Grinding method for pipelining slurry in manufacturing process of aluminium oxide

A pipeline and alumina technology, which is applied in the fields of alumina/hydroxide, grain processing, etc., can solve the problems of large constraints and many equipment in the process link, and achieve the promotion of cost reduction, optimization of pulp fineness, and convenient operation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

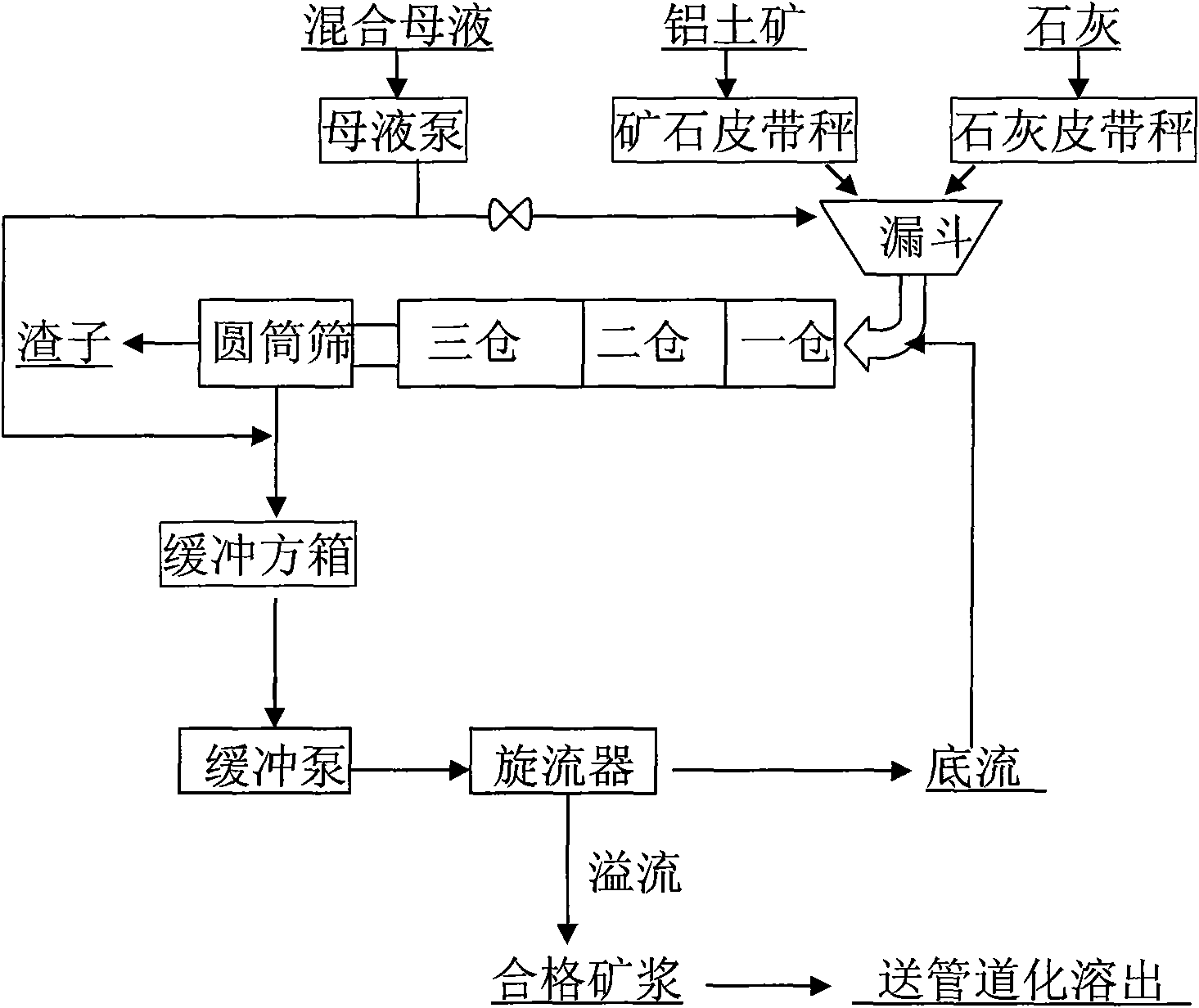

[0017] The specification of the three-chamber tube mill is φ3.2×12m, and the production capacity is 90t / h. The effective lengths of the three warehouses are 3m, 3m, and 5m respectively. Warehouse steel forging 60 tons. Add bauxite and lime to the three-chamber forced discharge tube mill through the grinding head bin and electronic belt scale in proportion, and mix a certain amount of mixed mother liquor into the mill. According to the different characteristics of bauxite, the amount of lime added is usually 9.5-12.5% of the weight of bauxite, and the amount of mixed mother liquor fed into the mill is controlled by the L / S in the mill in the range of 0.4-0.8. Calculated according to the ore load of the mill at 90t / h, the amount of lime to be added is 8.6-11.3t / h, and the amount of mixed masterbatch added to the mill is 26-53m 2 / h, according to the required solid content of the finished pulp is 300g / l, and the amount of mixed masterbatch that needs to be added at the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com