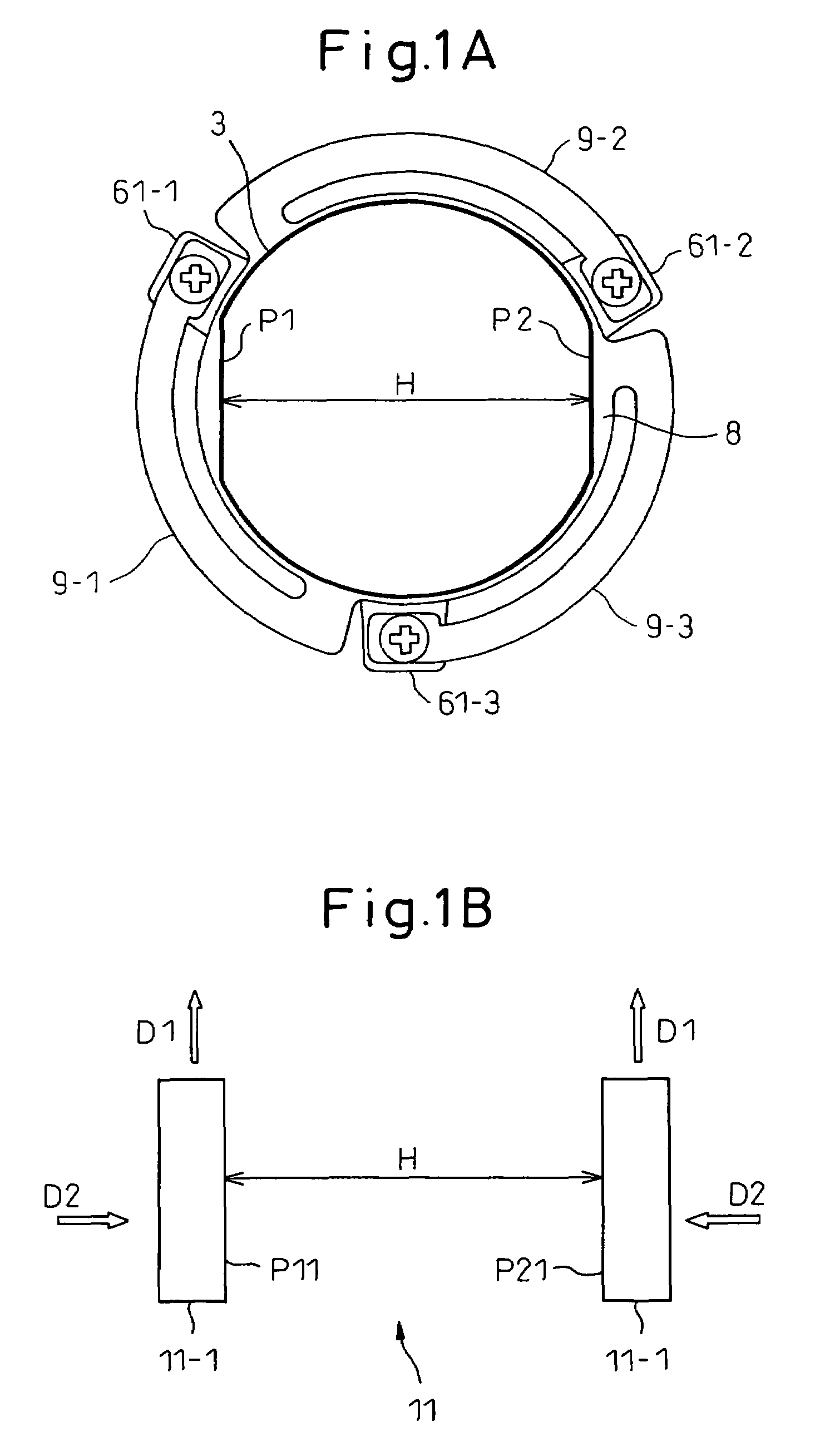

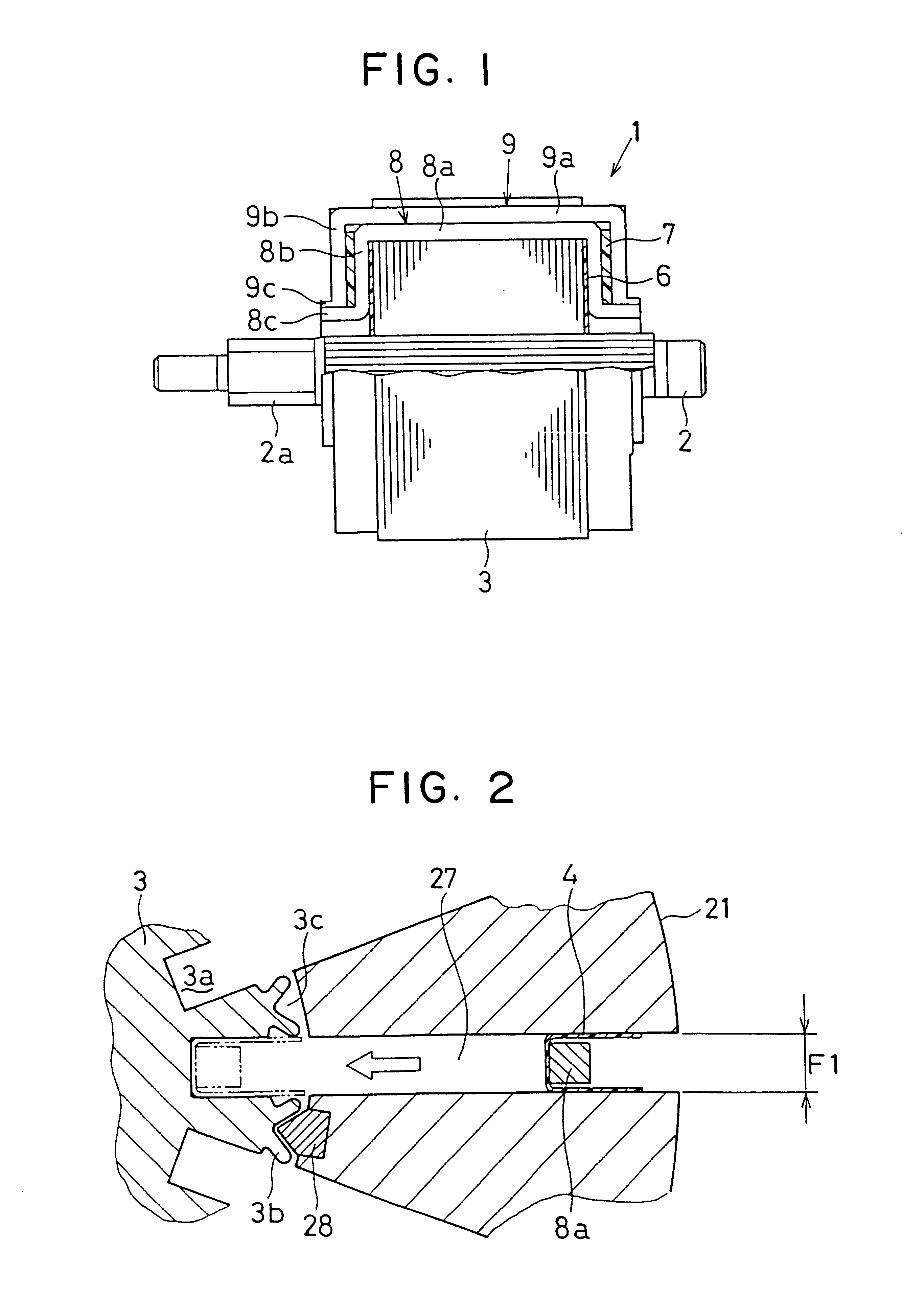

Exciter for directly vibrating board

ActiveUS20050184607A1Sufficient rotation torqueSufficient fastening torqueMechanical energy handlingPlane diaphragmsCoil insertionMental detachment

An exciter for directly vibrating a board, which enables a sufficient rotational torque to be obtained by a work tool at the time of attachment or detachment, provided with a magnetic circuit unit having an outside yoke comprised of a side wall and a bottom, a permanent magnet fastened to the bottom, and an inside yoke and with a coil inserted into a clearance between the side wall and inside yoke, the magnetic circuit unit being vibratably supported at the coupler member by elastic members, the coupler member being screwed with the bracket member fastened to the surface of the board, two parallel flat surfaces engaging with ends of a work tool being provided at an outer circumference of the outside yoke, and the work tool being turned to attach / detach the coupler member with respect to the bracket member.

Owner:FUJITSU GENERAL LTD

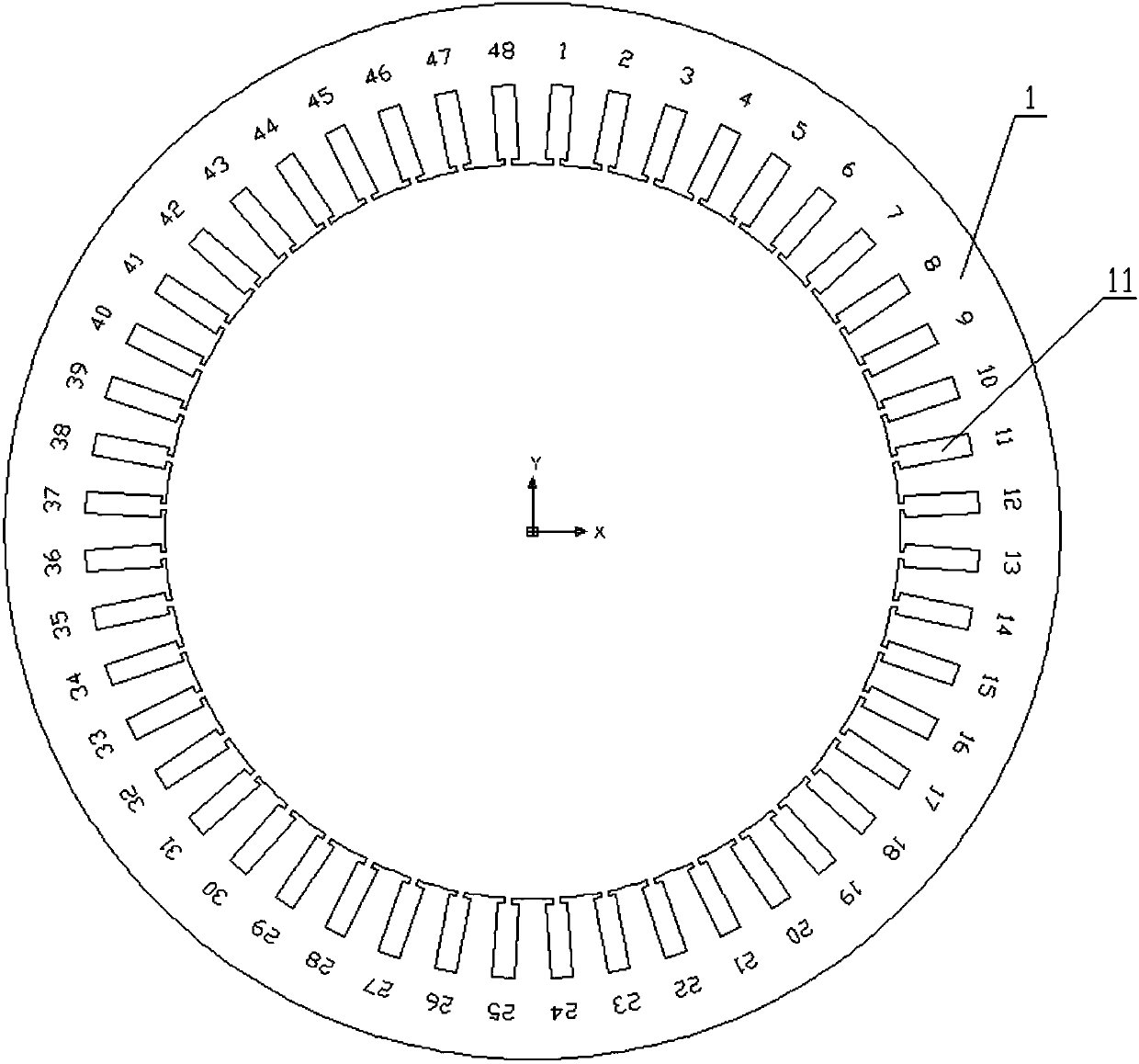

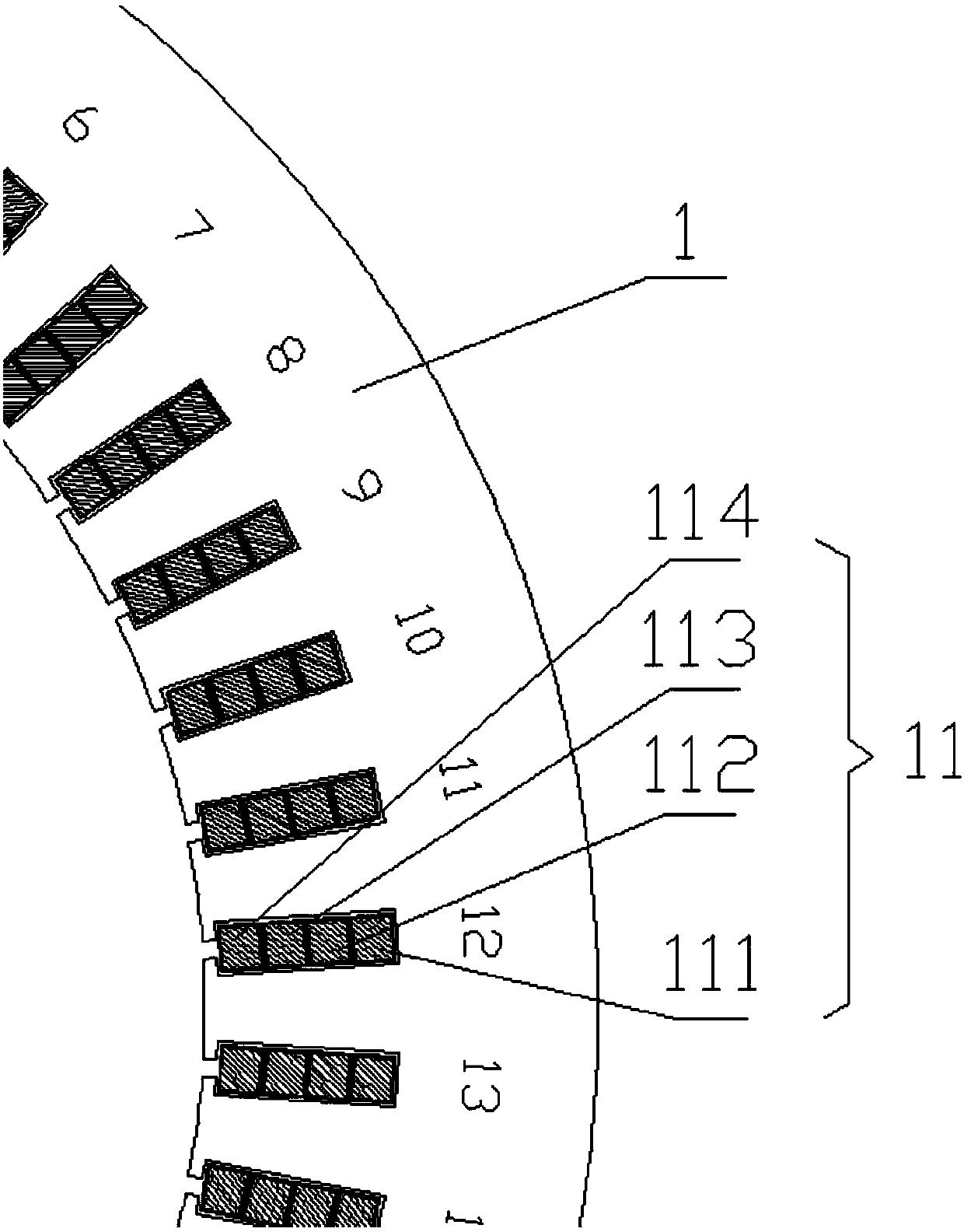

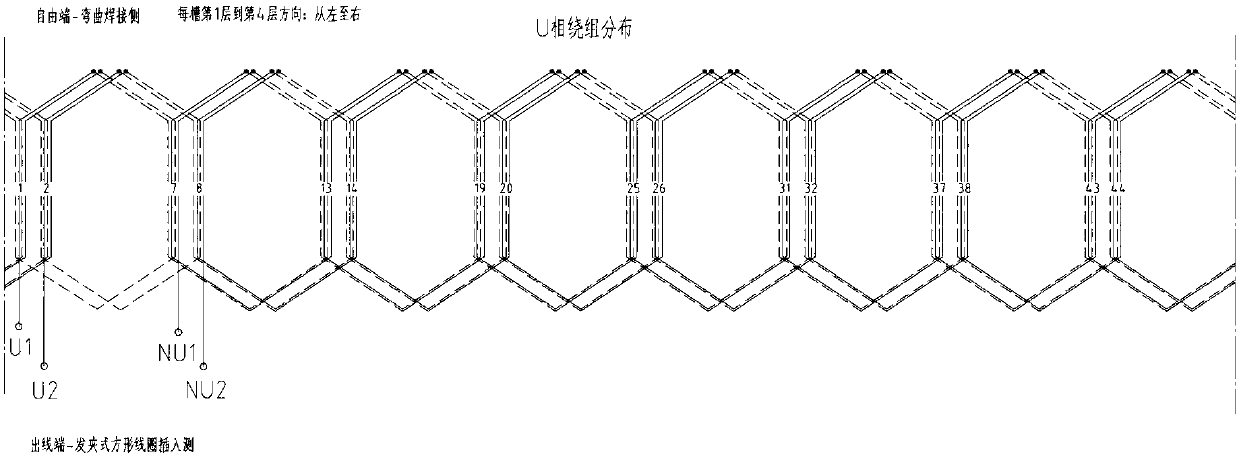

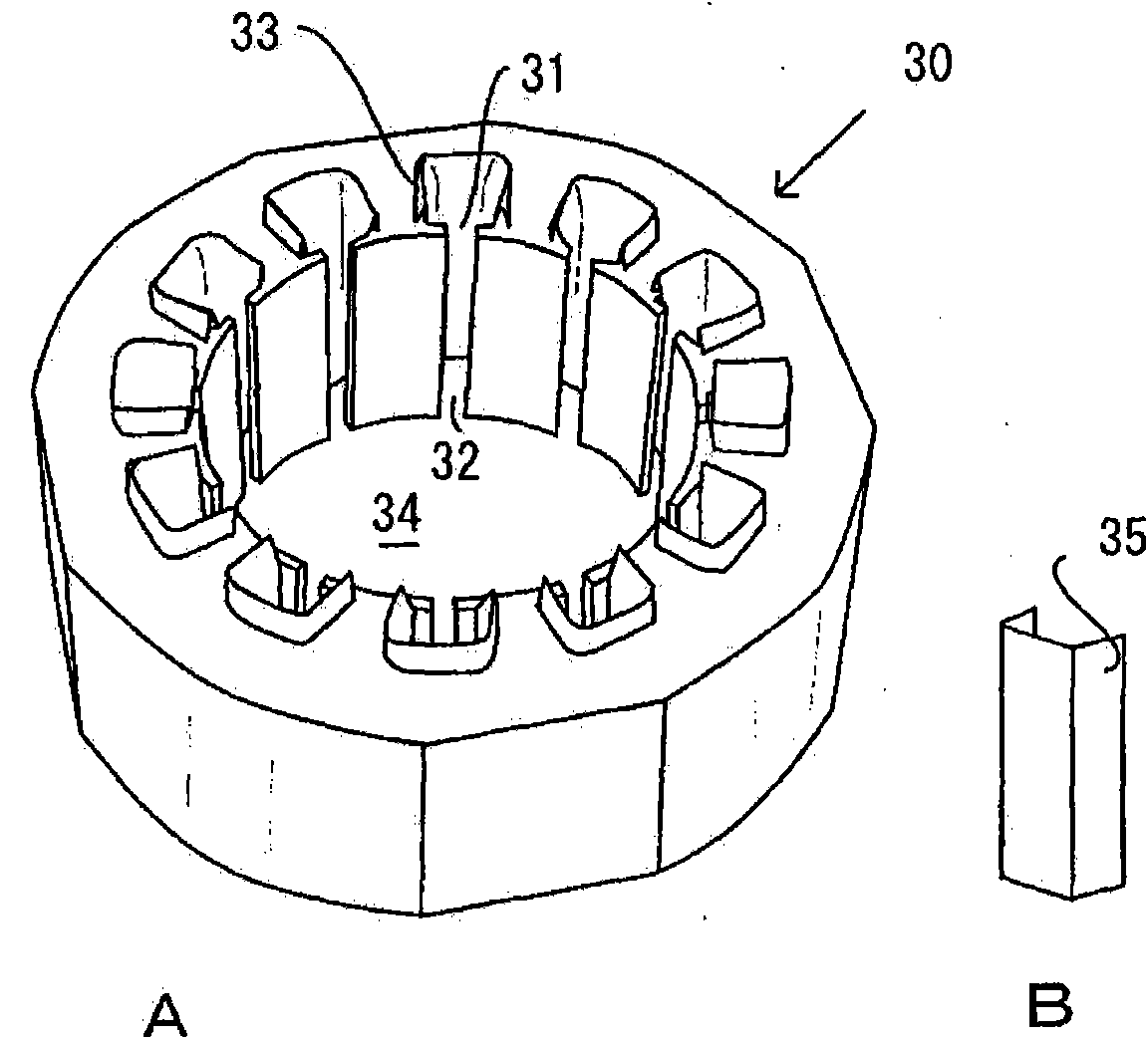

Stator winding of AC generator

PendingCN107565720AReduce copper consumptionImprove efficiencyMagnetic circuit stationary partsWindings conductor shape/form/constructionStator coilAlternating current

The present invention discloses a stator winding of an AC generator. The stator comprises 8 poles, and 48 equidistantly formed rectangular stator slots. The winding is in the form of a distributed winding. A coil is inserted into the each of the stator slots, wherein the cross-sectional shape of the coil is square. In this way, the winding is of a 3-phase and 2-way parallel type 6-pitch full-pitchwinding structure, or a 3-phase and 1-way parallel type 6-pitch full-pitch winding structure, wherein the number of slots per pole and per phase is 2. Each square coil is inserted into different layers of 2 different stator slots in the stator according to a predetermined rule to form the stator winding. 4 coils are placed in each stator slot and form a first layer, a second layer, a third layerand a fourth layer from outside to inside in sequence according to the radial direction of the stator. According to the invention, the contradictory problem between the performance of the generator and the volume of the generator can be well solved. The height of the end of the stator winding of the generator is reduced. The overall volume of the generator is reduced and the slot full rate of thewinding is improved. The performance of the generator is enhanced.

Owner:CHINA FIRST AUTOMOBILE

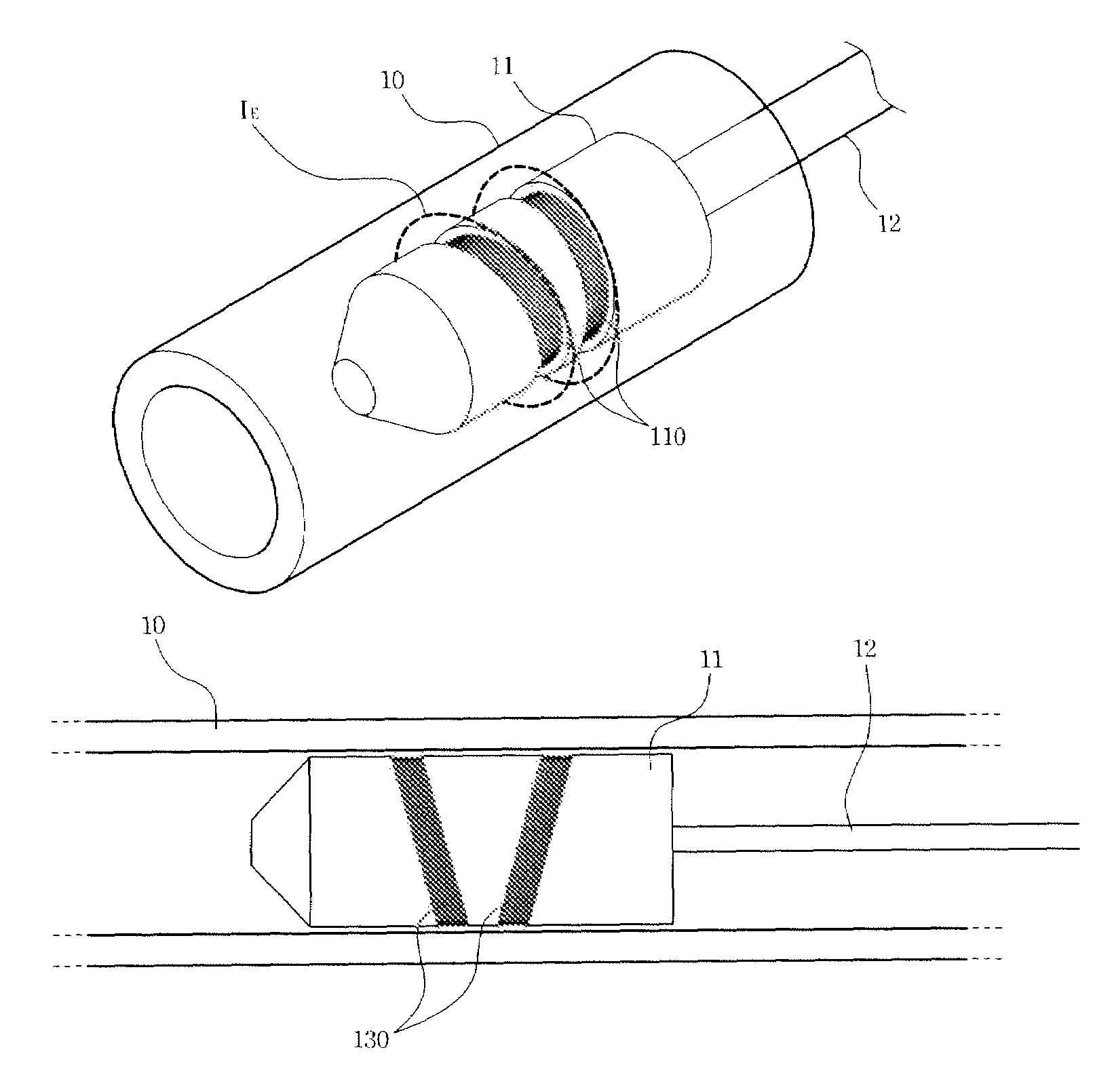

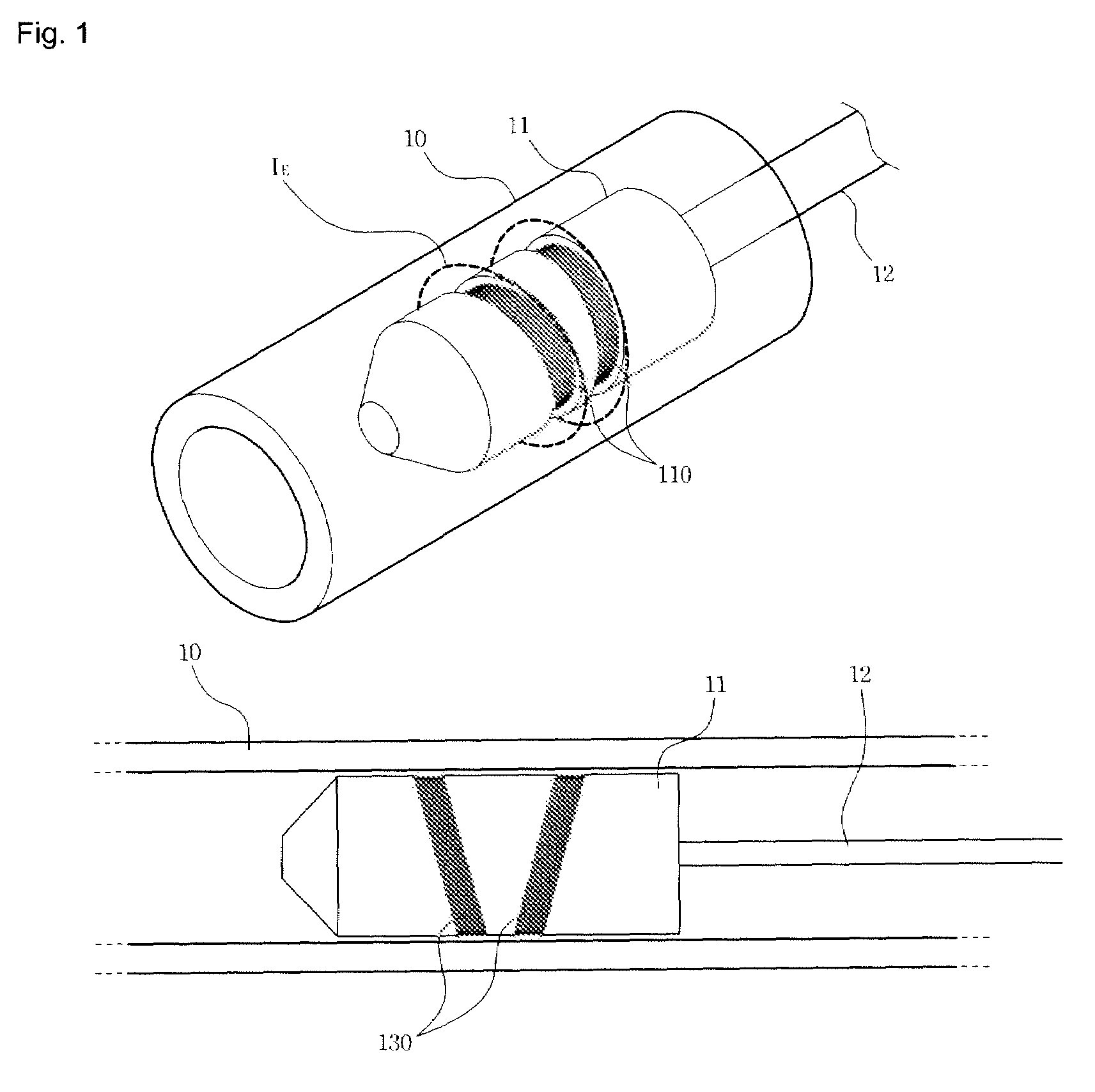

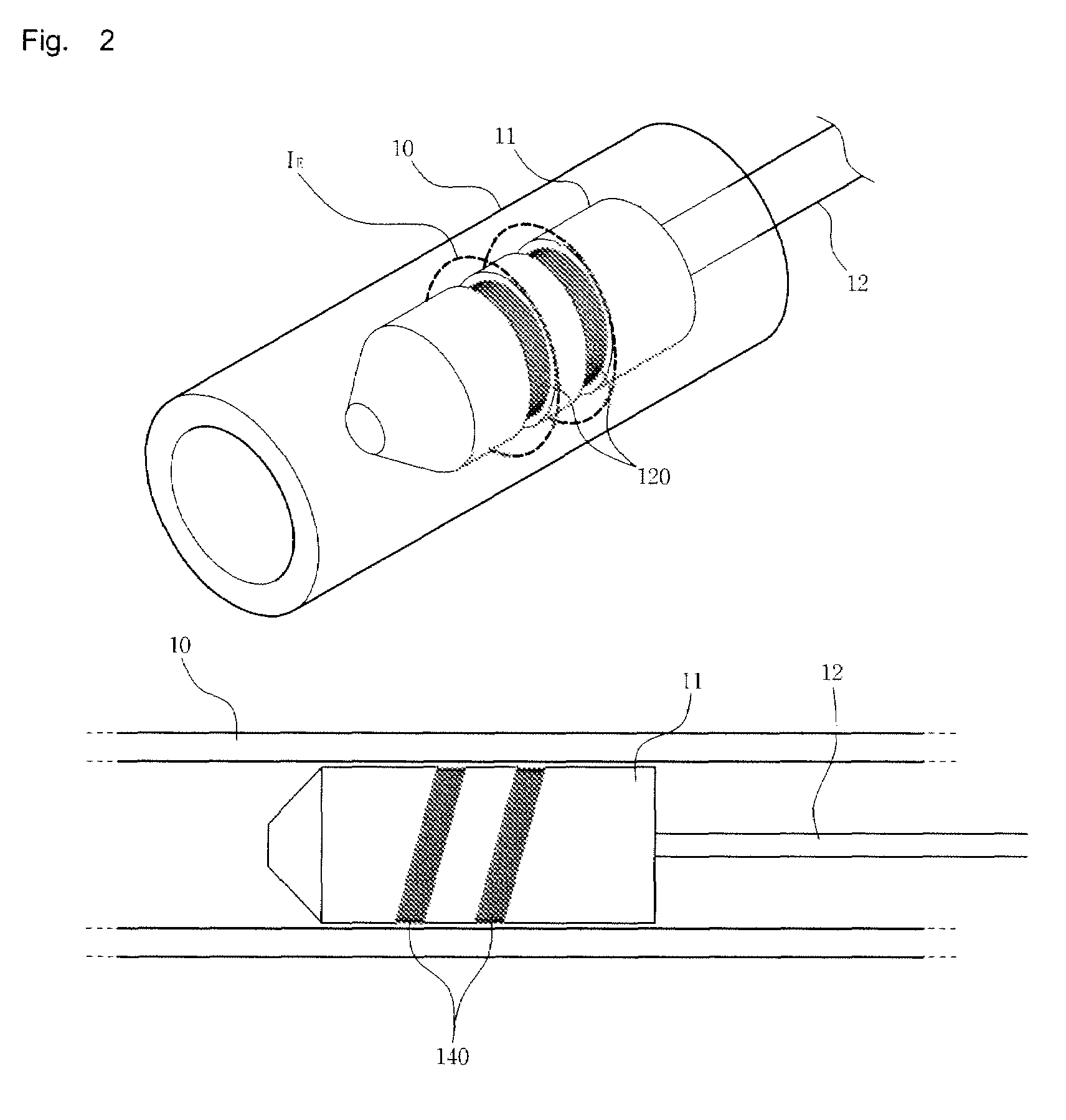

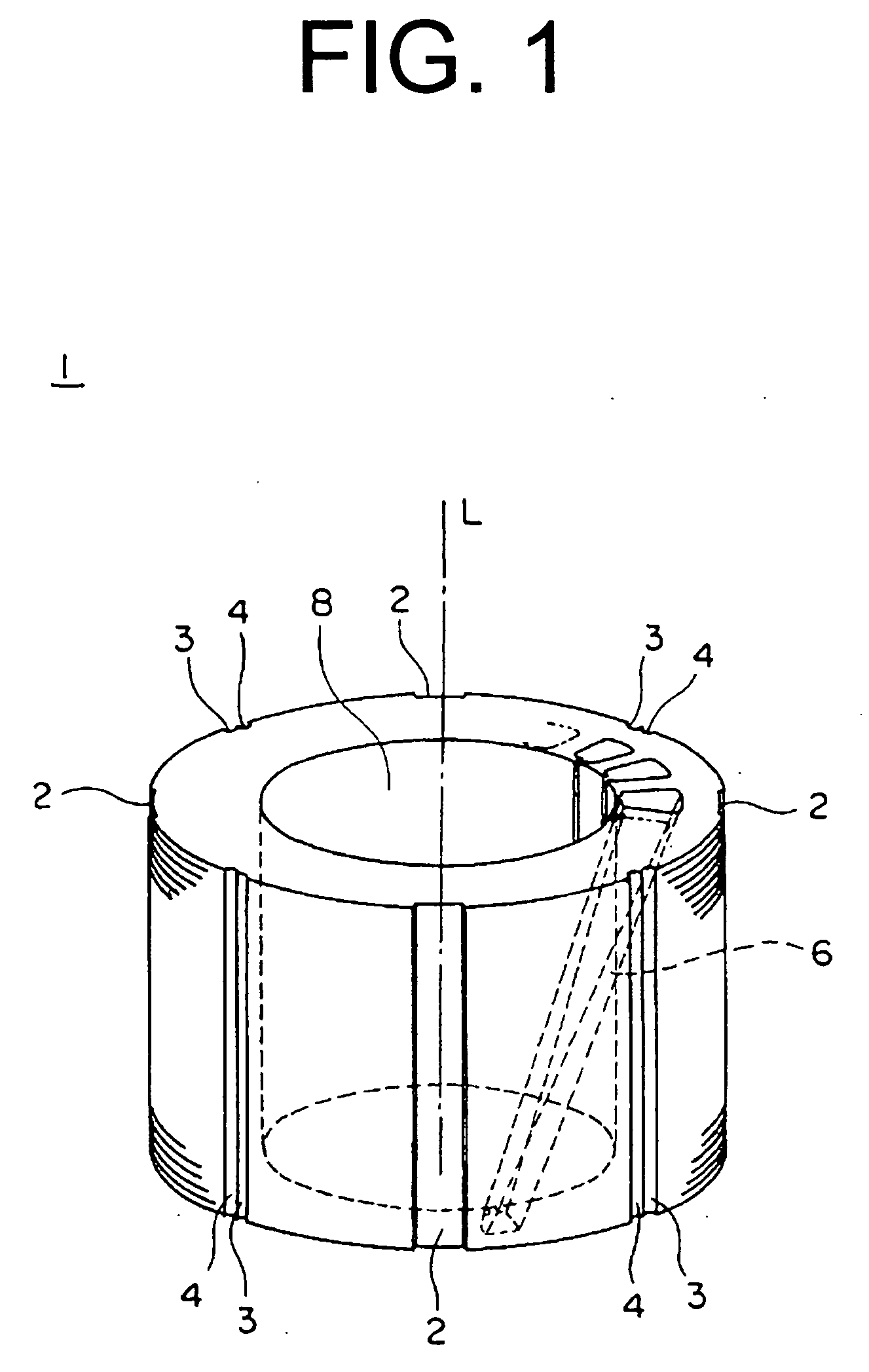

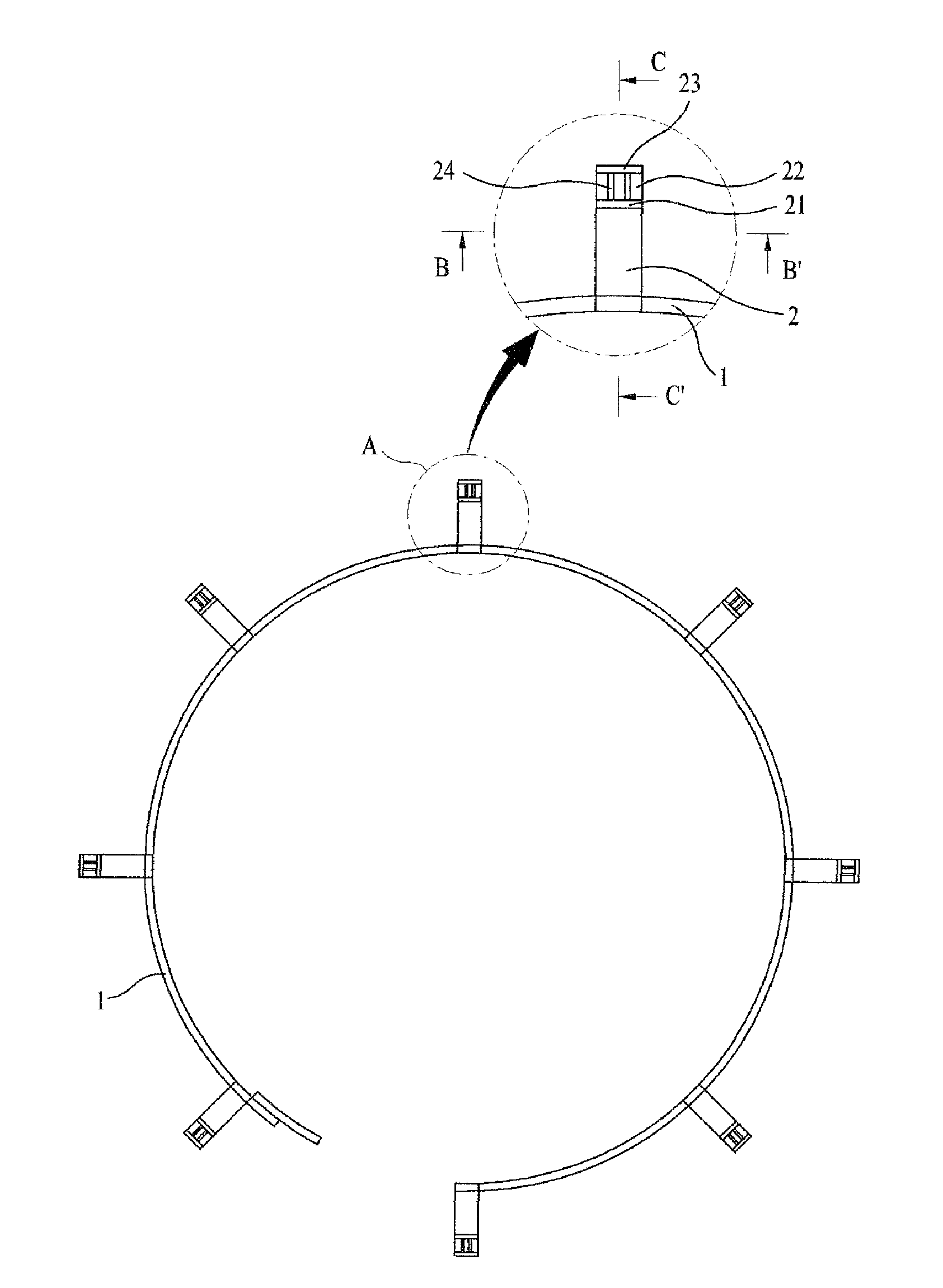

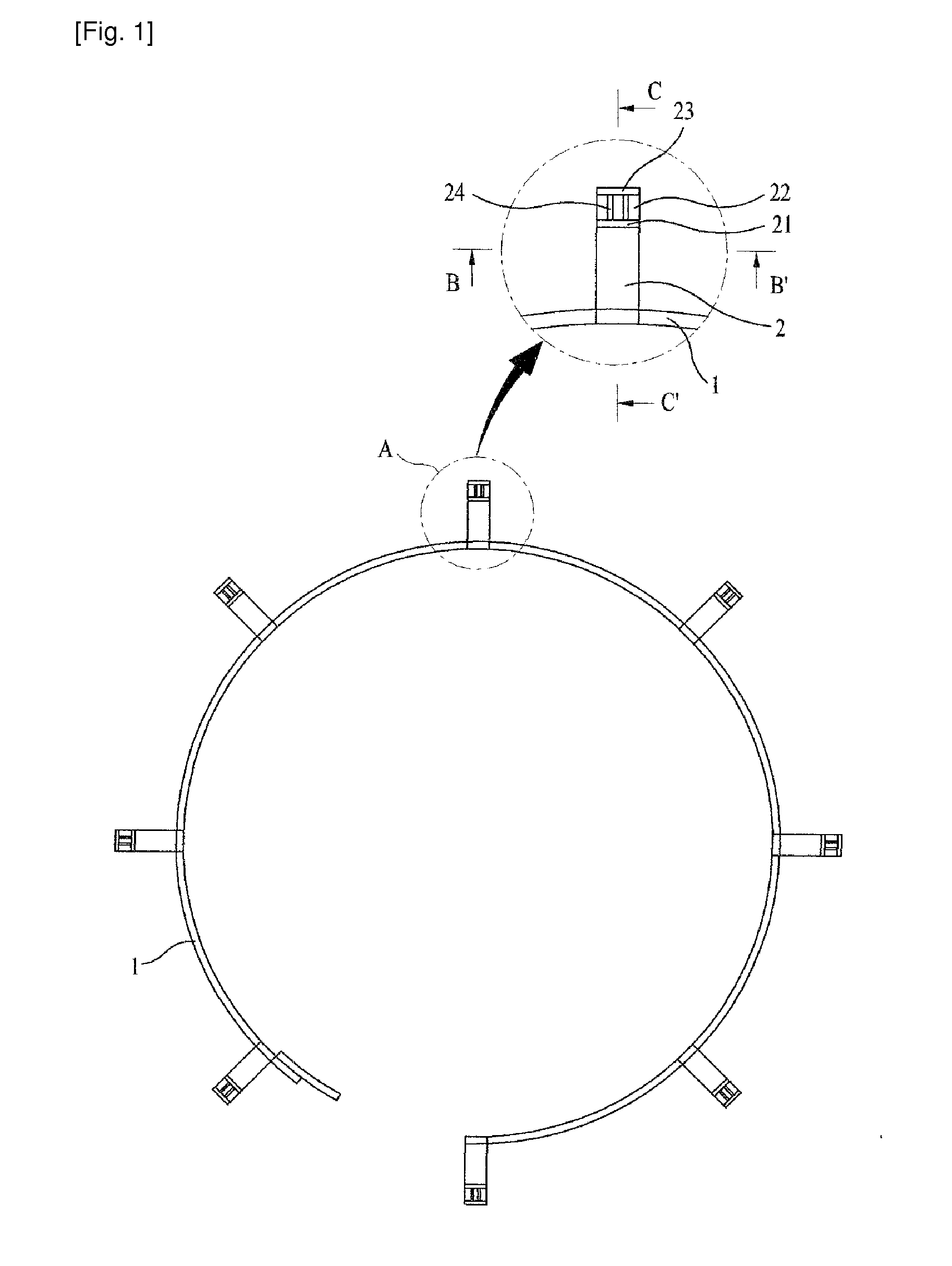

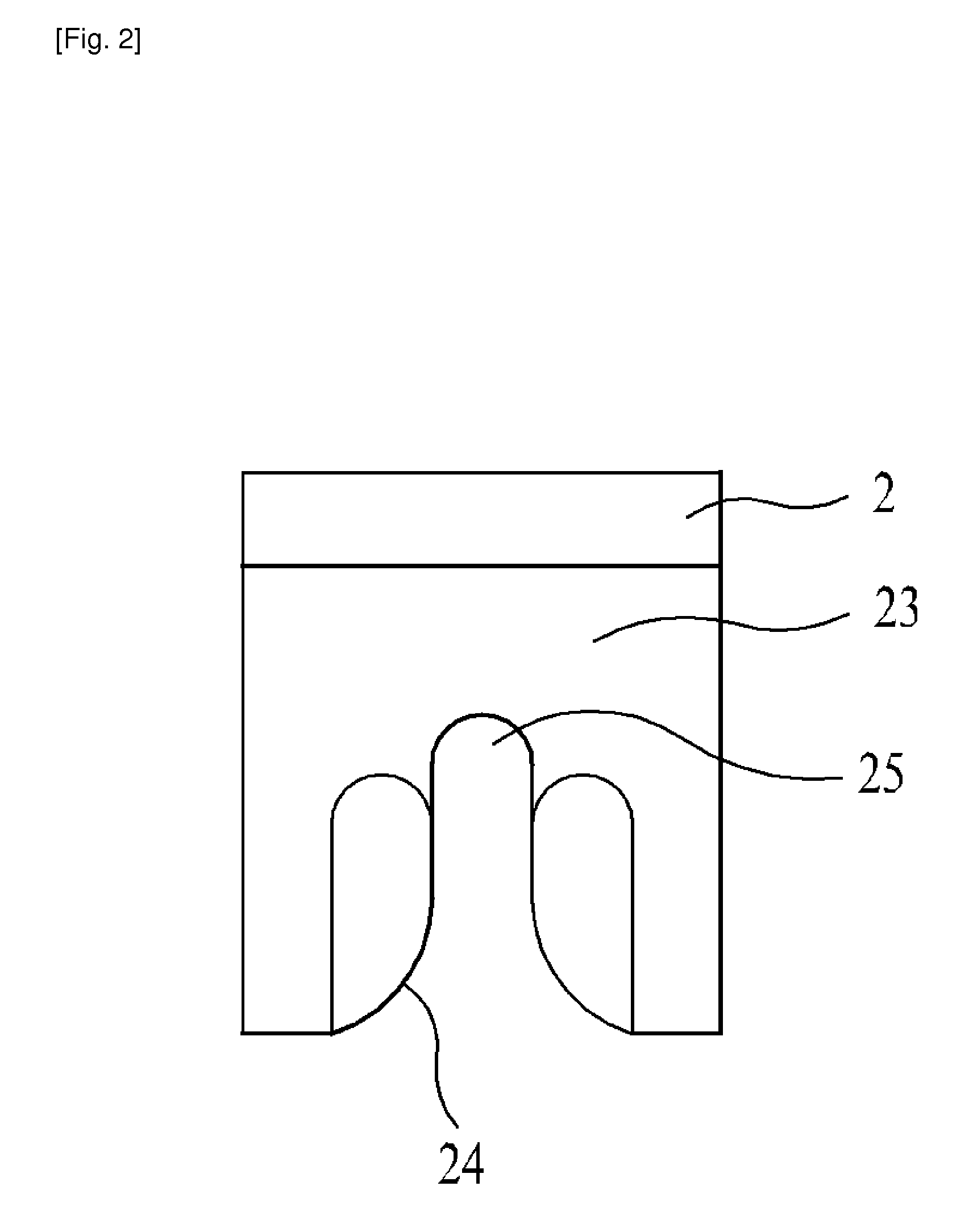

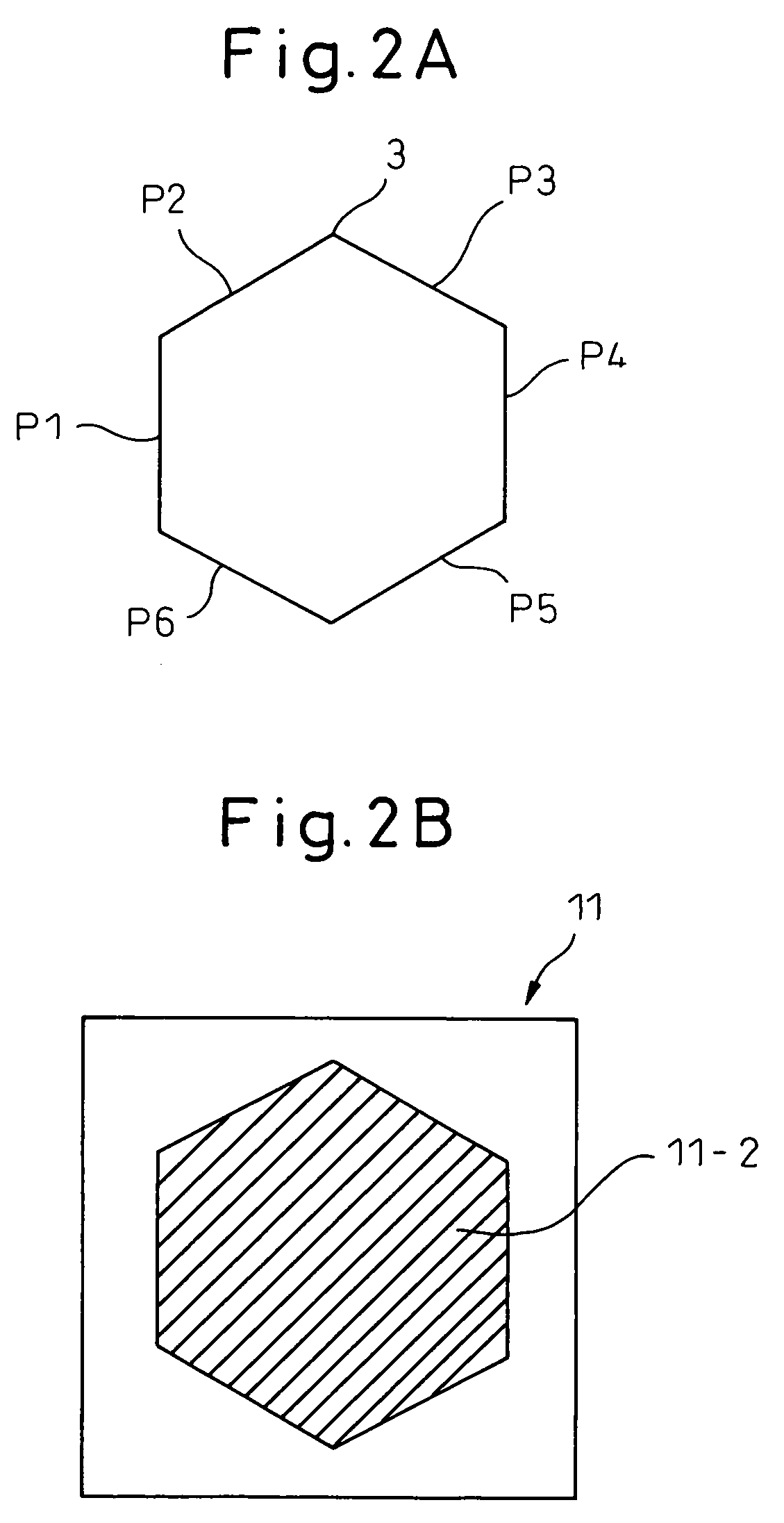

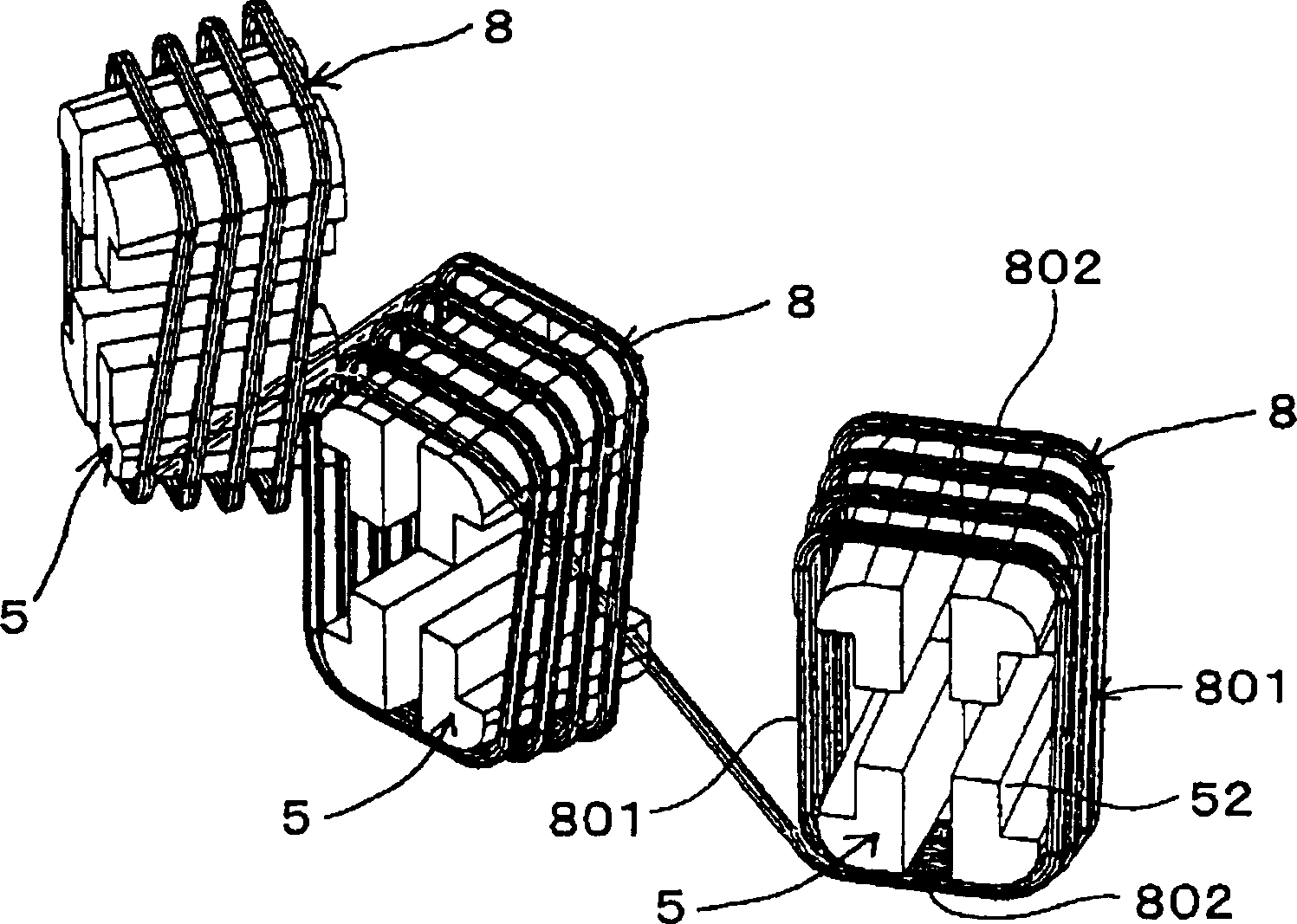

Sensor for detecting surface defects of metal tube using eddy current method

ActiveUS7705589B2Magnetic property measurementsMaterial magnetic variablesEddy currentAlternating current

A sensor for detecting surface defects of a metal tube solves a problem of a conventional eddy current probe in that it is difficult to detect a crack in the circumferential direction of a metal tube. The sensor includes a plurality of coils wound at a predetermined inclined angle. The plurality of coils is inserted into the inside of a metal tube. Alternating current is applied to the coils to measure a change in impedance of the coils due to a change in an eddy current generated in the metal tube, thus detecting a surface defect of the metal tube.

Owner:KOREA RES INST OF STANDARDS & SCI

Motor manufacturing process

InactiveUS7275299B2Reduce motor sizeReduce axial sizeEmbedding prefabricated windingsMetal working apparatusEngineeringMechanical engineering

A plurality of single-pole coils are retained by a coil retaining device, the single-pole coils are arranged such that the coil insertion portions of each single-pole coil confront the inner circumference openings of the slots and may be generally parallel to the axial direction of the motor core, each single-pole coil is moved linearly toward the motor core such that the coil retaining device and the moving locus before the adjoining coil insertion portions in the adjoining single-pole coils are inserted into the slots are parallel or approach the more from the inner circumference side to the outer circumference side and the two coil insertion portions of each single-pole coil are moved such that they may start their movements simultaneously and at equal velocities.

Owner:AISIN AW CO LTD

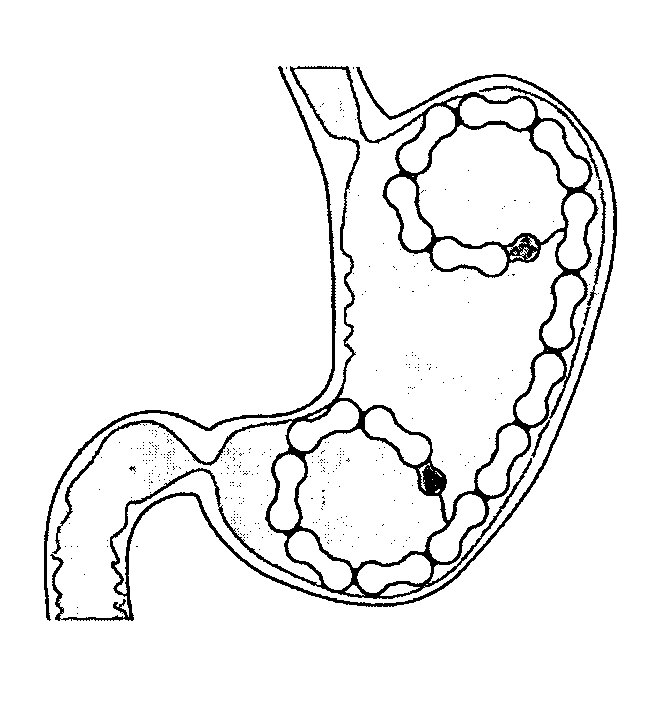

Method for inducting weight loss using a coil for insertion into a hollow body organ

A method for inducing weight loss in a patient by providing an implant for placement within the stomach. The implant having a member with an undeployed shape for delivery to the stomach and a deployed shape for implantation therein. The member has a plurality of links pivotably connected to each other, and a flexible elongated tether connected to the member. The method then involves delivering the member to the stomach while in its undeployed shape, and placing the member in its deployed shape by applying tension to the tether. The method also involves exerting an outward force against an interior of the stomach so as to bring together two substantially opposing surfaces of the hollow body by placing the member in its deployed position.

Owner:ETHICON ENDO SURGERY INC

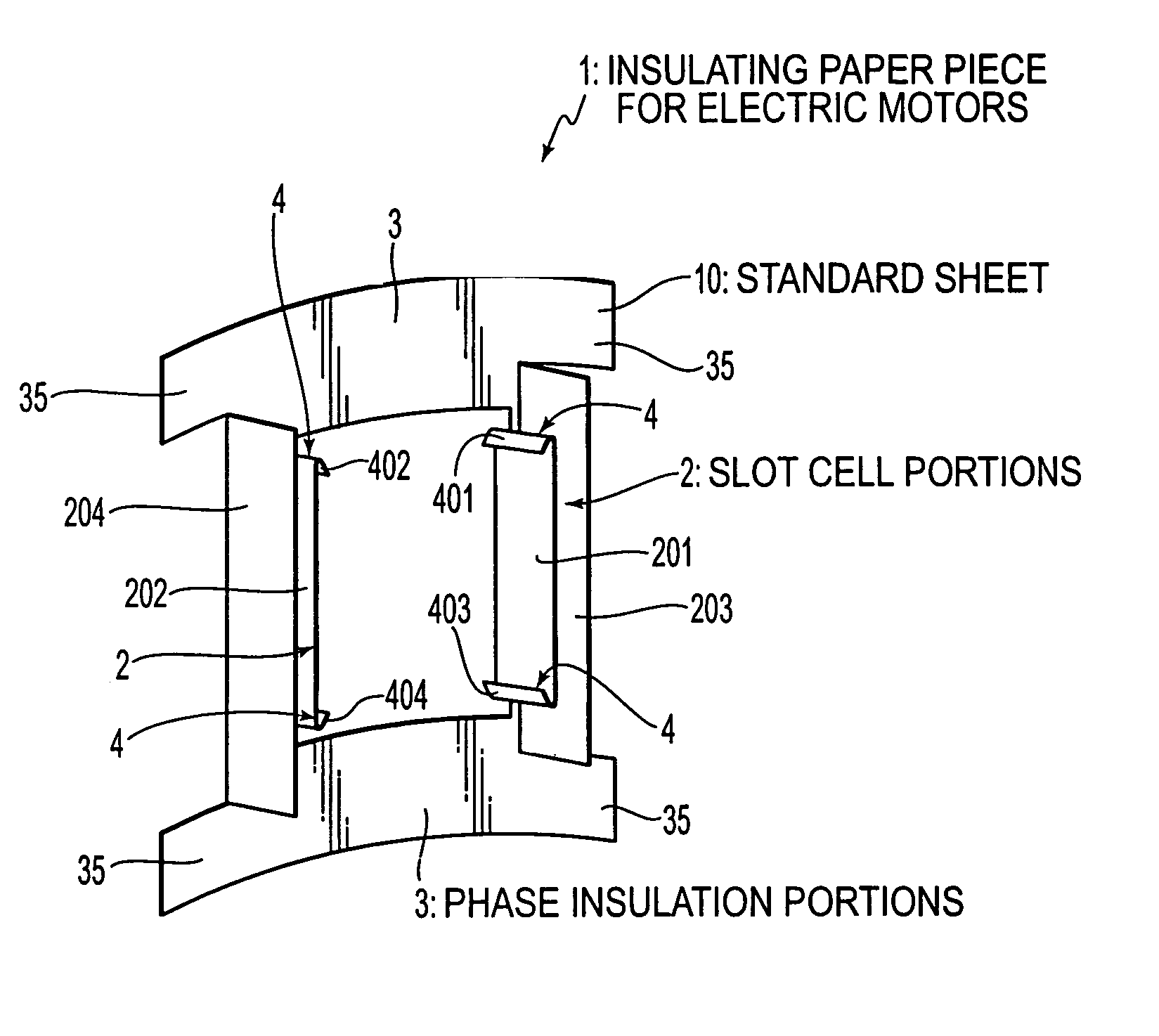

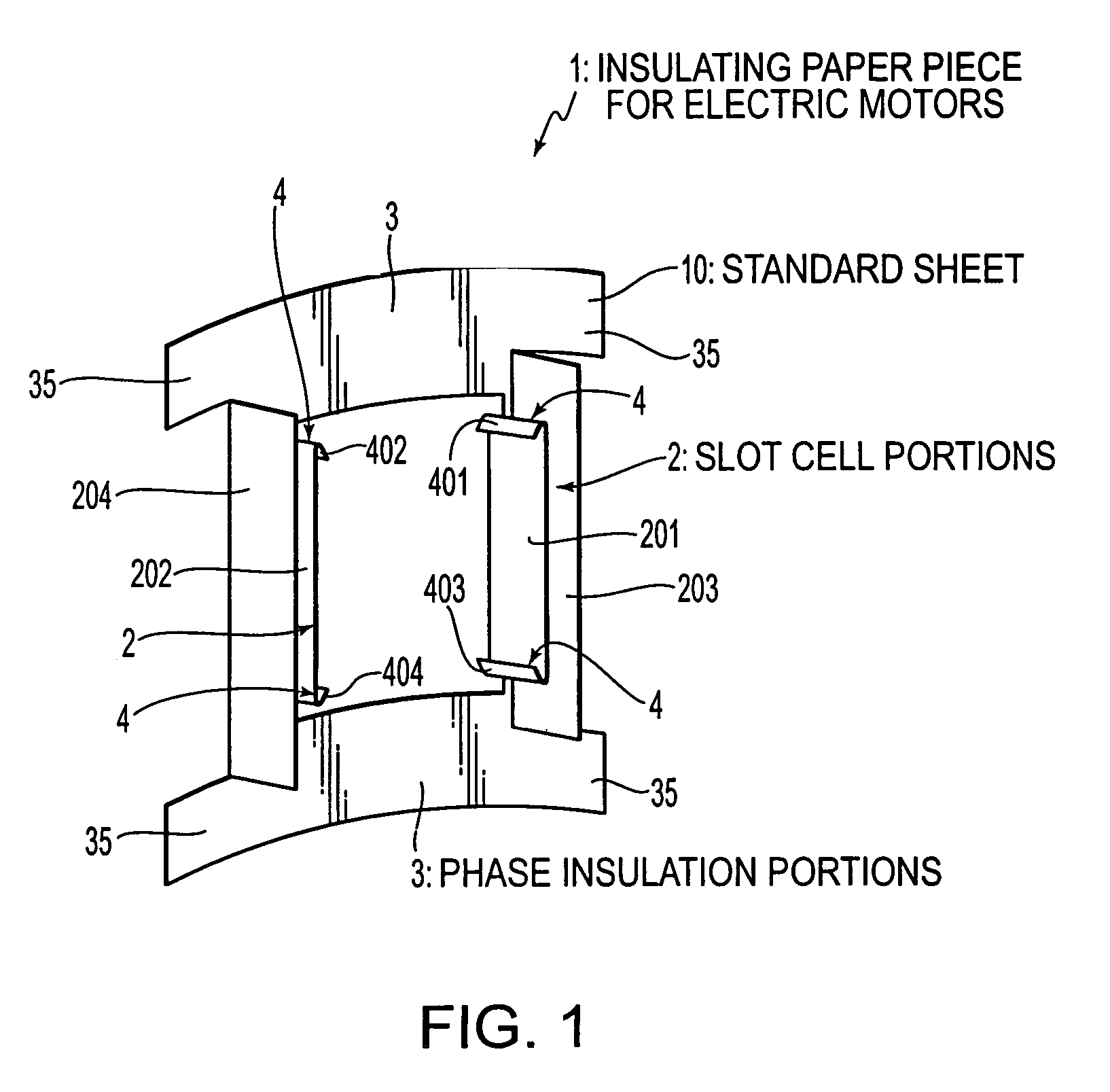

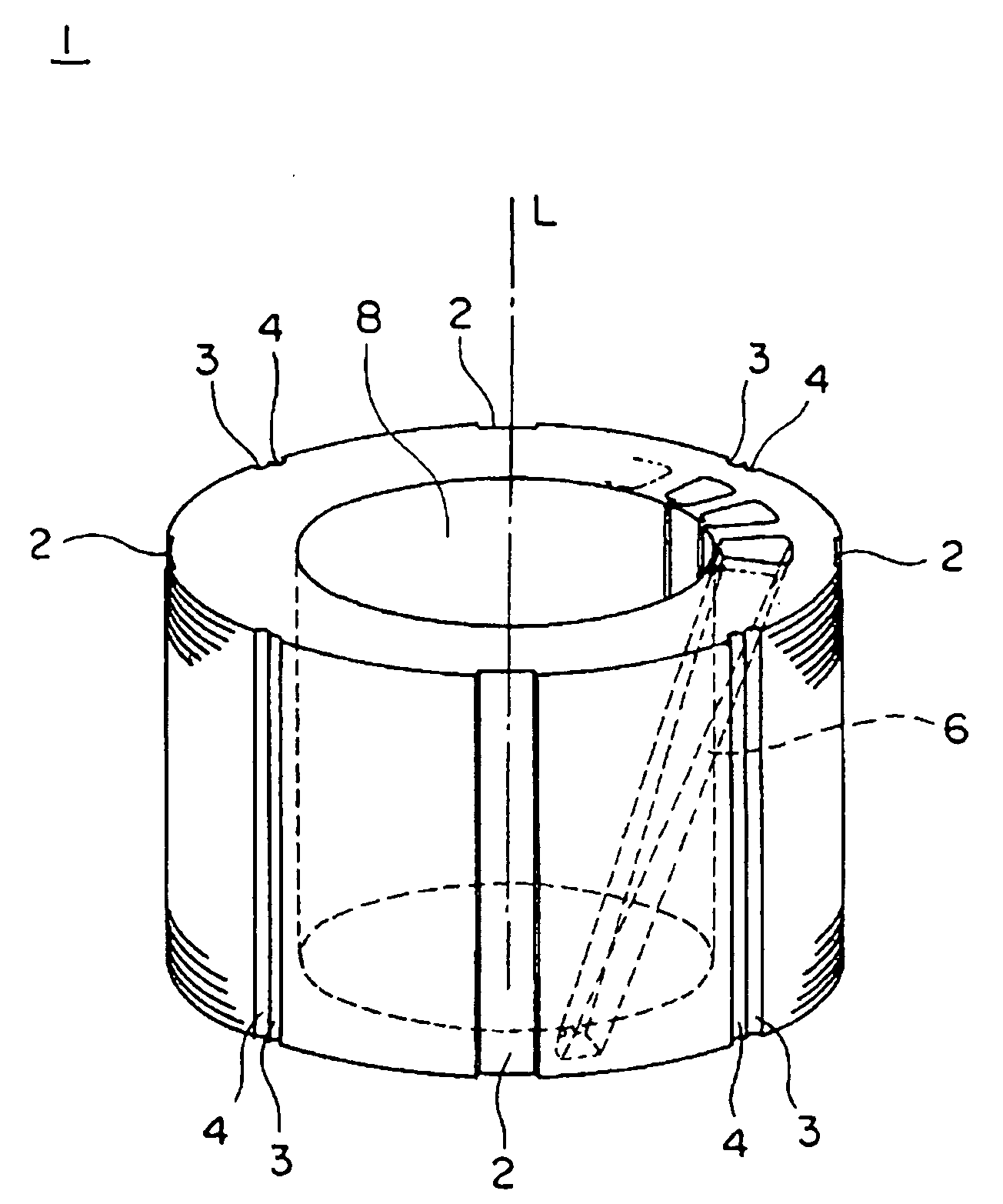

Insulating paper piece for electric motors and electric motor

InactiveUS6995491B2Good effectSpace minimizationWindings insulation shape/form/constructionEngineeringCoil insertion

An insulating paper piece for electric motors, capable of improving both electrical insulation between a coil and a stator core and electrical insulation between ends of coils of different phases without adversely affecting ease of coil insertion or the space taken up for the coil. A single insulating paper piece for electric motors contains at least two slot cell portions arranged in two slots of the stator core in which portions of one single pole coil are to be inserted, with two phase insulation portions arranged to connect respective ends of the two slot cell portions to form loops and disposed to face directly against coil ends of the single pole coil. The phase insulation portions comprise overlapping widthwise portions extended from both ends so that when a plurality of the insulating paper pieces for electric motors are mounted on the stator core, the respective overlapping portions of the adjacent insulating paper pieces overlap one another.

Owner:AISIN AW CO LTD

Stator and method of forming the same

InactiveUS20060267443A1Magnetic circuit rotating partsMagnetic circuit stationary partsCoil insertionPhysics

A stator includes a cylindrical stator core and a coil. The stator core is formed by stacking a plurality of core sheets. The stator core has a groove formed in an outer circumferential surface thereof and a slot. The coil is inserted in the slot. The groove is located parallel to an axis of the stator core and the slot is skewed with respect to the axis.

Owner:TOYOTA IND CORP

Systems and methods for using ferrite alignment keys in wireless remote sensors

ActiveUS7948385B2Resistance/reactance/impedenceFluid pressure measurement by electric/magnetic elementsMonitoring systemResonant sensor

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

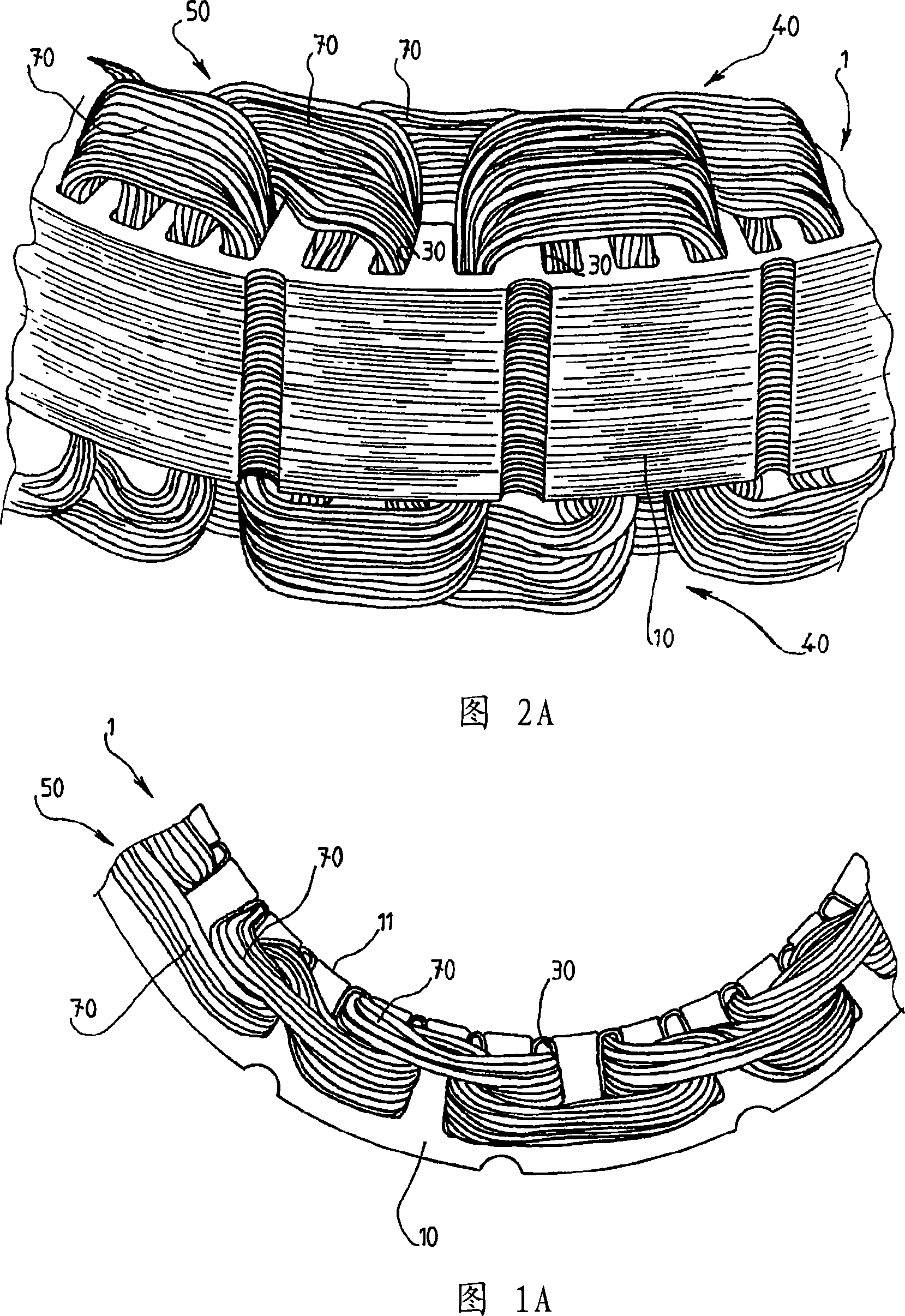

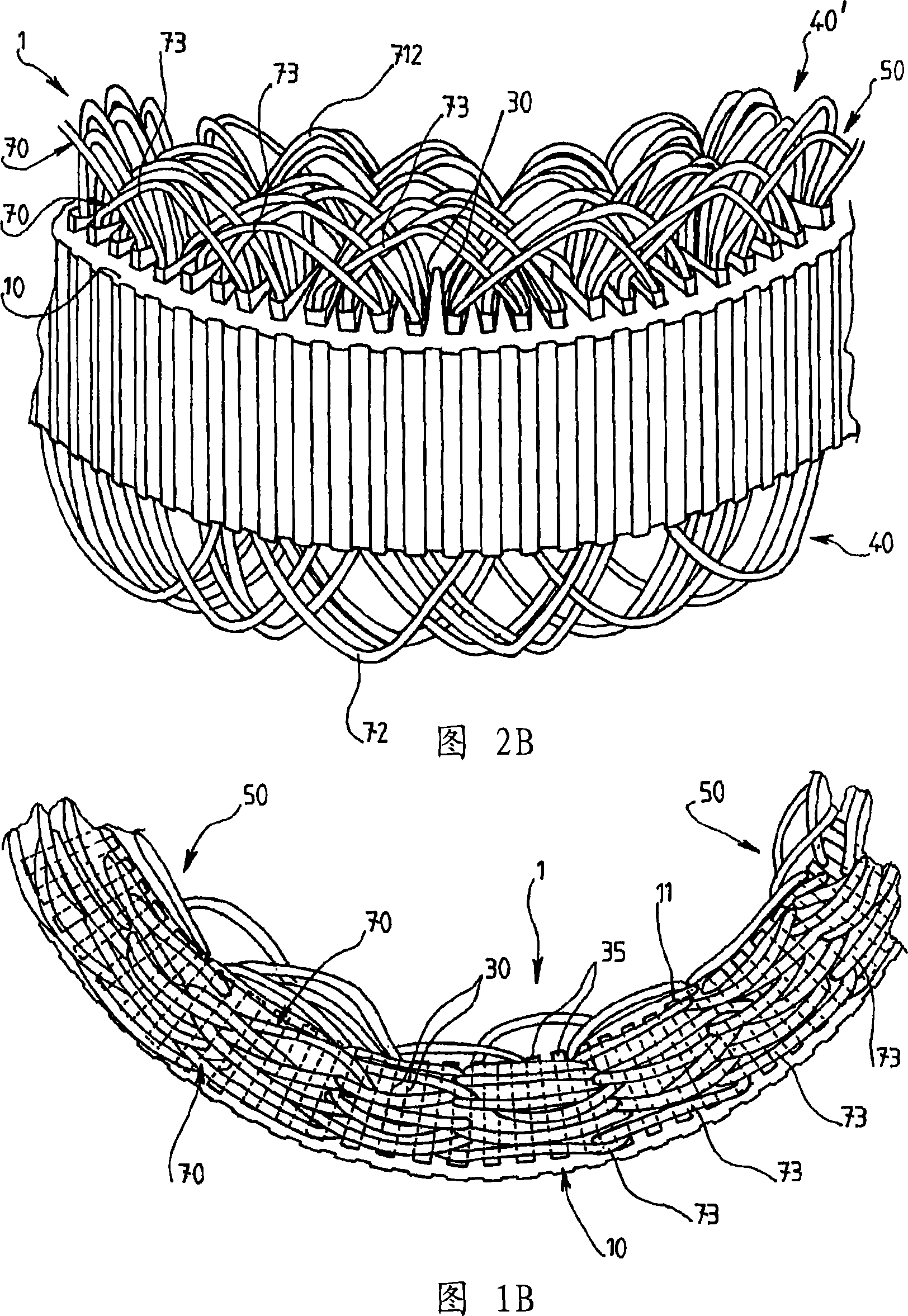

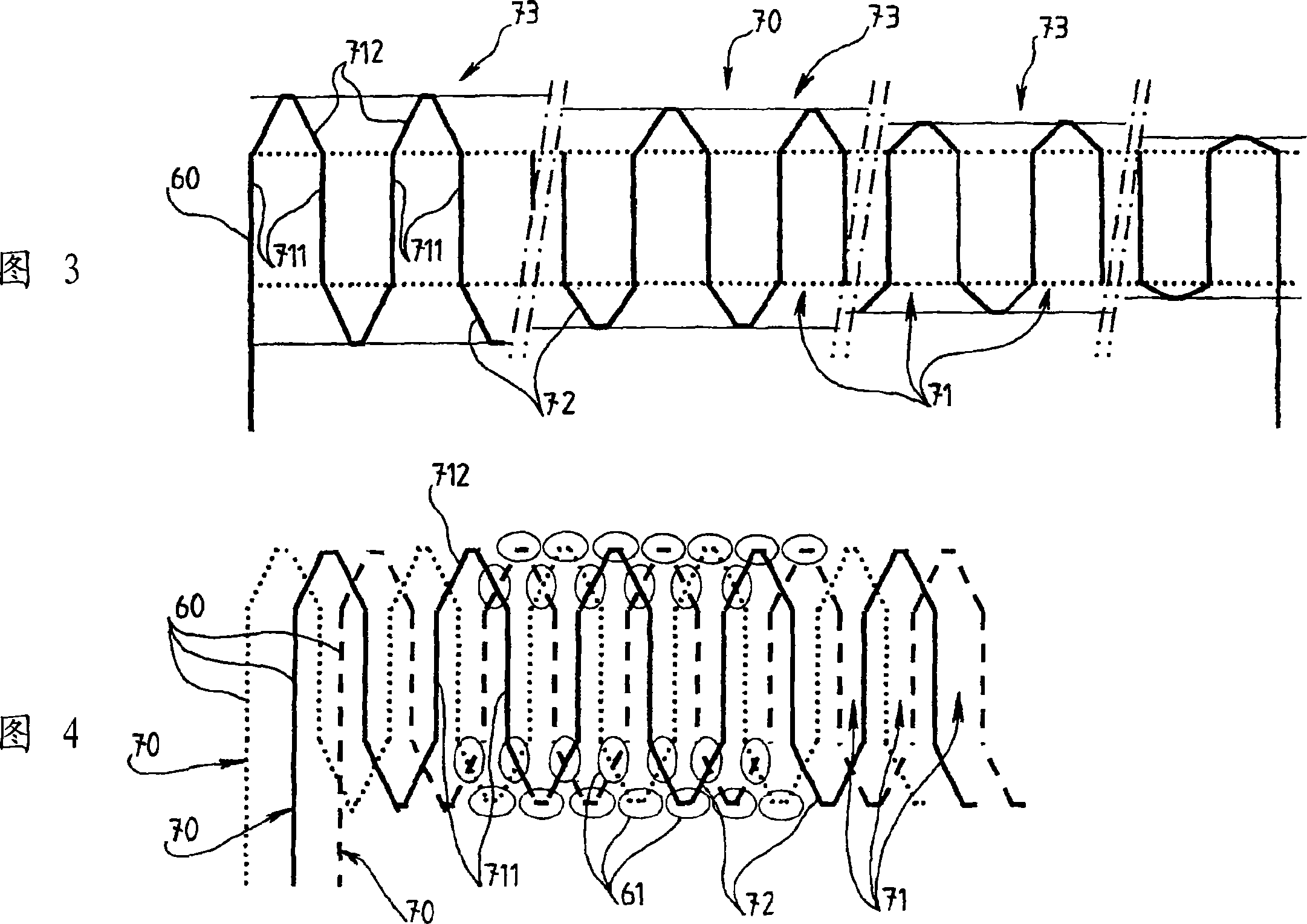

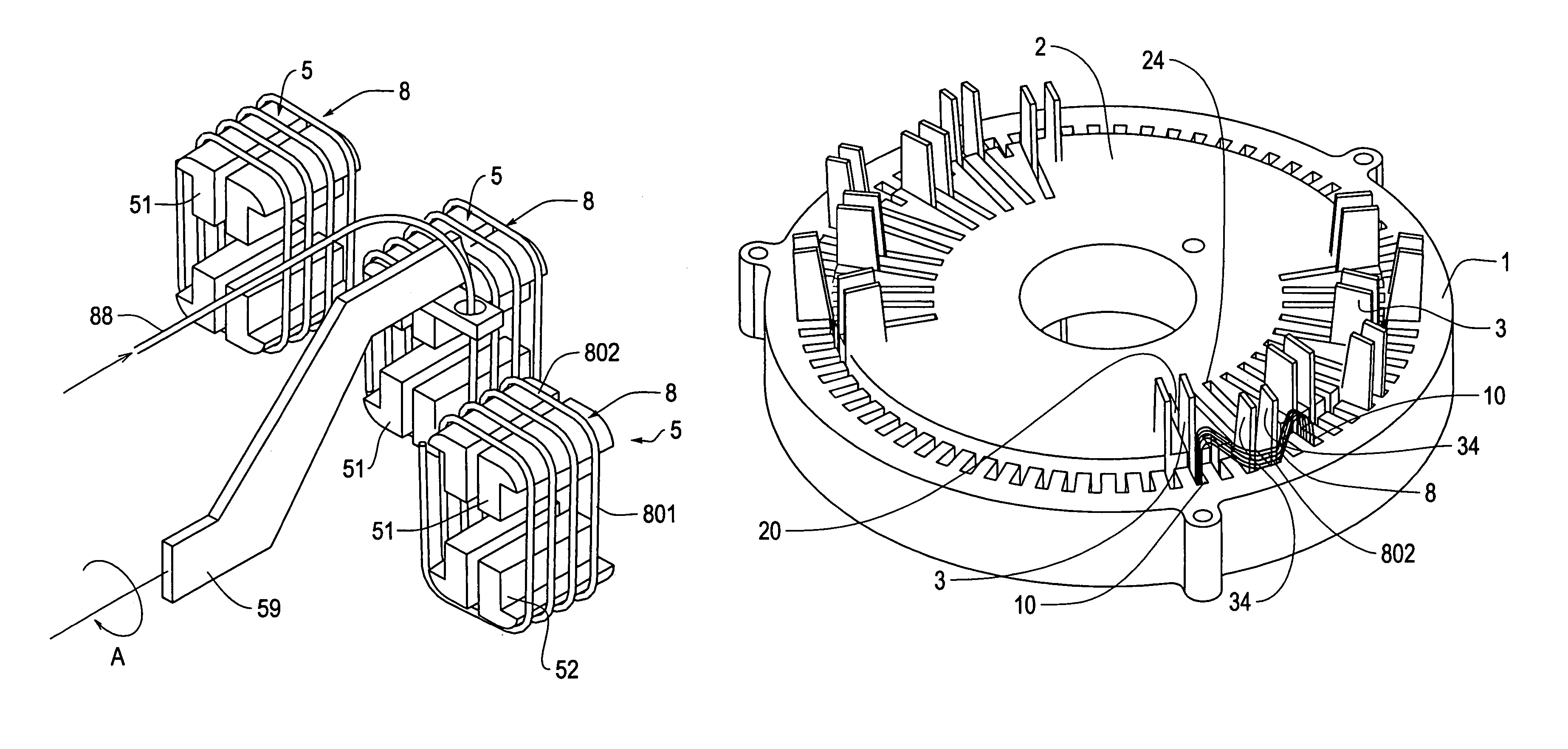

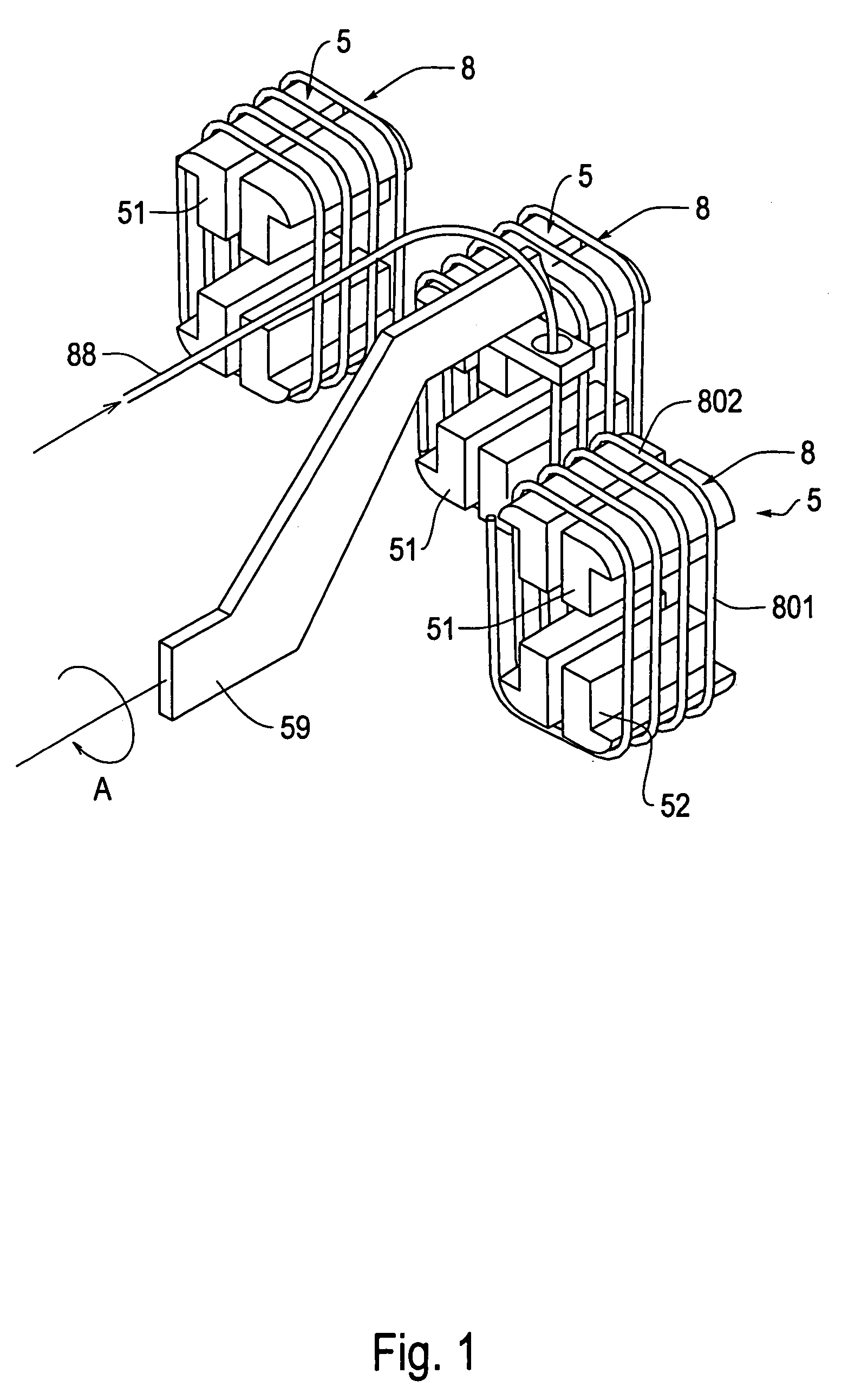

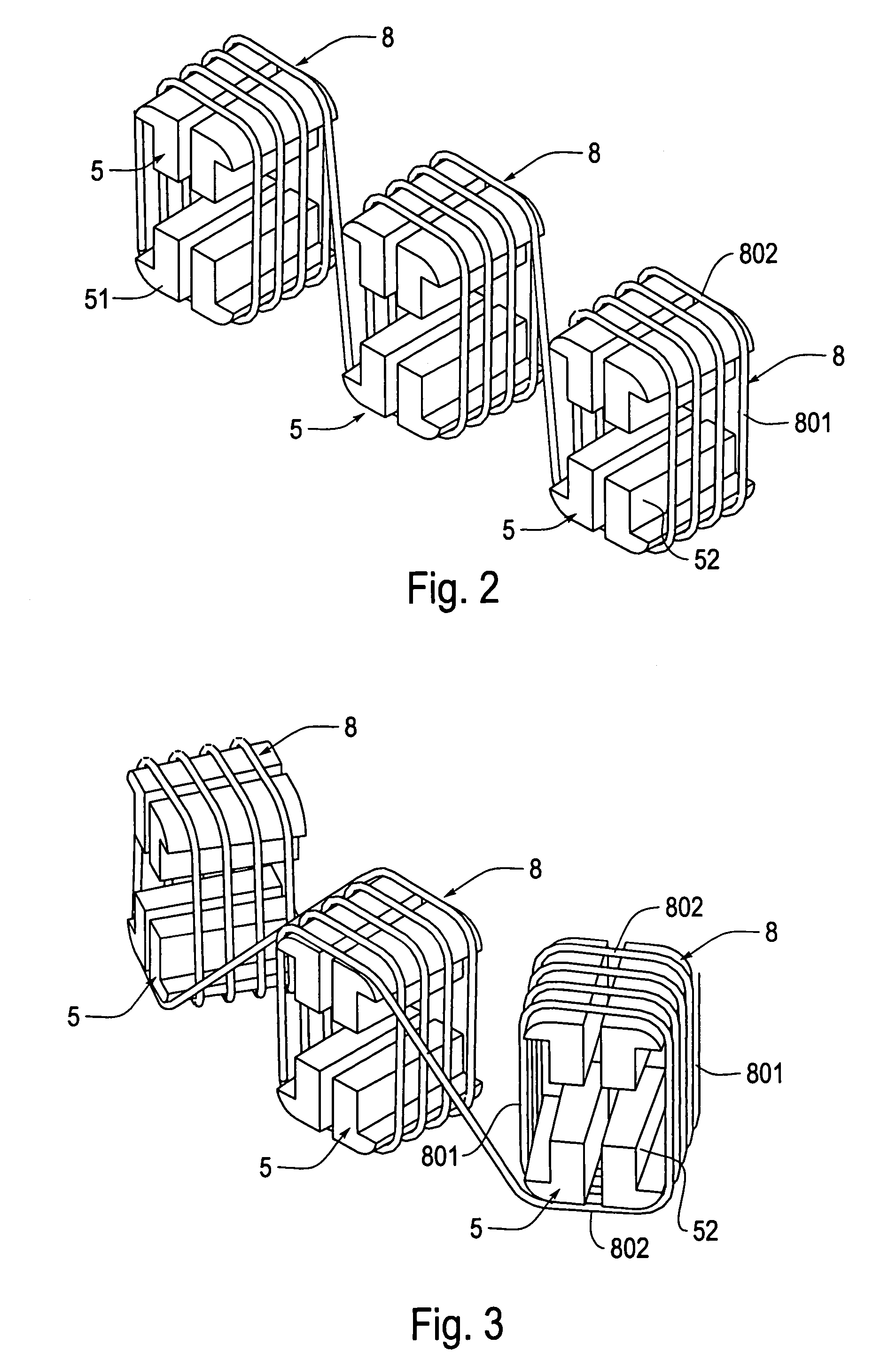

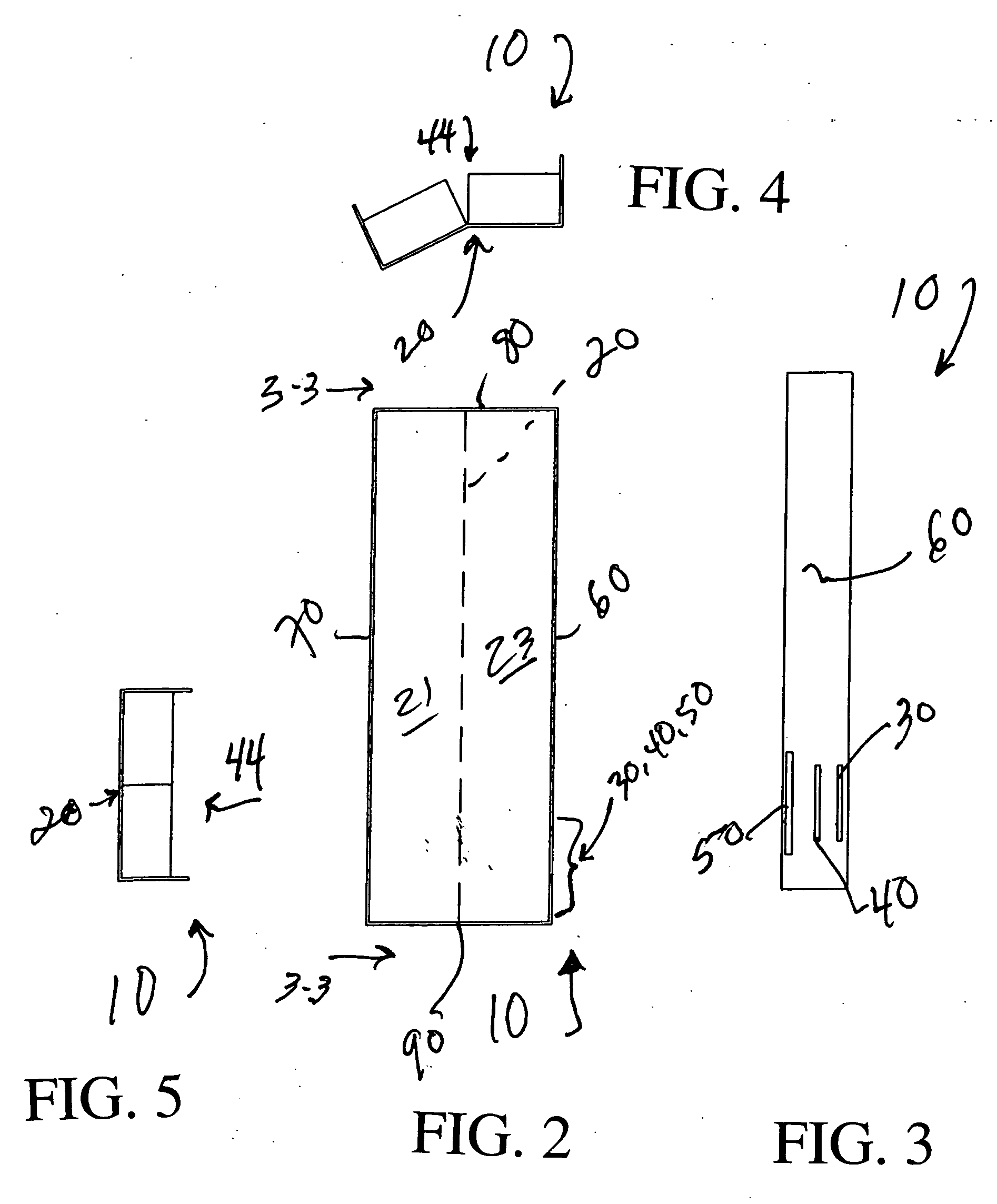

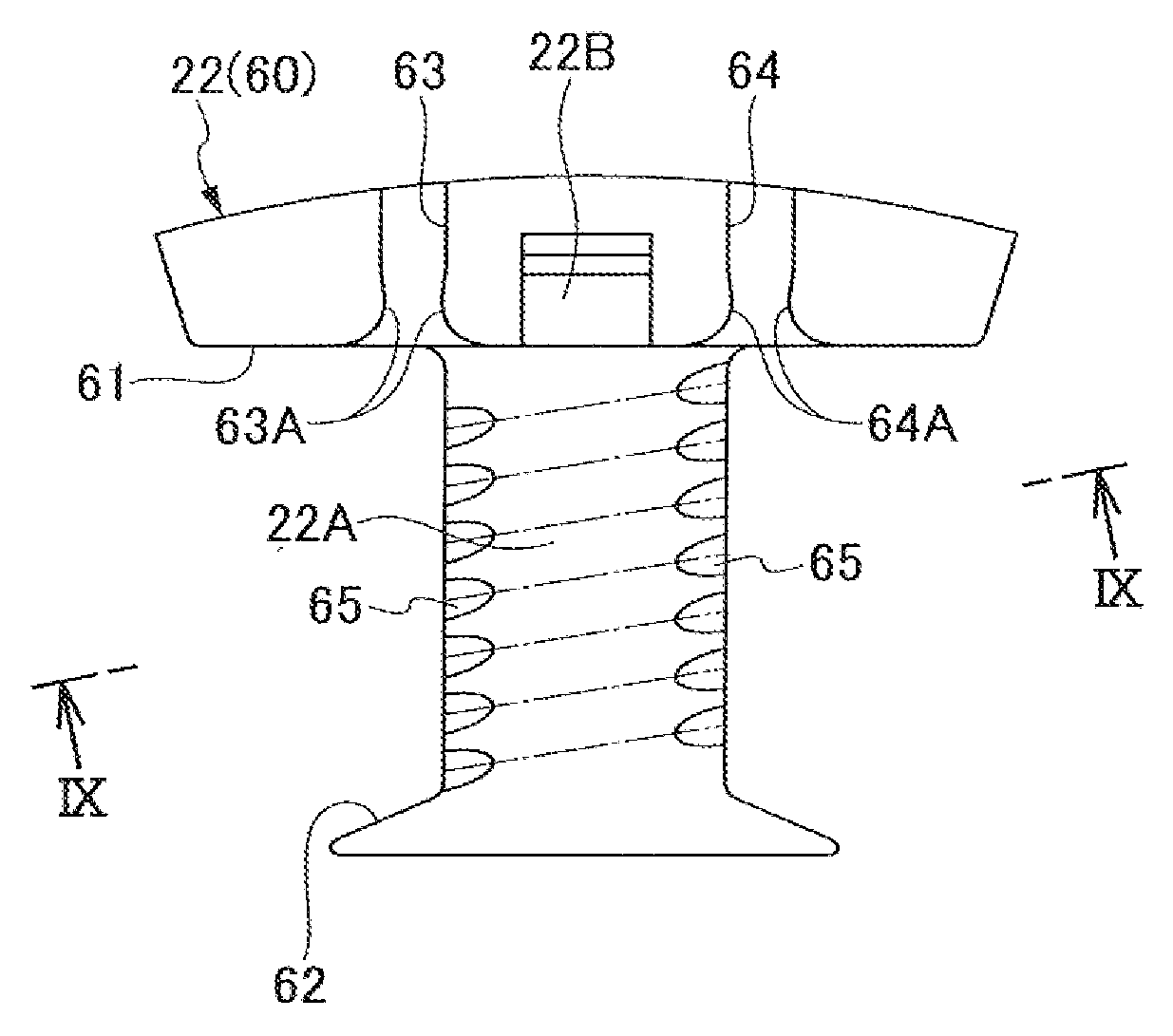

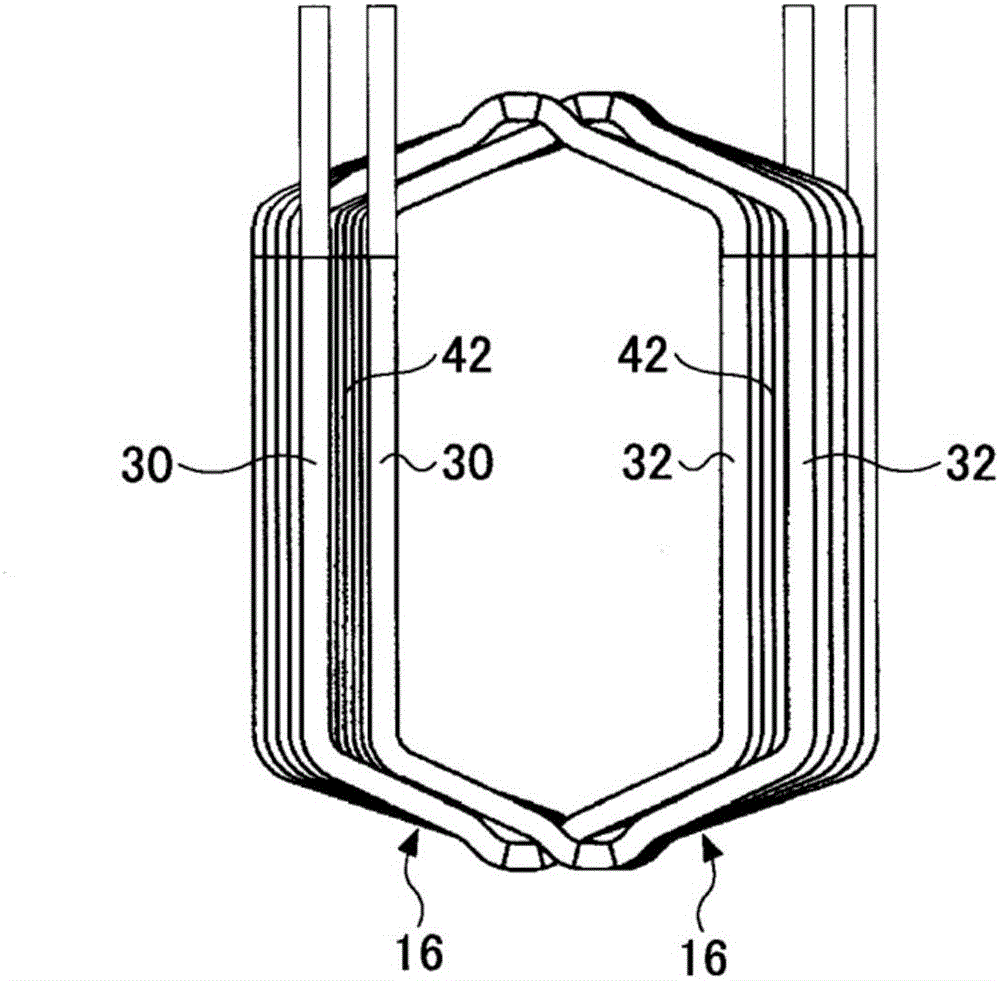

Method for inserting a coil in a polyphase rotating electrical machine stator, and associated stator

ActiveCN101084617AEmbedding prefabricated windingsWindings conductor shape/form/constructionAlternatorEngineering

The invention concerns a method for inserting a corrugated coil in an alternator stator, the coil comprising a number of wires (60), each designed to form around the inner surface of an assembly of plates a spiral including a number of turns (73) corresponding each to one turn of the inner surface. The method includes forming each wire (60), the latter being configured into a succession of recesses (71) comprising two lateral branches (711) designed to be inserted each into a slot (30); and inserting the turns (73) of each wire into a series of slots (30) of the stator, the turns of the various wires (60) being radially superimposed in a predetermined sequence. The invention is characterized in that the wires (60) are inserted in the slots (30) simultaneously, the turns (73) of the various wires (60) alternating in the predetermined stacking sequence.

Owner:VALEO EQUIP ELECTRIC MOTEUR

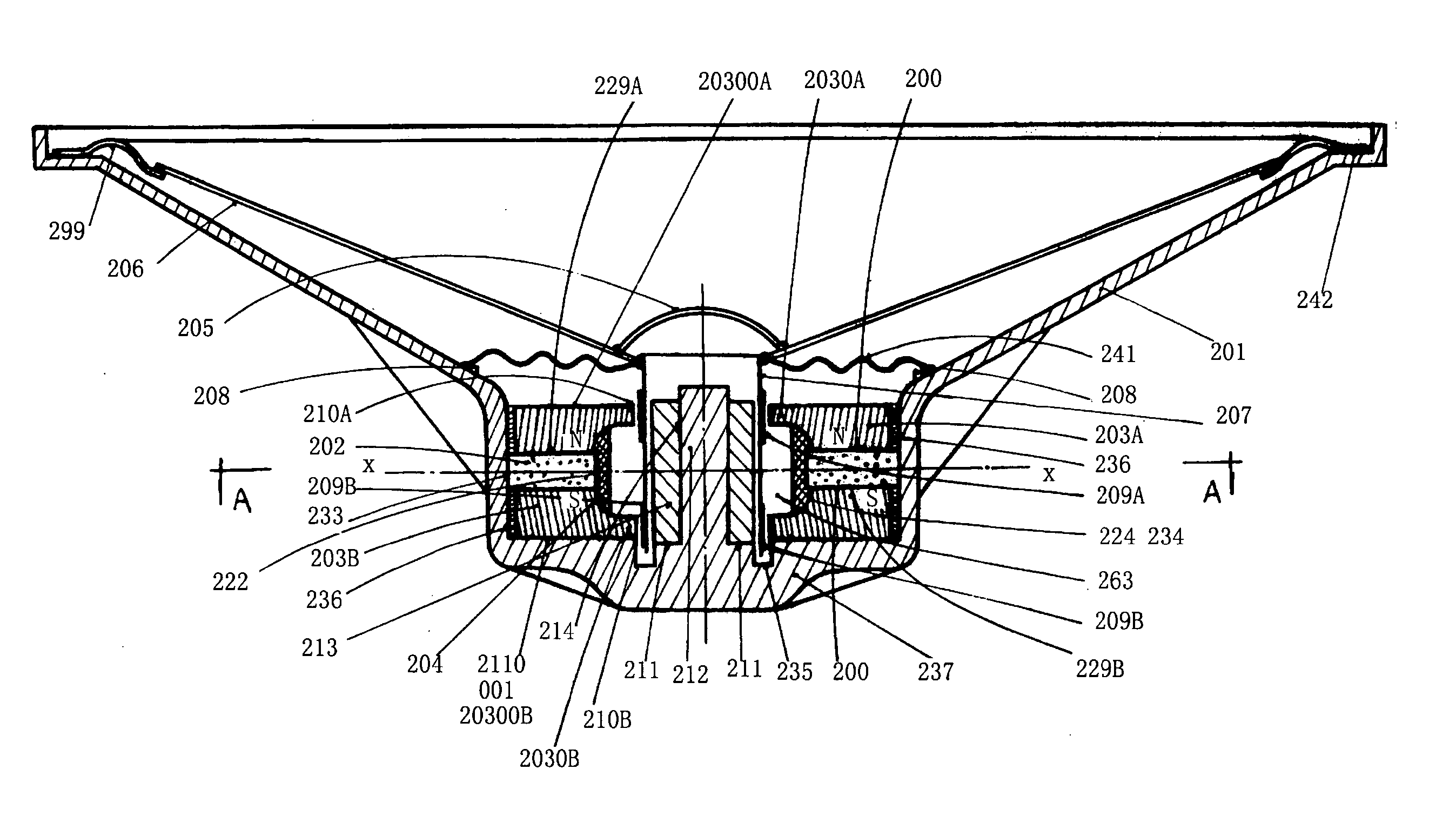

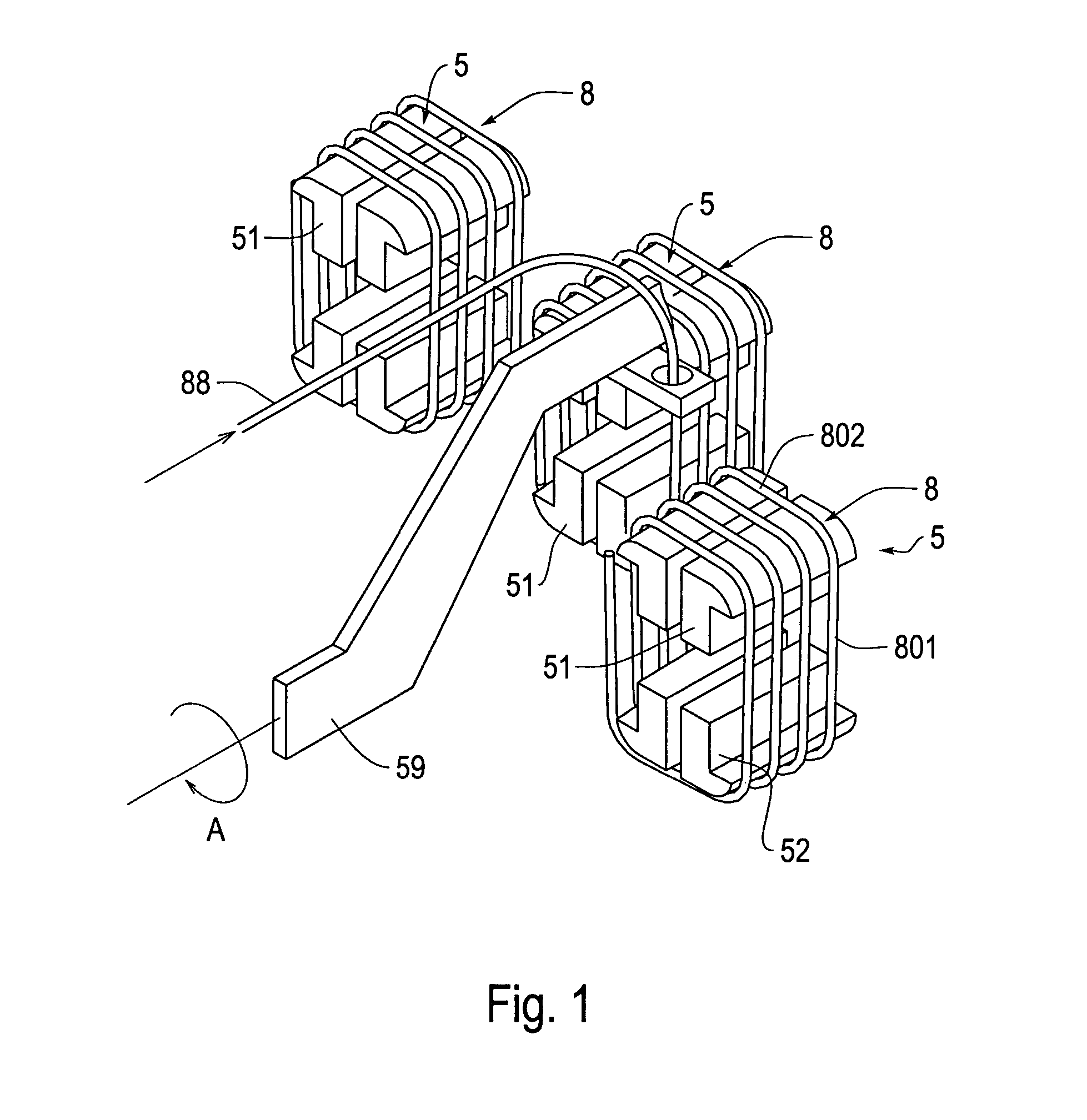

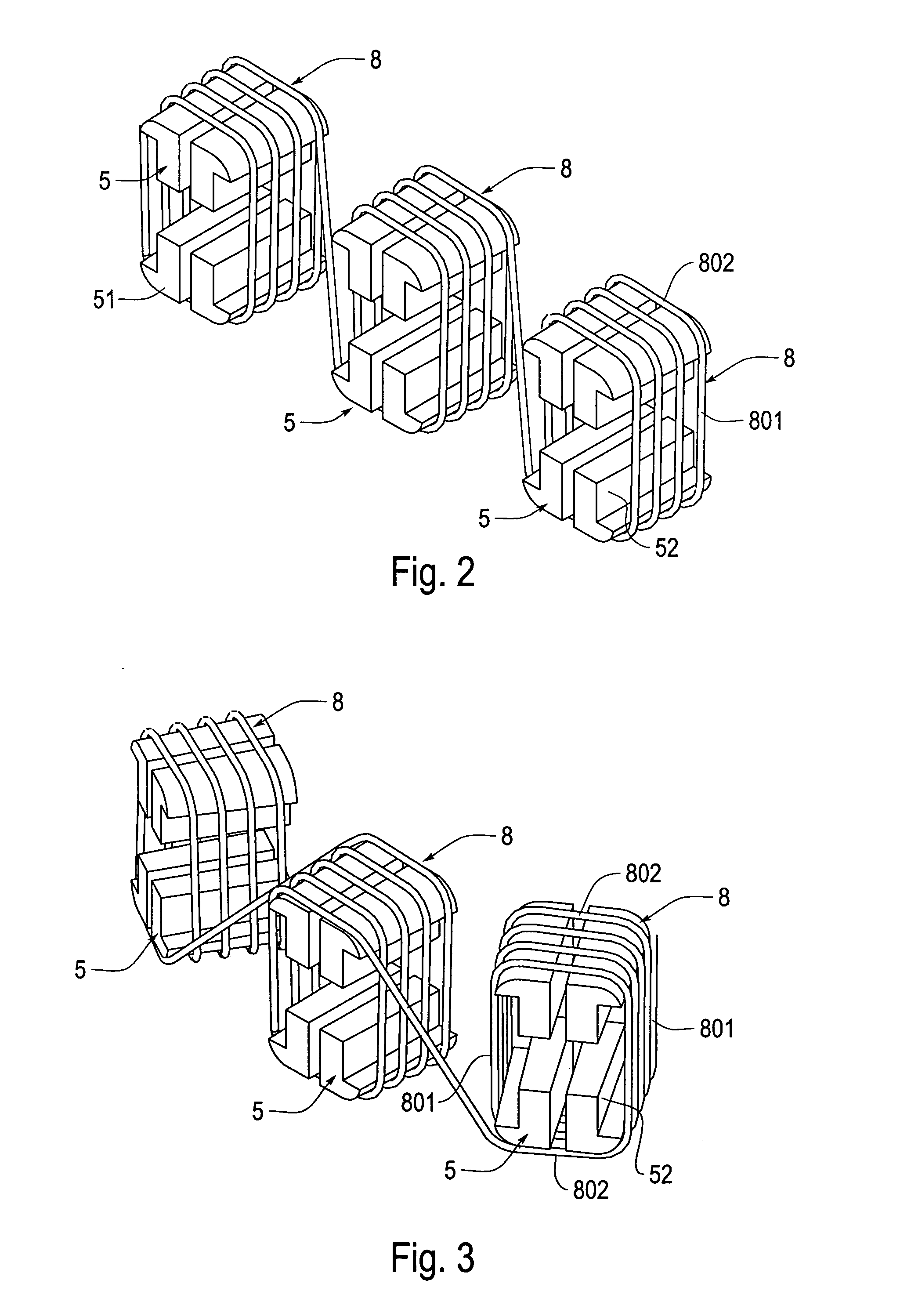

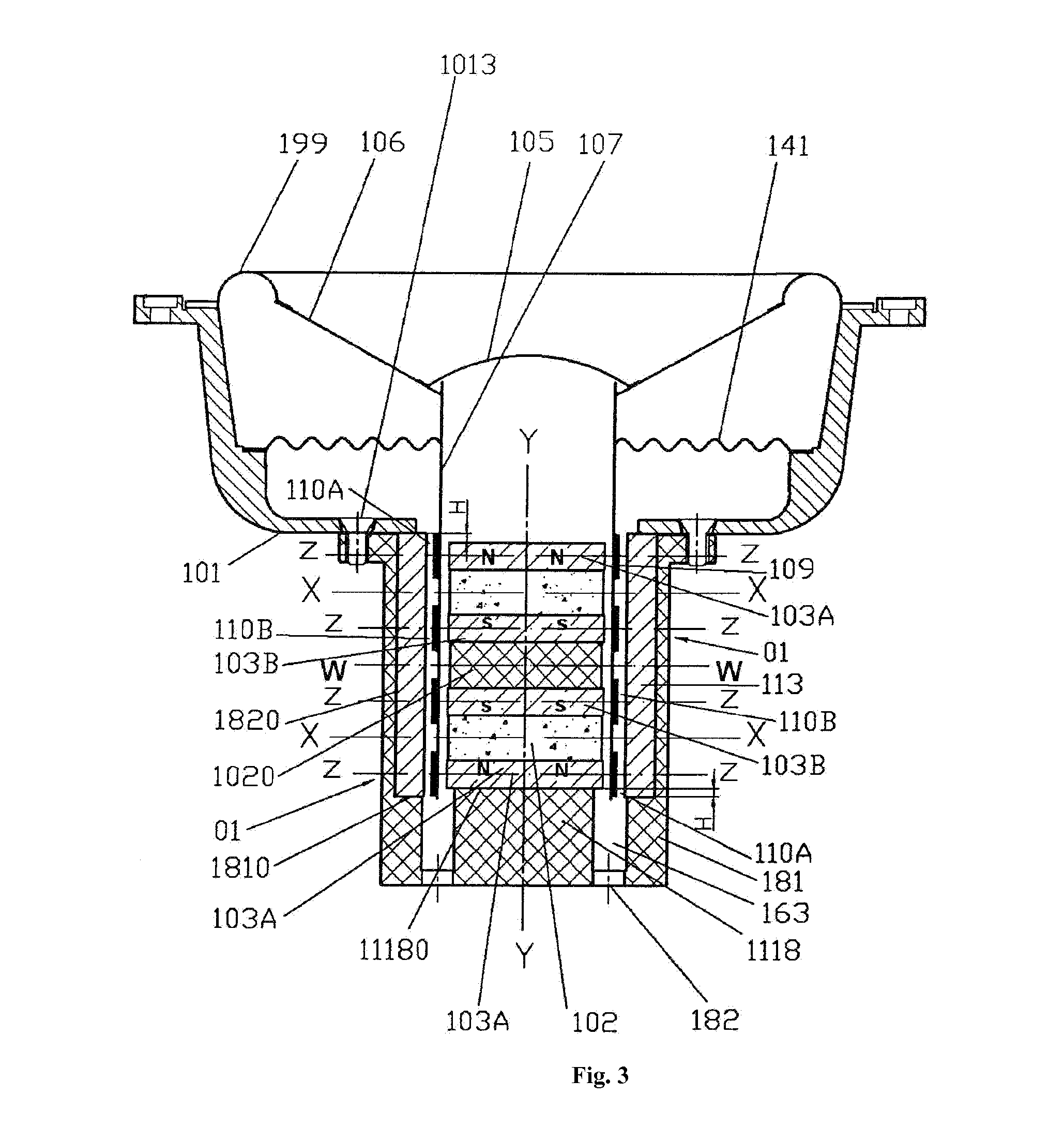

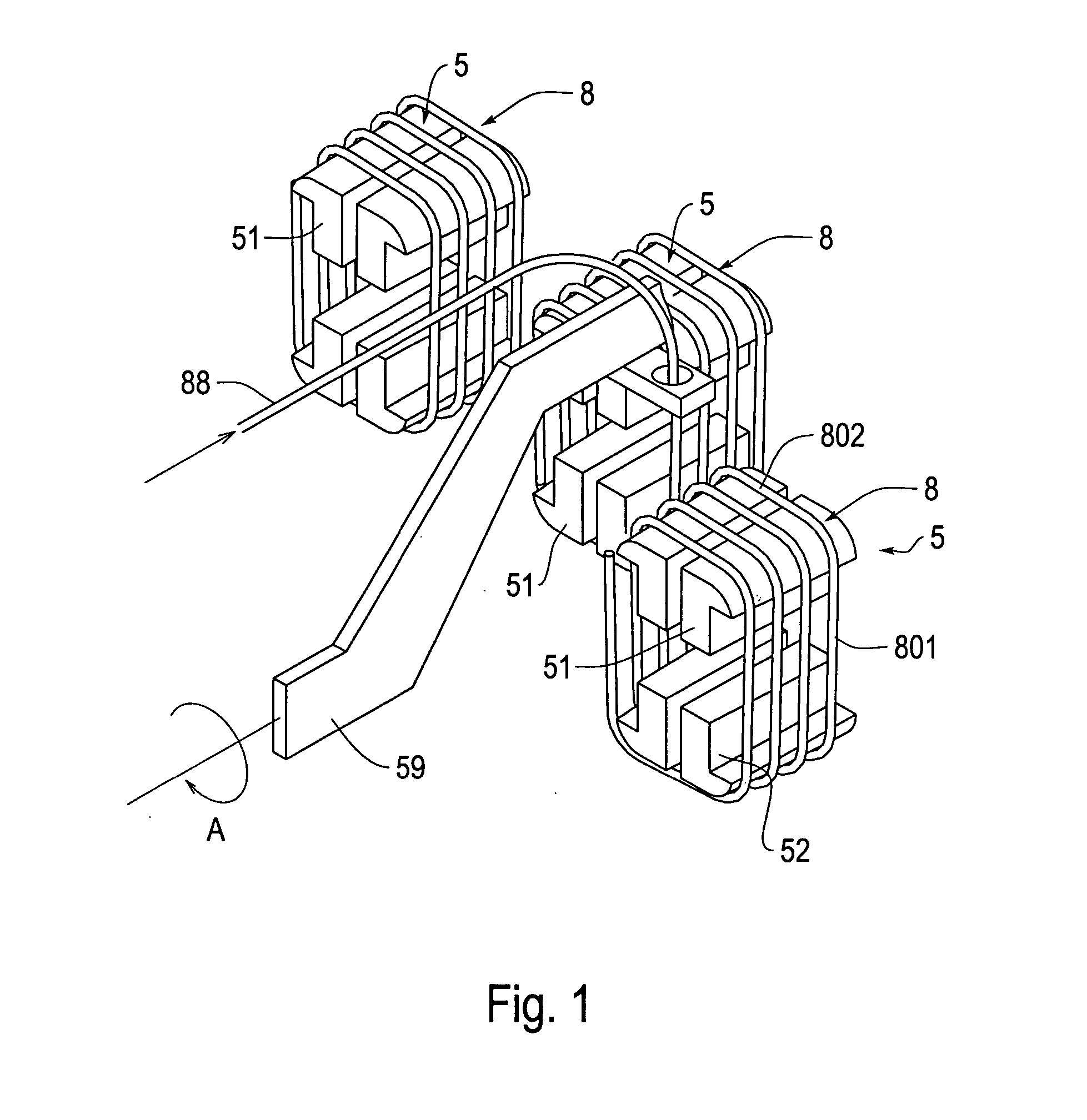

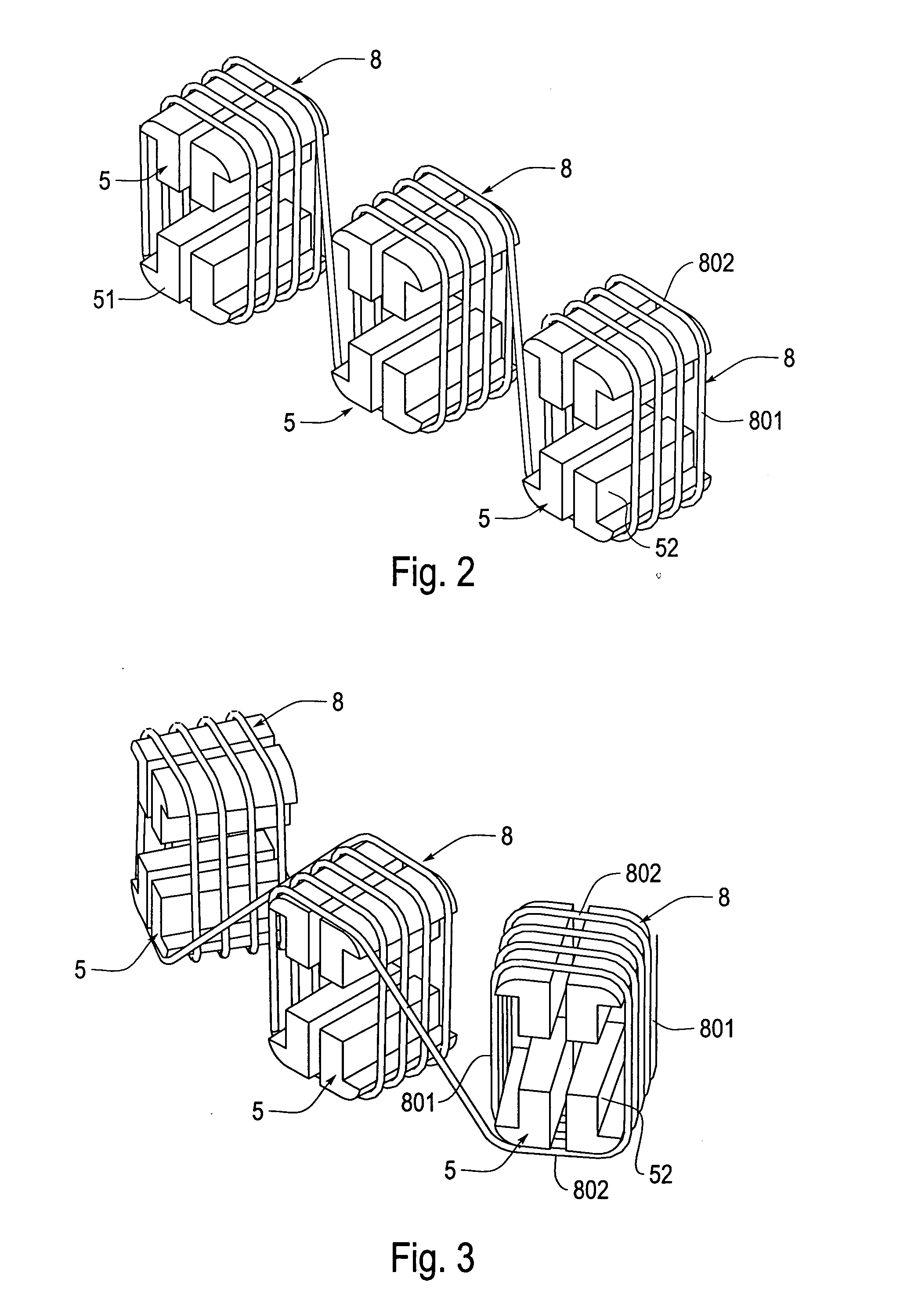

Multi-driver transducer having symmetrical magnetic circuit and symmetrical coil circuit

A multi-driver transducer having symmetrical magnetic circuits and symmetrical coil circuits, wherein one or more pieces of circular or annular partitions made of a non-magnetic material are used to bond two or more sets of dual magnetic gap and dual coil driver units (01 or 02) into one integrated magnetic core. Four or more coaxial isodiametric annular magnetic gaps are formed between the inner circumferential face or outer circumferential face of one or two tubular magnetic yokes embedded in an open-end tubular thin wall of the bracket and the vertical circumferential face of an upper pole plate and a lower pole plate of the magnetic core, four or more coaxial and isodiametric coils are inserted in the four or more coaxial and isodiametric annular magnetic gaps, and the winding direction, connection manner, and necessary technical features of the coils are governed; thus, the multi-driver transducer having one or more pairs of mutually-repelling magnets, symmetrical magnetic circuits, and symmetrical coil circuits is constituted. Back electromotive force and inductance acquired via induction by the transducer during the working process are mutually offset. The transducer has resistive load features or near-resistive load features, and has super-high sensitivity, high resolution, and high-fidelity quality.

Owner:ZHANG FAN

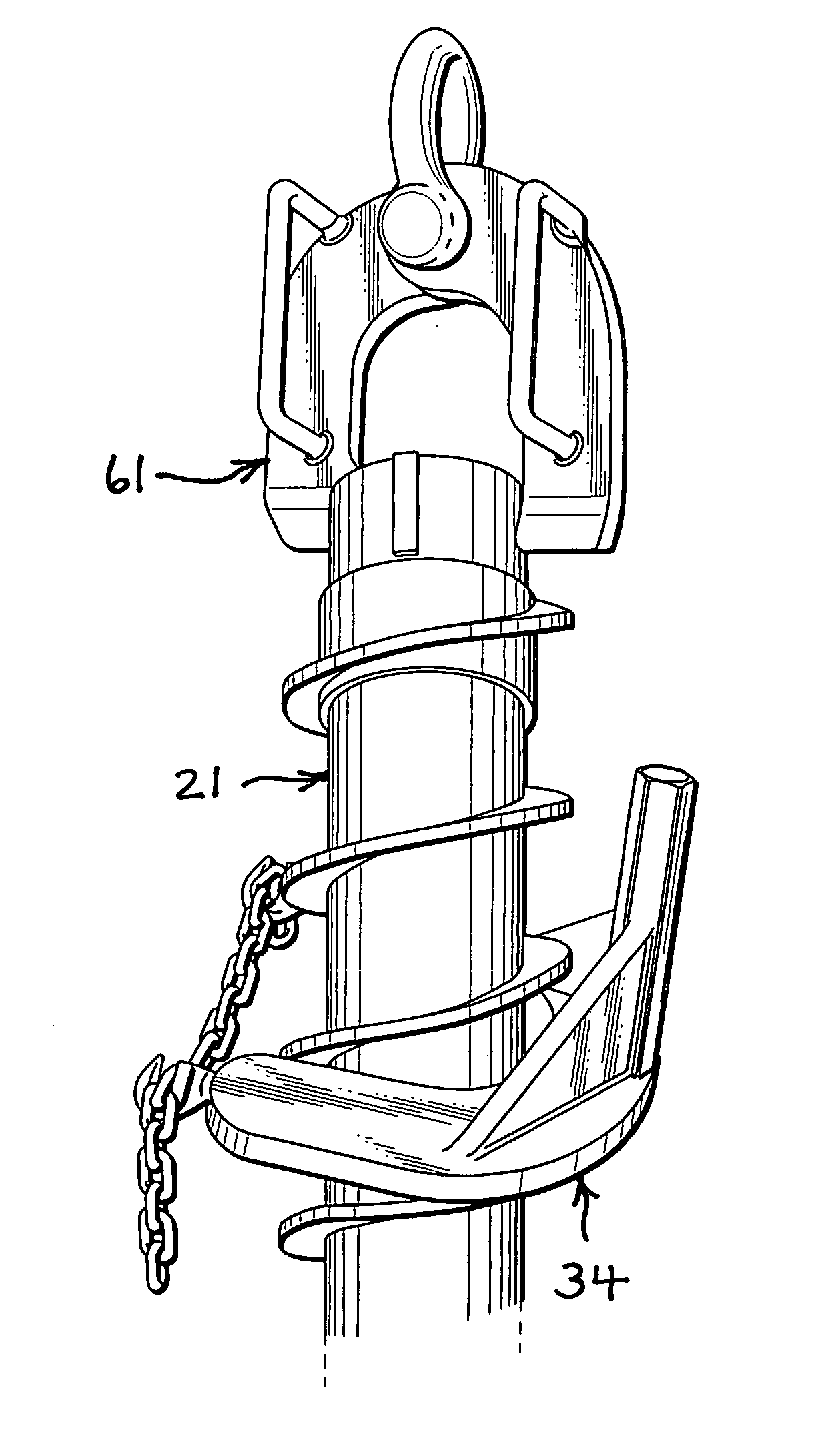

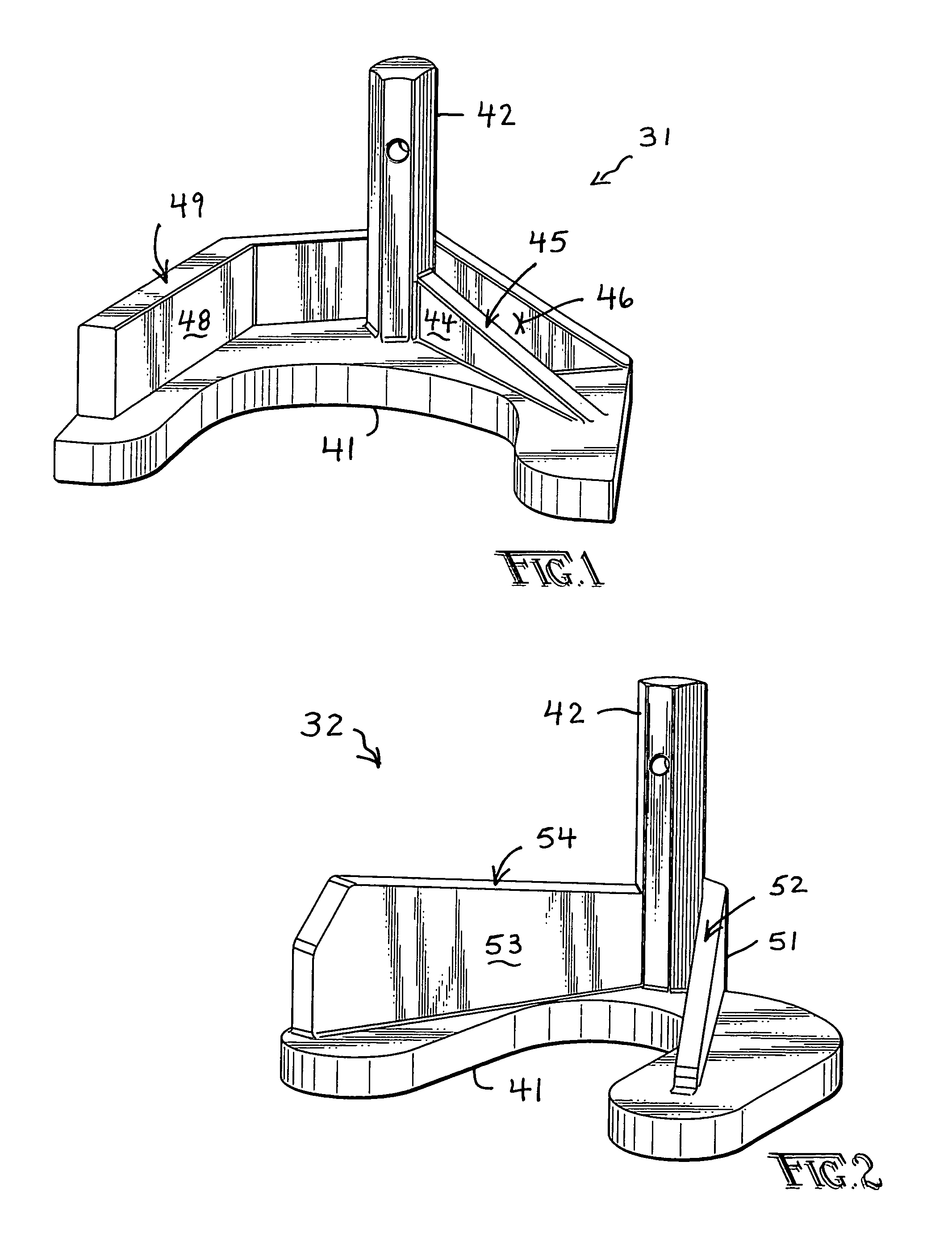

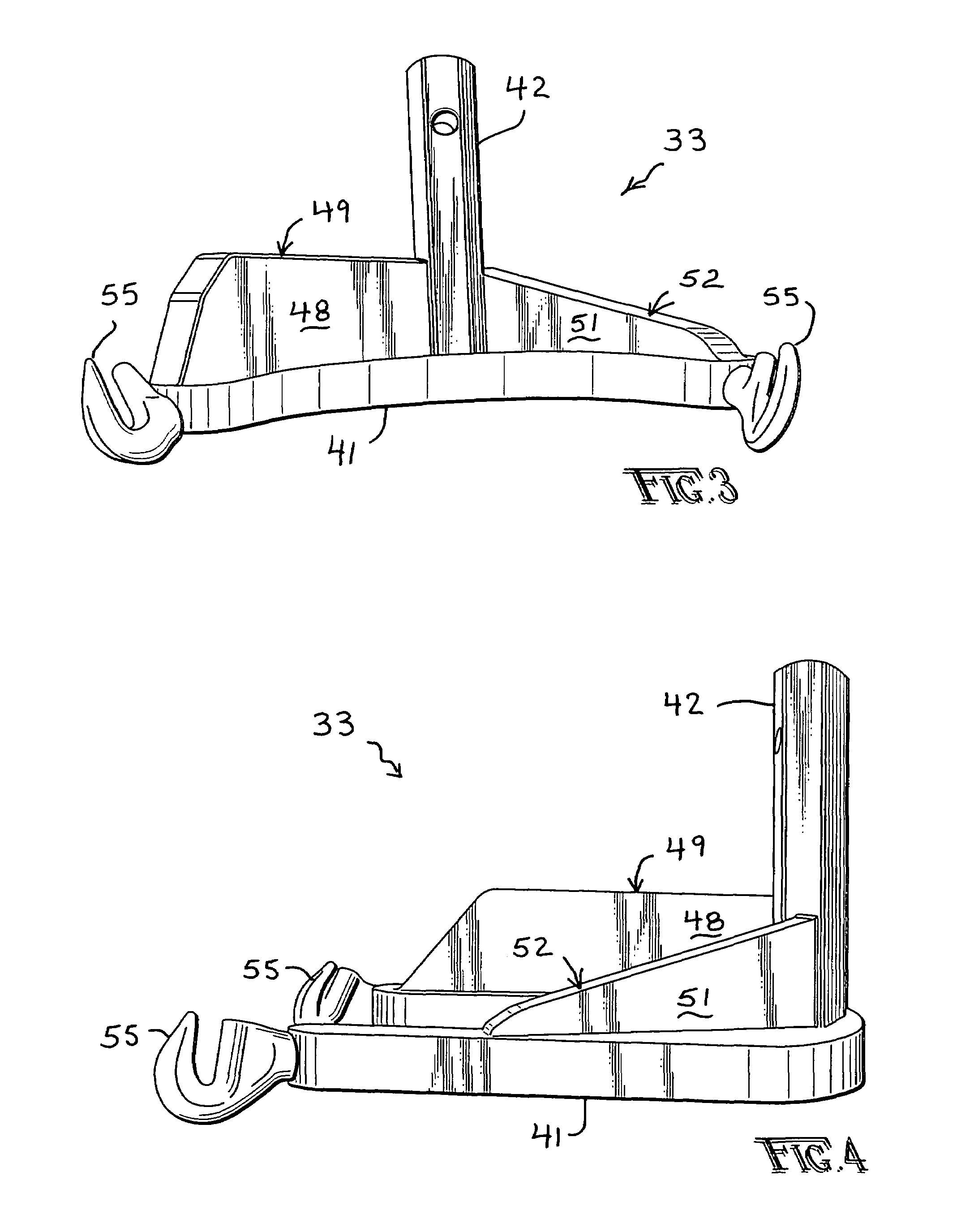

Accessories and method for hollow stem auger retraction

InactiveUS7708072B1Easy to controlDrilling rodsDrilling with mechanical conveyingHydraulic cylinderEngineering

Withdrawing a hollow stem auger string from a well includes a retractor having C-shaped inter-coil insertions and a hoist having tong-arms, one which terminates in an inwardly disposed pin. The retractor connects to a drilling rig's hydraulic cylinder vertical drive system, the hoist to a winch system thereof. The retractor engages the string by the C-shaped inter-coil insertion disposed between one coil of the helical flight of the topmost section of the string. The hoist engaged the top collar of the topmost section by the at least one pin inserting into a pin hole thereof. The string is lifted about the height of one section by the retractor, which is promptly disengaged. The topmost section is detached, and carried by the hoist to elsewhere to be dropped. The method repeats by re-engaging the retractor and hoist and then returning to the activity of lifting.

Owner:HUNZIKER DAVID G

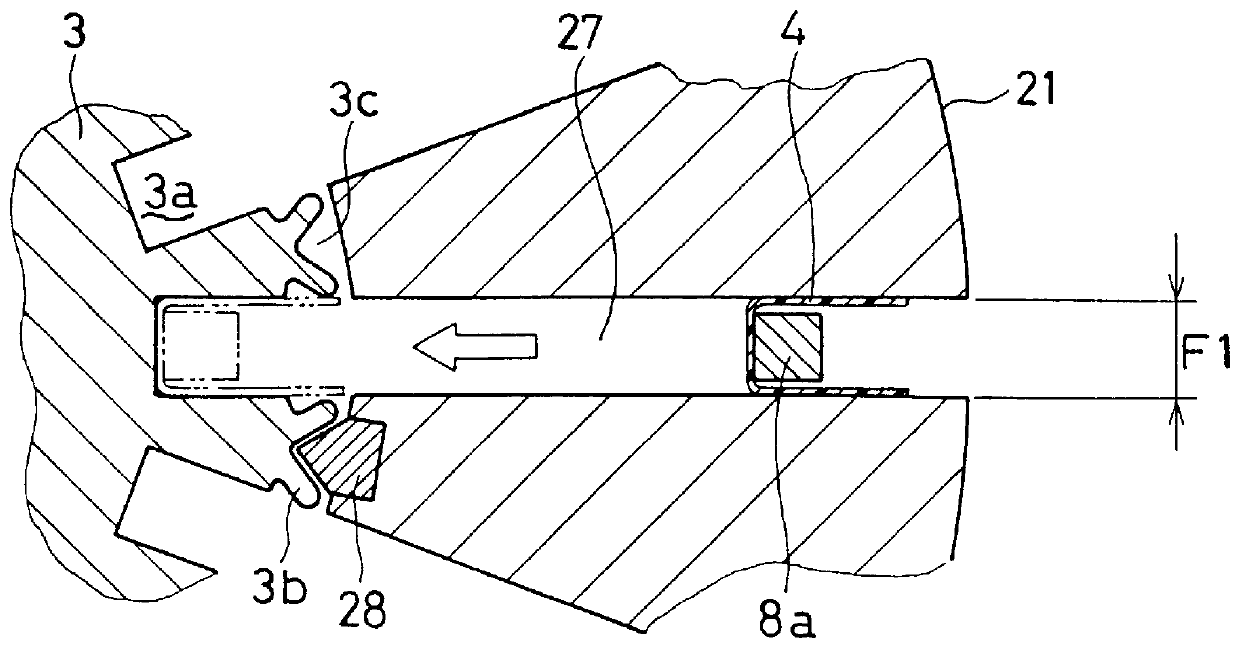

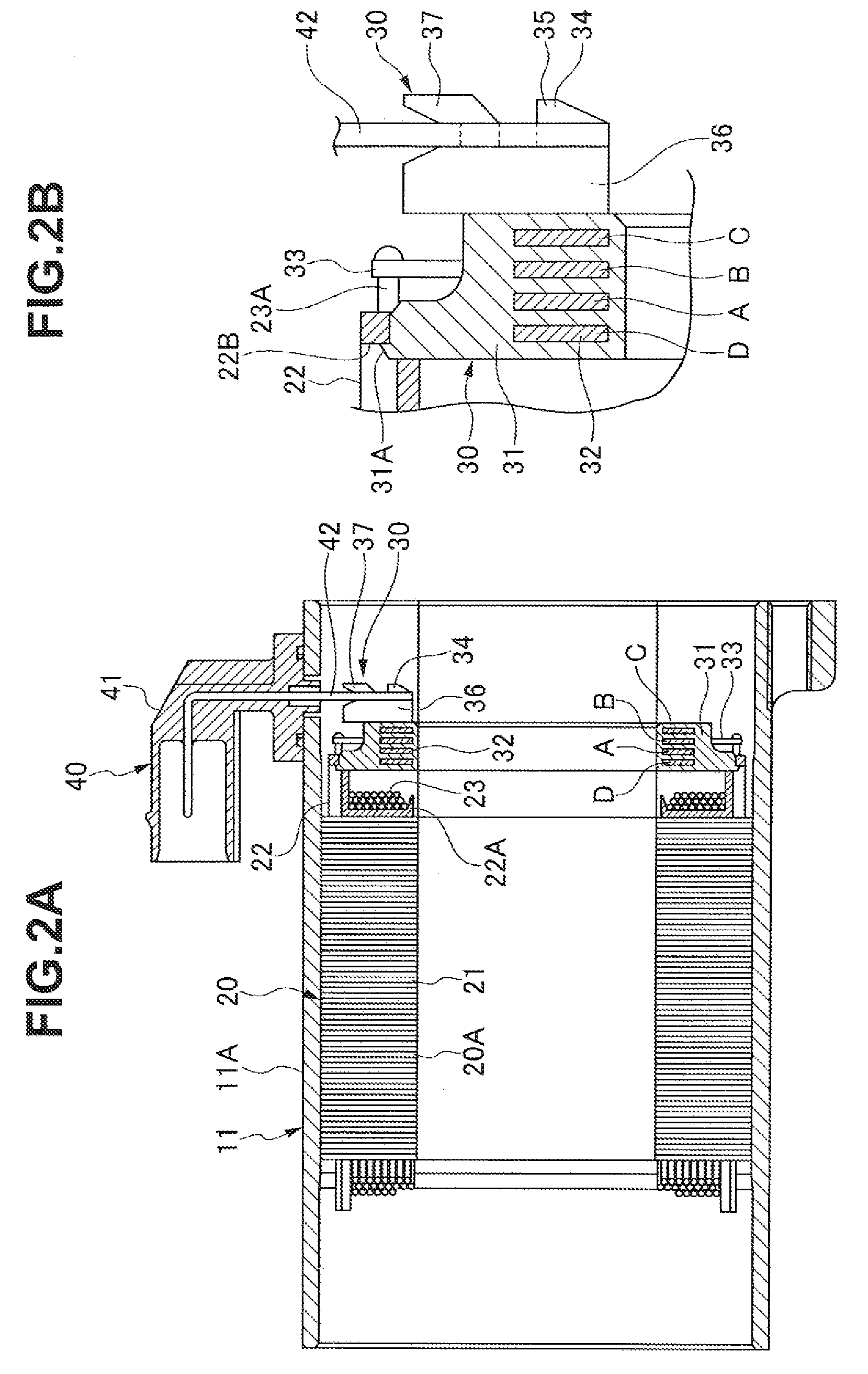

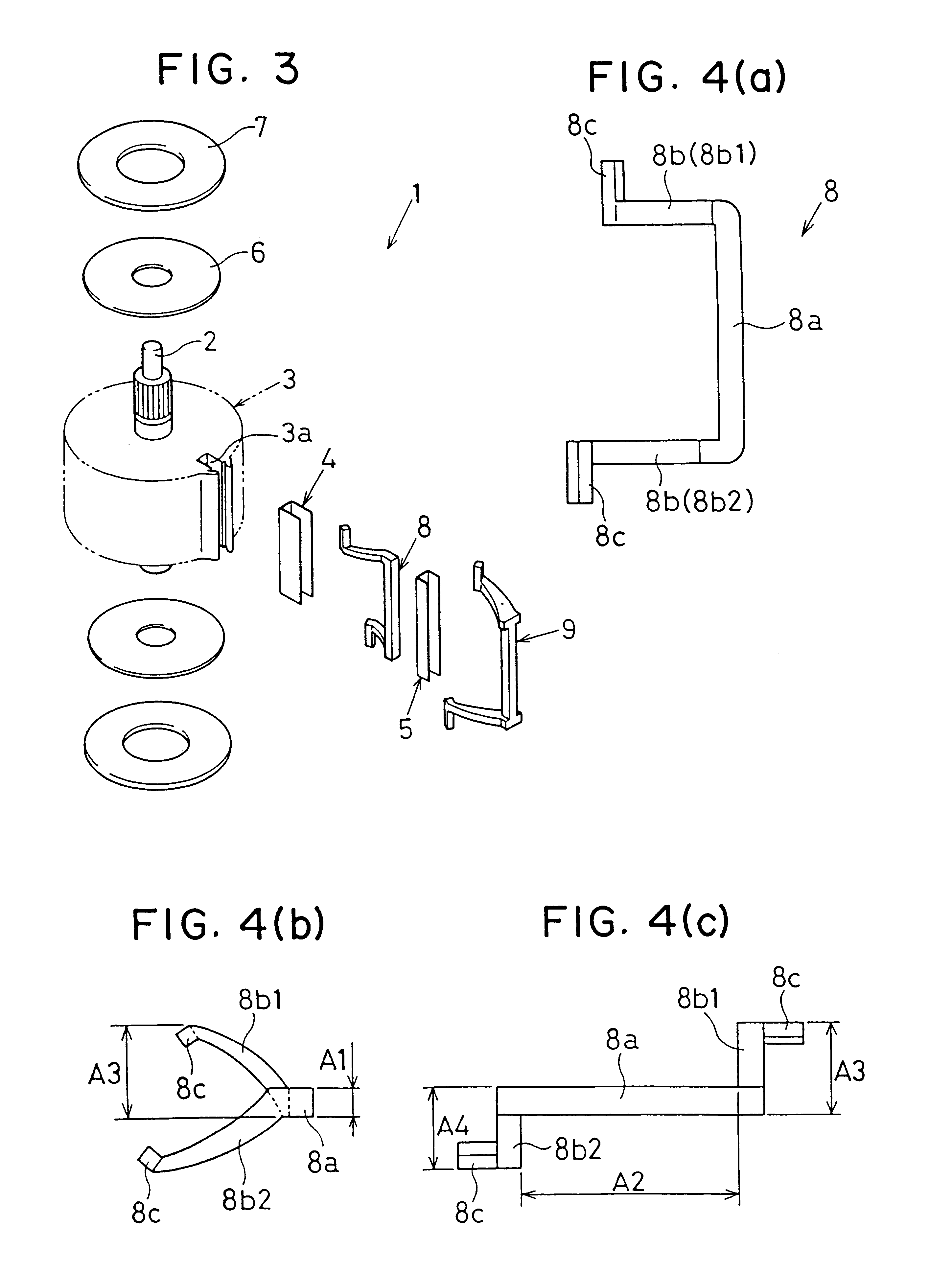

Motor manufacturing method

InactiveUS7185413B2Shorten the lengthUniform lengthManufacturing stator/rotor bodiesEmbedding prefabricated windingsCoil insertionElectric motor

A motor manufacturing method includes: a coil formation step of forming a unipolar coil, having coil inserting portions at two positions and coil end portions at two positions, in to a shape that changes such that a size in a height direction parallel to the coil inserting portion is larger in an inner peripheral side corresponding to a diametrical direction of a motor core along a direction of a winding axis center, than in an outer peripheral side; and a coil insertion step of disposing the unipolar coil in such a manner that the coil inserting portions in the unipolar coil respectively face toward inner peripheral opening portions of slots and are substantially parallel to an axial direction of the motor core, and inserting the coil inserting portions of the unipolar coil into the slots by moving the unipolar coil toward the motor core substantially linearly, while holding the motor core such that protrusion dimensions at both ends protruding from both end surface positions in an axial direction of the motor core are maintained substantially the same.

Owner:AISIN AW CO LTD

Magnetic chuck

InactiveUS20140043123A1Easy to assembleCost time be reducedElectromagnets without armaturesPermanent magnetsNon magneticCoil insertion

The present invention relates to a magnetic chuck. The present invention provides a magnetic chuck capable of attaching and processing a workpiece by magnetism, and the magnetic chuck comprises: a small-sized magnetic member which includes a magnetic substance having magnetic properties, and panel units that are respectively positioned on both sides of said magnetic substance through heat treatment and in which non-magnetic panels are inserted between a plurality of magnetic panels; a sidewall unit which has accommodation grooves by positioning respectively a first sidewall and a second sidewall on both sides of said small-sized magnetic member; coupling members which are coupled by penetrating said small-sized magnetic member and the sidewall unit; alnico magnets which are inserted into said accommodation grooves; coils which are inserted into said accommodation grooves, and enclose the alnico magnets; fillings which mutually couple said alnico magnets and said coils, and are filled in the accommodation grooves such that one side of the alnico magnets is exposed; and a first insulator which is equipped on one side of said first sidewall to allow magnetism, which flows into the first sidewall, to flow in another direction.

Owner:JIN YOUNG PRECISION MACHINE

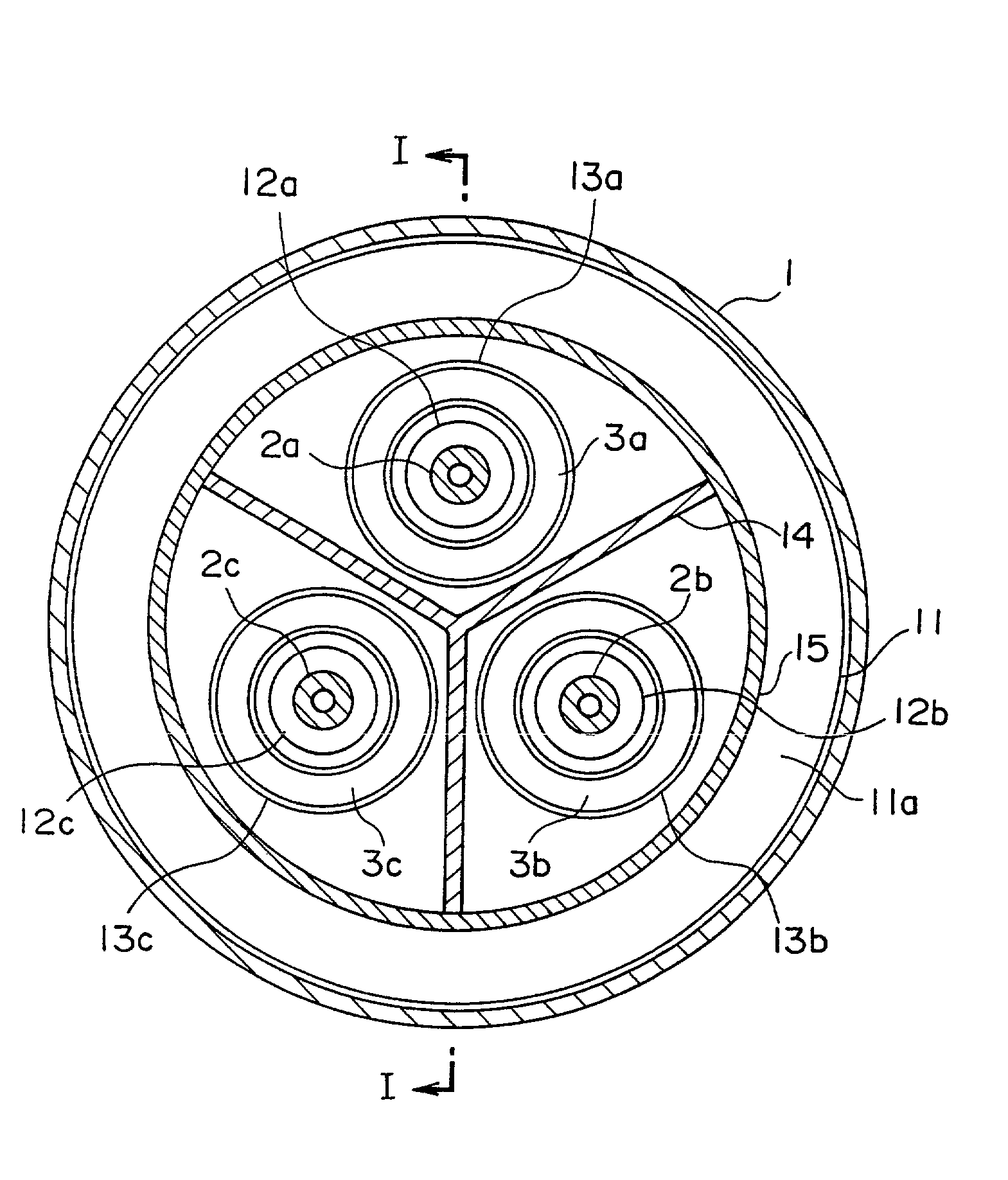

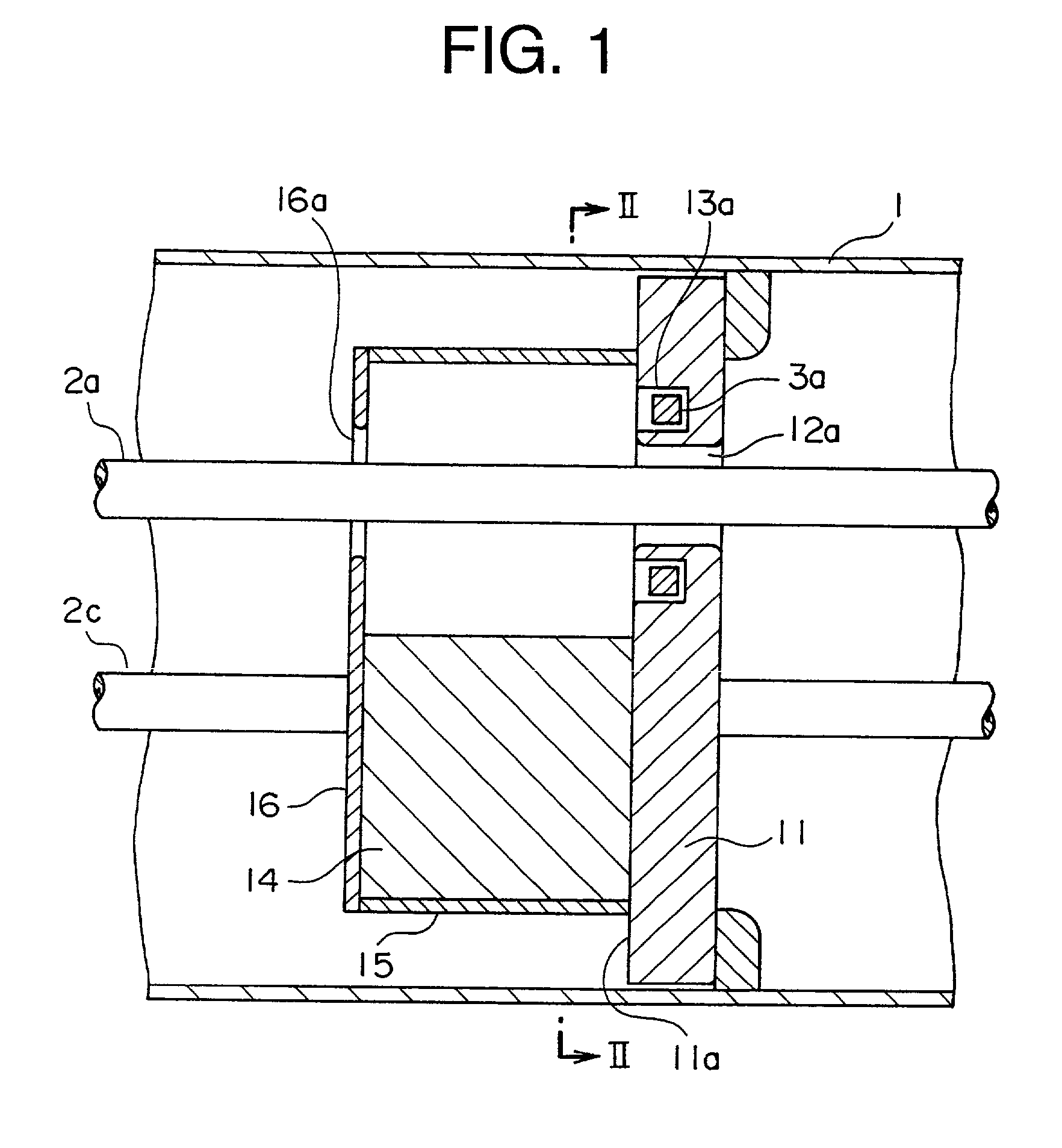

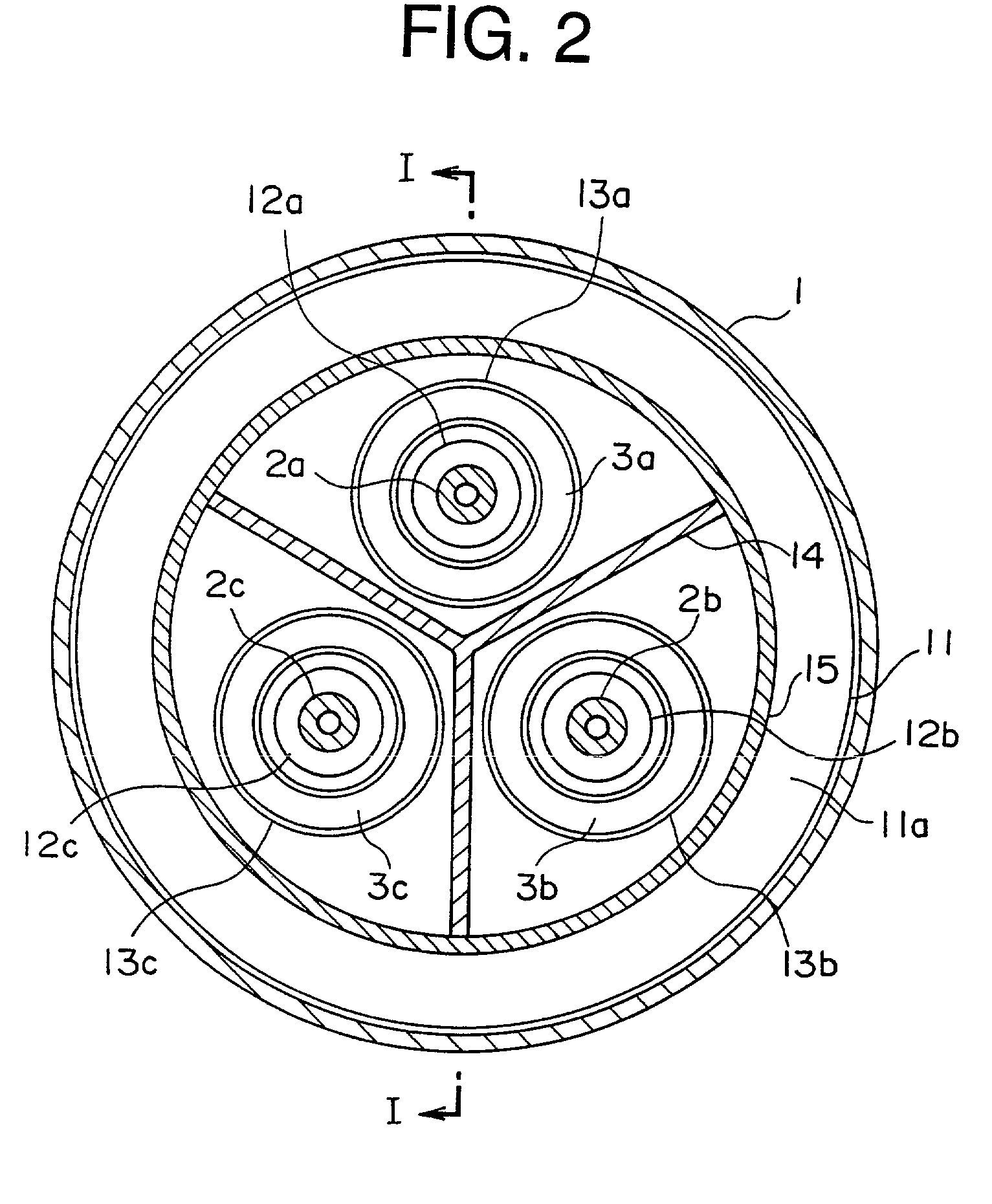

Three-phase current transformer

InactiveUS20020125978A1Simple structureTransformers/inductances coils/windings/connectionsTotally enclosed bus-bar installationsThree-phaseMagnetic shield

In a three-phase package type current transformer, first to third coil insertion slots are formed in a plate-like metal adaptor that serves as a magnetic shield. First to third Rogowskii coils are arranged in the first to third coil insertion slots. The metal adaptor is fixed with a phase-to-phase magnetic shield and an outer peripheral magnetic shield. An end magnetic shield is fixed to an end portion of the phase-to-phase magnetic shield.

Owner:MITSUBISHI ELECTRIC CORP

Motor manufacturing method

InactiveUS20050005422A1Reduce motor sizeReduce axial sizeEmbedding prefabricated windingsMetal working apparatusEngineeringMechanical engineering

A plurality of single-pole coils are retained by a coil retaining device, the single-pole coils are arranged such that the coil insertion portions of each single-pole coil confront the inner circumference openings of the slots and may be generally parallel to the axial direction of the motor core, each single-pole coil is moved linearly toward the motor core such that the coil retaining device and the moving locus before the adjoining coil insertion portions in the adjoining single-pole coils are inserted into the slots are parallel or approach the more from the inner circumference side to the outer circumference side and the two coil insertion portions of each single-pole coil are moved such that they may start their movements simultaneously and at equal velocities.

Owner:AISIN AW CO LTD

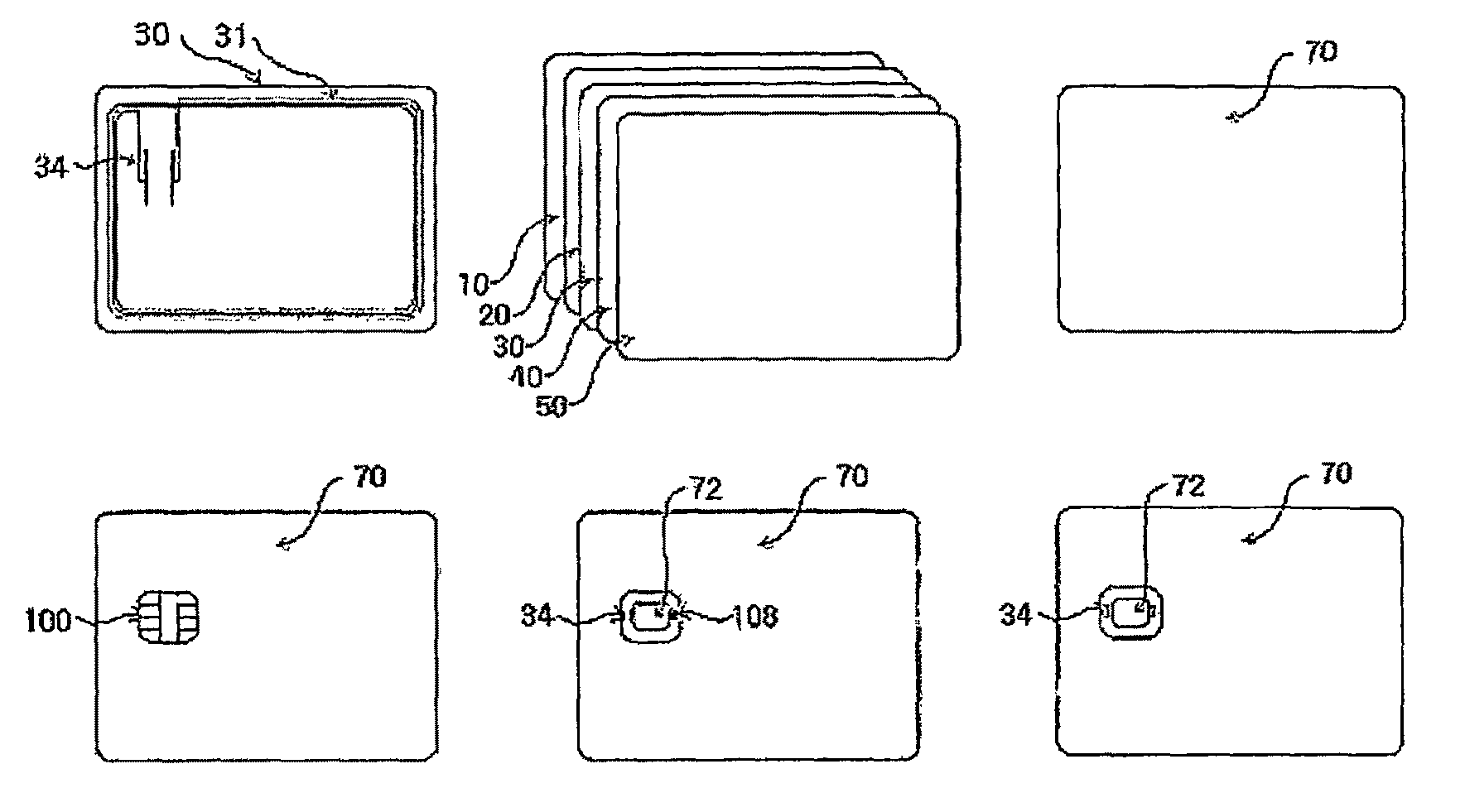

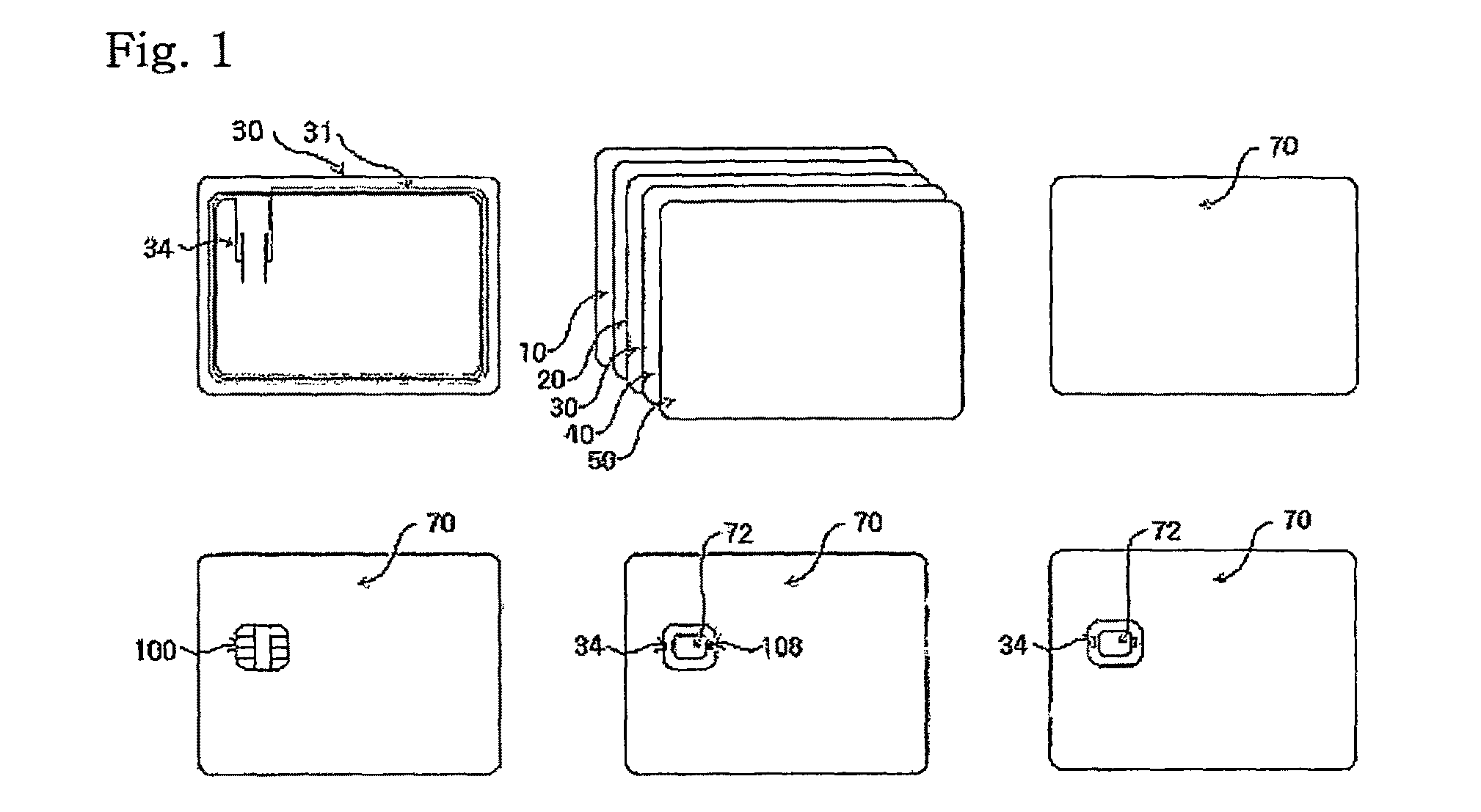

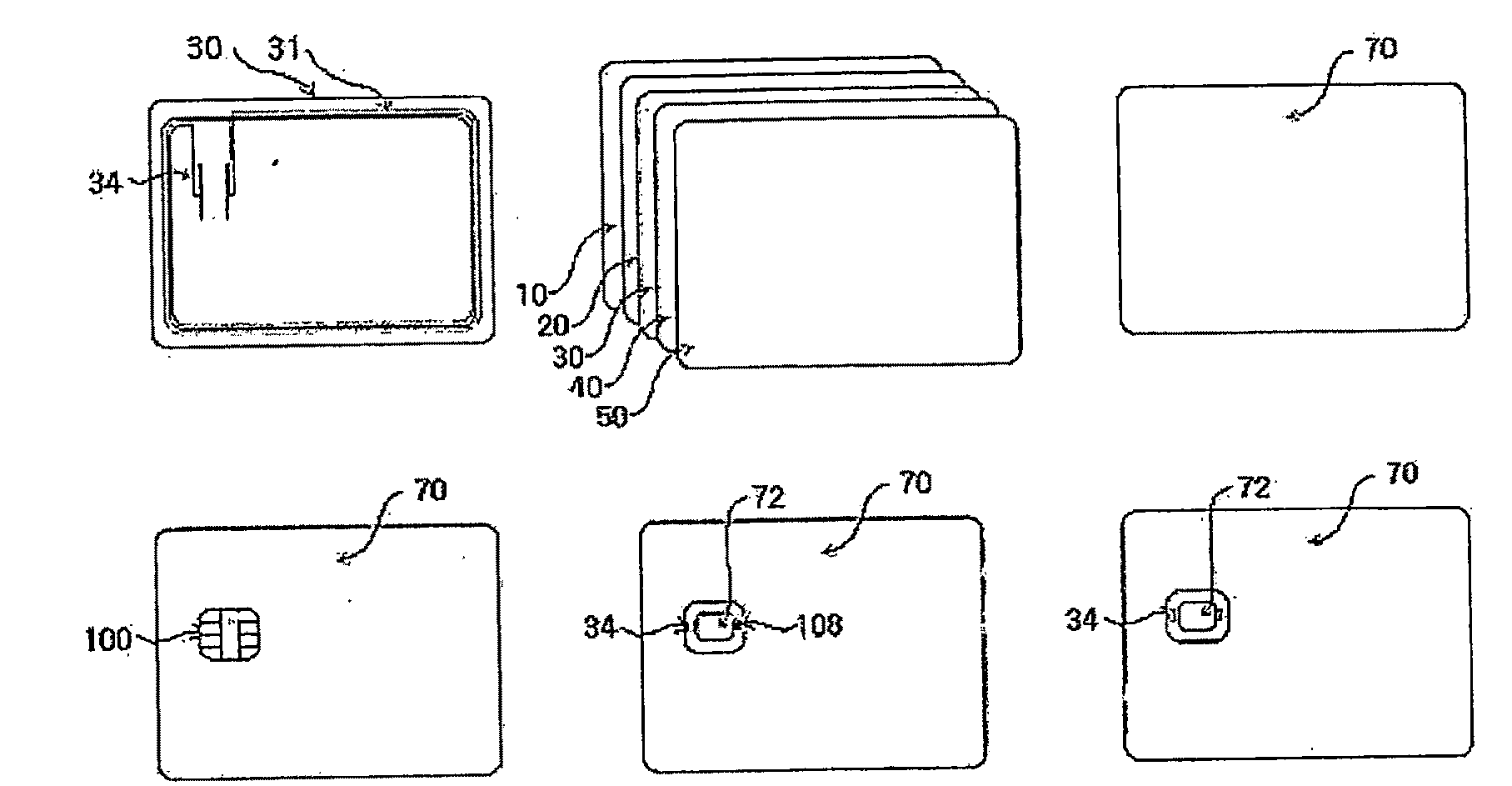

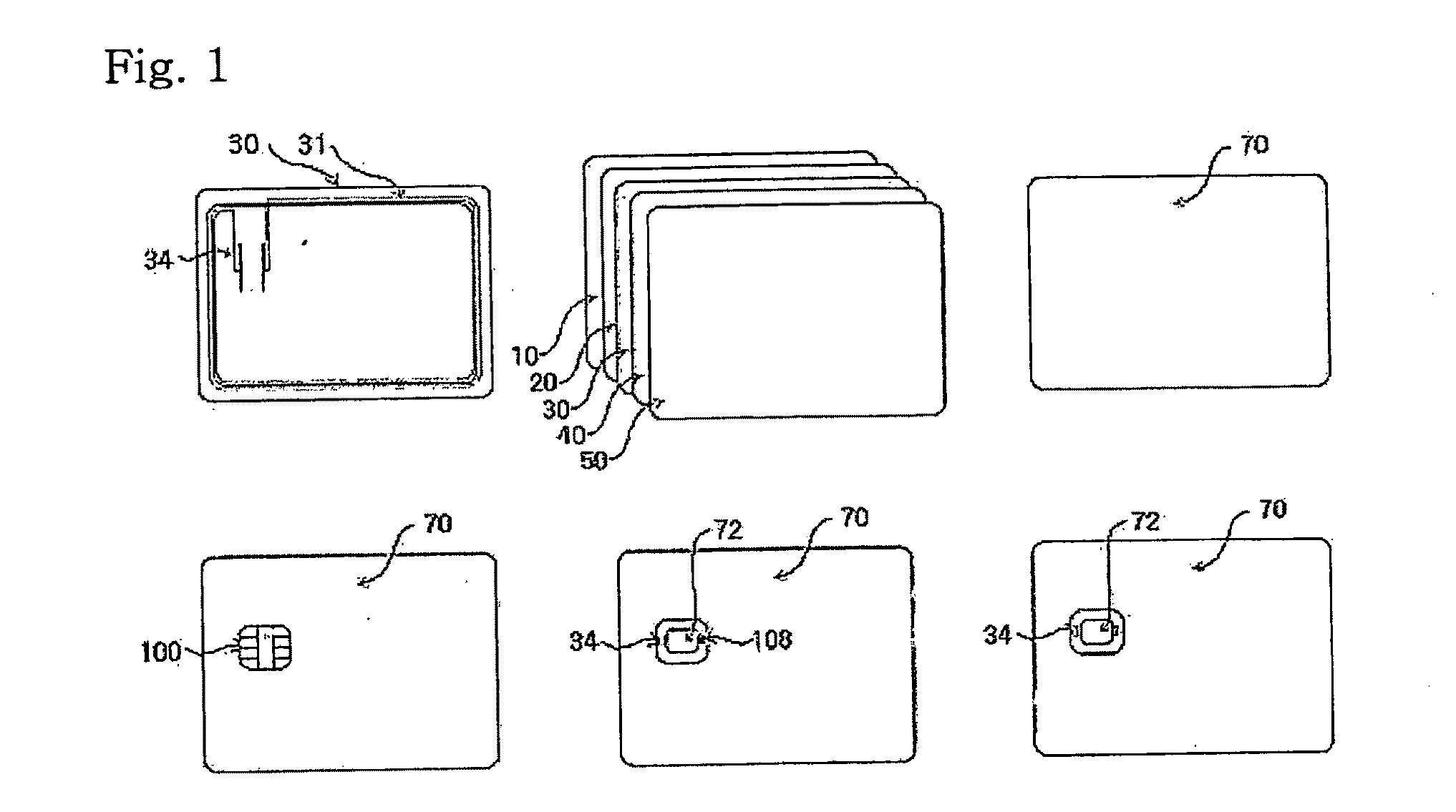

Combi-card and method for making the same

InactiveUS8181880B2Reduce conductivityImprove adhesion strengthSemiconductor/solid-state device manufacturingRecord carriers used with machinesFiberTectorial membrane

The present invention relates to a combi-card which can be used in a contact-type or noncontact-type fashion and a method for manufacturing the same. More particularly, this invention relates to a combi-card and a method for making the same, in which an inlay layer on which an antenna terminal made of a coil or conductive fiber is formed and a COB (chip on board) on which ACF (anisotropic conductor film) is applied, are pre-treated by a heating head and the like, the COB is attached to an antenna coil insertion layer, and an upper printing sheet with a protection film, and a lower printing sheet with a protection film, which are cut out to be suitable for the COB shape, are stacked to construct a combi-card.

Owner:KOREA MINTING SECURITY PRINTING & ID CARD OPERATING CORP

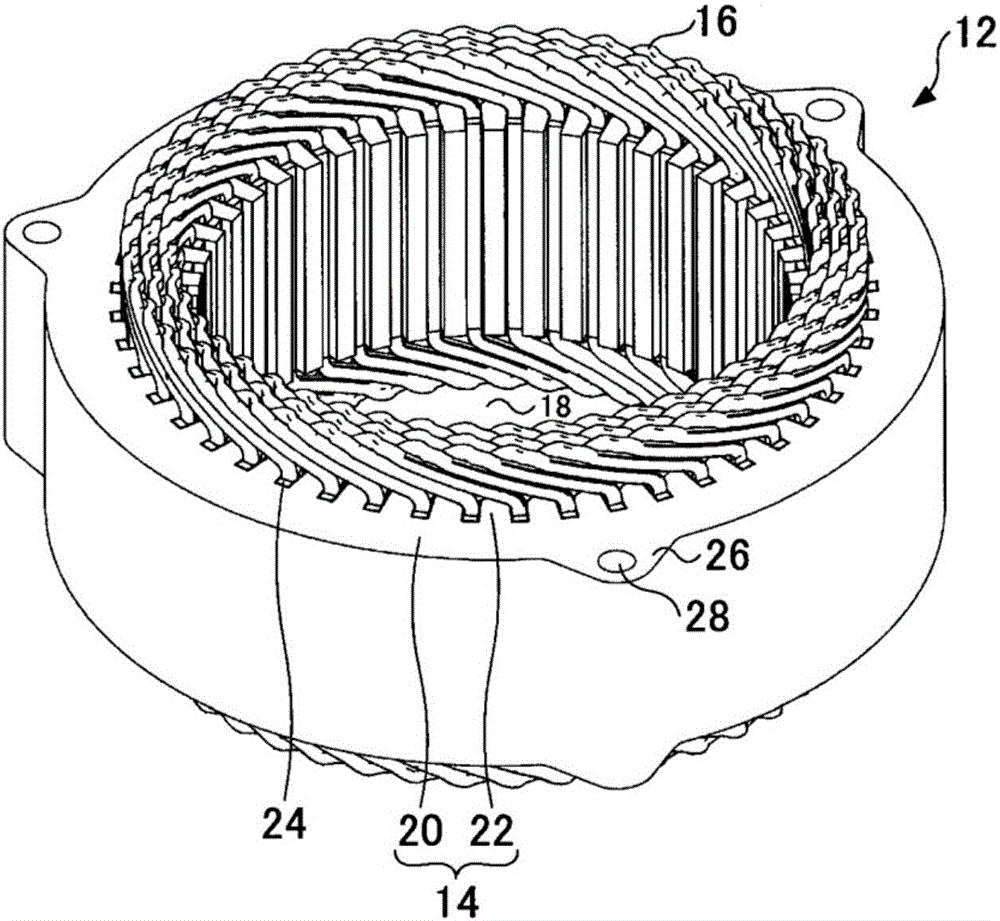

Stator of rotating electrical machine, method of manufacturing same, and apparatus for manufacturing same

InactiveCN103460561AReliable configurationWindings insulation shape/form/constructionEmbedding prefabricated windingsCoil insertionPaper cut

Owner:TOYOTA JIDOSHA KK

Coil insertion method and coil insertion device

ActiveCN102170202AReduce the overall heightReduced insertion resistanceEmbedding prefabricated windingsEngineeringCoil insertion

The invention relates to a coil insertion method and a coil insertion device. In the process of embedding a polyphase coil in a stator core groove and under the state that a coil curve part protrudes from the stator core top end, the curve part is expanded towards the direction deviating a stator core axle center, and the coil at the lower part and the coil at the upper part do not conflict with each other. The coil insertion device is provided with a coil end expansion means implementing the above method. Even when a polyphase coil is inserted, a coil insertion method and a coil insertion device which can reduce the height of the coil at the end part which protruding from the stator core end face.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

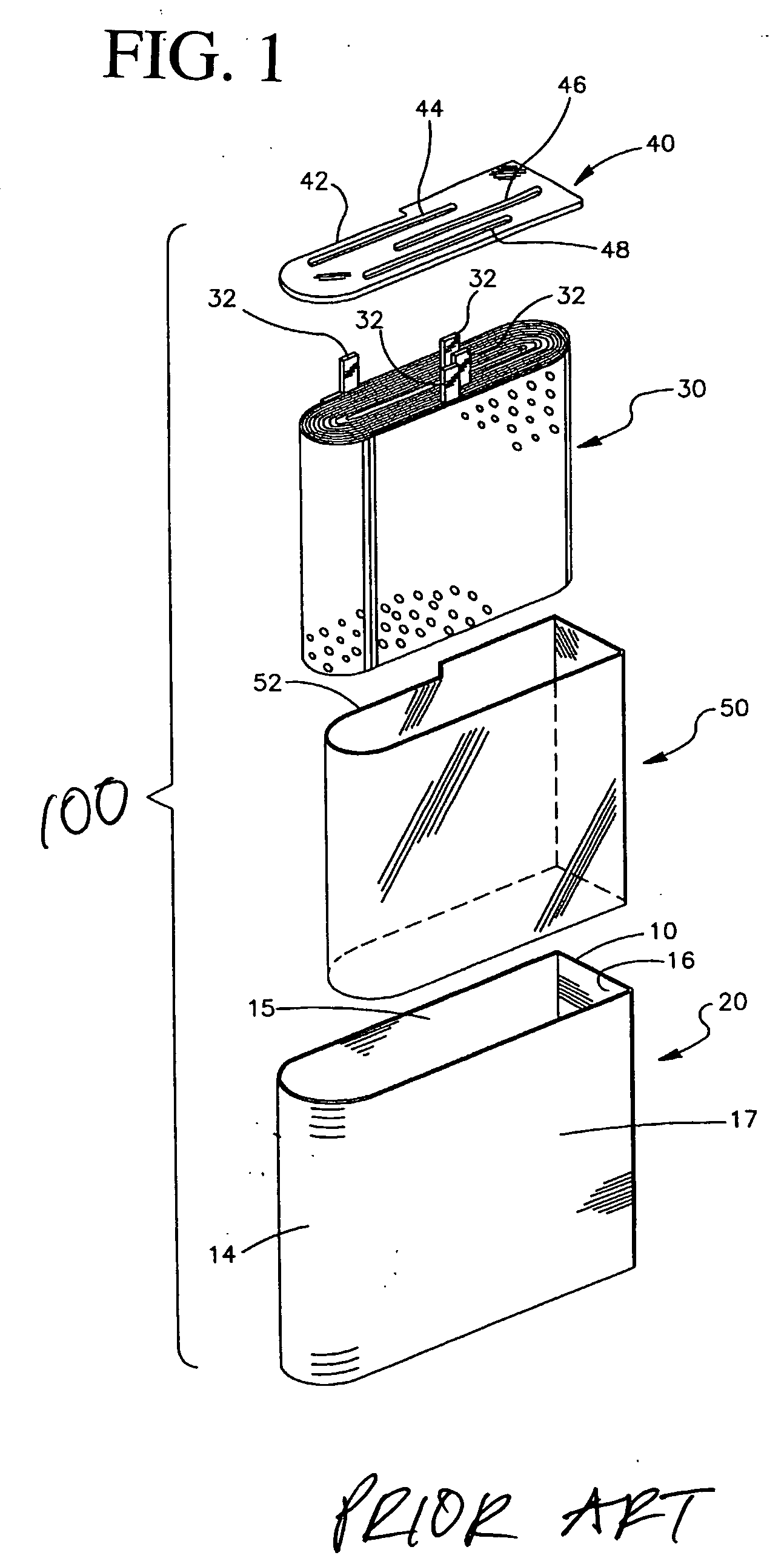

Hinged electrode cup and methods of fabrication for medical grade electrochemical cells

InactiveUS20060222939A1Enhances electrode coil insertionReduce the possibility of damageElectrotherapyCell seperators/membranes/diaphragms/spacersElectrode insertionLinearity

According to the present invention an improved insulator cup, or case liner, enhances electrode coil insertion by reducing the possibility of damage to the coil during insertion, protects electrode and separator from laser radiation during welding, and eases manual inspection of partially assembled components, among other advantages. The improved insulator cup includes a mechanical joint, or hinge-like feature, which pivotably couples opposing parts of the cup and greatly enhances coiled electrode insertion and subsequent component inspection prior to sealing a cover member over an electrode assembly disposed within a housing. The mechanical joint can comprise additional parts that adhere to a divided insulator cup or can be formed as an integral part of an insulator cup (e.g., a linear area of reduced thickness, of apertures, and / or perforations, etc.).

Owner:MEDTRONIC INC

Combi-Card and Method for Making the Same

InactiveUS20090200382A1Reduce electrical conductivityImprove adhesion strengthSemiconductor/solid-state device manufacturingRecord carriers used with machinesFiberTectorial membrane

The present invention relates to a combi-card which can be used in a contact-type or noncontact-type fashion and a method for manufacturing the same. More particularly, this invention relates to a combi-card and a method for making the same, in which an inlay layer on which an antenna terminal made of a coil or conductive fiber is formed and a COB (chip on board) on which ACF (anisotropic conductor film) is applied, are pre-treated by a heating head and the like, the COB is attached to an antenna coil insertion layer, and an upper printing sheet with a protection film, and a lower printing sheet with a protection film, which are cut out to be suitable for the COB shape, are stacked to construct a combi-card.

Owner:KOREA MINTING SECURITY PRINTING & ID CARD OPERATING CORP

Coil inserting method and coil inserting device

InactiveCN101453149AAvoid damageChange distanceEmbedding prefabricated windingsApplying solid insulationEngineeringCoil insertion

The present invention is to reduce interference of a slot wedge guide member and coils configured for guide the slot wedge inserted together when winding coils are inserted into stator core of a motor, and to reduce damage along the coils inserted together even for coils with short perimeter. According to the invention, processes of enlarging distance between the slot wedge guide member to the coils insertion end of the core are added after a part of normal coils insertion processes, then process of inserting coils is continue in condition that the coils insertion end of the core move away from the slot wedge guide member.

Owner:MITSUBISHI ELECTRIC CORP

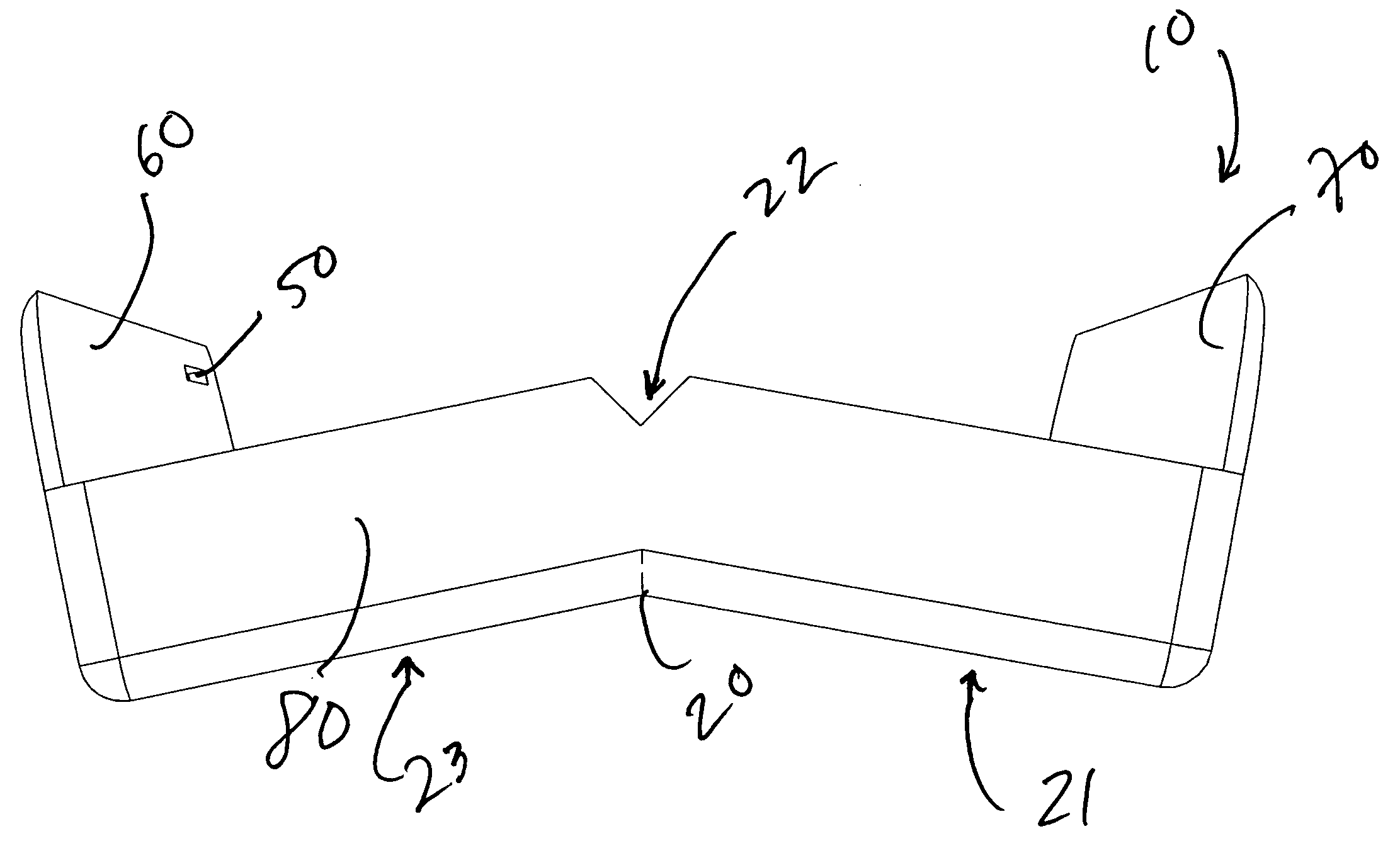

Bus bar of motor and bus bar housing

ActiveUS20130328426A1Improve productivityEasy connection workWindings conductor shape/form/constructionMechanical engineeringCoil insertion

Disclosed is a bus bar having a plurality of connection taps formed radially therefrom, the bus bar including: first, second and third faces extended sequentially from the end of each connection tap in such a manner as to have a U-like side shape; and a coil insertion portion having a groove formed in a length direction of each connection tap on the center portions of the first, second and third faces and having a thickness lower than the thicknesses of the first, second and third faces, the coil insertion portion having a coil inserted into the groove thereof.

Owner:NEW MOTECH

Exciter for directly vibrating board

ActiveUS7030522B2Sufficient rotation torqueSufficient fastening torqueMechanical energy handlingPlane diaphragmsCoil insertionMental detachment

Owner:FUJITSU GENERAL LTD

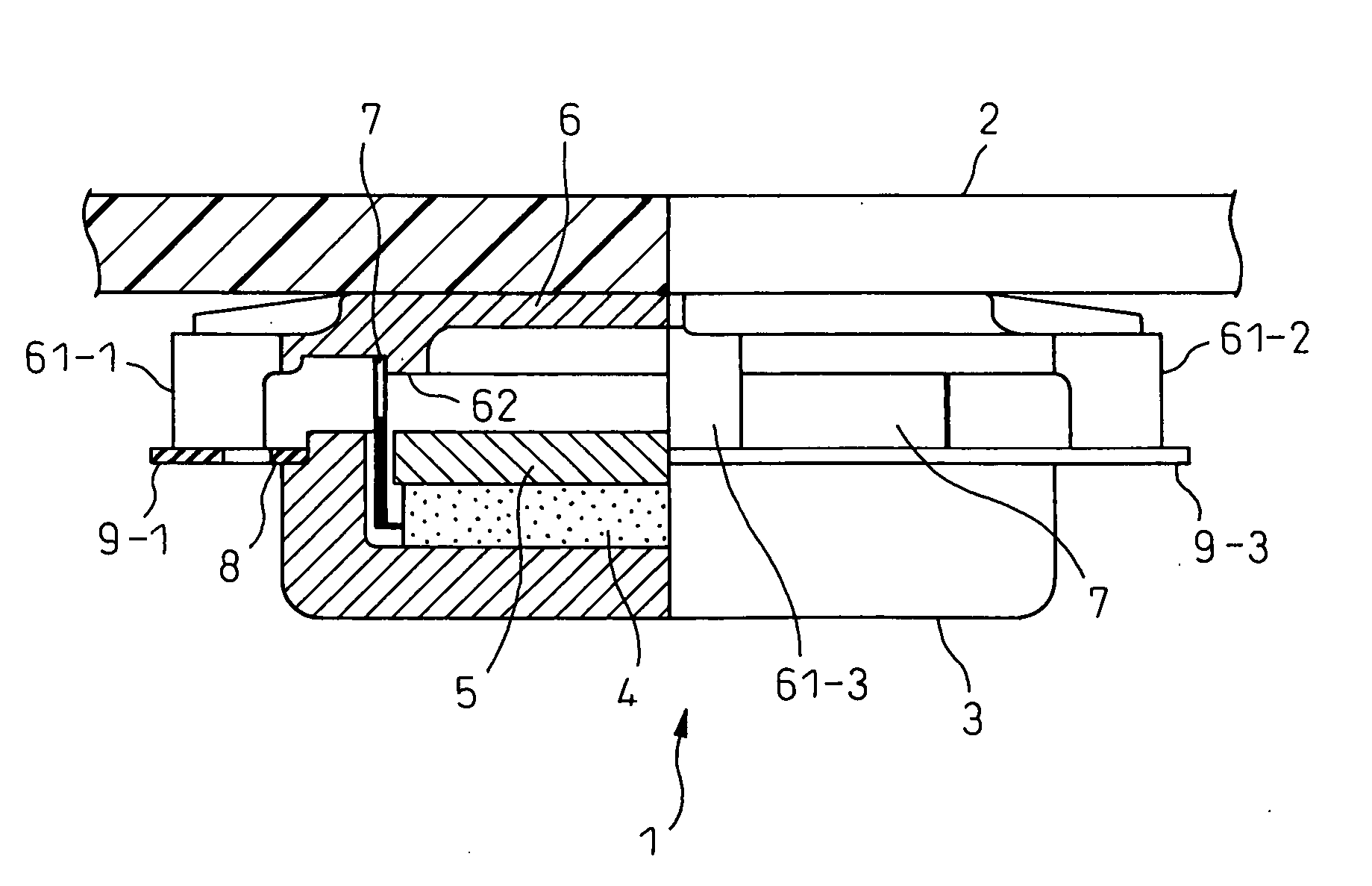

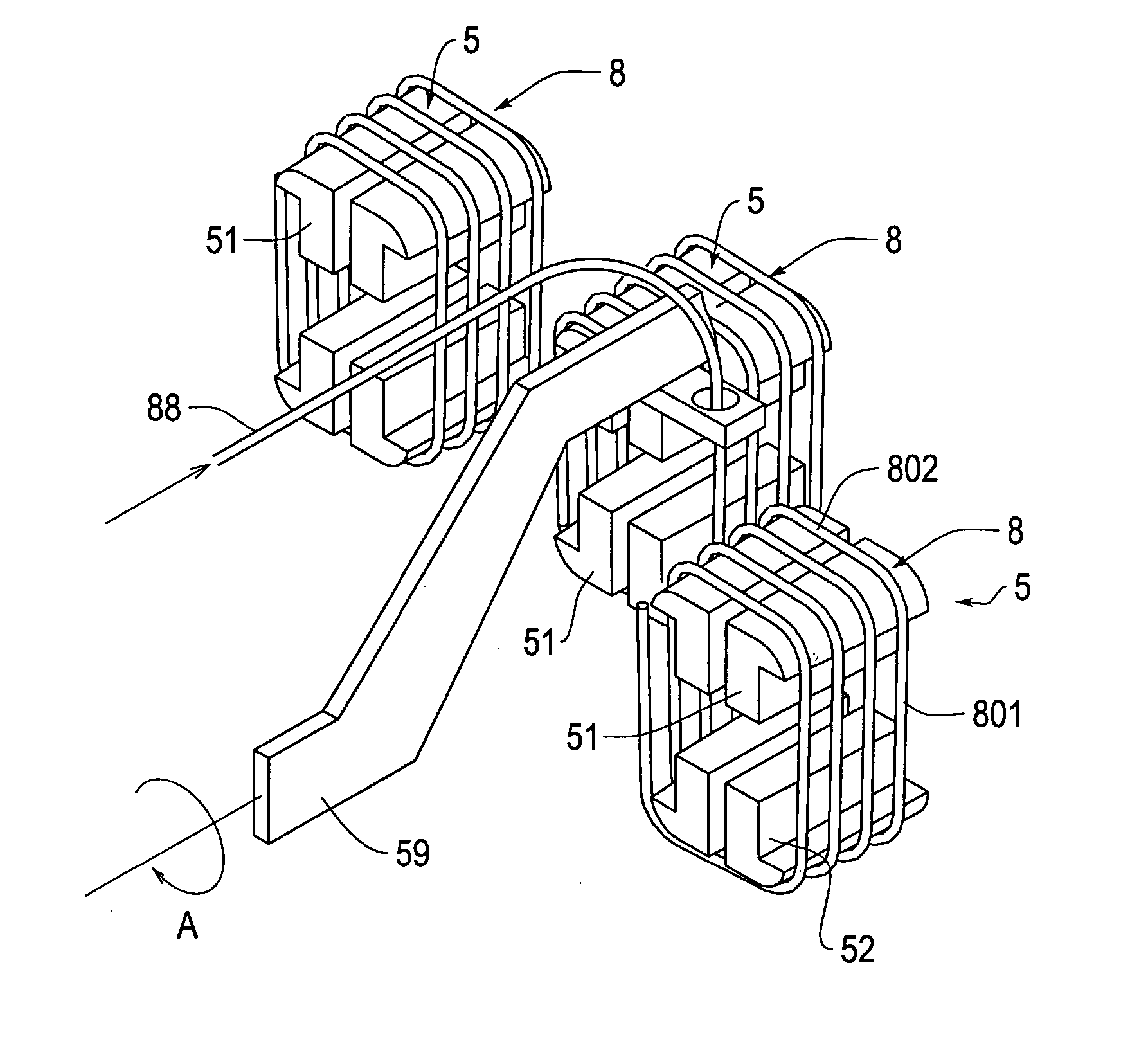

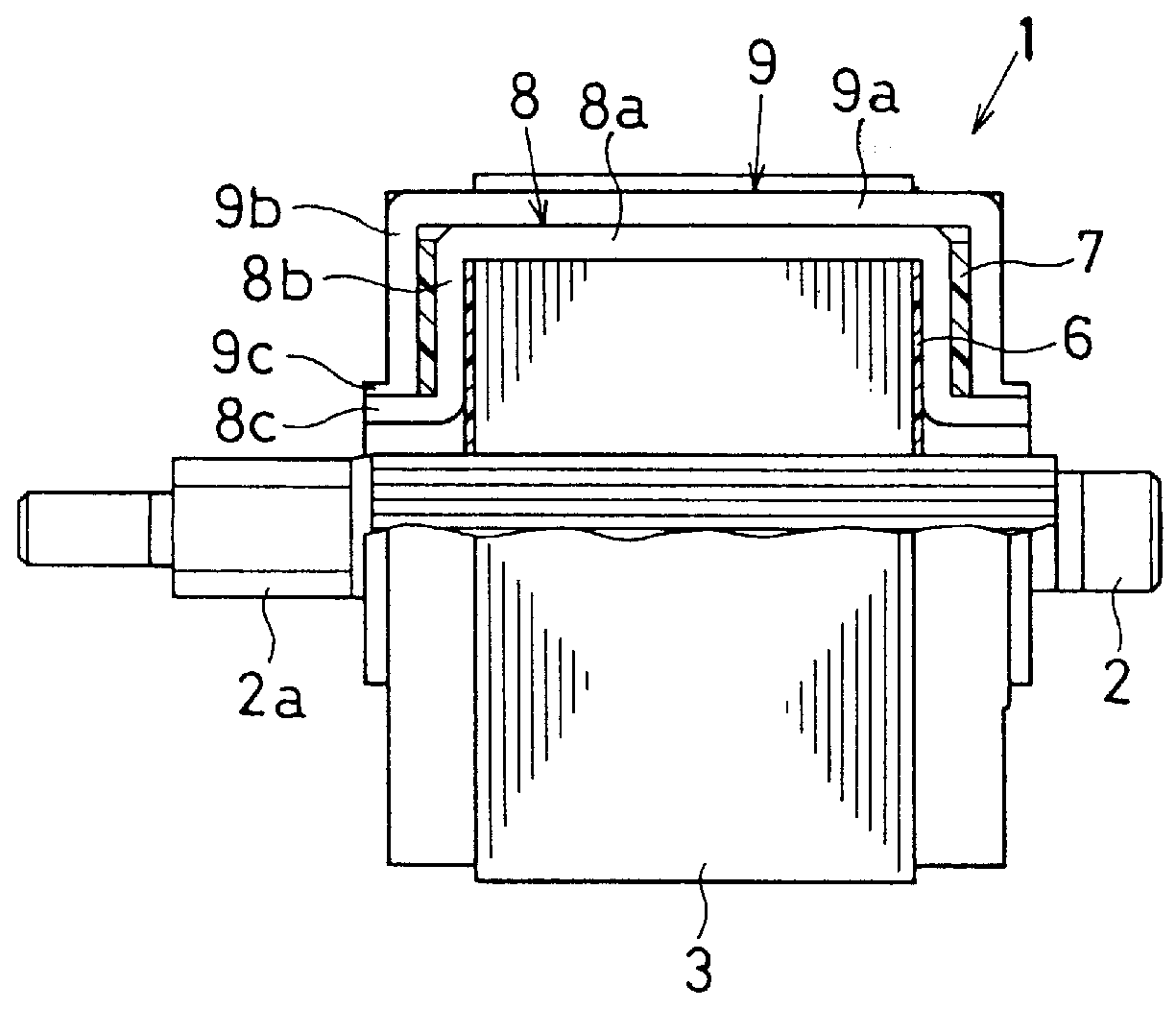

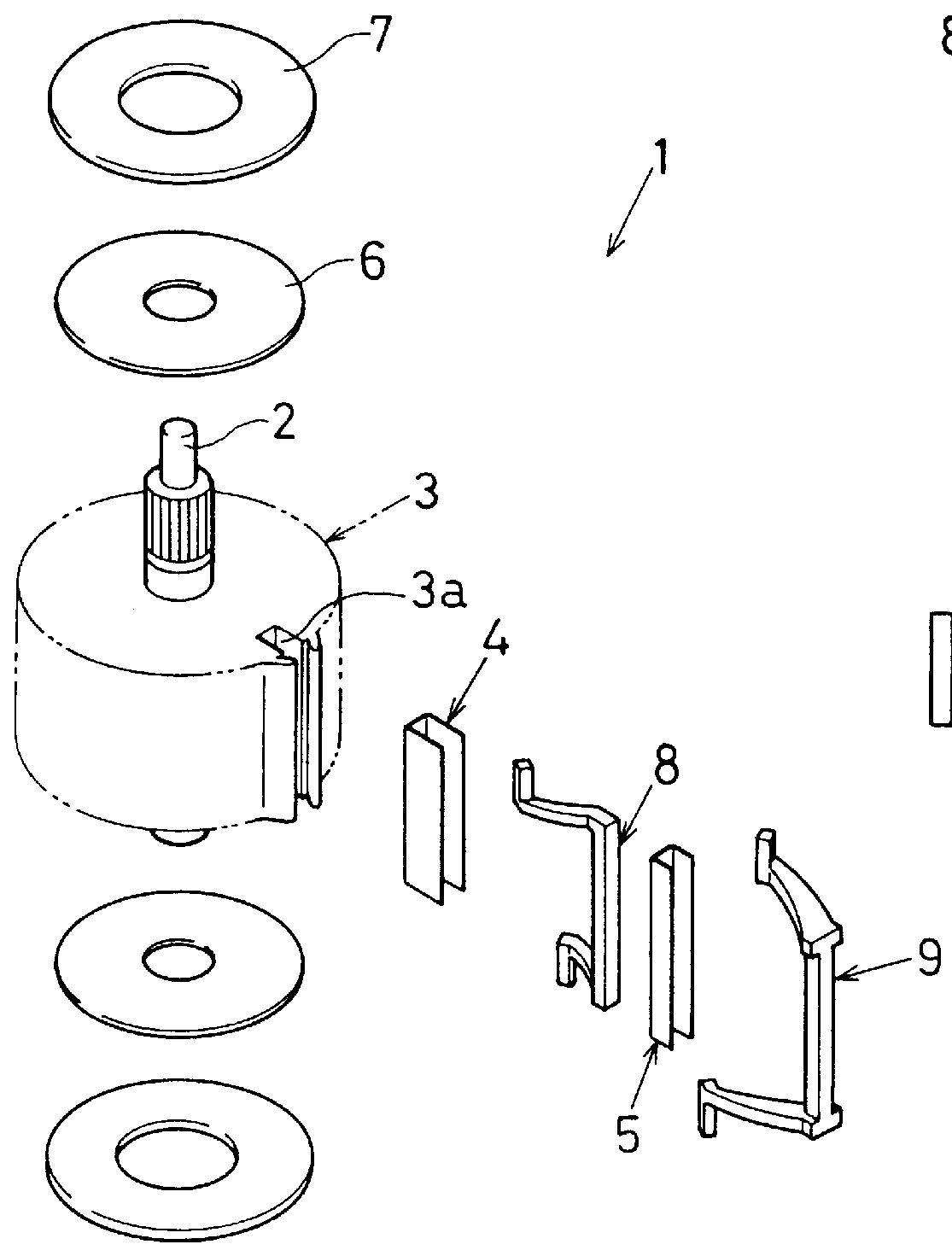

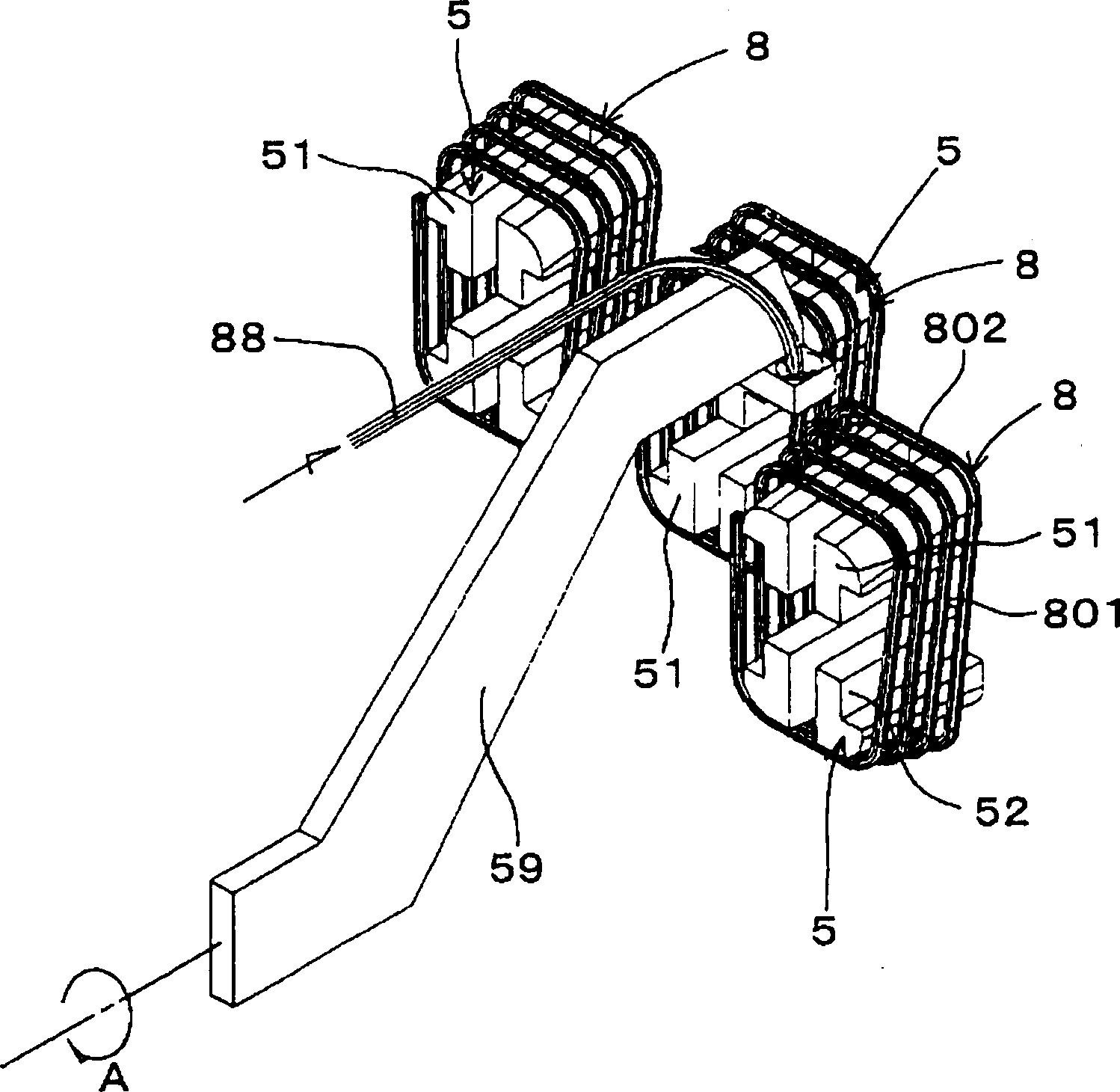

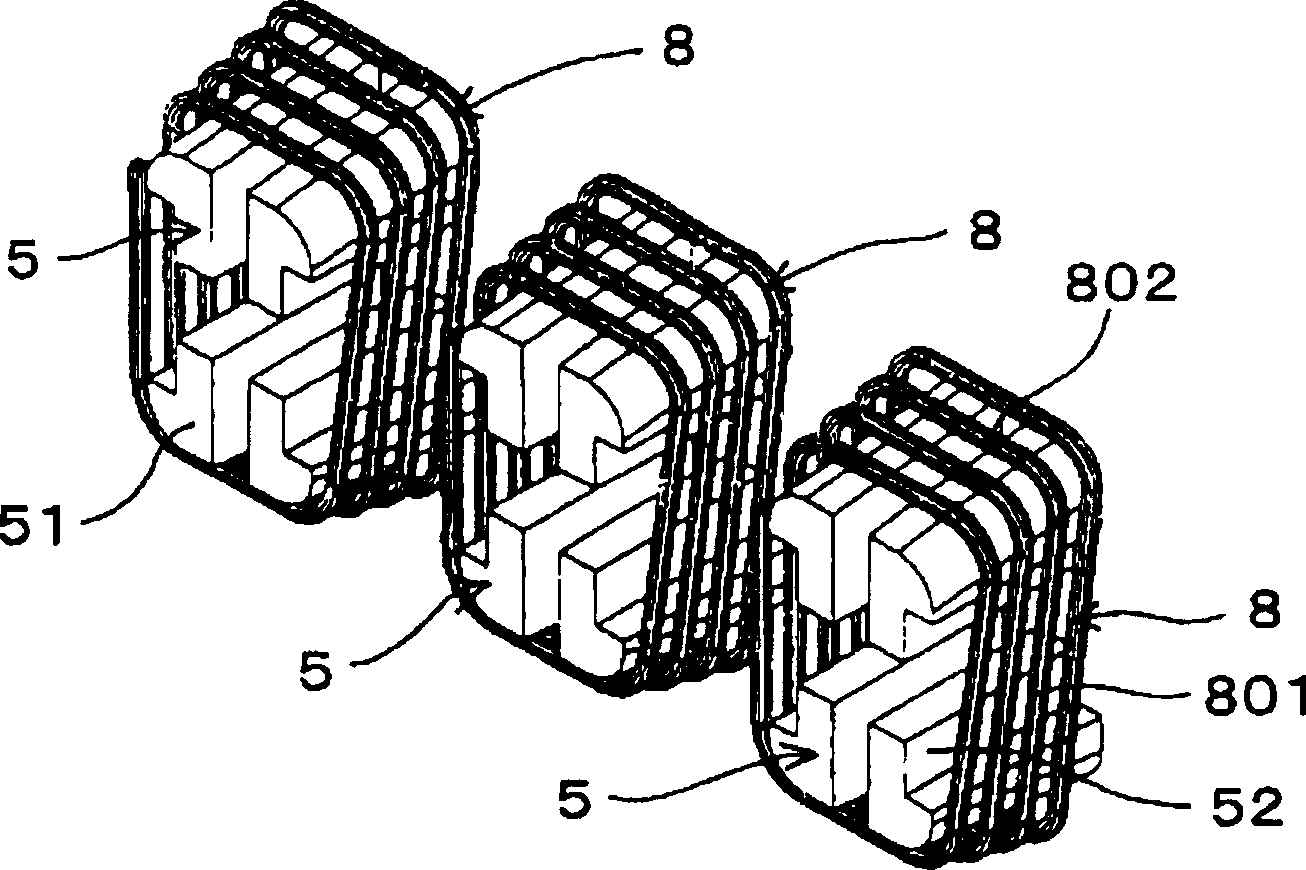

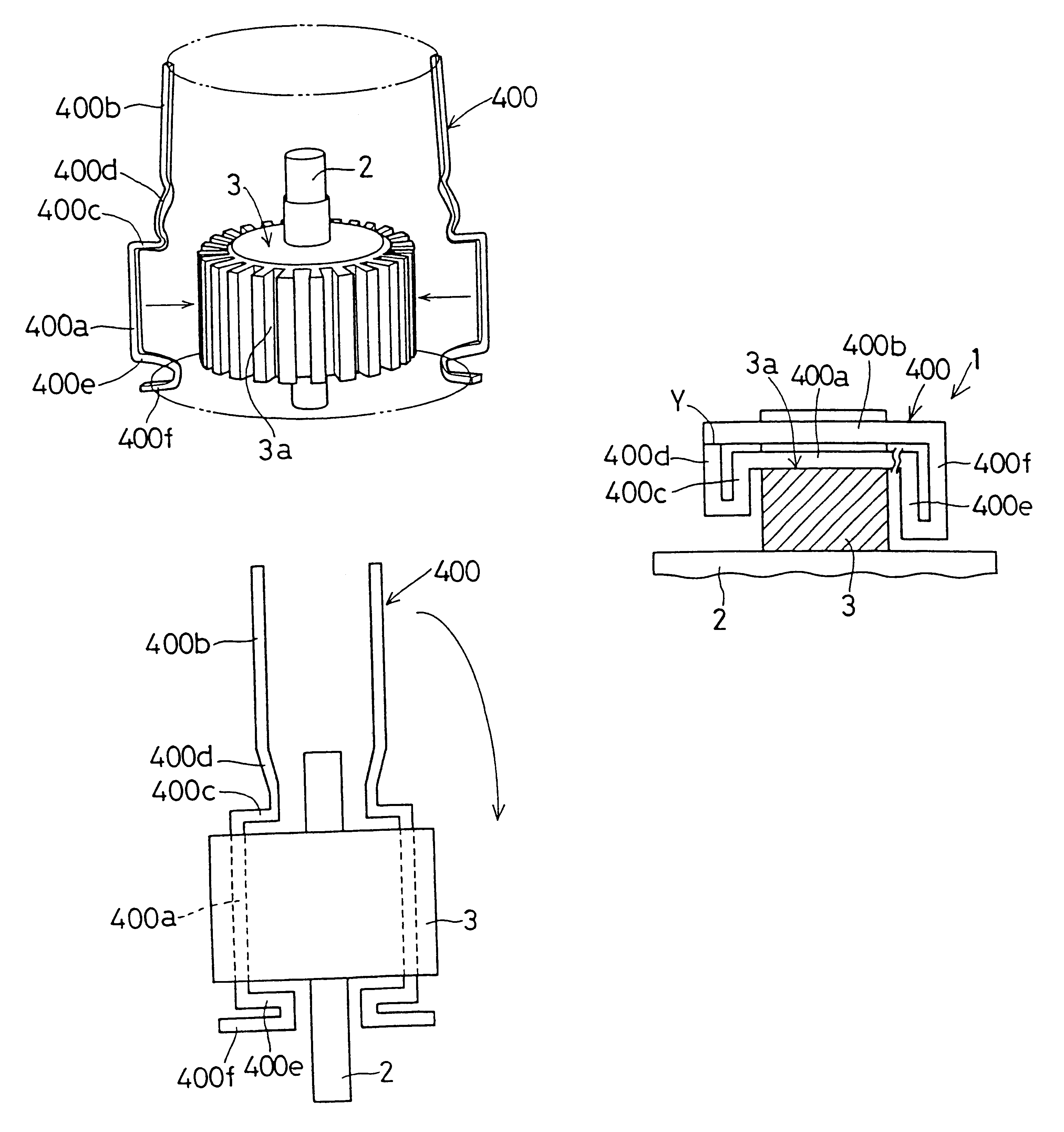

Driving apparatus and light amount adjustment apparatus

InactiveUS20060006968A1DownsizingIncrease productionMagnetic circuit stationary partsMaster clocksMagnetic polesCoil insertion

The invention provides a driving apparatus comprising: a magnet that is magnetized to at least two poles in a circumferential direction and fixed to a rotor axis formed with a soft magnetic material; first and second coils arranged in the same direction as the magnet with respect to the magnet-axis direction and arranged adjacent to an end surface of the magnet in the magnet-axis direction; the first magnetic pole portion excited by energizing the first coil; the second magnetic pole portion excited to a pole opposite to the first magnetic pole portion by energizing the second coil; and a yoke portion formed with a soft magnetic material for supporting the first and second magnetic pole portions. The first magnetic pole portion includes a first coil insertion portion that is inserted to an internal diameter portion of the first coil, and a first magnet facing portion that is arranged to face a magnetized outer circumferential portion of the magnet with a predetermined gap at a predetermined angle. The second magnetic pole portion includes a second coil insertion portion that is inserted to an internal diameter portion of the second coil, and a second magnet facing portion that is arranged to face a magnetized outer circumferential portion of the magnet with a predetermined gap at a predetermined angle.

Owner:CANON KK

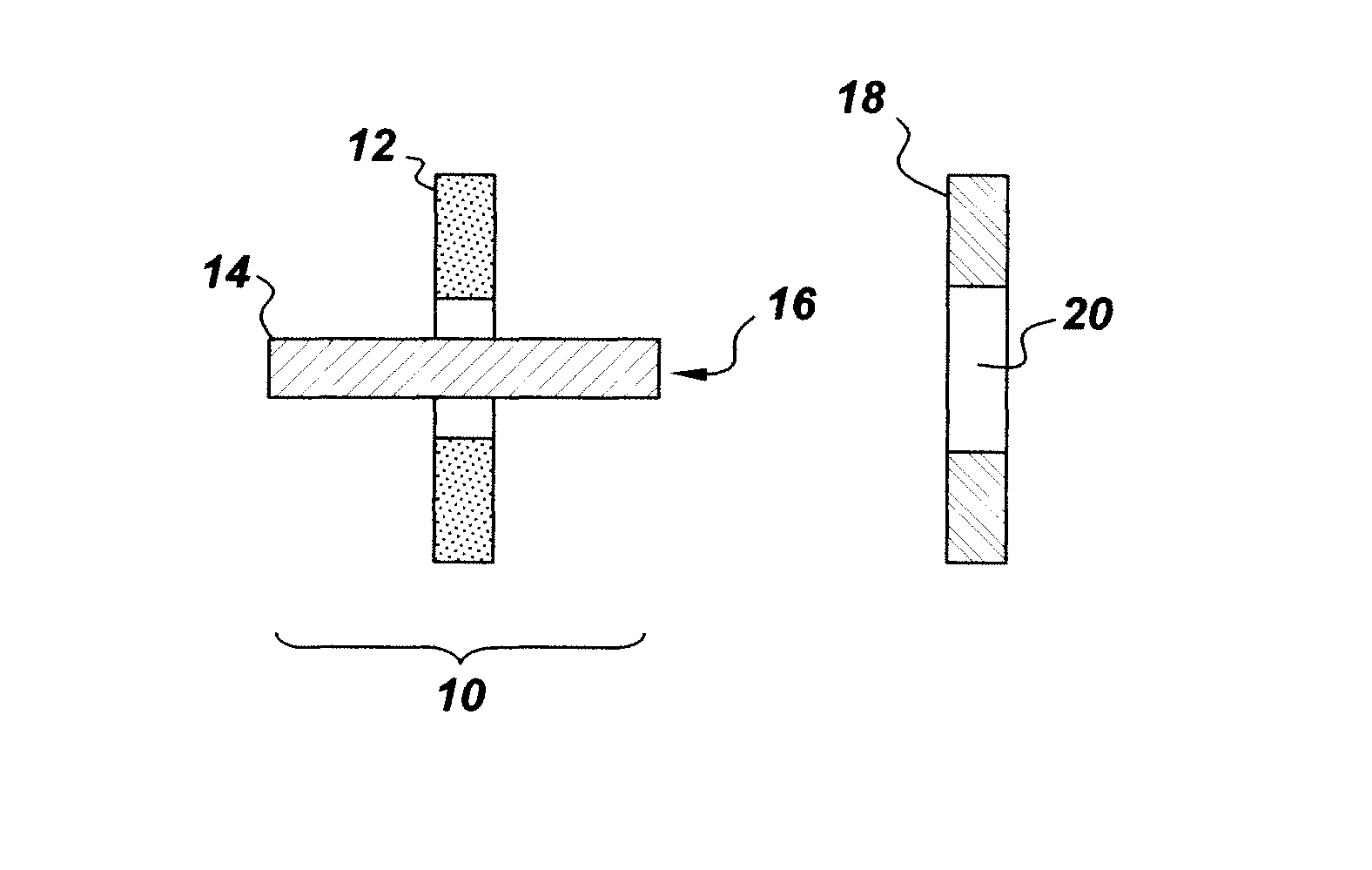

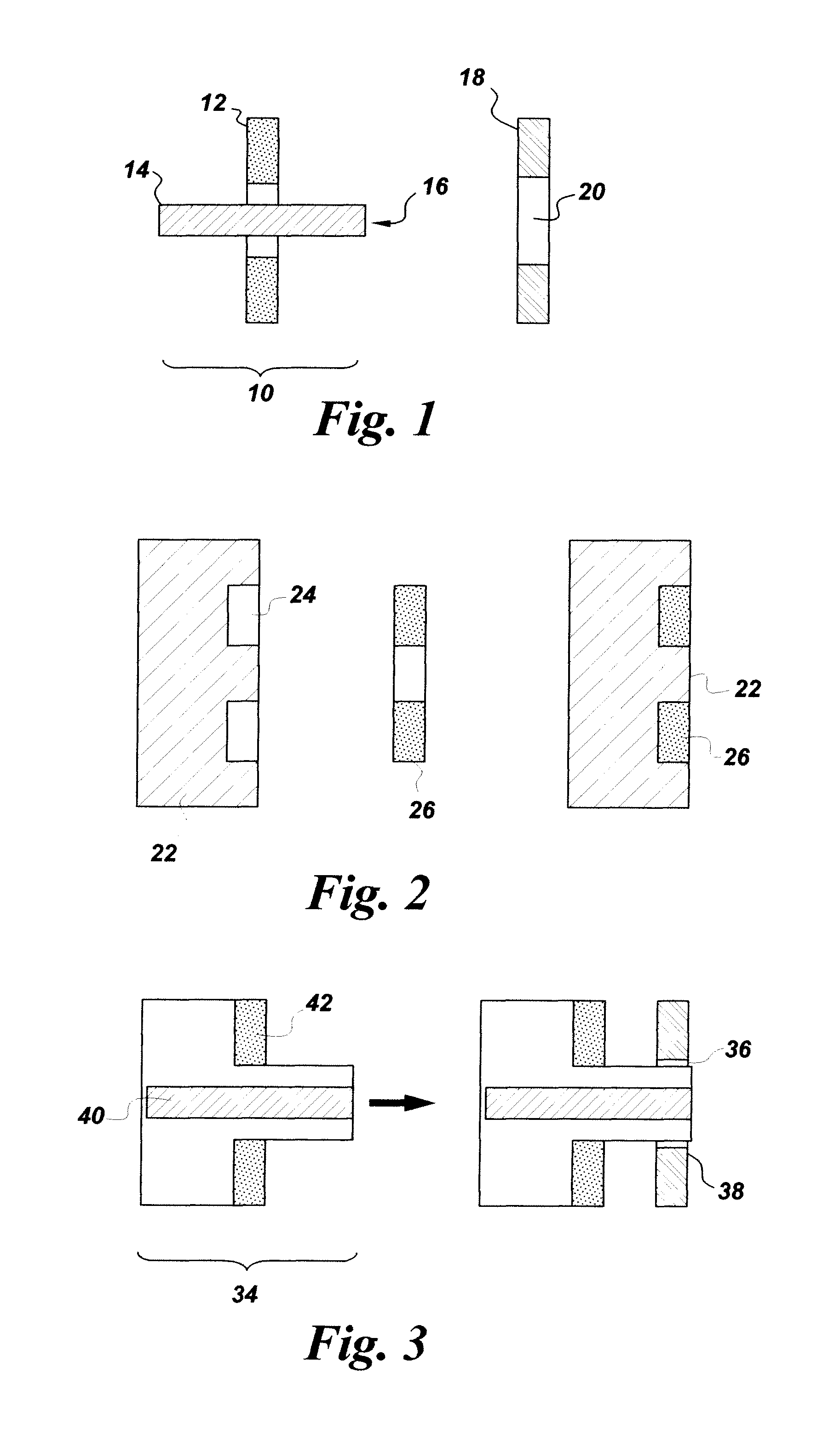

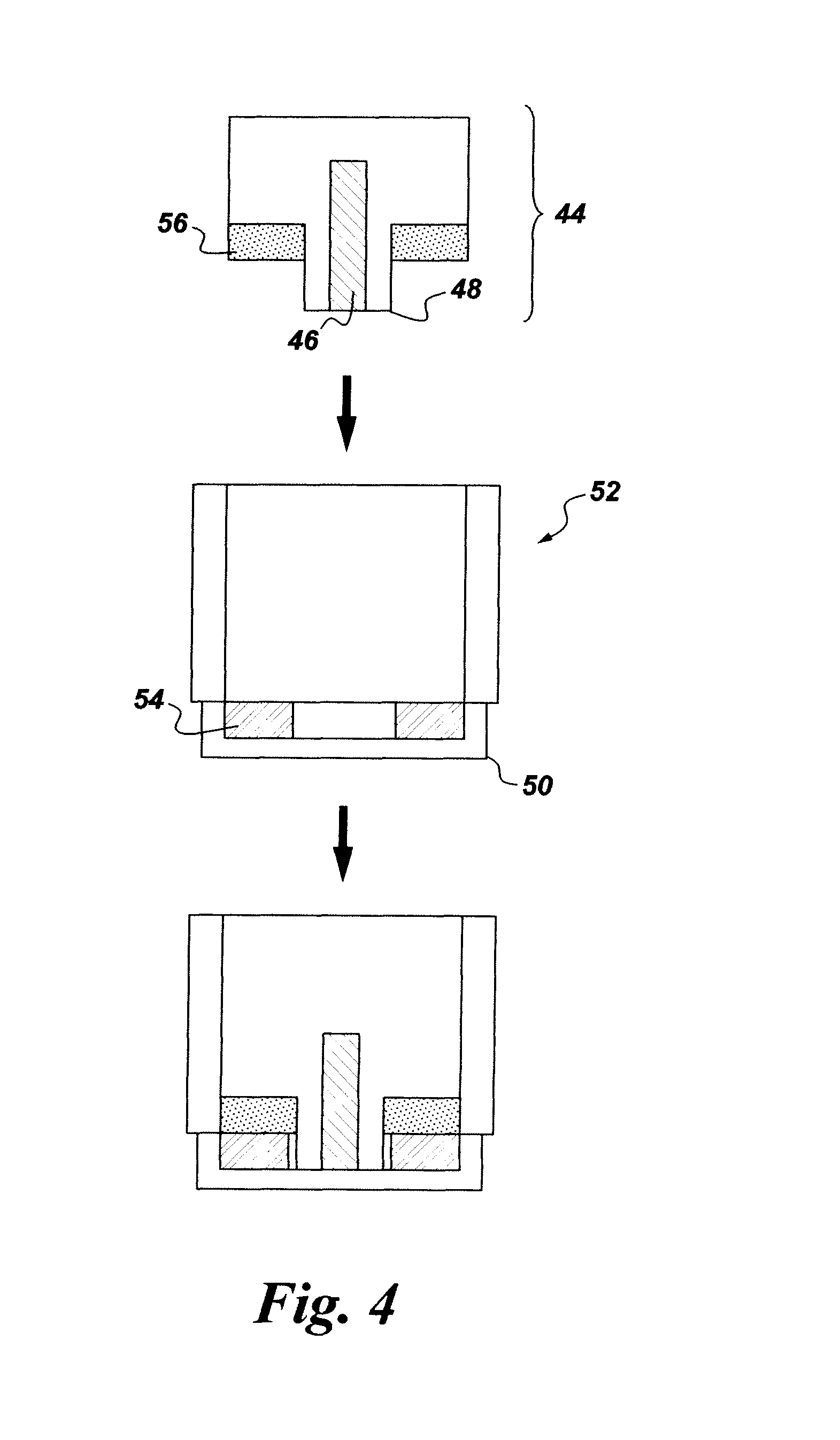

Rotor production method including assembling a slot insulator and coil trunk into a set prior to insertion into an armature core

In a production method of a rotor, a lower layer slot insulator is held at a slot insulator holding portion of a combining jig. A lower layer coil bar is inserted into a coil inserting path of the combining jig and is combined integrally with the lower layer slot insulator by being pushed together. Thereafter, the combined set is set in a coil integrating path of a coil holding member. The coil holding member is attached to a coil inserting device along with an armature core. The lower layer slot insulator and a lower coil trunk are integrally inserted into a slot of the armature core by pushing the lower layer coil bar in the coil integrating path. The lower layer coil trunk and an upper layer coil trunk may be formed integrally with respective coil arms as a single coil bar.

Owner:DENSO CORP

Motor manufacturing method

InactiveCN1596498ASimple configurationLess quantityMagnetic circuit stationary partsEmbedding prefabricated windingsEngineeringMechanical engineering

A motor manufacturing method, comprising the steps of holding a plurality of single-pole coils by a coil holding means, arranging the plurality of single-pole coils so that the coil insert parts of the single-pole coils are opposed to the inner peripheral opening parts of slots and positioned generally parallel with each other in the axial direction of a motor core, moving the single-pole coils generally linearly toward the motor core so as to be disengaged from the coil holding means so that the moving routes of the adjacent single-pole coils before being inserted into the slots of the adjacent coil insert parts become parallel with each other or close with each other starting at the inner peripheral side toward the outer peripheral side thereof and that two coil insert parts of the single-pole coils start the movement simultaneously and the speeds thereof become the same.

Owner:AISIN AW CO LTD

Rotating Armature

In a rotating armature in which a bobbin is attached to a core constituting a stator, a coil is wound around a coil winding portion of the bobbin, and a wind starting and a wind terminating of the coil are a respectively inserted to coil insertion grooves provided in an outer peripheral side than the coil winding portion in the bobbin, and coil come-off preventing locking portions are provided in the coil insertion grooves of the bobbin.

Owner:SHOWA CORP

Stator assembly method and stator assembly device

ActiveCN106416022ASuppresses Insertion LoadMagnetic circuitEmbedding prefabricated windingsEngineeringMechanical engineering

The purpose of the present invention is to suppress a coil deformation amount before inserting each coil into a slot when inserting a coil assembly from the inner diameter side toward outer diameter side of a circular ring-shaped stator core and thereby mounting the coil assembly on the stator core, said coil assembly being formed by combining a plurality of coils each having a coil end portion and a linear portion. A stator assembly method is a method for mounting a coil on a circular ring-shaped stator core having teeth and slots, said coil being formed of a conducting wire and having a slot-housed portion and a coil end portion. In the stator assembly method, a coil assembly is formed in which a plurality of coils are disposed in a circular ring shape, and a guide tool is disposed in the coil assembly. The coil assembly in which the guide tool is disposed is disposed in the inner diameter side space of the stator core and the coils are pushed out radially from the inner diameter side to the outer diameter side while maintaining a state in which the guide surface of the guide tool is parallel with a tooth wall surface, thereby inserting the slot-housed portions of the coils into the slots of the stator core while guiding the coils by the guide tool.

Owner:AISIN AW CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com