Method for producing tar and hydrocarbon fuel products from coal

A hydrocarbon fuel and tar technology, applied in the field of coal resource processing, can solve problems such as waste of coal, low utilization value of macromolecular substances, and reduction of coal resource utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] Example 1: The present invention uses coal to produce tar and natural gas products

[0123] The implementation steps of this embodiment are as follows:

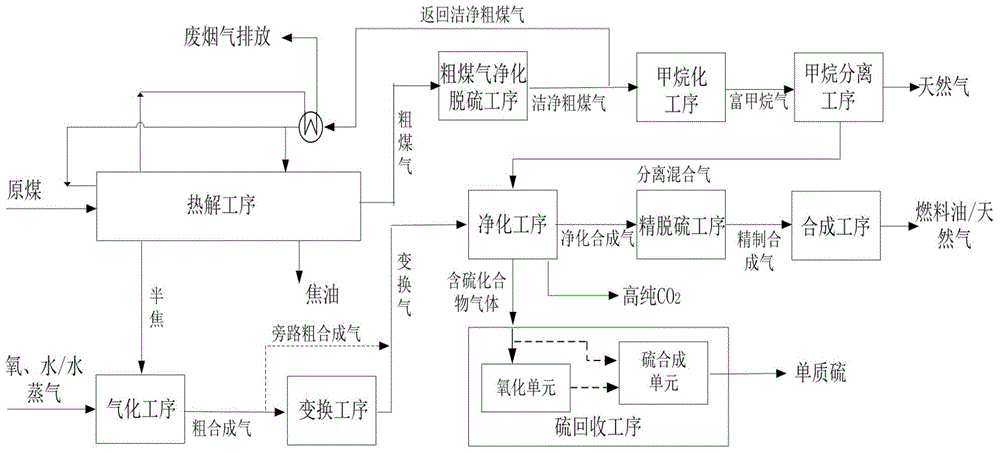

[0124] See attached for specific implementation steps figure 1 .

[0125] A. Pyrolysis

[0126] Taking a certain long flame coal in northern Shaanxi as raw material, using the methods specified in GB212-91 and GB476-91 for analysis, the coal quality analysis results are listed in Table 1.

[0127] The raw coal is ground to a particle size distribution of 100% by weight less than 500μm, of which 50% is less than 125μm, 40% is less than 75μm, and 25% is less than 44μm powder, and is transported to the heat through a feeding device at a feed rate of 5000kg / h. Solution process. The pyrolysis equipment used in the pyrolysis process is, for example, the pyrolysis equipment launched and sold under the trade name WR-800 pyrolysis reactor by Lanzhou Tianhua Chemical Machinery and Automation Research and Design Institute. The pulveriz...

Embodiment 2

[0149] Example 2: The present invention uses coal to produce tar, natural gas and fuel oil products

[0150] In addition to tar, this embodiment also produces two hydrocarbon fuel products at the same time.

[0151] A. Pyrolysis

[0152] Using the raw coal used in Example 1 as the raw material, the raw coal was initially crushed and ground to a particle size distribution of 100% by weight less than 500 μm, of which 70% was less than 125 μm, 50% was less than 75 μm, and 30% was powder less than 44 μm. And according to the 5000kg / h feed rate, it is transported to the pyrolysis process through the feeder. The pyrolysis equipment used in the pyrolysis process is, for example, the pyrolysis equipment launched and sold under the trade name WR-800 pyrolysis reactor by Lanzhou Tianhua Chemical Machinery and Automation Research and Design Institute. The pulverized coal undergoes pyrolysis reaction for 45 minutes at a temperature of 600°C and atmospheric pressure. Produce a gaseous mixed pr...

Embodiment 3

[0170] Example 3: The present invention uses coal to produce tar, natural gas and fuel oil products

[0171] The implementation steps of this embodiment are roughly the same as those of the embodiment 2, except that the selected processes and technical parameters of some processes are different.

[0172] A. Pyrolysis

[0173] Take the raw coal used in Example 1 as raw material, grind it to a powder with 100% less than 100μm and a particle size distribution that is broken and freely distributed, and transport it to the pyrolysis process through the feeder at a feed rate of 20t / h. The pyrolysis equipment used in the process is, for example, the pyrolysis equipment launched and sold under the trade name WR-800 pyrolysis reactor by Lanzhou Tianhua Chemical Machinery and Automation Research and Design Institute. The pulverized coal undergoes a pyrolysis reaction for 35 minutes under the conditions of a temperature of 800° C. and a gauge pressure of -0.05 MPa. Finally, tar with a mass fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com