Pneumatic type bubble-prevention assembling clamp

A technology for assembling fixtures and preventing air bubbles, which is applied in the direction of manufacturing tools, workpiece clamping devices, connecting components, etc., can solve the problems of unavoidable internal air bubbles, achieve the effects of preventing air bubbles, saving costs, and ensuring adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

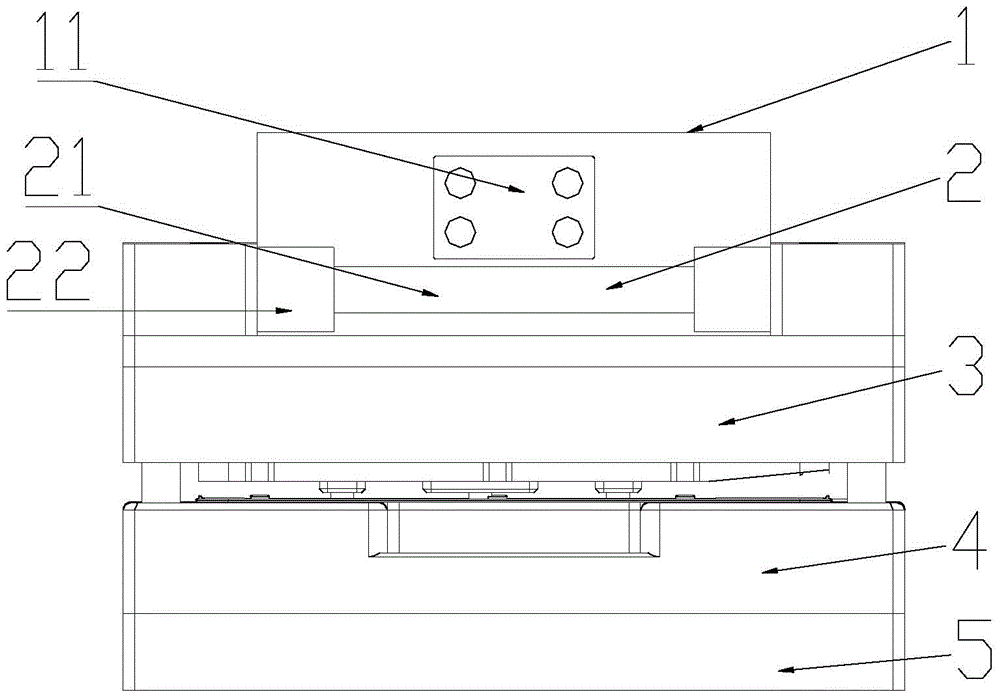

[0020] A pneumatic anti-bubble assembling fixture, comprising: an upper template fixing plate 1, an upper template turning structure 2, an upper template 3, a lower template 4, and a lower template fixing plate 5; A limit block 11 is set in the connection direction of the structure 2; the upper template turning structure 2 includes a rotating shaft 21 and pneumatic rotating heads 22 at both ends thereof, and the rotating shaft 21 is located below the limiting block 11; the pneumatic rotating head 22 is fixed to the upper template The plate 1 is fixedly connected; the upper template 3 is movably connected to the upper template fixing plate 1 through the rotating shaft 21; 32 and the upper mold back glue positioning post 33 located in the upper mold silicone insert 31 in the back-shaped depression; the upper mold silicone insert 31 has a wide side 311 and three narrow sides 312, the wide side 311 is corresponding to the narrow side 311. The cross section of the broad side in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com