Novel magnetite separation technology

A magnetite separation technology, applied in the field of magnetite separation technology, can solve the problems of not seeing the combined operation process of magnetic separation columns, and achieve the effects of simplifying the grinding process, improving quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

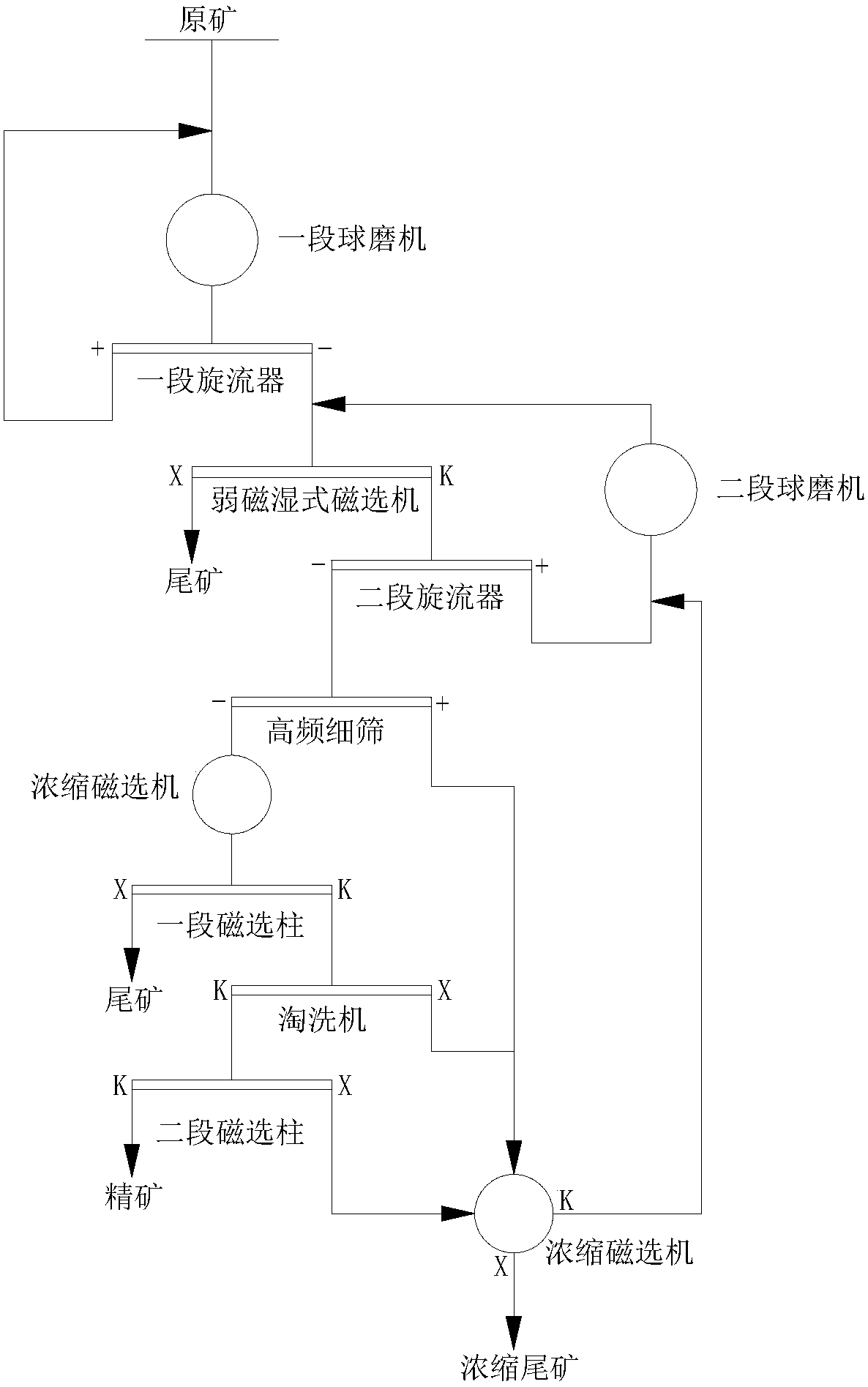

[0024] from figure 1 As can be seen, a kind of novel magnetite sorting process of the present embodiment, its step is:

[0025] Step 1: The raw ore is input into the first-stage ball mill for grinding, and the finished product enters the first-stage cyclone for classification, and the classified grit products are returned to the first-stage ball mill for regrinding;

[0026] Step 2: The overflow product after classification enters the weak magnetic wet magnetic separator for rough separation, and the weak magnetic rough separation concentrate enters the second-stage cyclone of the next stage for classification. The second-stage cyclone is a hydrocyclone. The grit after classification by the second-stage cyclone is input into the second-stage ball mill for re-grinding;

[0027] Step 3: The overflow product after being classified by the second-stage cyclone is input into a high-frequency fine screen for controlled classification;

[0028] Step 4: The under-screened product of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com