Particle composition for grinding

A composition and particle technology, applied in abrasives, other chemical processes, metal processing equipment, etc., can solve the problems of slow processing time, difficult control of processing accuracy, high consumption and low efficiency, etc., to improve grinding efficiency, improve firmness, Solve the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A particle composition for grinding, the components of which include in parts by weight: diamond (10 μm, concentration 1.8 carats / cm 3 ) 22g, 53g of aluminum oxide, 19g of zirconia, 4g of silicon dioxide, 1.5g of calcium stearate, 0.8g of KH550, 19g of epoxy resin powder and 5g of glass fiber.

[0020] Method of use: Use a circular plate (specification Φ578*Φ180mm) combined with PC and PVC as a carrier, uniformly bond or weld the particle composition on the surface of the carrier to form a grinding disc, and then fix the grinding disc on the double-sided adhesive On the surface grinder, the grinding disc is driven by the double-side grinder to grind the surface of the workpiece to be processed. During the grinding process, the recyclable cleaning fluid is used to rinse the surface of the workpiece to be processed.

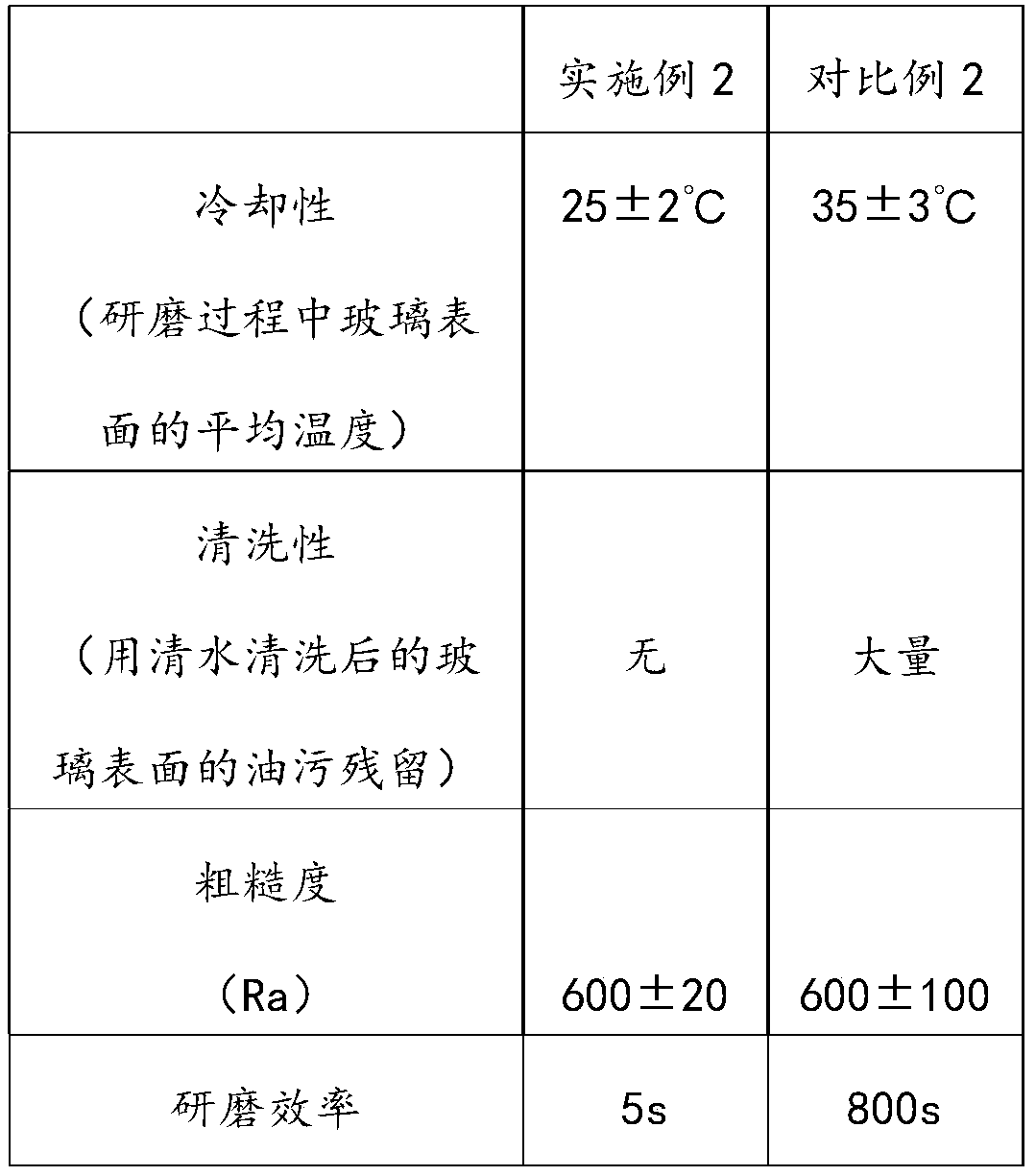

Embodiment 2

[0022] A particle composition for grinding, the components of which include in parts by weight: diamond (50 μm, concentration 2.5 carats / cm 3 ) 30g, aluminum oxide 28g, zirconia 17.5g, silicon dioxide 8.5g, calcium stearate 4g, KH560 1.6g, phenolic resin powder 24g and glass fiber 8g.

[0023] Method of use: Use a circular plate (specification Φ578*Φ180mm) combined with PC and PVC as a carrier, uniformly bond or weld the particle composition on the surface of the carrier to form a grinding disc, and then fix the grinding disc on the double-sided adhesive On the surface grinder, the grinding disc is driven by the double-side grinder to grind the surface of the workpiece to be processed. During the grinding process, the recyclable cleaning fluid is used to rinse the surface of the workpiece to be processed.

Embodiment 3

[0025] A particle composition for grinding, the components of which include in parts by weight: diamond (100 μm, concentration 3.2 carats / cm 3 ) 40g, aluminum oxide 43g, zirconia 15g, silicon dioxide 3g, calcium stearate 3g, KH570 0.6g, epoxy modified phenolic resin powder 16g and glass fiber 6g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com