Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Play a grinding role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag vertical mill grinding assisting activating agent and its compounding method

ActiveCN102745917APlay a grinding roleReduce manufacturing costSolid waste managementCement productionMetallurgyAluminum sulphate

The invention provides a slag vertical mill grinding assisting activating agent and its compounding method. The slag vertical mill grinding assisting activating agent is composed of, by weight percent: 10-12% of industrial salt, 3-6% of urea, 8-12% of triethanolamine, 10-15% of glycerol, 8-12% of an aluminum sulfate solution, 3-6% of beet molasses, 5-8% of polycarboxylic acid, and the balance a solvent. The method consists of: adding the industrial salt, the urea, the triethanolamine, the glycerol, the aluminum sulfate solution, the beet molasses, and the polycarboxylic acid into the solvent in order, fully dissolving each raw material when it is added, and conducting uniform stirring, then adding another raw material till all the raw materials are added into the solvent for dissolving, and mixing the mixture uniformly, thus obtaining the slag vertical mill grinding assisting activating agent, which can play a grinding assisting role and an activating role. By employing a compatible mode of chemical excitation and slag powder particle size distribution improvement, the slag vertical mill grinding assisting activating agent provided in the invention has an advantage complementary effect, not only adapts to low activity acidic slag, but also adapts to neutral and alkaline slag, and is applicable to both vertical mills and ball mills.

Owner:酒钢(集团)宏达建材有限责任公司

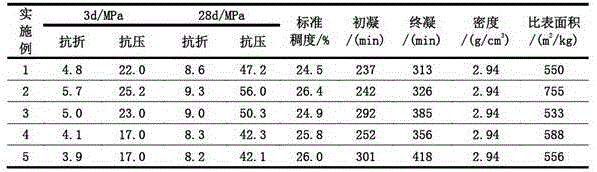

Retarded portland cement and preparation method thereof

InactiveCN105948544AProlong clotting timeIncrease late strengthCement productionSlagMaterials science

The invention relates to a retarded Portland cement and a preparation method thereof. The retarded Portland cement is prepared from the following components in percentage by weight: 52 to 58 percent of Portland cement clinkers, 22.2 to 25.5 percent of mixed slags, 14.8 to 17.5 percent of silica fume, and 5 percent of gypsum. The preparation method comprises the following steps of premixing a phosphorus slag, a vanadium-titanium bearing slag and a zinc slag according to the proportion to obtain a mixed slag a; mixing and grinding the mixed slag a, the Portland cement clinkers, the silica fume and the gypsum to prepare the retarded Portland cement. According to the retarded Portland cement provided by the invention, the usage amount of the Portland cement clinkers is reduced, so that the ingredient cost of producing the cement is effectively reduced, and the discharge of carbon dioxide is reduced; meanwhile, with the adding of the phosphorus slag and the silica fume, the problem that the long-term strength is reduced since the Portland cement clinkers are reduced is solved. The defects that the setting time is prolonged and the strength is reduced, or the strength is increased and the setting time is shorter due to the utilization of other materials in the prior art are overcome, and the obtained retarded Portland cement is remarkably prolonged in initial setting time and remarkably improved in long-term strength.

Owner:四川省宁南县白鹤滩水泥有限责任公司

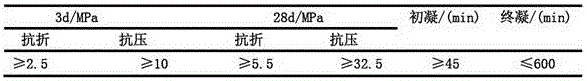

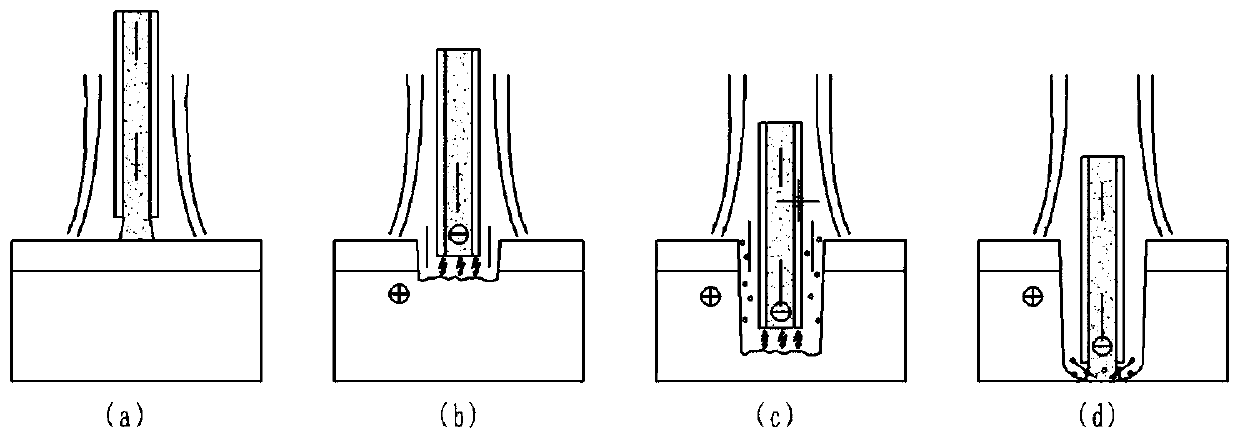

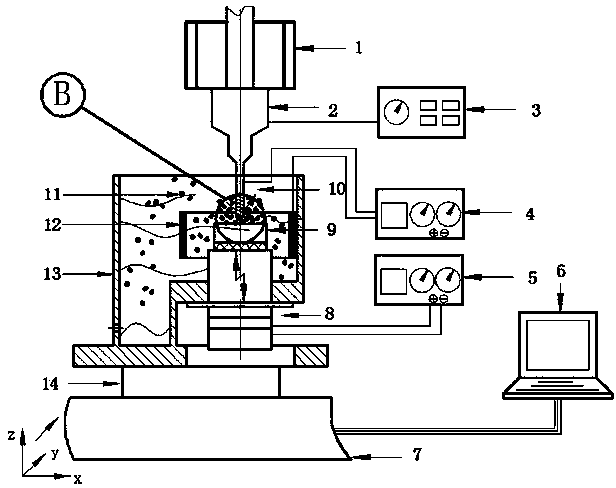

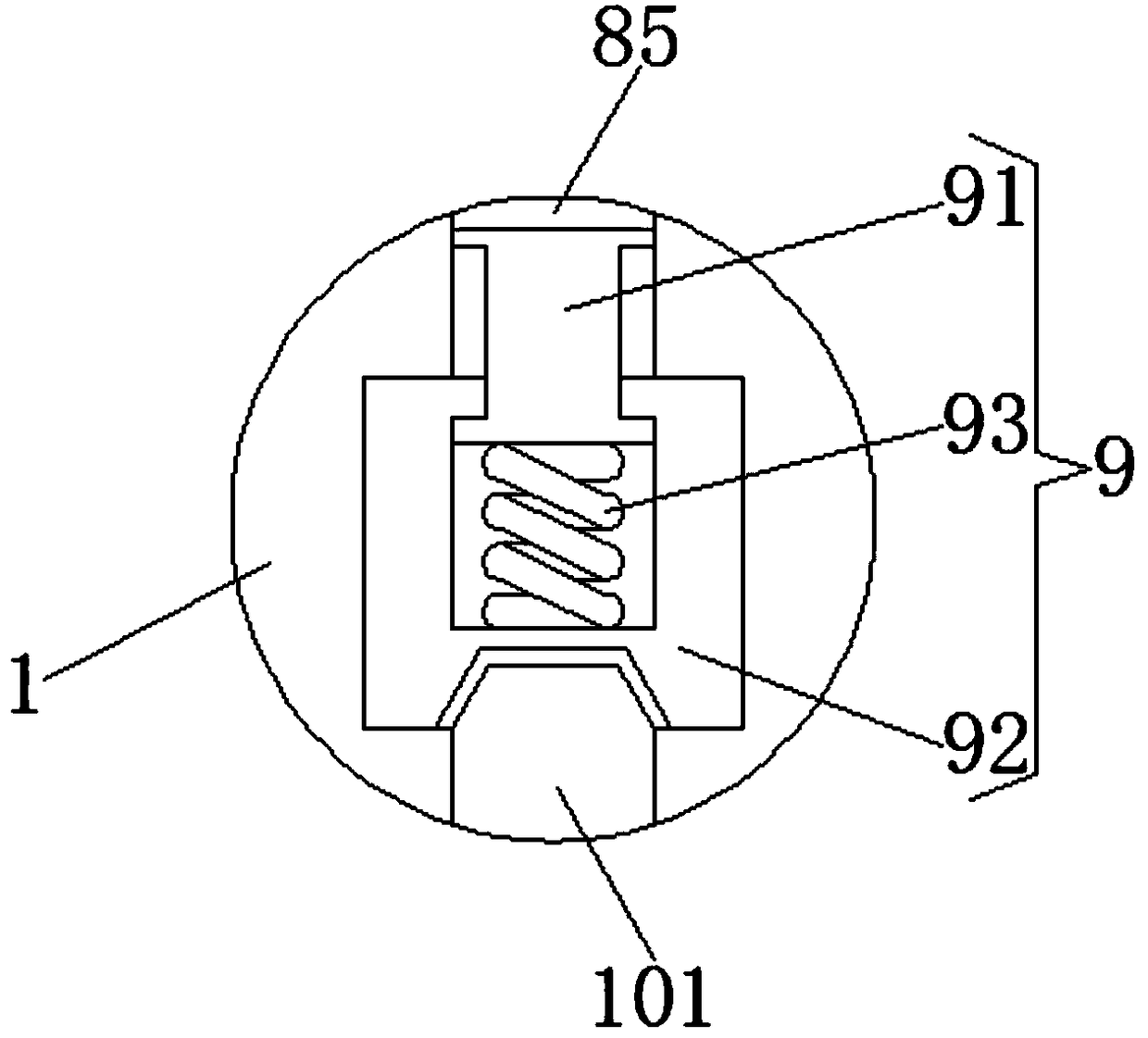

Electric spark-electrolysis combined machining device and machining method with micro abrasive inward spraying function

The invention discloses an electric spark-electrolysis combined machining device and machining method with a micro abrasive inward spraying function, and belongs to the field of micro-hole combined machining. The electric spark-electrolysis combined machining method with the micro abrasive inward spraying function is combined with abrasive grinding, electric spark corrosion and electrolytic corrosion, work liquid is sprayed out of a tube electrode with a certain pressure, the abrasive continuously impacts a workpiece, through the grinding effect, the surface insulation coating material is removed, after a metal matrix is exposed, the tube electrode is continuously fed, when the gap between the end face and the workpiece is smaller than the electric spark discharge gap, electric spark discharging appears in the end face and the workpiece under the high-pressure pulse effect, and high-speed punching is carried out; when the gap between the electrode side wall and the hole wall is largerthan the electric spark discharge gap, electrolysis corrosion removing is executed in the electrode side wall and the hole wall under the low-pressure pulse effect, the hole wall re-cast layer is removed, in the machining process, the abrasive is continuously supplied, machining efficiency is improved, small hole one-time rapid forming machining is achieved, operation is easy, and machining efficiency is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

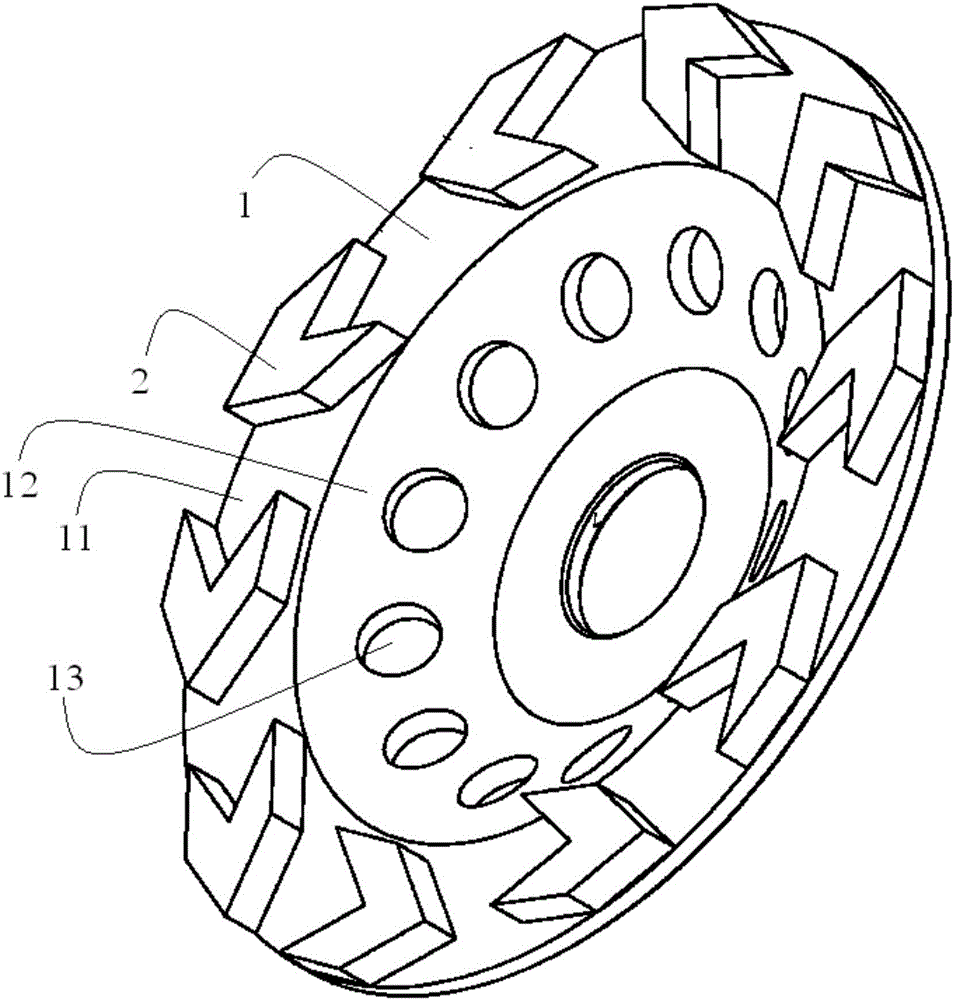

Superhard material cutting tool and preparation method thereof

ActiveCN101502926AGuaranteed smoothnessExclude smoothlySoldering apparatusOther manufacturing equipments/toolsSuperhard materialTool bit

The invention relates to a superhard material cutting tool and a preparation method thereof, which belongs to the technical field of superhard material. The superhard material cutting tool comprises a steel matrix and a cutting tool bit. The cutting tool bit consists of a polycrystalline diamond compact (1) and a diamond tool bit (2); 1 to 12 inclined cylindrical tanks used for welding the diamond compact are distributed on the outer circle surface of the steel matrix, and the center line of the inclined cylindrical tank forms a cutting angle with the cutting face; the diamond tool bit is welded on the surface of the steel matrix. The polycrystalline diamond compact is combined by PCD and cemented carbide matrix and is sintered from the mixture of diamond and the metal powder after being compacted; the structure thereof is in the shape of cylinder, ladder or squareness; the fringe area of the clad compact is the cutting blade. The superhard material cutting tool solves the materials hard to be processed in the cutting field, and ensures the surface of the machined part free of burr, nick, spray and chatter mark; the cutting and grinding combination not only improves the cutting speed, but also ensures the cutting quality.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

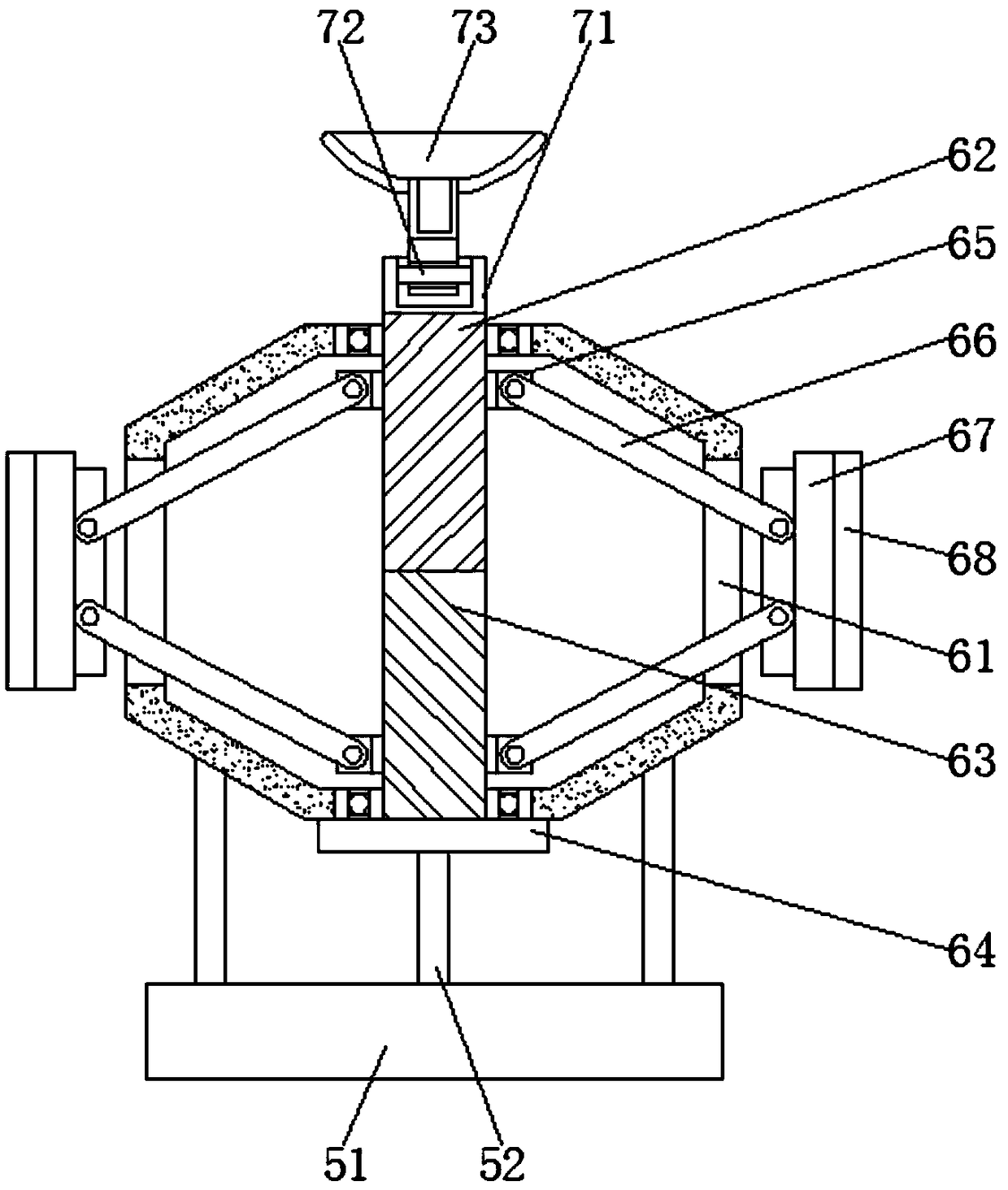

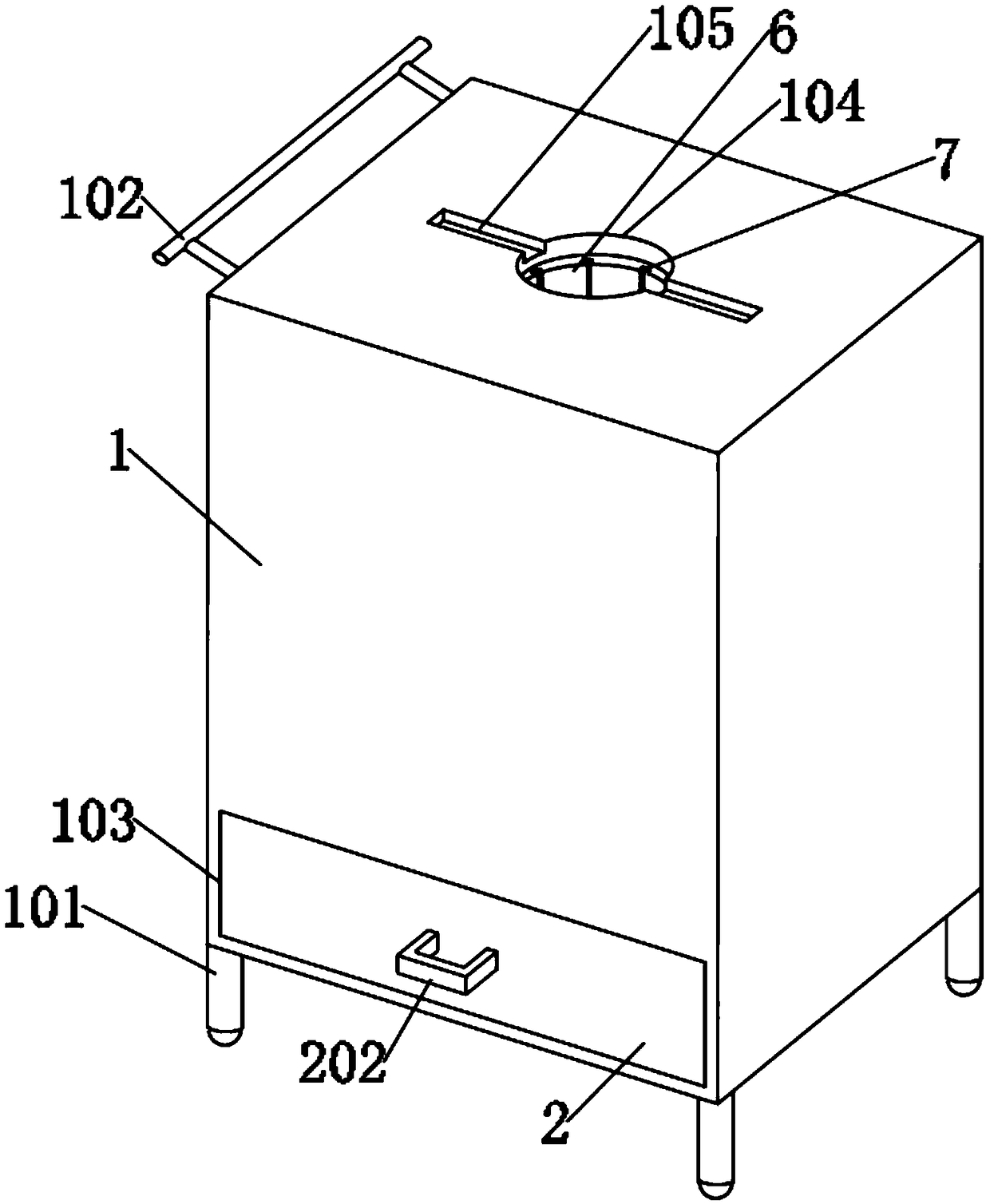

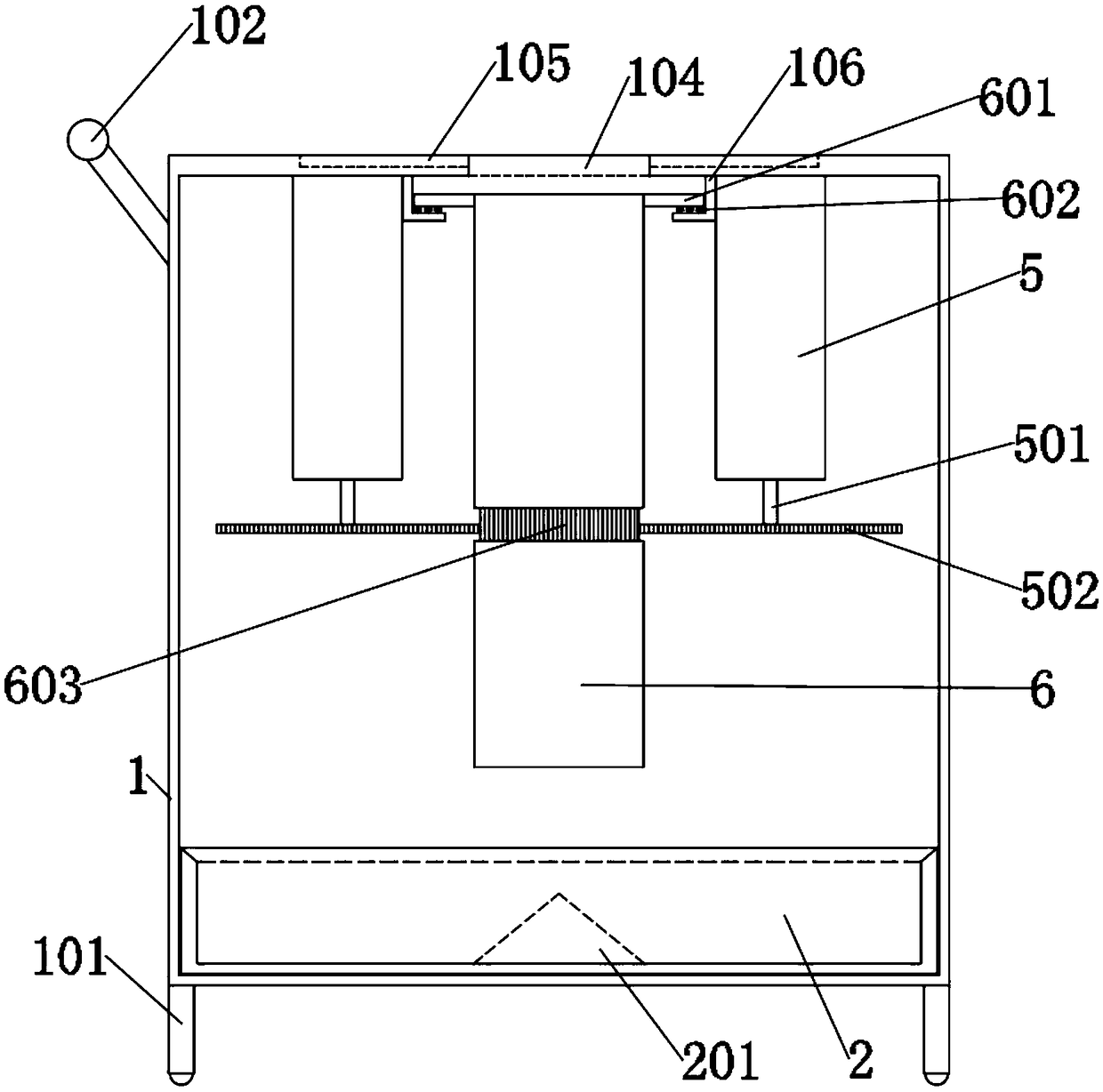

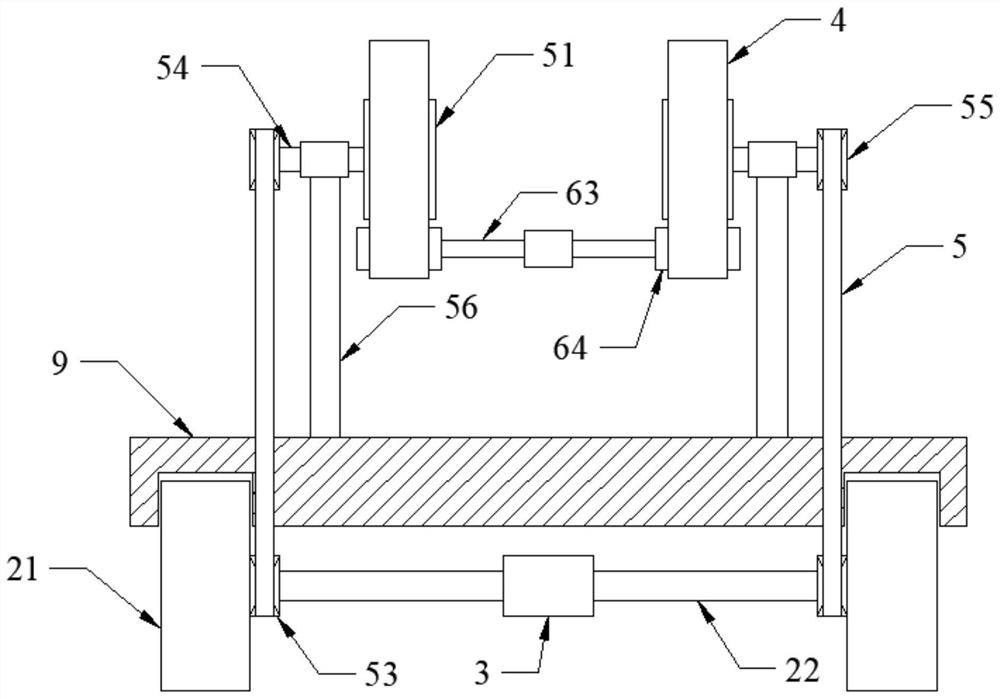

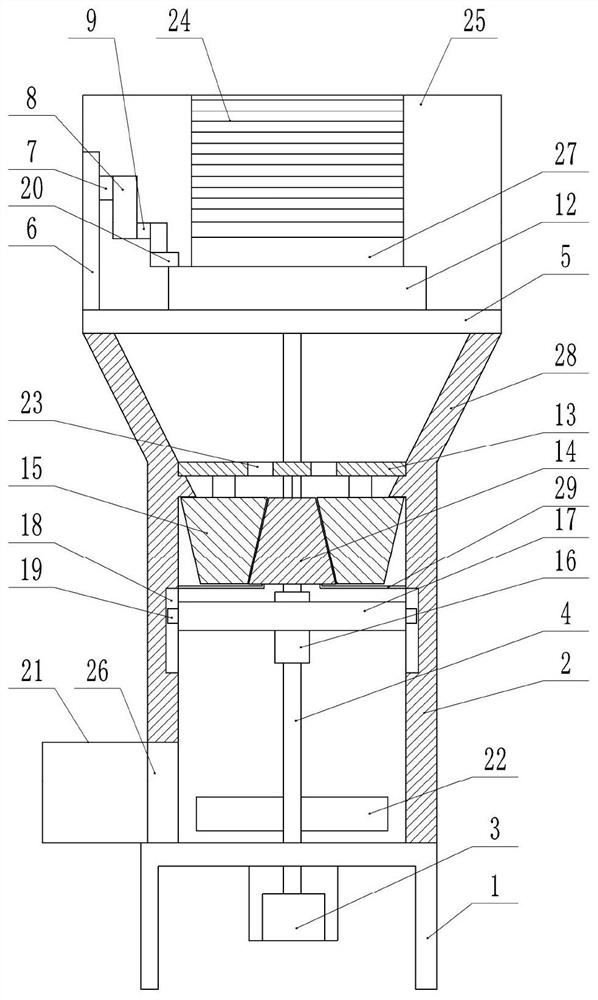

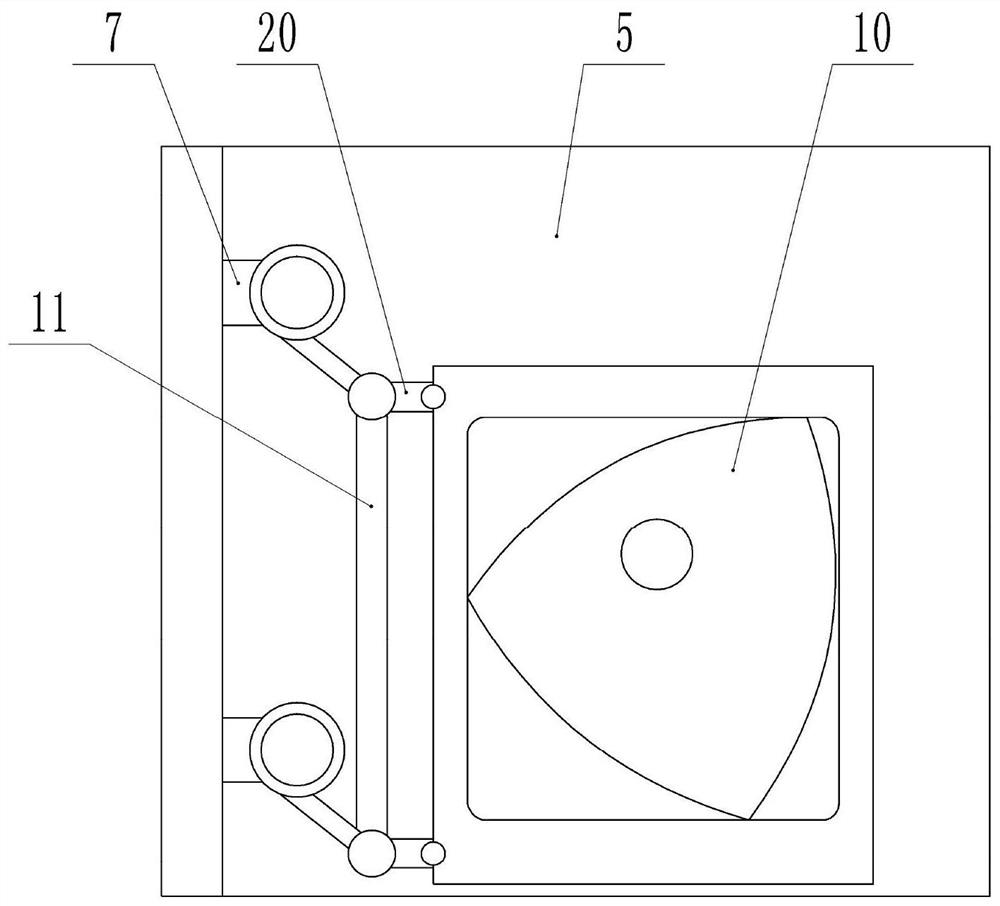

Powder grinding machine

The invention belongs to the technical field of powder grinding equipment, and particularly discloses a powder grinding machine. A rack is provided with a machine case in which a vertical rotating shaft is arranged; a driving portion drives the rotating shaft to rotate; a screen plate is arranged on the upper portion of the machine case; the portion, located above the screen plate, of the rotatingshaft is provided with a smashing portion; the position, located below the screen plate, of the machine case is rotationally provided with a disk which is fixedly arranged outside the rotating shaftin a sleeving manner; the position, located below the disk, of the rotating disk is coaxially and rotationally connected with a conical first grinding roller; a fixed rod is connected between the first grinding roller and the inner wall of the machine case; the disk is rotationally connected with a plurality of second grinding rollers in the shape of an inverted cone in the circumferential direction, and the first grinding roller and the second grinding rollers are attached and close to each other; and the portion, located above the screen plate, of the machine case is provided with a feedingport, and the lower portion of the machine case is provided with a discharging port. The powder grinding machine is mainly used for powder grinding, and solves the problem that in the process of preparing powder coating, steps for grinding blocky raw materials are more, and consequently the machining efficiency is lowered.

Owner:CHONGQING QICAIHONG CHEM

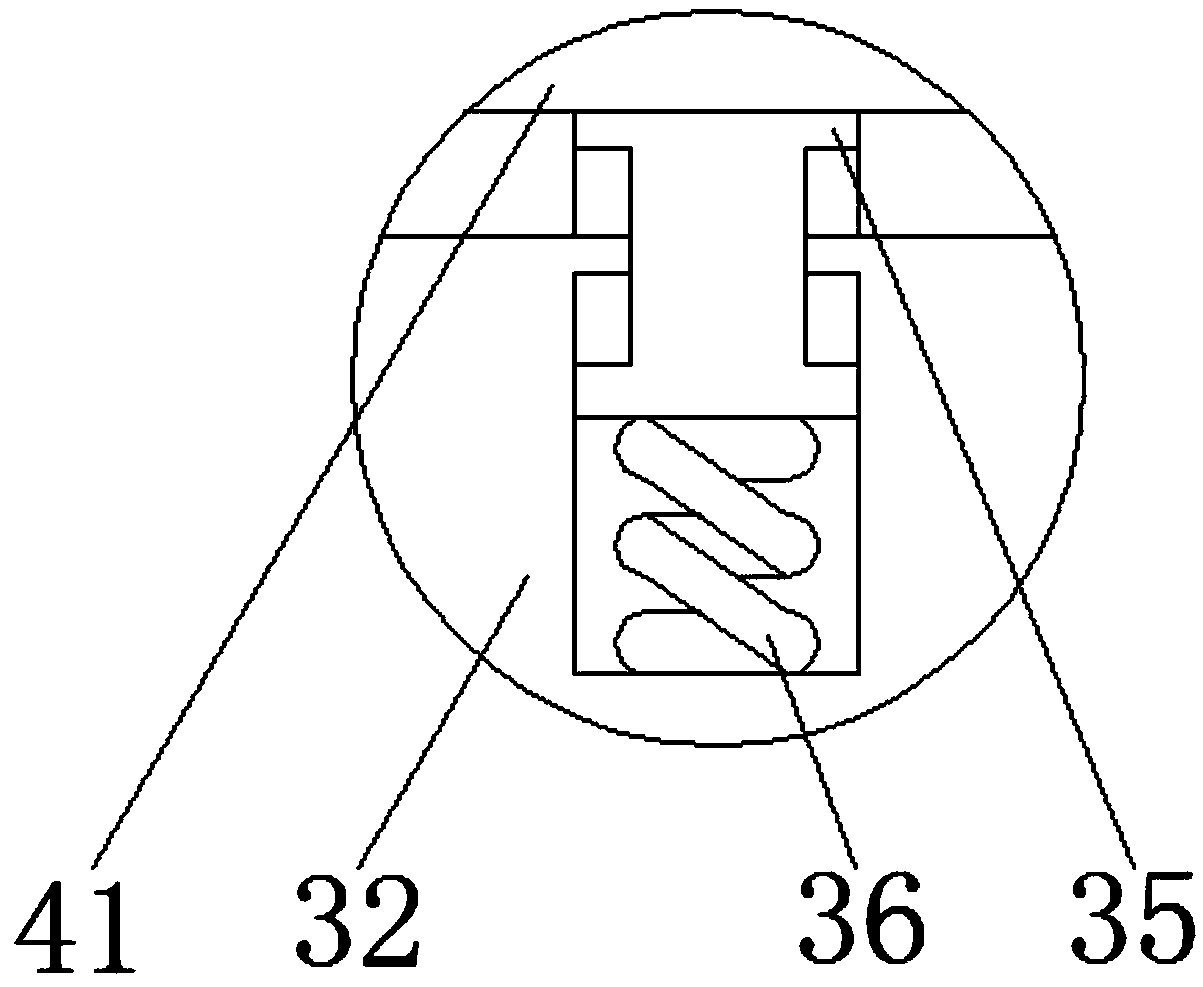

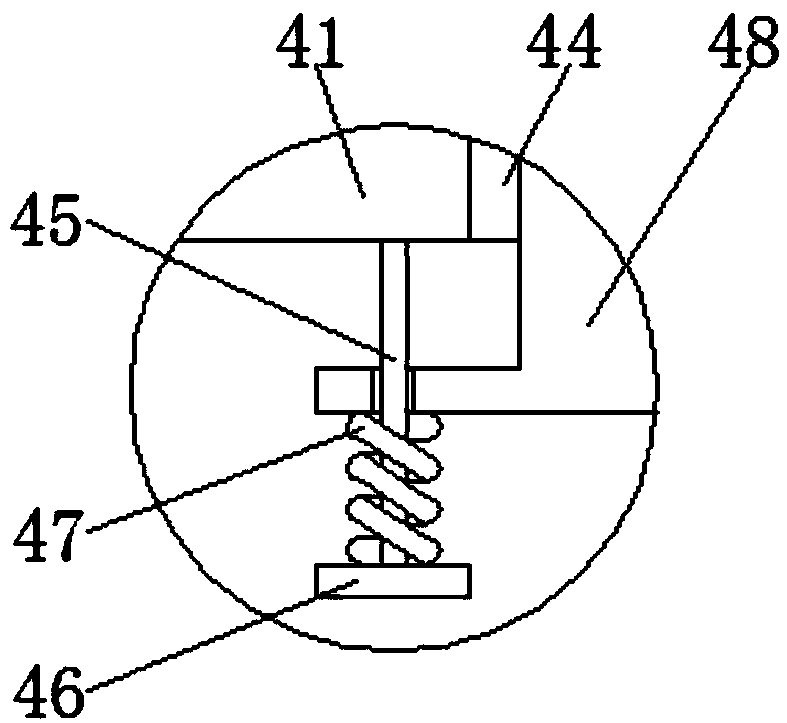

Adjustable grinding device

InactiveCN103506933APlay a grinding roleAct as a squeezeLapping machinesLapping toolsSurface roughnessEngineering

The invention discloses an adjustable grinding device which comprises a left nut, an outer sleeve, an adjusting shaft and a right nut. An inner tapered hole of the outer sleeve is combined with an outer tapered face of the adjusting shaft in a sleeved mode. The left nut and the right nut are relatively fixed on the adjusting shaft through bolts at the two ends of the adjusting shaft. Multiple straight grooves are formed in the periphery of the outer sleeve and boart sand is evenly cohered to the outer wall. When the grinding device is used for grinding, the grinding device penetrates into an inner hole of a metal part to be ground to rotate relatively and the grinding device and the metal part relatively move back and forth along the axis of the metal part so as to finish grinding. The adjustable grinding device is used for grinding and the inner hole of the metal part is not only ground, but also extruded. The inner hole of the metal part is smooth and possessed of higher surface roughness and precision. Grinding agents will not retain in pores of the surface of the inner hole of the metal part.

Owner:泰州市恒久转向器厂

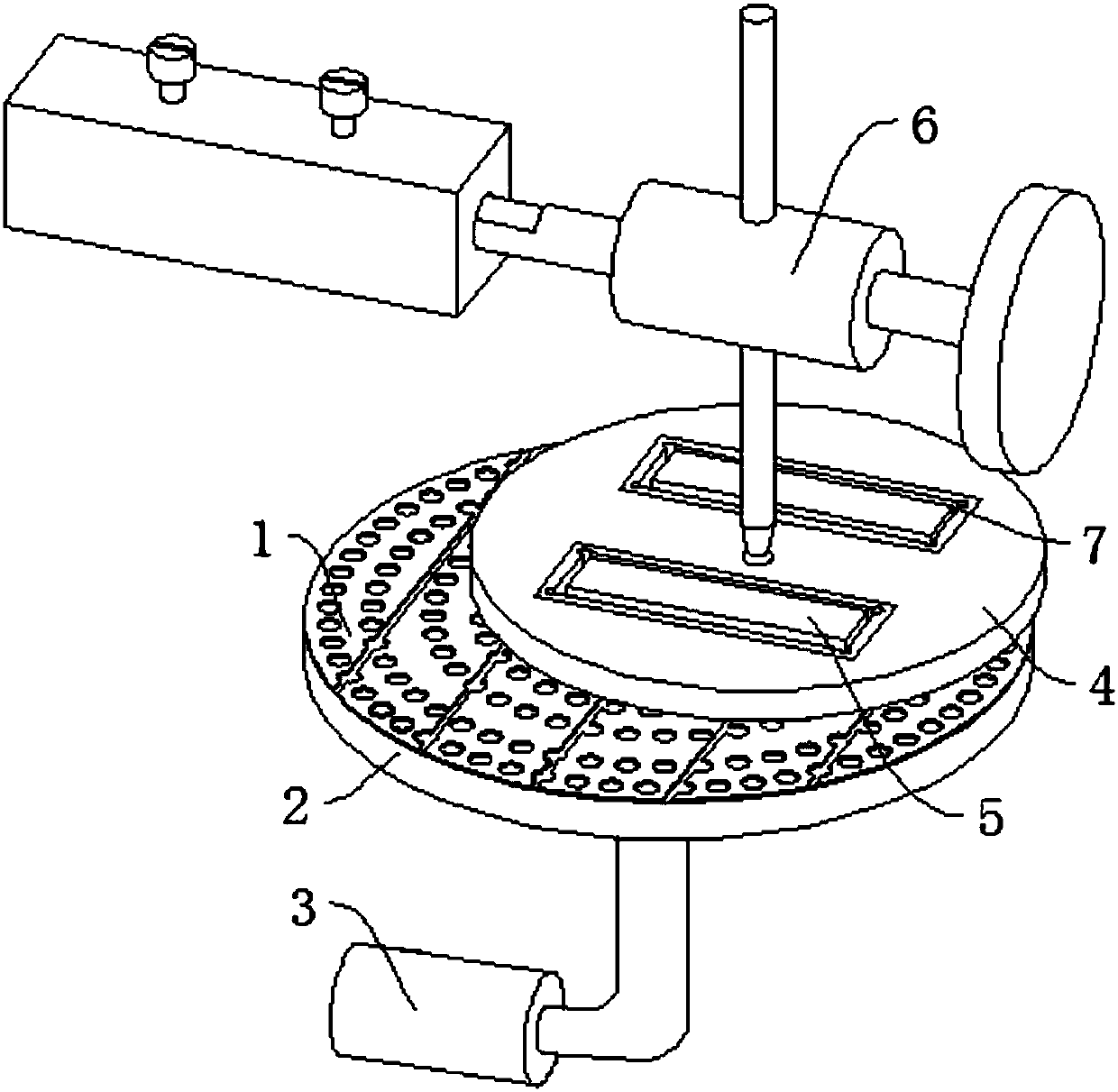

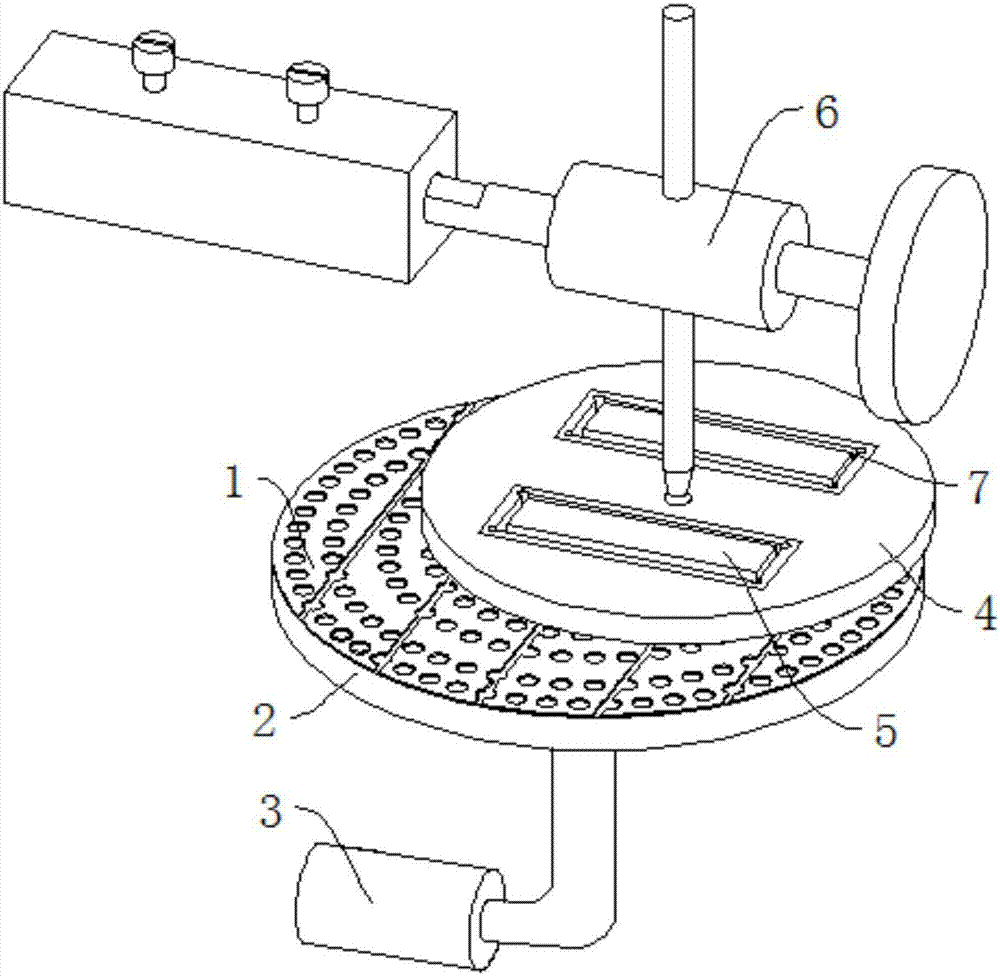

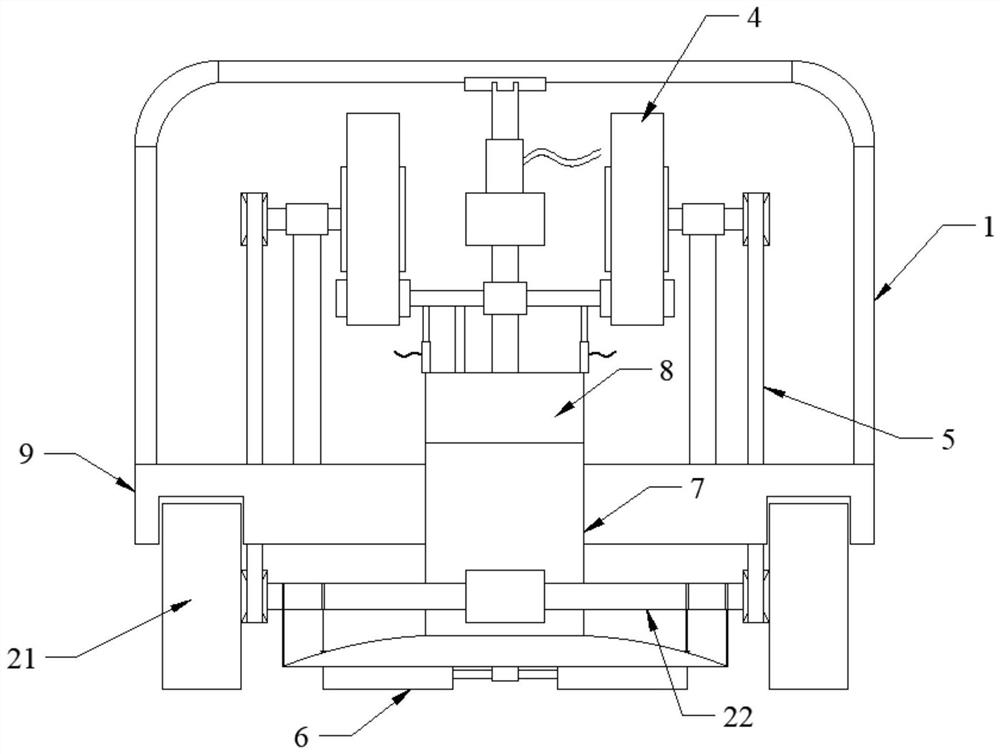

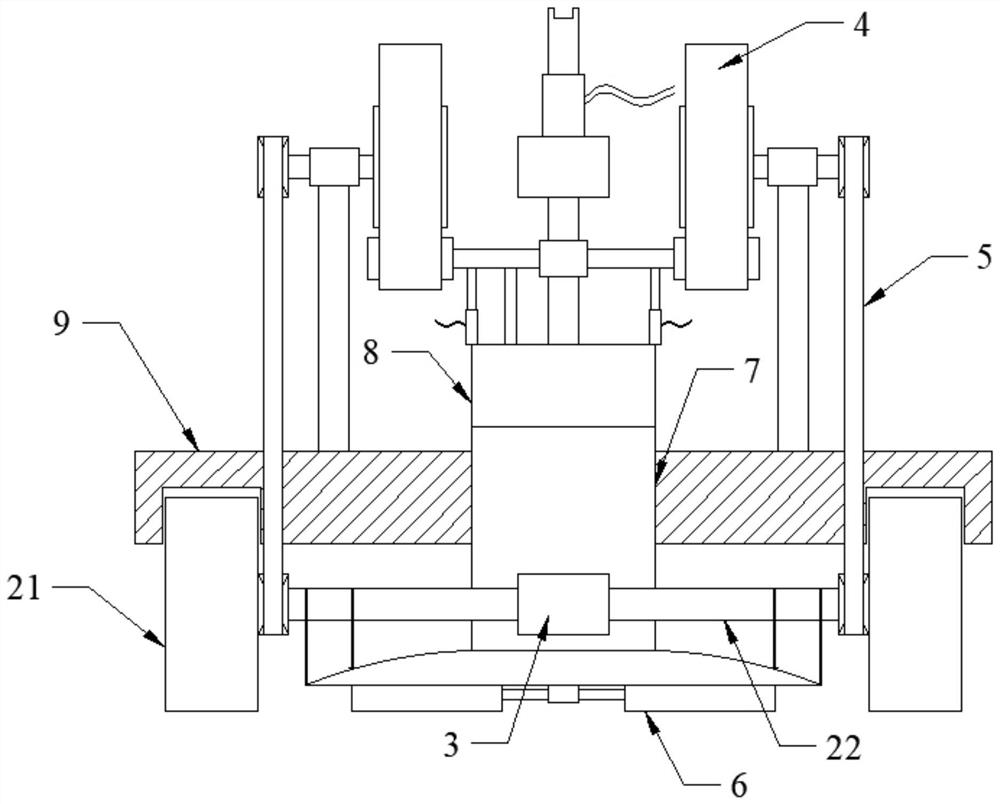

Optical lens polishing device and polishing process

InactiveCN107671605AGood suspensionGuaranteed roughnessOptical surface grinding machinesMachined surfaceEngineering

The invention discloses an optical lens polishing device. The optical lens polishing device comprises a polishing pad, a polishing pad base, a rotating driving device, a separator, pressing blocks anda polishing machine, wherein the polishing pad is arranged on the polishing pad base which is connected to the rotating driving device, the separator is arranged on the polishing pad and provided with multiple object containing grooves, the pressing blocks are arranged in the object containing grooves of the separator, a hole is formed in the middle of the separator, and the separator is connected to the polishing machine through the hole. The invention further discloses a polishing process. The polishing process particularly comprises the following steps of trimming a correction mold, trimming the polishing pad through the correction mold, cleaning the polishing pad, fixing the polishing pad to the polishing pad base, preparing a polishing solution, putting the polishing solution into apolishing solution circulating cylinder of the polishing machine, placing lenses into the object containing grooves of the separator, placing the pressing block on the lenses and starting the polishing machine and the rotating driving device for polishing. By this way, it can be guaranteed that machining faces of products are on the same plane, the products are stressed uniformly, and the polishing effect can be improved.

Owner:II VI OPTICS (SUZHOU) CO LTD

Bottle body label removal device for recycling round canned bottle

ActiveCN109047222AEasy to installLarge thrustGrinding drivesHollow article cleaningDrive motorEngineering

The invention discloses a bottle body label removal device for recycling a round canned bottle, and relates to the technical field of canned bottle recycling. The bottle body label removal device forrecycling the round canned bottle comprises a first shell, the top of the inner wall of the first shell is fixedly connected with a locking mechanism, the bottom of the inner wall of the first shell is fixedly connected with a driving mechanism, the inner wall of the locking mechanism is connected with a rotating rod through a bearing, and the bottom of the rotating rod is fixedly connected to thetop of the driving mechanism. According to the bottle body label removal device for recycling the round canned bottle, a driving motor is started, the canned bottle fixed on a fixing mechanism is rotated through a supporting mechanism, a handle is rotated, a third thread enables a first moving block to upwards move, under the action of a second connecting rod and a second moving block, a polishing block is moved to the side close to the canned bottle, after the polishing block is in contact with a label, the label is polished away through the polishing block, and removal of the label on the canned bottle is facilitated.

Owner:嘉兴市瑞鑫塑业有限公司

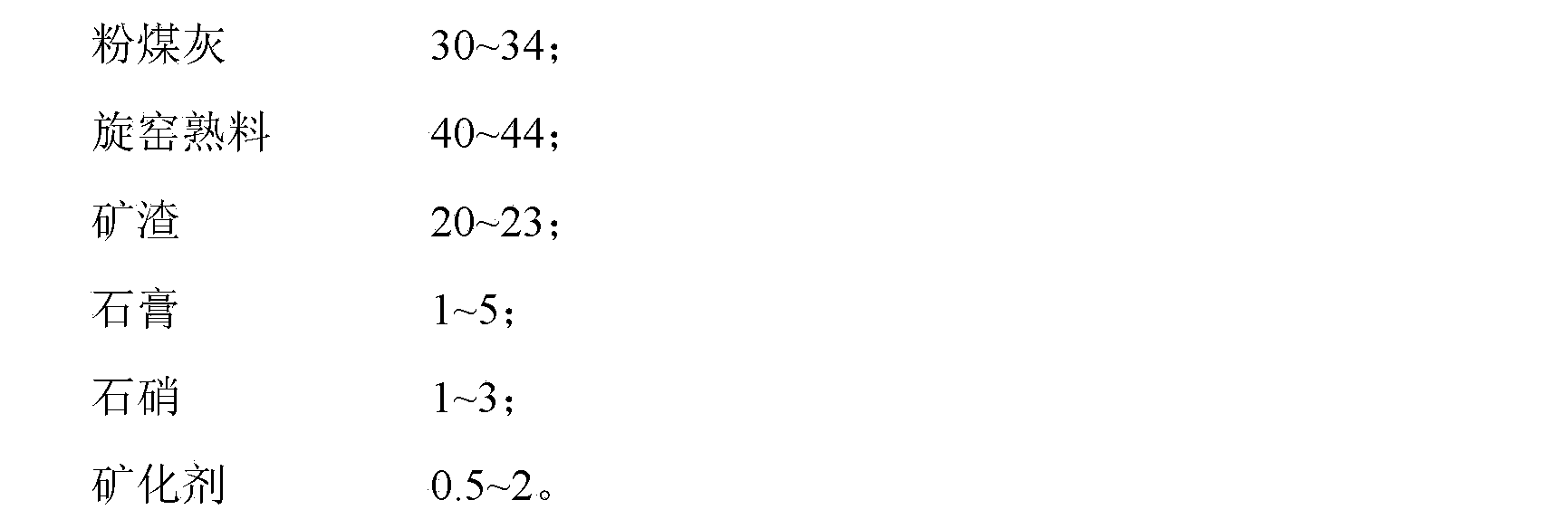

Fly ash cement and preparation method thereof

The invention relates to a fly ash cement. The fly ash cement comprises, by weight, 30 to 34 parts of fly ash, 40 to 44 parts of rotary kiln clinker, 20 to 23 parts of slag, 1 to 5 parts of gypsum, 1 to 3 parts of aggregate chips and 0.5 to 2 parts of a mineralizer. According to the invention, since fly ash, rotary kiln clinker and slag are used as the components of the fly ash cement, a great amount of fly ash produced after combustion of coal can be effectively utilized and rotary kiln clinker and slag are utilized at the same time; thus, a good promotion effect is exerted on environmental protection and resource utilization, production cost of an enterprise is reduced, and production efficiency of the enterprise is improved. According to detection results, the fly ash cement exceeds national standards for P-F32.5 fly ash cement in China, and the strength of the fly ash cement is not inferior to that of traditional slag P-S-A32.5 cement.

Owner:TIANJIN JIANKUN CEMENT

Optical lens polishing device and polishing technology

InactiveCN107253132AEven by forceImprove polishing effectLapping machinesAbrasive surface conditioning devicesEngineeringLens plate

The invention discloses an optical lens polishing device which comprises a polishing pad, a polishing pad base, a driving device, a separator, pressing blocks and a polishing machine. The polishing pad is arranged on the polishing pad base. The polishing pad base is connected to the driving device. The separator is arranged on the polishing pad. A plurality of placement grooves are formed in the separator. The pressing blocks are arranged inside the placement grooves in the separator. A hole is formed in the middle of the separator. The separator is connected to the polishing machine through a hole. The invention further discloses a polishing technology. The polishing technology comprises the specific steps of finishing a correction mold, finishing the polishing pad through the correction mold; cleaning the polishing pad; fixing the polishing pad to the polishing pad base; preparing a polishing solution; placing the polishing solution into a polishing solution circulation cylinder of the polishing machine; placing lenses into the placement grooves of the separator; placing the pressing blocks on the lenses; starting the polishing machine and the driving device for polishing. In this way, it is ensured that the product machining face is on the same plane, stress is uniform, and the polishing effect is improved.

Owner:II VI OPTICS (SUZHOU) CO LTD

Bottle body label removing device and method for circular canned bottle recycling

Owner:TAIZHOU HUANGYAN AISHANG PLASTIC CO LTD

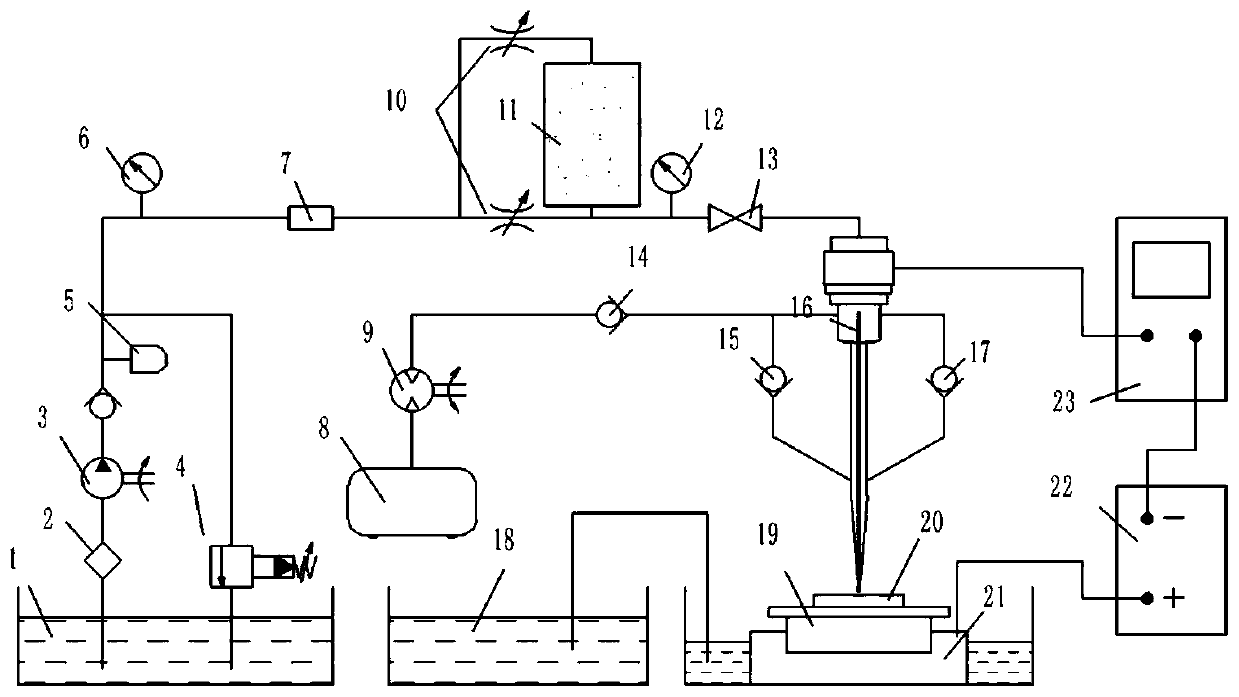

Electrophoresis and supersonic vibration assisted micro-milling and machining device

InactiveCN103909300AImproved material removalImprove processing efficiencyMilling equipment detailsMilling cutterElectrophoresis

The invention provides an electrophoresis and supersonic vibration assisted micro-milling and machining device. The electrophoresis and supersonic vibration assisted micro-milling and machining device comprises a vertical slide block, a superfine supersonic main shaft, a superfine supersonic main shaft power supply generator and a control panel, an electrophoresis assisted power supply, a superfine supersonic platform power generator, a control panel, a movement control system, a micro-three-dimensional motion platform, a superfine supersonic platform, a milling cutter and an electrophoresis assisted circular electrode. According to the electrophoresis and supersonic vibration assisted micro-milling and machining device, a solution with superfine milling particles is added into a common supersonic vibration assisted micro-milling and machining process; meanwhile, the electrophoresis assisted circular electrode is used and assisted voltage is applied to the micro milling cutter, so that an assisted electric field is generated between the electrophoresis assisted circular electrode and the micro milling cutter and the superfine milling particles are driven to move or be adsorbed on the micro milling cutter; the milling particles have the milling effect on a workpiece in a machining process; meanwhile, the solidified milling particles can also have the protection effect on the milling cutter so as to reduce the abrasion to the cutter. The milling particles can also be used for impacting the workpiece under the driving of supersonic vibration; the material removing efficiency is improved and the milling machining efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

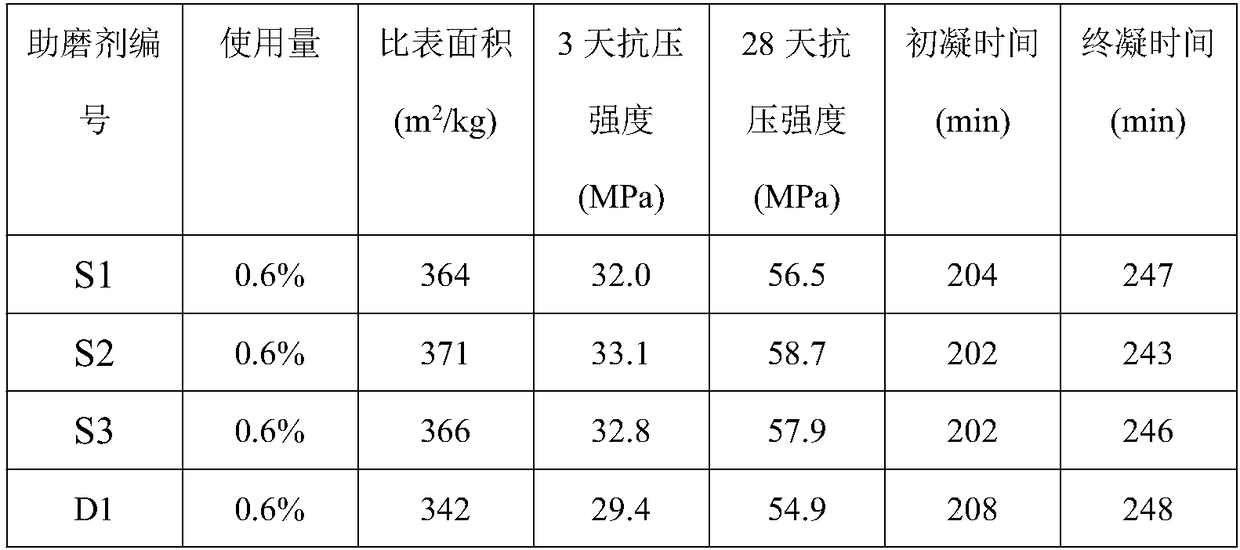

Cement grinding aid and preparation method therefor

The present invention discloses a cement grinding aid. The grinding aid comprises the following compositions components in parts by weightmass: 60-65 parts of alkali slag, 10-15 parts of straw ash, 15-20 parts of steel slag and 5-10 parts of calcium lignosulphonate, and the compositions components contain the following substances in based on the total mass percentage of the cement grinding aid by mass percentage: 30-41% of calcium oxide, 28-35% of silicon dioxidesilica, 8-16% of aluminum oxidealundum, 6-12% of sulfur trioxide and 5-8% of carbamideurea. The preparation method comprises the ofllowng steps: fFirstly, uniformly mixing and stirring the alkali slag, the straw ash, the steel slag and the calcium lignosulphonate are mixed and uniformly agitated; secondly, the mixture is preparing the mixture ed into spherical particles; lastlyand finally, stacking and curing the spherical particles are subjected to stacking, solidification and removing free water and partial part of water of crystallization removal, as a result to obtain, the a cement grinding aid is obtainedproduct. The cement grinding aid disclosed by the present invention is low in production cost, and good in product performance.

Owner:淮安市水泥厂有限公司

Red wine bottle surface label paper removing device based on dynamic friction

InactiveCN109332314AGood removal effectPlay a grinding roleHollow article cleaningWine bottlePulp and paper industry

The invention discloses a red wine bottle surface label paper removing device based on dynamic friction, and belongs to the technical field of red wine bottle recycling. The red wine bottle surface label paper removing device based on dynamic friction includes a base, a positioning mechanism is fixedly connected with the bottom of the left portion of the front side of the base; a guide rod is fixedly connected with the top of the positioning mechanism; a support plate is fixedly connected with the top of the guide rod; the rear side of the support plate is fixedly connected with the front sideof the base; a clamping mechanism is connected with the inner wall of the guide rod in a sleeving mode; and the rear side of the clamping mechanism is slidably connected with the front side of the base. According to the red wine bottle surface label paper removing device based on dynamic friction, a polishing roller rotates to polish a red wine bottle surface label paper so as to remove the red wine bottle surface label paper, so that the problems that the red wine bottle surface label paper needs removing before a red wine bottle surface is cleaned, but the label paper tightly adheres, and it is not convenient for an operator to directly remove the red wine bottle surface label paper are effectively solved.

Owner:南京溧水高新产业股权投资有限公司

Deburring device for water pump body production

ActiveCN109290878AQuick sandingPlay a grinding roleEdge grinding machinesGrinding wheel securing apparatusGear wheelEngineering

The invention provides a deburring device for water pump body production. The deburring device for water pump body production comprises an installation groove, an outer supporting spring, an outer supporting plate and polishing stone, wherein the outer side end of a threaded bolt is arranged in the middle of the inner side of a fixed piece through welding; the tail part of a motor is arranged at the top end of the inner part of a main body through a fixed connection way; a drive rod is arranged in the middle of the motor; the bottom part of the drive rod is connected with the middle position at the upper part of a gear through welding; the outer side of the gear contacts clamping teeth in a carrying groove in the middle of the outer side of a polishing bin; an extending piece contacts a carrying piece through a rotating wheel on the bottom part; the polishing bin can play a role in installing, fixing and driving the polishing stone to rotate, so that the polishing stone can be used forpolishing and removing burrs in different sizes on the outer side of a pump body; and the carrying groove is formed in the middle of the outer side of the polishing bin, and the clamping teeth are arranged in the carrying groove so as to play a role in contacting power transmitted from the gear.

Owner:徐州飞龙机电制造有限公司

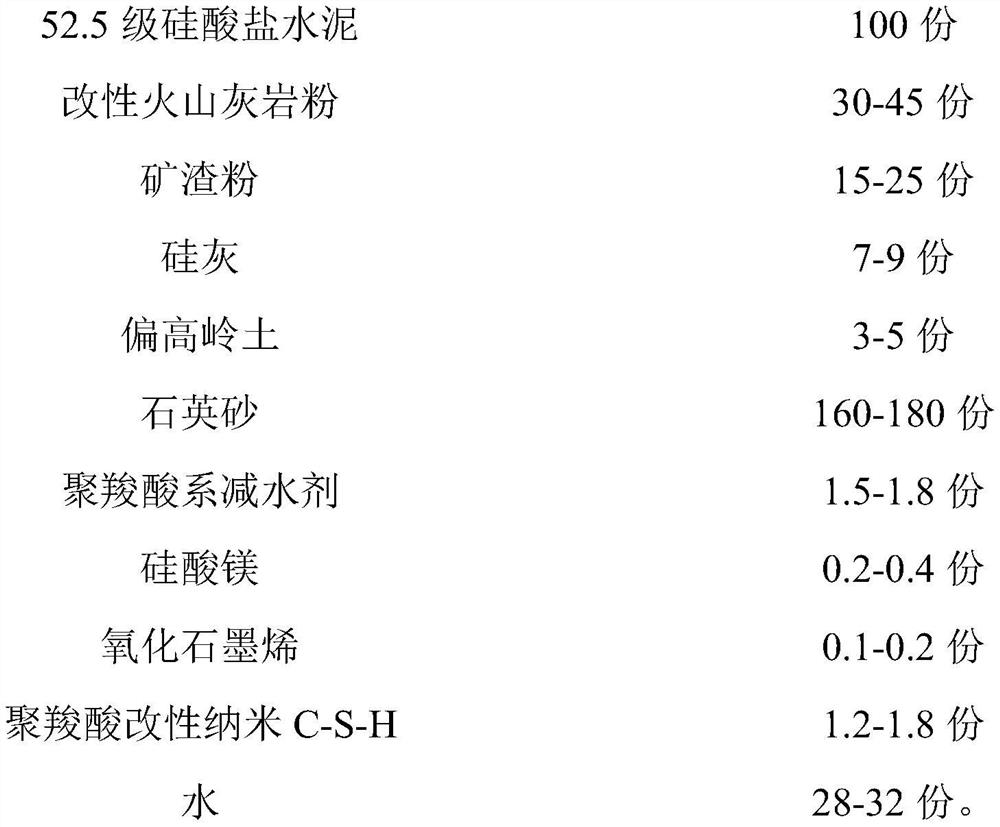

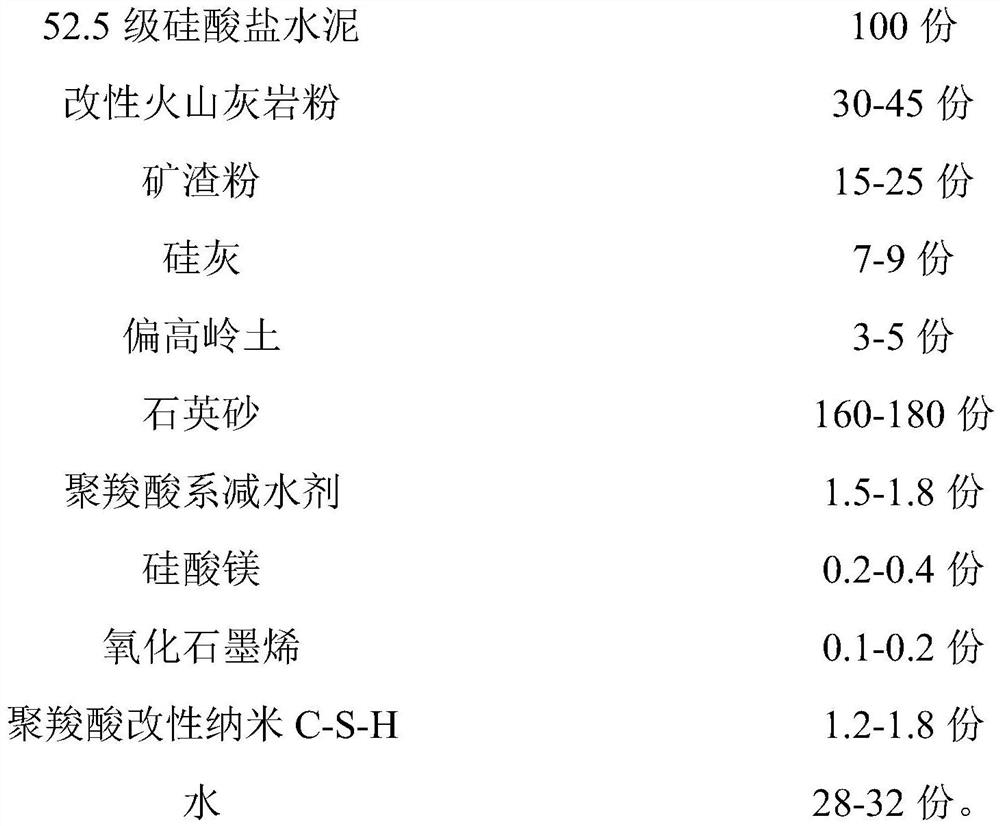

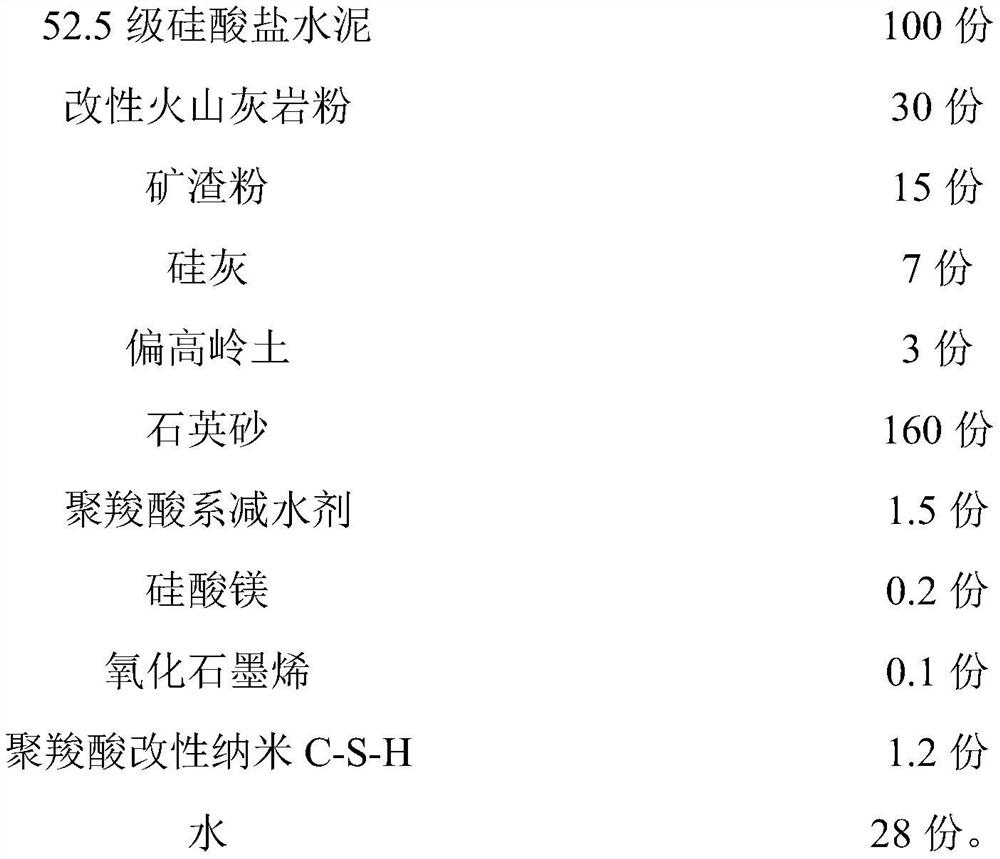

Ultra-high performance concrete prepared from modified volcanic limestone powder

The invention discloses ultra-high performance concrete prepared from modified volcanic limestone powder. The ultra-high performance concrete is prepared from 52.5-grade Portland cement, modified volcanic limestone powder, slag powder, silica fume, metakaolin, quartz sand, a polycarboxylic water reducer, magnesium silicate, graphene oxide, polycarboxylic acid modified nano C-S-H and water. The modified volcanic limestone powder is utilized to enhance the characteristics of of the ultra-high performance concrete including good fluidity, high strength and low preparation cost, so that the popularity and market competitiveness of the ultra-high performance concrete prepared by the invention are favorably improved. Therefore, the ultra-high performance concrete prepared by the invention is concrete with high comprehensive performance.

Owner:乌兰浩特市圣益商砼有限公司

Method for polishing diamond rectangle micropore mold die hole

ActiveCN101347914AKeep shapeWon't twist and breakBelt grinding machinesReciprocating motionElectrical and Electronics engineering

The invention discloses a method for polishing the die hole of a diamond rectangular microporous die; the basic proposal is as follows: the die is clamped in a clamp which is matched with the die, the position and direction of the die in the clamp can be adjusted, a polishing narrow band does up and down reciprocating motion to polish one group of opposite sides of the die hole of the die one by one, then the die turns at 90 degrees, the polishing narrow band polishes another group of opposite sides, in this way, the whole periphery in the die hole can be polished. The method for polishing the die hole of the diamond rectangular microporous die provided by the invention can polish a rectangular micropore, and can grind both the long edge and width edge of the rectangular die hole so as tofacilitate the maintenance of the shape of the die hole; the narrow band can not be distorted and broken in the polishing process, and the polishing efficiency is high.

Owner:CHENGDU HONGBO INDAL

High-efficiency and low-cost cement grinding aid and preparation method thereof

The invention discloses a high-efficiency and low-cost cement grinding aid, which comprises: 6-8 wt% of triethanolamine, 3-5 wt% of molasses, 4-8 wt% of polyether polyol, 22-35 wt% of paper pulp wastewater, 7-10 wt% of sodium thiosulfate, 1.5-3 wt% of anhydrous sodium acetate, 1-6 wt% of an air entraining agent, 3-6 wt% of polyhydroxycarboxylic acid, and the balance of distilled water, wherein theair entraining agent is sodium lignosulfonate or triterpene saponin, the polyhydroxycarboxylic acid is a product obtained by oxidizing polysaccharide, chlorine ions are removed from the paper pulp wastewater through resin exchange treatment, and the paper pulp wastewater has the Baume degree of 16-20 DEG Be and the pH value of 7. According to the present invention, the cement grinding aid uses the paper pulp wastewater as the raw material so as to effectively treat the wastewater of papermaking enterprises and reduce the production cost of the grinding aid; and by adding the polyhydroxycarboxylic acid, the water-cement ratio is reduced, the strength of the cement is increased, and the quality of the cement is ensured.

Owner:QUANZHOU CHAOXU NEW ENERGY TECH CO LTD

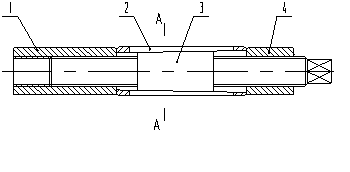

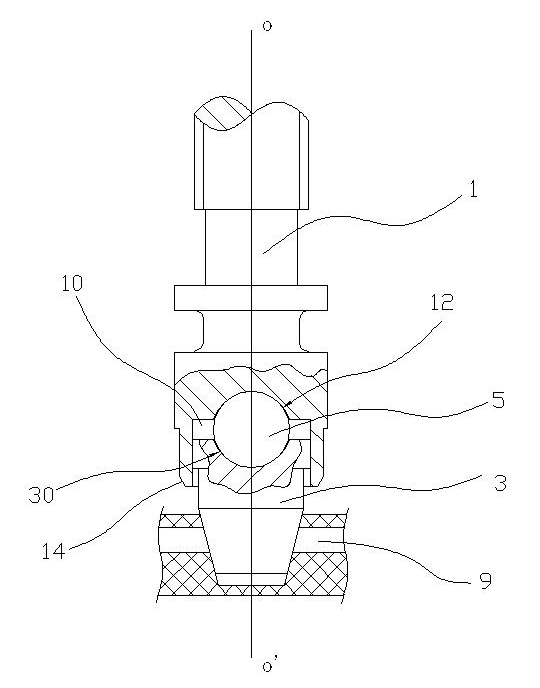

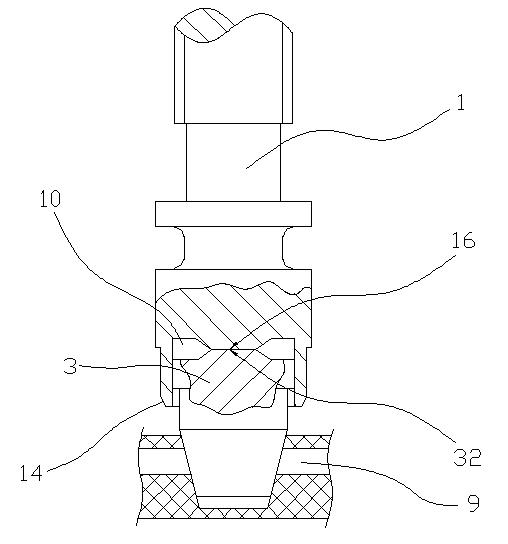

Valve rod

The invention discloses a valve rod comprising a rotary rod and a sealing plug. The valve rod is characterized in that the rotary rod and the sealing plug are of a split structure, and the rotary rod and the sealing plug can relatively rotate; and an end face pressing down the sealing plug is at least arranged on the rotary rod. In the valve rod disclosed by the invention, the rotary rod rotates and does not drive the sealing plug to rotate, and the sealing plug is pressed down when the rotary rod is screwed down so that the sealing plug only moves up and down, but not moves circularly, thus the abrasion of a conical surface or a sealing opening (a valve hole) of the sealing plug is reduced and the service life of the sealing plug is largely prolonged.

Owner:朱成伟

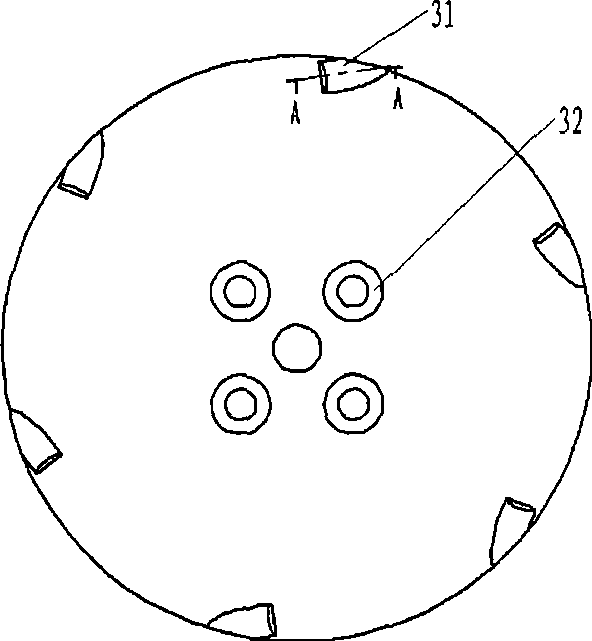

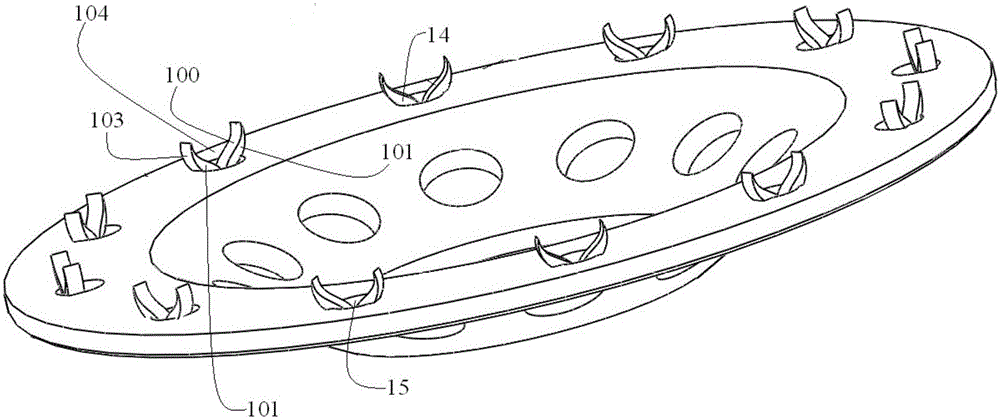

Terrace grinding wheel and manufacturing method thereof

ActiveCN105081994AGuaranteed connection strengthGuaranteed cutting forceBonded abrasive wheelsEngineeringGrinding wheel

The invention discloses a terrace grinding wheel and a manufacturing method thereof. The terrace grinding wheel comprises a base body and a plurality of tool bits sintered to the outer circle surfaceof the base body. Each tool bit comprises a front part and a rear part, wherein the top end of the front part is a sharp corner, and a groove is formed in the bottom end of the rear part. The tool bits are fixed to the base body through a hot press sintering method. According to the technical scheme, rapid cutting and smooth cutting removing are achieved, and the purpose of removing a terrace coating is achieved.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

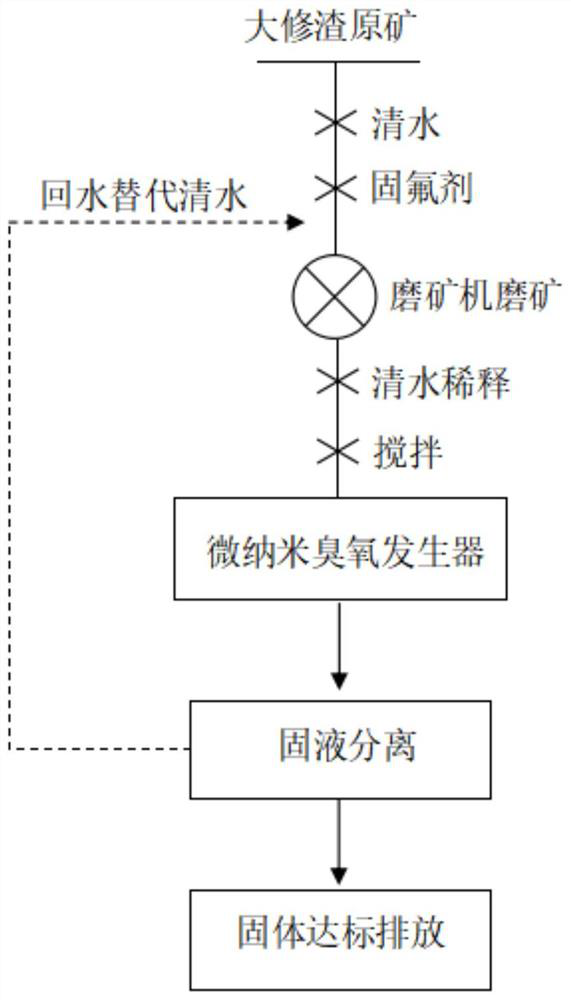

Method for efficiently removing cyanofluoride from electrolytic aluminum overhaul slag

The invention belongs to the technical field of overhaul slag treatment, and discloses a method for efficiently removing cyanofluoride from electrolytic aluminum overhaul slag, which comprises the following steps of: S1, crushing the electrolytic aluminum overhaul slag by using a crusher until the particle size is less than 60mm; S2, adding a fluorine fixing agent, the overhaul slag and clear water into the ball mill according to the mixing mass ratio of (1-5): 30: 18, carrying out mixing and ore grinding, and meanwhile carrying out fluorine fixing; S3, diluting the ore pulp in the step S2 with clear water until the concentration is 15%-40%, pouring the diluted ore pulp into an advanced oxidation reaction container of an ozone micro-nano generator, starting the ozone generator, introducing ozone into the leached slurry, and continuing to stir for reaction; and S4, carrying out solid-liquid separation on the ore pulp reacted in the step S3, and adding a separated liquid phase and a part of solid phase into the ore pulp obtained by ore grinding in the step S2. Compared with the prior art, the method provided by the invention comprises the four steps of crushing, ore grinding and fluorine fixing, micro-nano ozone cyanogen removal and solid-liquid separation, and has the advantages of simple process, short flow, high efficiency, low cost and the like.

Owner:河南资环矿业科技有限公司

Preparation method of feed for local chickens

InactiveCN109497326AImprove adsorption capacityIncrease the degree of mixingFood processingAnimal feeding stuffDiseaseFiltration

The invention relates to feed and in particular relates to a preparation method of feed for local chickens. The preparation method comprises the following steps: S1, after crushing egg shell powder, calcium fumarate, radix isatidis and cordate houttuynia respectively, and uniformly mixing; carrying out ball milling; adding de-ionized water and carrying out ultrasonic dispersion; adding clam shellpowder; stirring for reacting; performing suction filtration and removing a filtrate; washing, drying in vacuum, calcining and grinding to obtain a material a; S2, carrying out ultra-fine pulverization on corn flour, soybean meal, mountain flour, vivipara powder, corn gluten meal, lard dreg, feather protein powder, a vitamin complex, medical stone and sodium chloride respectively; sieving and uniformly mixing with the material a; drying, crushing and sieving to obtain the feed for the local chickens. The feed provided by the invention can be used for effectively improving the disease-resistingcapability and the egg yield of the local chickens.

Owner:安徽绿迪食品股份有限公司

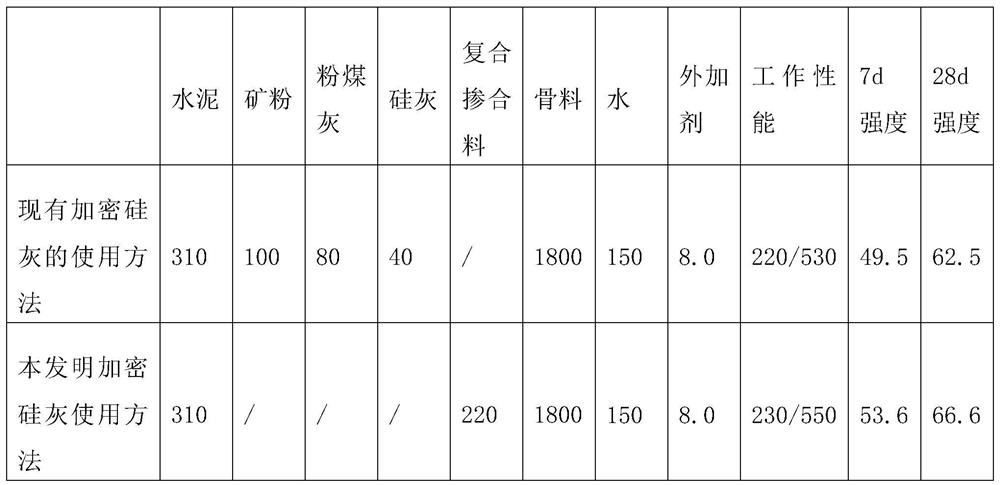

Densified silica fume composite admixture and application thereof in high-performance concrete

PendingCN113429144AImprove grindabilityRaise the ratioSolid waste managementAggregate (composite)Slag

The invention provides a densified silica fume composite admixture and application thereof in high-performance concrete. The composite admixture is prepared from the following raw materials: densified silica fume, limestone, manganese slag and nickel slag. The application of the composite admixture in the high-performance concrete comprises the steps of 1) conducting powder grinding preparation of the composite admixture, specifically, weighing the raw materials in percentage by mass, and then inputting the raw materials into a grinding machine for powder grinding; and 2) transporting the composite admixture to a commercial mixing station through a storage tank, adding coarse and fine aggregate and a cementing material into a stirrer, and stirring to obtain a finished product. The invention has the following advantages: 1, the admixture grain composition is optimized, and the performance and the later strength of the concrete are effectively improved; 2, the silica fume is prepared into the composite admixture, so that the transportation is convenient; 3, the proportion of the admixture in the cementing material in the concrete is large, and the admixture can be accurately metered in the preparation process; and 4, the admixture can be uniformly dispersed in the concrete in the stirring process of preparing the concrete, so that the stable quality of the high-performance concrete is ensured.

Owner:广西新途茂科技有限公司

Scraper grinding device

InactiveCN103144000AReduce fine bumpsQuality improvementEdge grinding machinesElectrography/magnetographyDigital copyImaging quality

A scraper grinding device comprises two opposite support parts, a cylindrical rolling part, two positioning parts and a driving part, wherein the two ends of the cylindrical rolling part are rotationally located on the two support parts; the two positioning parts are located on the two support parts respectively and used for positioning a scraper; the driving part is connected with the cylindrical rolling part and used for driving the cylindrical rolling part to rotate; and when the cylindrical rolling part rotates, the scraper is ground. The scraper grinding device can grind the scraper; when the distance between the cylindrical rolling part and the scraper is appropriate, after the cylindrical rolling part grinds the scraper, fine bumps at the edge of the scraper are decreased; the edge precision is improved; correspondingly, when the scraper is applied to imaging devices such as a digital copying machine, no toner missing happens when a toner is cleared; and the image quality can be improved.

Owner:KONICA MINOLTA BUSINESS TECHNOLOGIES (WUXI) CO LTD

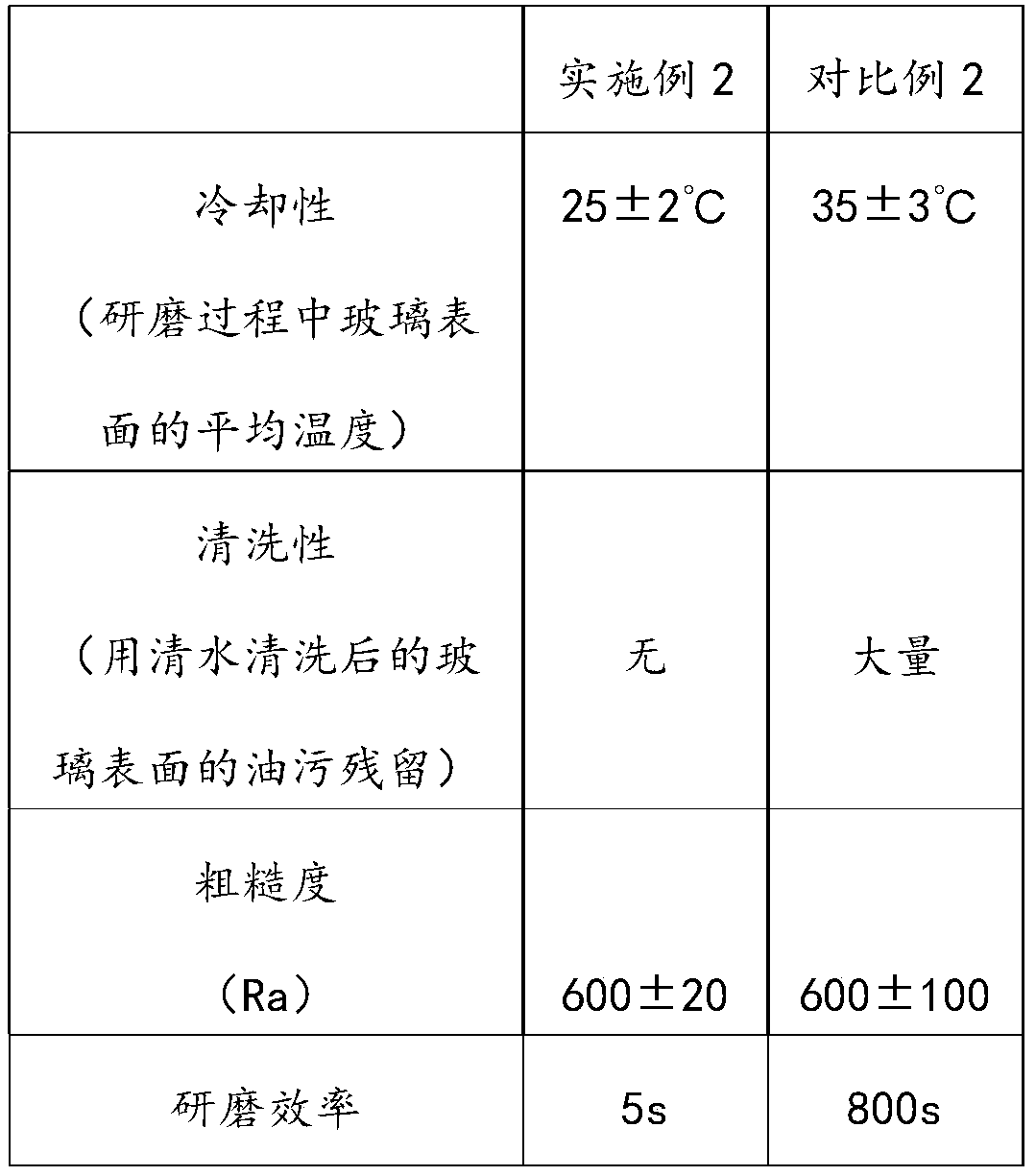

Particle composition for grinding

ActiveCN110699041AEasy to processImprove liquidityOther chemical processesAbrasion apparatusPolishingSurface roughness

The invention belongs to the technical field of precision grinding, and particularly relates to a particle composition for grinding. The composition in the form of a solid columnar particle and acts on the surface of a to-be-machined workpiece in the thinning and polishing process of the to-be-machined workpiece to achieve grinding effect; so on the basis that the surface roughness of the workpiece is accurately controlled, grinding efficiency is improved, manpower and material resource input is saved, and the problems of high cost, production pollution discharge and the like are solved. In addition, directed at the requirements of rough thinning, fine thinning, different products, different product roughness and the like, the particle composition can accurately meet diversified requirements of products by using diamonds with different particle sizes and concentrations.

Owner:烟台胜道电子科技有限公司

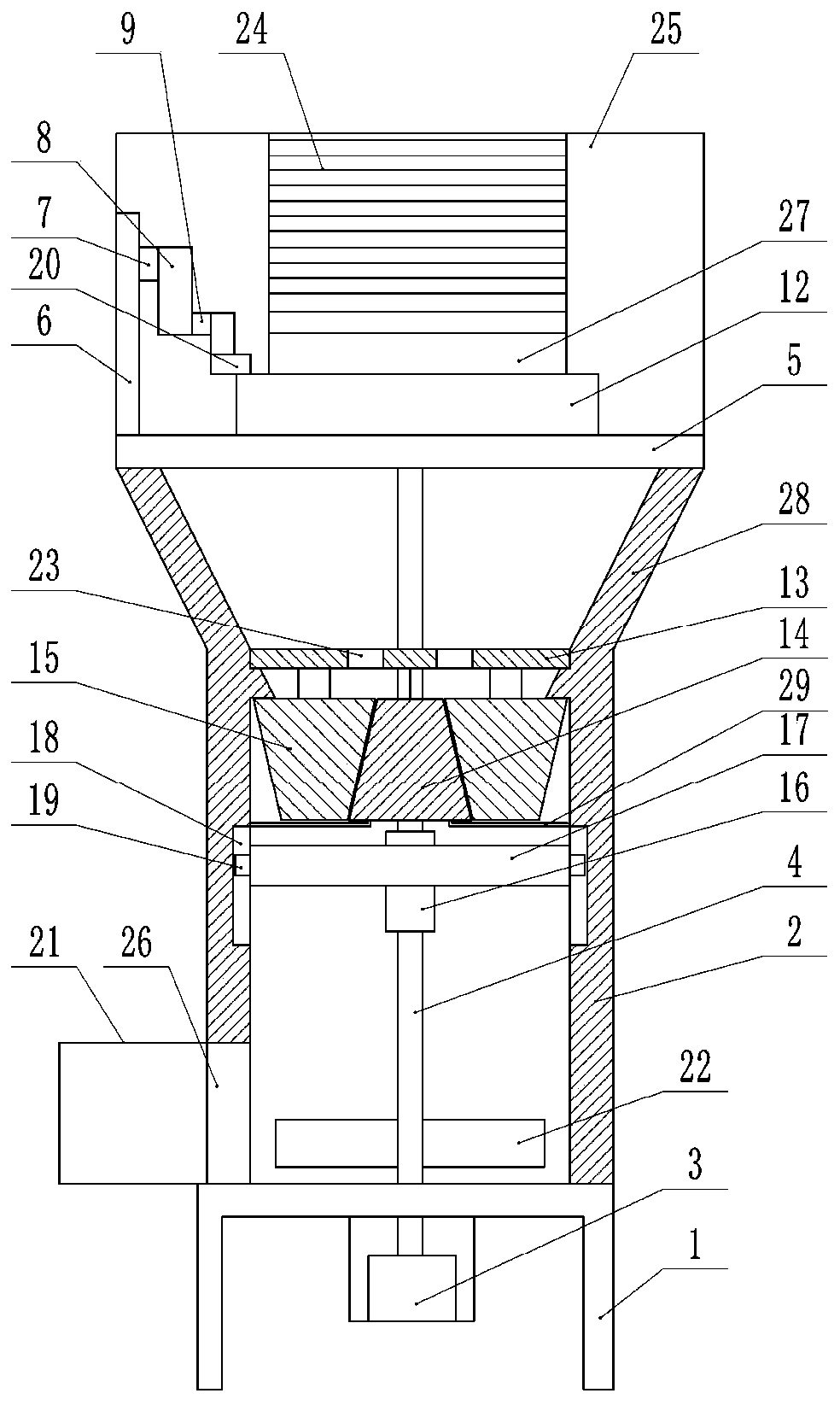

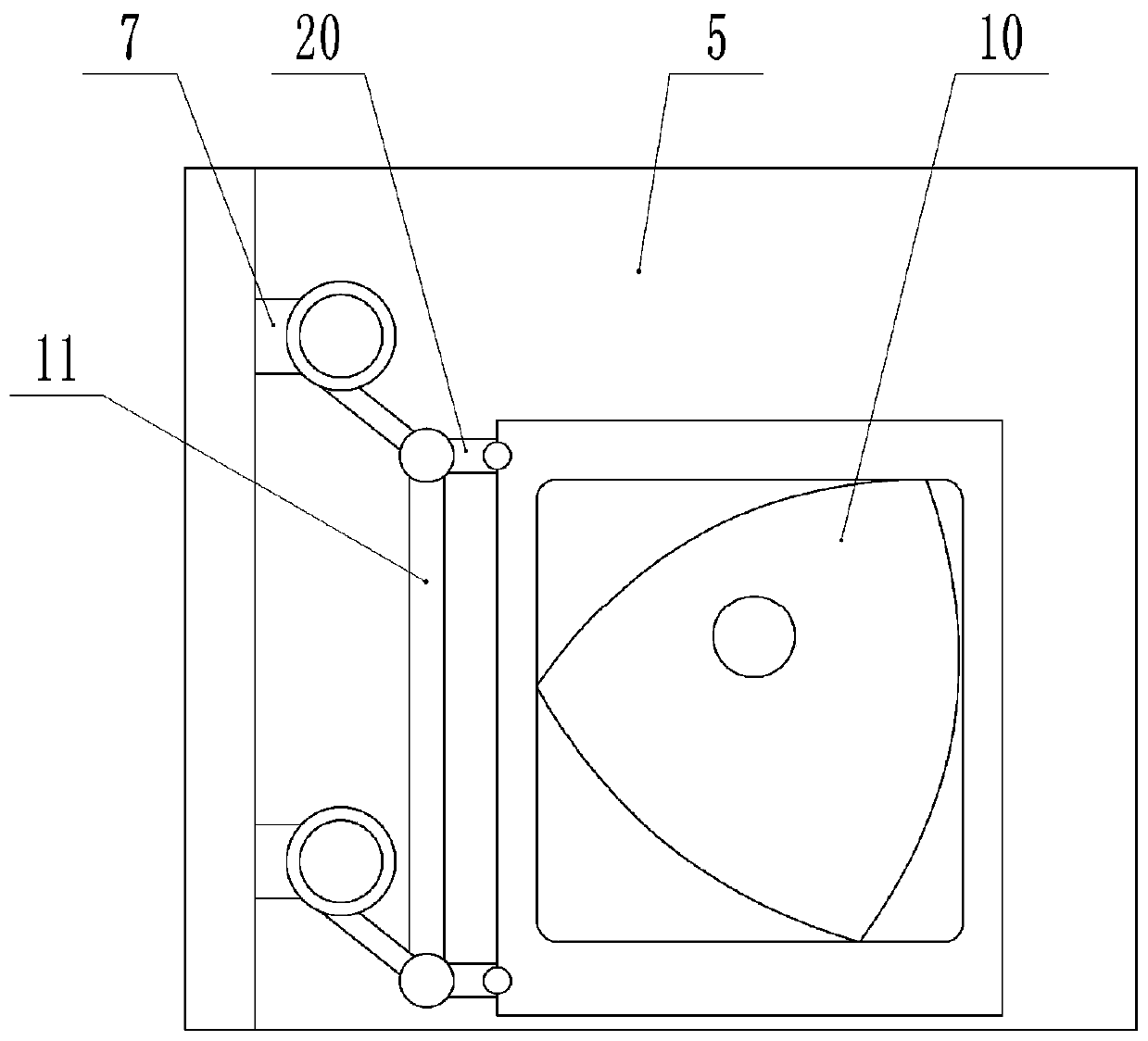

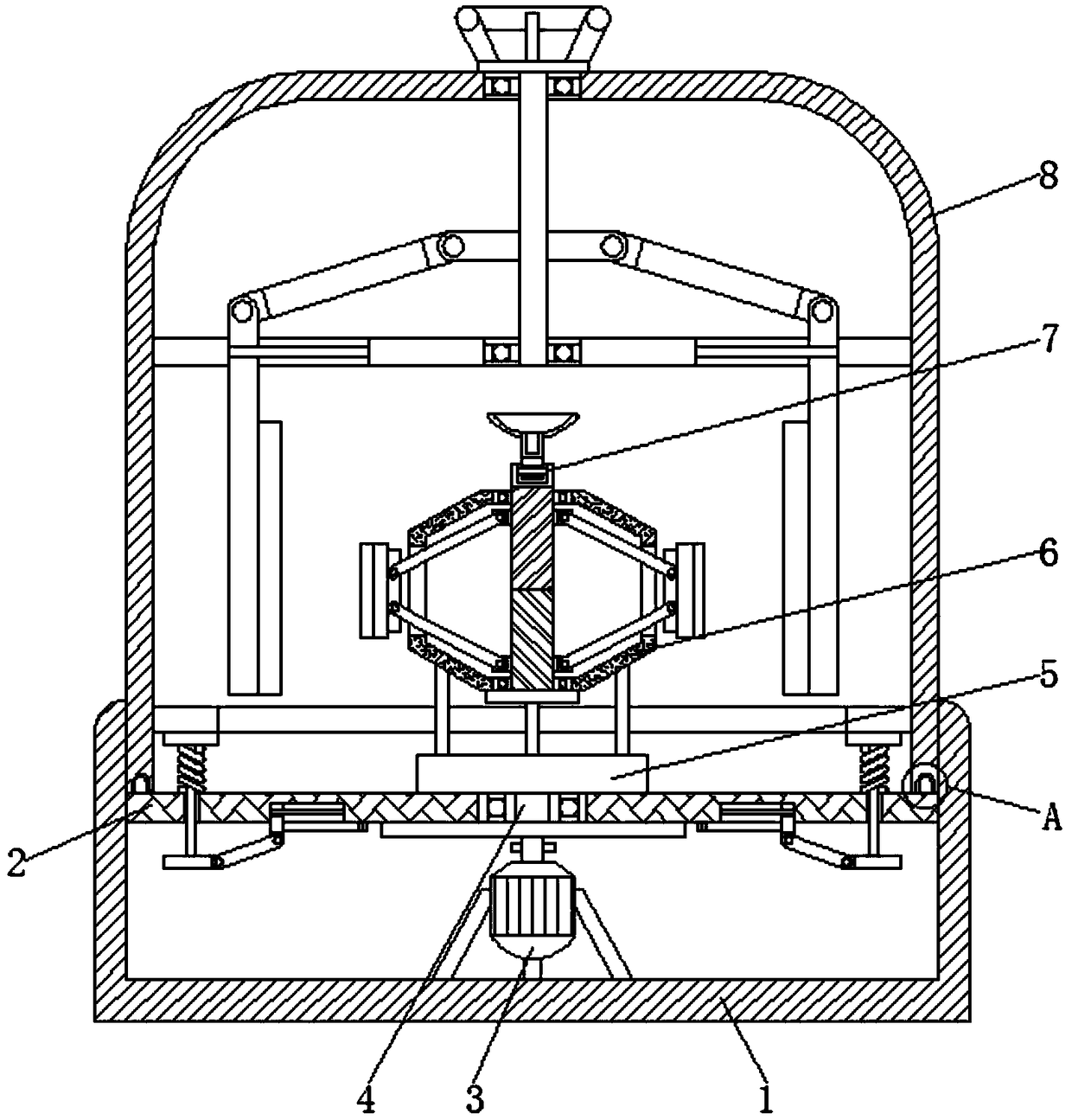

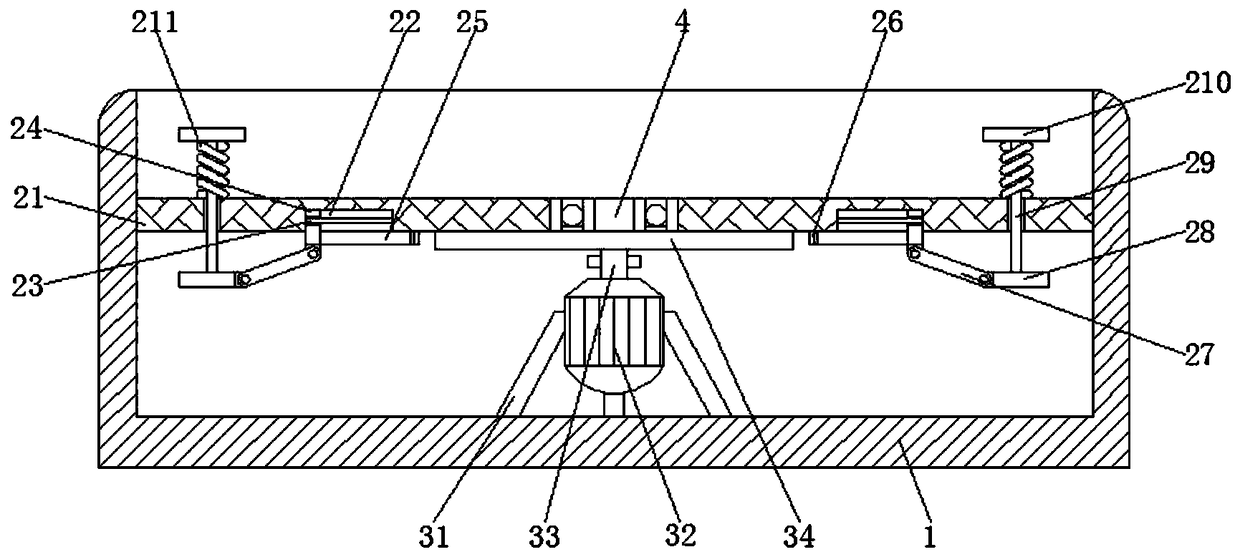

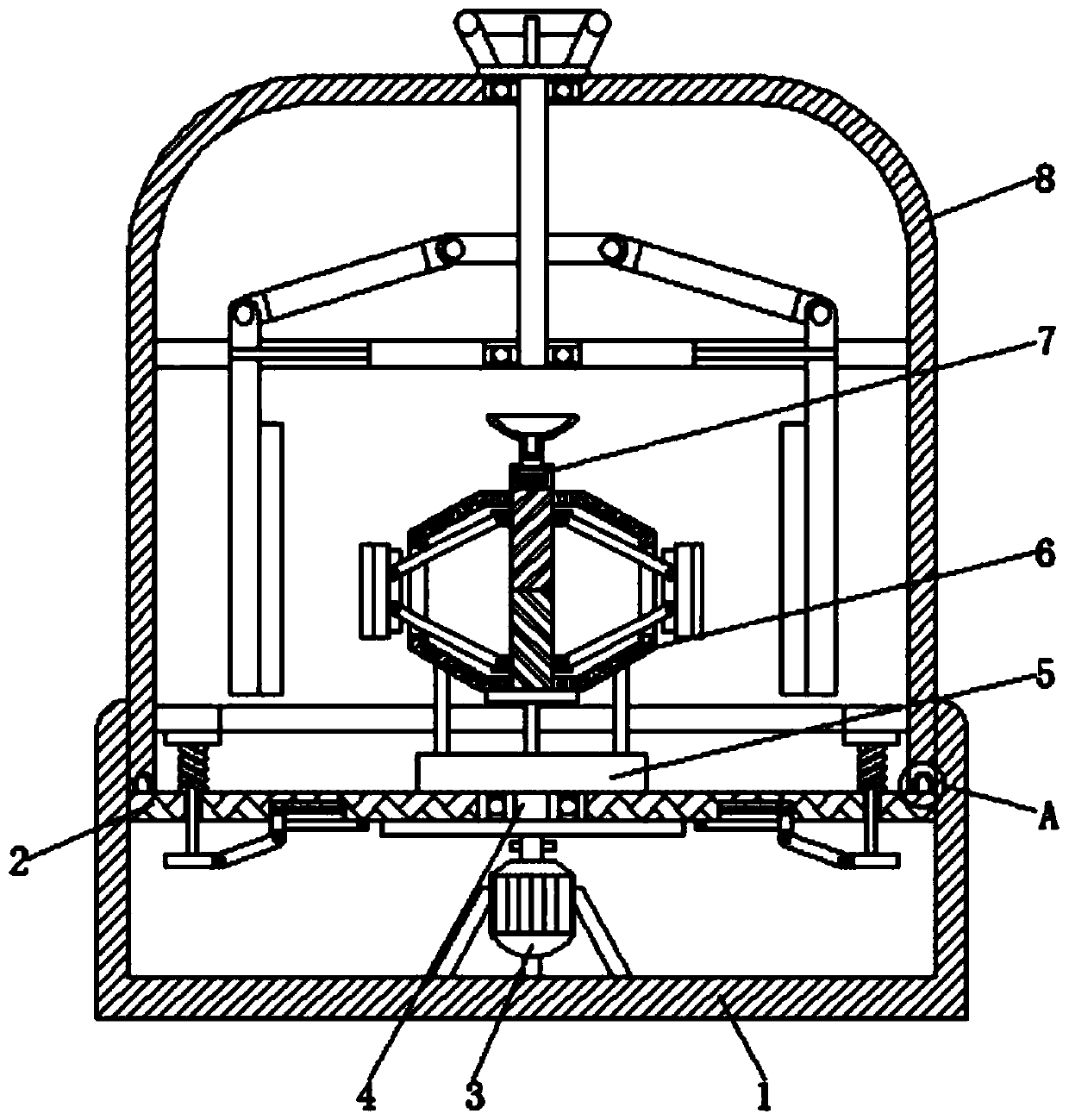

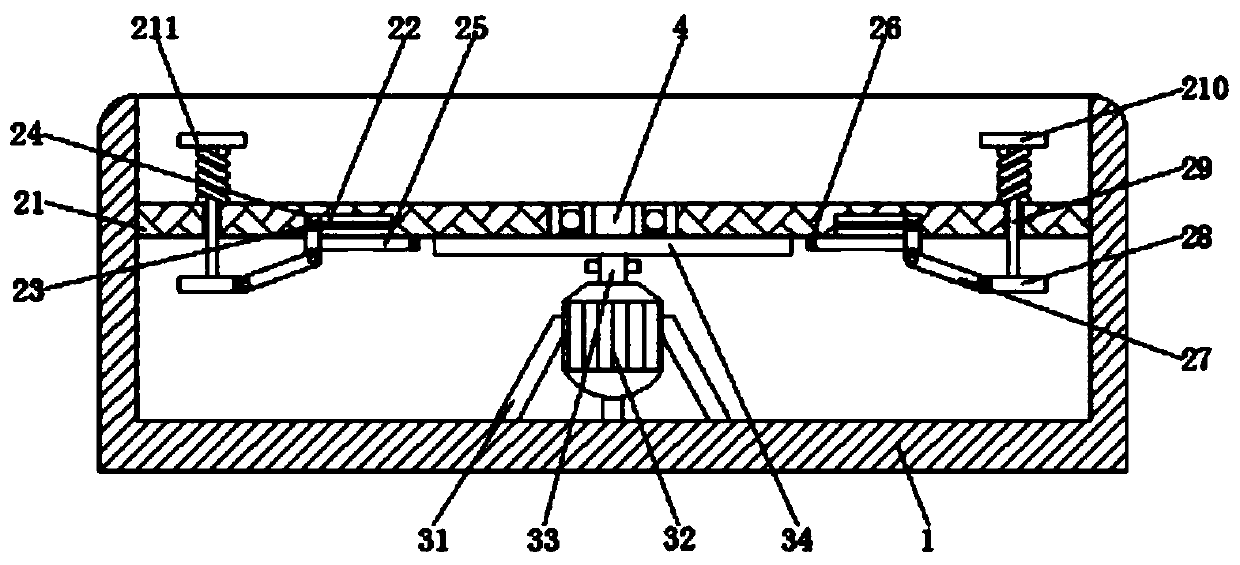

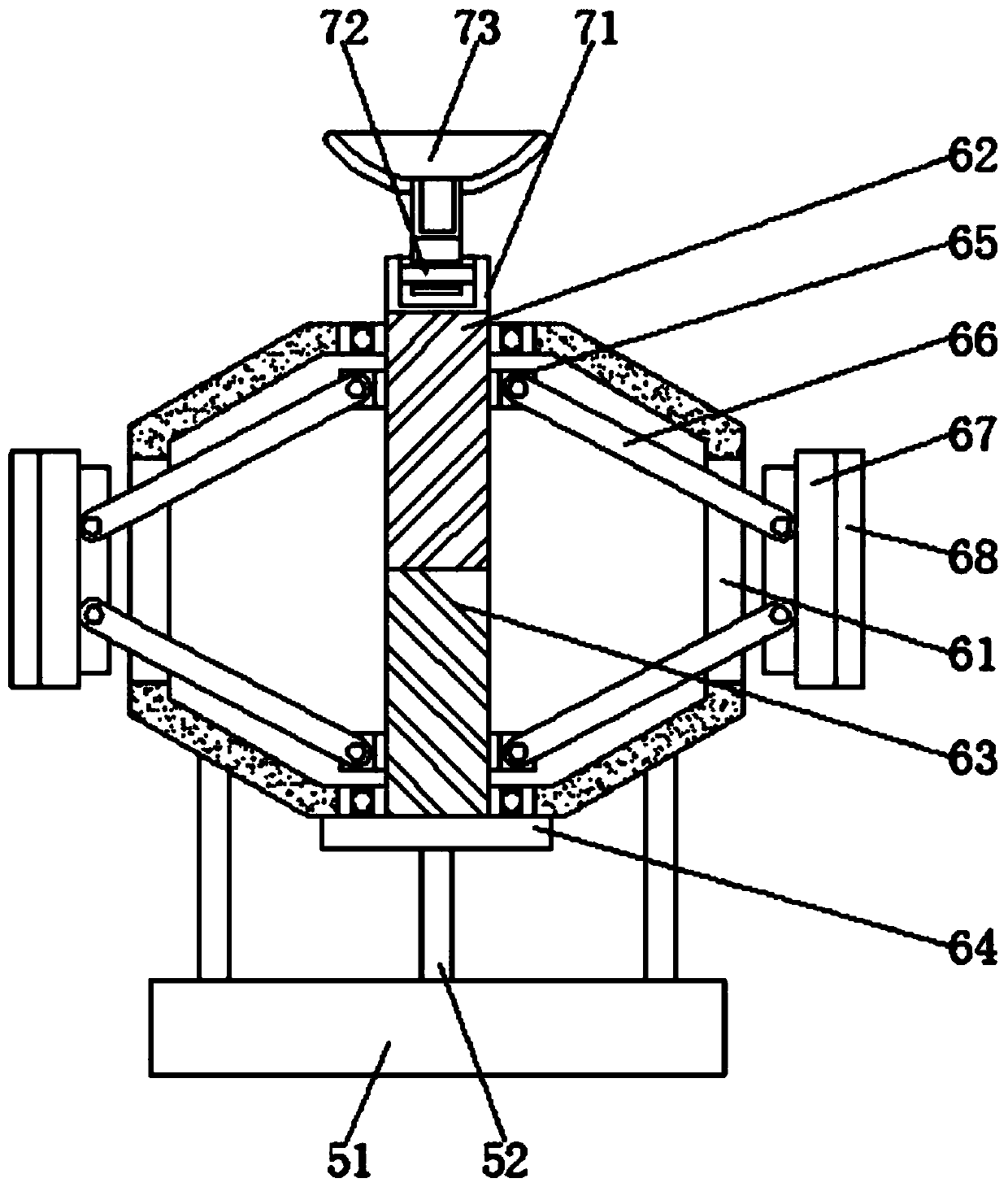

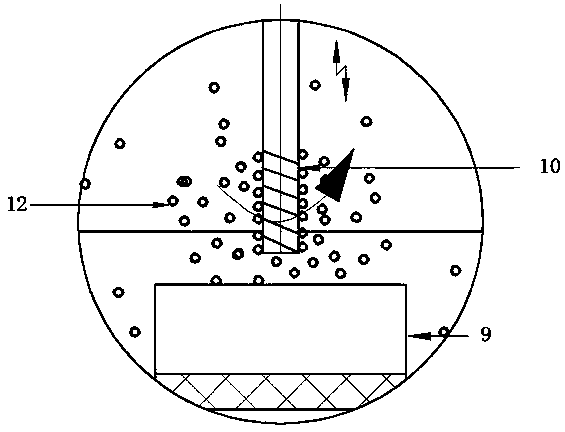

Low-noise ground grinding machine for indoor epoxy floor construction

PendingCN113319670APlay a grinding roleEasy to collect dustDispersed particle filtrationTransportation and packagingAir filtrationAir filter

The invention discloses a low-noise ground grinding machine for indoor epoxy floor construction. The low-noise ground grinding machine comprises a device body, a vehicle underframe, wheels, a driving motor, a conveying track, a power mechanism, a grinding mechanism, a dust collection mechanism and an air filter, wherein the vehicle underframe is fixedly arranged at the bottom end of the device body, the wheels are sequentially arranged at four corners of the vehicle underframe, the wheels are connected through a connecting shaft, the driving motor is assembled on the connecting shaft, the conveying track is horizontally arranged inside the device body in parallel, the conveying track is parallel to and located above the wheels, one end of the power mechanism is connected with the conveying track, the other end of the power mechanism is in transmission connection with the connecting shaft, the grinding mechanism and the conveying track are assembled and arranged inside the device body, the bottom end of the grinding mechanism makes contact with the ground, the air filter and the dust collection mechanism are assembled on the grinding mechanism, the dust collection mechanism is in transmission connection with the grinding mechanism, and the air filter is located above the dust collection mechanism and movably connected with the dust collection mechanism.

Owner:黄诚

Puffed chub bait

InactiveCN108669359AAvoid absorbing and dissolvingSolve perishableFood processingClimate change adaptationYeastSlag

The invention relates to the field of fish baits, and in particular relates to a puffed chub bait. The puffed chub bait comprises the following raw materials in parts by weight: 30 to 46 parts of soybean meal, 8 to 17 parts of fish meal, 5 to 11 parts of earthworm powder, 12 to 25 parts of spirulina powder, 4 to 13 yeast powder, 0.5 to 2.9 parts of sesame oil, 1 to 7 parts of tea slag, 0.1 to 0.6parts of modified graphite, and 3 to 18 parts of additives. The puffed chub bait is rich in nutrients and easy to absorb. The bait fed to water floats on water surface, and the feeding amount is easyto control. After the puffed bait has increased flavor and good palatability, and can play a food calling effect.

Owner:国营无为县水产养殖场

Special feed for free-range chickens

InactiveCN109362984AGood antibacterial effectImprove qualityFood processingAnimal feeding stuffAnimal scienceVegetable oil

The invention relates to a feed, in particular to a special feed for free-range chickens. The feed comprises the following raw materials in parts by weight: 10-40 parts of rice chaff, 40-80 parts of corn flour, 20-50 parts of sorghum powder, 10-30 parts of soybean meal, 5-15 parts of mole cricket powder, 1-5 parts of salt, 2-8 parts of an antibacterial agent, 2-7 parts of bone meal, 10-20 parts offish meal, 10-20 parts of seaweed powder, 10-20 parts of dried pumpkin peel, 2-7 parts of trace elements, 2-9 parts of vegetable oil, 1-5 parts of stone powder and 1-4 parts of a preservative. The feed has the effects of improving immunity, promoting digestion, improving egg yield and improving egg quality of free-range chickens.

Owner:安徽绿迪食品股份有限公司

a pulverizer

The invention belongs to the technical field of powder grinding equipment, and particularly discloses a powder grinding machine. A rack is provided with a machine case in which a vertical rotating shaft is arranged; a driving portion drives the rotating shaft to rotate; a screen plate is arranged on the upper portion of the machine case; the portion, located above the screen plate, of the rotatingshaft is provided with a smashing portion; the position, located below the screen plate, of the machine case is rotationally provided with a disk which is fixedly arranged outside the rotating shaftin a sleeving manner; the position, located below the disk, of the rotating disk is coaxially and rotationally connected with a conical first grinding roller; a fixed rod is connected between the first grinding roller and the inner wall of the machine case; the disk is rotationally connected with a plurality of second grinding rollers in the shape of an inverted cone in the circumferential direction, and the first grinding roller and the second grinding rollers are attached and close to each other; and the portion, located above the screen plate, of the machine case is provided with a feedingport, and the lower portion of the machine case is provided with a discharging port. The powder grinding machine is mainly used for powder grinding, and solves the problem that in the process of preparing powder coating, steps for grinding blocky raw materials are more, and consequently the machining efficiency is lowered.

Owner:CHONGQING QICAIHONG CHEM

Label removing device for cylindrical red wine bottle

ActiveCN109201636AAvoid pollutionEasy to collectHollow article cleaningCleaning using toolsElectric machineryDrive motor

The invention discloses a label removing device for a cylindrical red wine bottle and relates to the technical field of wine bottle recovery. The label removing device for the cylindrical red wine bottle comprises a base. A groove is formed in the upper surface of the base, and the left side and the right side of the inner wall of the groove are both fixedly connected with an adjusting mechanism.The upper surface of the adjusting mechanism is fixedly connected with a collecting mechanism. The top of the right side of the collecting mechanism is fixedly connected with a first supporting frame,and the upper surface of the first supporting frame is fixedly connected with a driving mechanism. According to the label removing device for the cylindrical red wine bottle, by arranging the drivingmechanism and a negative-pressure label removing mechanism, a driving motor is started, through mutual cooperation of a first gear and a second gear, the negative-pressure label removing mechanism isdriven to rotate, after a polishing block on the negative-pressure label removing mechanism makes contact with a label, the rotating polishing block polishes the label, a wine bottle body is manuallyrotated, thus the label on the wine bottle body is removed, and the label on the wine bottle body is removed conveniently.

Owner:浙江森创服装股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com