Apparatus for electrochemical machining of mask on cylindrical surface

A cylindrical surface and mask technology, applied in the direction of electrochemical processing equipment, the supply of processing working medium, metal processing equipment, etc., can solve the problem that the cathode device is not suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Attached below Figure 1 to 4 The implementation of the patent of the present invention will be further described.

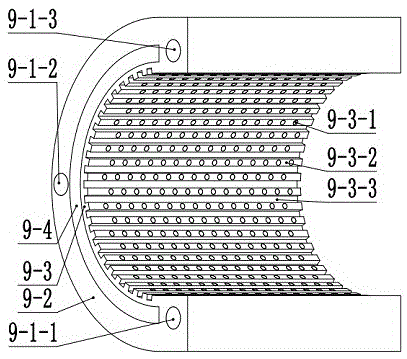

[0020] Such as Figure 1 to 4 As shown, a device for electrochemical machining of a cylindrical mask includes a liquid distribution 9, a front sealing end cover 7 and a rear sealing end cover 3. They are all made of aluminum alloy. The liquid distribution 9 includes an outer structure layer 9-2, a semi-circular arc-shaped structure layer 9-3, and an axially penetrating guide groove 9-4 placed between the outer structure layer 9-2 and the semi-circular arc-shaped structure layer 9-3. The groove depth of the diversion groove 9-4 is 1mm and the groove width is 0.65mm. The arc surface of the semi-circular arc structure layer 9-3 is provided with axially staggered and evenly distributed outlet grooves 9-3-3 and bosses 9-3-2. The arc radius of the arc surface of the semi-arc structure layer 9-3 is 20 mm. The central angle between the two adjacent outlet groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com