Valve rod

A technology of valve stem and rotating rod, which is applied in the direction of lifting valve, valve device, engine components, etc., and can solve the problem of sealing plug or sealing port wear, sealing plug head circular runout, difficulty in ensuring coaxiality, and difficulty in matching and sealing, etc. problems, to achieve the requirements of reducing hardness, improving service life, and eliminating shape and position errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

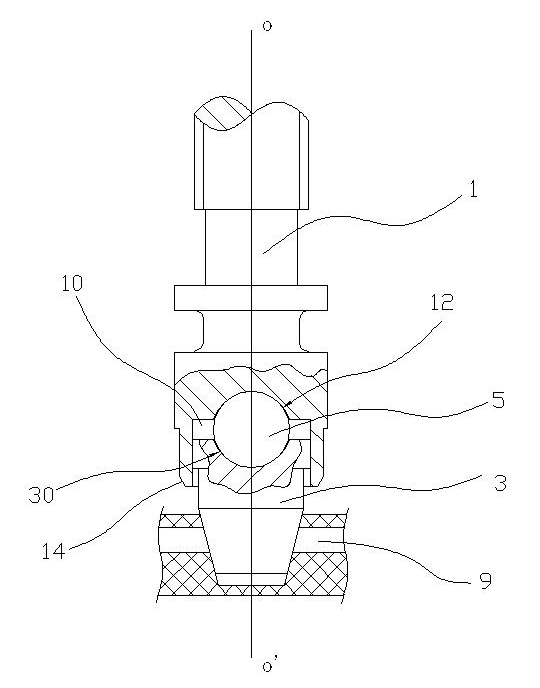

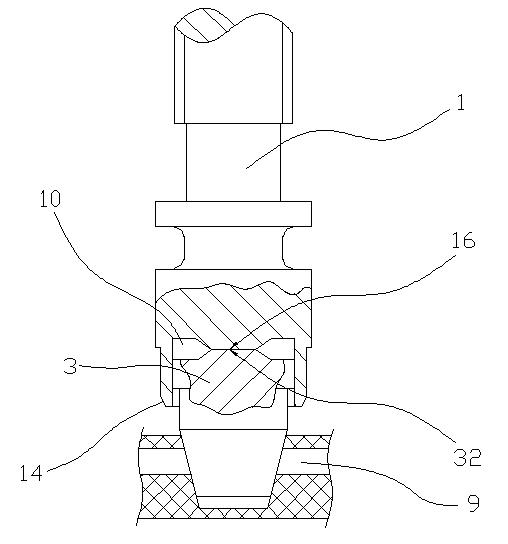

[0024] Embodiment 2. Compared with Embodiment 1, the only difference is that the top wall of the first concave hole 10 is in direct contact with the upper end surface of the sealing plug 3 . The upper end surface of the sealing plug 3 is a narrowing surface 32, so that when the top wall of the first concave hole 10 is in contact with the upper end surface of the sealing plug 3, the friction force is small, so that when the rotating rod 1 rotates, the sealing Plug 3 does not rotate together. It can be understood that a narrowing surface 16 can also be provided on the top wall of the first concave hole 10, as long as the top wall of the first concave hole 10 is in contact with the upper end surface of the sealing plug 3, the frictional force is small. Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com