Micro channel heat exchanger for heat pump air conditioner

A technology of micro-channel heat exchanger and heat pump air conditioner, which is applied in the direction of heat exchanger shell, heat exchange equipment, evaporator/condenser, etc., can solve problems that affect product function, reduce heat exchange efficiency of heat exchanger, and produce quality problems and other problems, to achieve the effect of reasonable product structure, simple and feasible processing, and small wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

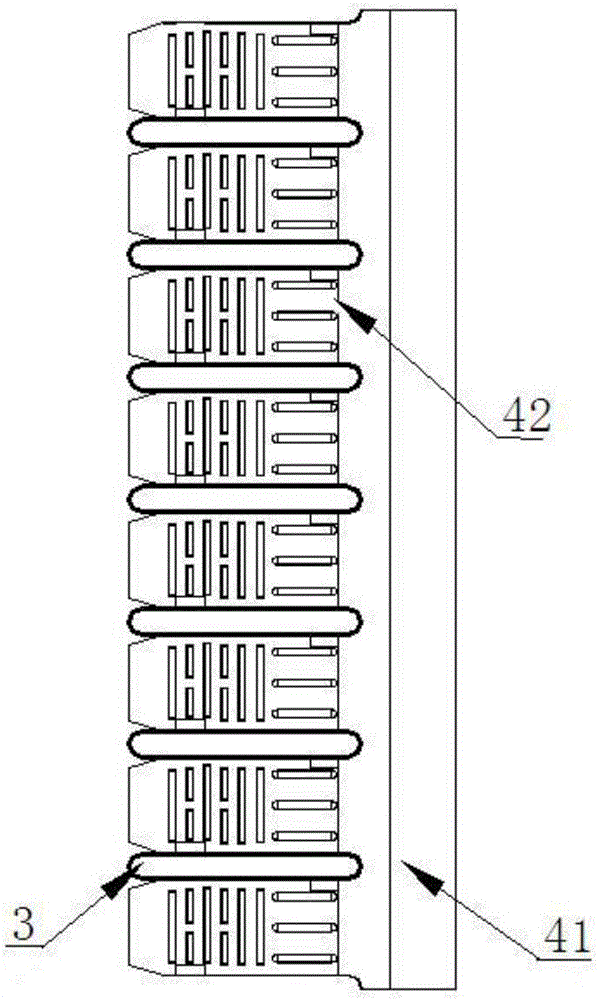

[0016] Such as figure 1 and figure 2 As shown, a microchannel heat exchanger for a heat pump air conditioner includes a vertically arranged hollow first header and a second header, and is horizontally spaced between the first header and the second header And several flat tubes 3 communicated with the first header and the second header, as well as being arranged at both ends of the first header and the second header and sealing the first header and the second header The end cover 11 of the first collecting pipe is connected with the inlet pipe 6 at the upper end of the first collecting pipe, and the outlet pipe 9 is connected with the lower end of the first collecting pipe, and also includes a plurality of fins 4 at intervals in parallel, and each fin 4 is arranged perpendicular to the flat pipe 3, Each fin 4 includes a plurality of heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com