Method for recycling fine pea coal in stone coal navajoite leaching residues

A stone coal vanadium ore, fine particle technology, applied in solid separation, flotation and other directions, can solve the problems of low vanadium conversion rate and leaching rate, long and complicated process flow, waste of coal-bearing minerals, etc., to simplify the grinding process, Reasonable process flow and effective recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

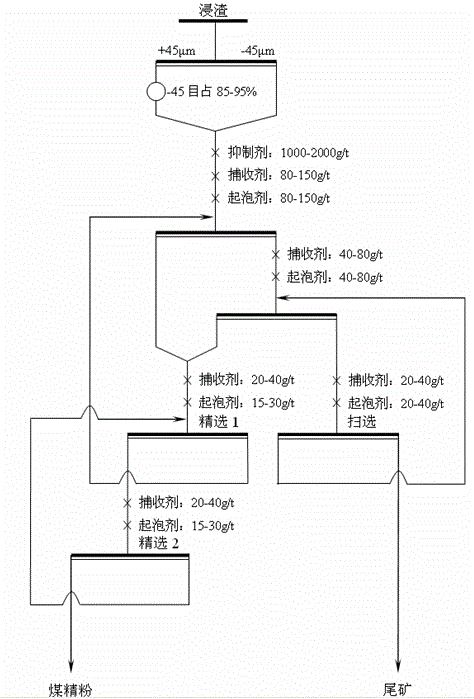

[0029] Example 1: The acid leaching slag of stone coal vanadium ore in this example is a high siliceous stone coal vanadium ore acid leaching slag sample obtained from Jianggu, Guizhou, containing 6.14wt% of fixed carbon, SiO 2 81.36wt%, CaO 0.83wt%, MgO 0.71wt%, Al 2 o 3 3.09wt% etc. use as figure 1 The process flow shown, the specific process parameters and beneficiation indicators are as follows:

[0030] (1) Use high-frequency vibrating sieve to pre-screen the acidic leaching residue of high-siliceous stone coal vanadium ore, and classify it into coarse-grained products with a particle size greater than 45 μm and fine-grained products with a particle size less than 45 μm

[0031] (2) Use a rod mill to finely grind the coarse-grained product obtained in step (1) until the ore particles with a particle size of less than 45 μm account for 90%, and the grinding concentration is 60wt%, and the obtained grinding product and step (1) are obtained The fine-grained products a...

Embodiment 2

[0037] Example 2: The acidic leaching slag of stone coal vanadium ore in this embodiment is a high-siliceous stone coal vanadium ore acid leaching slag sample obtained by sulfuric acid activation high-pressure leaching without roasting operation, which is taken from Shaanxi Shanjin, containing 7.81wt% of fixed carbon, SiO 2 73.96wt%, CaO 5.25wt%, MgO 0.063wt%, Al 2 o 3 0.47wt%; specific process parameters and beneficiation indicators are as follows:

[0038] (1) Use high-frequency vibrating sieve to pre-screen the acidic leaching residue of high-siliceous stone coal vanadium ore, and classify it into coarse-grained products with a particle size greater than 45 μm and fine-grained products with a particle size less than 45 μm

[0039] (2) Use a rod mill to finely grind the coarse-grained product obtained in step (1) until the ore particles with a particle size of less than 45 μm account for 95%, and the grinding concentration is 65wt%, and the obtained grinding product and...

Embodiment 3

[0045] Example 3: The acidic leaching slag of stone coal vanadium ore in this example is a sample of acidic leaching slag of stone coal vanadium ore matured and leached with concentrated sulfuric acid, taken from Zhenyuan, Guizhou, containing 14.65wt% of fixed carbon, SiO 2 66.78wt%, CaO 0.64wt%, MgO 0.16wt%, Al 2 o 3 4.81wt%; specific process parameters and beneficiation indicators are as follows:

[0046] (1) Use high-frequency vibrating sieve to pre-screen the acidic leaching residue of high-siliceous stone coal vanadium ore, and classify it into coarse-grained products with a particle size greater than 45 μm and fine-grained products with a particle size less than 45 μm

[0047] (2) Use a rod mill to finely grind the coarse-grained product obtained in step (1) until the ore particles with a particle size of less than 45 μm account for 85%, and the grinding concentration is 62wt%. The obtained grinding product and step (1) are obtained The fine-grained products are com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com