Method and system for modifying low-grade oil

A low-quality and modified technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, chemically processing tar pitch/petroleum pitch/natural pitch, petroleum industry, etc., to maintain long-term operation and reduce external rejection. Residues, the effect of high reforming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

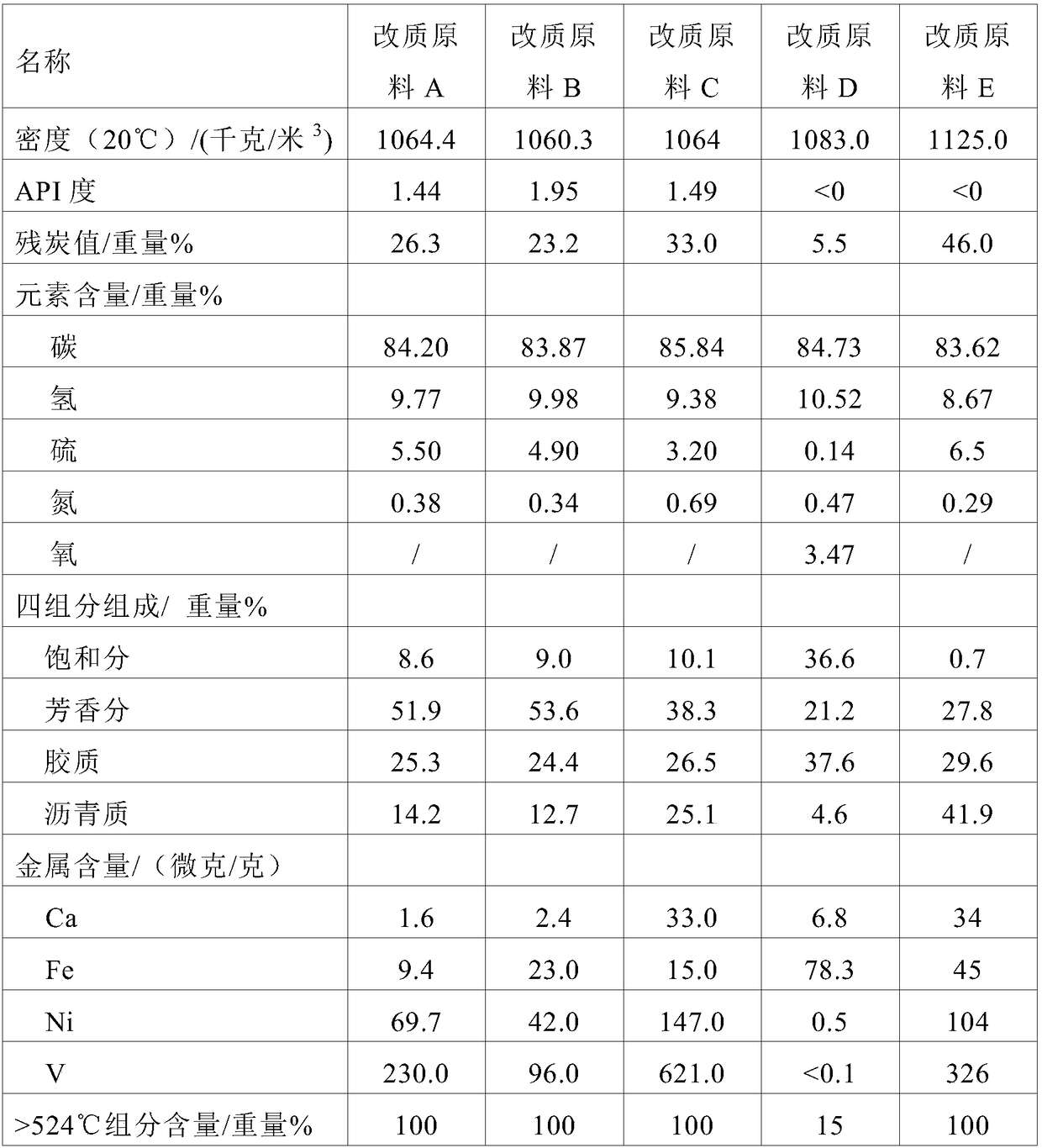

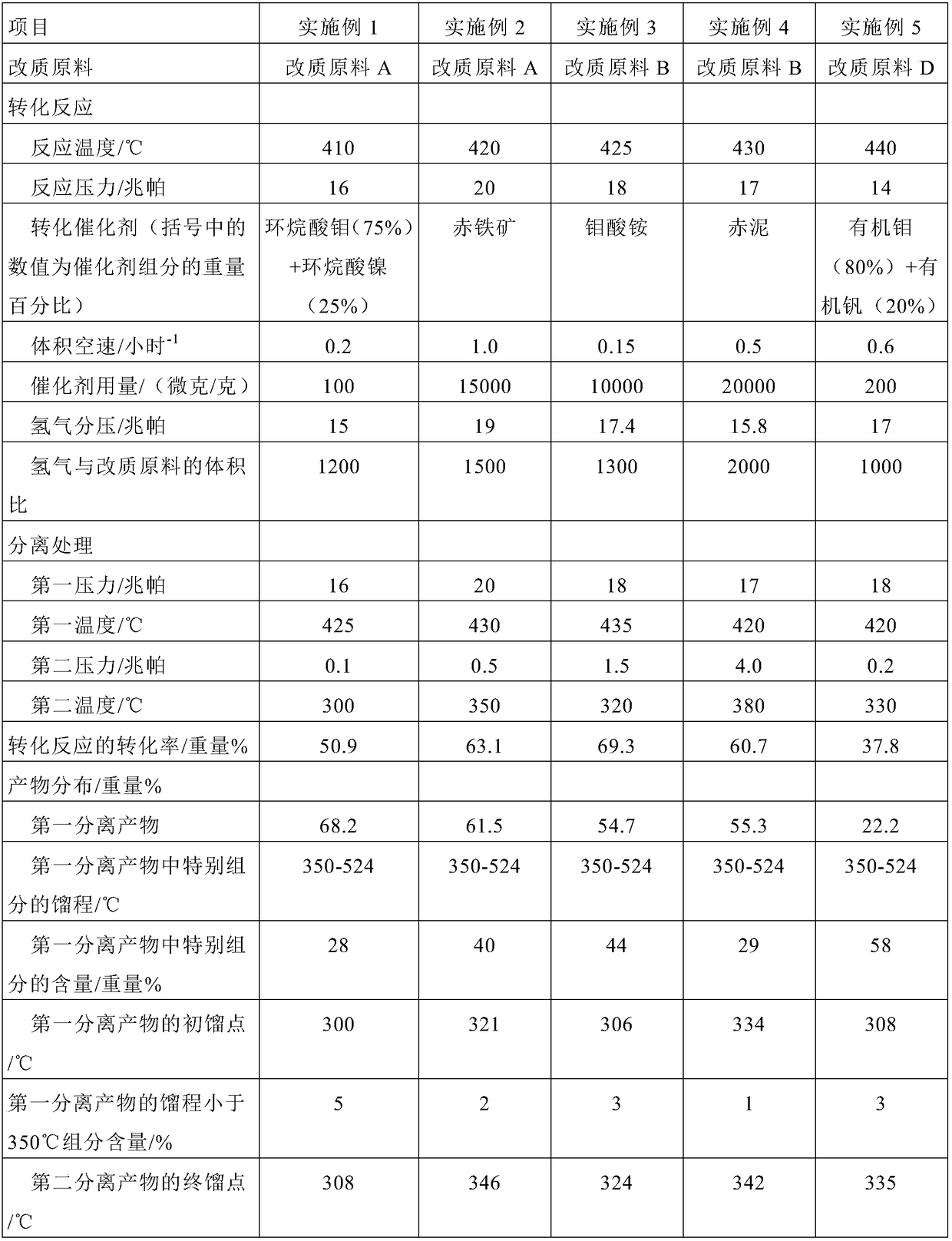

[0035] In one embodiment, the conversion reaction is carried out in the presence or absence of a conversion catalyst, and the conversion catalyst may contain at least one selected from the group consisting of Group VB metal compounds, Group VIB metal compounds and Group VIII metal compounds. species, preferably at least one of Mo compound, W compound, Ni compound, Co compound, Fe compound, V compound and Cr compound; the conditions of the conversion reaction may include: the temperature is 380-470 ° C, preferably 400- 440°C, the hydrogen partial pressure is 10-25 MPa, preferably 13-20 MPa, and the volume space velocity of the modified raw material is 0.01-2 hours -1 , preferably 0.1-1.0 hours -1, the volume ratio of hydrogen to the modified raw material is 500-5000, preferably 800-2000, based on the metal in the conversion catalyst and based on the weight of the modified raw material, the consumption of the conversion catalyst is 10-50000 micrograms / g, preferably 30-25000 μg...

specific Embodiment approach

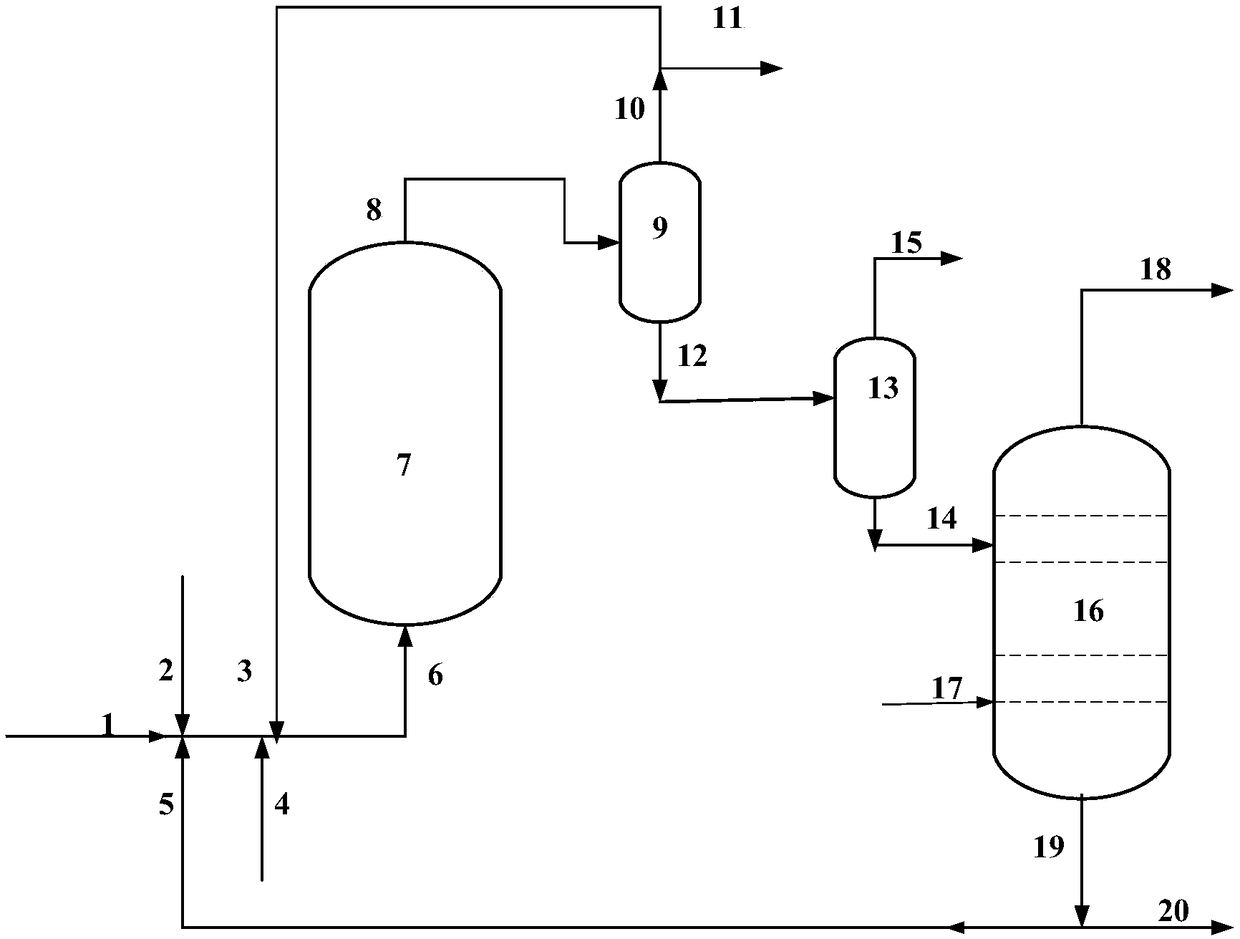

[0039] A specific embodiment, in step (2), the separation process includes step (2-1) and step (2-2):

[0040] (2-1) separating the conversion product obtained in step (1) at a first pressure and a first temperature to obtain a gas component and a liquid component; in step (2-1), gas products such as hydrogen are preferably separated, The gas component is rich in hydrogen, preferably with a hydrogen content of more than 85% by weight; for example, the first pressure can be 10-25 MPa, preferably 13-20 MPa. For the convenience of measurement, the first pressure generally refers to the gas group The outlet pressure when separating the separation device, the first temperature can be 380-470 ° C, preferably 400-440 ° C, for the convenience of measurement, the first temperature generally refers to the outlet temperature when the liquid component leaves the separation device; in this step The separation method can be distillation, fractional distillation and flash distillation, etc.,...

Embodiment 1-5

[0067] In a medium-sized device, the reformed raw material is first subjected to a conversion reaction, and then the conversion product is separated and treated. The separation treatment is carried out in two fractionation towers to obtain the first separated product and the second separated product. The specific details of the conversion reaction and the separated treatment Conditions and results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com