Rotary type fluidized bed back blow particle layer dust removing apparatus

A technology of dust collector and granular layer, which is applied in the field of rotary fluidized bed backflushing granular layer dust collector, can solve the problems of large backflush air volume, reduced dust removal efficiency, inconvenient operation, etc., and achieves low operating cost, reliable operation, The effect of easy dust collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

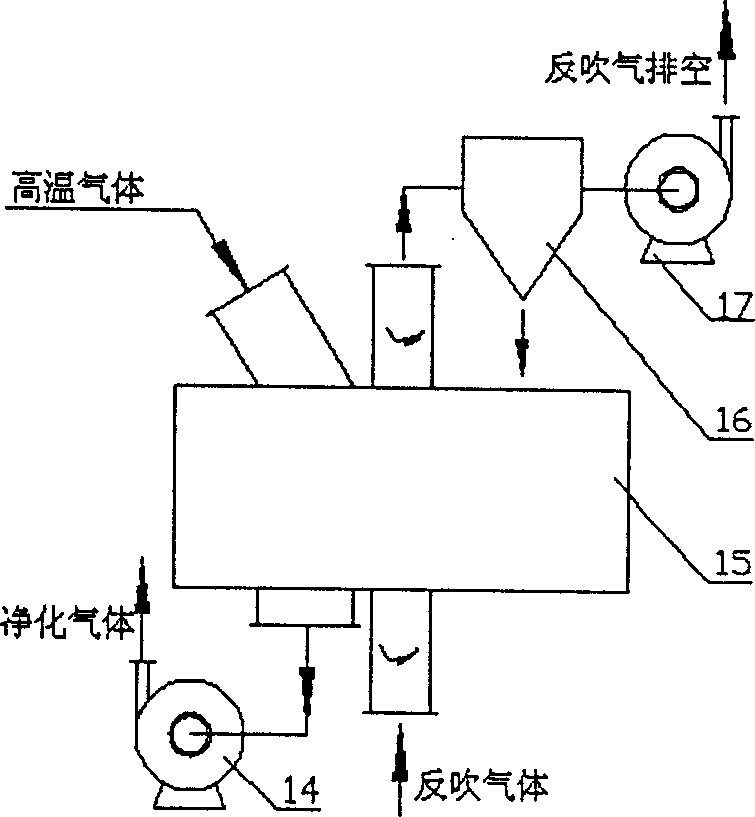

[0026] Examples of the present invention figure 1 As shown, it includes a dust-containing gas inlet hood 1 located at the upper part of the dust collector, a cylindrical particle layer dust collector 2, a packing layer unit cell 3 and a packing 4 of the dust collector, a purified gas outlet hood 5, and The rotary fluidized bed blowback mechanism composed of the exhaust suction hood 8 and the rotating exhaust pipe 9 rotates around the center of the cylindrical granular layer dust collector 2, and the exhaust suction hood 8 is set on the granular layer dust collector. In the air intake cover 1 on the top of the device.

[0027] Such as figure 2 As shown, the cross-section of the cylindrical granular layer dust collector is divided into three parts: the dust-laden airflow dedusting area 10 , the fluidized bed back-blowing ash cleaning area 12 and the sealed isolation area 11 , and each area is composed of several packing grids 13 .

[0028] The present invention is used for bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com