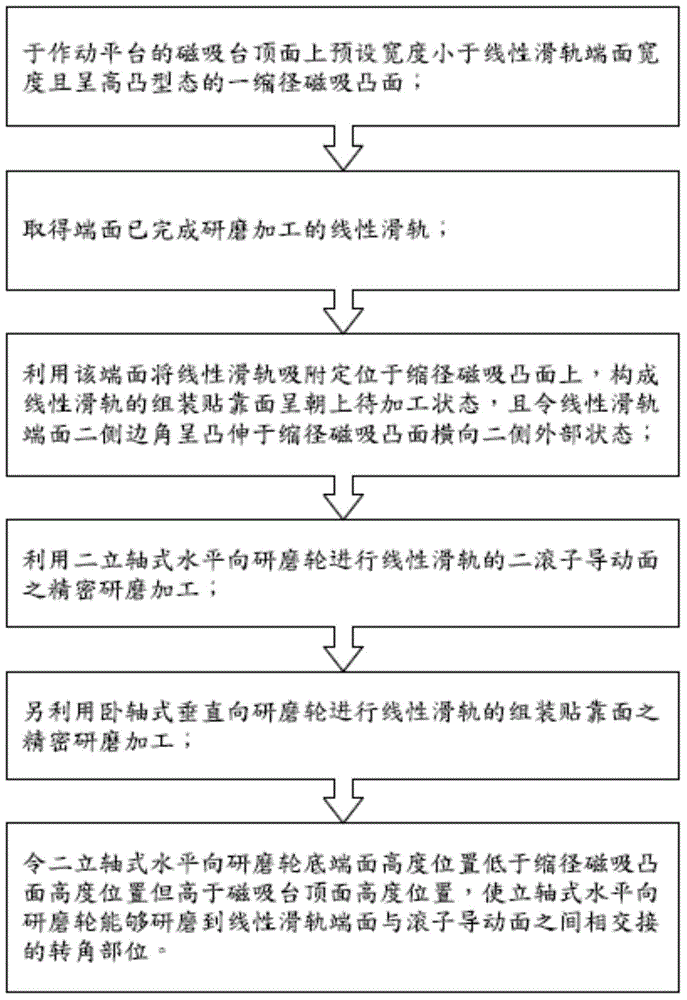

Linear sliding rail grinding method and grinding mechanism thereof

A technology of linear slideway and grinding mechanism, which is applied in the direction of grinding machine tools, grinding devices, grinding machines, etc., and can solve the problem that the grinding machine table 21 cannot achieve the ideal comprehensive flatness and closeness, cannot be flattened and close, linear slideway The limitations of the grinding process steps and other issues can achieve the effect of simplifying the grinding process, improving the processing quality and reducing the processing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

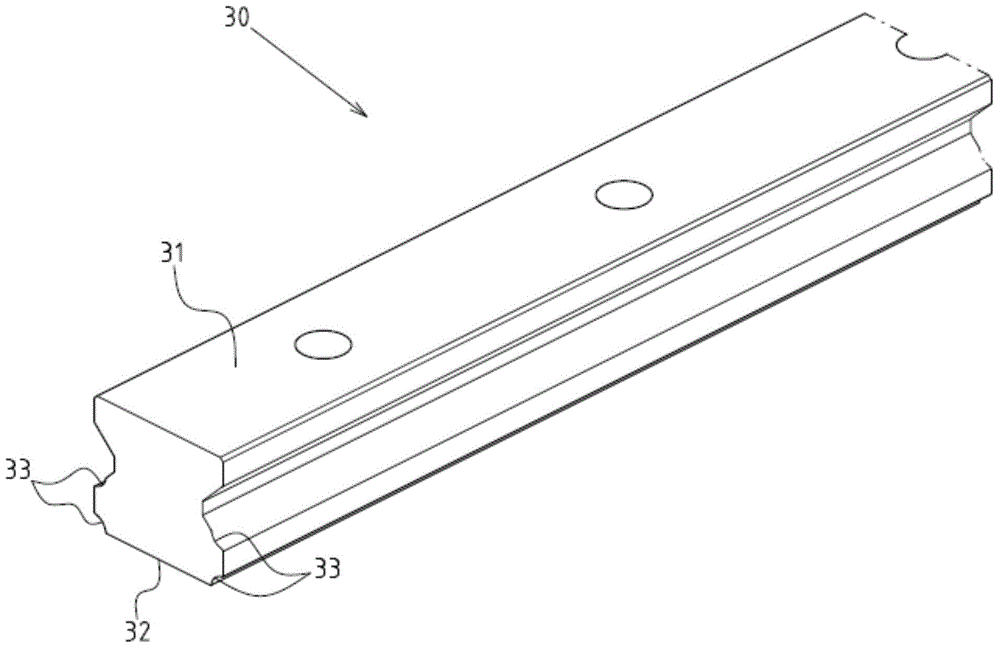

[0027] see Figures 2 to 7 As shown, it is a preferred embodiment of the linear slide rail grinding method and its grinding mechanism of the present invention; the linear slide rail 30 is detailed as image 3 As shown, it includes an assembly abutting surface 31, an end surface 32, and a pair of roller guide surfaces 33 formed on opposite sides of the linear slide rail 30 (note: the number of the roller guide surfaces 33 on each side without limitation); the method is carried out by a grinding mechanism 40, the grinding mechanism 40 includes: an elongated machine 405; a straddling stand part 41, which is arranged on the elongated machine in the form of a vertically spanning arch One place at 405; an actuating platform 42, which is set on the elongated machine platform 405 and can move forward and pass through the bottom of the cross-type stand part 41; a magnetic suction table 43, which is located on the actuating platform 42; Two vertical shaft type horizontal grinding wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com