Knife grinder

A knife sharpening machine and frame technology, which is applied in the directions of grinding machine parts, grinding workpiece supports, grinding drive devices, etc., can solve problems such as troublesome operation and reduce processing efficiency, and achieve improved processing efficiency and simplified process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

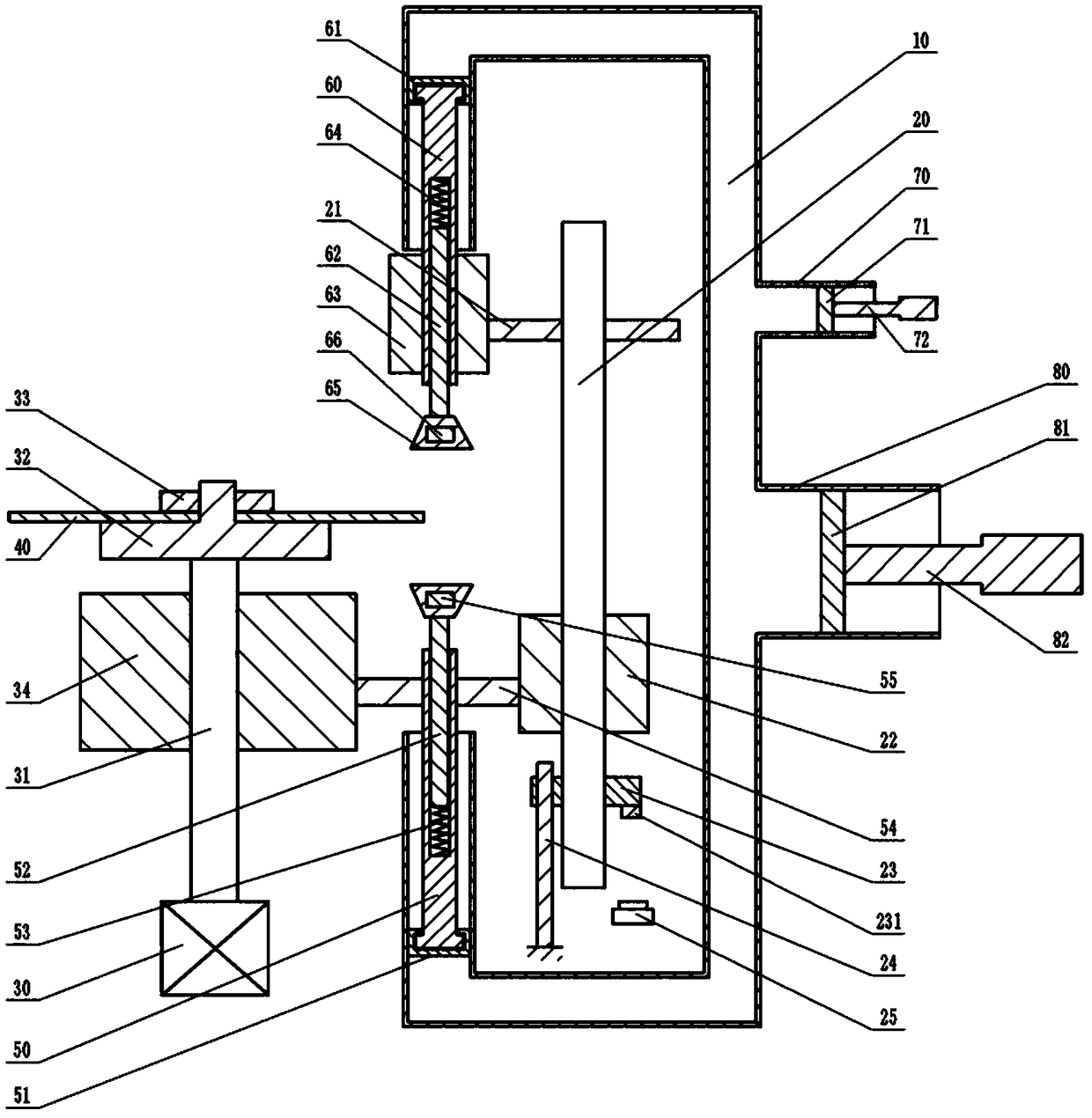

[0016] Instructions attached figure 1 The reference signs in include: connecting column 10, transmission shaft 20, output gear 21, second gear cylinder 22, nut 23, pressure block 231, limit rod 24, single control switch 25, motor 30, rotating shaft 31, mounting seat 32. Positioning block 33, third gear cylinder 34, circular blade 40, second plunger 50, second piston 51, second push rod 52, second extension spring 53, first gear 54, electromagnet 55, first Plunger 60, first piston 61, first push rod 62, first gear cylinder 63, first tension spring 64, grinding wheel 65, magnet 66, second annular cylinder 70, second pressure plate 71, second handle 72, the first An annular cylinder 80 , a first pressing plate 81 , and a first handle 82 .

[0017] Such as figure 1 As shown, the knife grinder includes a frame, a grinding unit, a transmission unit, a control unit and a clamping unit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com