Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "The grinding process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing tar and hydrocarbon fuel products from coal

InactiveCN104893748AIncrease varietyImprove utilization efficiencyGaseous fuelsLiquid hydrocarbon mixture recoveryWater dischargeMethanation

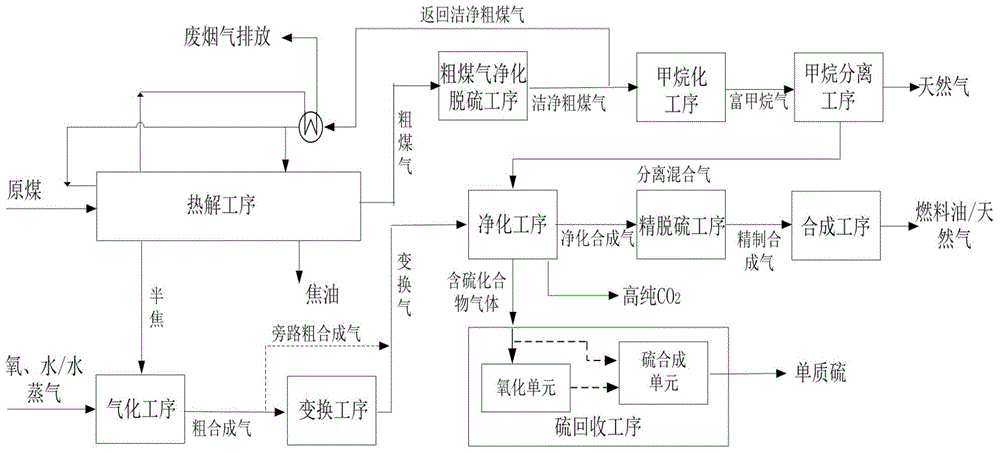

The invention relates to a method for producing tar and hydrocarbon fuel products from coal. The method comprises steps of pyrolysis, raw gas purification and desulfurization, a methanation process, a methane separation process, a gasification process, a conversion process, a purification process, a sulfur recovery process, a fine desulfurization process, a synthesis process and the like. With the adoption of the method, raw coal is firstly subjected to low-temperature pyrolysis and then subjected to gasification conversion, the types of coal chemical products are increased, and the utilization efficiency of the coal raw material is improved; the problem that low-rank coal cannot be gasified and utilized by a wet-process entrained-flow bed is solved, the raw material consumption during gasification is reduced, the waste water discharge is reduced, the greenhouse gas production amount in the process is reduced, and efficient class-based and quality-based utilization of the coal resource is realized.

Owner:XIAN ORIGIN CHEM TECH +1

Method for producing tar and hydrocarbon fuel products with coal

ActiveCN104531186AIncrease varietyImprove utilization efficiencyCarburetting airGaseous fuelsMethanationChemical products

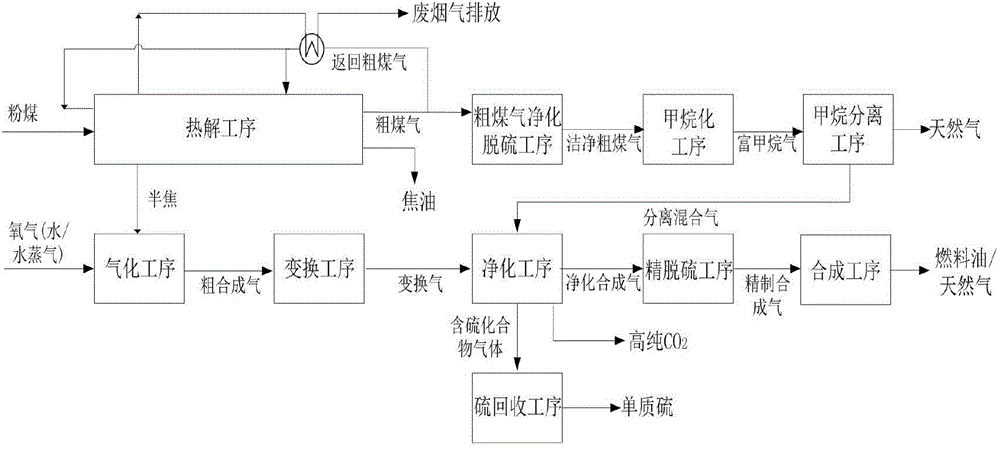

The invention relates to a method for producing tar and hydrocarbon fuel products with coal. The method comprises the steps such as pyrolysis, coarse gas purification and desulfuration, methanation reaction, gasification reaction, transformation reaction, purification treatment, sulfur recovery procedure, fine desulfurization treatment and synthesis procedure. According to the method provided by the invention, raw coal is subjected to low-temperature pyrolysis and then subjected to gasification transformation, which not only increases the number of categories of coal chemical products, but also increases the utilization efficiency of raw coal material. The method provided by the invention solves the problem that low-rank coal is hard to gasify and utilize with a wet-process entrained-flow bed, lowers the consumption of raw material in the gasification process, reduces the emission of waste water, lowers the production of greenhouse gas in the process and achieves the purpose of efficient classified and quality-divided utilization of coal resources.

Owner:THE NORTHWEST RES INST OF CHEM IND

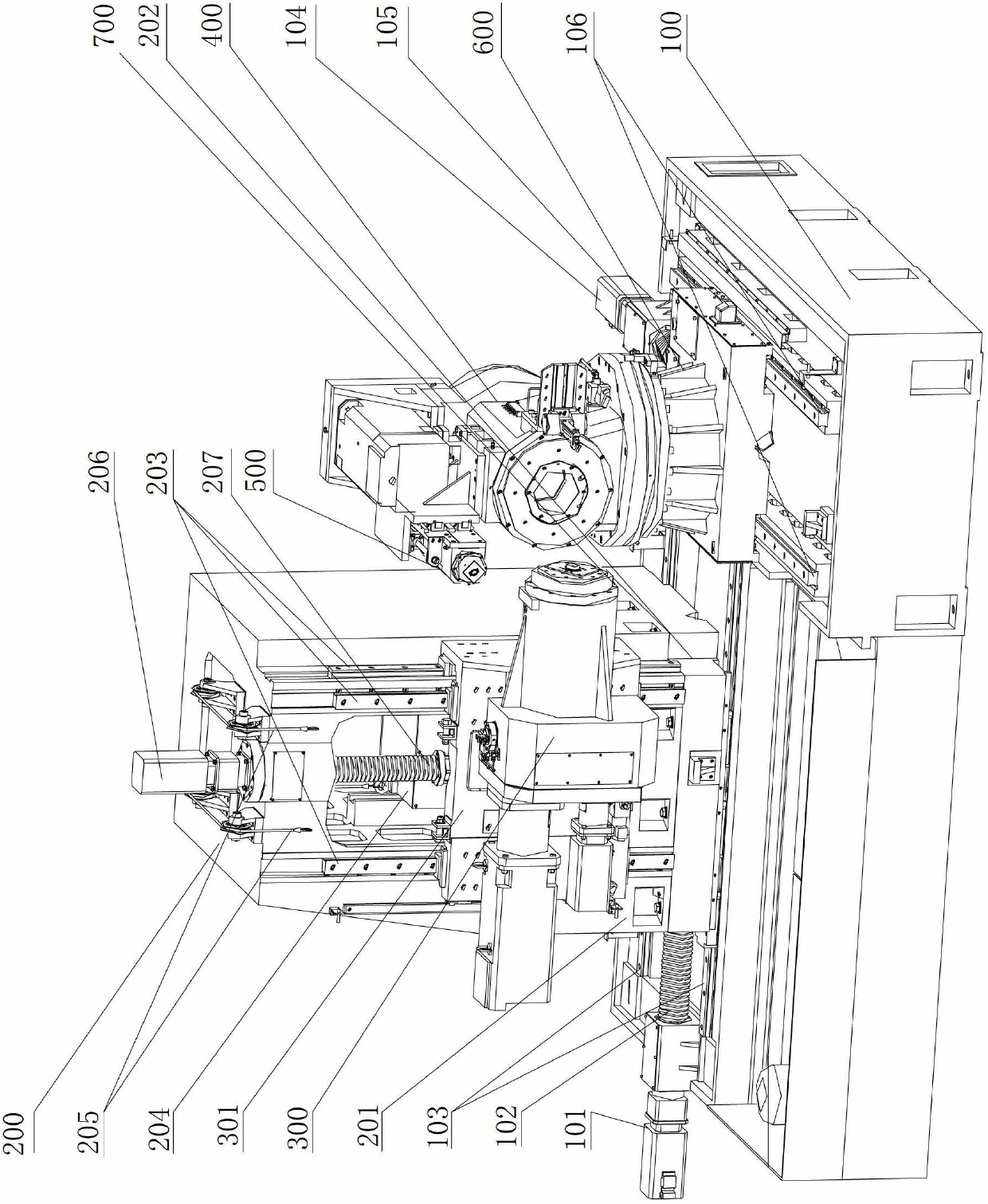

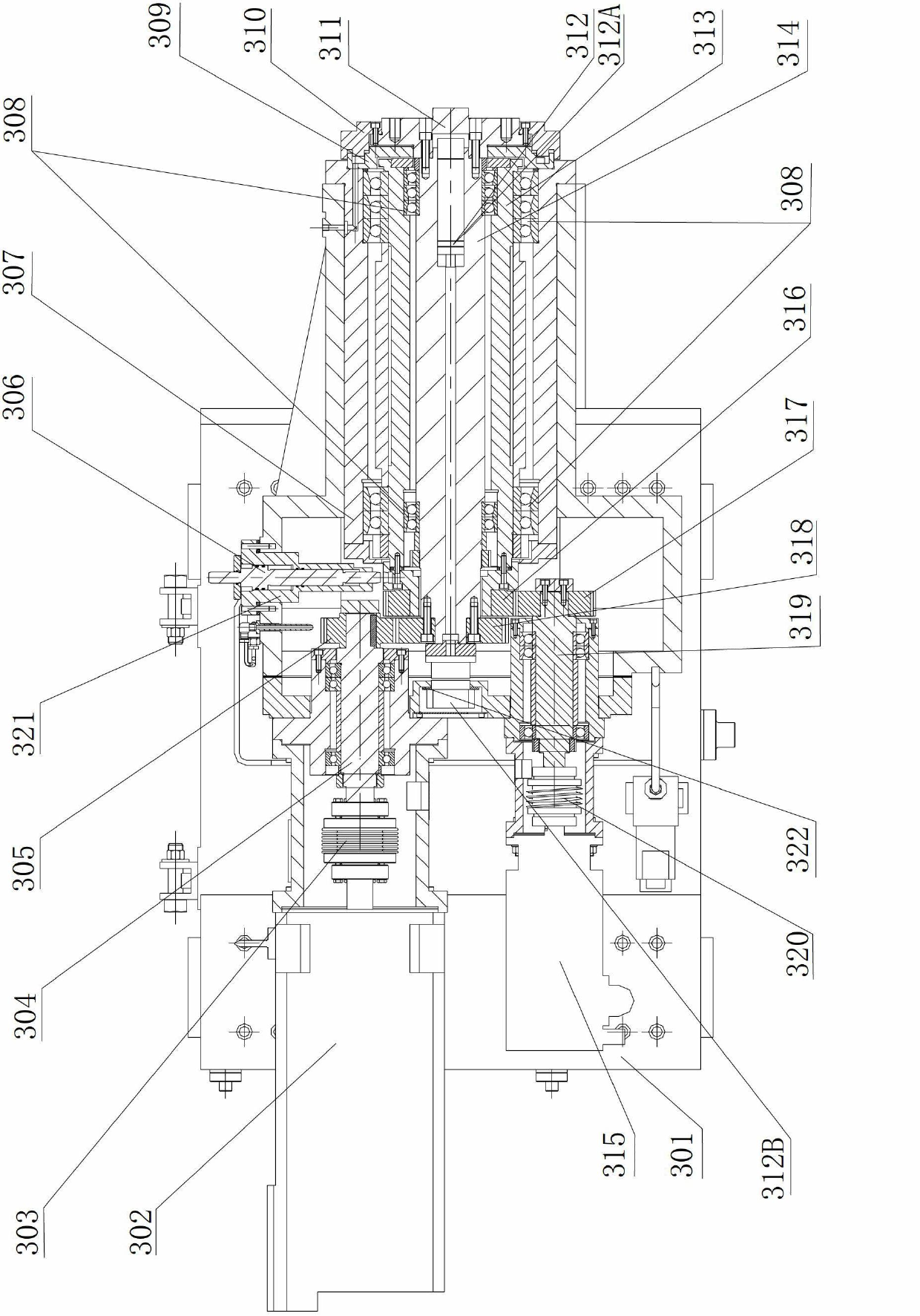

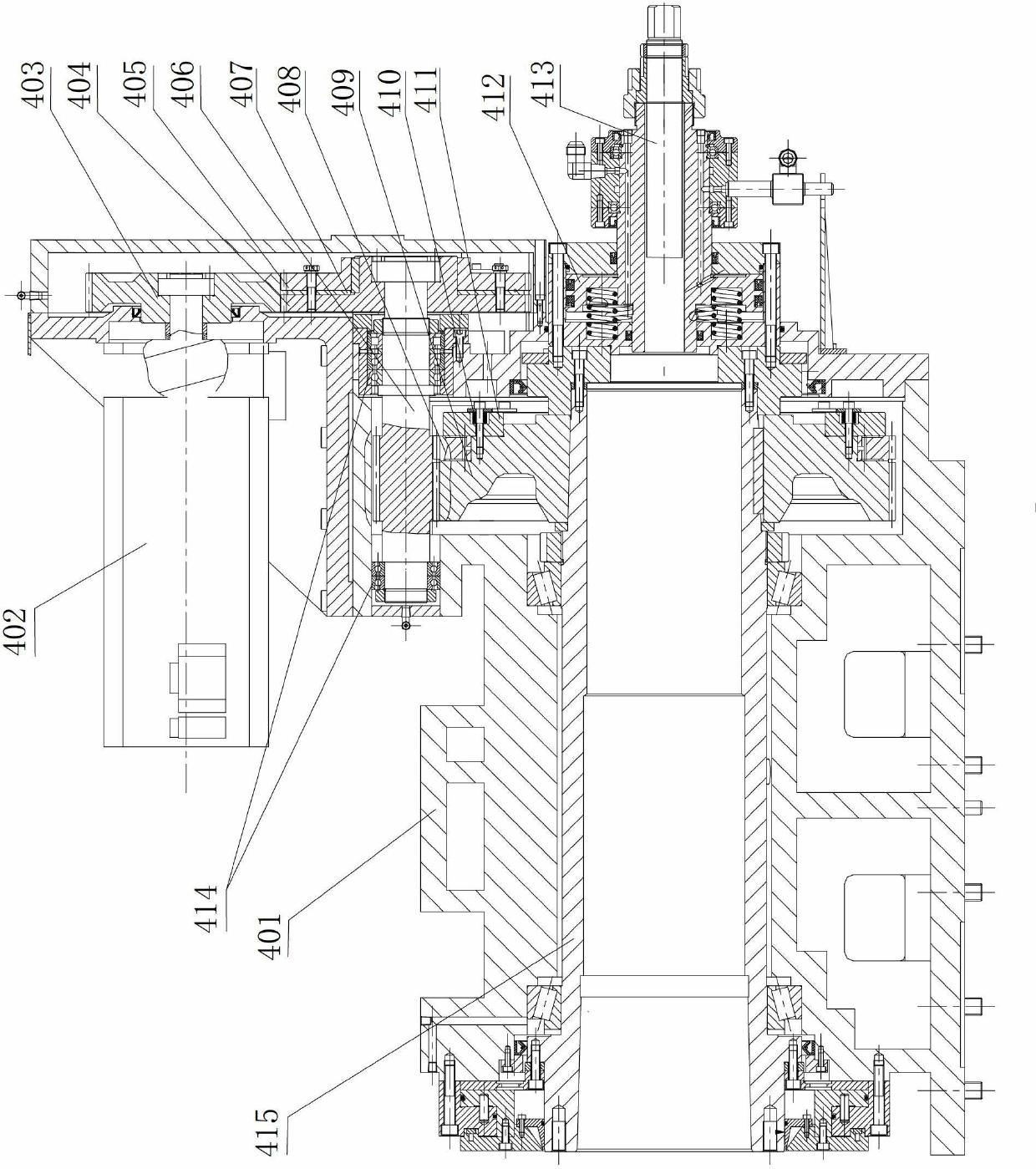

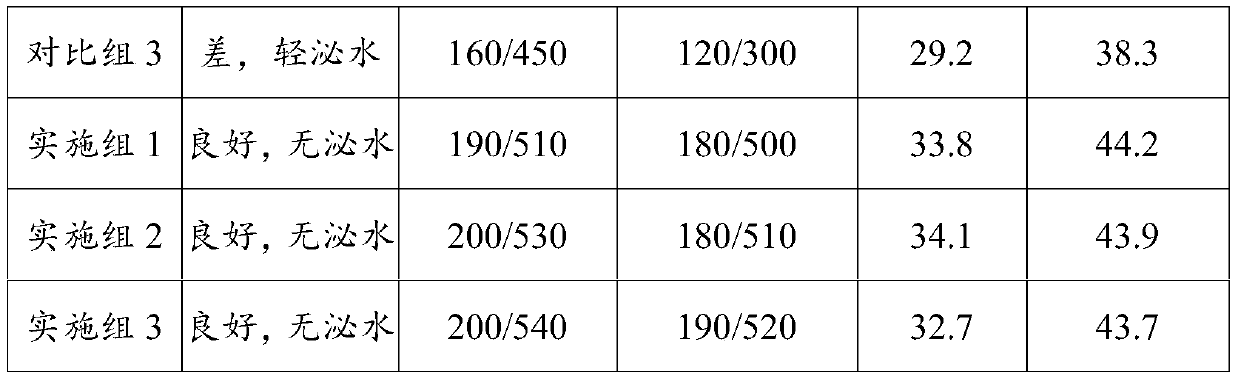

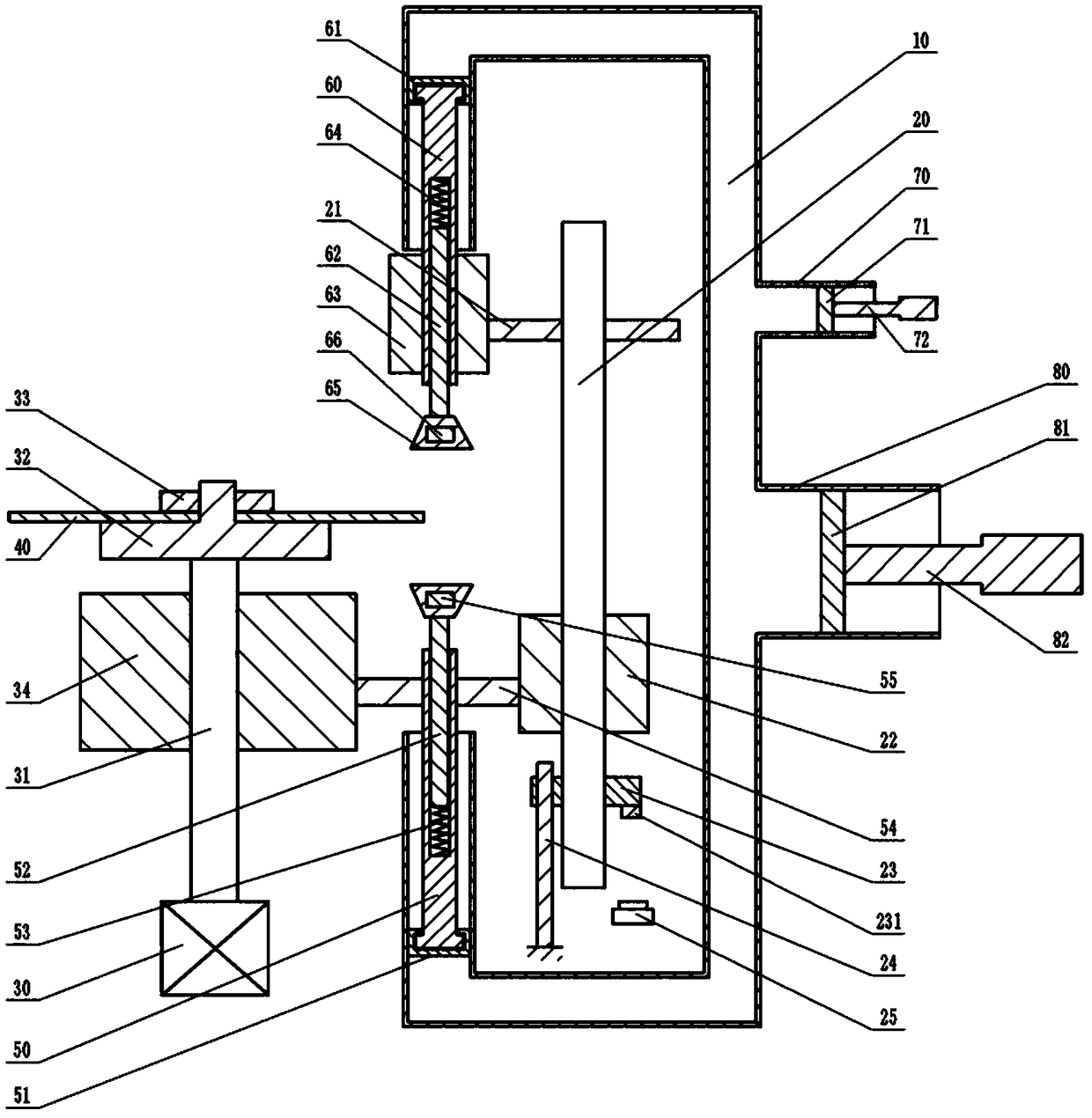

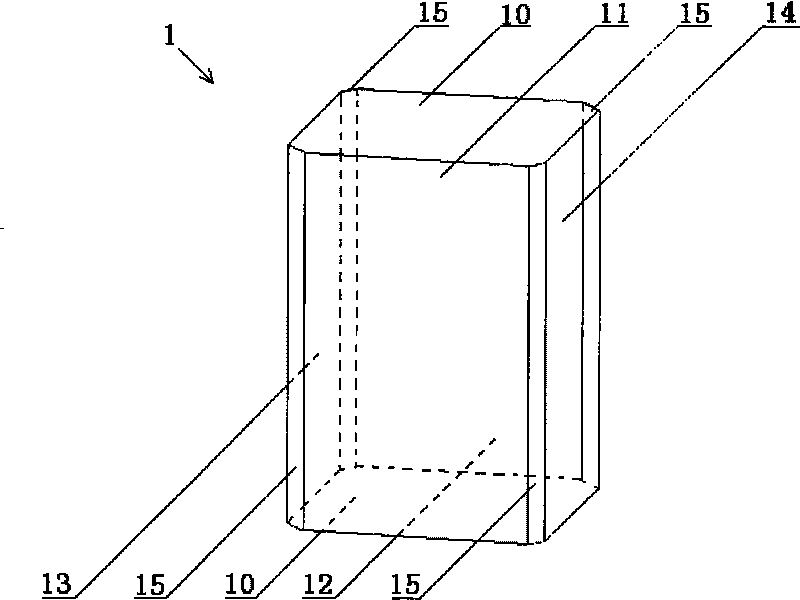

Numerically controlled spiral bevel gear grinding machine

ActiveCN102672281AReduce contact areaCoolingMeasurement/indication equipmentsLarge fixed membersDynamic balanceSlide plate

The invention relates to a numerically controlled spiral bevel gear grinding machine, comprising a bed, an upright, a grinding wheel spindle box, a workpiece spindle box, a grinding wheel dressing mechanism, a rotary worktable, an electrical system, a pneumatic system and a hydraulic system, and being characterized in that the bed is formed into an L-shaped structure having a slope on the surface thereof; a chip groove is formed at one side edge of the outer side of the bed, and an hollow upper upright is mounted on the bed through a sliding plate; the wall-mounted grinding wheel spindle box is mounted on the outer wall of the upper upright; a balance weight mechanism is arranged in the upper upright; a gear clearance eliminating mechanism is arranged on the workpiece spindle box; the grinding wheel spindle box employs a dual-shaft structure of a grinding wheel spindle and an eccentric spindle; an online dynamic balance device is arranged in the grinding wheel spindle box; and an online measuring device is mounted under the right side of the grinding wheel spindle. The numerically controlled spiral bevel gear grinding machine has the following advantages that: chip discharge is smooth and convenient; the degree of balance of the grinding wheel spindle is automatically adjusted through the online dynamic balance device; the rotary worktable is high in positioning accuracy and high in driving torque, and has a self-locking function; the gap of the workpiece spindle box is simple and convenient for clearance adjustment; and problems of unsteady transmission, and large gap and high noise of the gears are solved.

Owner:天津第一机床有限公司

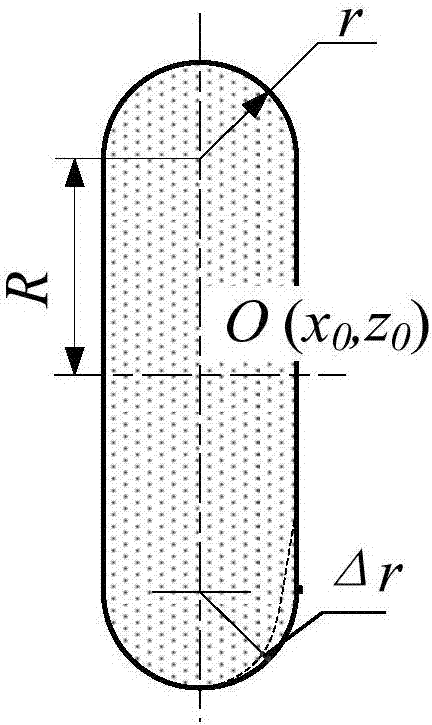

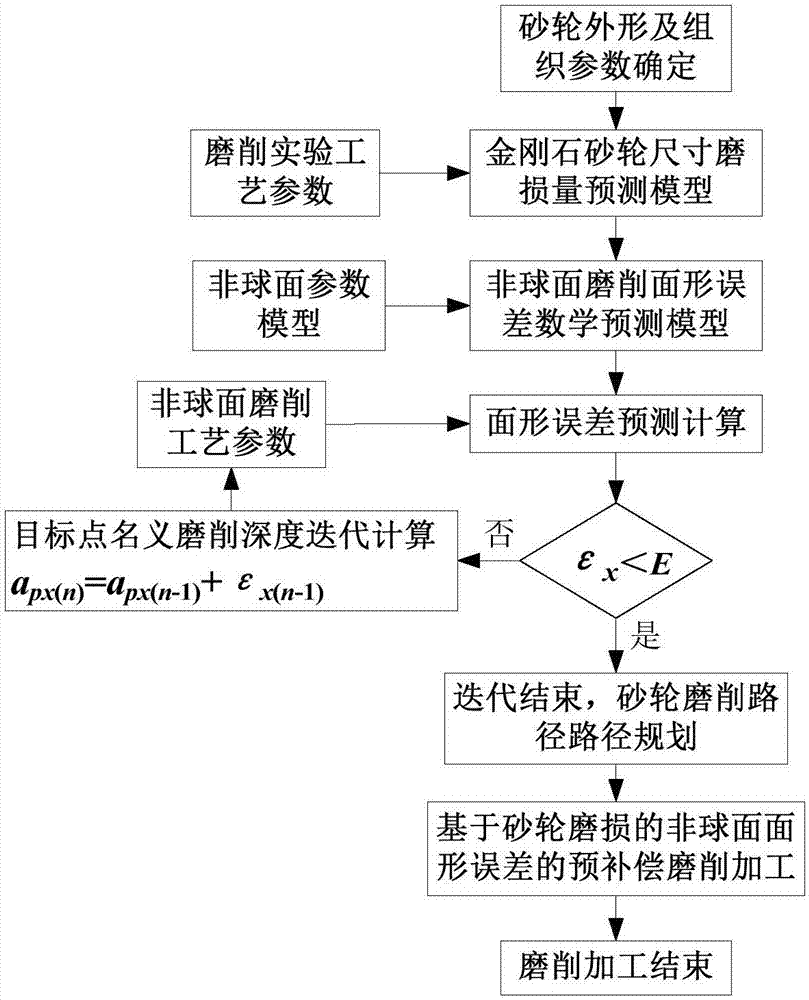

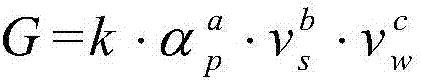

Large-caliber reflection mirror iterative precompensation grinding method based on grinding wheel wear prediction

ActiveCN107378687AExtended service lifeHigh precisionOptical surface grinding machinesTarget surfaceNumerical control

The invention relates to a large-caliber reflection mirror iterative precompensation grinding method, in particular to a large-caliber reflection mirror iterative precompensation grinding method based on grinding wheel wear prediction. In order to solve the problems that in the prior art, under the fixed nominal grinding depth, the target surface figure accuracy is achieved through repeated replacement of a grinding wheel for repeated grinding, consequently, the grinding wheel losses are serious, the surface figure accuracy is poor, and wear efficiency is low, the method comprises the steps of building a predication model of the grinding wheel grinding ratio G about the grinding parameter, secondly, building a radial size wear amount predication model at the grinding wheel wear point in the grinding process, thirdly, building a non-spherical-face surface-shape error predication model, fourthly, through the iterative precompensation method, calculating wear surface-shaped error values of all points on a non-spherical-face generatrix until the requirements are met and fifthly, recording nominal grinding depth final predication values of all contact points in the iterative process, and carrying out numerical control grinding machining programming and subsequent machining. The method is used for the technical field of grinding machining of an optical non-spherical-face reflection mirror.

Owner:HARBIN UNIV OF SCI & TECH

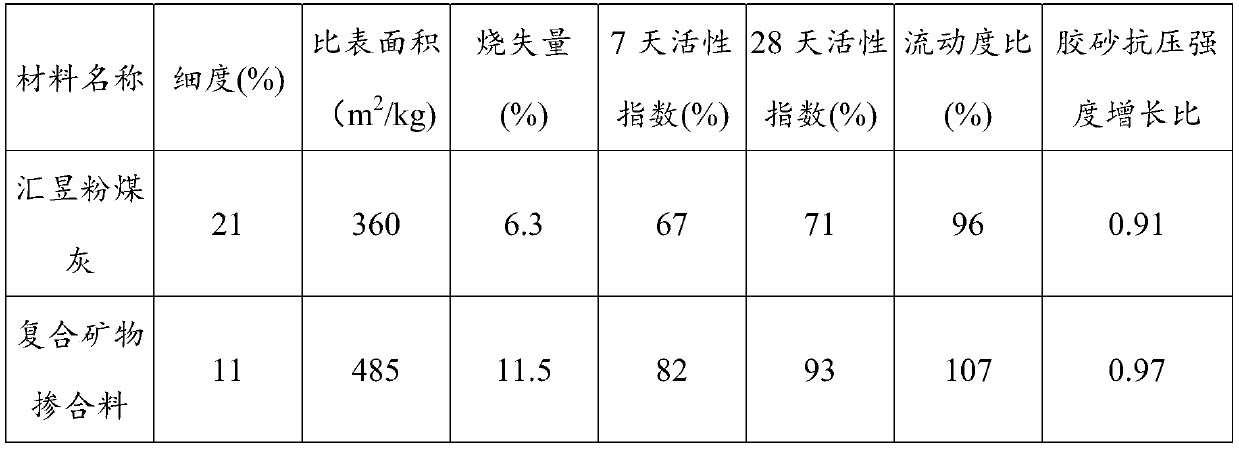

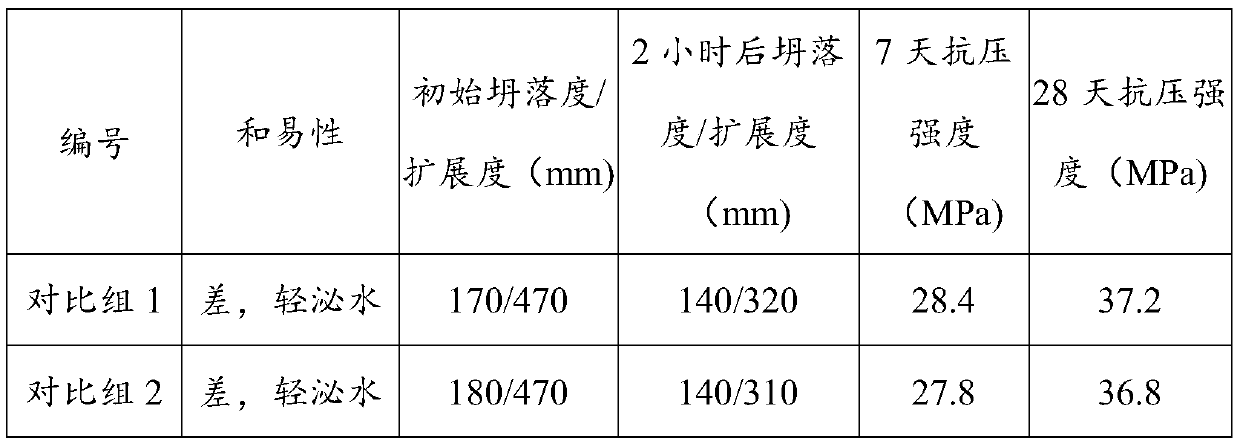

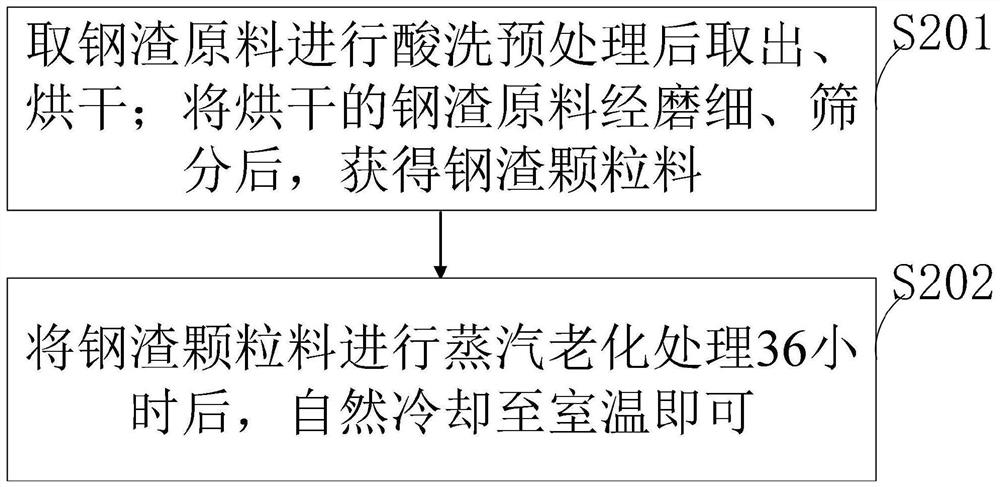

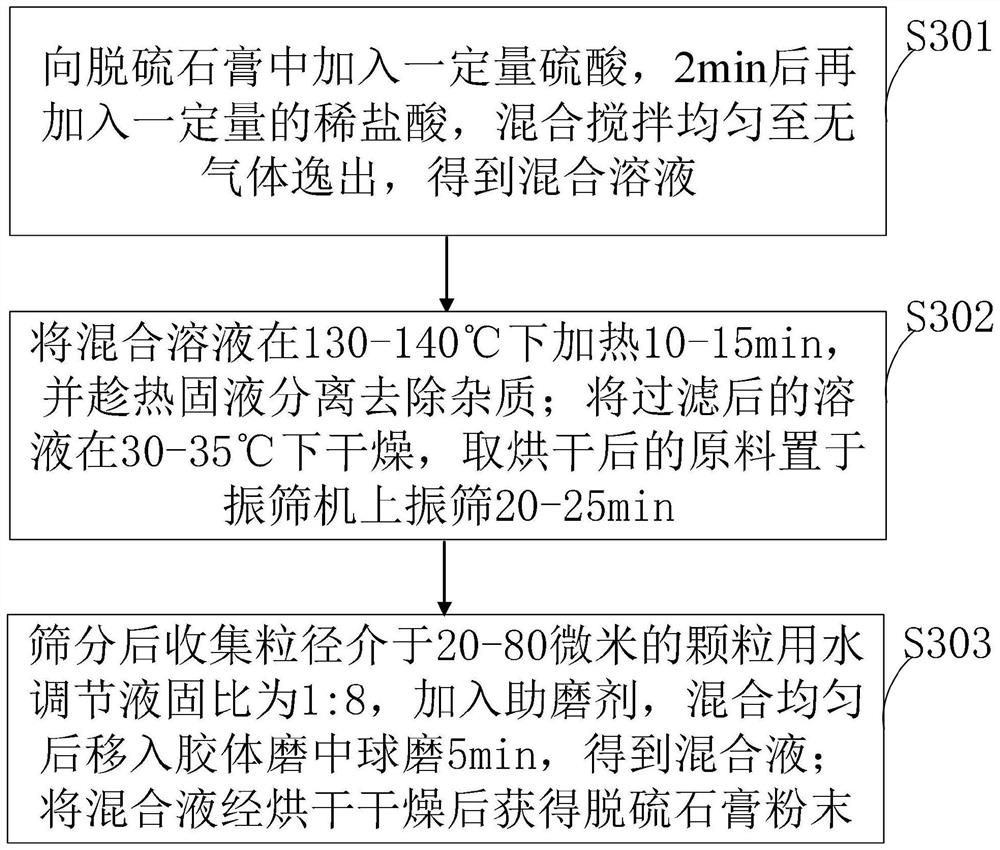

Composite mineral admixture, preparation method thereof and artificial sand concrete material containing composite mineral admixture

The invention relates to a composite mineral admixture, a preparation method thereof and an artificial sand concrete material containing the composite mineral admixture. Grinding raw materials: limestone powder, volcanic ash and granulated blast furnace slag are conveyed into a ball mill in proportion; a composite grinding aid accounting for 0.1-0.2% of the total mass of the grinding raw materialsis added at the same time; the mixture is grinded until the screen residue of a 0.045 mm sieve is less than or equal to 12%, and the specific surface area is controlled to be 450-500 m<2> / kg, therebyobtaining the composite mineral admixture. Limestone powder, natural volcanic ash and blast furnace slag are used as raw materials, a proper composite grinding aid is doped, the performance of the artificial sand concrete can be effectively improved, and the production cost is reduced.

Owner:广州市圣丰混凝土有限公司

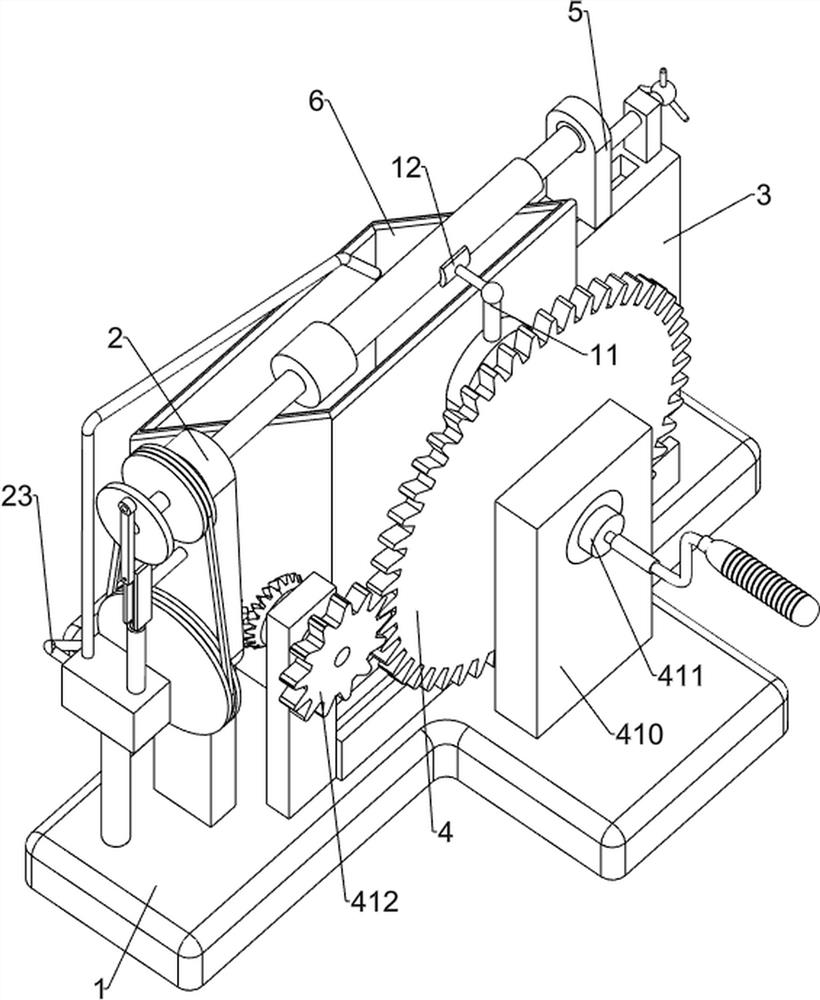

Knife grinder

ActiveCN108818166ASimplify the grinding processImprove processing efficiencyGrinding drivesOther manufacturing equipments/toolsDrive shaftGear wheel

The invention belongs to the technical field of knife grinding devices, and particularly discloses a knife grinder which comprises a frame, a grinding unit, a transmission unit and a clamping unit. The clamping unit comprises a mounting seat, a rotating shaft and a motor, the grinding unit comprises a communication column and an adjusting mechanism, a first piston is slidably connected in one sideof the communication column, a first plunger piston is rotatably connected on the first piston, a second piston is slidably connected in the other side of the communication column, a second plunger piston is rotatably connected on the second piston, grinding wheels are fixed onto the first plunger piston and the second plunger piston, a first gear cylinder is fixed onto the first plunger piston,a first gear is fixed onto the second plunger piston, the transmission unit comprises a transmission shaft rotatably connected on the frame, an output gear and a second gear cylinder are fixed onto the transmission shaft, the output gear is engaged with the first gear cylinder, the second gear cylinder is engaged with the first gear, and a third gear cylinder engaged with the first gear is fixed on the rotating shaft. A circular blade is grinded by the knife grinder, knife edges of two surfaces of the circular blade can be grinded, and working efficiency is improved.

Owner:重庆市开州区三中印务有限公司

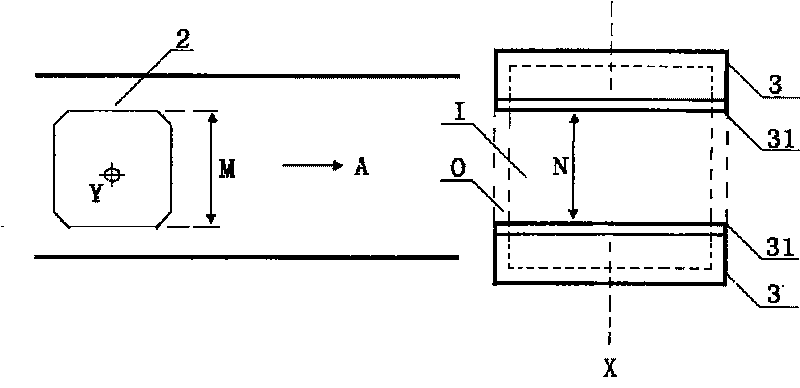

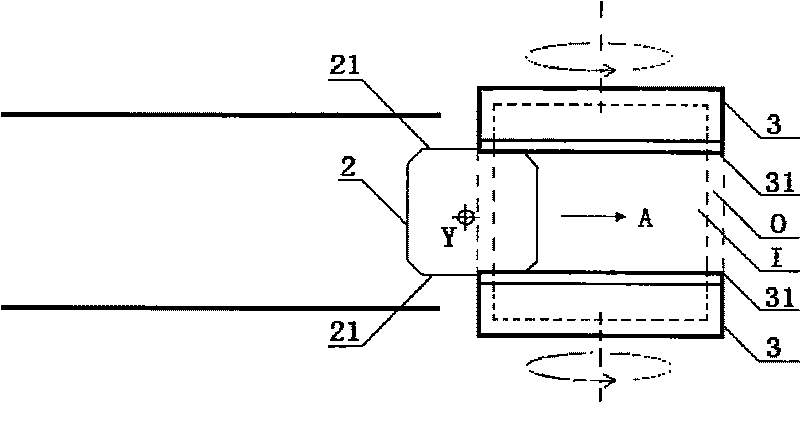

Method for rolling grinding of ground surface of single crystal silicon

ActiveCN101745850AEnsure accurate grinding dimensionsImprove qualityEdge grinding machinesPlane surface grinding machinesTransverse axisMetallurgy

The invention provides a method for the rolling grinding of the ground surface of single crystal silicon. The method comprises the following steps of: oppositely arranging a pair of cup-shaped grinding wheels along transverse axes so as to form an outer-ring grinding space and an inner-ring grinding space between the two cup-shaped grinding wheels; longitudinally arranging the single crystal silicon so as to make the surface to be rolling-ground surface vertical to the transverse axes of the cup-shaped grinding wheels; and when the two cup-shaped grinding wheels rotate around the transverse axes, driving the single crystal silicon to rotate around a longitudinal axis, and transferring the single crystal silicon to the outer-ring grinding space for rolling grinding. Due to the design, the method has the advantages of overcoming the defect existing in the prior art that the round grinding of the single crystal silicon is difficult to control, ensuring the accurate grinding size of the single crystal silicon and improving the quality of the single crystal silicon.

Owner:海宁市日进科技有限公司

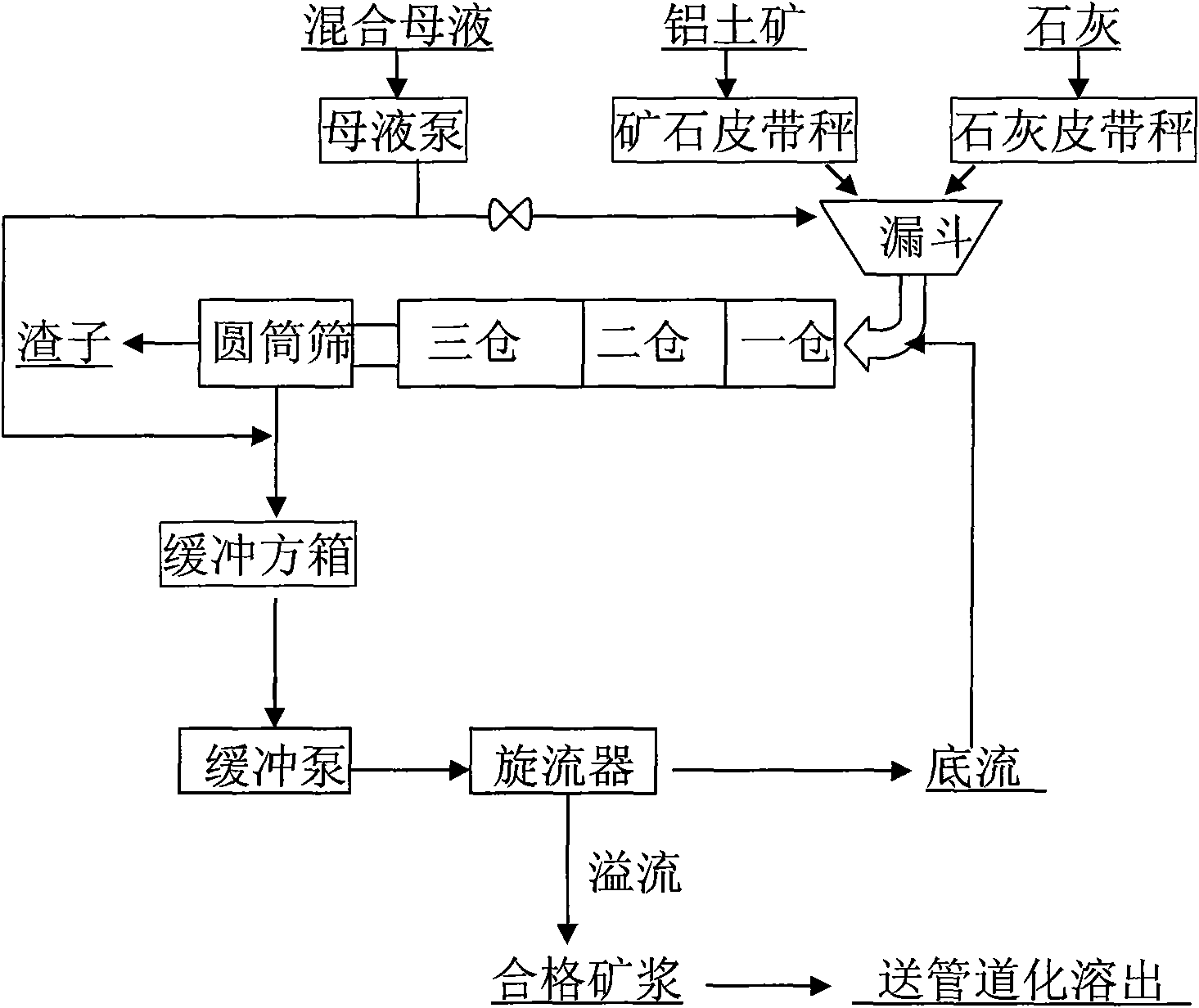

Grind grading technique for aluminum oxide raw material - monohydrallite

The invention relates to a grading process technology containing two procedures of grinding ore and grading in processing monohydrallite. Grinding equipment adopts two-bin overflow ball mill and grading equipment adopts hydraulic cyclone group, which cooperate with each other to form closed-circuit grading flow process. Two-bin overflow ball mill equips compartment board that can be adjusted to separate mill into two bins. The invention simplifies procedure and makes the operation convenient.

Owner:GUIYANG AL-MG DESIGN & RES INST

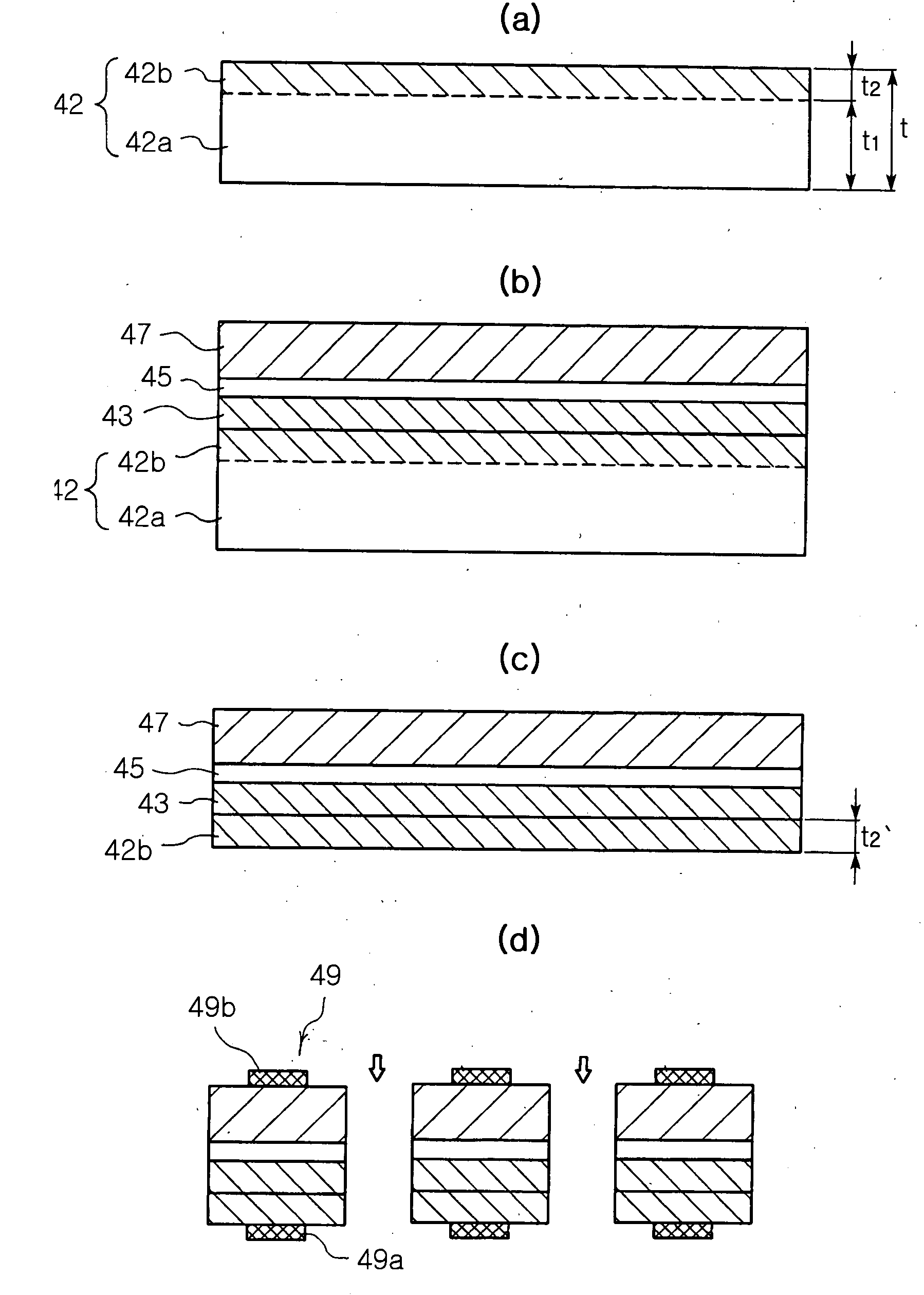

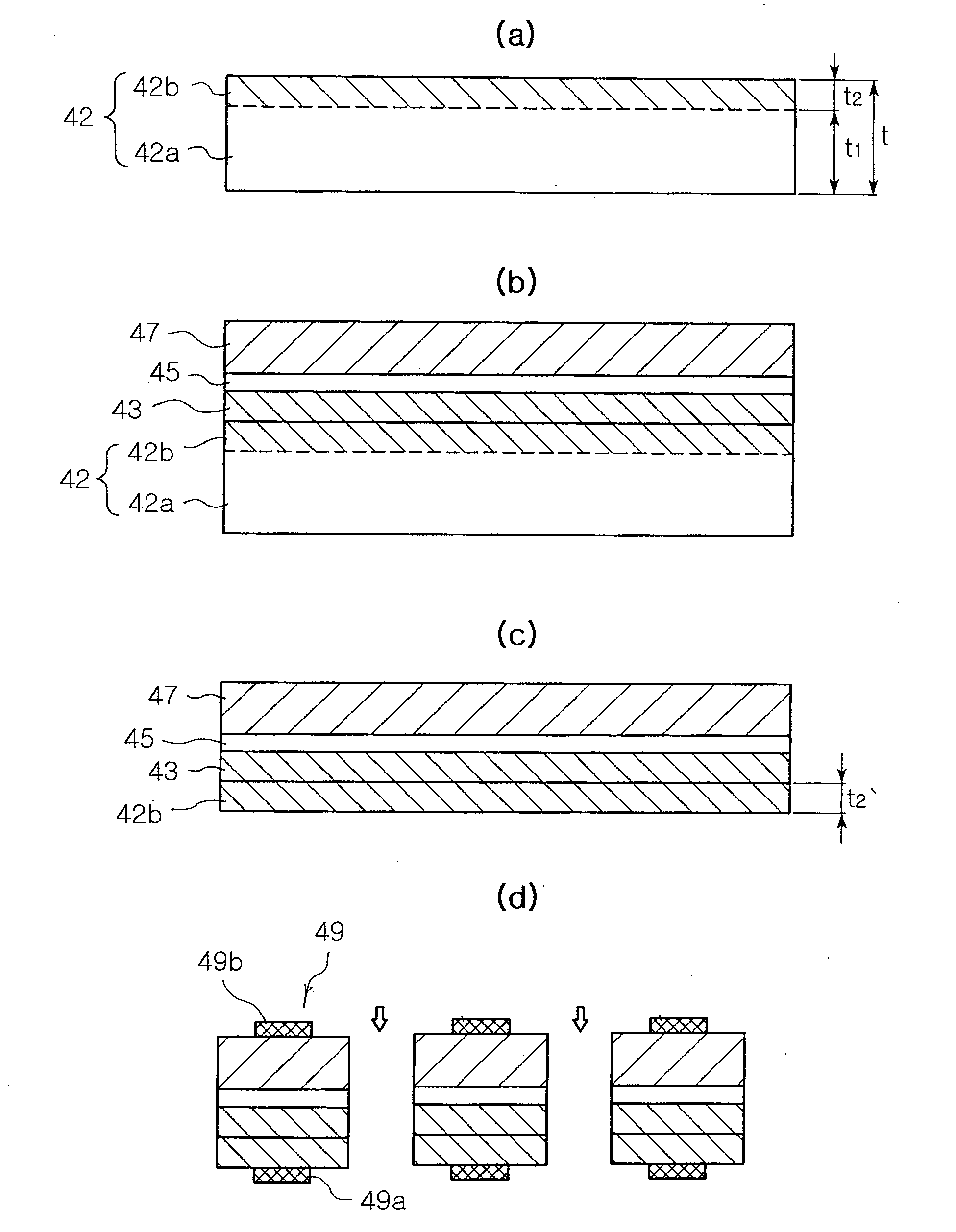

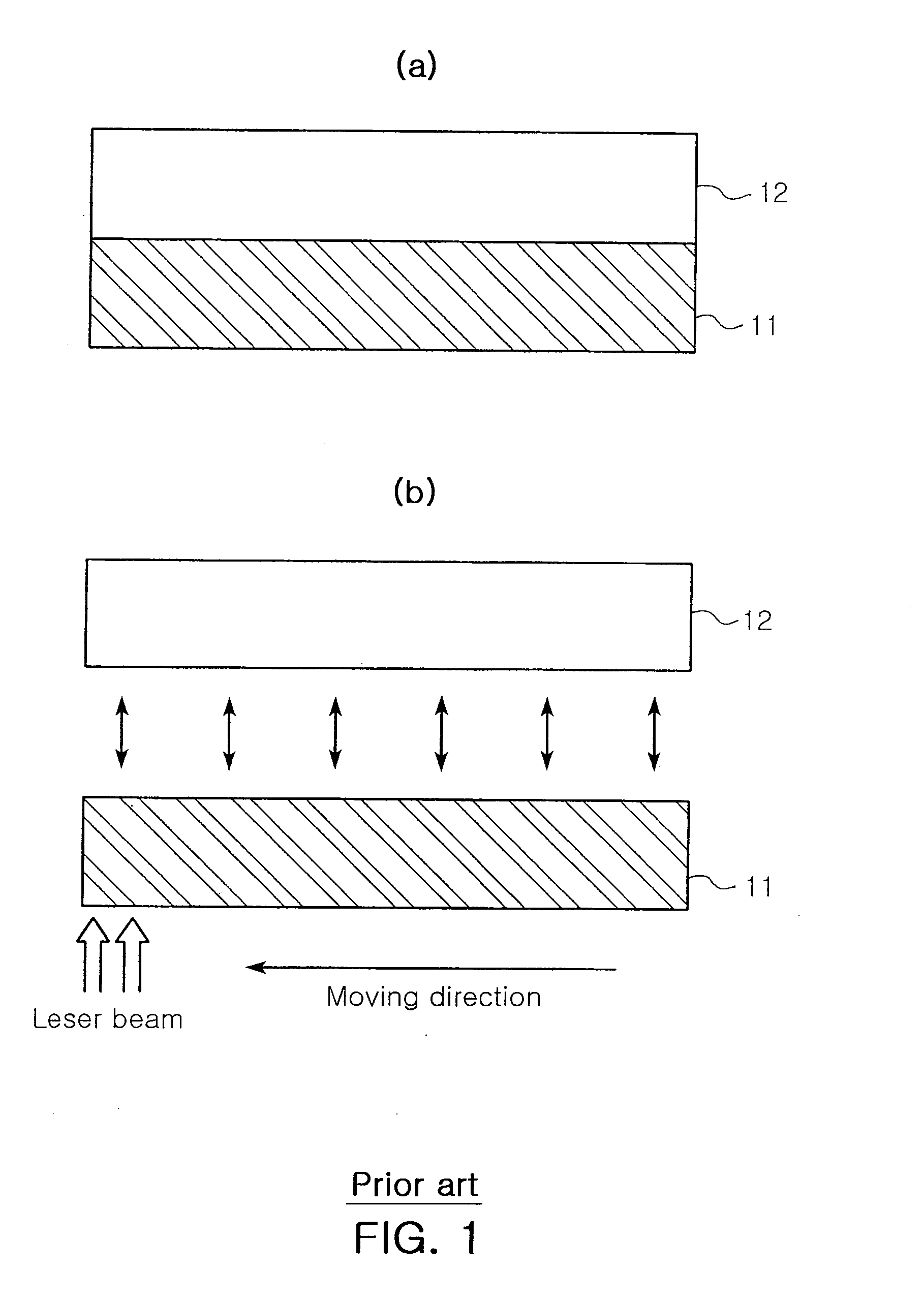

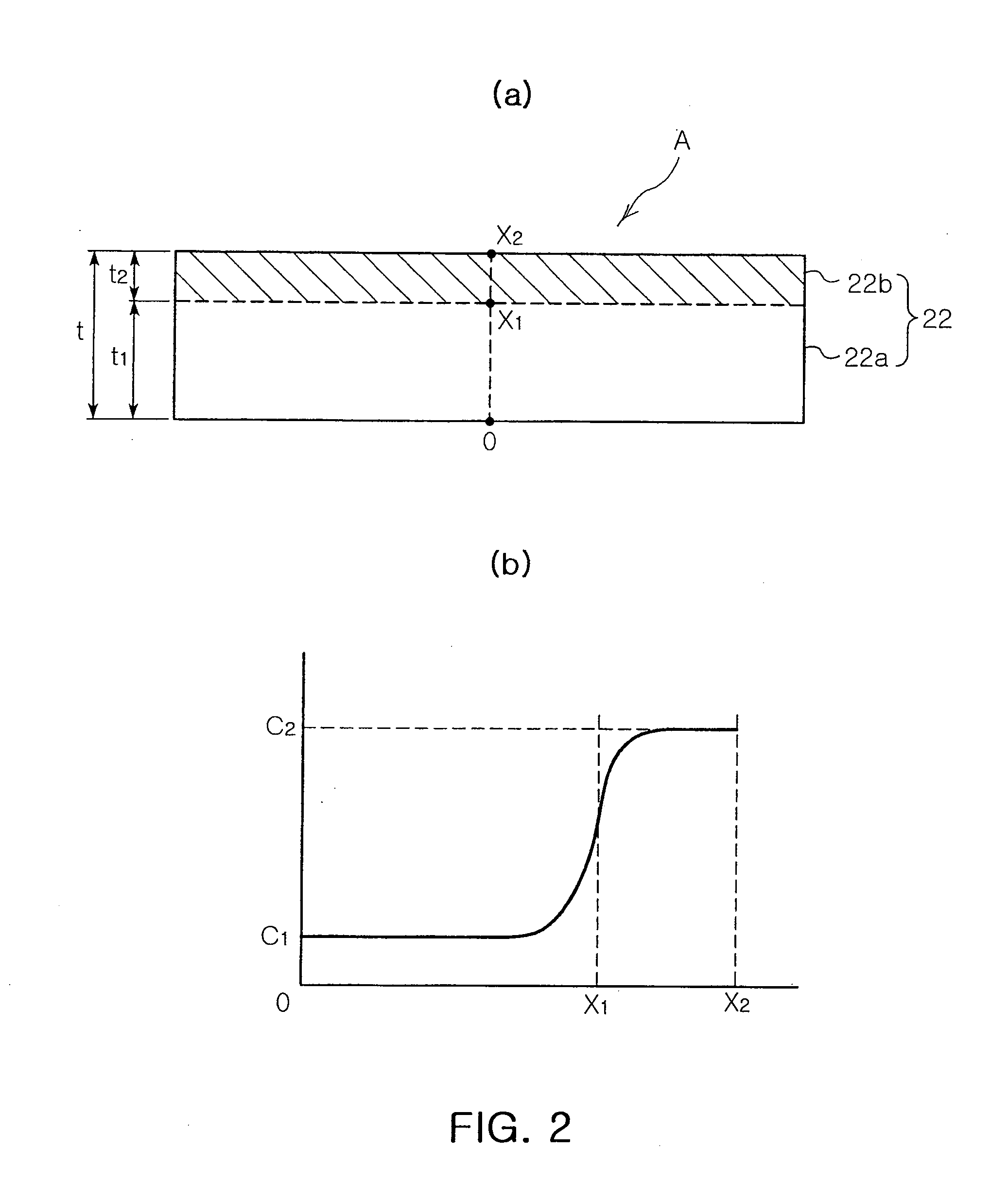

Nitride semiconductor single crystal substrate, and methods of fabricating the same and a vertical nitride semiconductor light emitting diode using the same

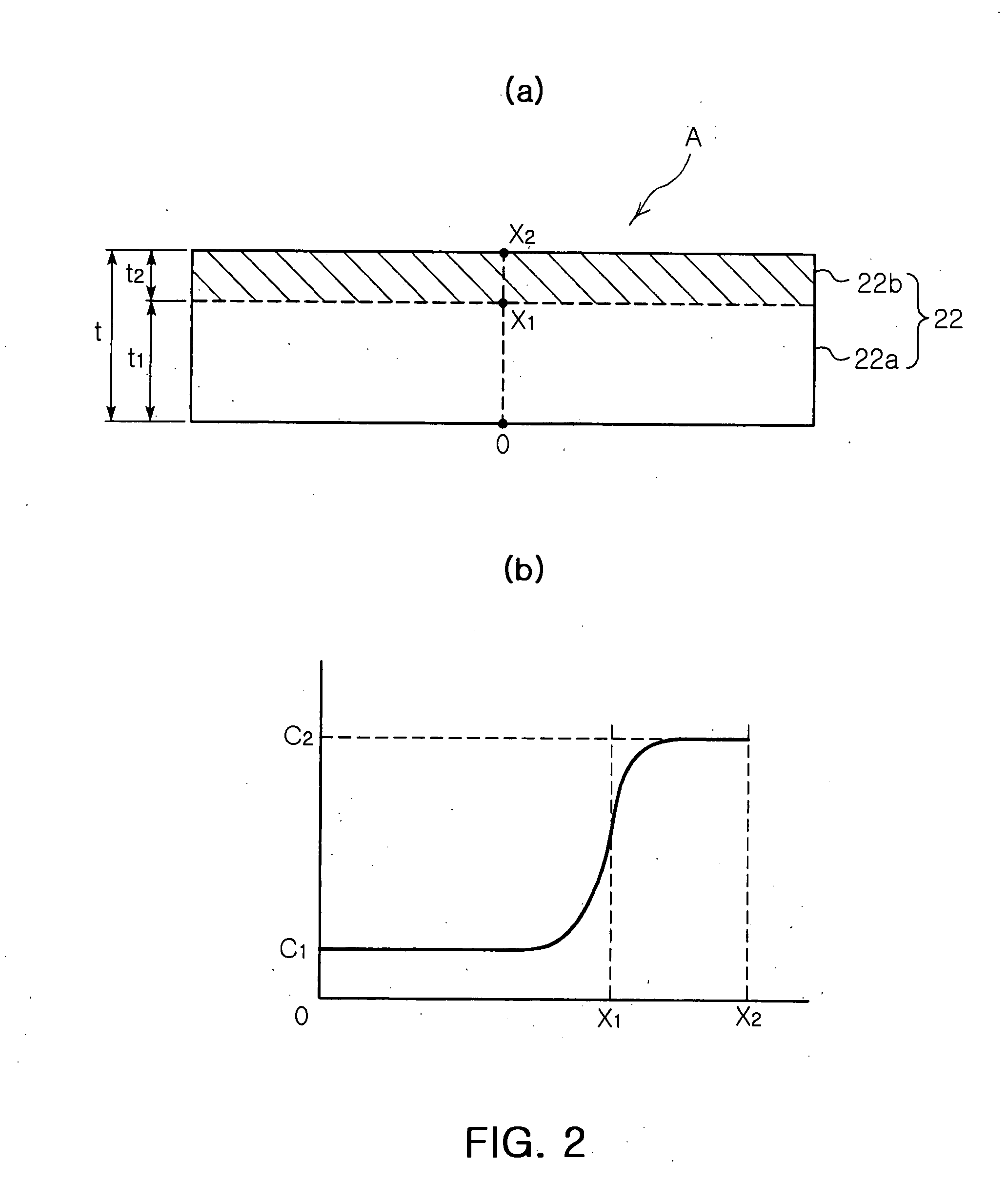

ActiveUS20070215983A1High crystallinityThe grinding process is simpleSemiconductor/solid-state device manufacturingDomestic applicationsSingle crystal substrateSingle crystal

A nitride semiconductor single crystal substrate, a manufacturing method thereof and a method for manufacturing a vertical nitride semiconductor device using the same. According to an aspect of the invention, in the nitride semiconductor single crystal substrate, upper and lower regions are divided along a thickness direction, the nitride single crystal substrate having a thickness of at least 100 μm. Here, the upper region has a doping concentration that is five times or greater than that of the lower region. Preferably, a top surface of the substrate in the upper region has Ga polarity. Also, according to a specific embodiment of the invention, the lower region is intentionally un-doped and the upper region is n-doped. Preferably, each of the upper and lower regions has a doping concentration substantially identical in a thickness direction.

Owner:SAMSUNG ELECTRONICS CO LTD

Grinding method for pipelining slurry in manufacturing process of aluminium oxide

InactiveCN101579649AImprove operating rateReduce unit consumptionGrain treatmentsAluminium oxides/hydroxidesCycloneSlurry

A grinding method of pipelining slurry in the manufacturing process of the aluminium oxide relates to the slurry grinding method in the manufacturing process of the aluminium oxide, which is characterized in that the grinding process adopts a three-bin strong drainage type tuber grinder to grind the ore; a cylinder screen is externally arranged at the discharge end of the grinder for one-time screen separation; a hydraulic cyclone is adopted for grading to constitute a closed circuit grinding process flow. On the basis of the current grinding techniques, the method of the invention takes up respective advantages, thus effectively simplifying the grind grading process flow, reducing grinding energy consumption and further optimizing the grinding fineness index, the invention further has the advantage of easy operation and management.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

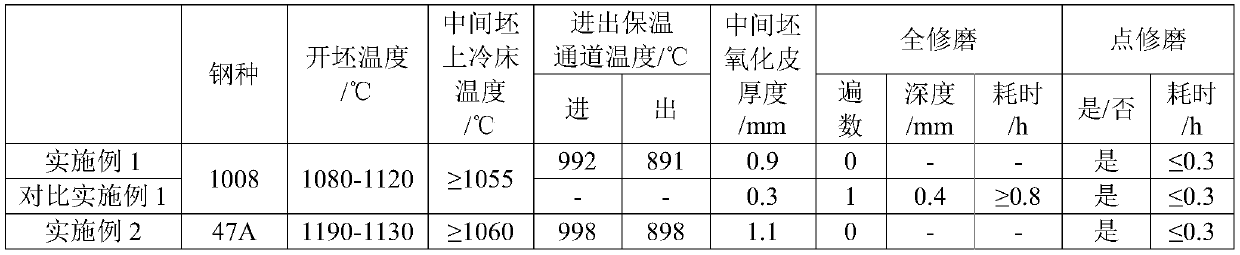

Method for eliminating surface defects of carbon steel intermediate blank

ActiveCN110340146AImprove oxidation effectReduce surface defectsTemperature control deviceMetal rolling arrangementsGranularityRoom temperature

The invention discloses a method for eliminating the surface defects of a carbon steel intermediate blank. The intermediate blank after blooming is subjected to air cooling-heat preservation channel slow cooling-air cooling to room temperature-shot blasting-magnetic particle inspecting-defect point grinding treatment, the intermediate blank after blooming is subjected to heat preservation and slowcooling in a specific temperature zone, waste heat of the intermediate blank is fully utilized, the formation of a surface scale is accelerated, the defect depth of a matrix is reduced, and the surface defect of the matrix is remarkably reduced. According to the method, three steel shots with different granularities are selected for shot blasting, so that the removal of the scale before magneticparticle inspection can be ensured, the surface roughness of the blank is reduced, and the identification rate of the magnetic particle inspection is improved. The grinding process is simplified, theproduction efficiency is greatly improved, the production consumption is reduced, and the generation of dust is reduced.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Open-flow powder mill

InactiveCN1709578AAvoid overgrindingImprove grinding efficiencyCement productionGrain treatmentsElectricityEngineering

This invention belongs to the power engineering, referring to cement and mineral sophistication production equipment. It includes revolving canister(8),front axletree seat(7),back axletree seat(10).The front of (8) is connected to (7) by axletree, the back to (10).There are feed-in meatus (1) and feed-out meatus (6) in (8).The character is that in (8) there are 1-3 picking power equipments. This invention integrates levigation and picking to increase output, reduce energy sourse, decrease expenditure. Comparing with the same scale equipment, its output increases by more than 20% and the consumption of electricity decreases by more than 30%.

Owner:WUHAN UNIV OF TECH

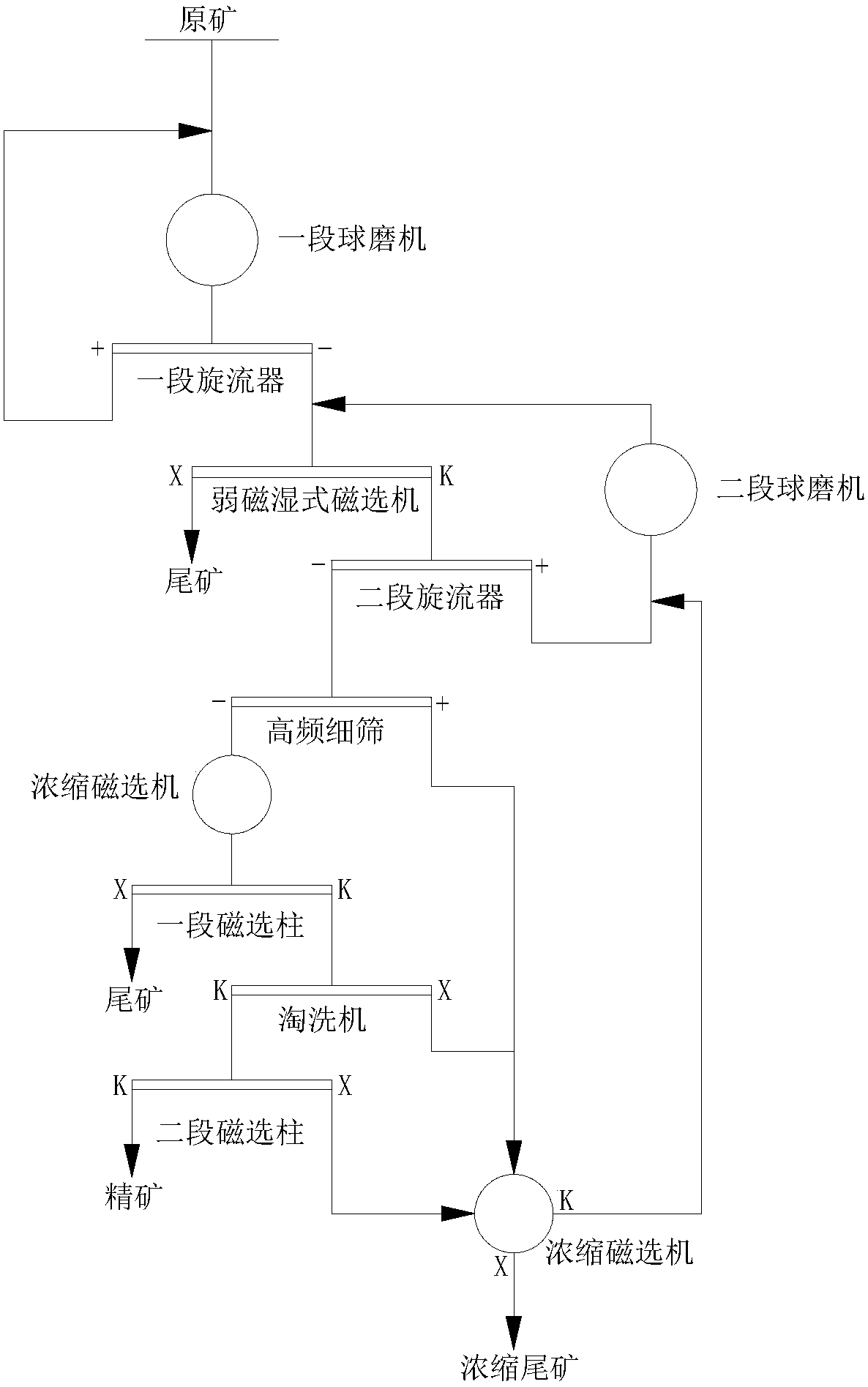

Novel magnetite separation technology

InactiveCN108393191AQuality improvementSimplify the grinding processWet separationSeparation technologyMagnetic separator

The invention discloses a novel magnetite separation technology, and belongs to the technical field of mine mineral separation. The novel magnetite separation technology comprises the following stepsthat one, raw ore is conveyed into a first-stage ball mill for grinding, and after the grinding, a product enters a first-stage swirler for grading; two, an overflow product enters a weak magnetism wet magnetic separator for rough separation, rough separation concentrate enters a second-stage swirler for grading; three, an overflow product is input to a high-frequency undersize sieve for re-grading; four, an undersized product is condensed by a concentration magnetic separator and then is input into a first-stage magnetic separation column for separation; and five, magnetic concentrate is fedinto an elutriation machine for treatment and enters a second-stage magnetic separation column for separation, and thus concentrate is obtained finally. The first-stage magnetic separation column, theelutriation machine and the second-stage magnetic separation column are connected in series in use, and the fineness of a graded product from the second-stage ball mill is thickened appropriately, sothat a new mineral separation idea of obtaining the concentrate in advance is formed, a traditional grinding separation process flow is simplified and the production cost is reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD

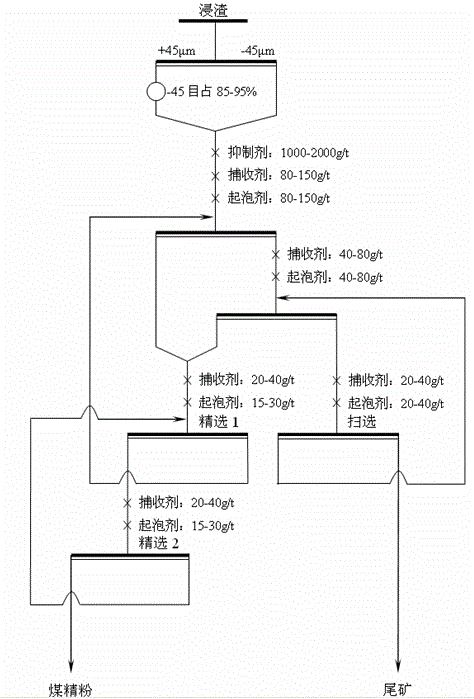

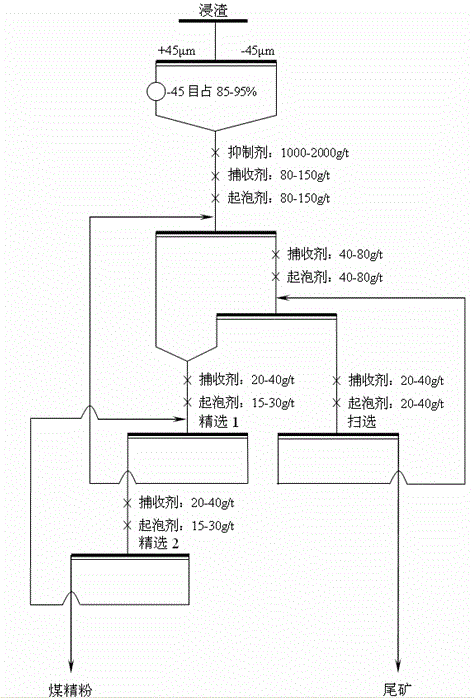

Method for recycling fine pea coal in stone coal navajoite leaching residues

The invention discloses a method for recycling fine pea coal in stone coal navajoite leaching residues, and belongs to the technical field of mineral processing engineering. The leaching residues are graded in advance and divided into coarse products and fine products; the coarse products are ground fine, and the ground products and the fine products are combined to form flotation feeding ore; flotation roughing is divided into two procedures, inhibitors, collectors and foaming agents are added in primary roughing, collectors and foaming agents are added in secondary roughing, foam products produced in two times of roughing are combined to form roughed concentrate, and products in grooves are roughed middling; after collectors and foaming agents are added into the roughed middling, scavenging is carried out, scavenged middling and final tailing are obtained, and the scavenged middling return to the second roughing procedure; the roughed concentrate is concentrated twice, a small quantity of collectors and foaming agents are added in the concentration process, the middling in the primary concentration returns to the primary roughing process, and middling in the secondary concentration returns to the first concentration process. The method is reasonable in process procedure, simple in procedure structure, wide in raw material adaptability, and easy to implement industrially.

Owner:KUNMING UNIV OF SCI & TECH

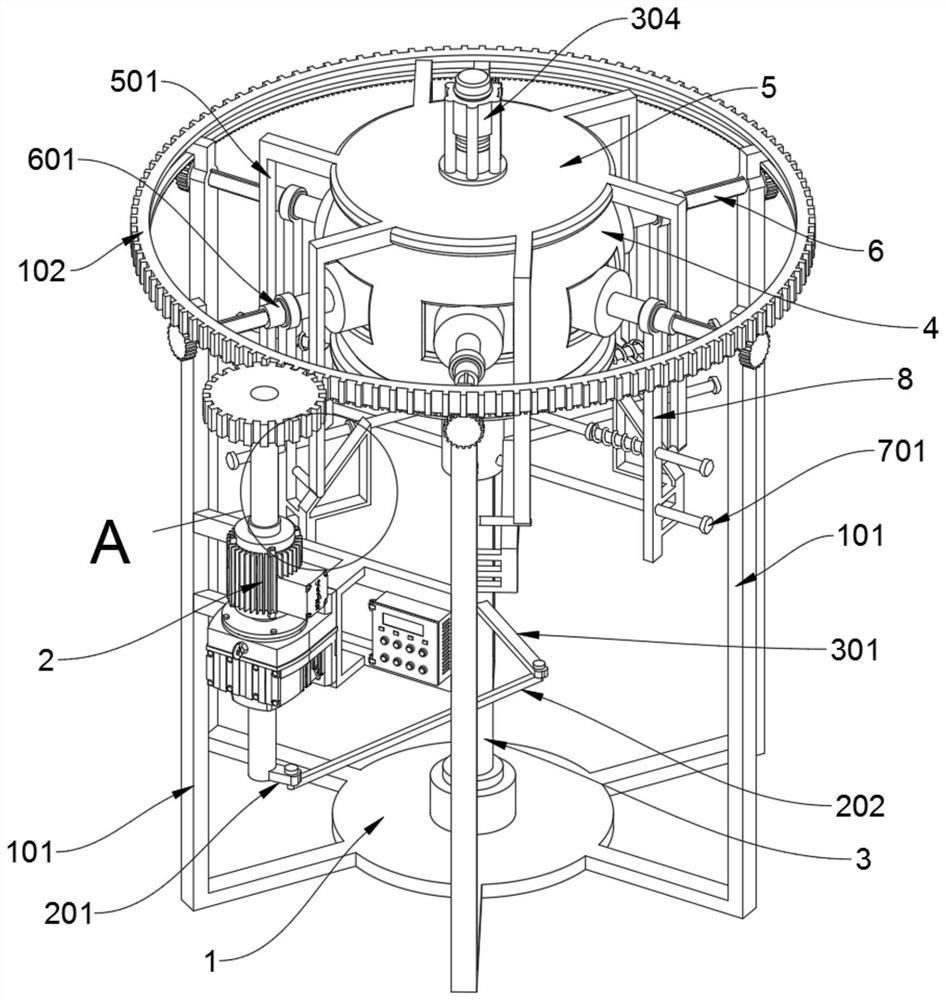

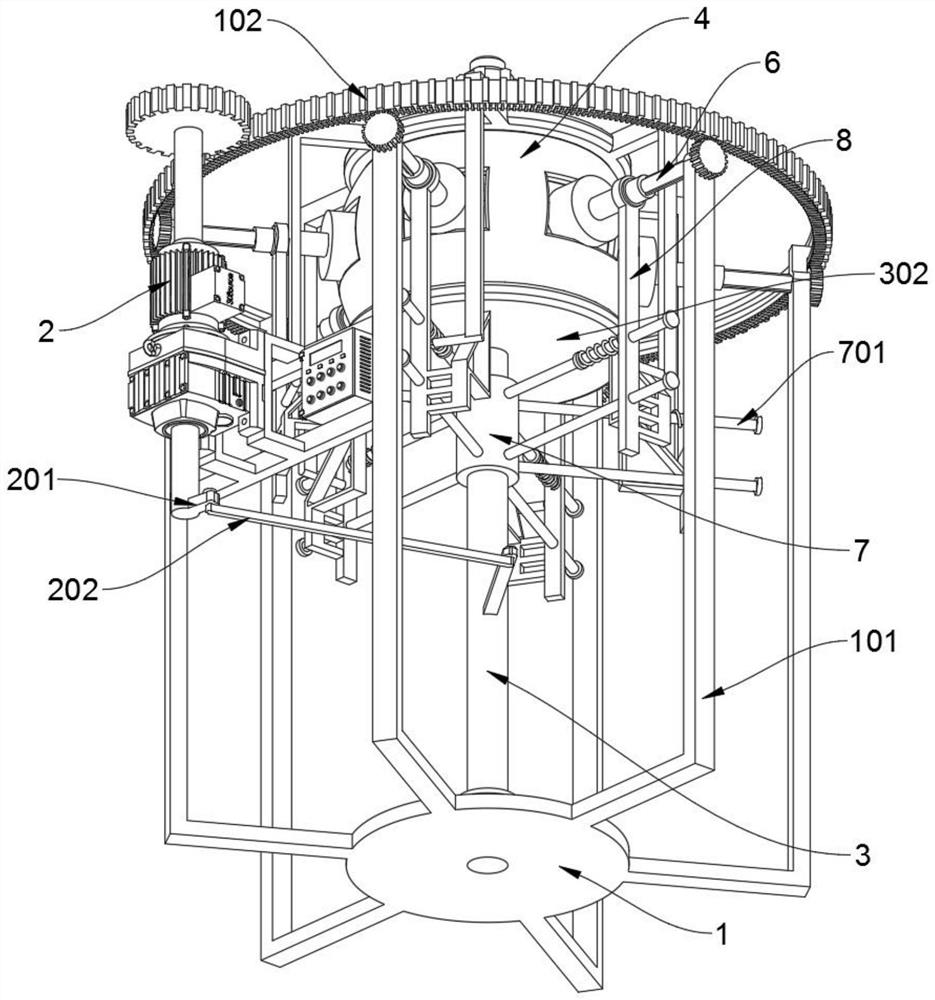

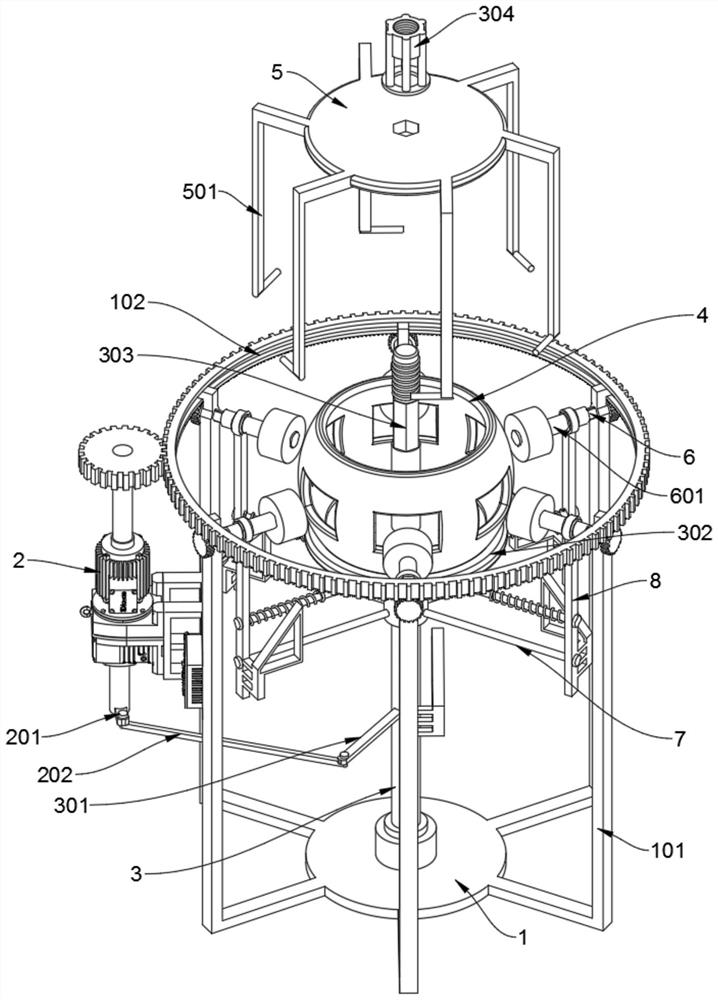

Position and angle adjustable ball cage retainer grinding tool

ActiveCN111823118AFull and thorough polishingAvoid missing sandingPolishing machinesGrinding drivesPolishingEngineering

The invention discloses a position and angle adjustable ball cage retainer grinding tool, and relates to the technical field of automobile accessory grinding equipment. The problems that in existing grinding equipment, a rotary grinding part (namely a grinding plate) is mostly in a circular structure, and is limited in diameter and length, so that the grinding part cannot be suitable for polishingtwo long sides of a rectangular window, and polishing is caused not thorough and comprehensive, and polishing omission is prone to occur. The position and angle adjustable ball cage retainer grindingtool comprises a base, wherein the base is integrally formed by welding and combining a central circular bottom plate and six vertical supporting legs for supporting in an annular array manner, wherein the top ends of the six vertical supporting legs are provided with L positioning clamping jaws in a welded and supported mode, and a toothed ring is mounted on the six L positioning clamping jaws in a sleeve rotating manner. Six position springs on six positioning shaft rods in the tool can perform rebounding, pushing, pulling and resetting on six vertical support positioning frames, six shaftsleeves and wire drawing polishing wheels, so that the trouble of manual sequential pulling of the six wire drawing polishing wheels is omitted.

Owner:王河水

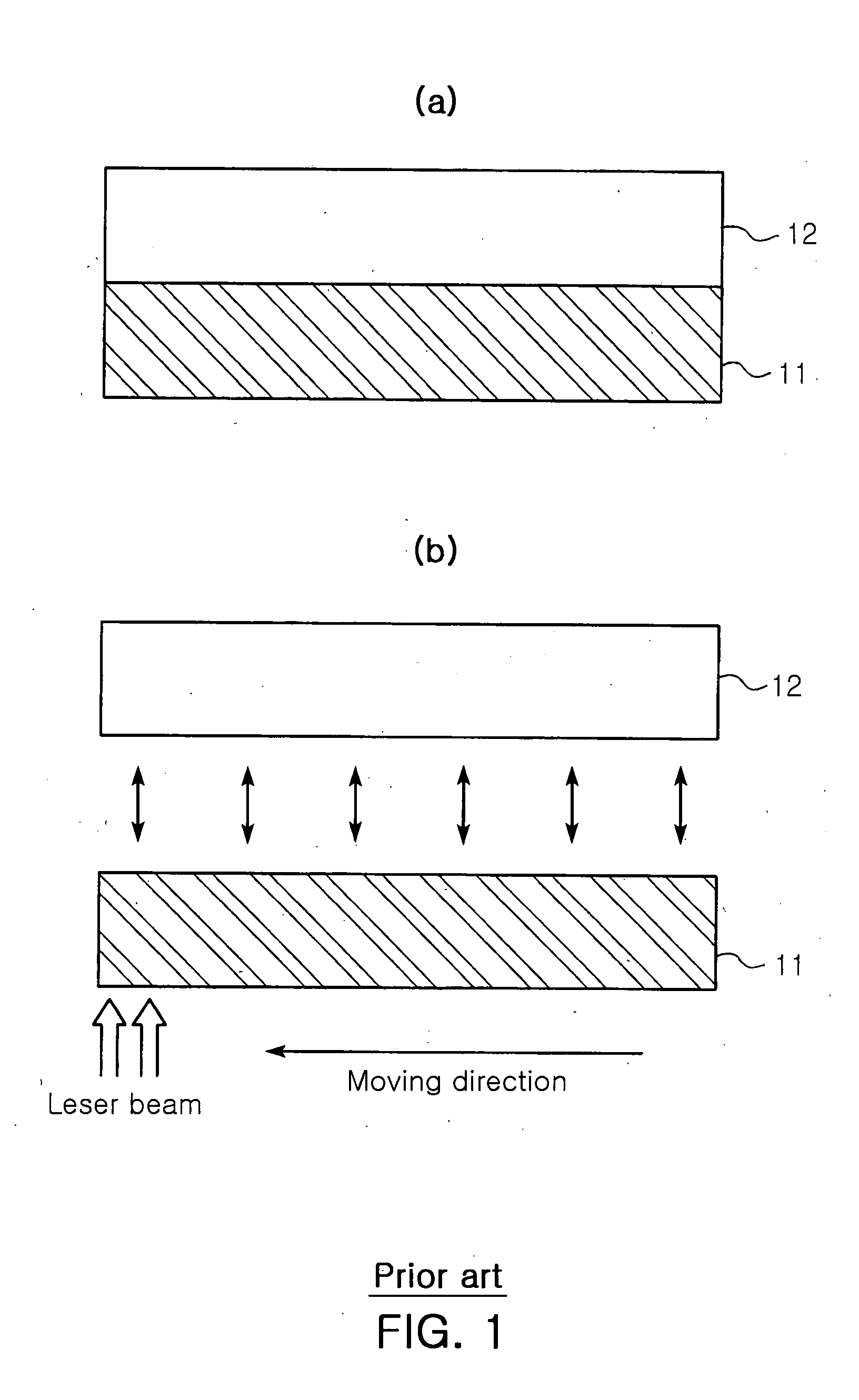

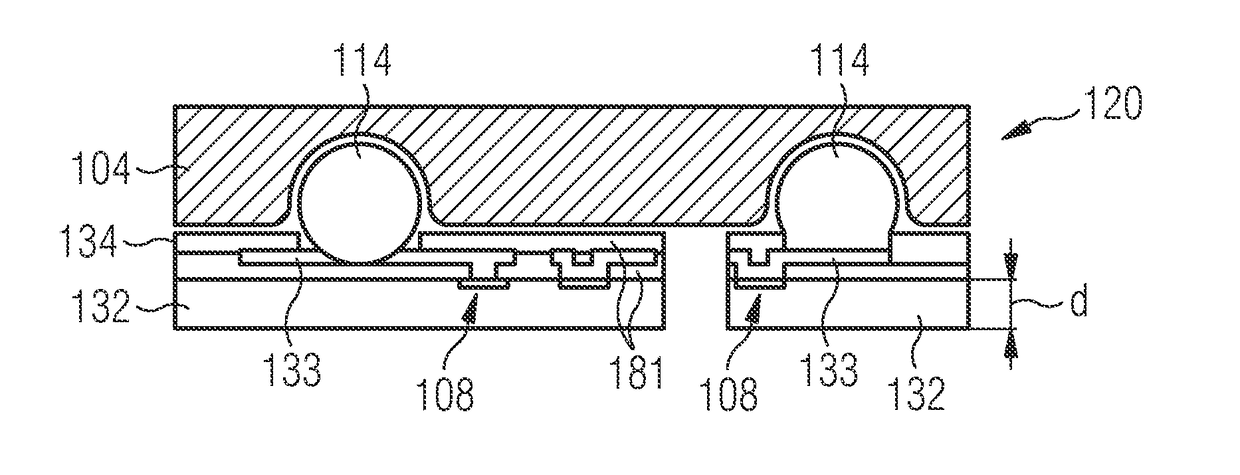

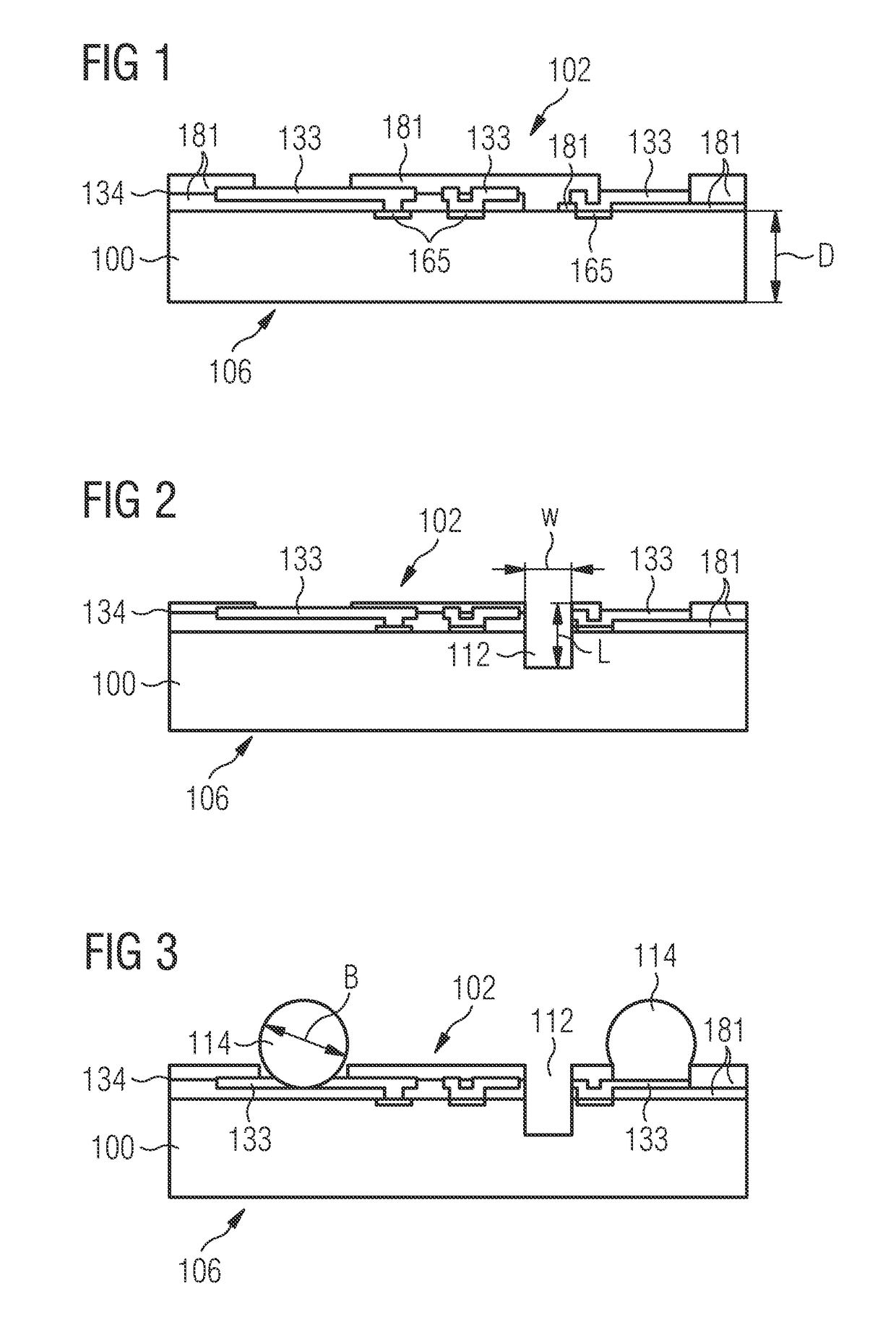

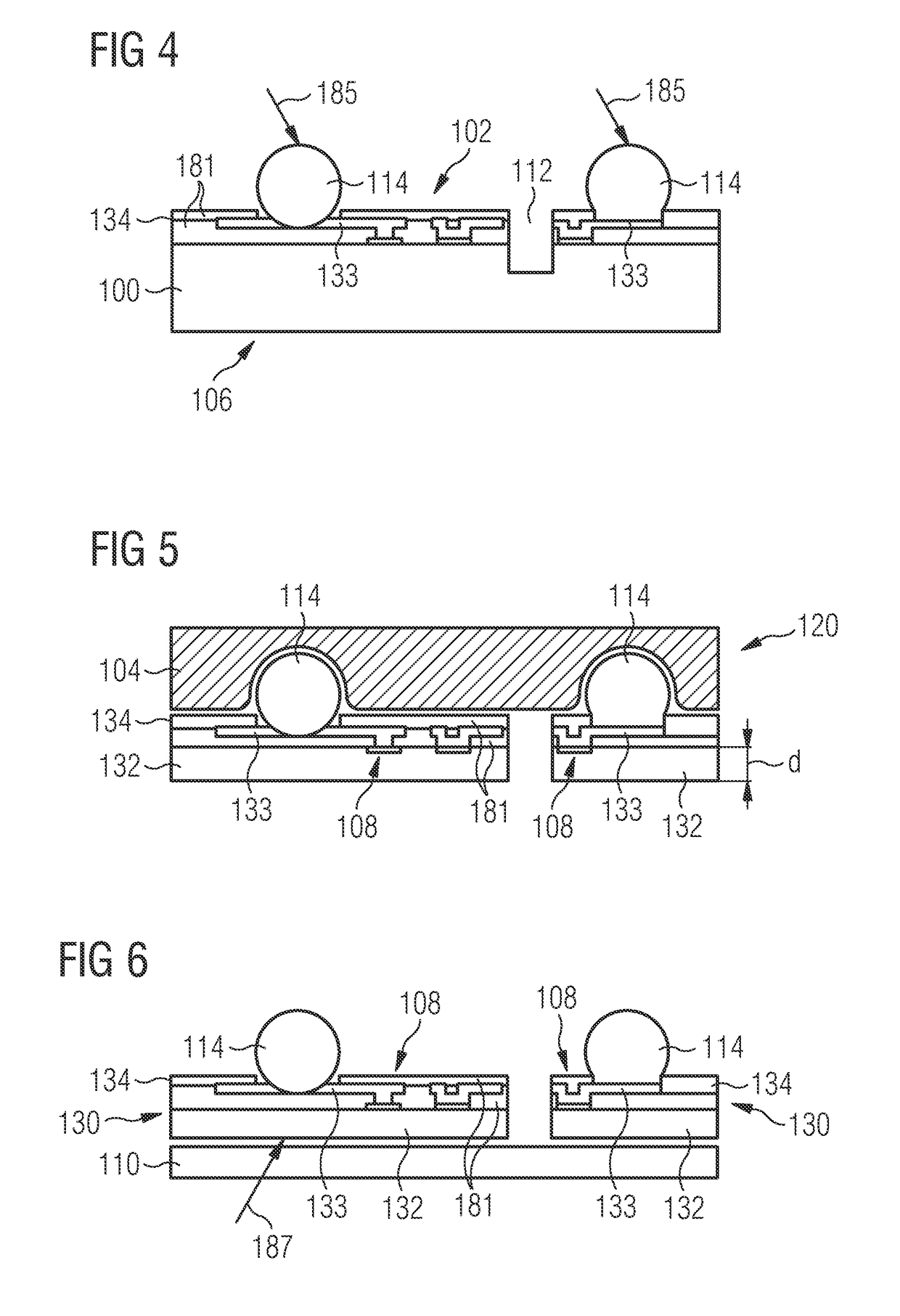

Handling thin wafer during chip manufacture

InactiveUS20180233470A1Thin thicknessMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesWaferingMechanical engineering

A manufacturing method is provided which comprises forming recesses in a front side of a wafer, connecting a first temporary holding body to the front side of the recessed wafer, thereafter thinning the wafer from a back side, connecting a second temporary holding body to the back side, and thereafter removing the first temporary holding body.

Owner:INFINEON TECH AG

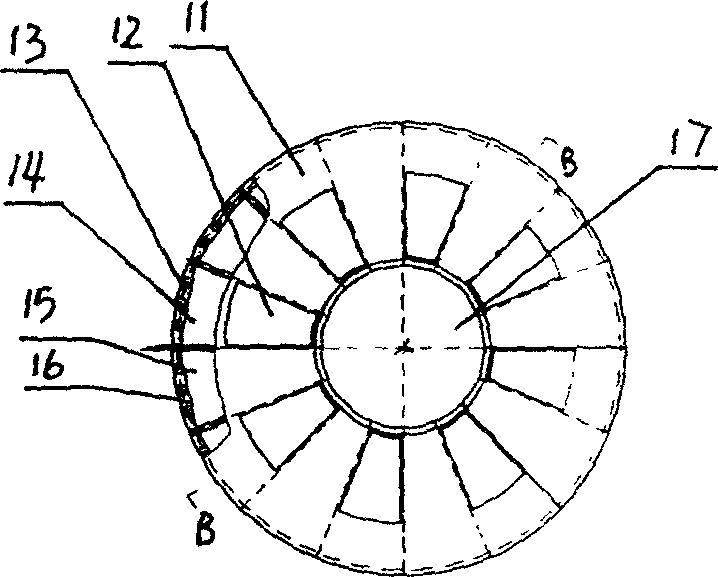

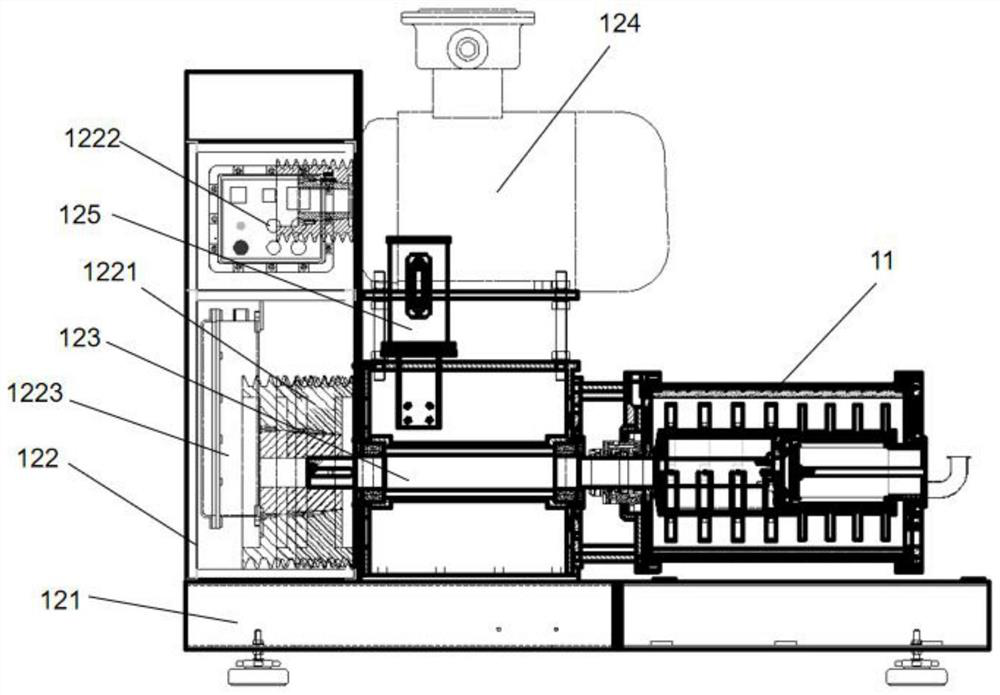

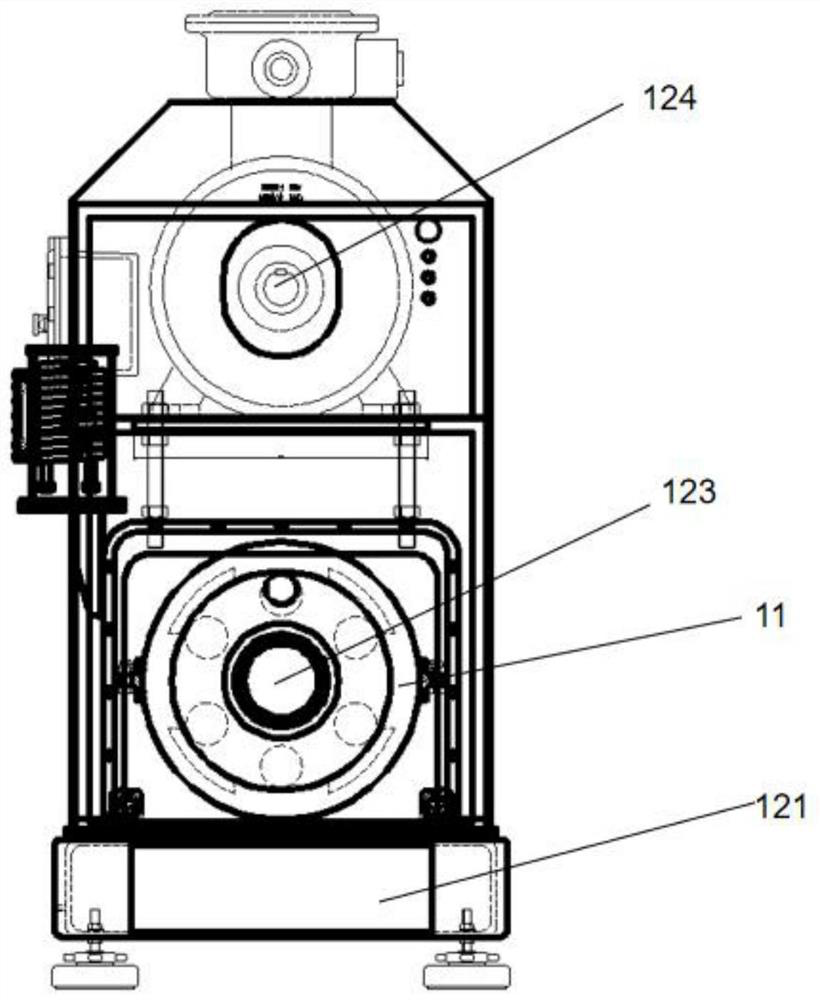

Reflection type grinding barrel, grinding system and grinding machine

Owner:湖南南国设备科技有限公司

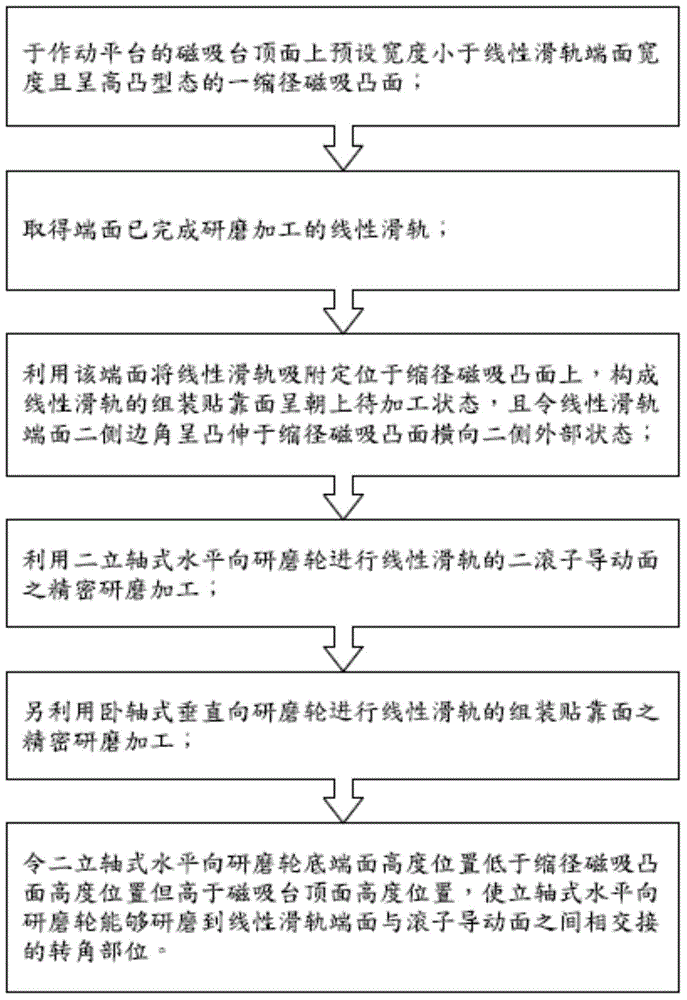

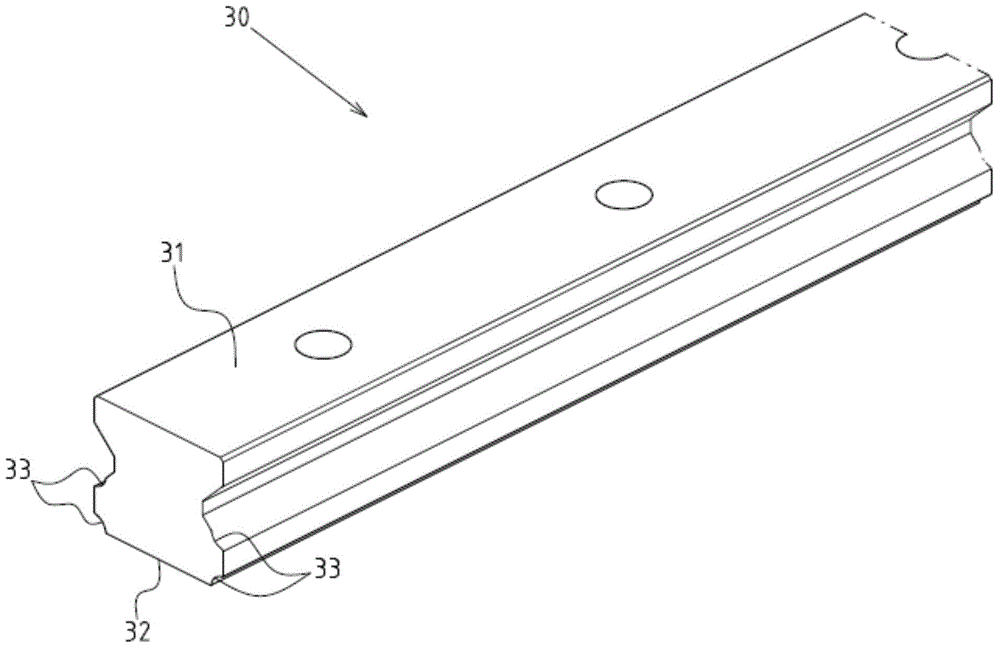

Linear sliding rail grinding method and grinding mechanism thereof

InactiveCN104416445AThe grinding process is simpleReduce machining errorsLapping machinesGrinding machinesEngineeringGrinding wheel

The invention discloses a linear sliding rail grinding method and a grinding mechanism thereof. The grinding mechanism comprises a magnetic table arranged on an actuating platform, two vertical-shaft horizontal grinding wheels and a horizontal-shaft vertical grinding wheel, wherein the two vertical-shaft horizontal grinding wheels and the horizontal-shaft vertical grinding wheel are arranged on a saddle type stand unit. The top surface of the magnetic table is provided with a reducing magnetic convex surface which is in a convex state, and the reducing magnetic convex surface is smaller than the width of the end surface of a linear sliding rail; the linear rail is attached and positioned onto the reducing magnetic convex surface through the end surface of the linear sliding rail for performing precise finishing on the guide surface and the assembling attaching surface of a roller; the height of the bottom end surfaces of the two vertical-shaft horizontal grinding wheels is lower than that of the reducing magnetic convex surface but higher than that of the top surface of the magnetic table, so that the vertical-shaft horizontal grinding wheel can grind the corner parts connected between the end surface of the linear sliding rail and the guide surface of the roller. The linear sliding rail grinding method and the grinding mechanism thereof can achieve the aim of simplifying the grinding process of the linear sliding rail, reducing the processing errors and improving the processing quality.

Owner:JOEN LIH MACHINERY

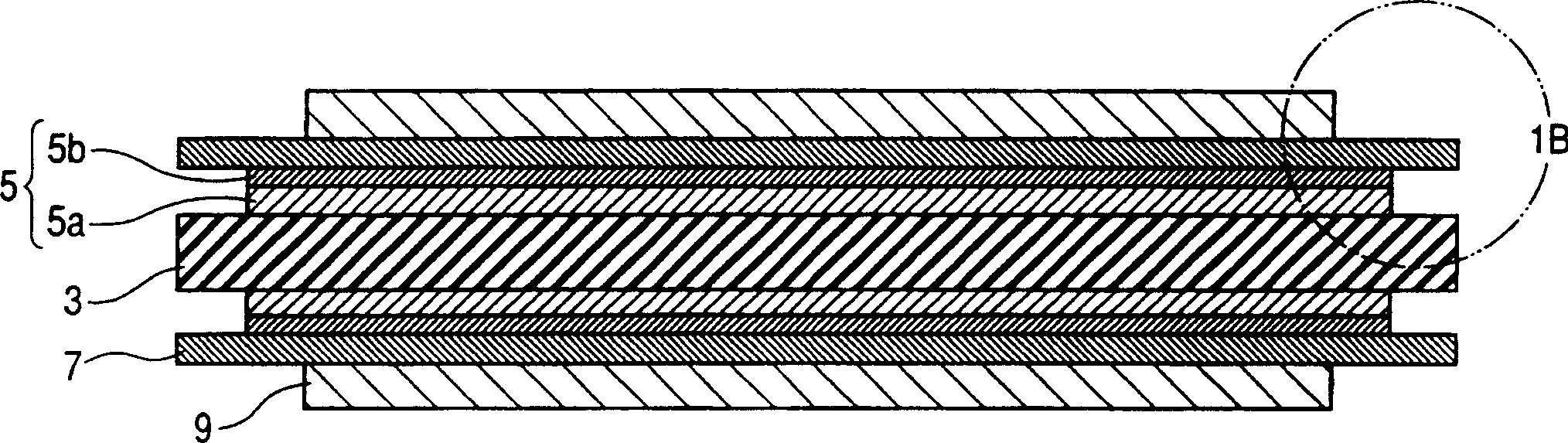

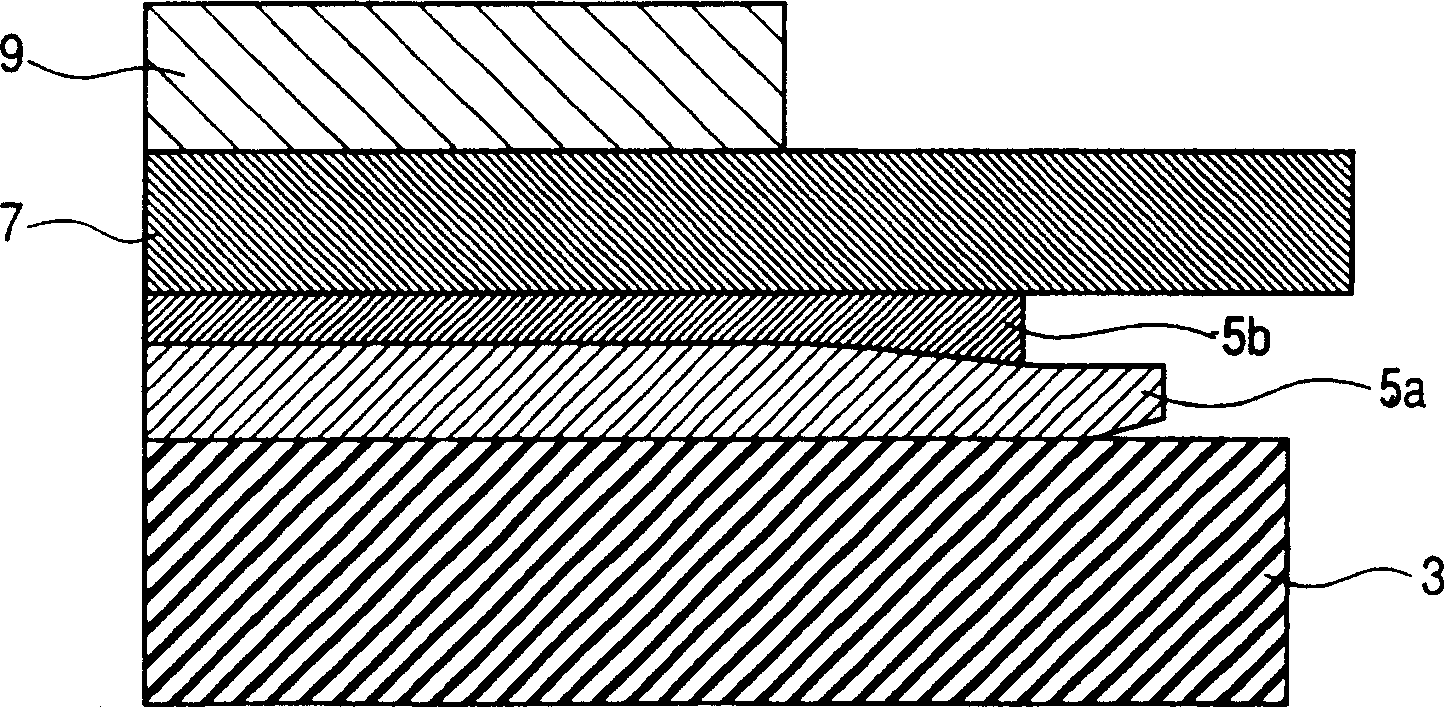

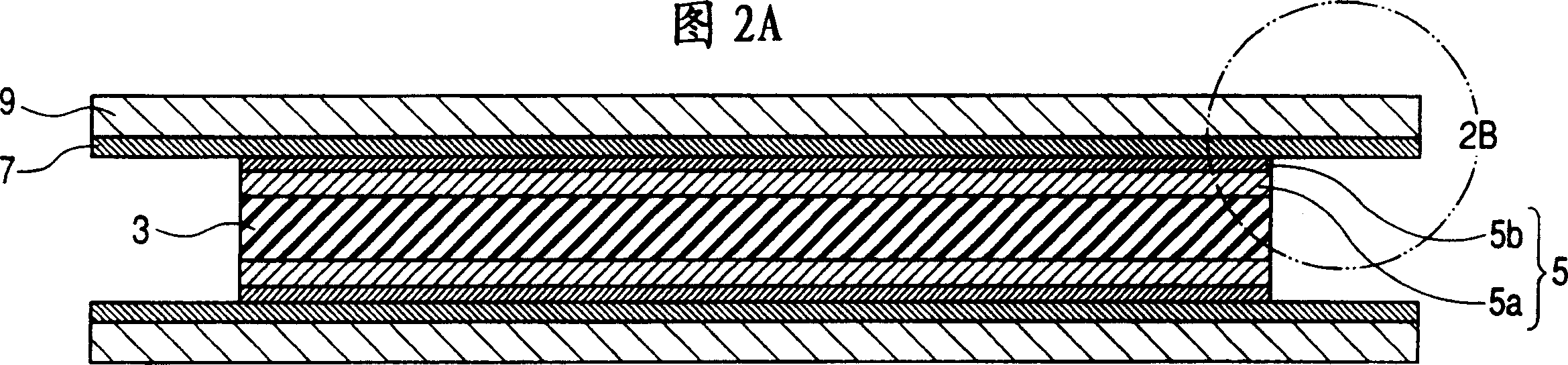

Method of manufacturing laminated substrate

InactiveCN1856223AImprove flatnessReduce grindingAutomatic/semiautomatic turning machinesPrinted circuit aspectsMechanical engineeringSteel plates

In a press process, a buffer member is placed on an RCC with a stainless steel plate between in such a way that the long sides and the short sides of the buffer member are aligned with the long sides and the short sides of the RCC respectively. The length of the long sides and the length of the short sides of the buffer member are designed to be smaller than the lengths of the long sides and the length of the short sides of the RCC respectively. With this feature, it is possible to reduce convexity on the RCC that is created in the peripheral region upon pressing the RCC to a core member.

Owner:TDK CORPARATION

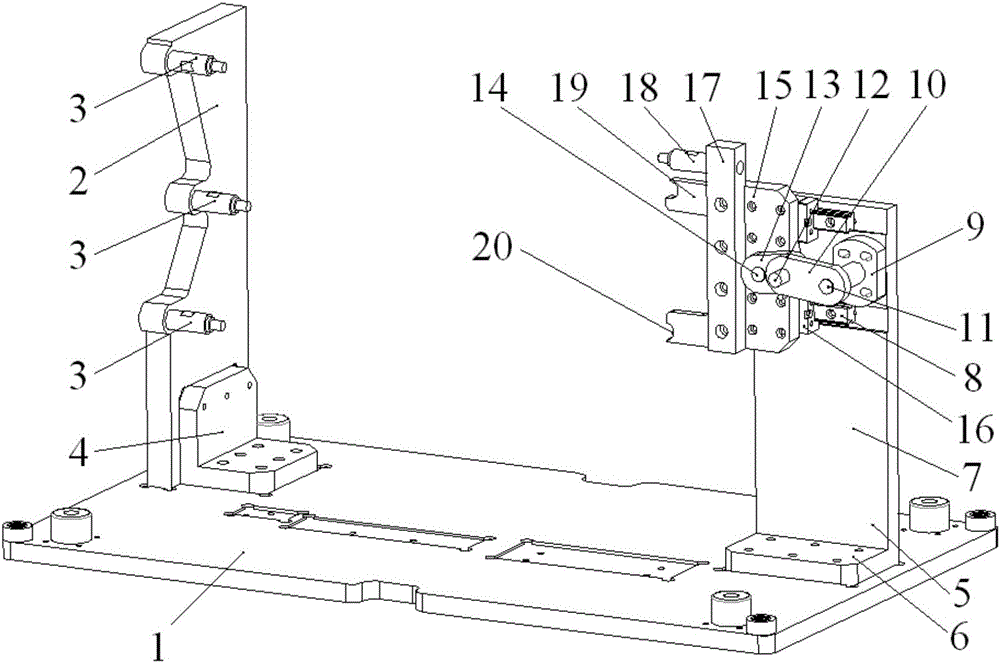

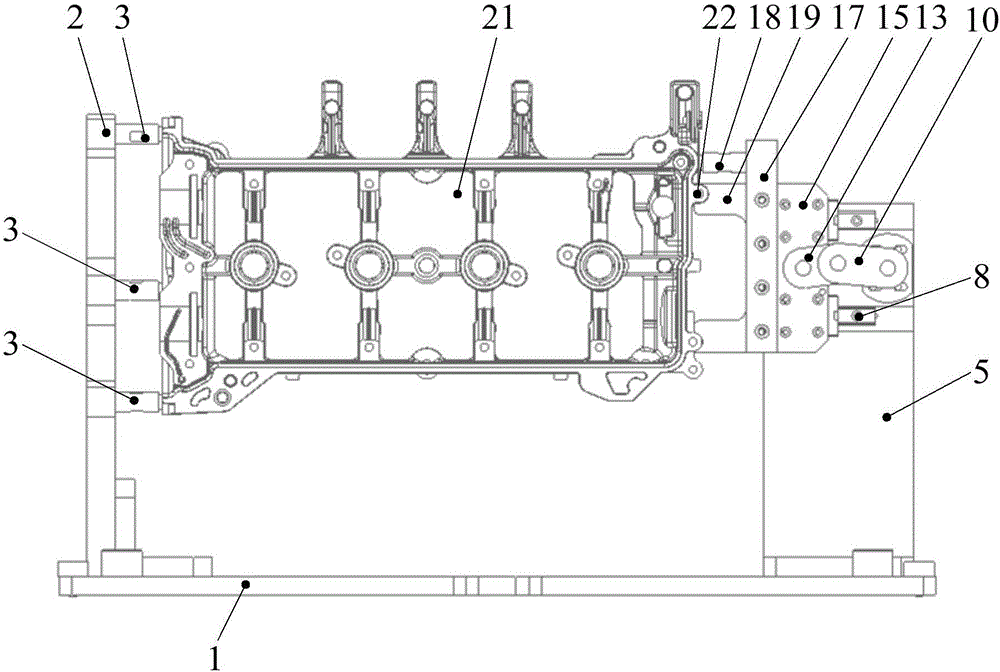

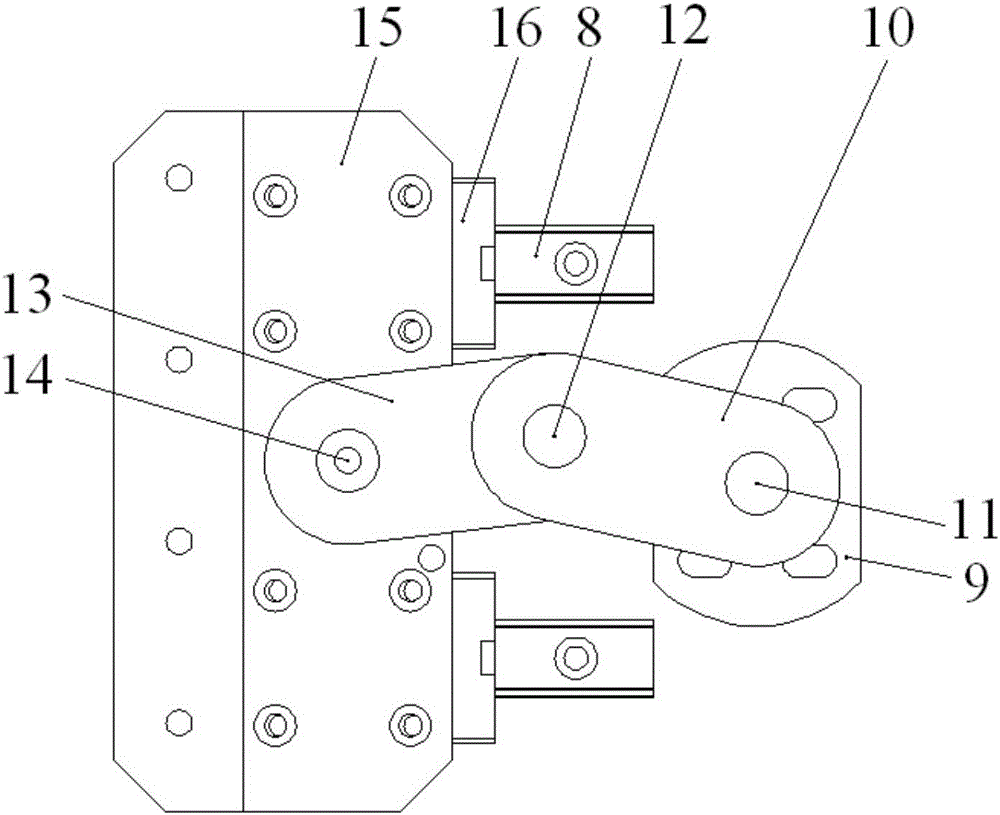

Fixture for grinding pressure casting

ActiveCN106475904AAchieve clampingAchieve positioningGrinding work supportsLocking mechanismPressure casting

The invention discloses a fixture for grinding a pressure casting. The fixture comprises a bottom plate; the bottom plate is vertically provided with a first side plate and a second side plate; the first side plate is horizontally and convexly provided with a first cylindrical pin towards the second side plate; the first cylindrical pin is matched with a round hole in one end surface of the pressure casting; the second side plate is provided with a locking mechanism comprising a first connecting plate, a second connecting plate, a push plate and a clamping plate; one end of the first connecting plate is connected to the second side plate through a first screw, and the other end of the first connecting plate is connected to one end of the second connecting plate through a movable screw; the other end of the second connecting plate is connected to the push plate through a second screw; the surface, close to the second side plate, of the push plate is fixedly provided with a slide block; the second side plate is horizontally provided with a guide rail; the slide block is arranged on the guide rail; the clamping plate is fixedly arranged on the push plate; the clamping plate is horizontally and convexly provided with a second cylindrical pin and a clamping block towards the first side plate; and the second cylindrical pin and the clamping block are matched with a round hole and a boss which are formed in the other end surface of the pressure casting. The fixture disclosed by the invention is precise in location, simple in clamping, suitable for large-scale processing of products and capable of increasing the production efficiency.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Softening method for wood for knitting

The invention discloses a softening method for wood for knitting. The softening method has the characteristics that the softening method is simple, the treatment period is shortened to 12~13 hours, the working efficiency is increased by 11.3%, the production cost is reduced by 12.6%, and the natural color of the wood is not changed. The softening method comprises the following steps: soaking battens in brine, so that not only sterilization but also dehydration at high temperature can be realized, cellular structures are changed, and permeation of a follow-up treating fluid is facilitated; carrying out high-temperature sand bath of the battens, and spacing the battens with wet leaves, so that the battens are dried after being wetted, fiber structures are softened preliminarily, and the permeability is enhanced; rapidly softening the fiber structures with a softener solution of high permeability, so that the obtained wood is soft, resistant to high temperature, free of cracking, and convenient for machining of wood chips and wood veneers with smooth surfaces, a polishing process is simplified, the softened wood can be free of mold and insects after long-term storage, and storage and use are facilitated; and finally, carrying out medium-temperature drying, so that water is slowly evaporated and cannot be regained, energy is saved, and the environment is protected.

Owner:阜南县东奥工艺品有限公司

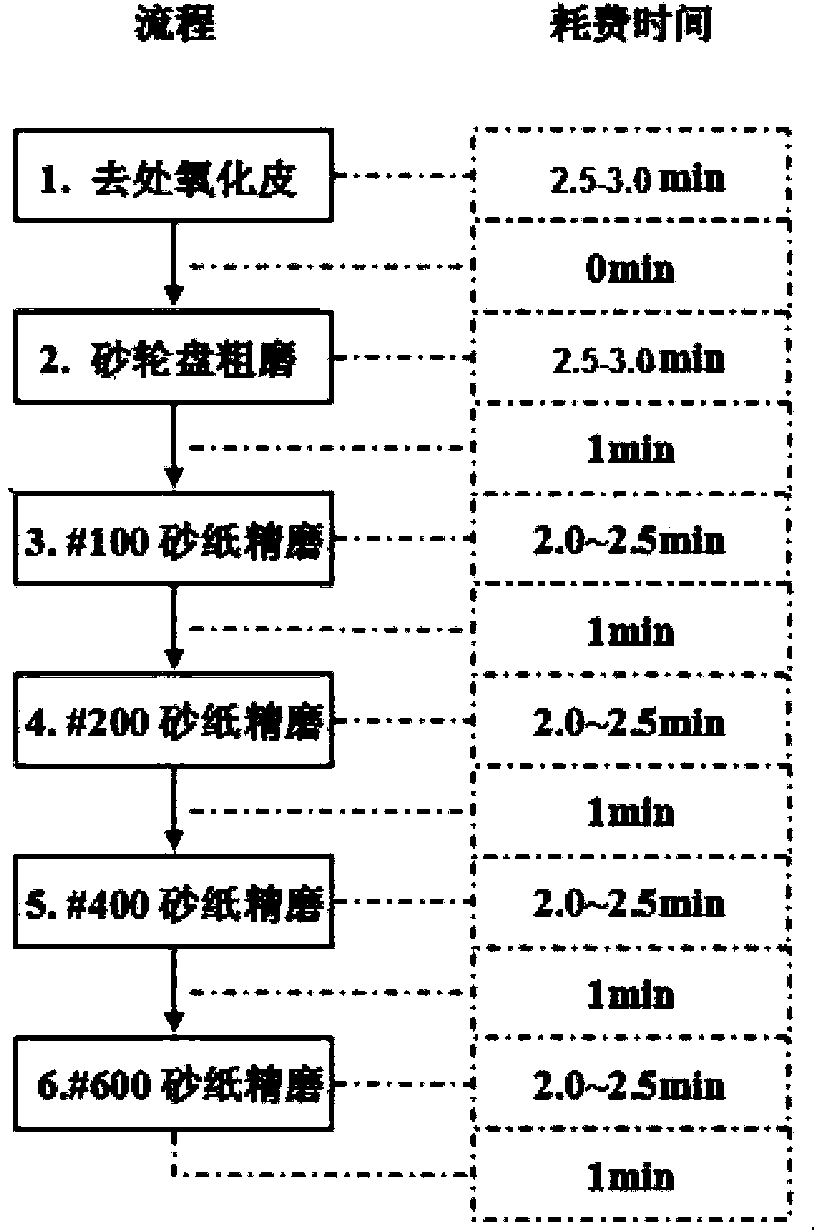

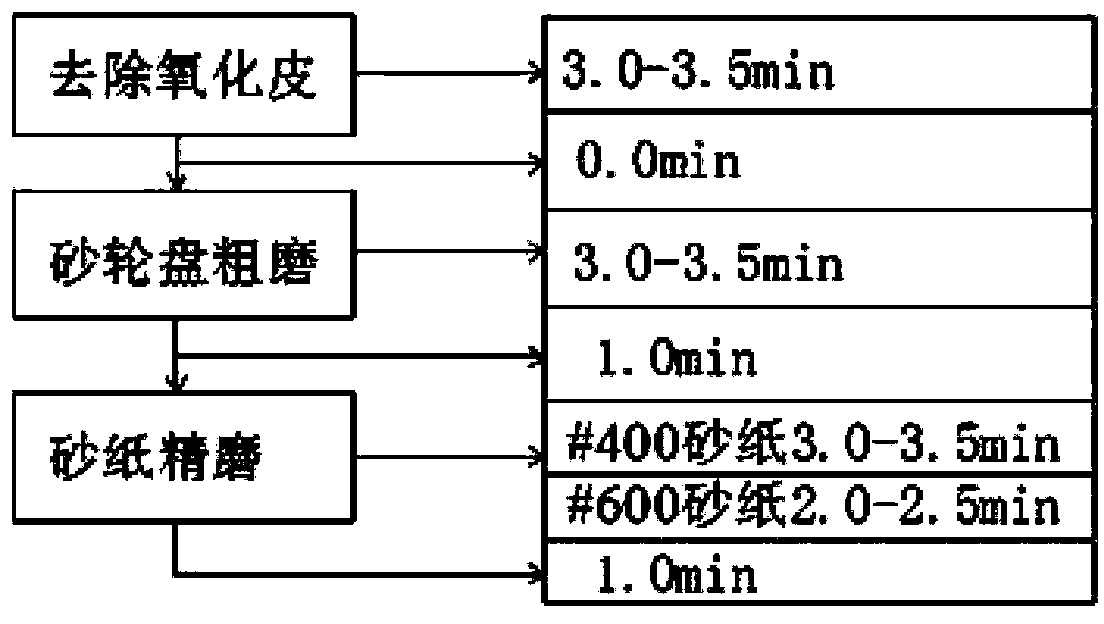

On-site metallographic examination polishing method applicable to tower material

InactiveCN103433813AImprove inspection efficiencySimplify the grinding processBelt grinding machinesPulp and paper industryTower

The invention relates to an on-site metallographic examination polishing method applicable to a tower material, and the method comprises the following steps that (1) oxide skin is removed; (2) an abrasive disc is used for roughly grinding; (3) abrasive paper is used for finely grinding: No. 400 abrasive paper and No. 600 abrasive paper are used on a polishing machine simultaneously, wherein the No. 400 abrasive paper is arranged above and the No. 600 abrasive paper is arranged below, the No. 400 abrasive paper is used for polishing and torn off and the No. 600 abrasive paper is exposed, and then the No. 600 abrasive paper is used for polishing until the testing requirements are met. According to the method, the time for on-site polishing is greatly saved, and the work efficiency of on-site metallographic examination is improved.

Owner:STATE GRID CORP OF CHINA +1

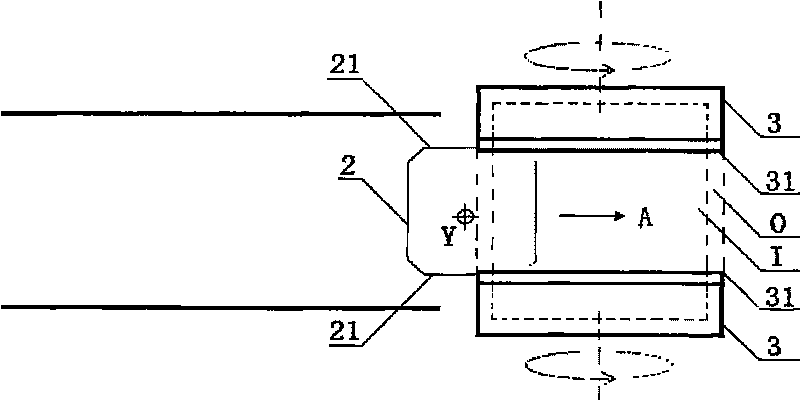

Method for grinding four sides and four corners of polycrystalline silicon

ActiveCN101745854APrecise grinding sizeImprove qualityEdge grinding machinesPlane surface grinding machinesTransverse axisEngineering

The invention provides a method for grinding four sides and four corners of polycrystalline silicon, which mainly comprises the following steps: oppositely arranging a pair of poculiform sand wheels along a transverse axis to ensure that an outer ring grinding space and an inner ring adjusting space are formed between the two poculiform sand wheels; when the two poculiform sand wheels rotate around the transverse axis, conveying the polycrystalline silicon to pass through the outer ring grinding space for double-side or double-corner grinding; and when the polycrystalline silicon enters the inner ring adjusting space, rotating the polycrystalline silicon around a longitudinal axis thereof so as to change to another side to be ground or another corner to be ground, and conveying the polycrystalline silicon out of the inner ring adjusting space to ensure that the polycrystalline silicon is subjected to the other double-side or double-corner grinding when passing through the outer ring grinding space. Therefore, a grinding process in the prior art is simplified, the accurate grinding size of the polycrystalline silicon is ensured, and the work efficiency and the quality of the polycrystalline silicon are improved.

Owner:海宁市日进科技有限公司

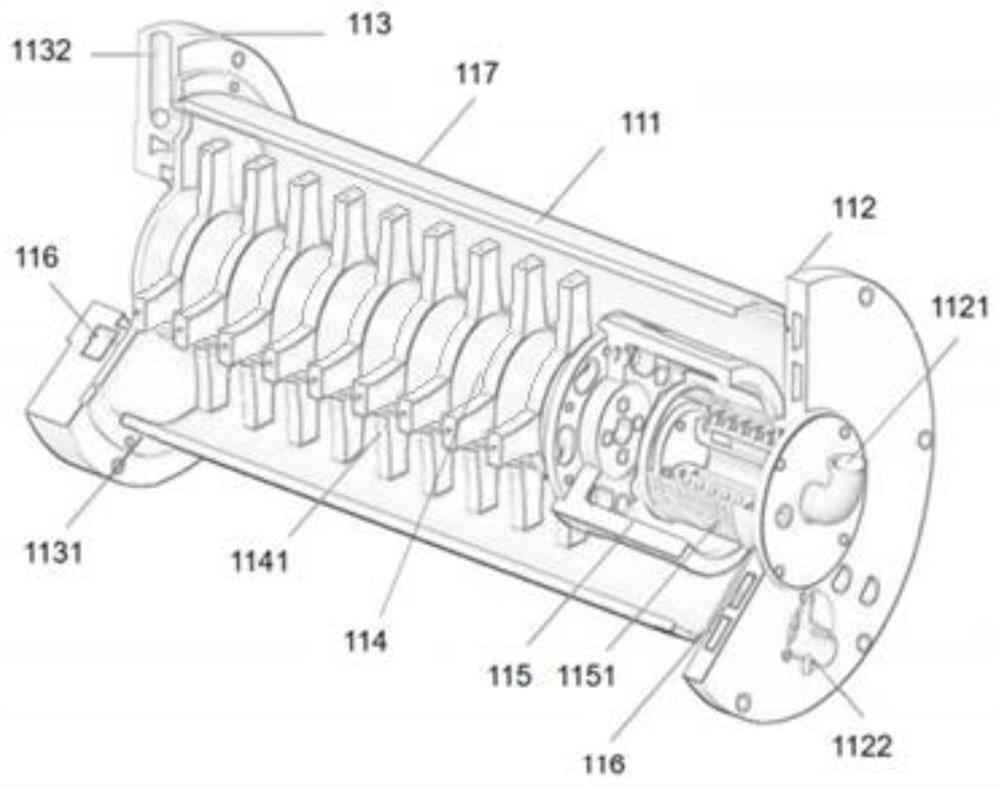

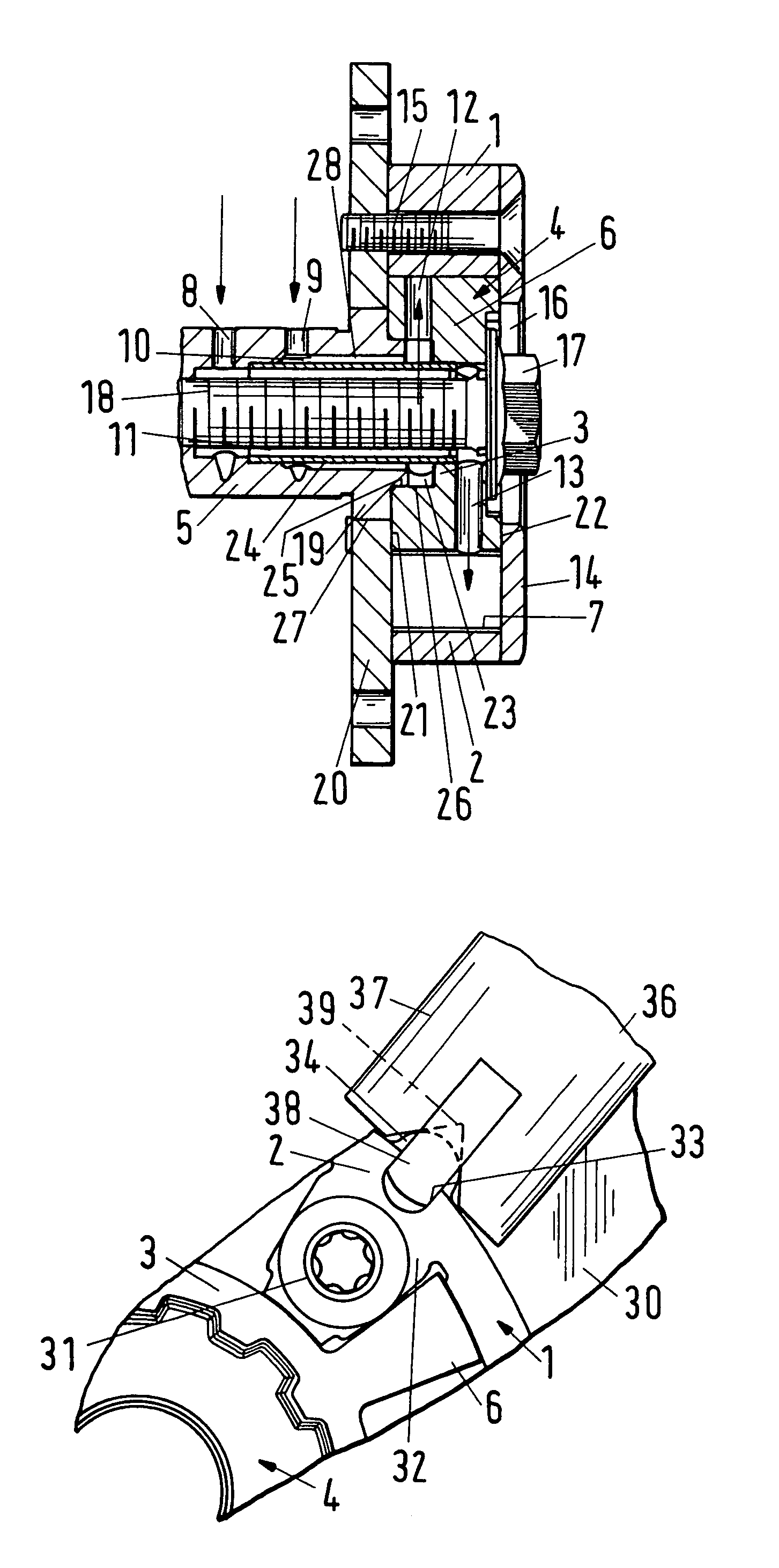

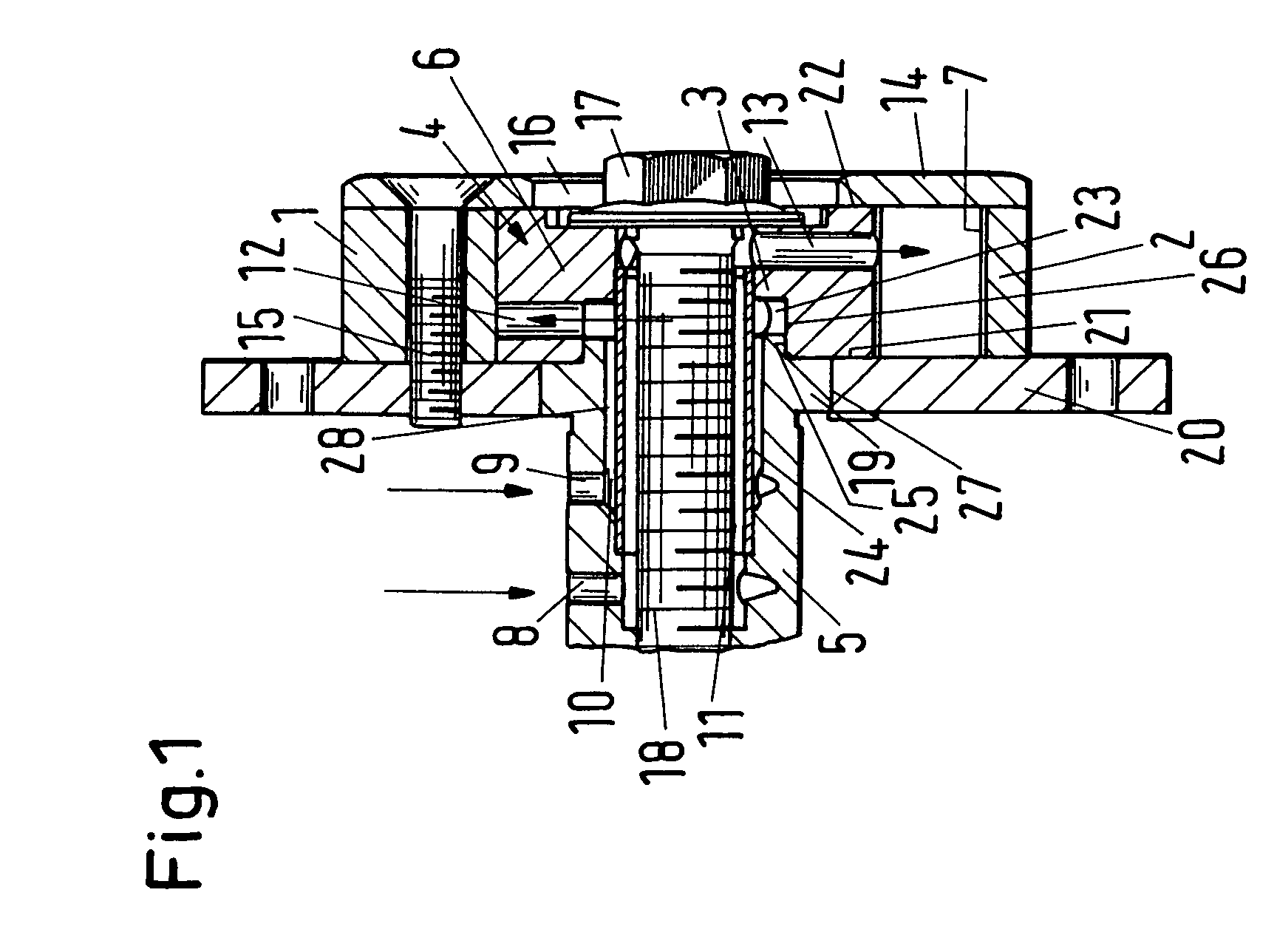

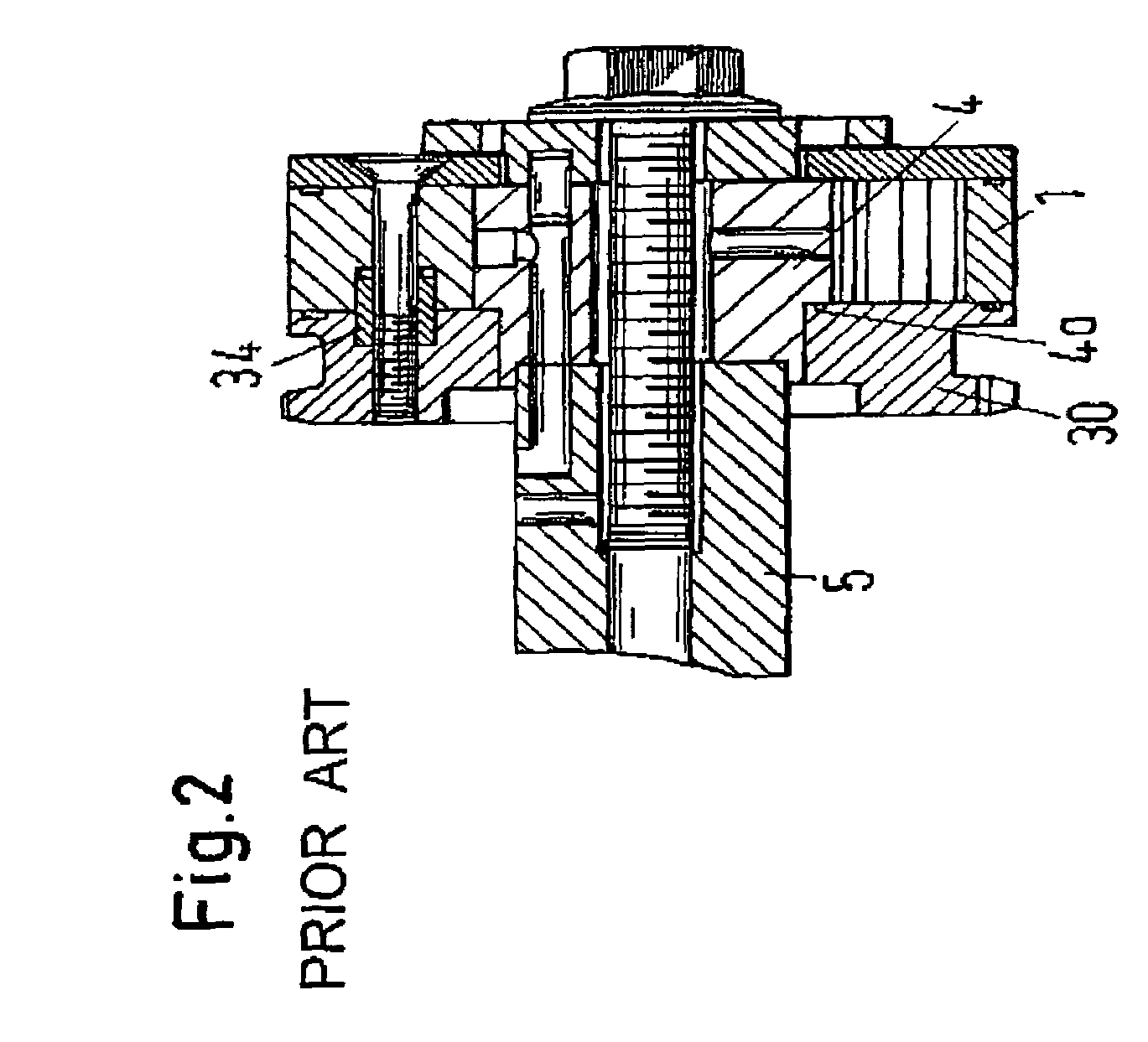

Device for adjusting a camshaft of an internal combustion engine of a motor vehicle

InactiveUS7117832B2Produced simply and inexpensivelySimple configurationCamsYielding couplingMobile vehicleDrive wheel

A device for adjusting a camshaft of an internal combustion engine of a motor vehicle has a stator and a rotor fixedly connected to a camshaft and rotatable relative to the stator. A drive wheel is fixedly connected to the stator and is centered by the camshaft. The stator has a peripheral area provided with a centering element interacting with a counter element provided on the drive wheel for aligning the drive wheel in a rotational direction relative to the stator.

Owner:HYDRAULIK RING

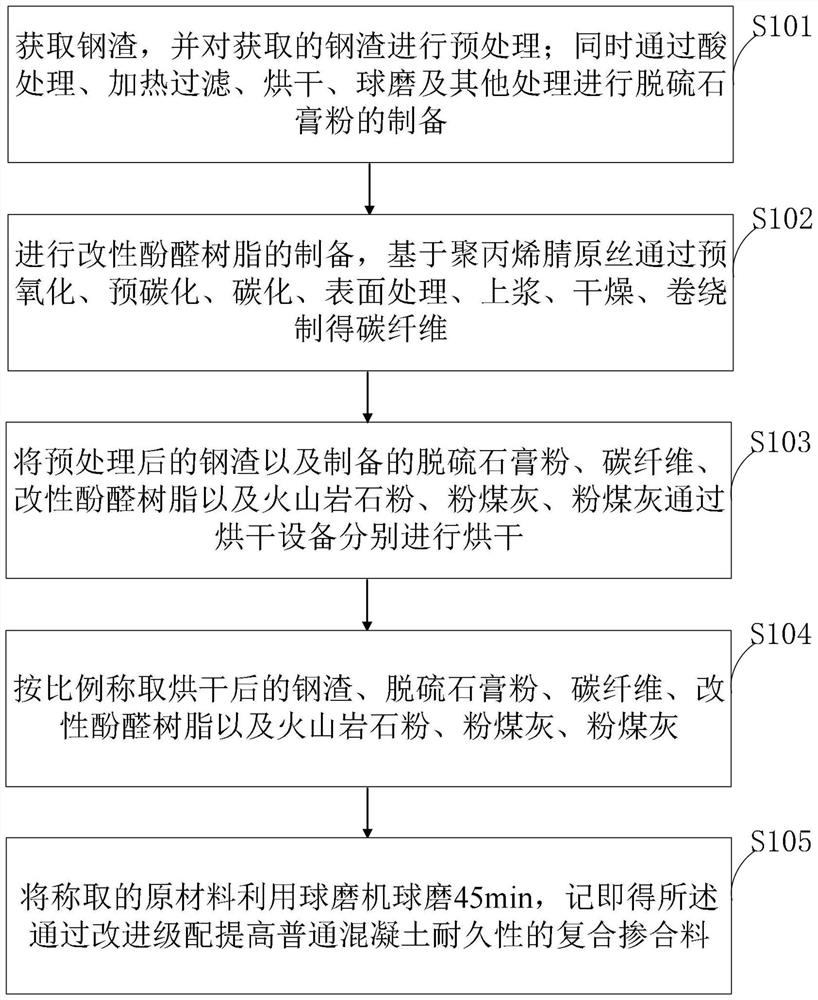

Composite admixture for improving durability of common concrete by improving grading

The invention belongs to the technical field of building materials, and discloses a composite admixture for improving the durability of common concrete by improving grading. The composite admixture for improving the durability of common concrete by improving grading is composed of the components in parts by mass: 25 to 30 parts of volcanic rock powder, 10 to 15 parts of steel slag, 10 to 15 parts of fly ash, 10 to 15 parts of desulfurized gypsum powder, 8 to 10 parts of carbon fiber, 8 to 12 parts of modified phenolic resin and 5 to 8 parts of activated aluminosilicate mineral. Through cooperation of the fly ash, the volcanic rock powder and the steel slag, proper fluidity can be provided for the concrete, the porosity is reduced, the compactness of a system can be improved, the use amount of water can be reduced, and the durability of the concrete is further improved. The carbon fibers, the modified phenolic resin, the fly ash, the volcanic rock powder and the steel slag are added and blended, so that the pore structure of the concrete is improved, the compactness of the concrete is improved, and the durability of the concrete is improved.

Owner:GUIZHOU UNIV OF ENG SCI

A method for recovering microfine coal in acidic leaching slag of stone coal vanadium ore

The invention discloses a method for recovering coal in the acidic leaching slag of stone coal vanadium ore, which belongs to the technical field of mineral processing engineering; the leaching slag is pre-classified into coarse-grained products and fine-grained products; the coarse-grained products are finely ground, Grinding products and fine-grained products are combined into flotation feed; flotation roughing operation is divided into two stages, adding inhibitors, collectors and foaming agents in the first roughing, and adding collectors in the second roughing and foaming agent, the foam products of the two roughings are combined into a roughing concentrate, and the product in the tank is a roughing ore; the roughing ore is added with a collector and a foaming agent and then swept to obtain the swept ore and the final tailings , Sweep the middle ore and return to the second roughing operation; the rougher concentrate is selected twice, and a small amount of collector and foaming agent are added in the selection operation, and the middle ore selected for the first time returns to the first roughing operation , the middle ore selected for the second time returns to the first selection operation. The invention has reasonable technological process, simple process structure, wide adaptability to raw materials and easy industrial implementation.

Owner:KUNMING UNIV OF SCI & TECH

Nitride semiconductor single crystal substrate, and methods of fabricating the same and a vertical nitride semiconductor light emitting diode using the same

ActiveUS20100105159A1High crystallinityThe grinding process is simplePolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystal substrateElectrical polarity

A nitride semiconductor single crystal substrate, a manufacturing method thereof and a method for manufacturing a vertical nitride semiconductor device using the same. According to an aspect of the invention, in the nitride semiconductor single crystal substrate, upper and lower regions are divided along a thickness direction, the nitride single crystal substrate having a thickness of at least 100 μm. Here, the upper region has a doping concentration that is five times or greater than that of the lower region. Preferably, a top surface of the substrate in the upper region has Ga polarity. Also, according to a specific embodiment of the invention, the lower region is intentionally un-doped and the upper region is n-doped. Preferably, each of the upper and lower regions has a doping concentration substantially identical in a thickness direction.

Owner:SAMSUNG ELECTRONICS CO LTD

Submicron-sized dispersed liquid preparing method

InactiveCN1552509AReduce dispersionThe grinding process is simpleMixing methodsPolymer scienceDisperser

Owner:IND TECH RES INST

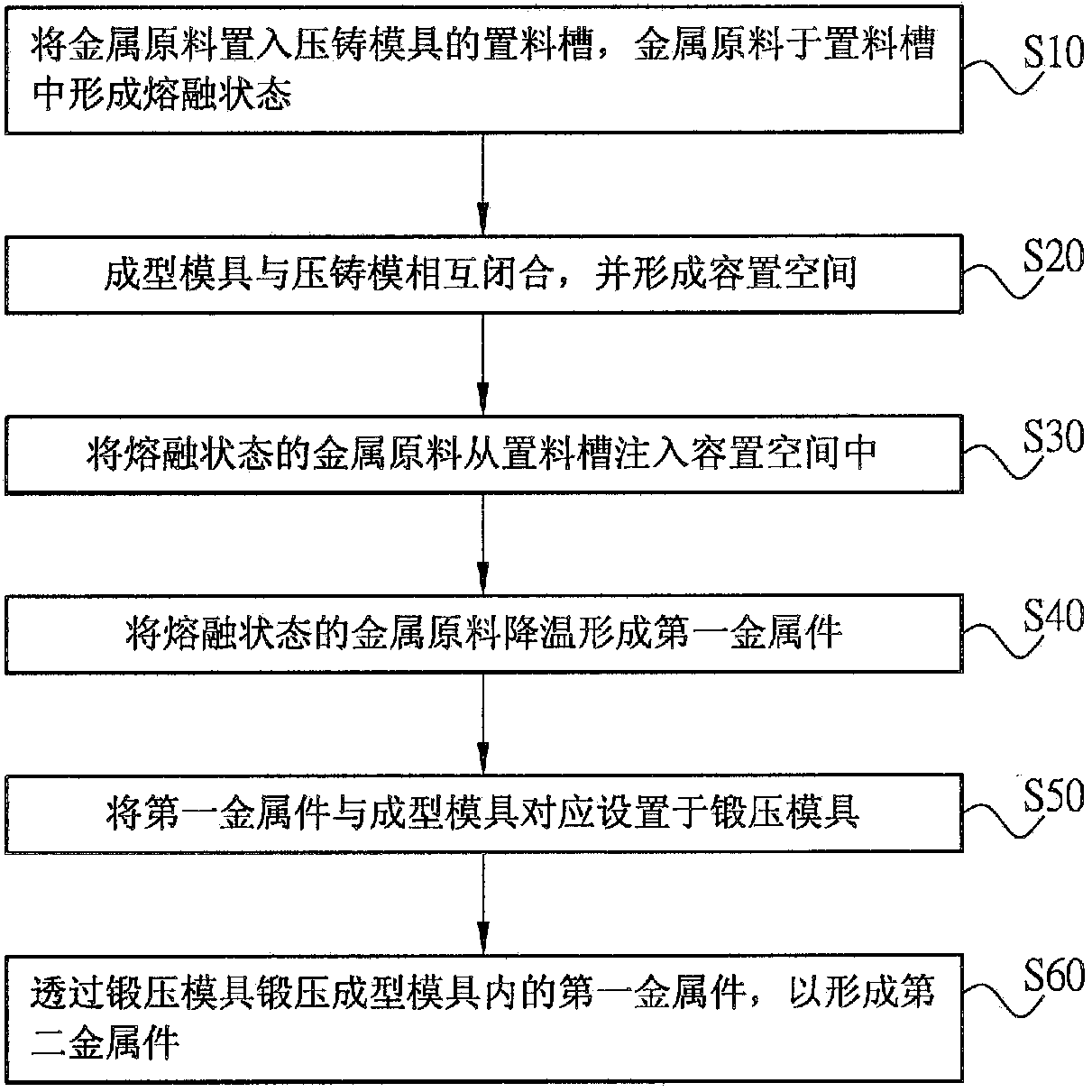

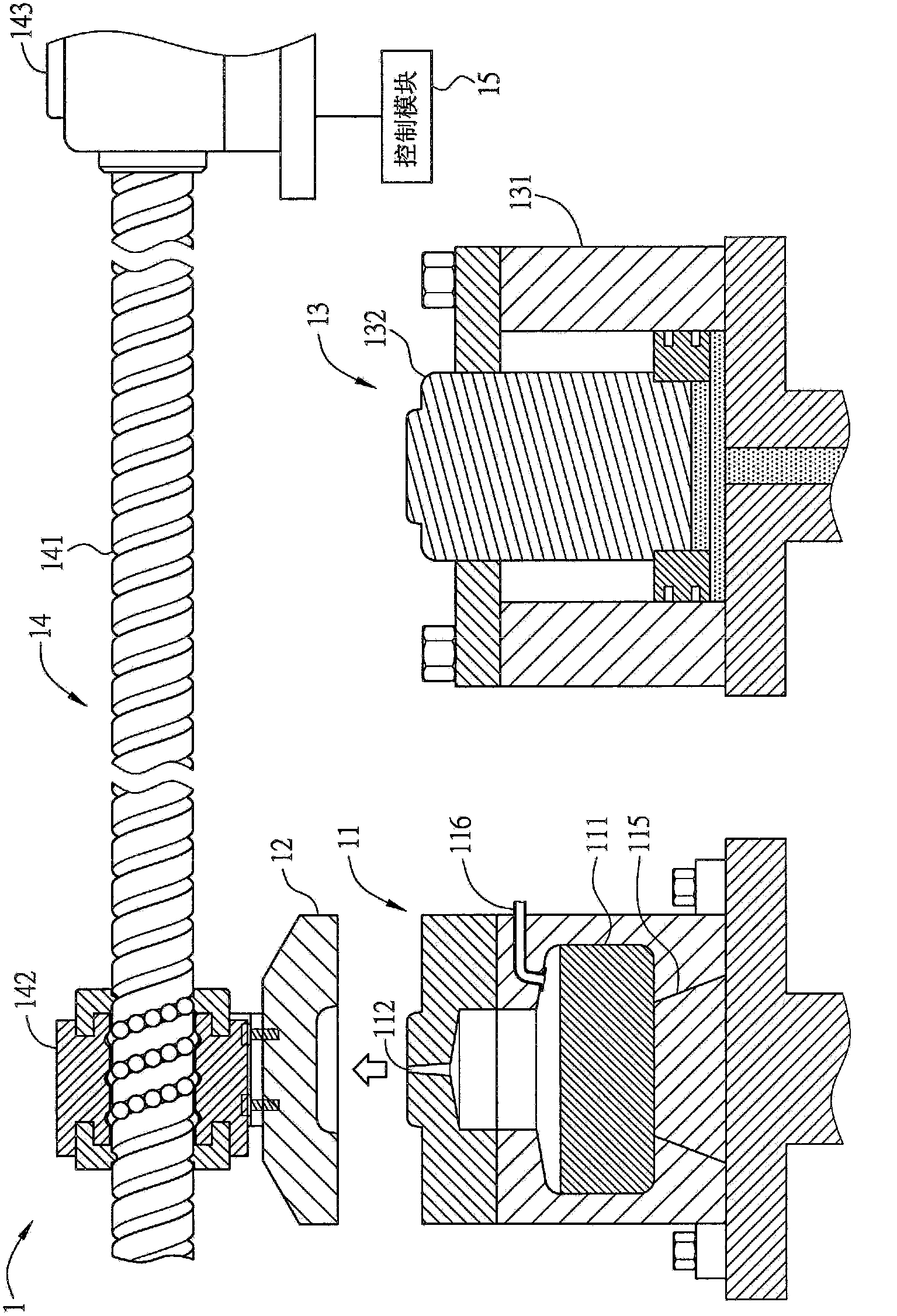

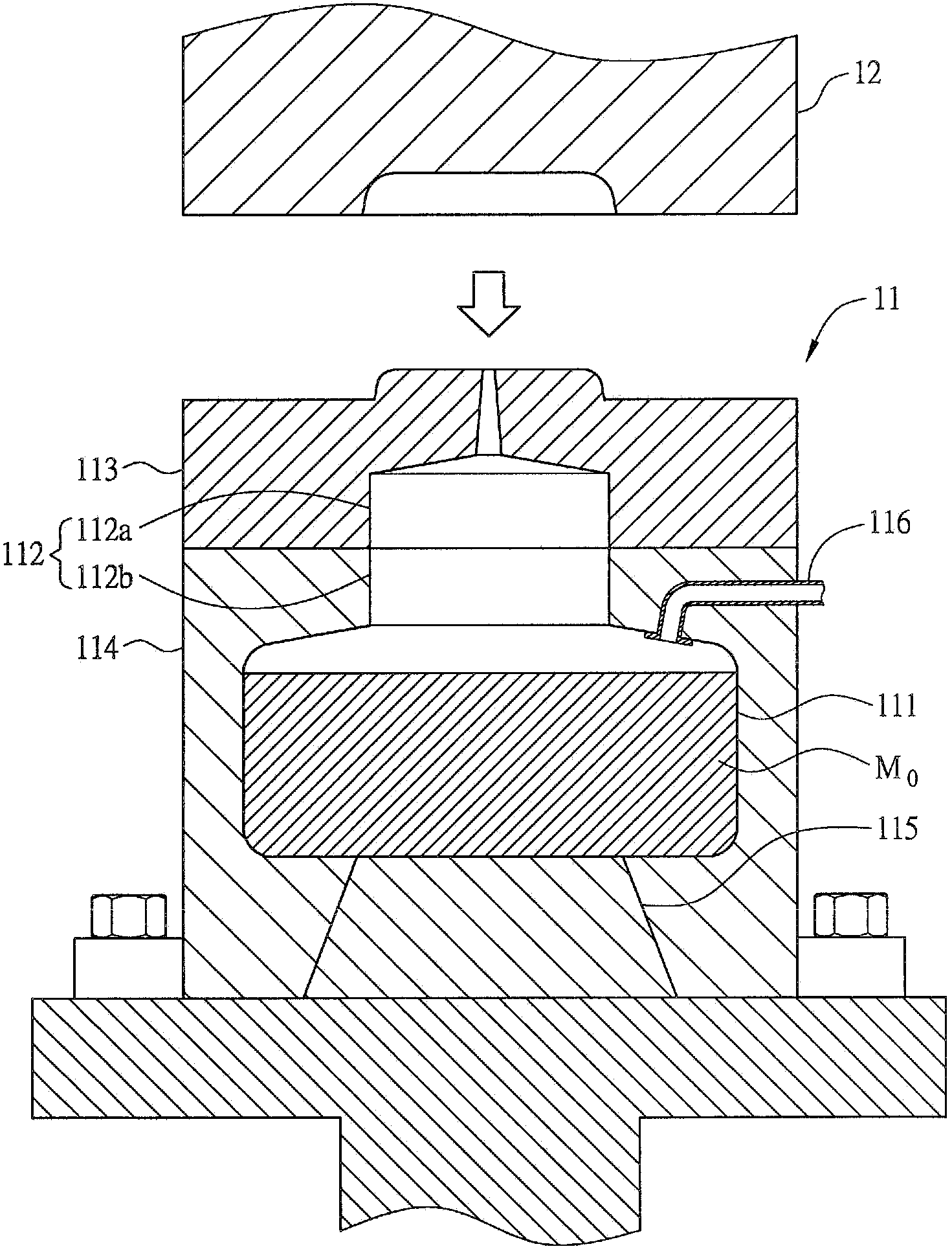

Casting and forging method of metal piece, and casting and forging apparatus

InactiveCN103418771ASimple processReduce processing timeForging/hammering/pressing machinesDie castingHigh intensity

The invention discloses a casting and forging method of metal piece. The casting and forging method comprises the following steps of putting a metal raw material in a material-placing groove of a die-casting mold, the metal raw material forming a melt state in the material-placing groove; closing a forming mold and the die-casting mold to form an accommodate space; pouring the metal raw material in the melt state into the accommodate space from the material-placing groove; cooling the metal raw material in the melt state to form a first metal piece; placing the first metal piece and the forming mold in a forging mold accordingly; and forging the first metal piece in the forming mold by the forging mold to form a second metal piece. The invention also discloses a casting and forging apparatus of the metal piece. With the casting and forging method and the apparatus, an effect that can be achieved by forging five times with a known forging technology can be achieved in one forging time; tedious processes can be simplified; process time is shortened; and the metal piece has high strength and precision. Moreover, due to the the design of transferring the forming mold together with the first metal piece into the forging mold without replacing the forming mold, a processing reference point can be can further fixed.

Owner:ASUSTEK COMPUTER INC

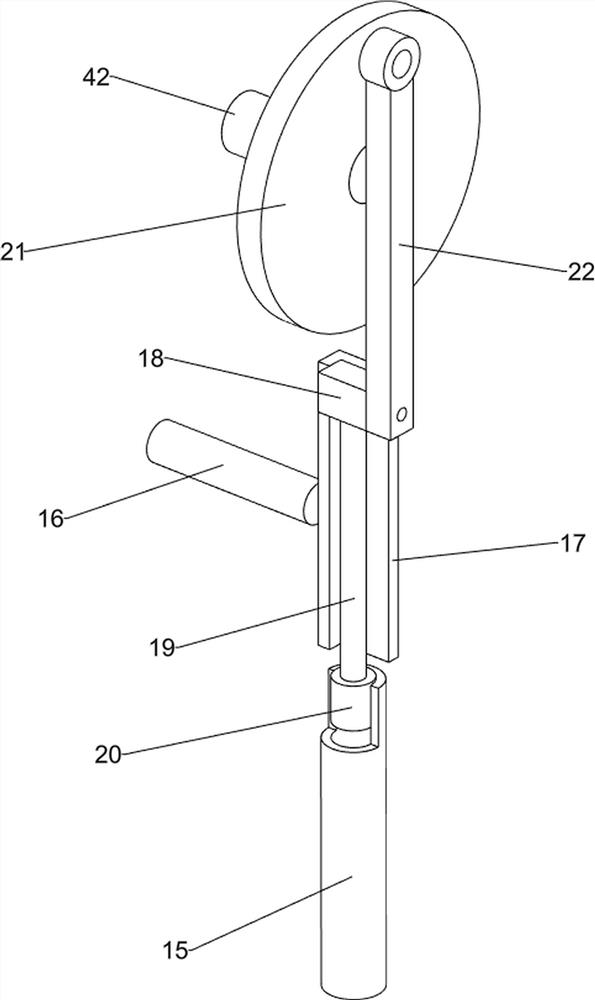

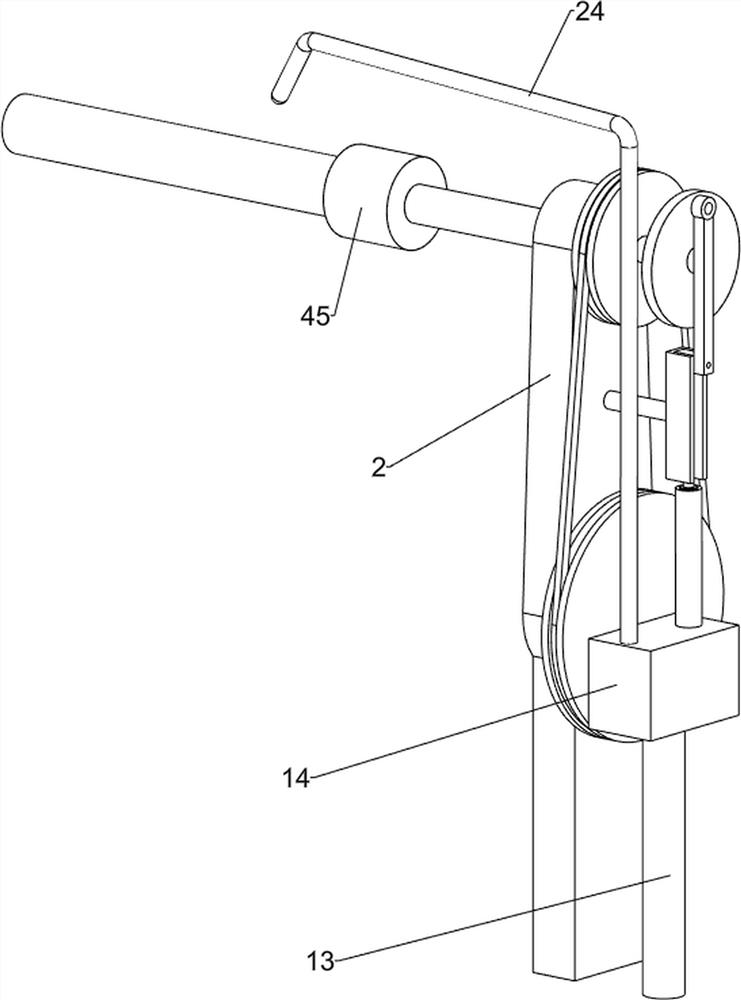

Rolling pin grinding device

ActiveCN111805323AShape specificationThe grinding process is simpleRevolution surface grinding machinesCleaning using liquidsEngineeringPhysics

The invention relates to a grinding device, in particular to a rolling pin grinding device. The rolling pin grinding device is uniform in grinding shape and can conduct grinding and cleaning at the same time. The rolling pin grinding device comprises a base, a cushion block, a rotating mechanism, a clamping mechanism and a water tank, wherein a support is arranged on one side of the top of the base; the cushion block is arranged on the other side of the top of the base; the rotating mechanism is arranged on one side of the middle of the top of the base; the clamping mechanism is arranged at the upper end of the cushion block and matched with the rotating mechanism; and the water tank is arranged on one side of the middle of the top of the base and located between the cushion block and thesupport. According to the rolling pin grinding device, through cooperation of the rotating mechanism and the clamping mechanism, a rolling pin is fixed and then ground, the grinding procedure is simpler, and the shape of the ground rolling pin is standard.

Owner:泰安泰悦食坊食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com