Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156results about How to "Exclude smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Range hood capable of self-adaptively regulating rotating speed of fan

ActiveCN102538046AImprove adaptabilityImprove smoke exhaust effectDomestic stoves or rangesLighting and heating apparatusFlueSmoke

The invention discloses a range hood capable of self-adaptively regulating the rotating speed of a fan. The range hood comprises a range hood shell, a motor arranged in the range hood shell and a speed regulation control circuit capable of controlling the rotating speed of the fan, wherein the motor is connected with an air outlet through an exhaust pipeline; and the air outlet is communicated with a public flue. The range hood is characterized by being provided with a sensor capable of detecting the pressure variation of the public flue, wherein an induction output end of the sensor is connected with an input end of the speed regulation control circuit; and an output end of the speed regulation control circuit is connected with the motor. When the pressure variation of the public flue is detected by the sensor, a corresponding decision is made; according to output power of a motor system which is required under corresponding pressure, the rotating speed of the fan of the range hood can be self-adaptively regulated, so that the smoke exhausting effect of the public flue is improved, and the flue is prevented from being plugged; and simultaneously, cooking fumes in a room can be smoothly removed, and a smoke exhaust environment of a kitchen is effectively improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

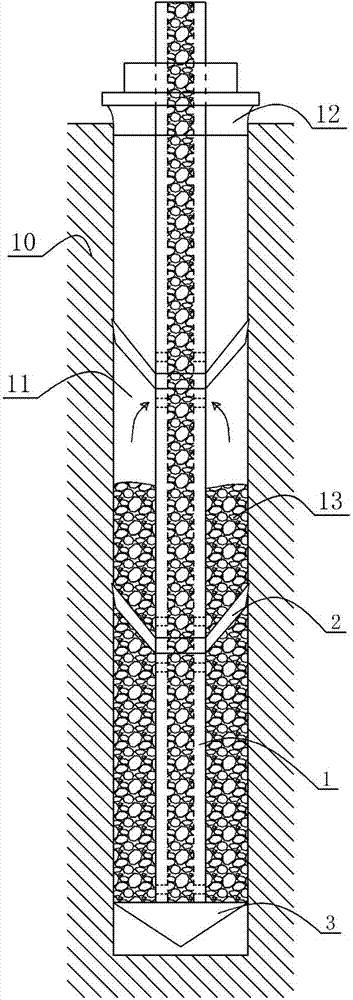

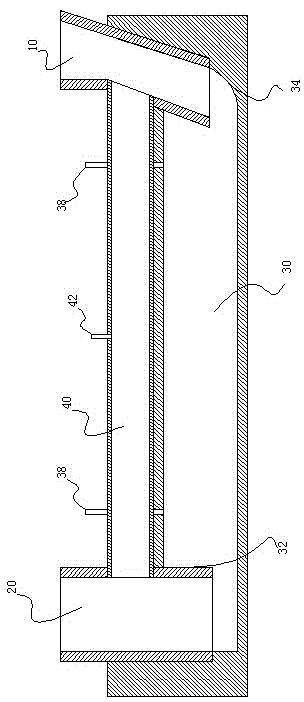

Multi-level back-grasp-type hollow anchor rod and construction method thereof

InactiveCN103572757AIncrease contact areaOutflow smoothlyBulkheads/pilesAnchoring boltsRock boltCement mortar

The invention discloses a multi-level back-grasp-type hollow anchor rod. The multi-level back-grasp-type hollow anchor rod comprises an anchoring rod with a grouting passage inside, an anchor head is fixed at the lower end of the anchoring rod, a plurality of back-grasp buckles are fixed on the anchoring rod, a grout outlet is formed in the anchor head, and the parts, at the upper side of the back-grasp buckles, of the anchoring rod and the parts, at the lower side of the back-grasp buckles, of the anchoring rod are provided with grout outlets and air return holes respectively, and the grout outlets and the air return holes are communicated with the grouting passage. Compared with the construction method of a hard rock body and a soil body, the construction method of the multi-level back-grasp-type hollow anchor rod comprises the steps of (a) preparation of equipment, (b) measurement and distribution of holes, (c) drilling, (d) hole cleaning and detection, (e) inserting of the anchor rod, (f) installation of a grout stop plug, (g) screwing of nuts and (h) grouting, and the anchor rod is directly inserted through the anchor head according to the construction method of a soft soil body, sand and water. The multi-level back-grasp-type hollow anchor rod and the construction method of the multi-level back-grasp-type hollow anchor rod increase the contact area and anchoring force between the anchor rod and the hole wall and prevent the anchor rod from falling out and injuring people. A uniform cement mortar layer can be formed around the anchor rod through the grout outlets and the air return holes, the damage of corrosion is avoided, and the purpose of long-time supporting is achieved.

Owner:SHANDONG JIAOTONG UNIV

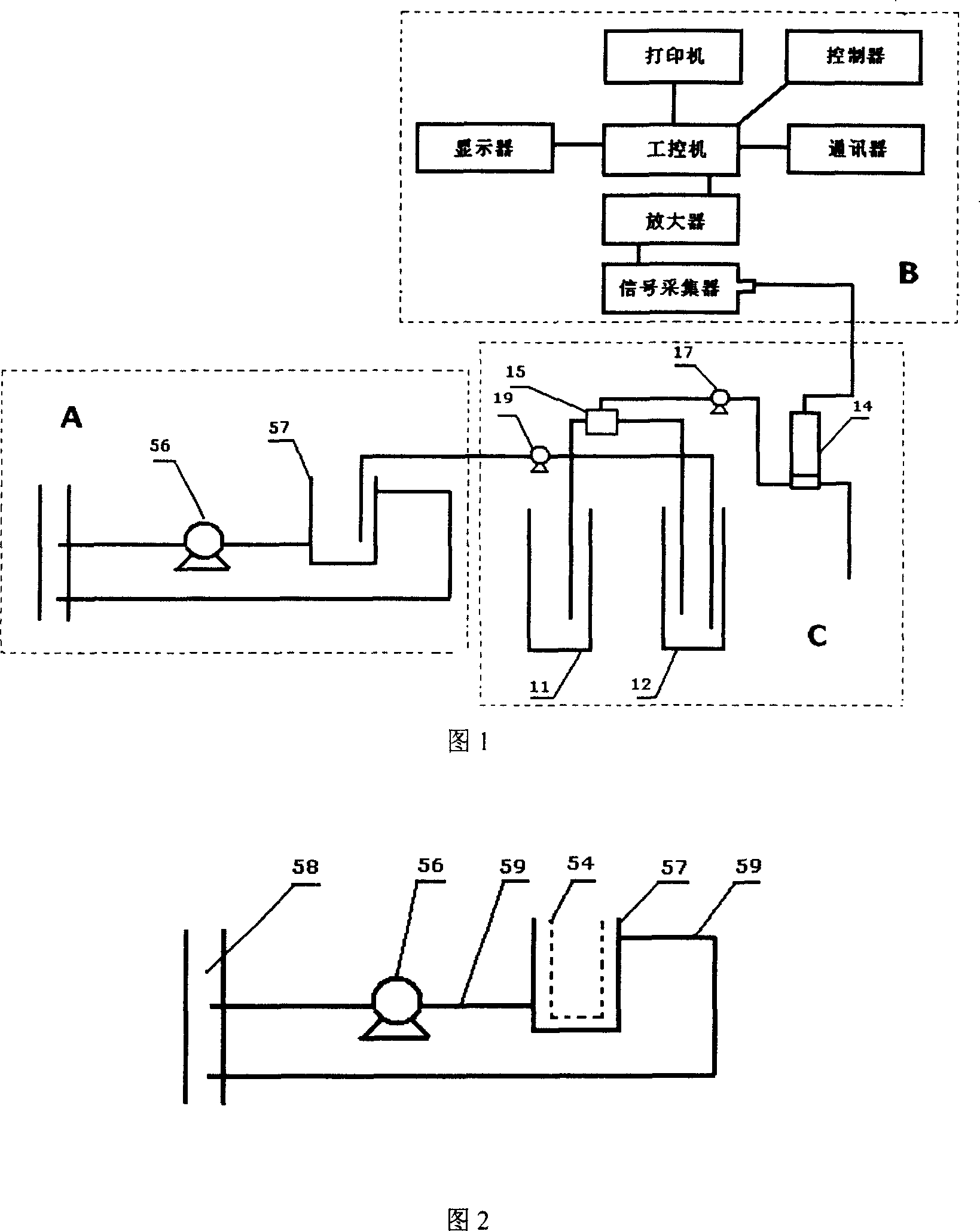

Sensor type on-line monitor of biochemical oxygen demand

InactiveCN101000341AImprove measurement stabilityOut-of-the-boxMicrobiological testing/measurementMaterial analysis by electric/magnetic meansInstrumentationSoftware

A BOD on-line detector of sensor type is prepared as transferring sample in filter element of sampling unit A to sample cup of measuring unit C through sampling pump, connecting microbiological membrane transducer of measuring unit C to electrode interface of controlling unit B, applying instrument software to directly calculate out BOD of sample based on measurement signals of microbiological membrane transducer through signal collector and signal amplifier.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Double cylinders bundled type straw biogas digester

InactiveCN104371913AEasy feedingLong fermentation routeGas production bioreactorsWaste based fuelGlass fiberPlastic materials

The invention discloses a double cylinders bundled type straw biogas digester. A biogas digester body is composed of a feed pipe, a discharge pipe, a fermentation pipeline and a hydraulic pressure chamber. The fermentation pipeline is horizontally arranged. The feed pipe inclines to be connected with the fermentation pipeline. The discharge pipe is vertically arranged to be connected with the fermentation pipeline. The hydraulic pressure chamber with two ends communicated is arranged at the top of the fermentation pipeline along the center axis of the fermentation pipeline and is communicated with the side wall of the feed pipe and the side wall of the discharge pipe. Air ducts are communicated with the fermentation pipeline. According to the arrangement, straws are conveniently fed in, due to the straight cylinder type fermentation pipeline, a fermentation path of the straws is prolonged, biogas is smoothly exhausted through the air ducts, and blocking never occurs; structure is reasonable, and the whole biogas digester is made of glass fiber reinforced plastic material or made by connecting PVC (polyvinyl chloride) pipelines.

Owner:陆永成

Claus tail gas SO2 sorbent and preparation and use thereof

ActiveCN104209084AStable adsorption sulfur capacityPromote absorptionOther chemical processesDispersed particle separationSorbentLanthanum

The invention relates to a Claus tail gas SO2 sorbent and preparation and use thereof; a transition metal, magnesium and aluminum nitrate with the mole ratio of 1:0.1-5:0.05-2 are dissolved in a water solution for preparation of a 1mol / L solution taking the transition metal for calculation; sodium hydroxide and sodium carbonate with the mole ratio of 1:0.1-2 are dissolved in water for preparation of a 1mol / L solution taking the NaOH for calculation; the two solutions are mixed; a precipitate formed by filtering is washed with water until the pH is 7; the precipitate is processed by drying, calcining and crushing to obtain hydrotalcite-like compound powder; 50g of the hydrotalcite-like compound powder is taken, a Ce, yttrium or lanthanum salt solution is added for immersion, high temperature resistant cement and carboxymethyl cellulose are added, and then the sorbent is obtained by calcining. The SO2 content in the tail gas is lower than 500ppm after adsorption desulfurization with the sorbent, and the sorbent SO2 sulfur adsorption capacity (taking SO2 for calculation, m mSO2 / m sorbent) is above 10%.

Owner:PETROCHINA CO LTD

Frame support arch tunnel lining structure

InactiveCN106089244AAvoid cracking and bulgingPromote excretionUnderground chambersDrainageEngineeringStructural engineering

The invention discloses a frame support arch tunnel lining structure. The side wall structure cracking damage due to insufficient drainage capacity when underground water increases dramatically in rainy and flood seasons is effectively avoided, the action of underground water on a tunnel lining bottom structure is reduced or even eliminated, and thus the damage risk of underground water to the lining structure in rainy and flood seasons is eliminated. The frame support arch tunnel lining structure comprises a primary arch wall supporting structure, a secondary lining structure body and a waterproofing and drainage system located between the primary arch wall supporting structure and the secondary lining structure body. The secondary lining structure body comprises an arch crown section, side wall sections and an inverted arch section. The side wall sections are side wall frame support structures and are used as bearing structures of the arch crown section. The inverted arch section is a tunnel bottom frame structure with an internal cavity. A bottom plate is laid on the top face of the tunnel bottom frame structure. An annular end opening of the waterproofing and drainage system is led to the internal cavity of the tunnel bottom frame structure.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

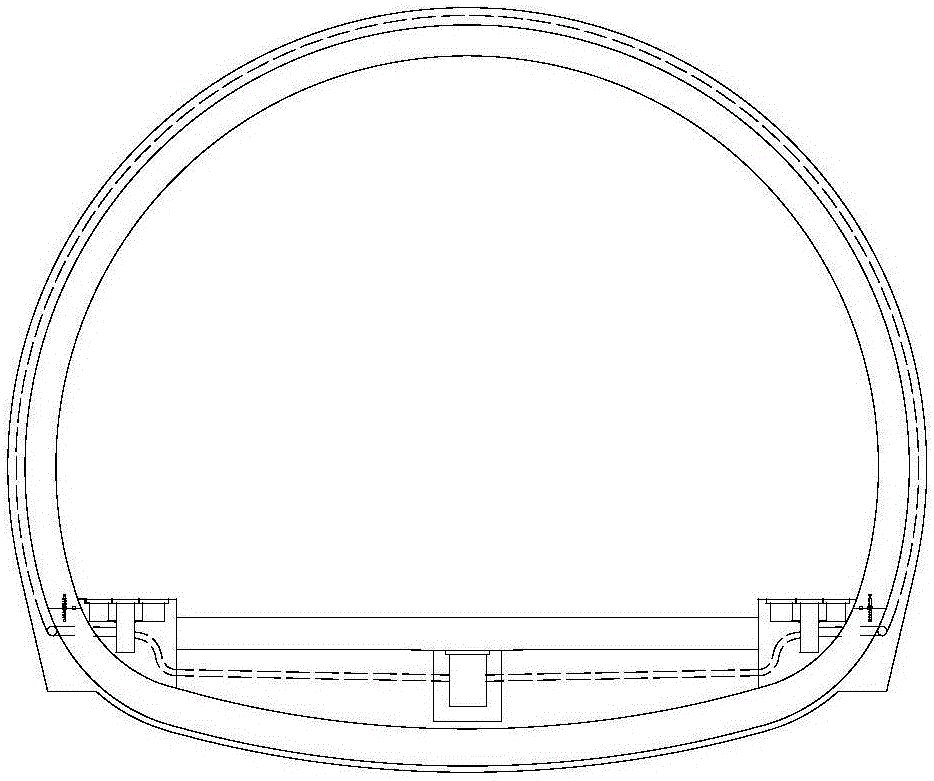

Box type tunnel-bottom composite arched tunnel lining structure with water drain function

ActiveCN105840210AAvoid cracking and bulgingExclude smoothlyUnderground chambersTunnel liningWater dischargeStructural engineering

The invention discloses a box type tunnel-bottom composite arched tunnel lining structure with a water drain function, so as to effectively prevent underground water from being introduced into a tunnel, to overcome the immersion, which is caused as the water discharge capacity of side ditches and a central ditch in the tunnel are insufficient in a rainfall-flood season, of a road bed by the underground water, and to guarantee that an underground water level is lower than the bottom plate of the tunnel, thereby removing the risk that the underground water destroys a lining structure, particularly a tunnel-bottom structure, in the rainfall-flood season. The box type tunnel-bottom composite arched tunnel lining structure with the water drain function comprises an arch wall primary supporting structure, a secondary lining structure and base leveling layers, wherein the arch wall primary supporting structure, the secondary lining structure and the base leveling layers are arranged from exterior to interior; a waterproof water drain system arranged between the arch wall primary supporting structure and the secondary lining structure communicates with a central water discharge channel. The secondary lining structure comprises an arch wall secondary lining and a box type bottom plate structure which consists of a bottom plate and a channel plate; the two ends of the bottom plate are fixedly connected with the bottom end of the arch wall secondary lining; the channel plate is sunken relative to the plate surface of a top plate to form the central water discharge channel. The upper parts of two side walls of the channel plate are provided with water sluicing pipes which are buried at intervals along the extension direction of a line; the inner end of each water sluicing pipe communicates with the central water discharge channel; the outer end of each water sluicing pipe penetrates through the base leveling layers to a base of the tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Automatic bale breaker

InactiveCN103350803AIncrease speedRemove completelyArticle unpackingEngineeringMechanical engineering

The invention discloses an automatic bale breaker which comprises a bale breaking device, a feeding end assembly, a screening device, a discharging device and a drive device. The bale breaking device comprises a bale breaking shell assembly, an upper cutting device and a lower cutting device. The feeding end assembly is installed below the bale breaking device, the screening device comprises a screening cylinder and a box body, the discharging device comprises a discharging assembly and a bag outlet assembly, the drive device comprises a machine frame, a speed reducer, a driving assembly and a driven assembly, a cutter clamp is arranged between the upper cutting device of the bale breaking device and the lower cutting device of the bale breaking device, and a carrier roller is arranged in an inlet of the bale breaking device. The screening cylinder comprises screening cylinder guide rails and roller blades, the screening cylinder guide rails are arranged at the two ends of the screening cylinder, and the roller blades are arranged on the inner side face of the screening cylinder. On the basis of the principle of screening cylinder rotating type conveying and separation, double-shaft multi-blade crossed type cutting is utilized by the automatic bale breaker, and the aims of automatically breaking the bale and automatically discharging the bale are achieved.

Owner:ZHEJIANG BORETECH

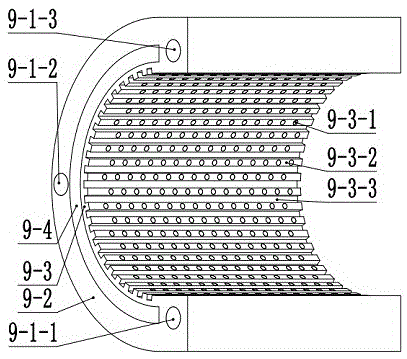

Apparatus for electrochemical machining of mask on cylindrical surface

InactiveCN105921831AFit tightlyExclude smoothlyMachining working media supply/regenerationEngineeringPorous medium

The invention patent discloses an apparatus for electrochemical machining of a mask on a cylindrical surface. The apparatus includes a liquid matching body, a front seal end cover and a rear seal end cover. The liquid matching body includes an external structure layer, a semicircle arc structure layer, an axially through diversion trench disposed between the outer structure layer and the semicircle arc structure layer. The arc surface of the semicircle arc structure is provided with liquid outlet grooves and bosses distributed in a staggered and uniformly toward an axial direction. The adjacent liquid outlet grooves and the bosses have a central angle of 3-10 degrees. The bosses are provided with liquid inlets at equal distances (d) along the axial direction. The front seal end cover and the rear seal end cover are in detachable sealing coupling with two axial ends of the liquid matching body respectively. A drainage groove communicates with the diversion trench. The apparatus in the invention is conducive to the discharge of an electrolytic product in an inter-electrode porous medium filled type mask electrolytic machining method, can improve the flow field uniformity at an anode surface of a cylindrical workpiece, further improves the quality of the electrochemical machining, is especially suitable for electrochemical machining of cylindrical surfaces, and is simple in structure, easy to operate and low in process cost.

Owner:HENAN POLYTECHNIC UNIV

Special evaporator for heat-pipe refrigerating hybrid air-conditioner

InactiveCN101818972AImprove reliabilityImprove energy savingEvaporators/condensersAir conditioning systemsEngineeringAir conditioning

A special evaporator for a heat-pipe refrigerating hybrid air-conditioner contains a finned pipe heat exchanger, a gas collecting pipe, a liquid distribution head, a liquid distribution pipe and a heat exchange pipe. The special evaporator is characterized in that a liquid collecting pipe is arranged between the heat exchange pipe and the liquid separating pipe, and the liquid separating pipe runs through the liquid collecting pipe to insert and stretch into the heat exchange pipe; the gas collecting pipe adopts a U-shaped pipe which is composed of a first rising vertical pipe, a second rising vertical pipe and an oil return bend pipe; and the heat exchange pipe is communicated with the first rising vertical pipe through the finned pipe heat exchanger. The special evaporator of the invention realizes the fusion of performance and safety of a vapor compression refrigerating mode and a heat-pipe natural circulation mode on the same evaporator through a special pipeline design, ensures oil return safety of the vapor compression refrigerating mode, and reduces the pipe resistance of the evaporator. The evaporator which is applicable to the heat-pipe refrigerating hybrid air-conditioning unit has simple structure, low cost and obvious effect, thus effectively solving the problems of oil return and resistance reduction of the unit, and improving the operating reliability and high efficiency.

Owner:TSINGHUA UNIV +1

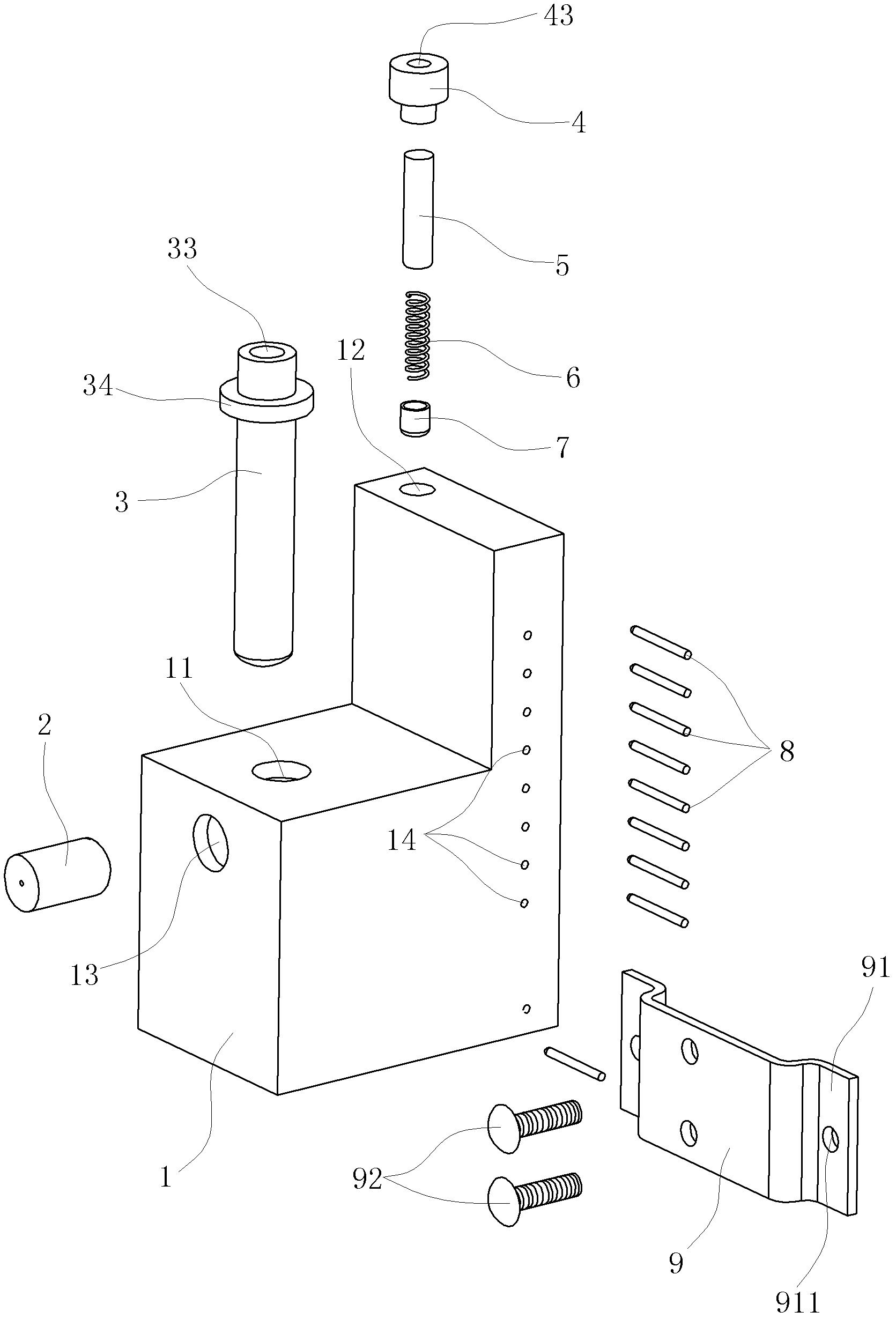

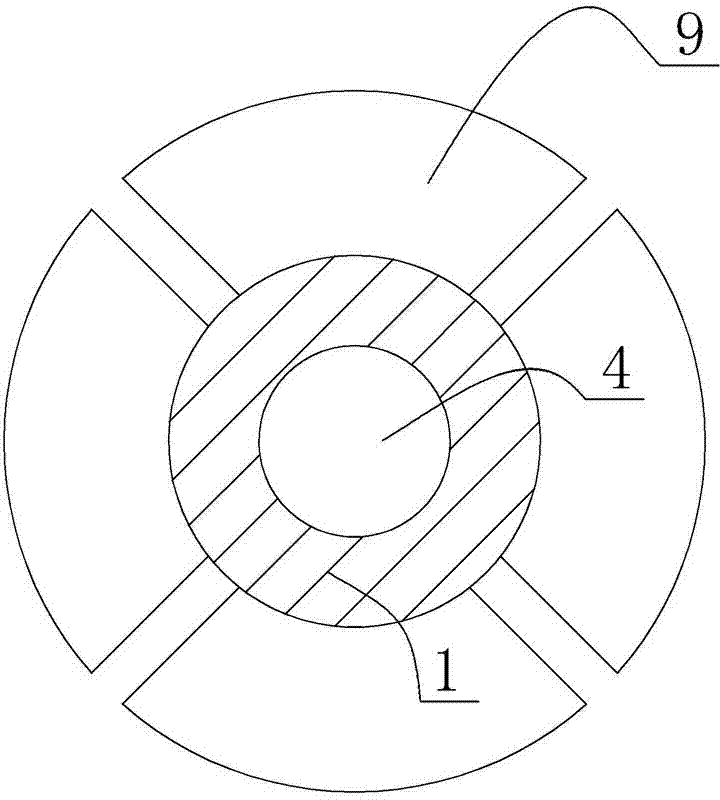

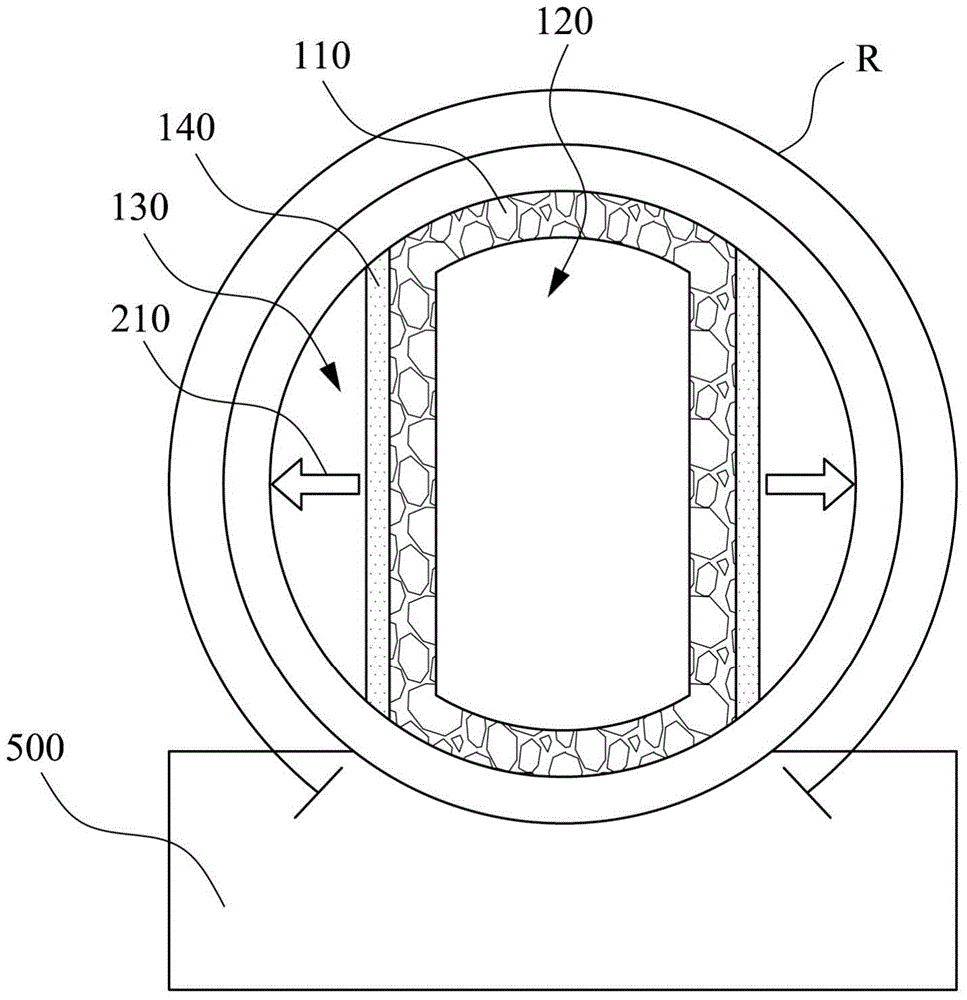

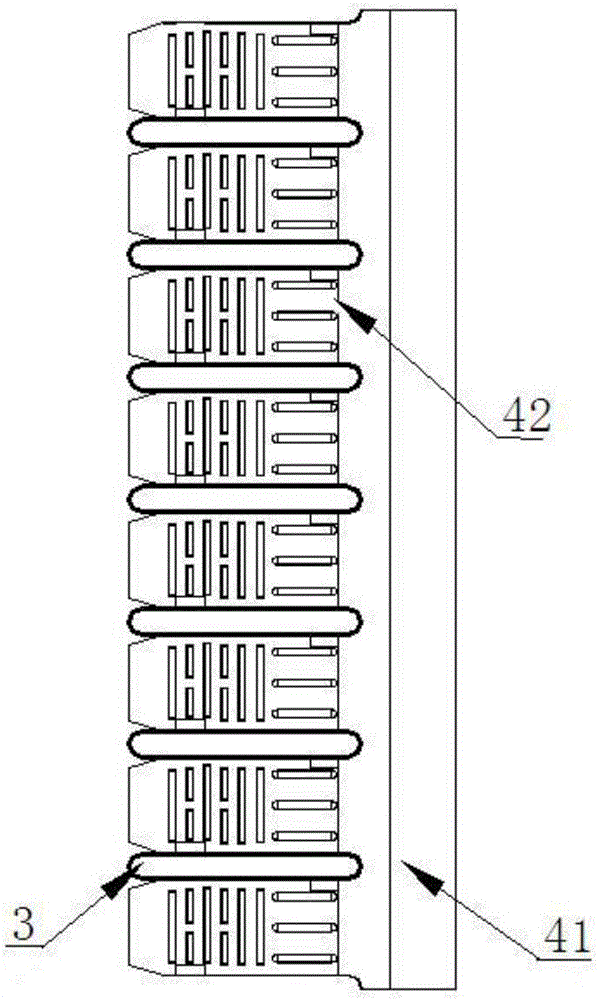

Grout sleeve for connecting prefabricated member steel bars and construction method of grout sleeve

InactiveCN103590541ASimple constructionLow costBuilding reinforcementsBuilding material handlingRebarRubber ring

The invention discloses a grout sleeve for connecting prefabricated member steel bars and a construction method of the grout sleeve, relating to the technical field of precast concrete members. The grout sleeve is used for solving the connection problem of prefabricated member steel bars and has the advantages of simplicity in construction, low cost, high strength and reliability in connection. The grout sleeve comprises a sleeve body, sealing rings and a set bolt, wherein the sleeve body is provided with a grout hole and a vent hole; the set bolt is arranged in the middle of the sleeve body; massive bulges are arranged on the inner wall of the sleeve body; the sealing rings are arranged at two ends in the sleeve body. When a prefabricated member is assembled, two reserved steel bars of the prefabricated member are inserted from two ends of the sleeve body, are fixed by the set bolt and squeeze into the elastic sealing rubber rings, then, a cement-based grouting material is filled from the grout hole, and the two reserved steel bars are connected to form a whole body through the sleeve. The grout sleeve can be used for connecting various prefabricated member steel bars.

Owner:SHENYANG JIANZHU UNIVERSITY

Separated maintainable tunnel lining structure

ActiveCN106437748APromote excretionEasy to excludeUnderground chambersDrainageStructural engineeringFlood season

The invention provides a separated maintainable tunnel lining structure to effectively avoid the phenomenon that a side wall structure is fractured and damaged due to the fact that underground water soars in rain-flood seasons but the discharge capacity is insufficient, improve the hydraulic pressure and floating resistant capacity of the lining structure and reduce the damage risks of underground water in rain-flood seasons to the lining structure, especially a tunnel bottom structure. The separated maintainable tunnel lining structure comprises an arch wall primary supporting structure, a water prevention and discharge system and a lining structure body which are arranged from outside to inside. The lining structure body comprises a secondary arch lining, a side wall frame supporting structure, a filling wall and a tunnel bottom pile-plate structure. The tunnel bottom pile-plate structure comprises a base plate laid on a base confining bed and anchorage piles longitudinally and transversely arranged along a tunnel at intervals. The upper ends of the anchorage piles are fixedly connected with the base plate. The two circumferential ends of the water prevention and discharge system lead to longitudinal drainage ditches formed in the two transverse sides of the base plate.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

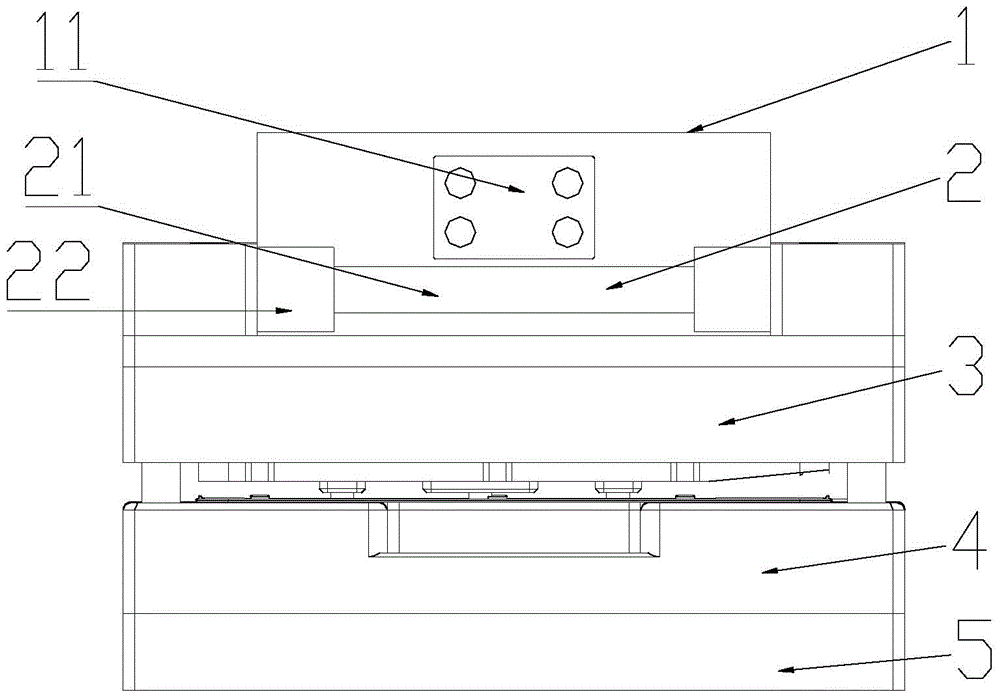

Multi-spindle multi-structural selection free type numerically controlled bevel gear machine tool

The invention discloses a multi-spindle free type numerically controlled spiral bevel gear and skew gear machine tool. The tool body is equipped with a post 1 which performs rectilinear motion along a horizontal linear guide rail at the Y direction and a post 2 which performs the rectilinear motion along a horizontal linear guide rail at the horizontal direction vertical to the Y direction. The post 1 is used for supporting a pivot 113. An axis B of the pivot 113 is arranged in a horizontal plane. A tool main spindle box 10 for mounting a tool spindle is fixedly connected on the pivot. The tool main spindle box 10 can rotate around a horizontal pivot axis B which is vertically intersected with a tool main spindle axis C. The post 2 is used for supporting a gear main spindle box 20, and a gear main spindle for mounting a gear rotates around an axis A in the gear main spindle box 20. The gear main spindle box 20 can perform linear elevation at the vertical direction on the post 2. The machine tool can effectively lower center of gravity of the whole machine tool and improve natural vibration frequency of vibration resistance performance of system; and the machine tool causes the numerical control and mechanical system to easily and stably complete the operating process of machining gears in the high-precision state.

Owner:湖南创远盖尔数控机床有限公司

Tube fin type parallel flow heat exchanger

InactiveCN102798252AImprove heat transfer efficiencyEasy to realize industrial productionEvaporators/condensersHeat exchanger casingsInterior spaceSurface layer

The invention provides a tube fin type parallel flow heat exchanger, which comprises flow collecting pipes, fins and coolant pipes, wherein at least mutual contact parts of the flow collecting pipes, the fins or the coolant pipes are made of a composite material with at least two-layer structure; and the melting point temperature of a mutual contact surface layer material is lower than the melting point temperature of a base layer material. Each coolant pipe is a hollow pipe, each fin with a through hole folding edge is sleeved on the coolant pipe, two ends of each coolant pipe are inserted into turned-up edge holes of a flow collecting pipe, and the inner space of each coolant pipe is communicated with that of each flow collecting pipe; after the coolant pipes, the flow collecting pipes and the fins are assembled, the whole body is heated to a temperature between the melting point temperature of the surface layer material and the melting point temperature of the base layer material; the surface layer material is melted to play a role of a brazing material; and the heat exchanger is welded into a whole. Industrialized production of the tube fin type parallel flow heat exchanger can be realized, the welding quality is consistent and easy to control, automatic assembly of the heat exchanger can be realized and the long-term use performance of the heat exchanger is kept consistent.

Owner:王康平 +2

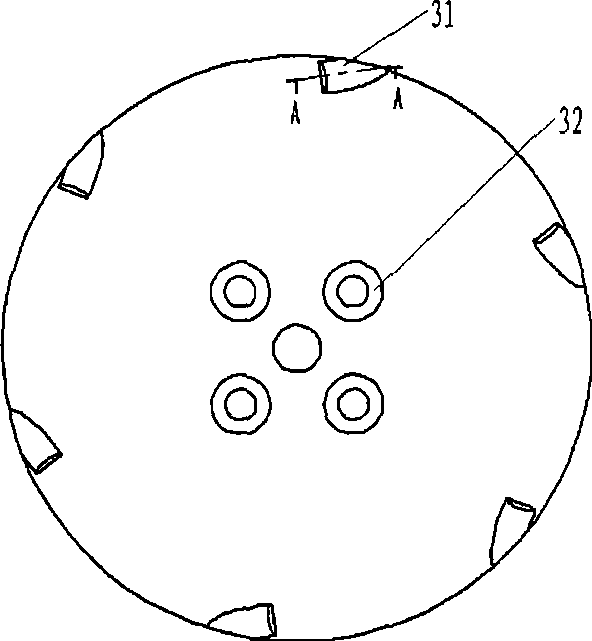

Fuel cell stack flow field plate capable of supporting high-current density discharging

ActiveCN108172857ASmall shape and position errorImprove consistencyCollectors/separatorsFluid fieldEngineering

The invention relates to a fuel cell stack flow field plate capable of supporting high-current density discharging. The fuel cell stack flow field plate comprises a negative flow field plate and a negative flow field plate, wherein back surfaces of the negative flow field plate and the negative flow field plate are oppositely connected, a water ripple-type air flow field passage and a water ripple-type hydrogen flow field passage are respectively processed in front surfaces of the negative flow field plate and the positive flow field plate, a cooling water flow field passage is processed between the back surfaces of the negative flow field plate and the positive flow field plate, a pair of common air passages, a pair of common hydrogen passages and a pair of common water passages are arranged on the negative flow field plate and the positive flow field plate and communicate with each other, and an air inlet / outlet, a hydrogen inlet / outlet and a cooling water inlet / outlet of an inlet port and an outlet port which are connected with the air flow field passage, the hydrogen flow field passage and the cooling water flow field passage are respectively formed. The flow field plate employs more optical runner design, more excellent material formula and more optimal assembly mode, so that the purposes of large-current discharging, temperature uniformity, low-temperature rapid startingsupporting, loading and rapid response to load change are achieved.

Owner:TONGJI UNIV

High efficiency diesel pile hammer and gas piston structure thereof

The invention discloses a high-efficiency diesel pile hammer which comprises a piston, a cylinder hammer and a guide rod. The guide rod is arranged fixedly on the piston body, and the cylinder hammer can move to and fro along the guide rod. The piston is equipped with a gas nozzle. The gas nozzle is a pressure gas nozzle equipped with a single-way valve. The working end surface of the piston is equipped with at least one gas nozzle. In addition, an oil nozzle is also arranged on the working end surface. The diesel pile hammer and the piston structure of the hammer not only ensures that the reliable construction work can be conducted with the pile hammer in case of the soft soil stratum and other unfavorable soil conditions, but also can discharge the combustion waste gas in a gas cylinder chamber smoothly. Moreover, the pile hammer is provided with the strong blasting capability and the favorable heat radiation conditions. Thus, the piling efficiency is greatly promoted, and the invention is widely applicable for the diesel pile hammers of different specifications and types.

Owner:江苏东达集团股份公司

Connecting and grouting sleeve for assembled prefabricated member steel bars and construction method thereof

InactiveCN103556786AResolve connectionFirmly connectedBuilding reinforcementsBuilding material handlingRubber ringRebar

The invention discloses a connecting and grouting sleeve for assembled prefabricated member steel bars and a construction method thereof, aims at solving the connection problem of the assembled prefabricated member steel bars and has the advantages of simplicity in construction, low cost, high strength and reliability in connection. The connecting and grouting sleeve comprises a sleeve body, sealing rings and a position-limiting bolt, wherein a grouting hole and an exhaust hole position-limiting bolt are arranged on the sleeve body, a block-like bulge is arranged on the inner wall, and the sealing rings are arranged at the two ends in the sleeve body. When prefabricated members are assembled and constructed, the position-limiting bolt is screwed in, two reserved steel bars of the assembled prefabricated members are inserted into limited positions from the two ends of the sleeve body, the elastic sealing rubber rings are squeezed in, cement-based grout is grouted from the grouting hole, and the two reserved steel bars are connected through the sleeve to form a whole. The connecting and grouting sleeve disclosed by the invention can be used for connecting the various assembled prefabricated member steel bars.

Owner:SHENYANG JIANZHU UNIVERSITY

Pneumatic type bubble-prevention assembling clamp

ActiveCN104088875AHigh degree of automationLow costWork holdersFastening meansSilica gelMechanical engineering

The invention relates to the technical field of clamps, in particular to a pneumatic type bubble-prevention assembling clamp. The pneumatic type bubble-prevention assembling clamp comprises an upper die plate fixing plate, an upper die plate overturn structure, an upper die plate, a lower die plate and a lower die fixing plate. The upper die plate is movably connected with the upper die plate fixing plate through a rotating shaft, the upper die plate comprises a square-ring-shaped protruding upper die silica gel insert, an upper die plate vacuum absorption locating structure and an upper die gum locating column located in the square-ring-shaped concave part of the upper die silica gel insert, the upper die silica gel insert is provided with one wide edge and three narrow edges, the wide edge cross section in the direction from the wide edge to the corresponding narrow edge is an inclined plane, the lower plate comprises a product locating boss, a lower die plate vacuum absorption locating structure and an upper die gum locating column interworking hole corresponding to the upper die gum locating column, and the lower die plate is fixedly connected to the lower die fixing plate and is connected to an air pressure gauge at the same time. According to the pneumatic type bubble-prevention assembling clamp, accurate bonding and compression of products and gum can be achieved at the same time, gas between the products and the gum can be discharged smoothly in the mode of simulating rolling bonding, and no bubble is generated.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

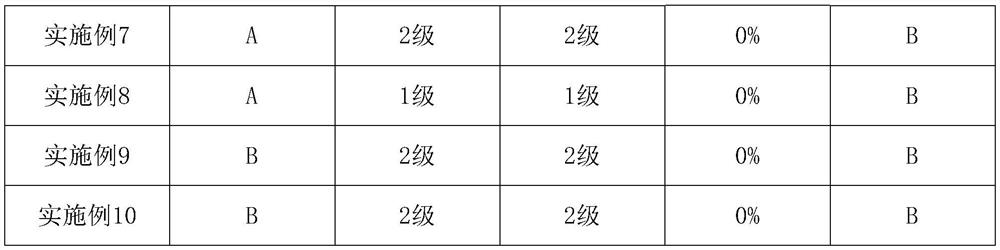

High-cold region solar cell panel with snow melting antifreeze function

InactiveCN105591602ADisadvantages affecting normal power generationSlide down easyPhotovoltaicsPhotovoltaic energy generationGlass coverControl system

The invention relates to a high-cold region solar cell panel with a snow melting antifreeze function. The high-cold region solar cell panel comprises a rectangular solar cell panel assembly and a frame, wherein the solar cell panel assembly is formed by adhering a glass base plate, a rear PVB plate, a solar cell sheet, a front PVB plate and a glass cover plate in a stacked mode from the back to the front, a layer of electric heating wires which obtain signals from and is controlled by a control system are printed on the back surface of the glass cover plate in a network mode, the frame is formed by enclosing an upper frame-edge section bar, a lower frame-edge section bar, a left frame-edge section bar and a right frame-edge section bar, the upper frame-edge section bar and the lower frame-edge section bar are symmetrically arranged, their longitudinal cross sections are T-shaped, the left frame-edge section bar and the right frame-edge section bar are symmetrically arranged, their transverse cross sections are approximately E-shaped, and the solar cell panel assembly is clamped and fixed among the upper frame-edge section bar, the lower frame-edge section bar, the left frame-edge section bar and the right frame-edge section bar. According to the invention, the structure is simple and reasonable, the operation is convenient, the implementation is easy, and the disadvantage of affected power generation due to incapability of timely removal of falling snow on a conventional solar cell panel in a high-cold region can be effectively solved.

Owner:余新洛

Metal reduction method

The invention discloses a metal reduction method, comprising the following steps: manufacturing a mixed material containing metal to a group or a block; and then heating to a predetermined temperature to carry out reduction reaction. The mixed material containing metal comprises a mineral containing metal and a reducing agent; and the particle diameter of the reducing agent is above 1mm. The metal reduction method has the advantages of fast reaction speed, low reaction temperature and low energy consumption.

Owner:QIANQIU ENERGY SHANGHAI

Heat pipe

ActiveCN104422320AImprovement of the problem of reduced heat transfer capacityImprove blockageIndirect heat exchangersEvaporationEngineering

The invention provides a heat pipe. The heat pipe comprises a pipe casing, a liquid absorbing core and an elastic layer; the pipe casing forms into a sealing chamber and comprises an evaporation end and a condensing end; the liquid absorbing core is tightly adhered to the internal surface of the pipe casing; at least a gap is formed between the external side of the liquid absorbing core portion which is arranged inside the evaporation end and the pipe casing; the elastic layer tightly coats the external side of the liquid absorbing core to block condensing liquid to penetrate the gap; the liquid absorbing core is driven to recover when the condensing liquid is condensed.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

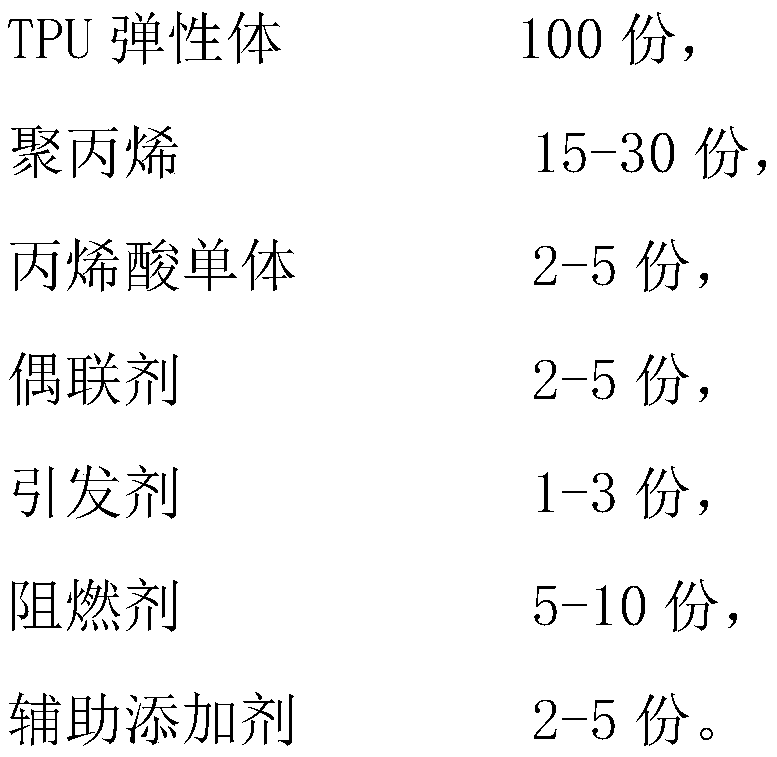

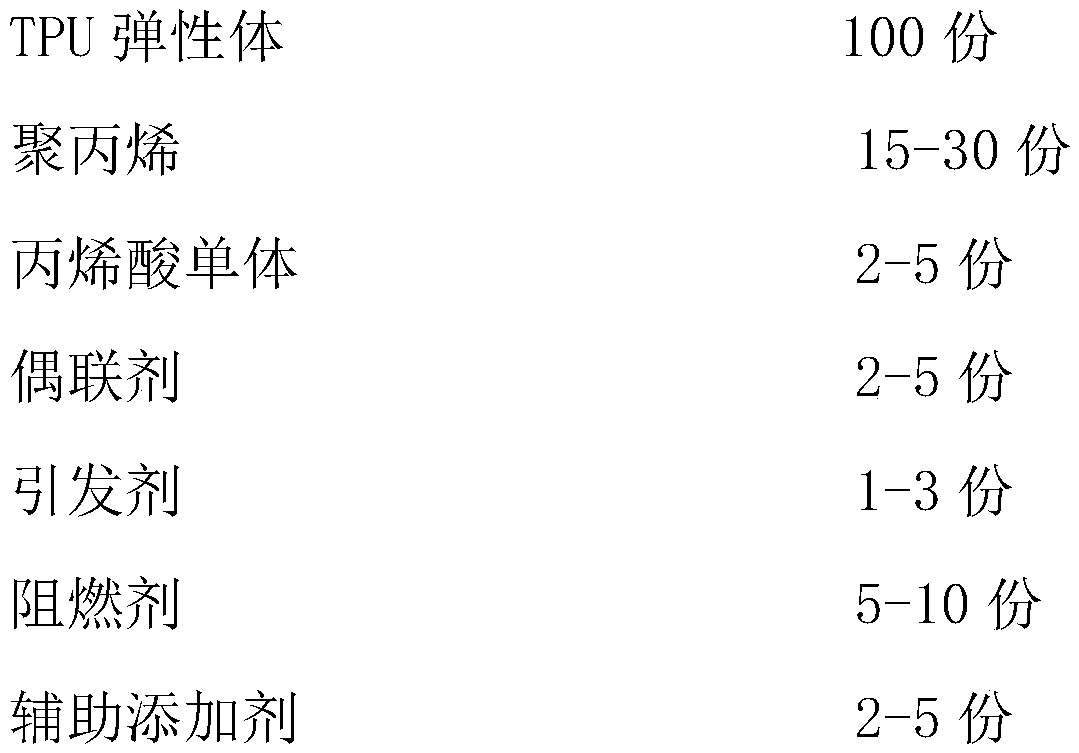

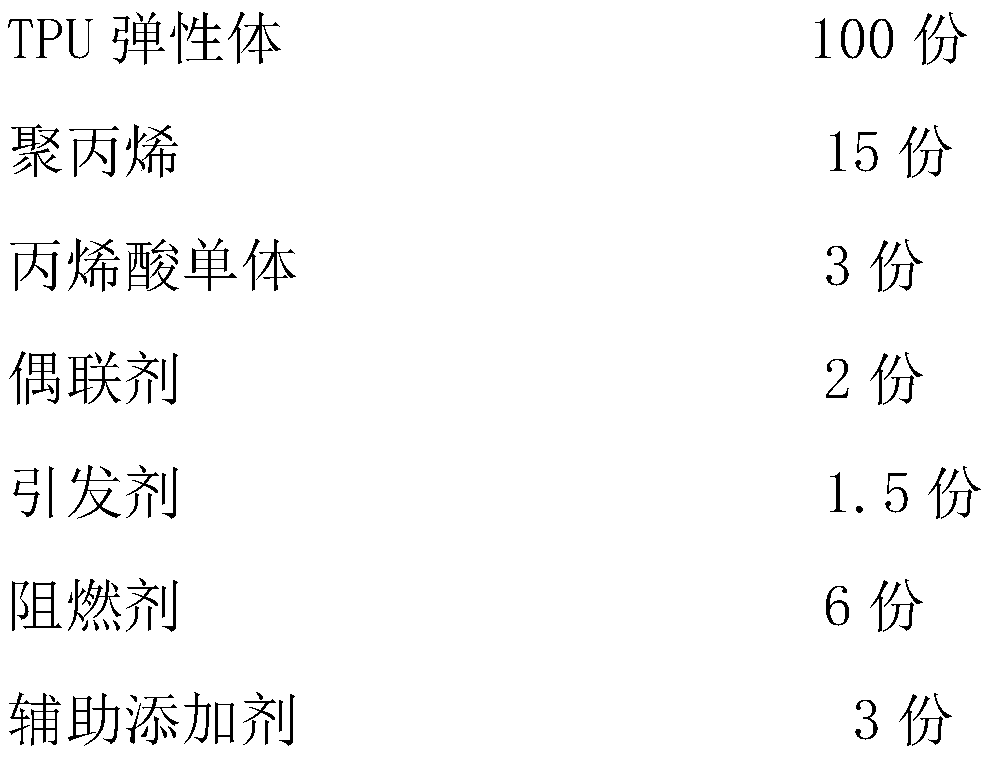

Thermoplastic polyurethane optical film and coating method thereof

InactiveCN109735240ARigid and flexible performanceNo impact resistanceOrganic non-macromolecular adhesiveFilm/foil adhesives without carriersRubber materialMass ratio

The invention provides a thermoplastic polyurethane optical film. The thermoplastic polyurethane optical film is obtained by mixing thermoplastic polyurethane (TPU) and polypropylene (PP) according toa mass ratio to obtain a basic material and preparing from acrylic monomers, coupling agents, initiators, fire retardants and auxiliary additives. The thermoplastic polyurethane optical film has hightransparency, excellent mechanical properties, high weather and chemical resistance, high-and-low temperature resistance and good bonding properties, and can be melted, flowable, transparent, and extremely-low initially viscous under a certain temperature, thereby being capable of serving as an optical coating rubber material for touch display screens; touch display screen components bonded by the thermoplastic polyurethane optical film have the advantages of simplicity and convenience in process, convenience in bubble elimination, easiness in rework, high production efficiency, low cost andthe like, and touch display screen components coated with the thermoplastic polyurethane optical film have the advantages of good optical performance, excellent mechanical property, high chemical andweather resistance and good environmental performance, so that the thermoplastic polyurethane optical film is an excellent optical rubber material.

Owner:SHENZHEN GAOREN ELECTRONICS NEW MATERIAL

Superhard material cutting tool and preparation method thereof

ActiveCN101502926AGuaranteed smoothnessExclude smoothlySoldering apparatusOther manufacturing equipments/toolsSuperhard materialTool bit

The invention relates to a superhard material cutting tool and a preparation method thereof, which belongs to the technical field of superhard material. The superhard material cutting tool comprises a steel matrix and a cutting tool bit. The cutting tool bit consists of a polycrystalline diamond compact (1) and a diamond tool bit (2); 1 to 12 inclined cylindrical tanks used for welding the diamond compact are distributed on the outer circle surface of the steel matrix, and the center line of the inclined cylindrical tank forms a cutting angle with the cutting face; the diamond tool bit is welded on the surface of the steel matrix. The polycrystalline diamond compact is combined by PCD and cemented carbide matrix and is sintered from the mixture of diamond and the metal powder after being compacted; the structure thereof is in the shape of cylinder, ladder or squareness; the fringe area of the clad compact is the cutting blade. The superhard material cutting tool solves the materials hard to be processed in the cutting field, and ensures the surface of the machined part free of burr, nick, spray and chatter mark; the cutting and grinding combination not only improves the cutting speed, but also ensures the cutting quality.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

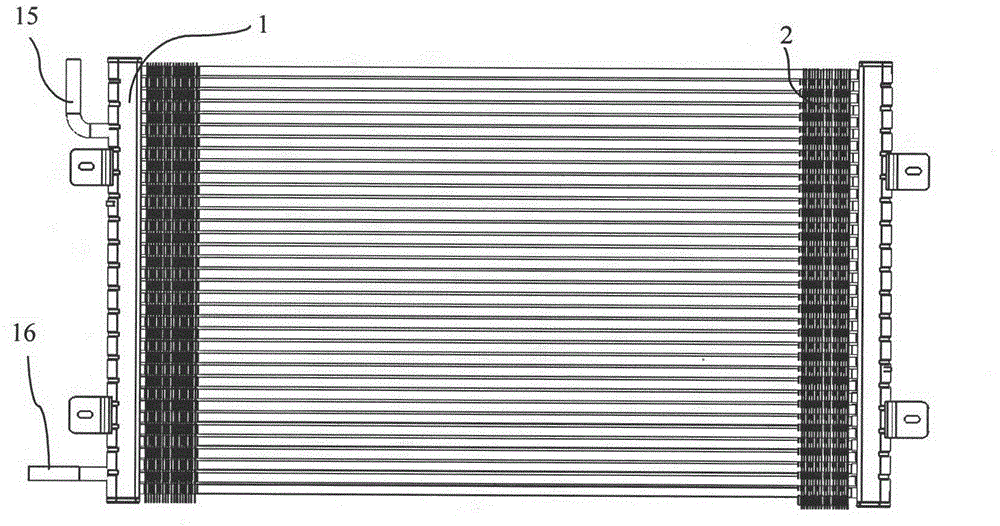

All aluminum pipe finned parallel flow heat exchanger and production method thereof

InactiveCN102798253AImprove heat transfer efficiencyEasy to realize industrial productionEvaporators/condensersWelding/cutting media/materialsSurface layerEngineering

The invention discloses an all aluminum pipe finned parallel flow heat exchanger comprising a collecting pipe, a fin and a cold refrigerant pipe, wherein at least the contact part of the collecting pipe, the fin or the cold refrigerant pipe is made of composite aluminum; and the melting point temperature of a composite aluminum surface layer is lower than that of a base layer. The cold refrigerant pipe is provided with an inner fin; the fin with a through hole edgefold is sleeved on the cold refrigerant pipe; two ends of the cold refrigerant pipe are inserted into a flanging hole of the collecting pipe; and the internal space of the cold refrigerant pipe is communicated with the internal space of the collecting pipe. After the collecting pipe, the fin and the cold refrigerant pipe are assembled, the overall all aluminum pipe finned parallel flow heat exchanger is heated to the temperature between the melting point temperature of the composite aluminum surface layer and the melting point temperature of the base layer; the surface layer is smelted and plays the role of brazing solders; and the all aluminum pipe finned parallel flow heat exchanger and accessories thereof are welded into a whole. The industrial production of the all aluminum pipe finned parallel flow heat exchanger can be realized, the welding quality is consistent, the welding is easy to control, the automatic assembly of the heat exchanger can be realized, and the consistency of long-term usage performance of the heat exchanger is kept.

Owner:王康平 +2

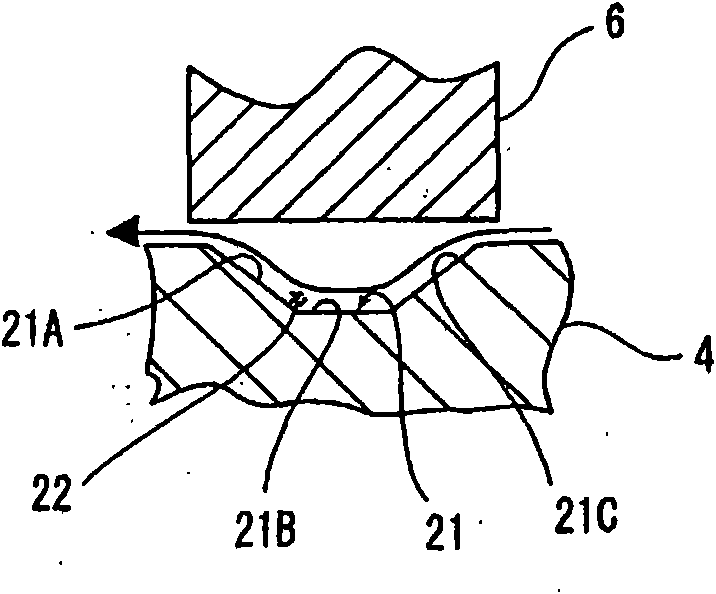

Vane type vacuum pump

InactiveCN101657644AExclude smoothlyAvoid dischargeRotary piston pumpsRotary piston liquid enginesForeign matterSquare cross section

A vane type vacuum pump (1) is provided in the vicinity of a suction passage (11) for sucking air into a pump chamber (2), and has an escape groove (21) for communicating the space A on the front sideand the space B on the rear side in the rotational direction of a vane (6) during reverse rotation thereof to allow lubricant to escape from the space A on the front side to the space B on the rear side. The escape groove (21) is provided in a side plate (4), and the wall surface (21A) of the escape groove becoming the rear side in the rotational direction of the vane (6) during reverse rotationthereof is a slope enlarged on the opening side as compared with the bottom surface (21B) of the escape groove. Preferably, the other wall surface (21C) of the escape groove is also a slope enlarged on the opening side as compared with the bottom surface. As compared with a case where the escape groove (21) has a square cross-section, foreign matter and abrasion powder (22) are allowed to escape from the escape groove (21) smoothly.

Owner:TAIHO INDUSTRIES CO LTD

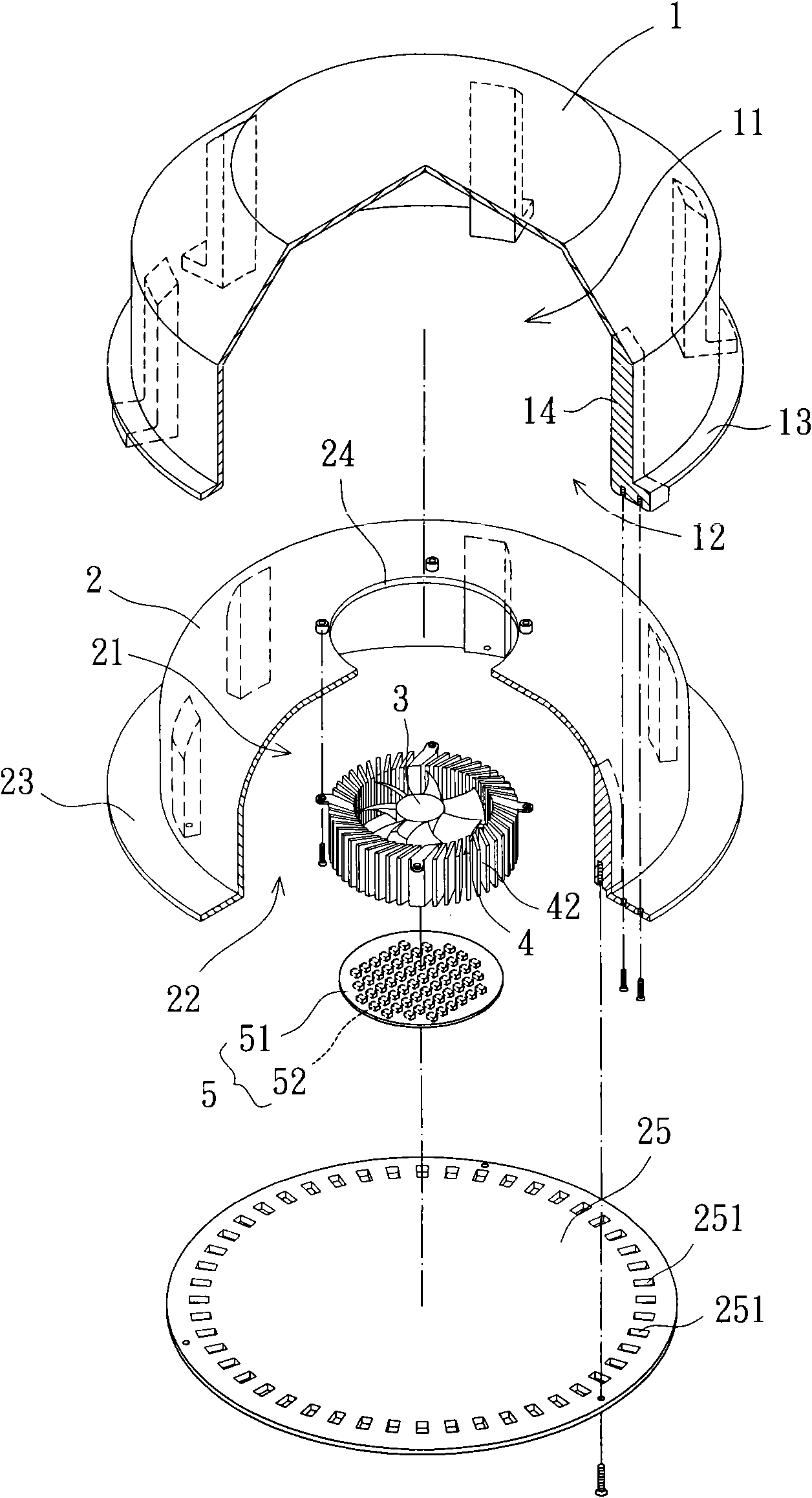

Lamp bulb with heat dissipation function

InactiveCN103343903AExclude smoothlyReduce the temperaturePoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat spreader

The invention discloses a lamp bulb with a heat dissipation function. The lamp bulb comprises a lamp holder, a light emitting assembly and a heat sink, wherein the lamp holder is provided with air exhaust holes. The heat sink comprises a body and cooling fins, a heat dissipation channel is formed between every two adjacent cooling fins, and at least one air exhaust hole is formed inside each heat dissipation channel. The lamp bulb has the relatively good heat dissipation effect and long service life.

Owner:SUZHOU RENES OPTOELECTRONICS TECH CO LTD

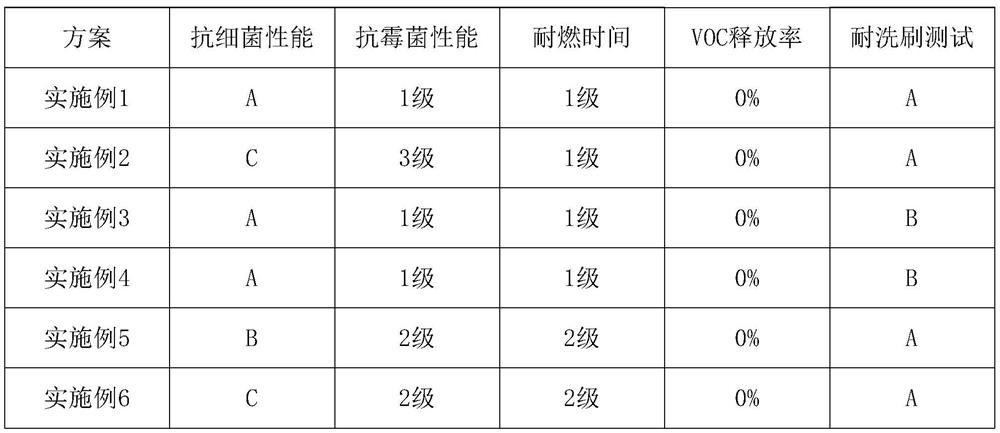

Antibacterial, mildew-proof and flame-retardant silicate interior wall coating and preparation method thereof

PendingCN113004733AImprove stabilityExtended service lifeFireproof paintsAntifouling/underwater paintsCelluloseHydroxyethyl cellulose

The invention relates to the field of building coatings, in particular to an antibacterial, mildew-proof and flame-retardant silicate interior wall coating and a preparation method thereof. The antibacterial, mildew-proof and flame-retardant silicate interior wall coating is prepared from, by mass, 30-60 parts of slurry, 45-55 parts of filler, 20-65 parts of diluent A, 10-25 parts of diluent B and 1-3 parts of auxiliaries; the slurry is prepared from the following components in parts by mass: 2 to 6 parts of hydroxyethyl cellulose, 0.3 to 1 part of a wetting agent, 0.1 to 1 part of a dispersing agent, 0.1 to 0.8 part of a de-foaming agent and 0.1 to 0.5 part of other auxiliary agents; the filler comprises the following components in parts by mass: 10-30 parts of carrier nano silver, 5-15 parts of titanium dioxide, 5-10 parts of kaolin, 10-15 parts of talcum powder and 10-30 parts of heavy calcium carbonate; the auxiliaries comprise the following components in parts by mass: 2-10 parts of propylene glycol, 0.1-3 parts of a defoaming agent, 0.1-1 part of a rheological modification auxiliary and 0.1-0.6 part of a polyurethane thickening agent. The antibacterial, mildew-proof and flame-retardant silicate interior wall coating disclosed by the invention is excellent in antibacterial, mildew-proof and flame-retardant properties, green, environment-friendly and long in service life.

Owner:纽沃得复合建材(上海)有限公司

Container trailer being convenient to pack and transport

InactiveCN101881048AEasy to disassemble and installTake advantage ofBuilding constructionsEngineeringWall plate

The invention relates to a container trailer being convenient to pack and transport, which comprises a chassis, a top tray, four upright posts which are respectively arranged on four corners and detachably join the chassis and the top tray, and wall boards which are arranged between the chassis and the top tray to form four side walls of the container trailer; four corners of both the top tray and the chassis are provided with a connection column which is connected with a corresponding upright post, the upper end of the upright post is provided with a vertical connection part which is closely propped against one edge of the connection column and a horizontal carrying part which is vertical to the connection part and carries the connection column of the top tray, the lower end of the upright post is provided with a vertical connection part which is closely propped against one edge of the connection column of the chassis and a horizontal joining part which is vertical to the connection part and is supported by a top surface of the connection column of the chassis, and the connection columns of the chassis and the top tray are respectively connected with the connection parts of the upright posts through a plurality of fixed pieces.

Owner:SHENZHEN CHIXIAO BUILDING TECH

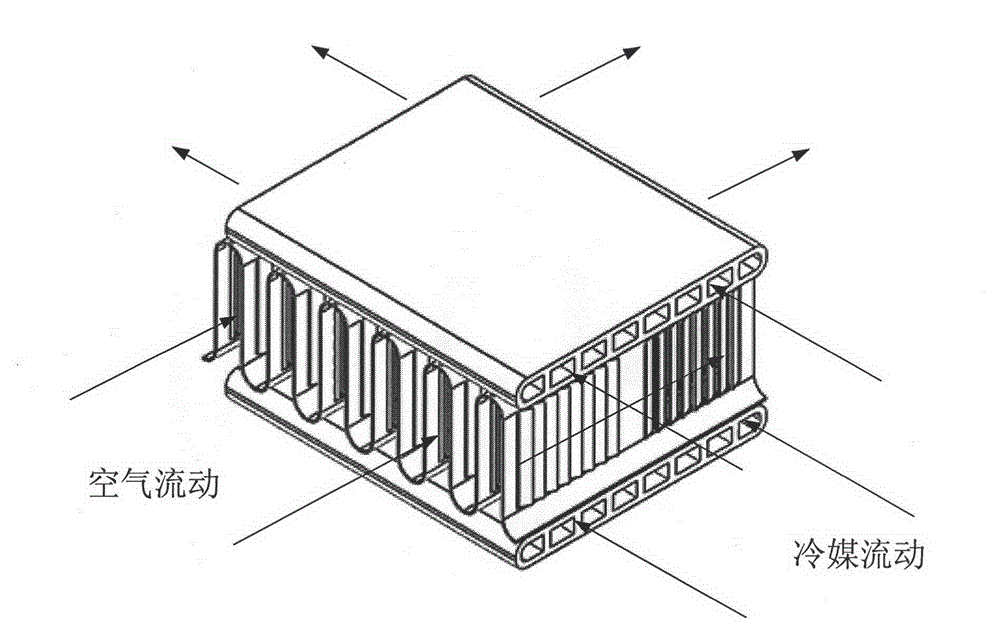

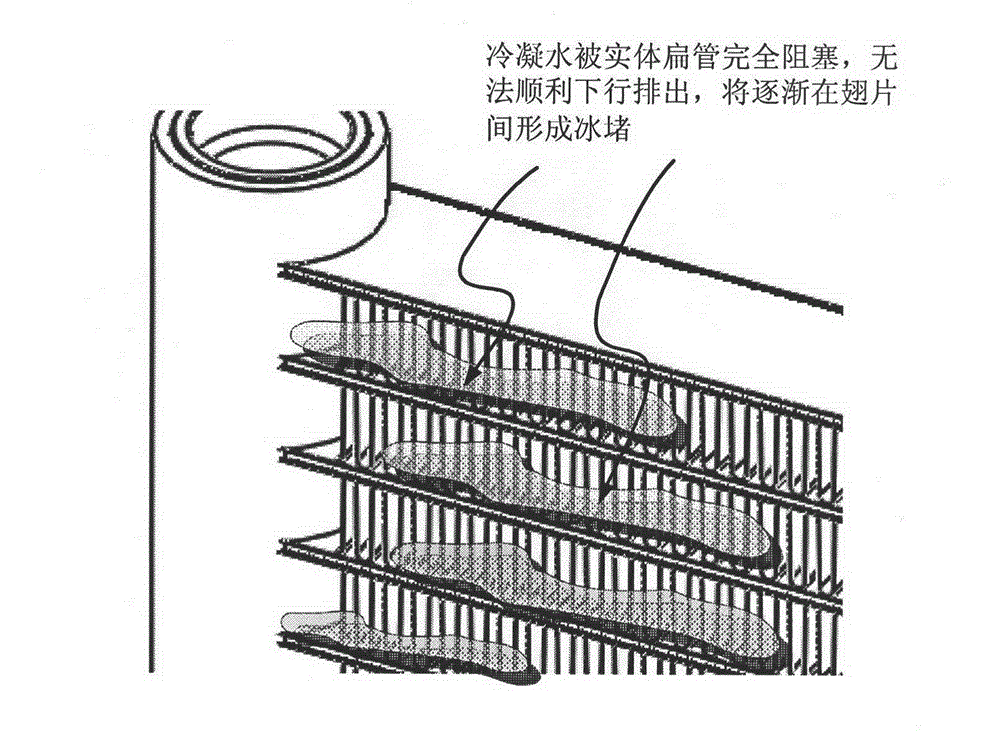

Micro channel heat exchanger for heat pump air conditioner

InactiveCN105135753AReduce wind resistanceReasonable product structureEvaporators/condensersHeat exchanger casingsRefrigerantCondensed water

The invention discloses a micro channel heat exchanger for a heat pump air conditioner. The micro channel heat exchanger comprises a hollow first collecting tube and a hollow second collecting tube which are vertically arranged, a plurality of flat tubes which are horizontally spaced between the first collecting tube and the second collecting tube and communicate with the first collecting tube and the second collecting tube, and end covers which are arranged at the two ends of each of the first collecting tube and the second collecting tube for sealing the first collecting tube and the second collecting tube, wherein the upper end of the first collecting tube communicates with an inlet tube; the lower end of the first collecting tube communicates with an outlet tube; a micro channel for allowing a refrigerant to flow is arranged in the flat tubes; and a flow-splitting spacer for blocking the refrigerant is arranged in the first collecting tube and the second collecting tube. The micro channel heat exchanger for the heat pump air conditioner is small in air resistance, and capable of smoothly discharging condensed water formed on the surface of the heat exchanger and improving the heat exchange efficiency; and the heat exchanger product is reasonable in structure, and is simple and feasible to process.

Owner:浙江康盛热交换器有限公司

Light fitting

InactiveCN102052613AImprove airflow and heat dissipationExtended service lifePoint-like light sourceLighting heating/cooling arrangementsAirflowEngineering

The invention discloses a light fitting which comprises an outer cover, an inner shell seat, a fan, a radiator and a light-emitting element, wherein the outer cover is provided with a first accommodating chamber and a first opening; the inner shell seat is provided with a second accommodating chamber and a second opening, and is additionally provided with a through hole; the through hole is communicated with the first accommodating chamber and the second accommodating chamber; the inner shell seat is arranged in the first accommodating chamber; the second opening and the first opening are opposite; an interval is formed between the outer cover and the inner shell seat so as to form an air flow passage; the fan is adjacent to the through hole; the fan is provided with two air flow circulation sides; the two air flow circulation sides are used for inhaling and blowing out air flow, so that the air flow passes the through hole; and one side of the bottom plate of the radiator faces the fan, and the other side of the bottom plate of the radiator is provided with the light-emitting element. According to the invention, preferable air flow circulation and heat dissipation efficiency can be provided so as to avoid the influences on the service life and luminous efficacy of the light fitting.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com