Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about How to "Easy to collect dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

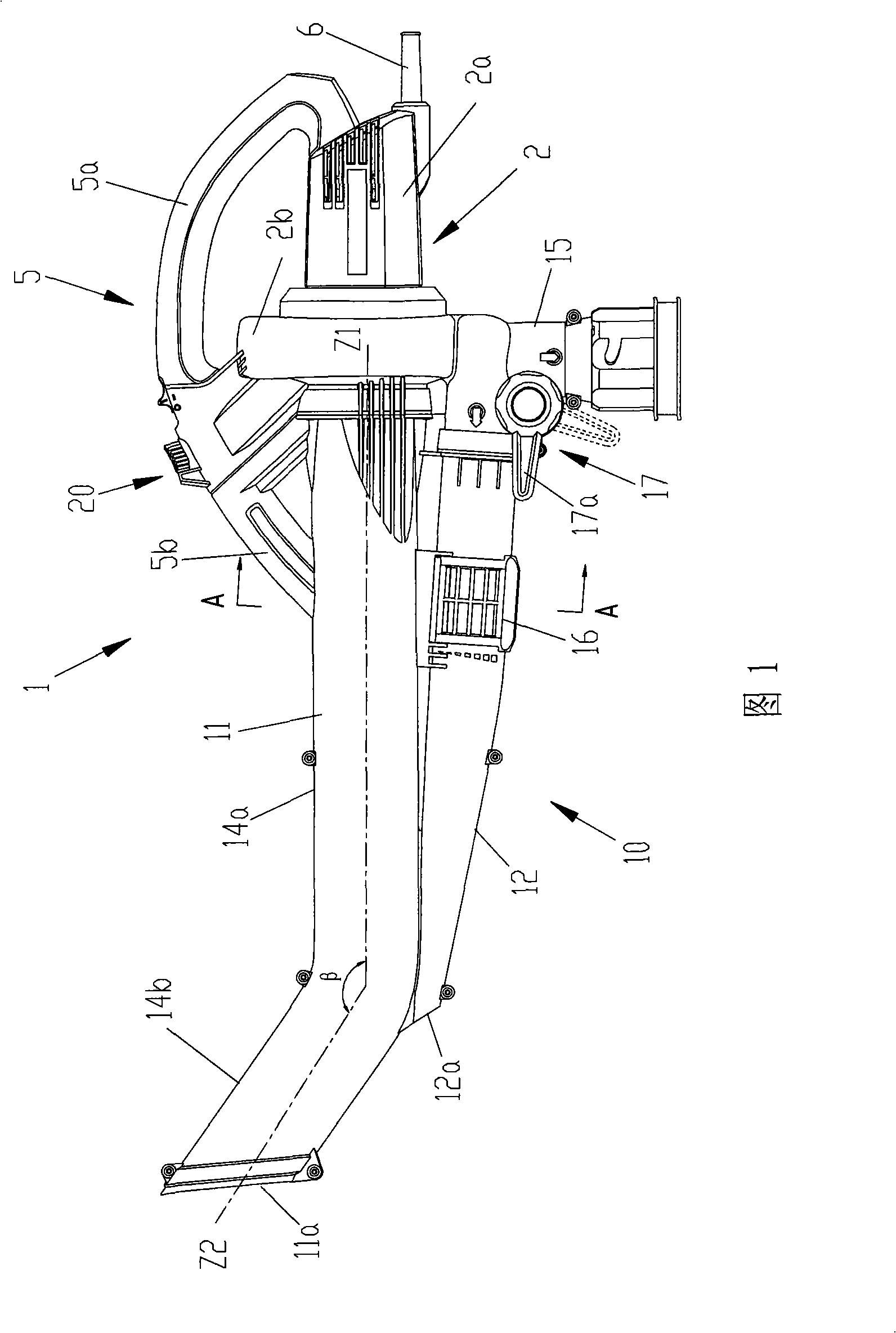

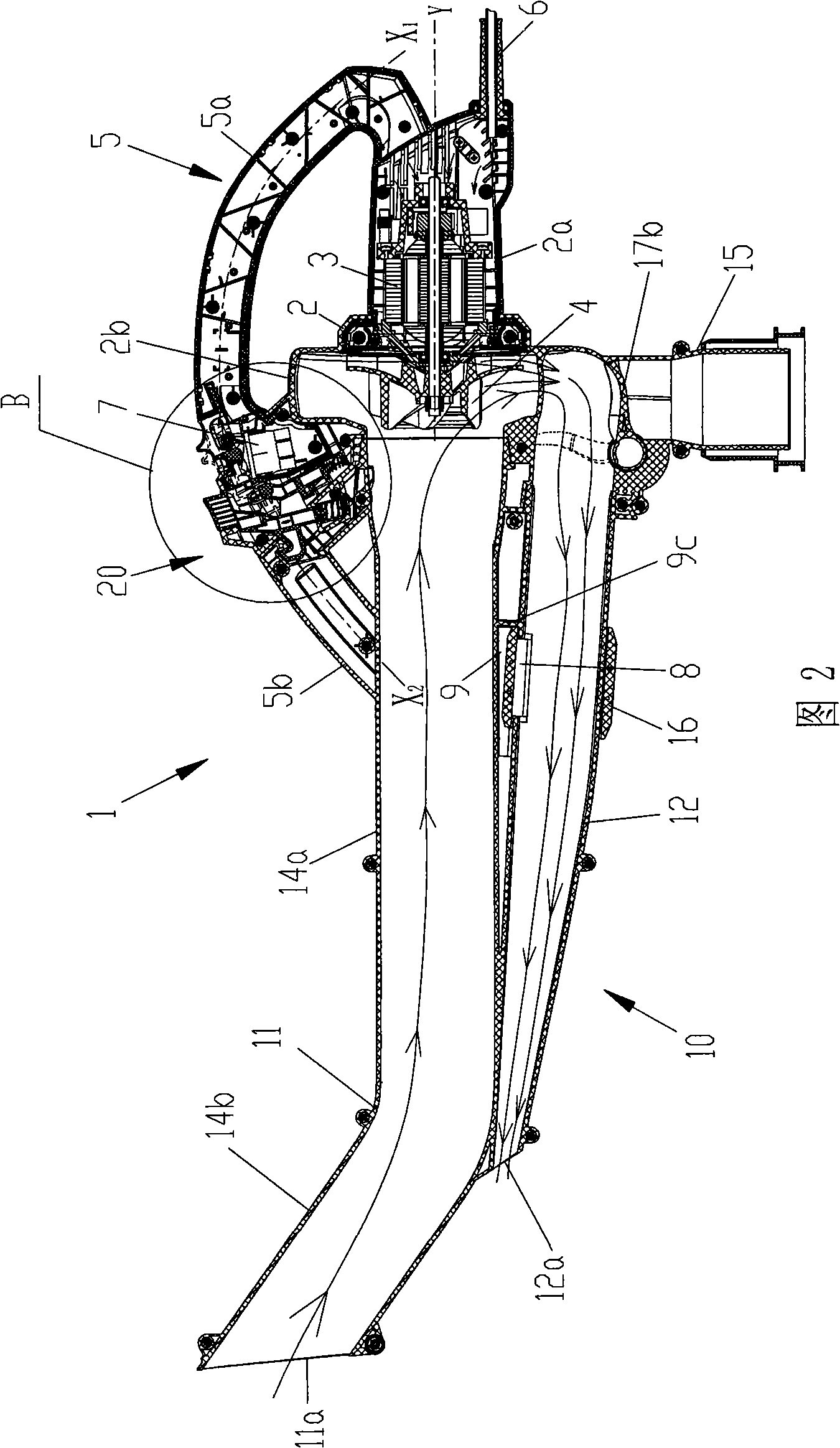

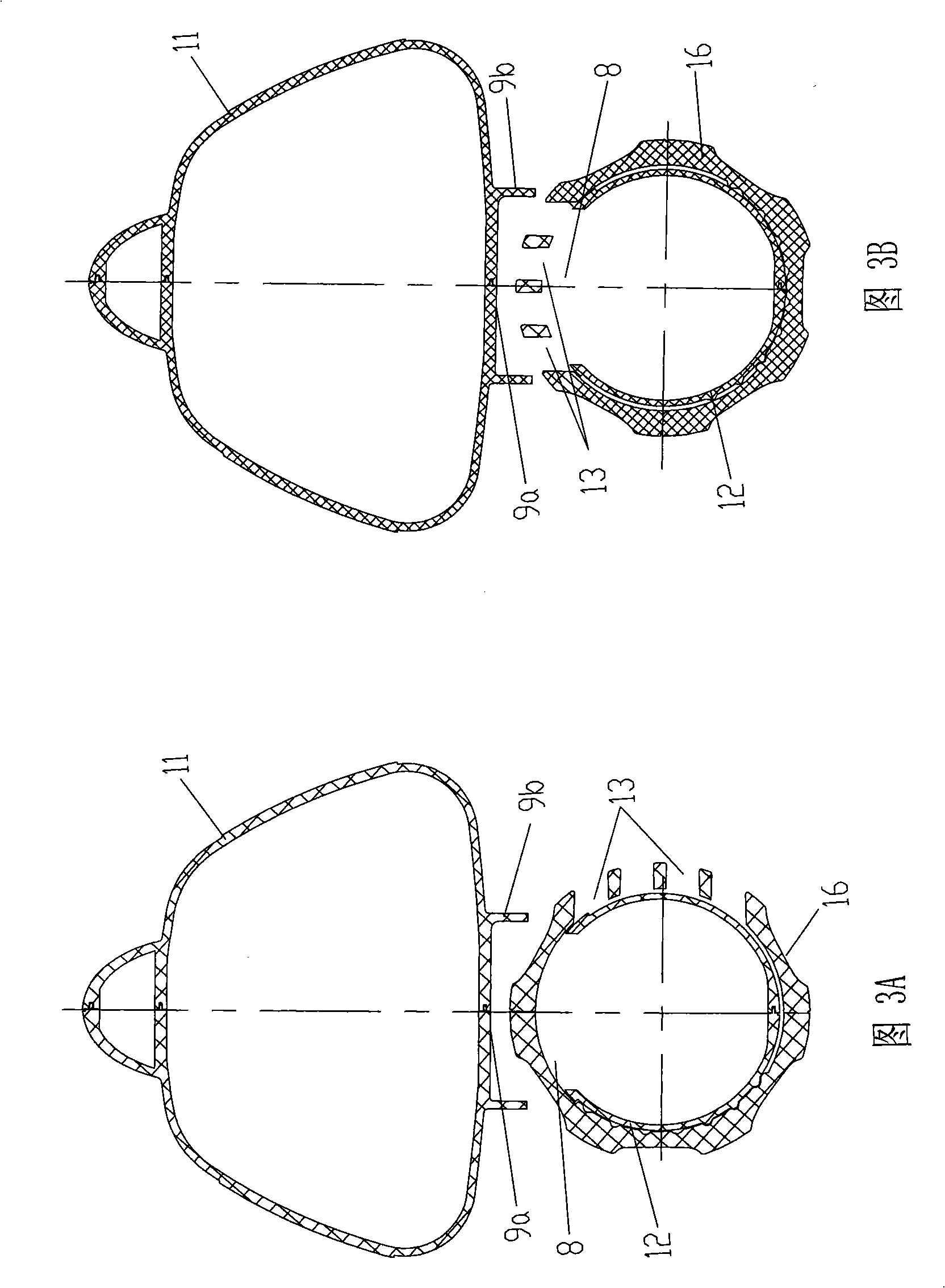

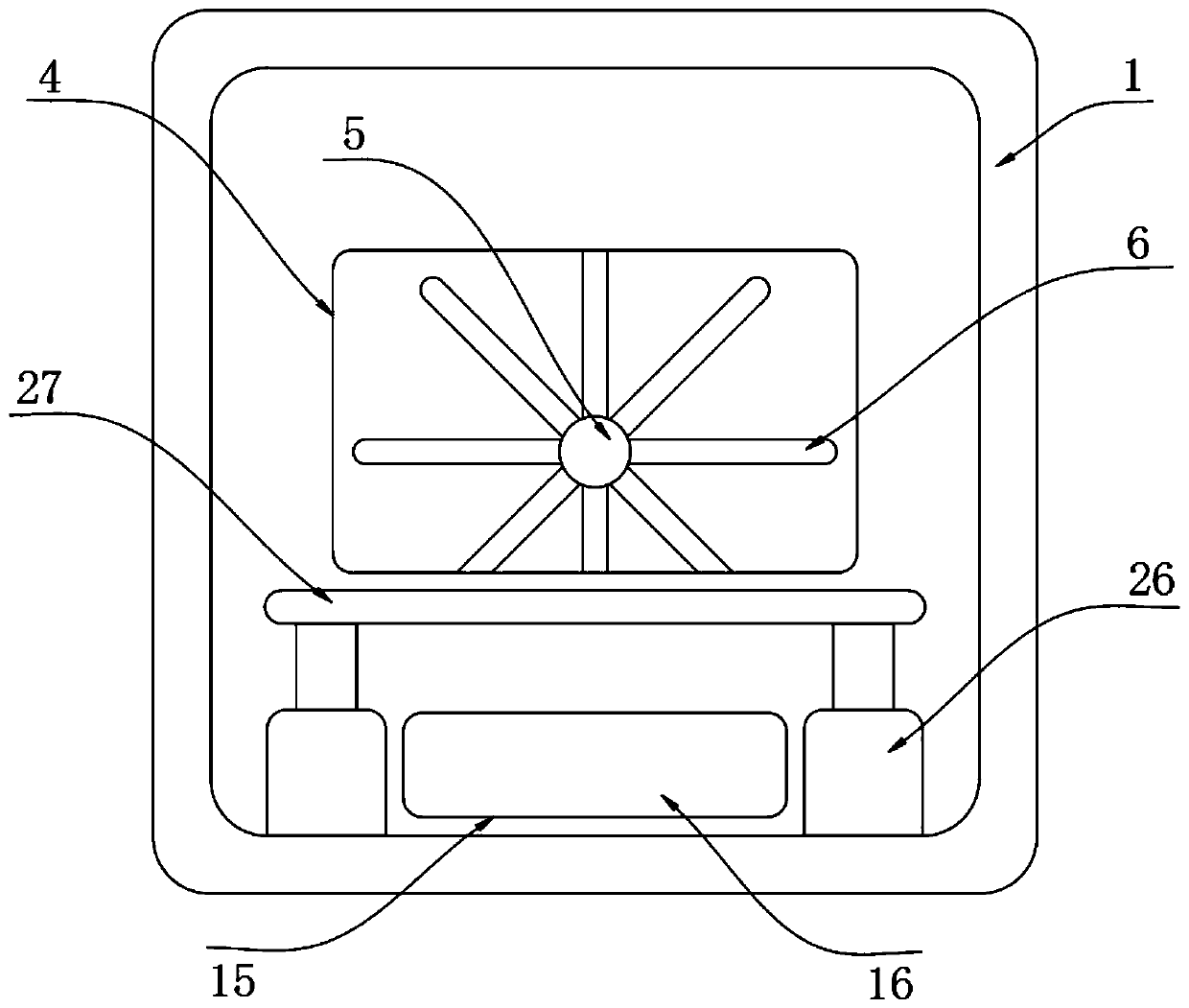

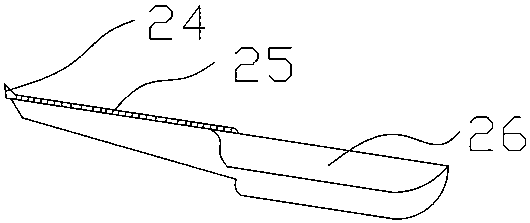

Pressure-vacuum machine

ActiveCN101327109AEasy to collectEasy to storeSuction cleanersRoad cleaningEngineeringMechanical engineering

The present invention relates to a portable blowing-drawing machine which can be operated by a monolever, and comprises a host shell, an operating handle, a motor arranged in the shell, a fan which is driven by the motor to rotate, a switch for controlling the rotation of the motor, a blowing pipe connected with the host shell and a drawing pipe. The drawing pipe and the blowing pipe are fixedly connected and extend towards one side of the shell; the drawing pipe is provided with a main body part extending along a longitudinal axial line and a bending part which bends at a certain degree with the extending axial line of the drawing pipe; the structure of the drawing pipe ensures the monolever operation becomes easier and more convenient with good effect of dust collection.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Wet method dedusting system of centrifugal axial flow-type vacuum pump and corresponding dust collector and floor cleaning machine

ActiveCN101639074AIncrease the cross-sectional areaEasy to collect dustCarpet cleanersPump componentsLow noiseProduct gas

The invention provides a wet method dedusting system of a centrifugal axial flow-type vacuum pump and a dust collector and a floor cleaning machine using the system. The invention designs a centrifugal axial flow-type vacuum pump which exhausts along the axial direction of the pump shell and has low noise, and a special speed reduction barrel is arranged in the pump shell. The invention also designs a special wet method dedusting flow which is applicable to industrial dedusting and civilian-used dust collector at the same time and can lead the dust containing amount in exhausted gas to be zeroor near zero, the work flow is subsequent to the flow of removing crude dust such as hop-pocket dedusting and the like, and air current can pass through plastic foam for three time to achieve the purpose of completely purifying on the condition of fully wetting with water. In The invention uses the principle and the equipment of the dedusting system to design a wet method dust collector, and improve and perfect the vacuum floor cleaning machine.

Owner:胡宁成

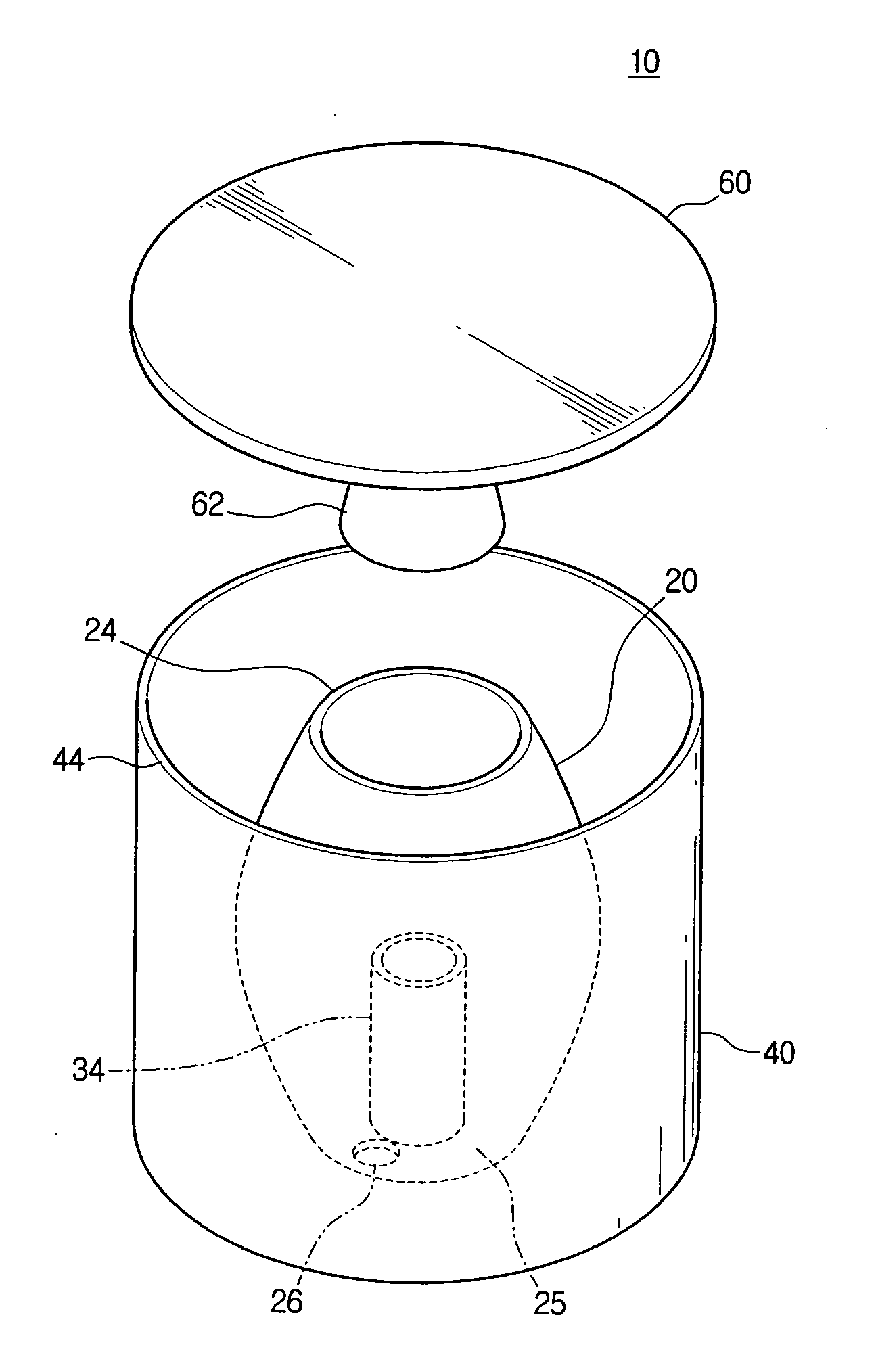

Dust collector of vacuum cleaner

InactiveUS7662202B2Improve dust removal efficiencyReduce total pressure lossCleaning filter meansCombination devicesMechanical engineeringVacuum cleaner

Disclosed is a dust collector of a vacuum cleaner. The dust collector comprises: a cyclone body forming a cyclone chamber and having a bottom wall and an air inlet, air being admitted into the cyclone chamber and rotating in the cyclone chamber; an outlet pipe extending upwardly from the bottom wall of the cyclone body; and a dust-bin body surrounding the cyclone body in such a manner that a dust collection space is formed between the dust-bin body and the cyclone body. The inner diameter of the cyclone body is increased as approaching a height near the top end of the outlet pipe from the bottom wall of the cyclone body.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

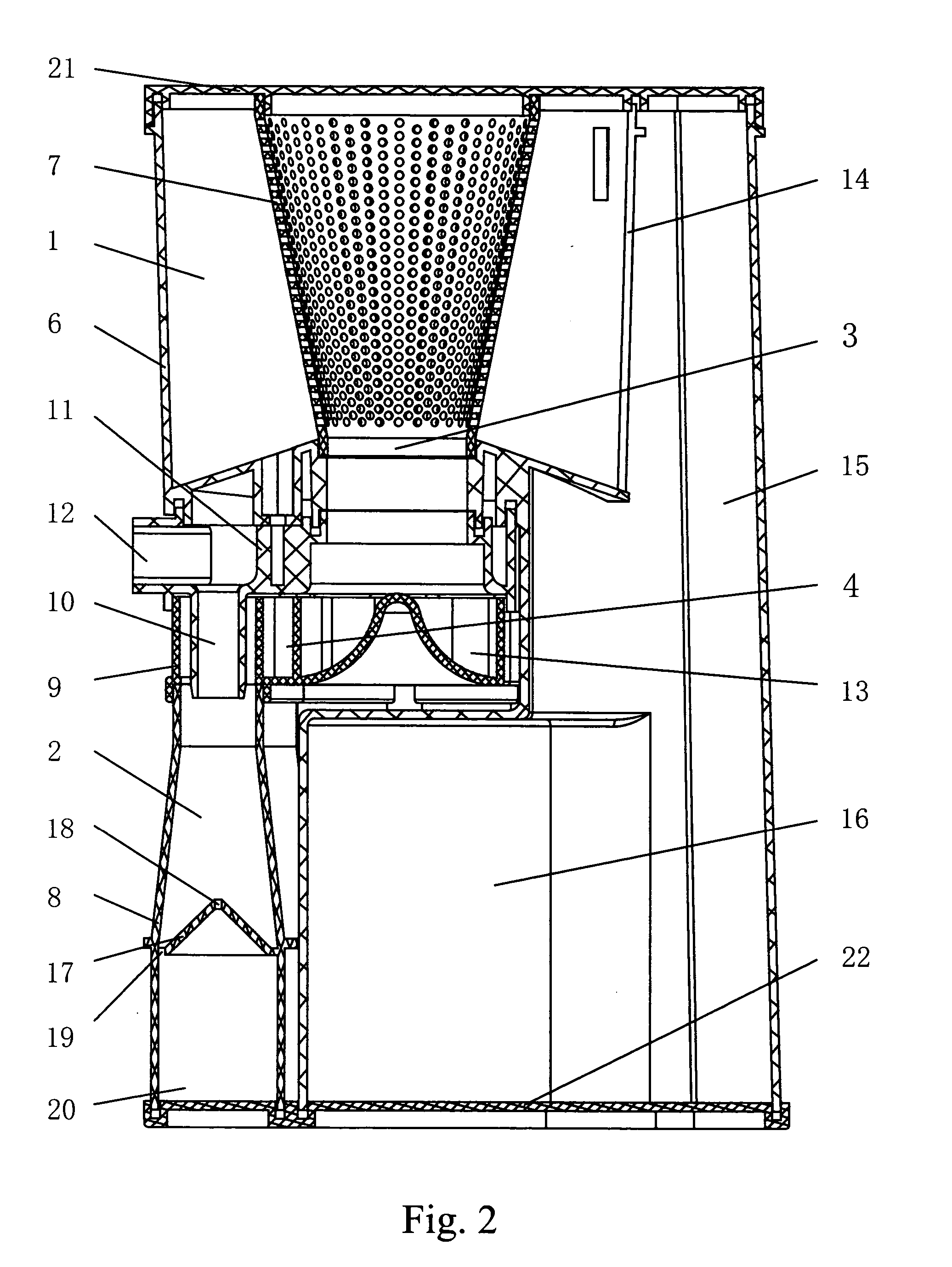

Built-in suspended cyclone separator

The invention relates to a built-in suspended cyclone separator which comprises a handle, a gas inlet port, a conical filter, an elliptic dust collection barrel, a circular cyclone chamber, an upper cover, a conical filter, and a bottom cover, wherein the circular cyclone chamber is arranged on the upper part of the elliptic dust collection barrel, and part of the side wall of the circular cyclone chamber and the wall of the elliptic dust collection barrel are connected to form an integral body; the upper cover is connected with the upper end of the elliptic dust collection barrel; the conical filter is arranged in the middle of the circular cyclone chamber; the bottom cover is connected to the lower end of the elliptic dust collection barrel; the circular cyclone chamber is composed of a circular barrel wall and a bottom; the bottom of the circular cyclone chamber on one side of a dust discharge port is extended to the wall of the elliptic dust collection barrel to form a bottom extension part; a dust baffle, which has the same degree of arc with the edge of the bottom of the circular cyclone chamber and perpendicularly extends downwards, is arranged below the bottom extension part of the dust discharge port; and the elliptic dust collection barrel is in an elliptic shape with open upper and lower ends. The invention has the advantages of compact structure, small pressure loss, high dust collection capacity, and simple and convenient operation. In addition, the built-in suspended cyclone separator is provided with the dust baffle which can prevent dust from flowing back and has the function of effective dust accumulation, therefore, the built-in suspended cyclone separator has high dust separation performance.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

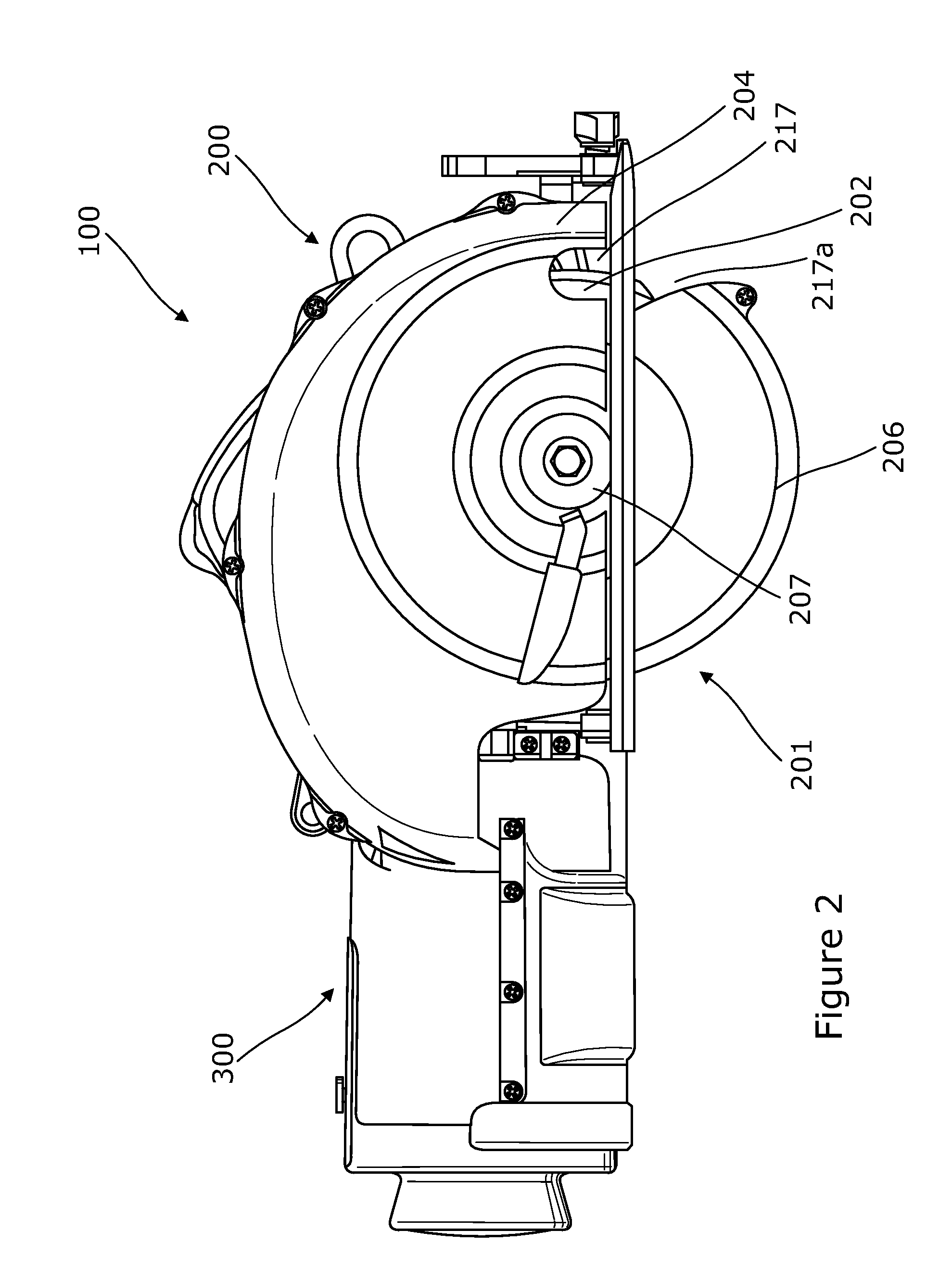

A cutting apparatus

InactiveUS20160016270A1Easy to collectHigh speedMetal sawing accessoriesDispersed particle filtrationAir filtrationParticulates

A cutting apparatus comprising a cutting tool and a collection assembly designed for diverting, collecting and disposing dust generated during the cutting process. The apparatus includes a cutting tool, a collection assembly together with an optional dust separator and / or collection container. The air stream generated around the blade of the cutting tool during operation diverts the generated dust particulates into the collection assembly of the cutting tool. The air stream can also transport the dust into the dust separator which transfers the dust into the collection container, when present. Optionally, the collection container further comprises an air filtration assembly for storing and disposing the dust.

Owner:JAMES HARDIE TECH LTD

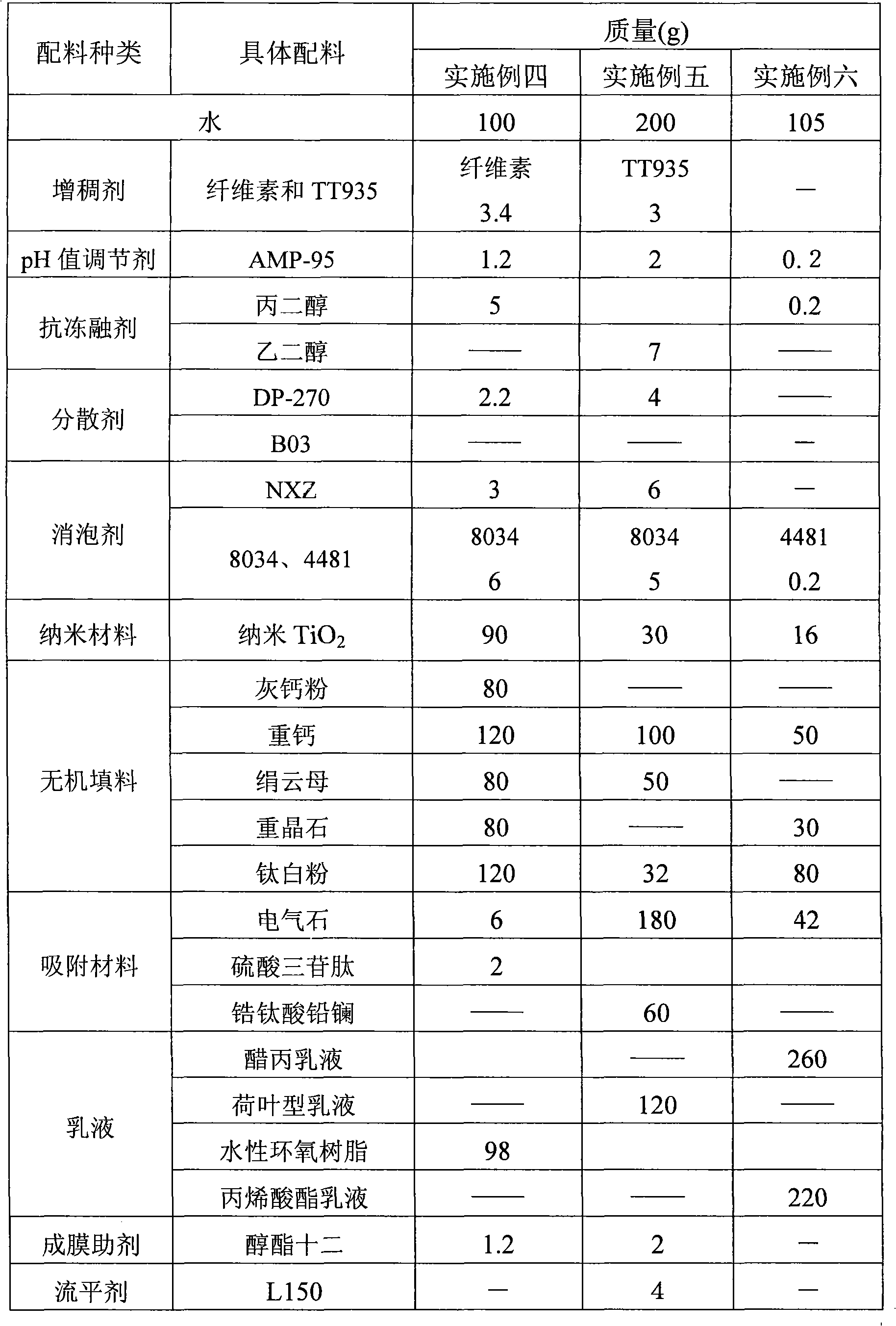

Dust absorbing, dust removing inner wall decorative coating and preparation thereof

ActiveCN101348627APlay a decorative effectImprove adsorption capacityDispersed particle separationEpoxy resin coatingsCrystalline materialsDust fall

The invention provides dust absorption and dust falling decorative paint for an internal wall and a preparation method thereof, belonging to the building material field. The paint in every 100 weight portion at least comprises 1 to 40 weight portions of a sorbing material, 2 to 15 weight portions of a nanometer material and 20 to 60 weight portions of an inorganic filling material. The paint which takes a crystalline material with the pyroelectric effect such as tourmaline, triglycine sulfate, and lead lanthanum zirconate titanate as an adsorption function material and the paint is obtained by adding nanometer materials such as nanometer titanium dioxide, etc., has the eight times dust collection and dust falling capacities of the prior paint, has the contact angle less than 45 degrees, and the scrubbing resistance more than 4,500 times, meets the requirement of the internal wall paint high-class products, is applied to the surface of the building, and has the functions of dust absorption, dust falling, and easy cleanness besides the function of the inside surface decorative material.

Owner:CHINA BUILDING MATERIALS ACAD

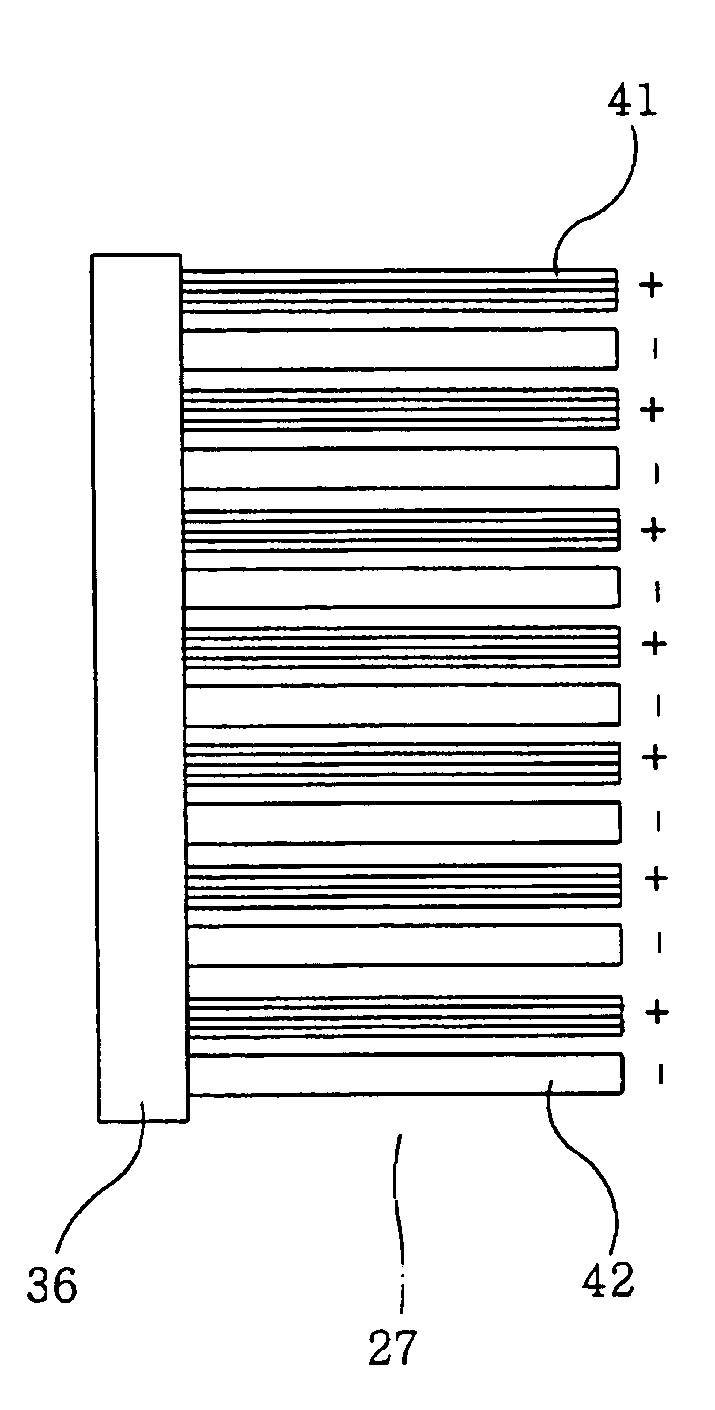

Subsection dedusting device for a vacuum cleaner

ActiveUS20070089381A1Increase air volumeImprove dust removal efficiencyCleaning filter meansCombination devicesCycloneEngineering

This invention discloses a subsection dedusting device for a vacuum cleaner comprising an upper cyclone separator including a wind outlet and several lower cyclone separators located below said upper cyclone separator, wind inlets of said lower cyclone separators in fluid communication with said wind outlet of said upper cyclone separator, thereby increasing wind quantity while reducing the whole bulk of the machine, and keeping a relatively high dedusting efficiency, and besides the lower cyclone separator of the present invention adopts a pervasion construction, and air flow rotates in a decelerated and acentric state in the conical barrel, thereby the pressure loss of the air flow is little, and accordingly, obtain a good dust suction effect.

Owner:SUZHOU KINGCLEAN FLOORCARE

Electric vacuum cleaner

InactiveCN102334957AReliable attractionEasy to collect dustElectric equipment installationPower flowDust detection

The invention provides an electric vacuum cleaner, which is provided with: a vacuum cleaning head provided with an electromotor performing rotation and drive of a rotary brush; a movement speed detection part detecting movement speed of the vacuum cleaning head; a circuit detecting part detecting ground state; an electric air blower making the vacuum cleaning head generate attraction force; a collection dust detection part detecting the attracted dust; a signal control part controlling the revolution of the electromotor and the electric air blower according to the movement speed detection part, the circuit detecting part, and the collection dust detection part. Therefore, the ground state can be mastered, making the revolution of the electromotor and the electric air blower collect dust optimally.

Owner:PANASONIC CORP

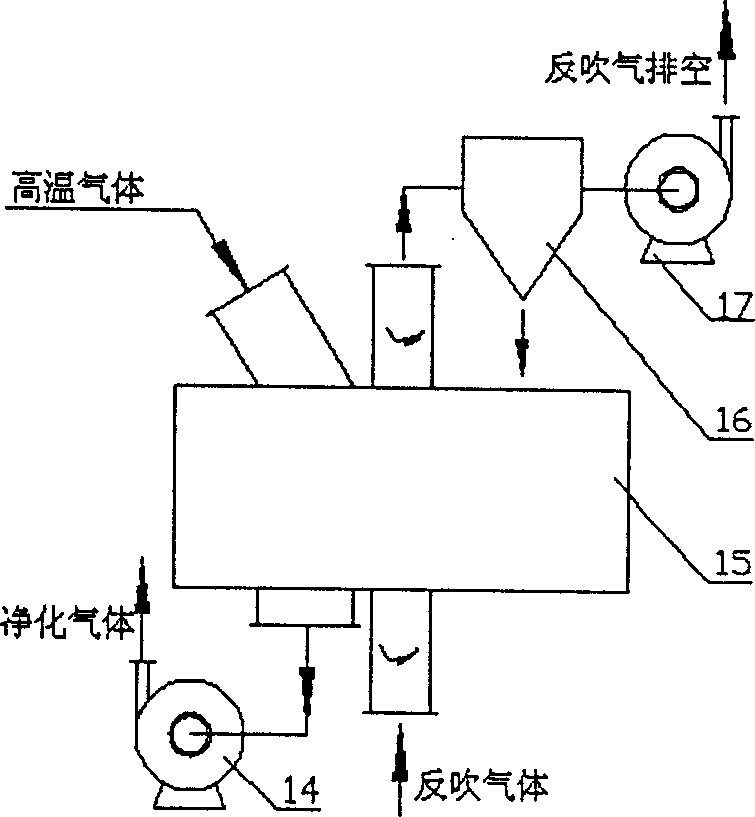

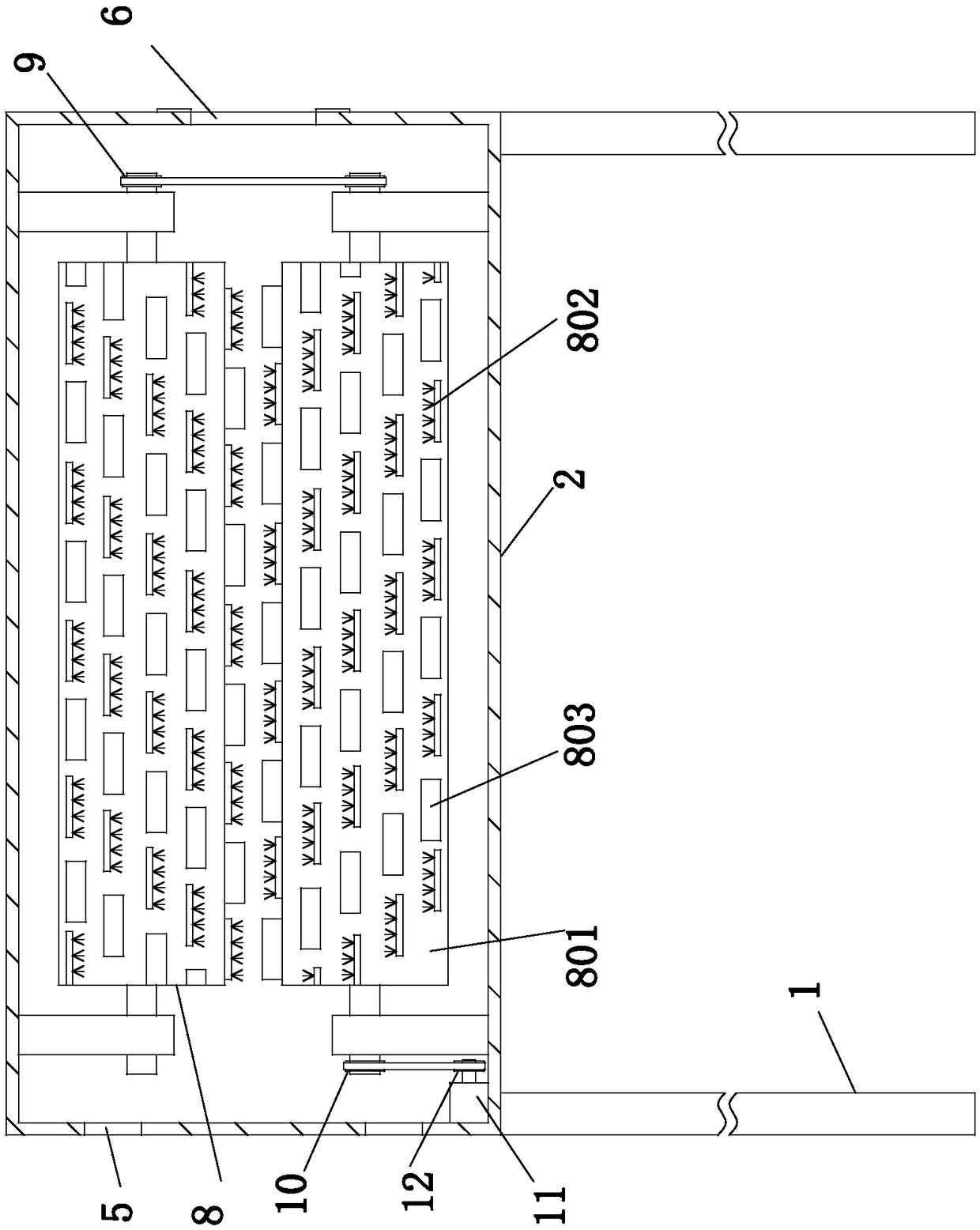

Rotary type fluidized bed back blow particle layer dust removing apparatus

InactiveCN1475295AEasy to collect dustCleaning structure is simpleDispersed particle filtrationFluidized bedAirflow

A cleaner based on particle-layer dusting technique, fluidized-bed back-blowing cleaning technique and rotary mechanism features that its rotary fluidized bed back-blowing mechanism is composed of exhausting air-sucking hood, and rotary exhausting exhaust tube, it is rotating around the circular center of cylindrical particle-layer duster, and back-blowing airflow flows through said back-blowing mechanism from bottom to top to fluidize the particles in cleaning region for carrying dust outward. Its advantages are continuous and reliable dusting and cleaning, and low cost.

Owner:JIANGSU UNIV

Voice coil motor

InactiveUS20140355142A1Stable and powerful pushing forceStrong torquePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive transducersActuatorVoice coil

A VCM actuator for a lens and driving the lens for focusing includes a fixed module, a mobile module and a spring module. The fixed module includes a case and the magnet module is disposed along the inner side of the case. The mobile module includes a lens holder and a coil looping the lens holder. The lens holder is movably disposed in the case and the coil is fastened to the lens holder positioning to the magnet module. The spring module abuts the fixed module and mobile module. The case has an opening and along the rim of each corner of the opening a magnet guiding tab is formed. The guiding tabs extend between the lens holder and coil and are positioned toward the gaps between the magnet module, and each magnet guiding tab has a backbone and two wing portions extending from the backbone.

Owner:SILITECH TECH CORP

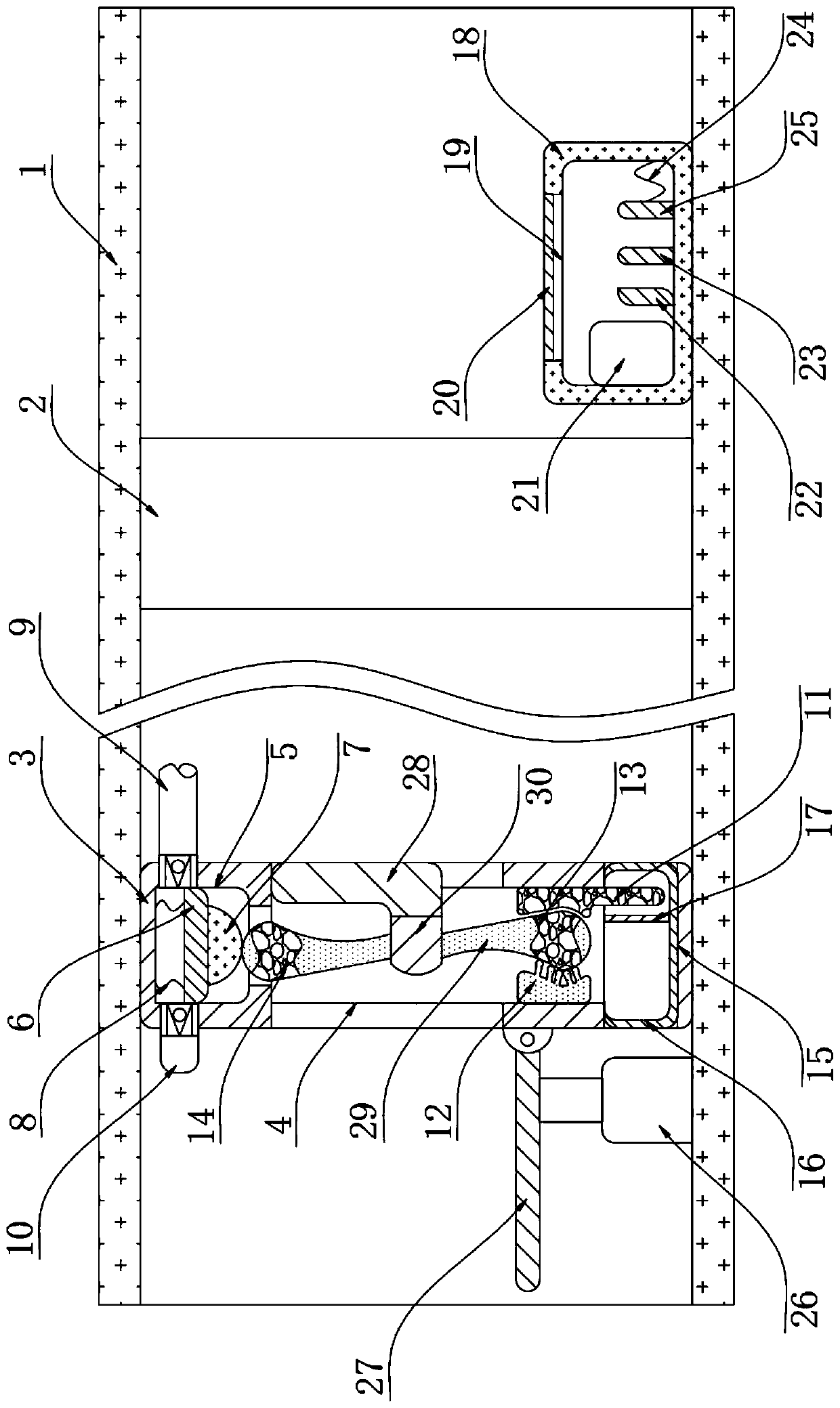

Abrasive belt polishing machine

ActiveCN103978416AAvoid spreading and splashingEasy to collect dustBelt grinding machinesGrinding/polishing safety devicesDrive wheelEngineering

The invention provides an abrasive belt polishing machine, belongs to technical field of machines, and solves the problem that scraps produced by the conventional abrasive belt polishing machine are easily accumulated in an outer cover since the scraps are scattered in the outer cover and cannot be absorbed away through a dedusting pipe due to heavy weight. The abrasive belt polishing machine comprises a frame and a workbench arranged on the frame, wherein a driving wheel, a driven wheel and a polishing belt which sleeves the driving wheel and the driven wheel are arranged in the workbench; the lower part of the workbench is hinged to the frame and can rotate relative to the frame; an operating hole through which a workpiece can be in contact with the polishing belt is formed in the workbench; the frame below the operating hole is connected with a dust collecting hopper; a length-adjustable baffle plate mechanism which can be used for leading dust produced during polishing operation into the dust collecting hopper is connected between the workbench and the frame. The abrasive belt polishing machine is provided with the dust collecting hopper and the baffle plate mechanism, so that the scraps can be effectively prevented from splashing and can be led into the dust collecting hopper through the baffle plate mechanism, and a good dust and scrap collecting effect is achieved.

Owner:陈美青

Dust collection sensing device of automatic cleaner

A dust collection sensing device of an automatic cleaner comprises: a main body with a placing chamber provided inside and a channel is provided on a side of the placing chamber, a dust collecting box installed within the placing chamber and an extended vacuuming pipe being provided on a side of the dust collecting box with an end thereof extending though the channel, a sensing assembly comprising a signal sending element and a signal receiving element, which are installed separately on the two opposite wall surfaces of the channel and are corresponding to the two sides of the bottom of the vacuuming pipe, and a warning indicator installed on the main body and connected to the signal receiving element of the sensing assembly electrically.

Owner:YAN JASON

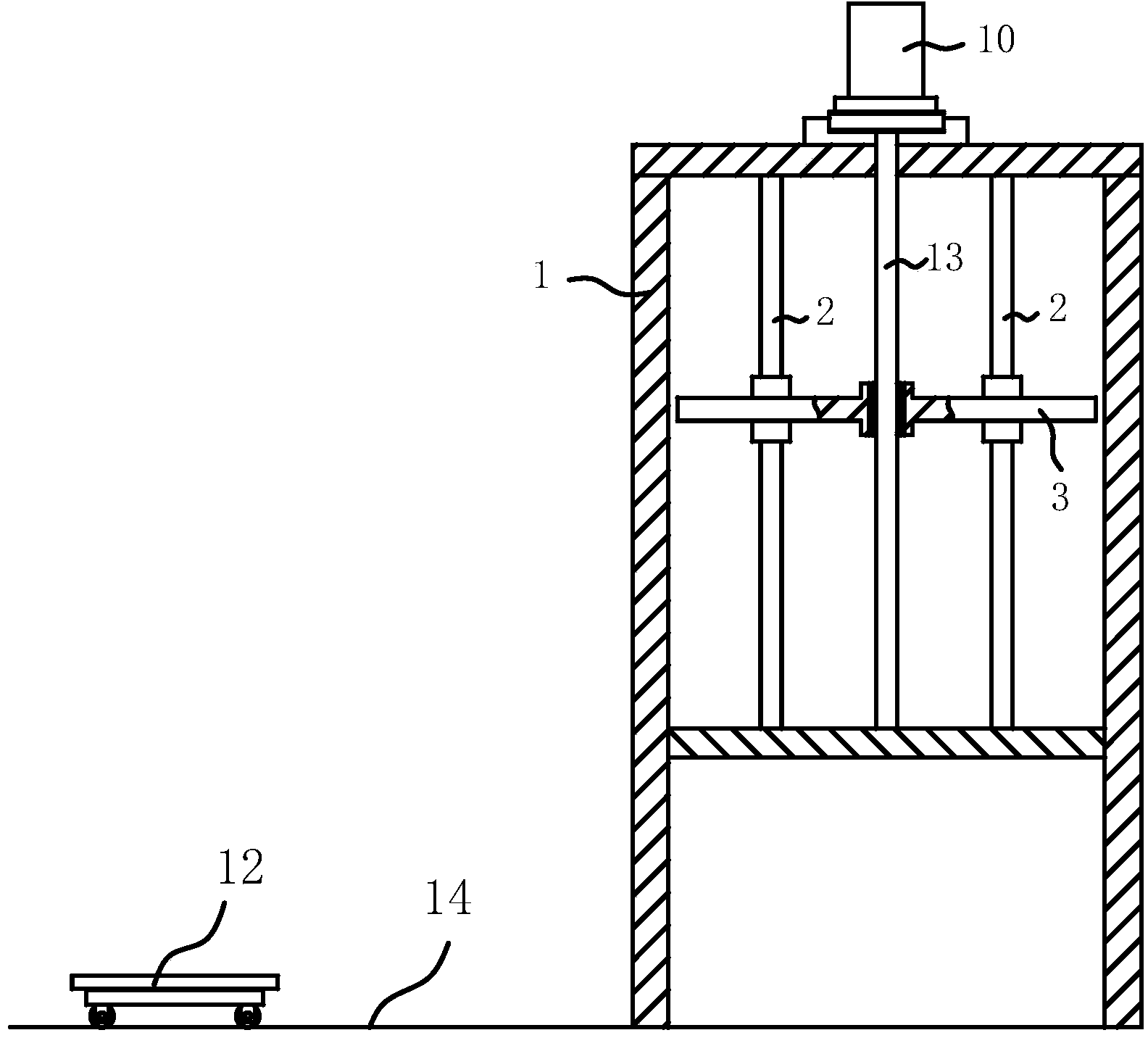

Dust sucking plant with adjustable air quantity

The invention relates to a dust sucking plant with adjustable air quantity, which comprises an adjusting air door (1), a dust sucking nozzle (2), a dust sucking cover (3) and a connecting tube (4), and is characterized in that: the dust sucking nozzle (2) is fixed on the dust sucking cover (3) through a standard component; the adjusting air door (1) is arranged on the upper plane of the dust sucking nozzle (2); and the connecting tube (4) is fixed on the lower part of the dust sucking nozzle (2) and is connected with a dust collector. When the dust sucking plant works, the adjusting air door (1) is rotated according to the dust quantity in a tabletting working chamber to change the drift diameter in the dust sucking nozzle (2) to adjust the air quantity so as to change the suction and achieve ideal dust suction effect.

Owner:上海天和制药机械有限公司

Explosion-proof ventilation device for underground engineering

ActiveCN110821543AAchieve ventilationReduce dilutionCombination devicesMining devicesVentilation tubeStructural engineering

The invention discloses an explosion-proof ventilation device for underground engineering. The explosion-proof ventilation device for the underground engineering comprises a ventilation pipe and a fanmounted inside the ventilation pipe, the inner wall of the ventilation pipe is fixedly provided with an adjustment device for adjusting the rotation speed of the fan, a treatment box is fixed on theinner wall of the ventilation pipe, the side wall of the treatment box is provided with a ventilation groove in a penetrating mode, an L-shaped connecting rod is fixed on the inner wall of the ventilation groove, a rotating shaft is rotationally connected to the side wall of the connecting rod, and a plurality of rotating plates are fixed to the circumferential side wall of the rotating shaft. Theexplosion-proof ventilation device has the advantages that when the concentration of mashgas of an underground passage is relatively high, and air input by an air outlet pipe is not enough to reducethe concentration of the mashgas, a detector can emit an acousto-optic alarm, the emitted sound can be used for prompting a worker for prevention, the emitted flash can reduce the value of resistanceof a photoresistor, so that the attraction force of an electromagnet to an electricity connecting piece is increased, then the rotation speed of the fan is reduced, the air suction amount per unit time is reduced, then the concentration of the mashgas in the ventilation pipe is reduced, and explosion is avoided.

Owner:JIANGSU JIANWEI PROTECTION ENG TECH CO LTD

Dust collector of vacuum cleaner

InactiveUS20070289269A1Easy to separateReduce flow rateCleaning filter meansCombination devicesEngineeringMechanical engineering

Disclosed is a dust collector of a vacuum cleaner. The dust collector comprises: a cyclone body forming a cyclone chamber and having a bottom wall and an air inlet, air being admitted into the cyclone chamber and rotating in the cyclone chamber; an outlet pipe extending upwardly from the bottom wall of the cyclone body; and a dust-bin body surrounding the cyclone body in such a manner that a dust collection space is formed between the dust-bin body and the cyclone body. The inner diameter of the cyclone body is increased as approaching a height near the top end of the outlet pipe from the bottom wall of the cyclone body.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

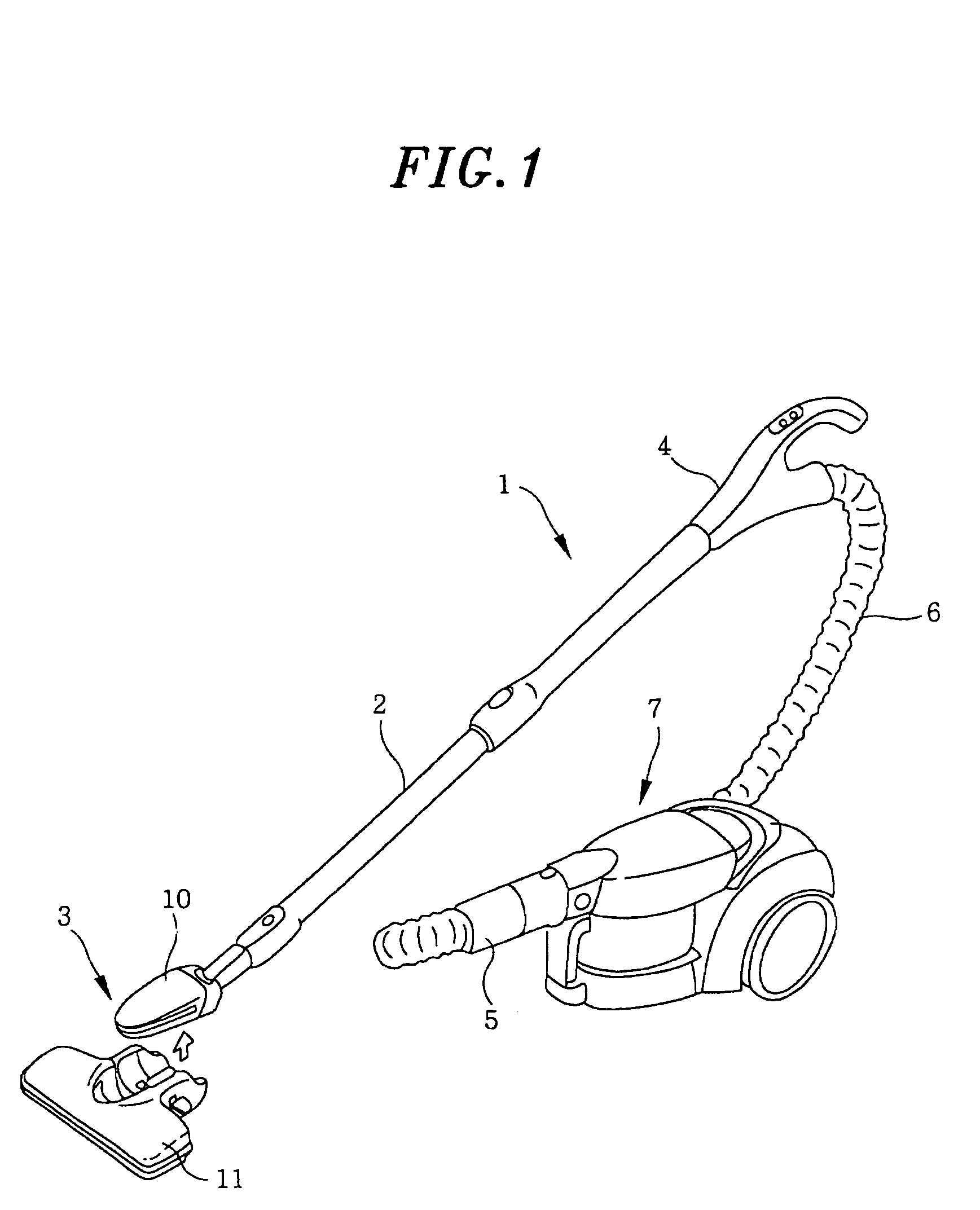

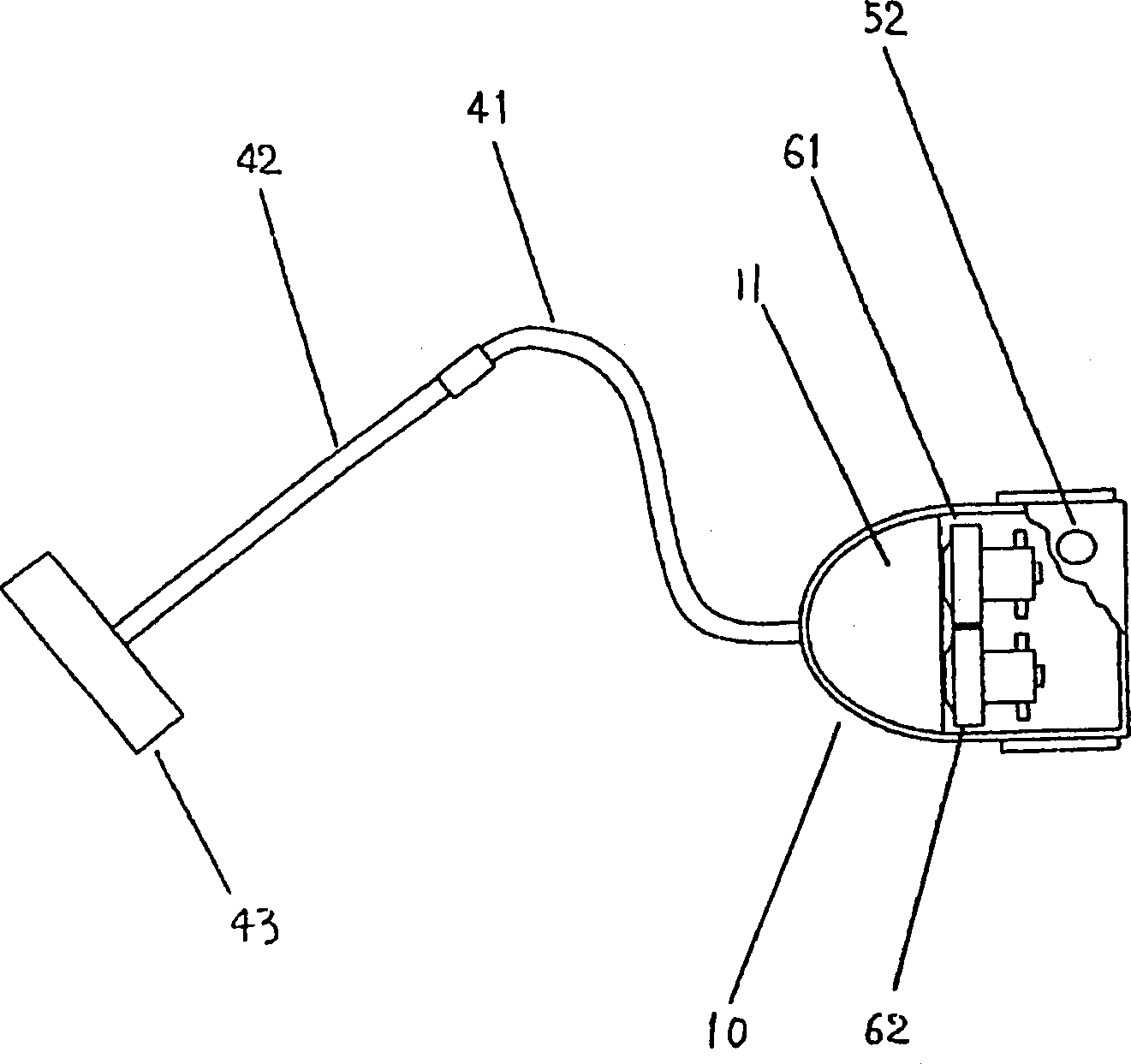

Suction unit for use in an electric vacuum cleaner and electric vacuum cleaner employing same

InactiveUS7257852B2Easy to collect dustImprove usabilityCarpet cleanersSuction hosesVacuum cleanerGenerating unit

A suction unit for use in an electric vacuum cleaner and an electric vacuum cleaner includes a floor nozzle and a mini nozzle detachably secured to the floor nozzle. When a suction head of the mini nozzle is secured to the floor nozzle, an air communication is provided therebetween. Further, the mini nozzle is provided with an ion generating unit.

Owner:PANASONIC CORP

Environment-friendly woodwork vertical polishing machine

InactiveCN101628392ANo reflective splashReasonable layoutBelt grinding machinesGrinding/polishing safety devicesEngineeringAbsorption effect

The invention relates to an environment-friendly woodwork vertical polishing machine which comprises a stand, a driving mechanism and two rollers arranged on the stand, wherein an O-shaped abrasive belt is rewound on the two rollers, and a horizontal workbench is arranged opposite to one side of the O-shaped abrasive belt. The environment-friendly woodwork vertical polishing machine is characterized in that the workbench comprises an outer surface plate and an inner fence framework, wherein the fence framework used as a draught port is communicated with a draught pipe, and the other end of the draught pipe is connected with a dust removing mechanism which is a bag type dust removing device. The invention combines the functions of polishing and dust removing into one machine, has the advantages of reasonable arrangement and compact structure and overcomes the defects of heavy dust and poor environment in the operation of prior polishing machines for a long time. Especially, a plurality of square holes of the fence framework are used as draught ports for enlarging the horizontal draught area and the vertical draught area of the draught ports without affecting workpiece arrangement for polishing. The invention has obvious dust absorption effect, and does not have reflection and splashing phenomena of wood chips and dust in suspended grinding or placing operation.

Owner:ZHEJIANG JITIAN ENVIRONMENTAL PROTECTION TECH

Multi-function board eraser structure

InactiveUS20110154608A1Easy to collect dustIncrease elasticityCleaning filter meansBoard cleaning devicesPower switchingWear resistant

A multi-function board eraser structure includes a dust-collecting device, a flexible pipe, a wiping absorber opening and a mobile guiding track. The dust-collecting device is small in volume, has intense absorbing forces and is capable of moving about as well as being devised with a light-indicative power switch, an overload protective fuse base, an overheating protective indication lamp, and a dust-collecting chamber saturated pressure switch display. Above the dust-collecting chamber are a dust-collecting breach and a scraping plate for absorbing dust accumulated at the wiping absorber opening for restoring the wiping absorber opening to an optimal status for further usage. The wiping absorber opening has a wiping plane, which is an arched body for gathering chalk dust at a middle section of the main body during a wiping process and is made of a highly elastic material for facilitating dust collection. The wiping plane is covered by a velvet plane that is highly electrostatic and wear-resistant. Thus, the velvet plane not only favors collection of dust being wiped off but offers replacement conveniences.

Owner:TSOU TUN HUANG

Incoming fabric beating de-dusting device of circular screen printer

ActiveCN109228622AImprove dust removal effectEfficient removalMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses an incoming fabric beating de-dusting device of a circular screen printer. The incoming fabric beating de-dusting device comprises a supporting frame, a de-dusting box is arranged on the supporting frame, a beating de-dusting mechanism is arranged in the de-dusting box, the front side and the rear side of the beating de-dusting mechanism are provided with fabric compressionrollers respectively, and a fabric inlet and a fabric outlet are formed in the front side and the rear side of the de-dusting box. Fabric guide rollers are arranged at the fabric inlet and the fabricoutlet respectively, an air inlet and an exhaust inlet are formed in the two ends of the de-dusting box respectively, and the exhaust inlet is connected with a dust collection mechanism. The beatingde-dusting mechanism comprises two beating de-dusting rollers which are arranged up and down, the beating de-dusting rollers comprise roller bodies, and the surfaces of the roller bodies are providedwith two brush assemblies and two beating assemblies, wherein the brush assemblies and the beating assemblies are helically distributed. The incoming fabric beating de-dusting device has the advantages of being capable of effectively improving the de-dusting effect.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

Dust collection method of dust collector, dust collector and computer readable storage medium

InactiveCN108175332AEasy to collect dustSimple and convenientElectric equipment installationSystem stabilityEngineering

The invention discloses a dust collection method of a dust collector, the dust collector and a computer readable storage medium. The method comprises the steps that a current motor running parameter and a current dust collection effect value are acquired by the dust collector, wherein the current dust collection effect value is a scalar parameter for measuring the dust collection effect of the dust collector at the current moment; whether or not a difference value of the current dust collection effect value and a preset dust collection effect value exists in a preset difference value range isjudged; if not, the motor running parameter is adjusted, and the difference value of the adjusted dust collection effect value and the preset dust collection effect value is in the preset difference value range. According to the dust collection method, the dust collection effect value of the dust collector is kept within the preset difference value range of a preset dust collection effect, the dust collector is kept in the optimal dust collection effect, and the method is easy and convenient to implement, low in cost, good in system stability, low in noise and high in control precision.

Owner:FORTIOR TECH SHENZHEN

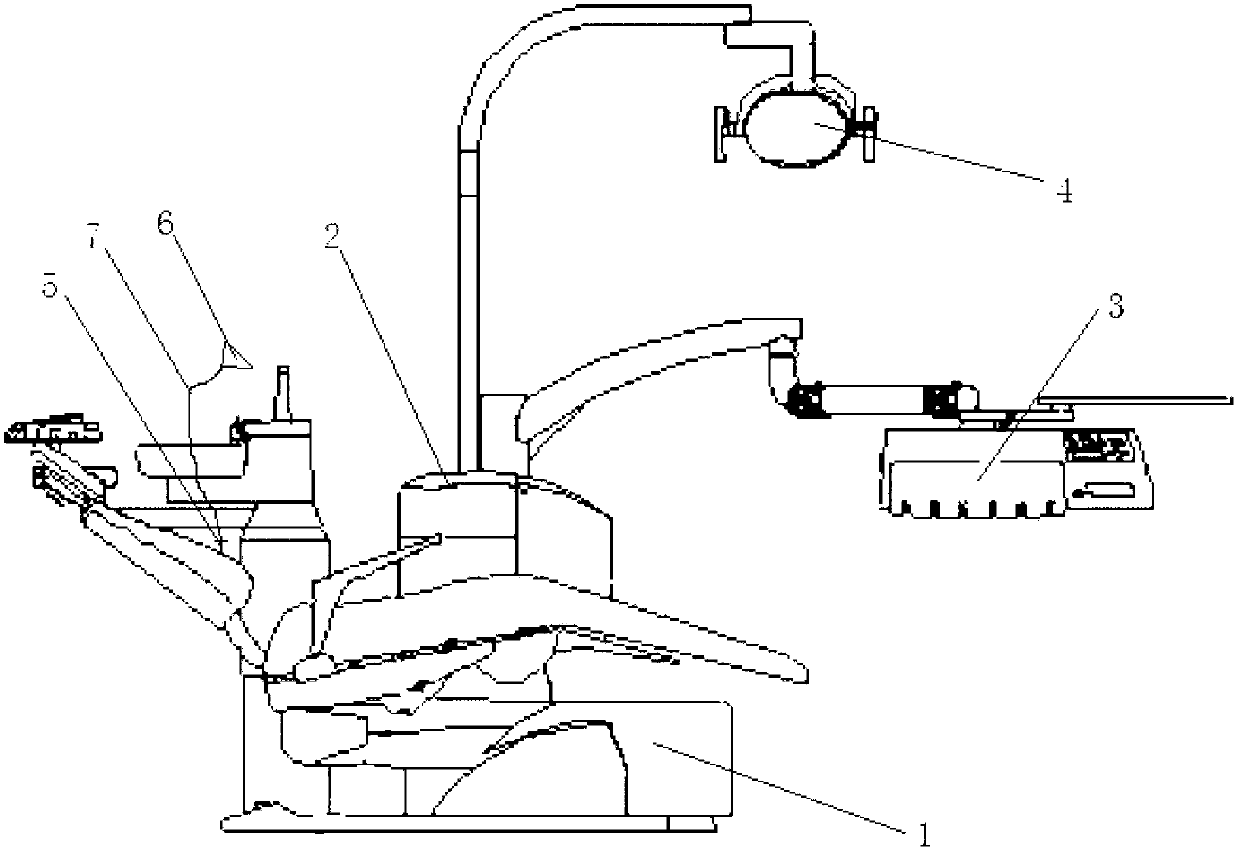

Dental chair with dust hood

InactiveCN103126848AEasy to vacuumReduce volumeOperating chairsDental chairsDental chairInstrument tray

The invention discloses a dental chair with a dust hood and overcomes the defects that a vacuum cleaner is big in size, inconvenient to move and high in noise, and the utilization rate of a high negative pressure absorption pipeline is low. The structure of the dental chair with the dust hood comprises a dental chair body, a side box, an instrument tray and an oral cavity cold light lamp, wherein the side box is provided with the high negative pressure absorption pipeline. The dental chair with the dust hood further comprises the dust hood, and the dust hood is connected with the high negative pressure absorption pipeline through a wind pipe. The reversed side of the dust hood is provided with a clamp holder, and the dust hood can be directly fixed on a treatment platform through the clamp holder. The high negative pressure absorption pipeline is fully used by the dental chair with the dust hood, the dust can be absorbed conveniently, and the vacuum cleaner is small in size, low in noise, convenient to move and obvious in dust absorption effect. The dental chair with the dust hood is suitable for promotion and application in oral clinics.

Owner:SHANDONG UNIV

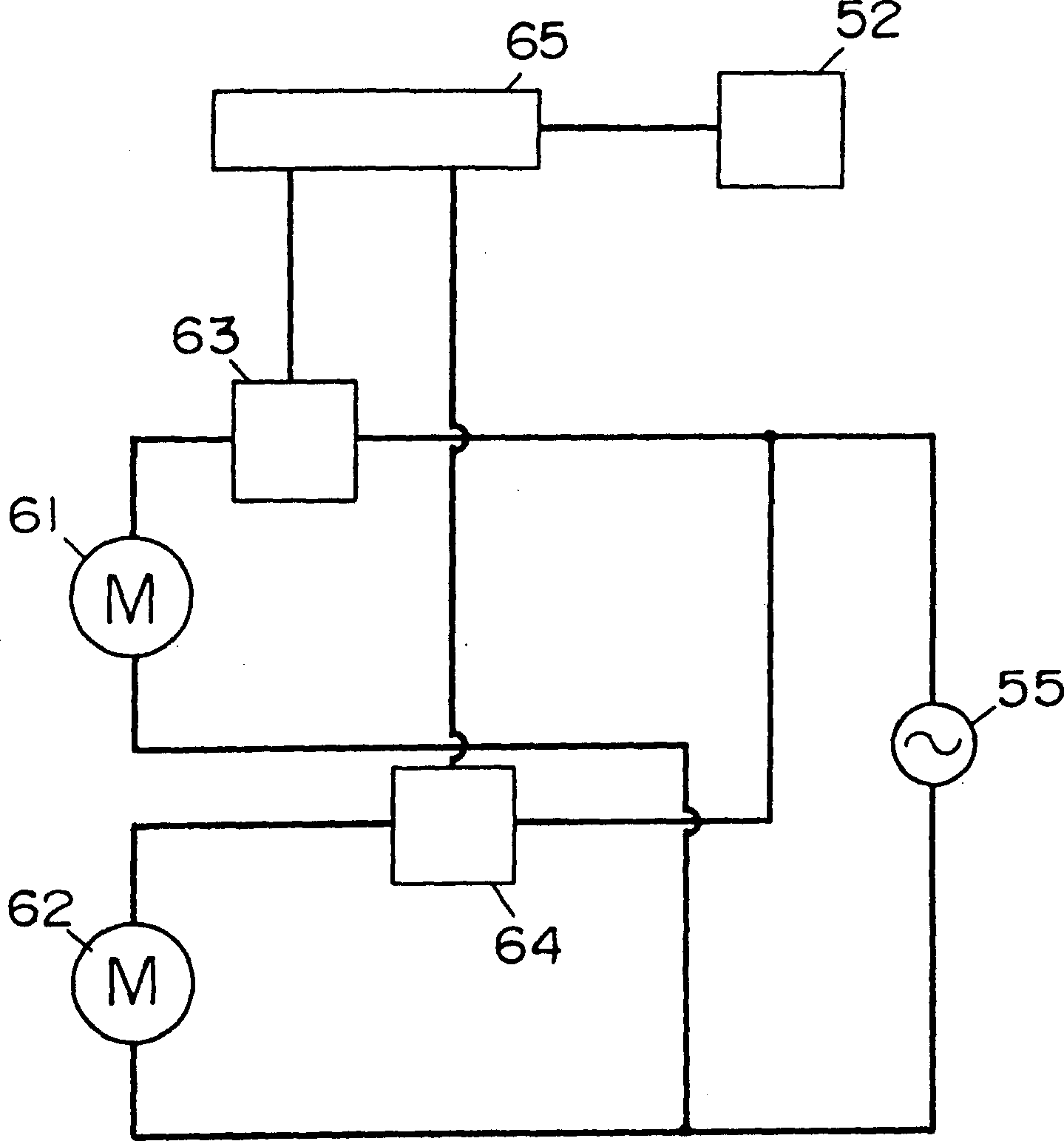

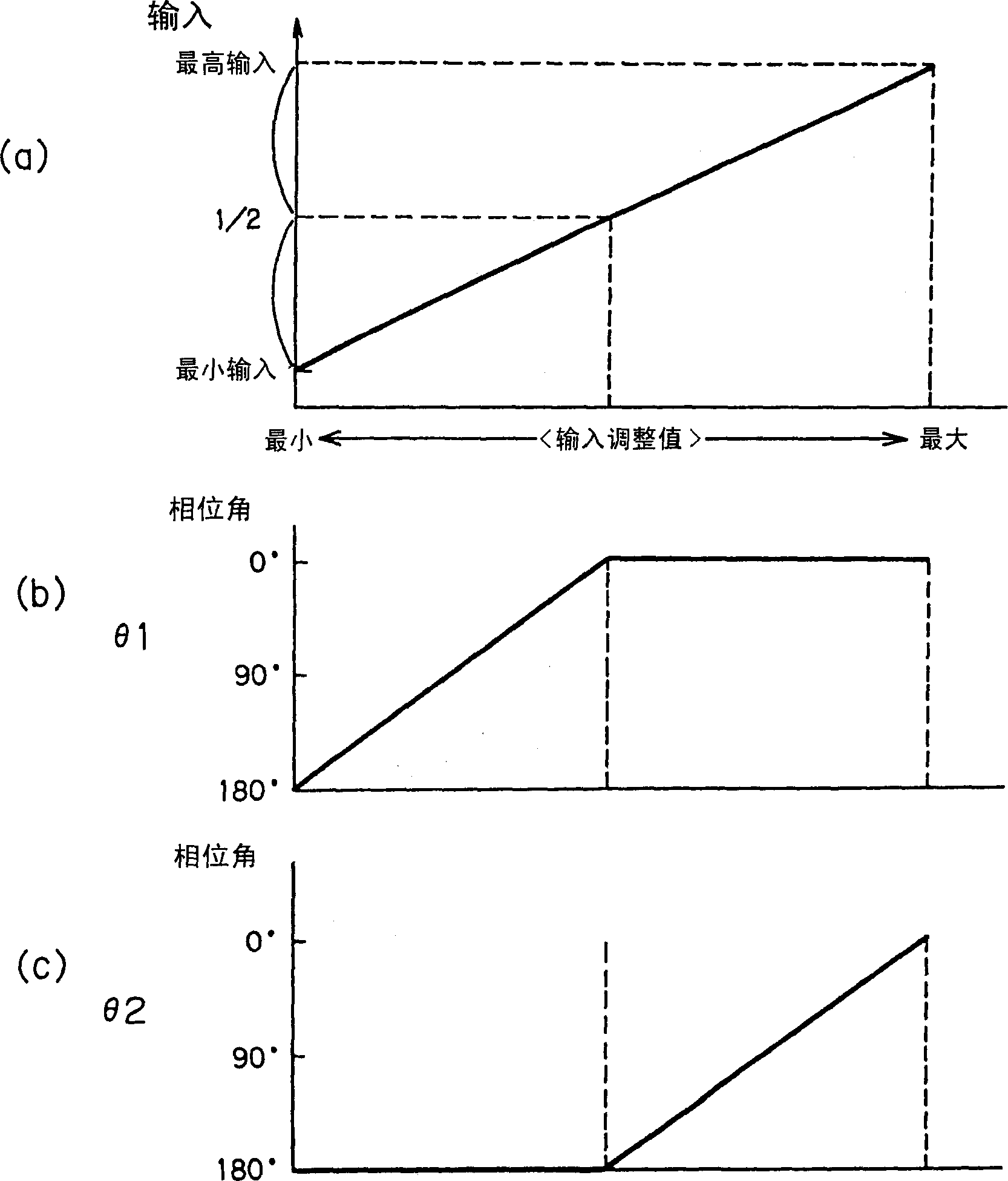

Vacuum cleaner

InactiveCN1895142AIncrease input powerIncrease electric powerMotor fan assembly mountingElectric equipment installationInput controlElectricity

The invention provided a vacuum cleaner for which the raise in inputs is possible, and also, which can realize an input control by a phase control in a broad range. The vacuum cleaner is equipped with a first control means (63) which controls a first electric blower (61), a second control means (64) which controls a second electric blower (62), an input adjusting means (52), a commercial power source (55), and a main control means 65 which controls the first control means 63 and the second control means (65) in response to a signal from the input adjusting means. The total of the maximum power consumption of the first and second electric blowers is approximately 1,600W or higher. At the same time, the vacuum cleaner is constituted in such a manner that the first electric blower is connected with the commercial power source through the first control means, and the second electric blower is connected with the commercial power source through the second control means 64 respectively in parallel. The electric vacuum cleaner achieves the raise in input, suppresses the generation of a high harmonic electric current by the phase control, and allows the input control over the whole range of the maximum input and lower.

Owner:PANASONIC CORP

Multifunctional dust remover

InactiveCN108478099AQuality improvementGood vacuum effectMechanical apparatusSuction filtersEngineeringHigh adhesion

The invention discloses a multifunctional dust remover, and belongs to the technical field of dust removal. The multifunctional dust remover comprises a main machine, and a distribution channel is arranged in the main machine. A water storage bucket is arranged above the left side of the main machine, and support rods are arranged on the left and right sides of the main machine. Universal wheels are arranged at the lower ends of the support rods, and a baseplate is connected to the bottom of the main machine. A brush is arranged under the baseplate, exhaust openings are formed in both sides ofthe brush, and water injection nozzles are formed in both sides of the exhaust openings. The dust removal effect is good, dust with high adhesion on the ground can be absorbed, and the functions of water spray and scraping washing are further achieved. In the process of dust collection, negative oxygen ions can be released to improve the surrounding air quality.

Owner:宁波北仑区川大普科电子科技有限公司

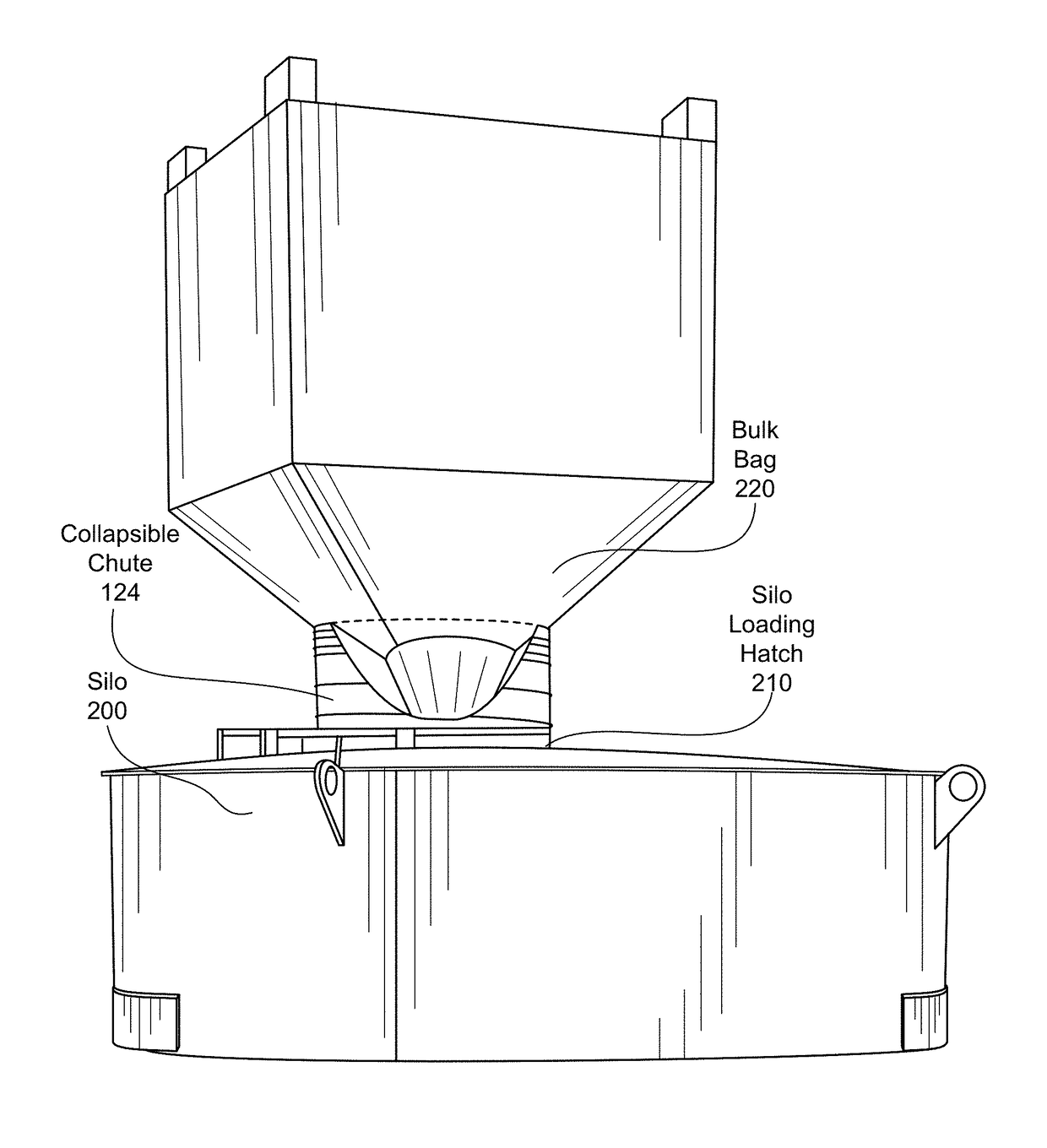

Portable system and methodology that facilitates dust collection within a silo apparatus

ActiveUS20170304761A1Easy to collect dustPrevent escapeCombination devicesDispersed particle filtrationEngineeringSilo

Aspects to facilitate dust collection are disclosed. In one aspect, a chute provides a dust seal between a bulk bag of material and a silo loading hatch. Here, the dust seal comprises a first seal between a first end of the chute and the bulk bag, and a second seal between a second end of the chute and the silo loading hatch. In another aspect, a collapsible chute is extended between a silo loading hatch and a discharge chute of a bulk bag such that the collapsible chute forms a dust seal between the silo loading hatch and the bulk bag. Contents of the bulk bag are released via the discharge chute so that the contents of the bulk bag flow into the silo loading hatch. For this embodiment, the dust seal prevents airborne dust associated with the flow from escaping into an exterior portion of the collapsible chute.

Owner:JPL GLOBAL

Dry-mixed mortar dust-proof agent and dry-mixed mortar containing same

The invention provides a dry-mixed mortar dust-proof agent which can reduce dust generated in the production, transportation and application processes of dry-mixed mortar. The dust-proof agent is obtained by adopting a dry powder blender for stirring in advance and uniformly mixing, by weight, 55-85% of fibers and 5-15% of bentonite, and then spraying 10-30% of silicone oil uniformly into a mixture in the stirring process, wherein the fibers are obtained by pulverizing natural wood chips, halm or straw into powder with the diameter ranging from 0.1 mm to 0.5 mm, then soaking the powder in hot water for two hours at the temperature ranging from 90 DEG C to 100 DEG C, and finally conducting the drying. According to the dust-proof agent, the cost is low, the additive amount is small, dust generated by other raw materials of the dry-mixed mortar can be well adsorbed, dust generated in the dry-mixed mortar production and application processes can be effectively reduced, net structures can be formed in the hardening process of the mortar, and cracks in the hardening process of the mortar can be greatly reduced. The invention further provides the dry-mixed mortar containing the dust-proof agent, and the mortar comprises 12-40% of inorganic cementing materials, 60-85% of aggregate, 0.8-2.0% of additives and 0.6-0.8% of the dust-proof agent.

Owner:广东龙湖科技股份有限公司

Vacuum dust collector

InactiveCN101721165AEasy to collect dustExtended service lifeSuction cleanersExhaust valveAir filter

The invention discloses a vacuum dust collector which comprises an upper cover component and a bottom shell component, wherein the space surrounded by the upper cover component and the bottom shell component is internally provided with a dust collecting barrel and a motor component in parallel; the right side of the motor component is provided with a plurality of motor air inlet holes; the bottom of the motor component is provided with a plurality of motor air outlet holes; an air way channel is formed between the bottom of the motor component and the bottom shell component; the air way channel is communicated with an exhaust hole and the motor air outlet holes; the left side of the motor component is provided with the exhaust hole; the right side at the bottom of the bottom shell component is provided with an air inlet hole; and the air inlet hole is communicated with the motor air inlet holes by the dust collecting barrel. The vacuum dust collector leads the air temperature at the exhaust hole of the dust collector to be greatly reduced, avoids an air filtering component arranged at the exhaust hole being deformed caused by long-term heating, prolongs the service life of the air filtering component arranged at the exhaust hole of the dust collector, and ensuring the dust collector to achieve better dust collecting effect.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Straw perforating machine

PendingCN111483018AAccurate concentricityPrecise positioningStationary drilling machinesCane mechanical workingElectric machineryEngineering

Disclosed is a straw perforating machine. A workbench is fixedly arranged on a machine frame. A perforating mechanism is arranged on the workbench. The perforating mechanism is structurally characterized in that a liner sliding rail is fixed to the workbench, the linear sliding rail is sleeved with a sliding seat in an inserted mode, a perforating motor support is fixedly arranged on the sliding seat, a perforating motor is fixed to the perforating motor support, a spindle box is fixed to the sliding seat, the perforating motor drives a spindle of the spindle box through a synchronous belt wheel and a synchronous belt to rotate, and a perforating drill bit is installed on the spindle of the spindle box. A translation motor is fixed to the workbench. A lead screw is fixedly arranged on a rotating shaft of the translation motor, the lead screw and a nut are in screw connection together, and the nut is fixed to the lower portion of the sliding seat. Automatic perforating machining can beperformed on a wood material and a bamboo material, so that the materials are machined into wood and bamboo straws. The straw perforating machine is simple in structure and convenient to maintain, andfeeding and positioning are precise and rapid.

Owner:安吉庚康科技有限公司 +1

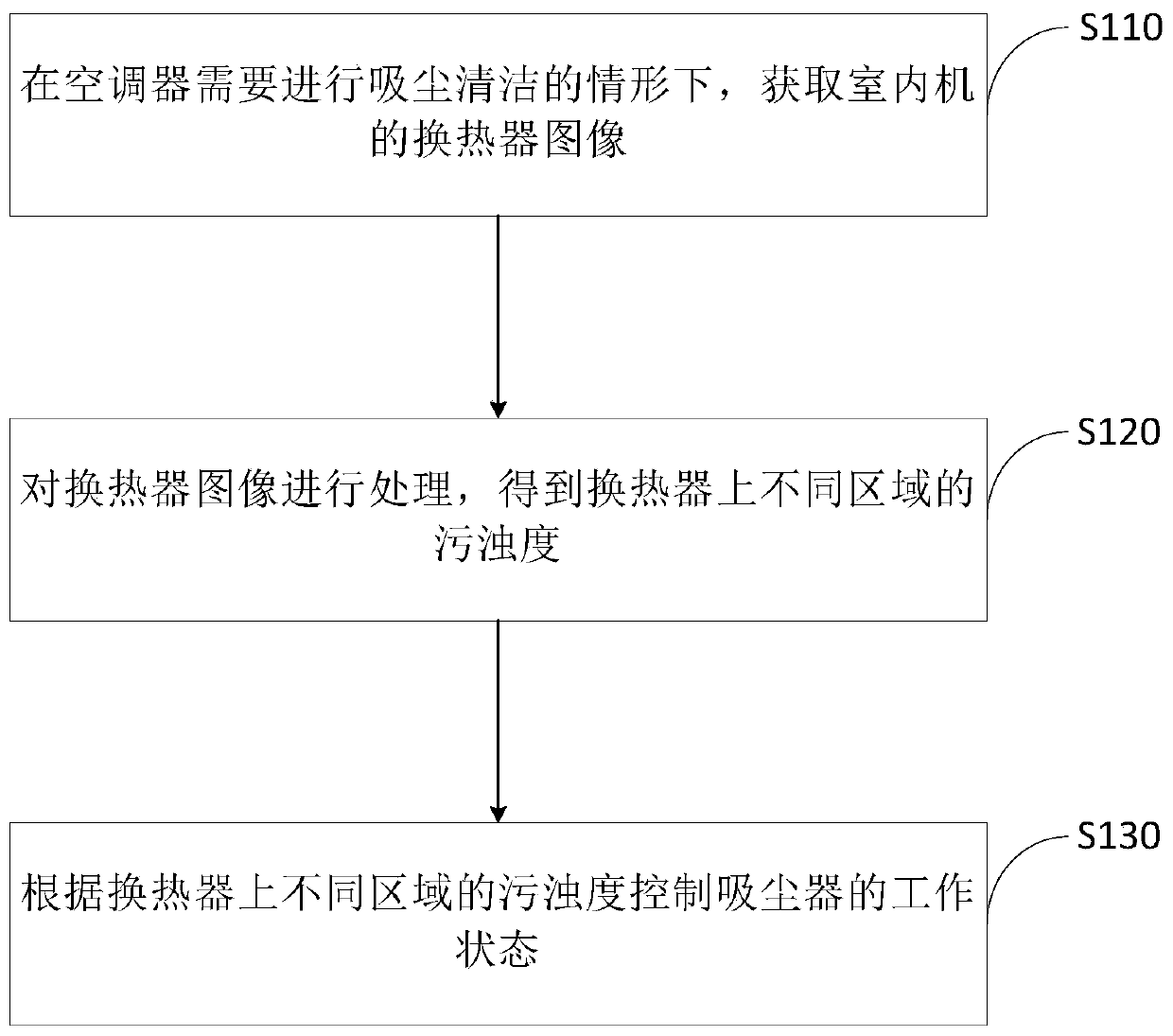

Air conditioner self-cleaning control method

ActiveCN109916036AGood vacuum effectEnhanced self-cleaningMechanical apparatusEngineeringPlate heat exchanger

The invention belongs to the technical field of air conditioners, and particularly provides an air conditioner self-cleaning control method. In order to improve the self-cleaning effect of the air conditioner, the air conditioner comprises an indoor unit and a dust collector arranged on the indoor unit, the dust collector can move relative to a heat exchanger of the indoor unit and can absorb duston the heat exchanger in the moving process. The self-cleaning control method based on the air conditioner comprises the following steps that the image of the heat exchanger of the indoor unit is acquired under the condition that the air conditioner needs to carry out dust collection and cleaning; the image of the heat exchanger is processed to obtain the dirty degrees of different areas on the heat exchanger; and the working state of the dust collector is controlled according to the dirty degrees of different areas on the heat exchanger. Due to the fact that the dirty degrees of different areas on the heat exchanger are different, the working intensity of the dust collector needs to be different. Therefore, the self-cleaning effect of the air conditioner can be effectively improved through independently treating dirty objects in different areas on the heat exchanger.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Multi-drill-bit graphite machining equipment

ActiveCN104227852AMeet processing needsSimple structureWorking accessoriesStone-like material working toolsGear wheelElectric machinery

The invention relates to the field of multi-drill-bit graphite product drilling equipment. The multi-drill-bit graphite machining equipment comprises a vertical frame and a lifting platform arranged on the frame, wherein the lifting platform is arranged on a polished lever on the upper part of the frame, and is driven to ascend and descend through the rotation of a lead screw; the lead screw is connected with a lifting motor; a main revolving shaft and a plurality of auxiliary revolving shafts are vertically arranged on the lifting platform; the main revolving shaft is arranged in the center of the lifting platform; the auxiliary revolving shafts uniformly surround the periphery of the main revolving shaft; the main revolving shaft and the auxiliary revolving shafts are connected through a gear; the main revolving shaft and the auxiliary revolving shafts are provided with through holes along the axis direction respectively; the upper end part of the main revolving shaft is provided with a belt wheel, and is connected with a driving motor arranged on the upper end face of the lifting platform through a belt; the upper end parts of the main revolving shaft and the auxiliary revolving shafts are connected with a dust sucking device respectively through suction pipes; plate-like tools are arranged on the lower end heads of the main revolving shaft and the auxiliary revolving shafts; the revolving shaft through holes are isolated symmetrically by the tools. The multi-drill-bit graphite machining equipment is simple in structure, has a good dust-removing effect, and is equipment special for deep-hole machining of large and medium-sized graphite crucibles.

Owner:于海东

Reversible mobile belt conveyer

The invention provides a reversible mobile belt conveyer. According to the reversible mobile belt conveyer, a first dust collection device and a second dust collection device are arranged at the machine head discharging end and the machine tail discharging end respectively, the first duct collection device comprises a first hopper which is arranged outside the machine head discharging end in a covering mode, a first dust collection pipeline which can be used for supplying negative pressure is connected to the outside of the first hopper in a sealed mode, the first dust collection pipeline can move along with the first hopper, the second dust collection device comprises a second hopper which is arranged outside the machine tail discharging end in a covering mode, a second dust collection pipeline which can be used for supplying negative pressure is connected to the outside of the second hopper in a sealed mode, and the second air collection pipeline can move along with the second hopper. According to the reversible mobile belt conveyer, the dust collection devices are arranged at the machine heat discharging end and the machine tail discharging end respectively, and thus the dust collection requirement can be met when discharging is conducted at any end; in the whole airtight operating process aiming at raise dust and air carriers of the raise dust, tracking type dust collection can be achieved under different working conditions and in different working states, the air volume is small, and the dust collection effect is good.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com