Numerically controlled spiral bevel gear grinding machine

A technology of spiral bevel gears and gear grinding machines, which is applied in the direction of gear teeth manufacturing devices, gear cutting machines, belts/chains/gears, etc. It can solve problems such as excessive clearance, inability to adjust the grinding wheel, and increase vibration, so as to reduce grinding Effect of temperature, simplification of grinding process, and reduction of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

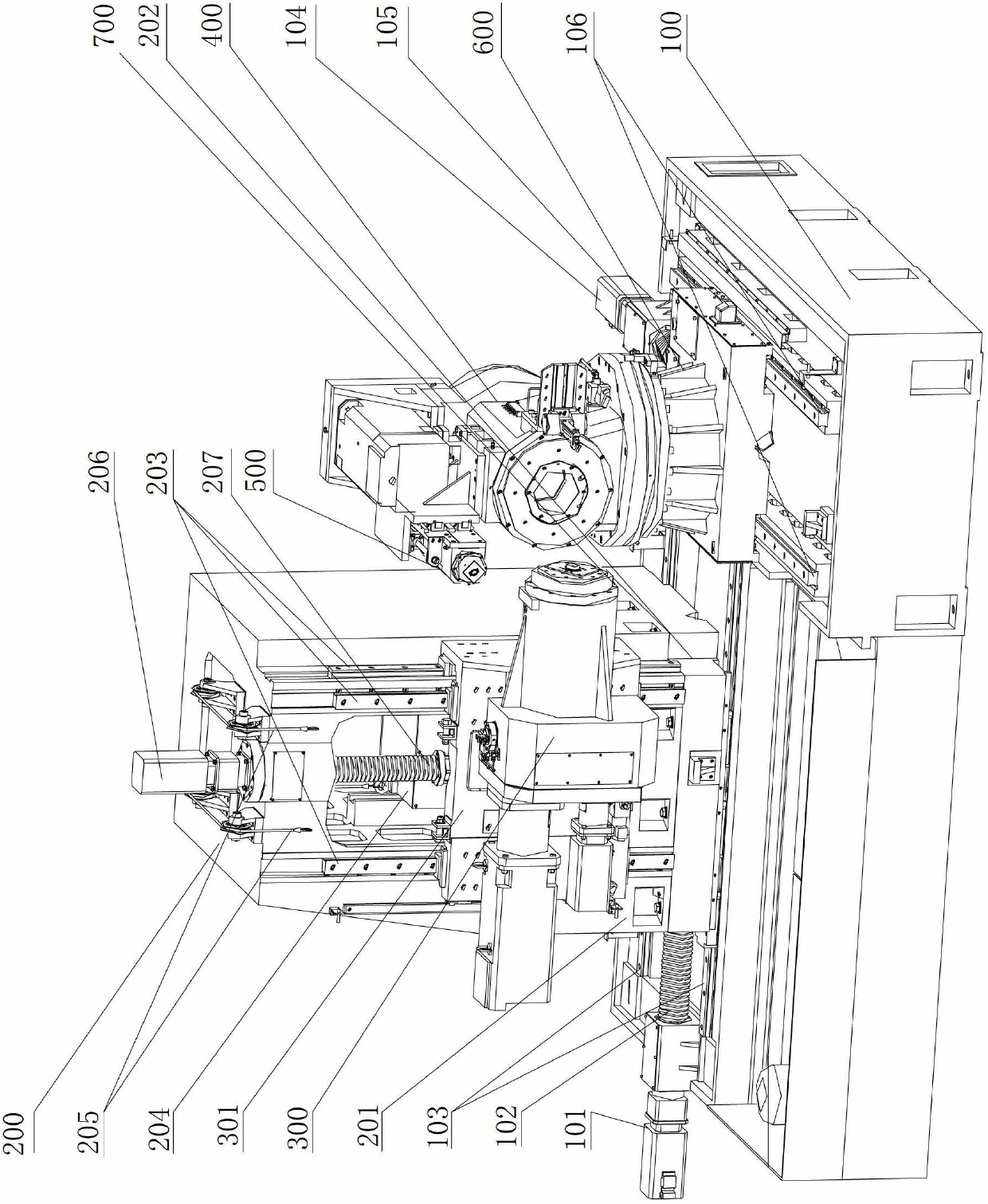

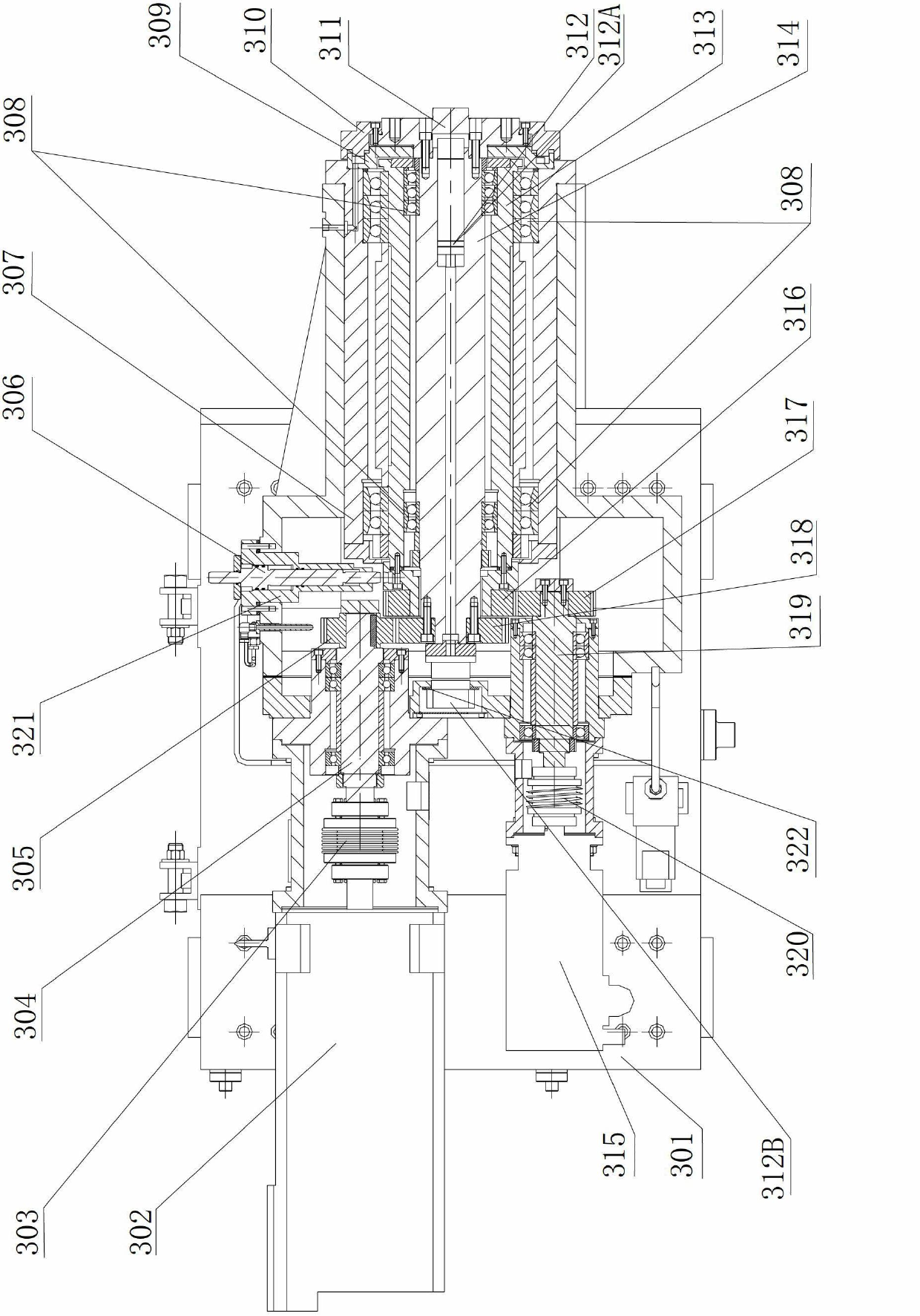

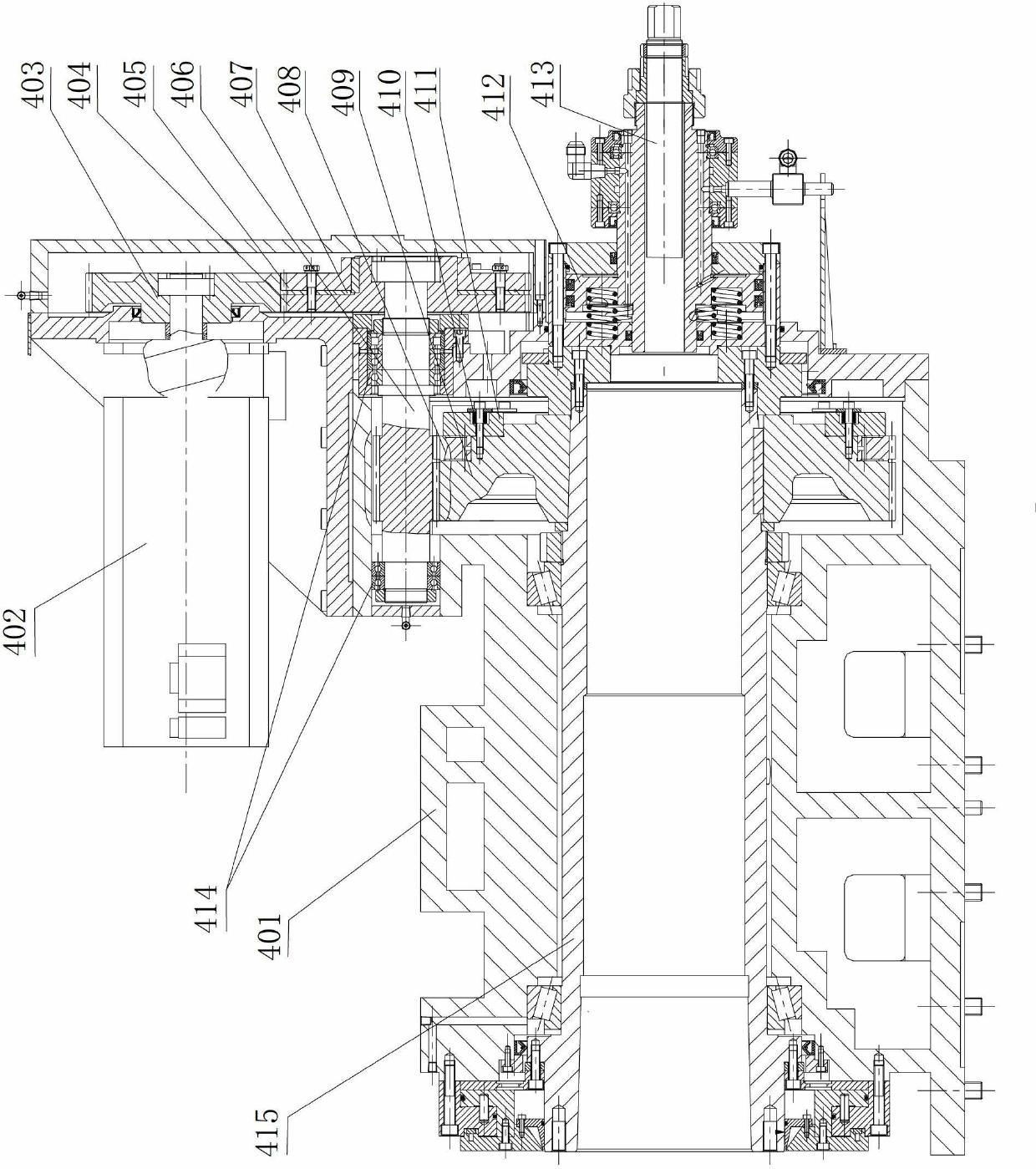

[0031] see Figure 1-Figure 7 , CNC spiral bevel gear grinding machine, including bed 100, column 200, grinding wheel headstock 300, workpiece headstock 400, grinding wheel correction mechanism 500, rotary table 600, electrical system, pneumatic system and hydraulic system, the electrical system , pneumatic system and hydraulic system are not shown in the figure. The rotary table is installed on the bed through the second linear guide rail 106, the workpiece spindle box 400 is installed on the rotary table, and the second ball screw 105 is driven by the second servo motor 104 to make the rotary table 600 move along the second linear guide rail 106. Move back and forth on the bed. A grinding wheel correction mechanism is installed on the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com