Method for preparing hydrogen by coal gasification

A coal gasification and hydrogen technology, applied in chemical instruments and methods, hydrogen production, hydrogen and other directions, can solve the problems of high methane content and low conversion rate of coal char

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

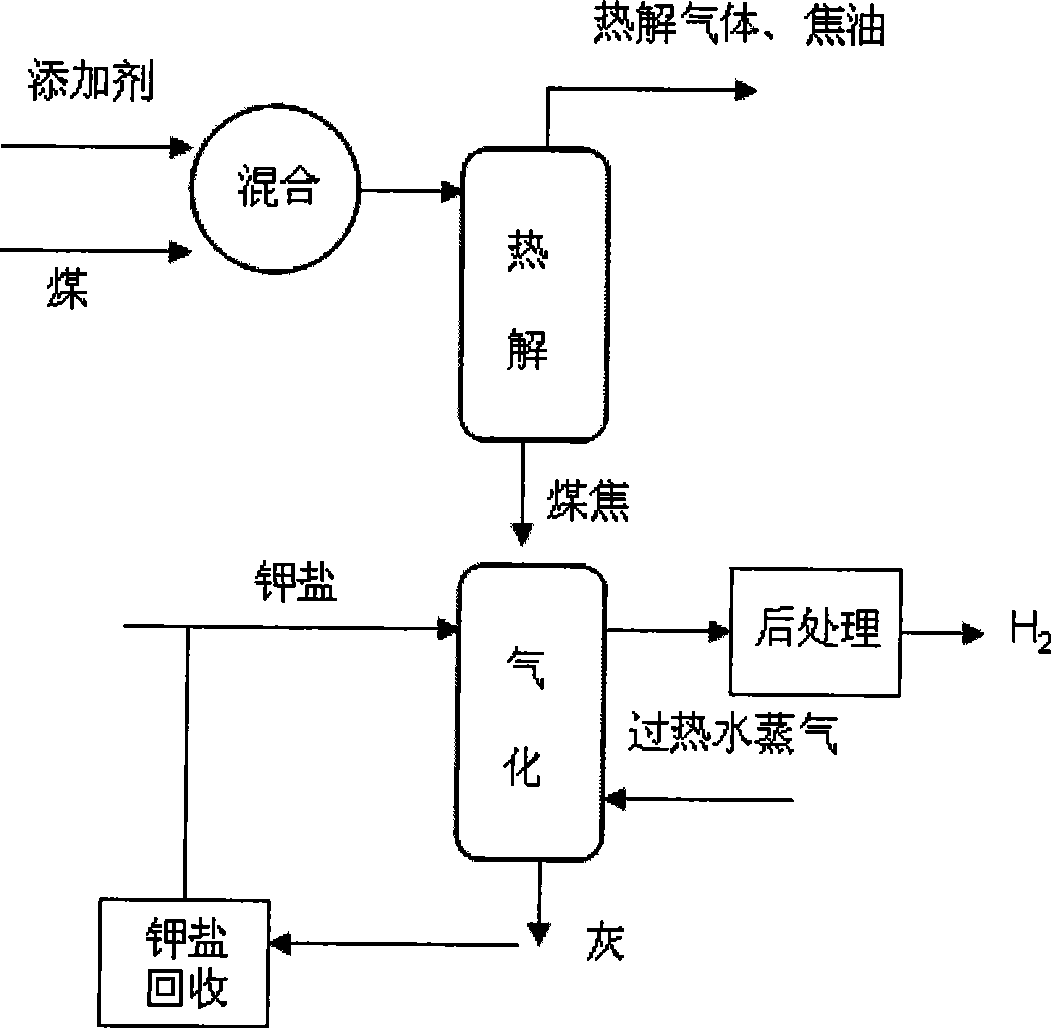

[0040] "Two-stage" coal gasification hydrogen production method

[0041] (1) Thermal cracking of raw coal (first stage operation):

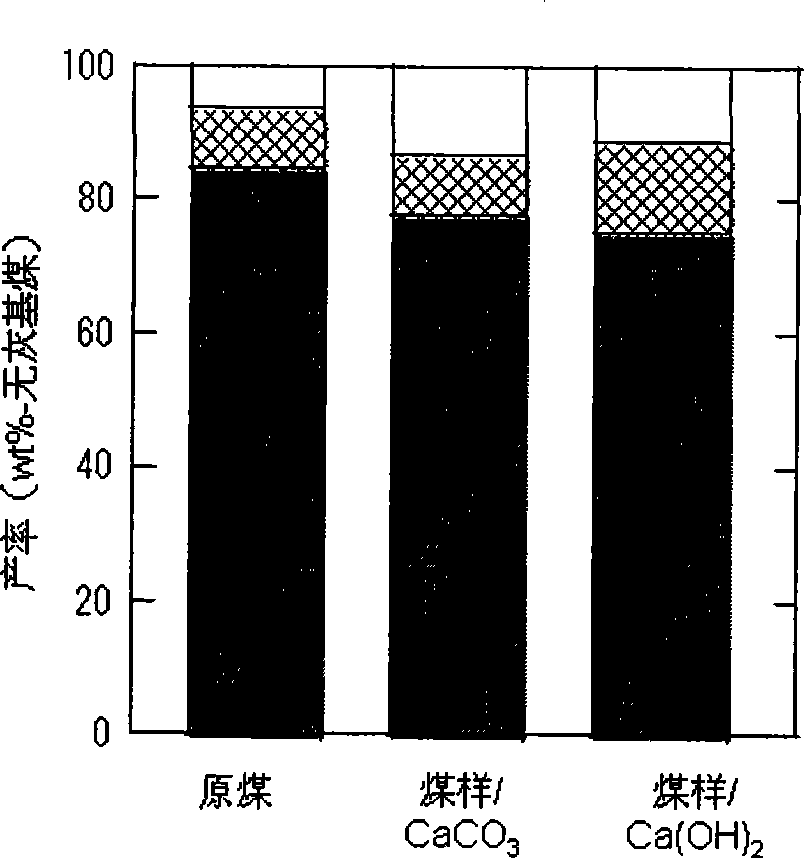

[0042]The raw coal, the mixture of raw coal and calcium hydroxide (wherein the content of calcium hydroxide is 10wt%) or the mixture of raw coal and calcium carbonate (wherein the content of calcium carbonate is 10wt%) is placed in the fixed bed pyrolysis reactor respectively, in Under the same conditions [i.e. under normal pressure (1atm) and air isolation], heating for pyrolysis, the pyrolysis temperature is 500°C to 900°C, and the distribution of the pyrolysis products is as follows: figure 2 shown.

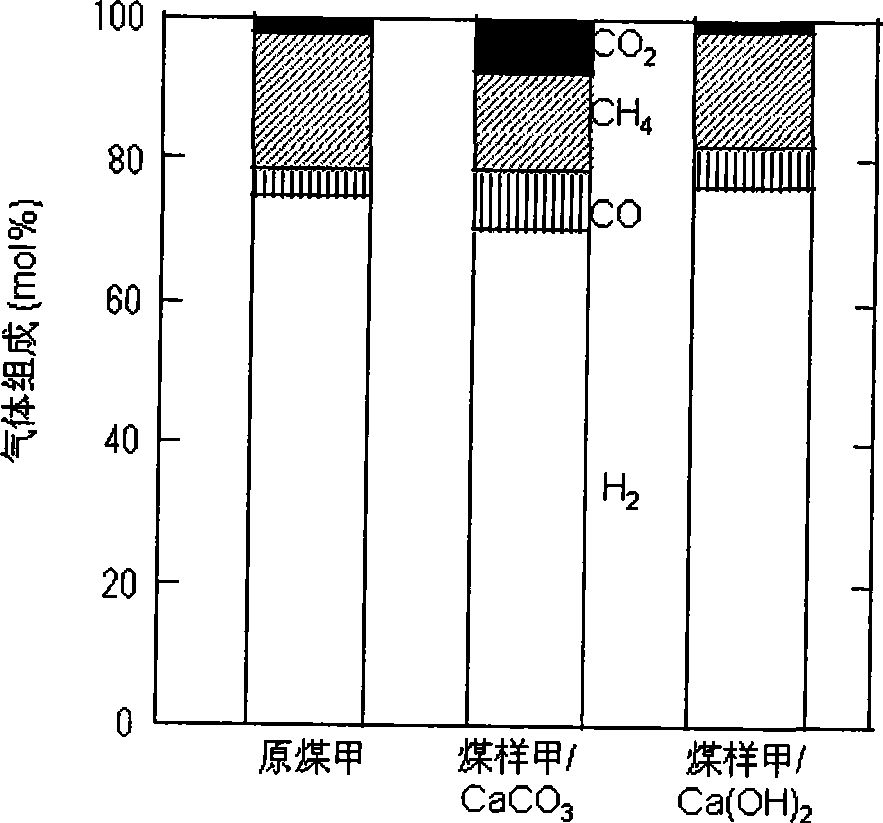

[0043] Among them, the gas components are volatilized and separated out from the reactor, and the gas components are quantitatively analyzed by gas chromatography. The results are shown in image 3 ;

[0044] The tar product was collected in a cold trap, the amount of tar was analyzed by gravimetric method, and the benzene, toluene and xylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com