Composite admixture for improving durability of common concrete by improving grading

A technology of ordinary concrete and composite admixtures, which is applied in the field of building materials, can solve the problem of insufficient depth and comprehensiveness, the lack of systematic theoretical guidance for the preparation and application of mineral admixtures, and the inability to effectively improve the workability of concrete. Concrete compactness and strength And durability and other issues, to achieve good economic and social benefits, improve durability, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

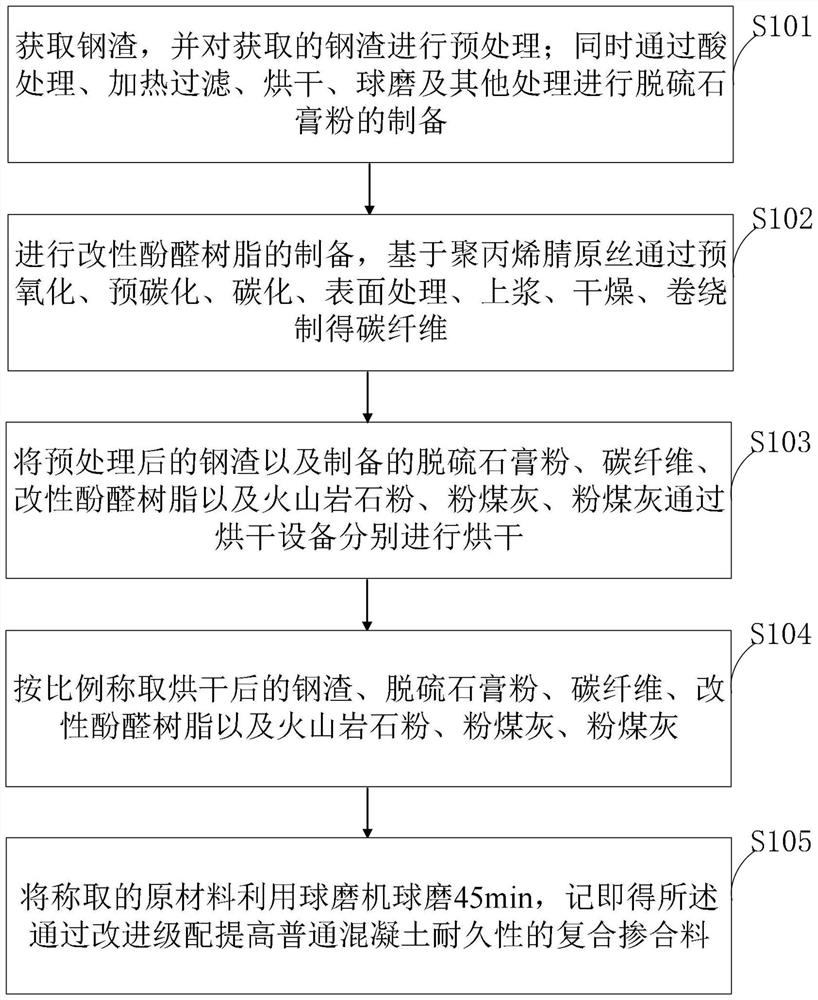

[0040] Aiming at the problems existing in the prior art, the present invention provides a composite admixture that improves the durability of ordinary concrete by improving the gradation. The present invention will be described in detail below with reference to the accompanying drawings.

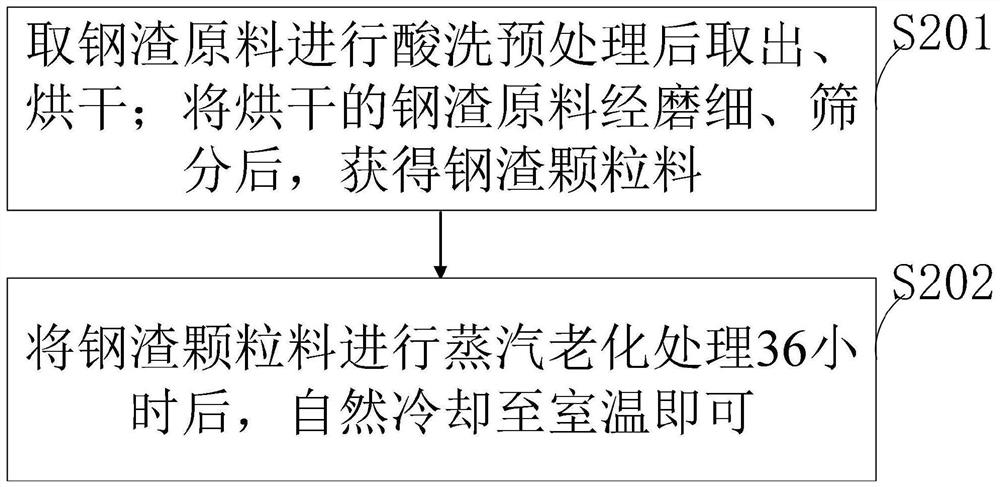

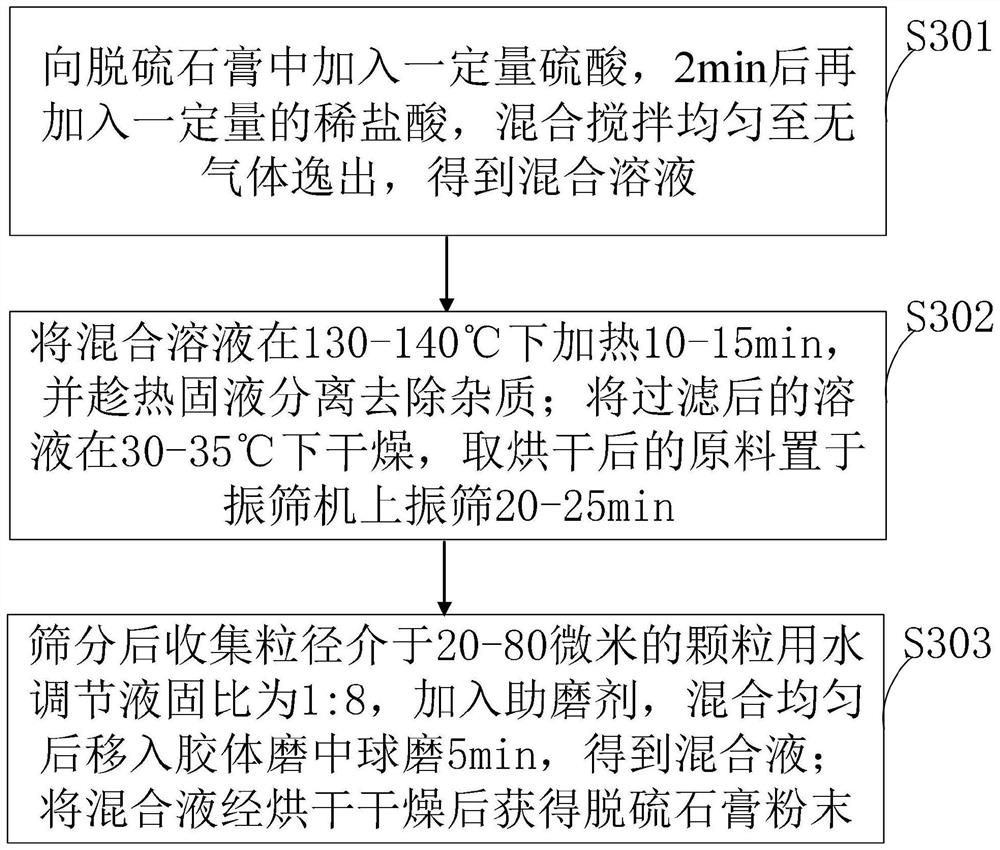

[0041] The composite admixture that improves the durability of ordinary concrete by improving the gradation provided by the embodiments of the present invention is composed of 25-30 parts by mass of volcanic rock powder, 10-15 parts of steel slag, 10-15 parts of fly ash, and 10 parts of desulfurized gypsum powder. -15 parts, 8-10 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com