Method for efficiently removing cyanofluoride from electrolytic aluminum overhaul slag

A technology of overhaul slag and electrolytic aluminum, which is applied in the field of electrolytic aluminum overhaul slag to remove cyanide and fluoride, can solve the problem that most of cyanide and fluoride in overhaul slag cannot be leached, cannot be removed, and can not be achieved. Harmful and other issues, to achieve the effect of improving the utilization rate of ozone, shortening the processing time, and improving the grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

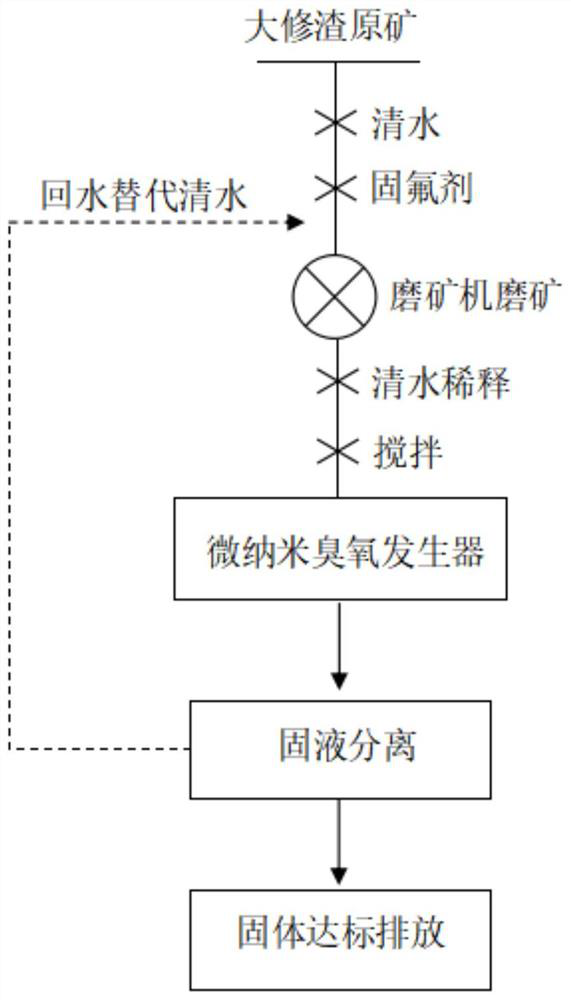

[0032] In an embodiment of the present invention, a method for removing cyanofluoride from overhaul slag is provided, which specifically includes the following steps:

[0033] S1. Weigh 20g of fluorine-fixing agent, 600g of overhaul slag raw ore (toxicity analysis of leachate: fluoride ion content 6370mg / L, hydrogen cyanide ion content 33mg / L) and 360g of clean water and put them into the ball mill together. Based on the wet grinding leaching process, The ball mill is used for wet grinding and fluorine-fixing treatment of overhaul slag to obtain overhaul slag slurry;

[0034] Specifically: the fluorine-fixing agent uses powdered quicklime with a calcium oxide purity of more than 90% to play a grinding-aiding and fluorine-fixing effect in the above-mentioned wet grinding; when the fineness of the overhaul slag is -0.075mm, it accounts for 90-100% Grinding is completed at this time, and the overhaul slag slurry is discharged.

[0035] S2. Dilute the overhaul slag slurry in step...

Embodiment 2

[0040] In an embodiment of the present invention, a method for removing cyanofluoride from overhaul slag is provided, which specifically includes the following steps:

[0041] S1. Weigh 20g of fluorine-fixing agent, 600g of overhaul slag raw ore (toxicity analysis of leachate: fluoride ion content 6370mg / L, hydrogen cyanide ion content 33mg / L) and 360g of clean water and put them into the ball mill together. Based on the wet grinding leaching process, The ball mill is used for wet grinding and fluorine-fixing treatment of overhaul slag to obtain overhaul slag slurry;

[0042] Specifically: the fluorine-fixing agent uses powdered calcium chloride with a calcium oxide purity of more than 90% to play a grinding-aiding and synergistic effect of fluorine-fixing in the above-mentioned wet grinding; Grinding is completed at 100%, and the overhaul slag slurry is discharged.

[0043]S2. Dilute the overhaul slag slurry in step S1 to 15% with clear water, pour it into the advanced oxida...

Embodiment 3

[0048] In an embodiment of the present invention, a method for removing cyanofluoride from overhaul slag is provided, which specifically includes the following steps:

[0049] S1. Weigh 40g of fluorine-fixing agent, 600g of overhaul slag raw ore (toxicity analysis of leachate: fluoride ion content 6370mg / L, hydrogen cyanide ion content 33mg / L) and 360g of clean water and put them into the ball mill together. Based on the wet grinding leaching process, The ball mill is used for wet grinding and fluorine-fixing treatment of overhaul slag to obtain overhaul slag slurry;

[0050] Specifically: the fluorine-fixing agent uses powdered quicklime with a calcium oxide purity of more than 90% to play a grinding-aiding and fluorine-fixing effect in the above-mentioned wet grinding; when the fineness of the overhaul slag is -0.075mm, it accounts for 90-100% The ore grinding is completed at this time, and the overhaul slag slurry is discharged.

[0051] S2. Dilute the overhaul slag slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com