Control method of electronic expansion valve

A technology of electronic expansion valve and control method, which is applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., which can solve the problem that the reliability and safety of the system cannot be guaranteed, the efficiency of the compressor is reduced, and the system operation Instability and other problems, to achieve the effect of protecting reliable and safe operation, reducing lag time, and shortening adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

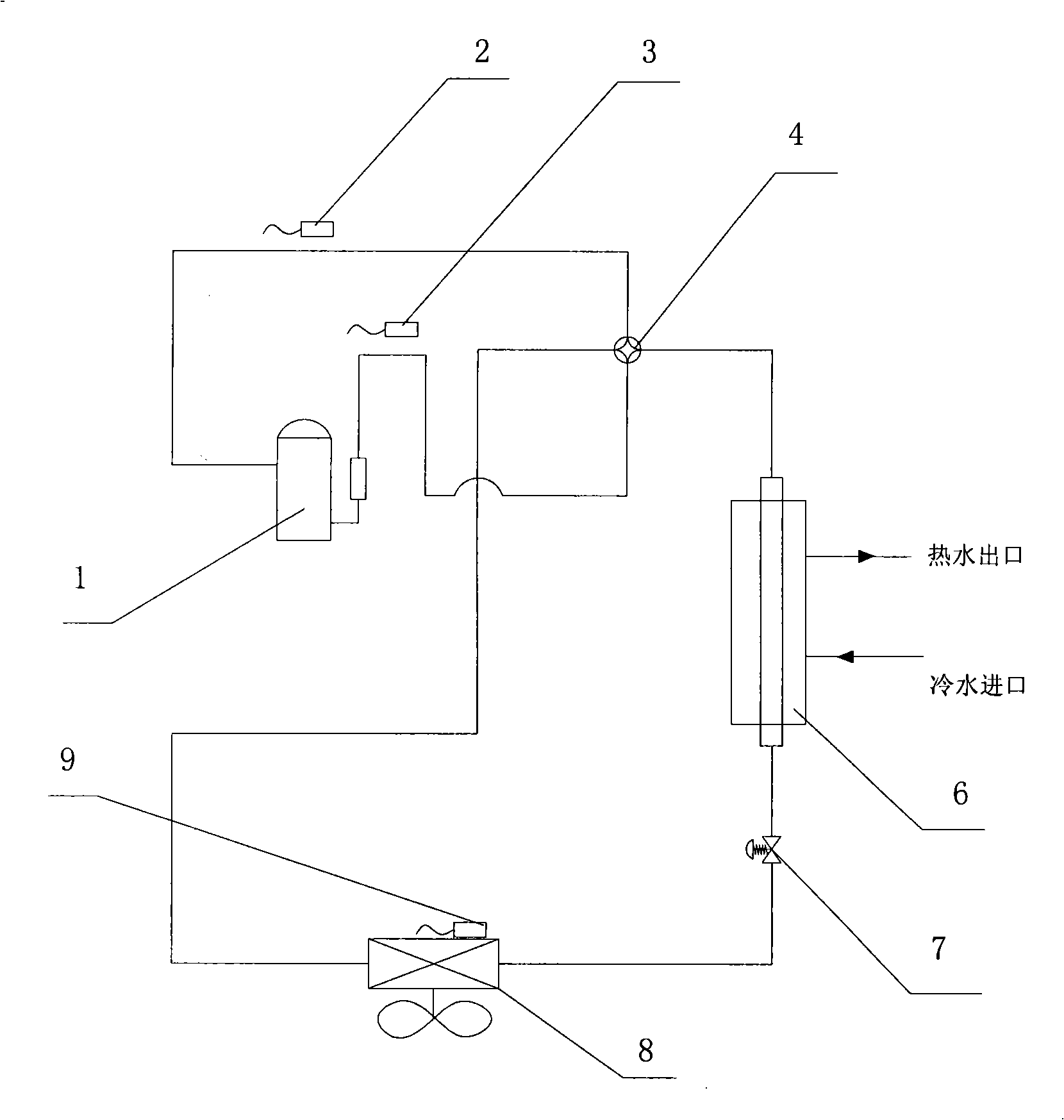

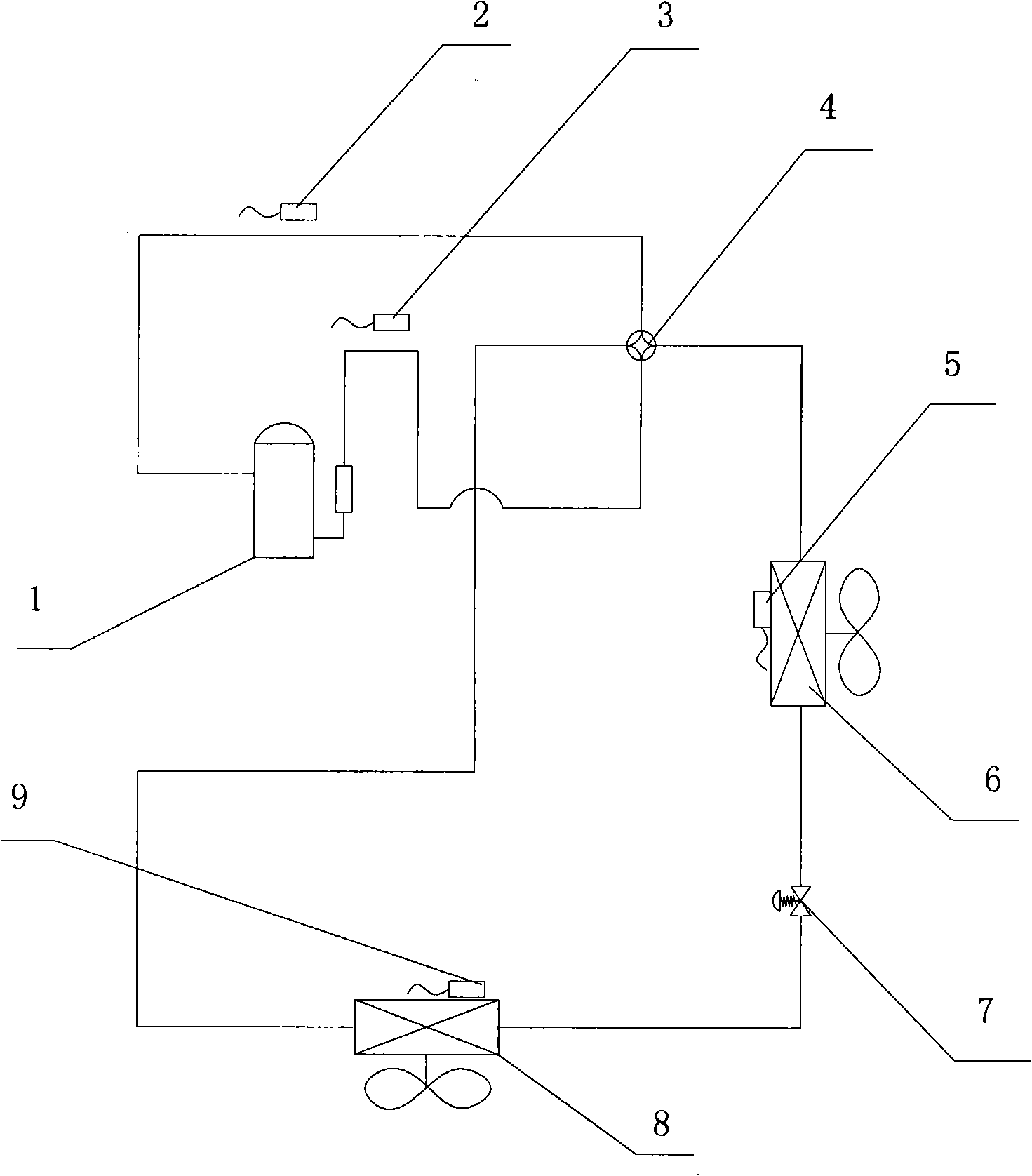

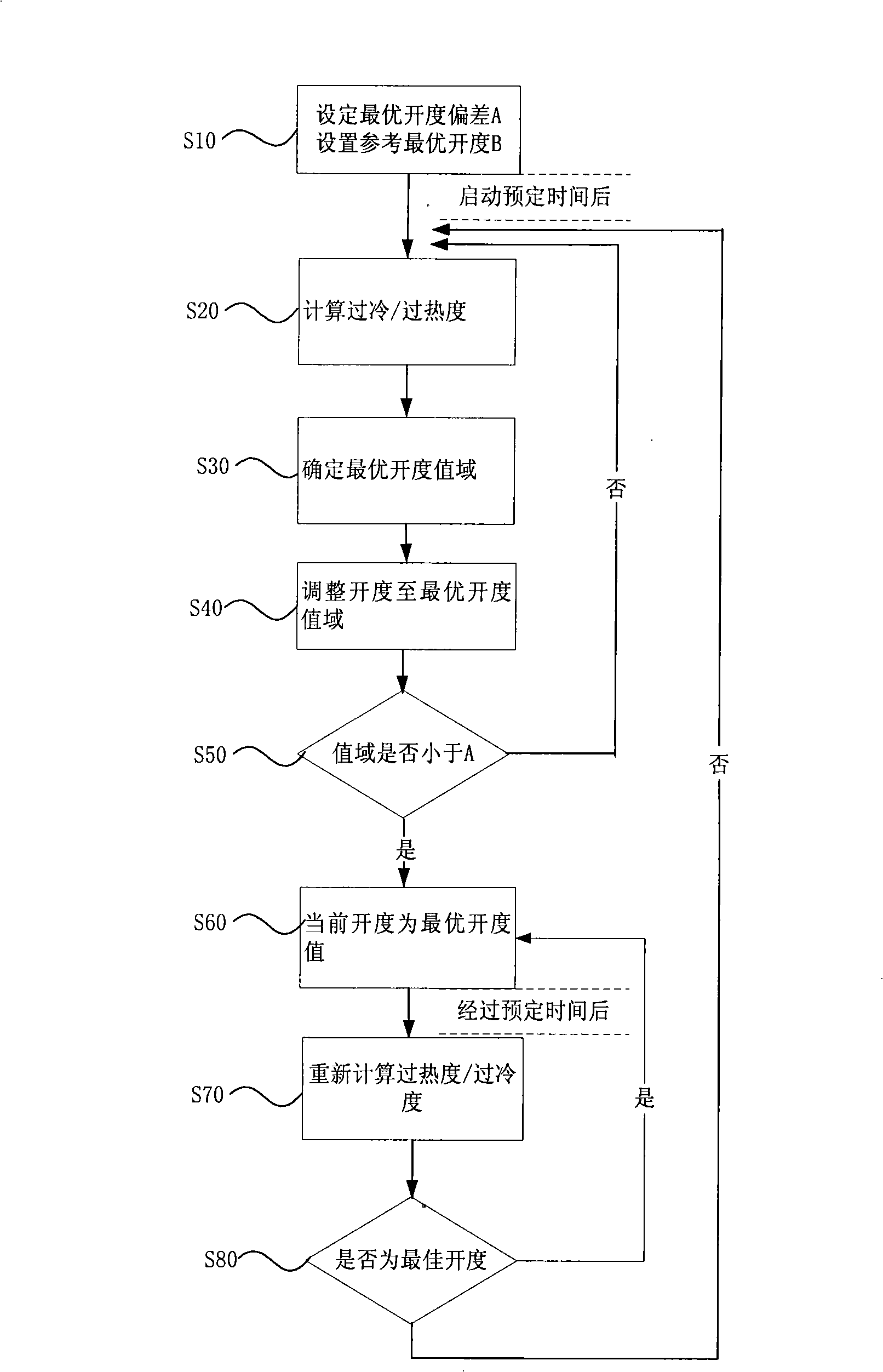

[0026] In order to facilitate understanding of the present invention, reference is made to the attached figure 1 , 2 , 3, illustrate the embodiment of the present invention, but the scope of protection of the present invention is not limited to this embodiment.

[0027] attached figure 1 The middle is the heat pump water heater system diagram. According to the operating principle of the system, as the water temperature continues to rise, the system exhaust temperature, pressure and refrigerant flow rate are constantly changing. Due to this dynamic change, the system has to perform real-time monitoring. Adaptive operation control, in which the electronic expansion valve control plays a key role, and the relevant temperature sensors include: exhaust, suction, and evaporator tube temperature sensor temperature bulbs, corresponding to labels 2, 3, and 9 respectively. The electronic expansion valve 7 presses the control flow according to each input parameter (such as image 3 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com