Reactor and process for upgrading heavy hydrocarbon oils

a technology for hydrocarbon oil and reactors, applied in chemical/physical processes, bulk chemical production, supercritical conditions, etc., can solve the problems of difficult to bring remote, heavy oil resources closer, and the infrastructure required for the handling, recovery and recycling of diluent could be expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

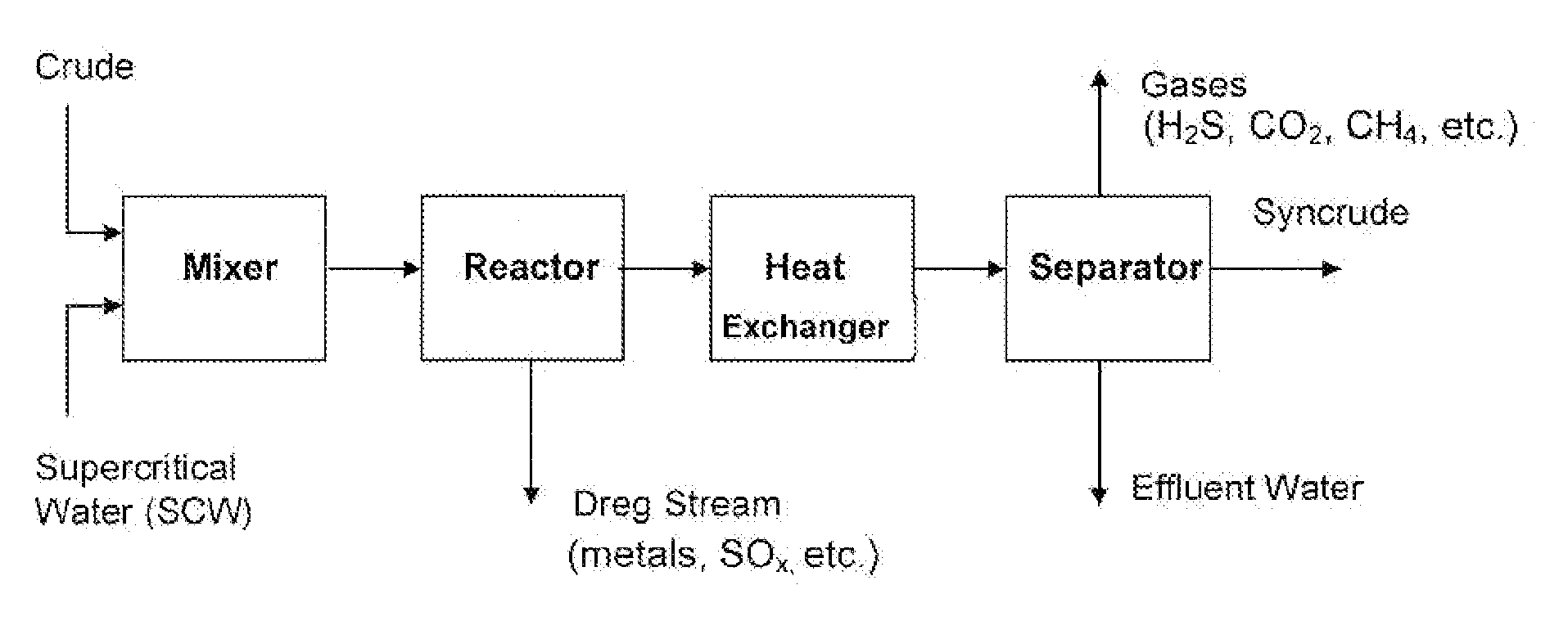

[0075]Oil and supercritical water are contacted in a mixer prior to entering the reactor. The reactor is equipped with air inner tube for collecting the products (syncrude, excess water, and gas), and a bottom section where any metals or solids comprising a “dreg stream” of indeterminate properties or composition may accumulate. The shell-side of the reactor is kept isothermal during the reaction with a clamshell furnace and temperature controller. Preferred reactor residence times are 20-40 minutes, with preferred oil / water volume ratios on the order of 1:3. Preferred temperatures are around 374°-400° C., with the pressure at 3200-4000 psig. The reactor product stream leaves as a single phase, and is cooled and separated into gas, syncrude, and effluent water. The effluent water is recycled back to the reactor. Sulfur from the original feedstock accumulates in the dreg stream for the most part, with lesser amounts primarily in the form of H2S found in the gas phas...

example 2

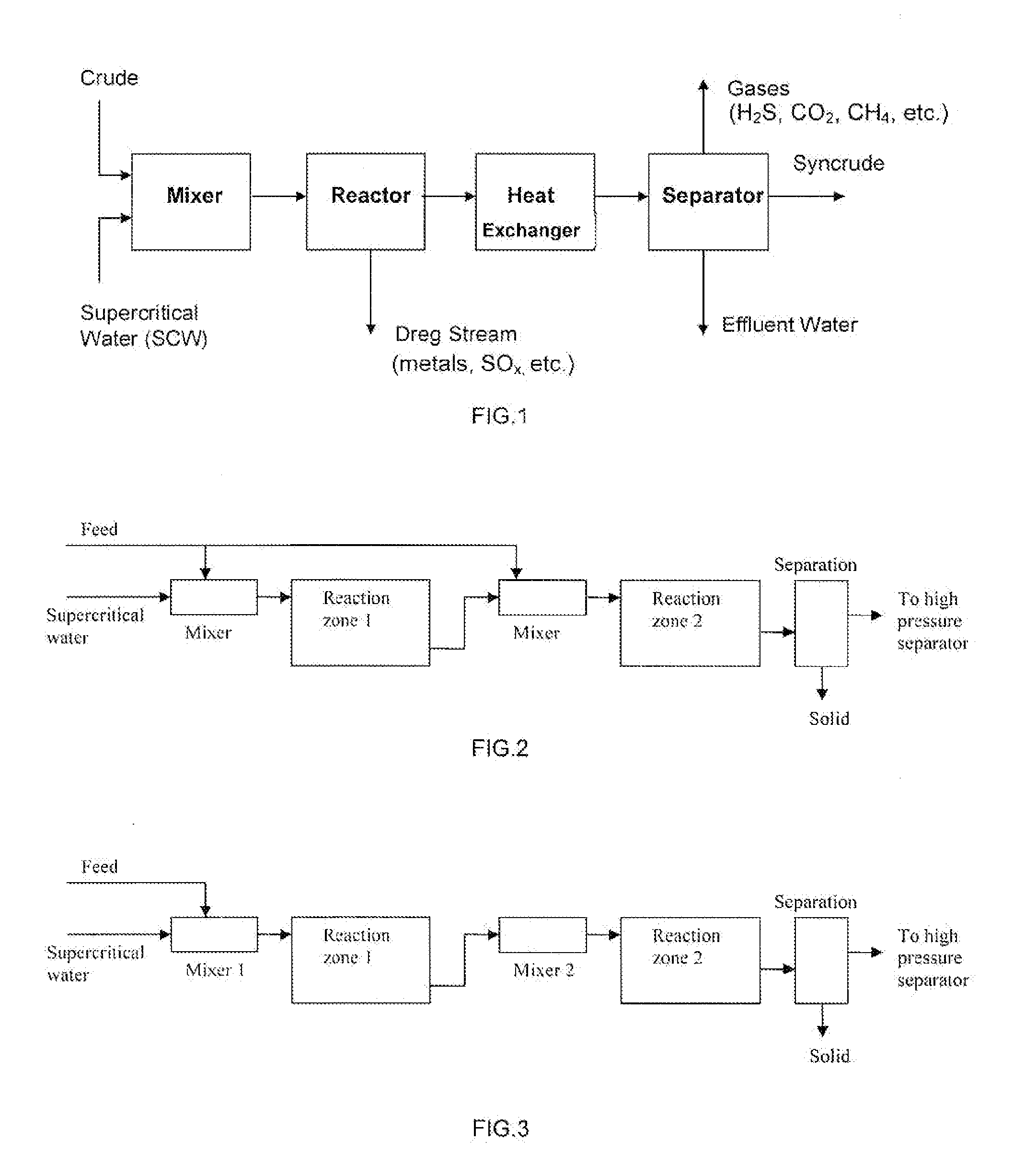

Properties of the Product Syncrude

[0077]A Hamaca crude oil was diluted with a diluent hydrocarbon at a ratio of 5:1 (20 vol % of diluent:). The diluted Hamaca crude oil properties were measured before reacting it with the supercritical water process as referred to in Example 1 and FIG. 2. The properties of the crude were as follows, 12.8 API gravity at 60 / 60; 1329 CST viscosity @40° C.; 7.66 wt % C / H ratio, 13.04 wt % MCRT; 3.54 wt % sulfur; 0.56 wt % nitrogen, 3.05 mg KOH / gm acid number; 1.41 wt % water; 371 ppm Vanadium; and 86 ppm Nickel. The diluted Hamaca crude oil after the super critical water treatment was converted into a syncrude with the following properties: 24.1 API gravity at 60 / 60: 5.75 CST viscosity @40° C., 7.40 wt % C / H ratio; 2.25 wt % MCRT; 2.83 wt % sulfur; 0.28 wt % nitrogen; 1.54 mg KOH / gm acid number; 0.96 wt % water; 24 ppm. Vanadium; and 3 ppm Nickel. Substantial reductions in metals and residues were observed, with simultaneous increase in the API gravity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com