Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Achieving temperature uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

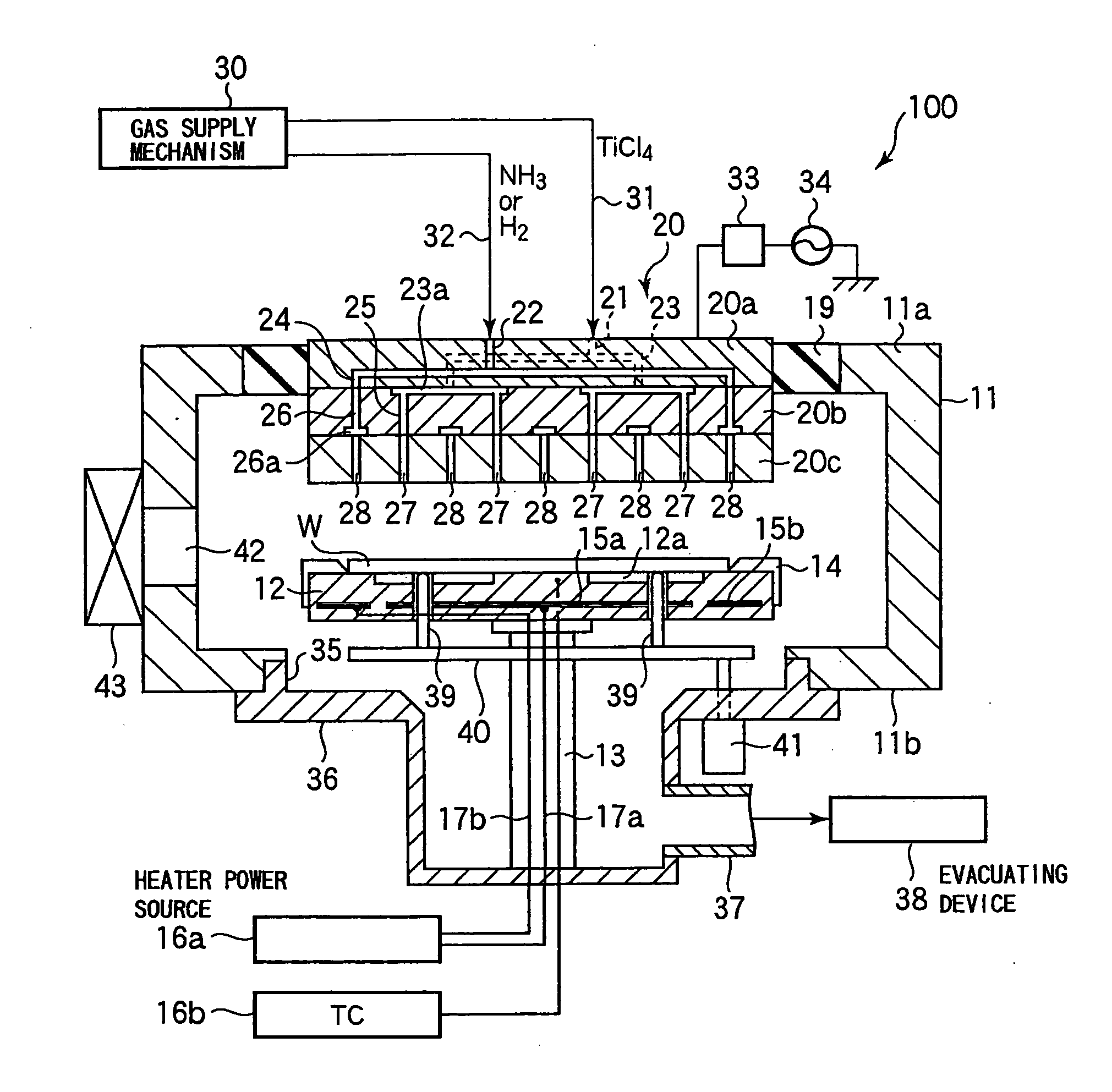

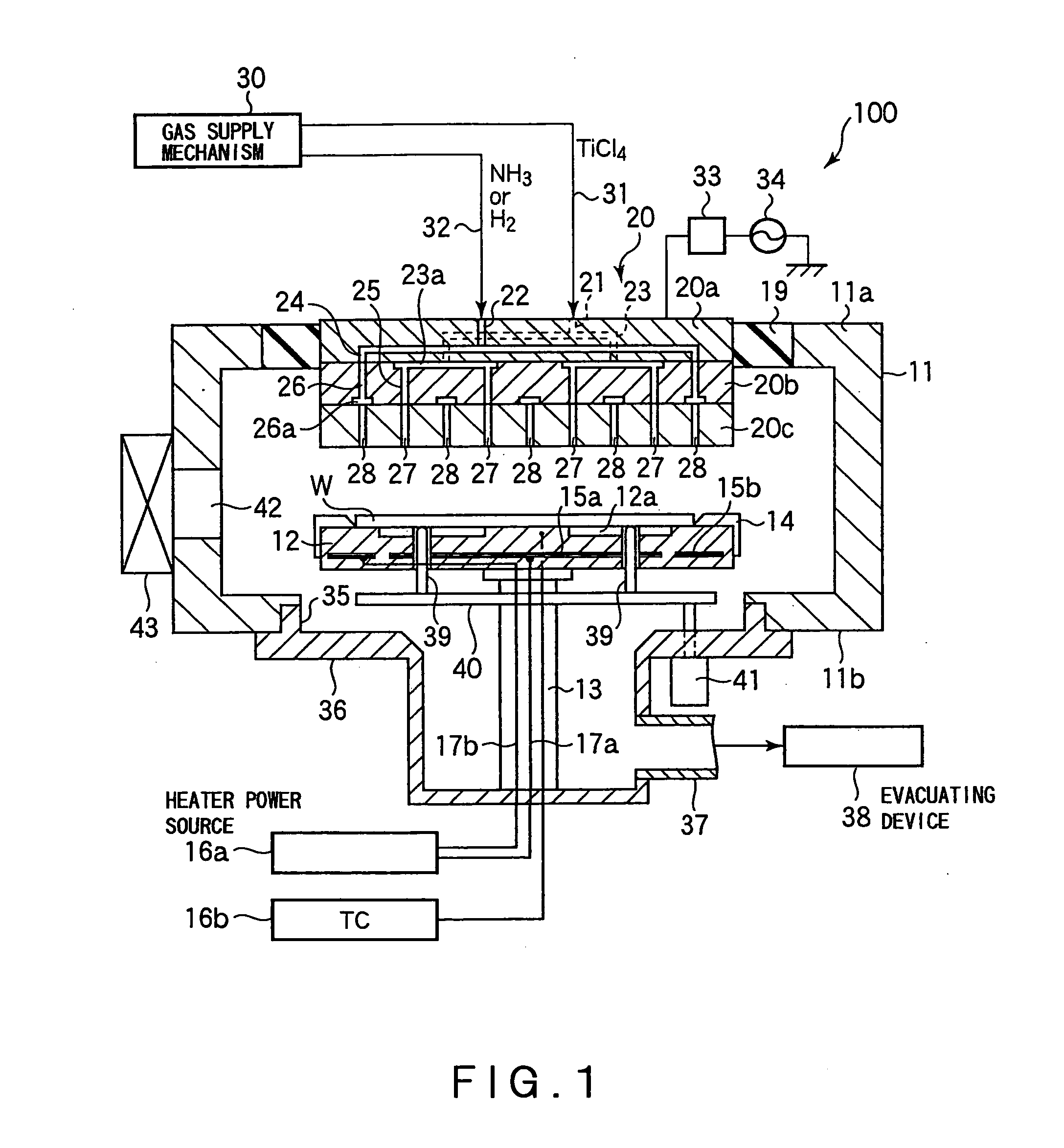

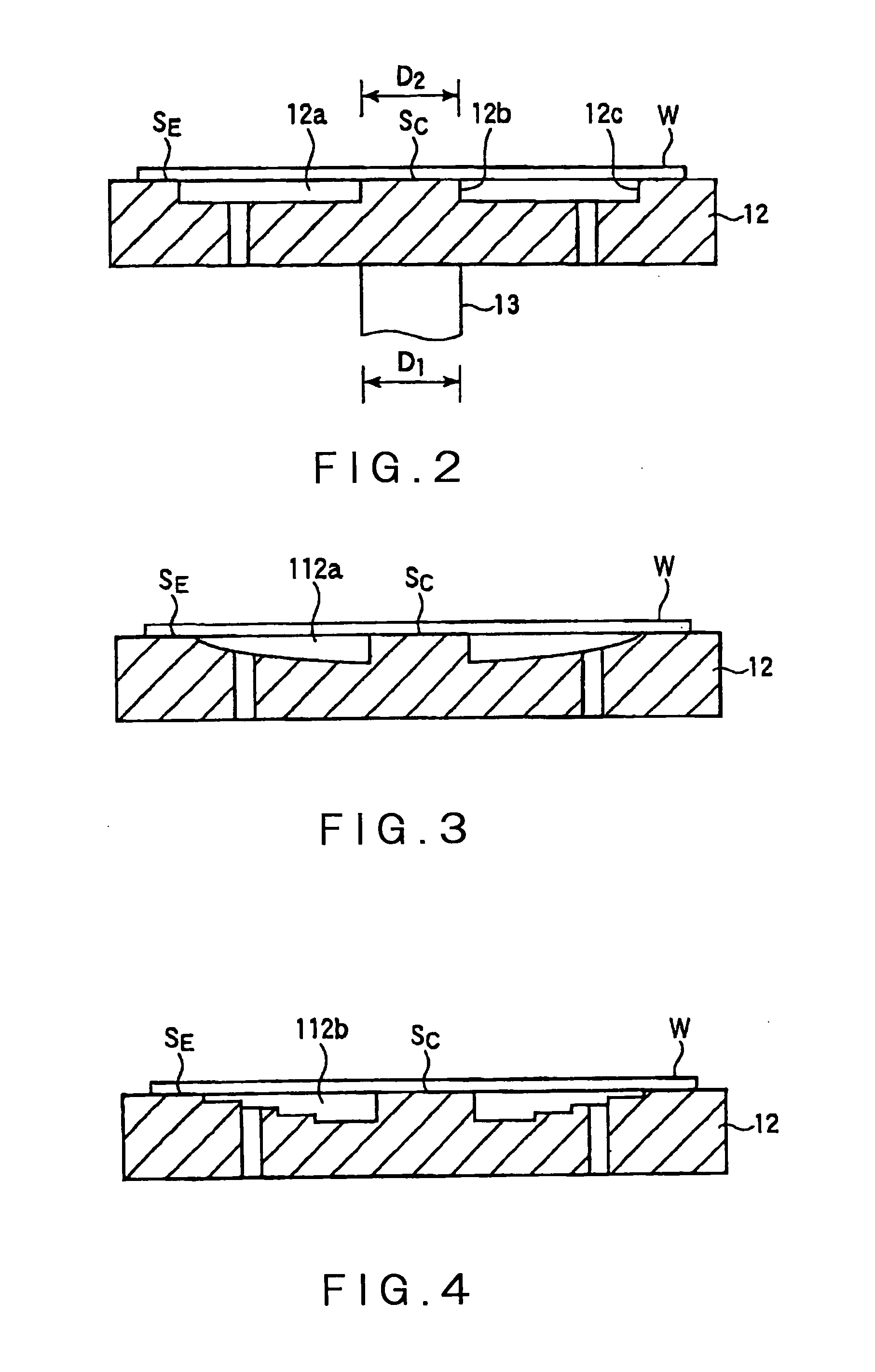

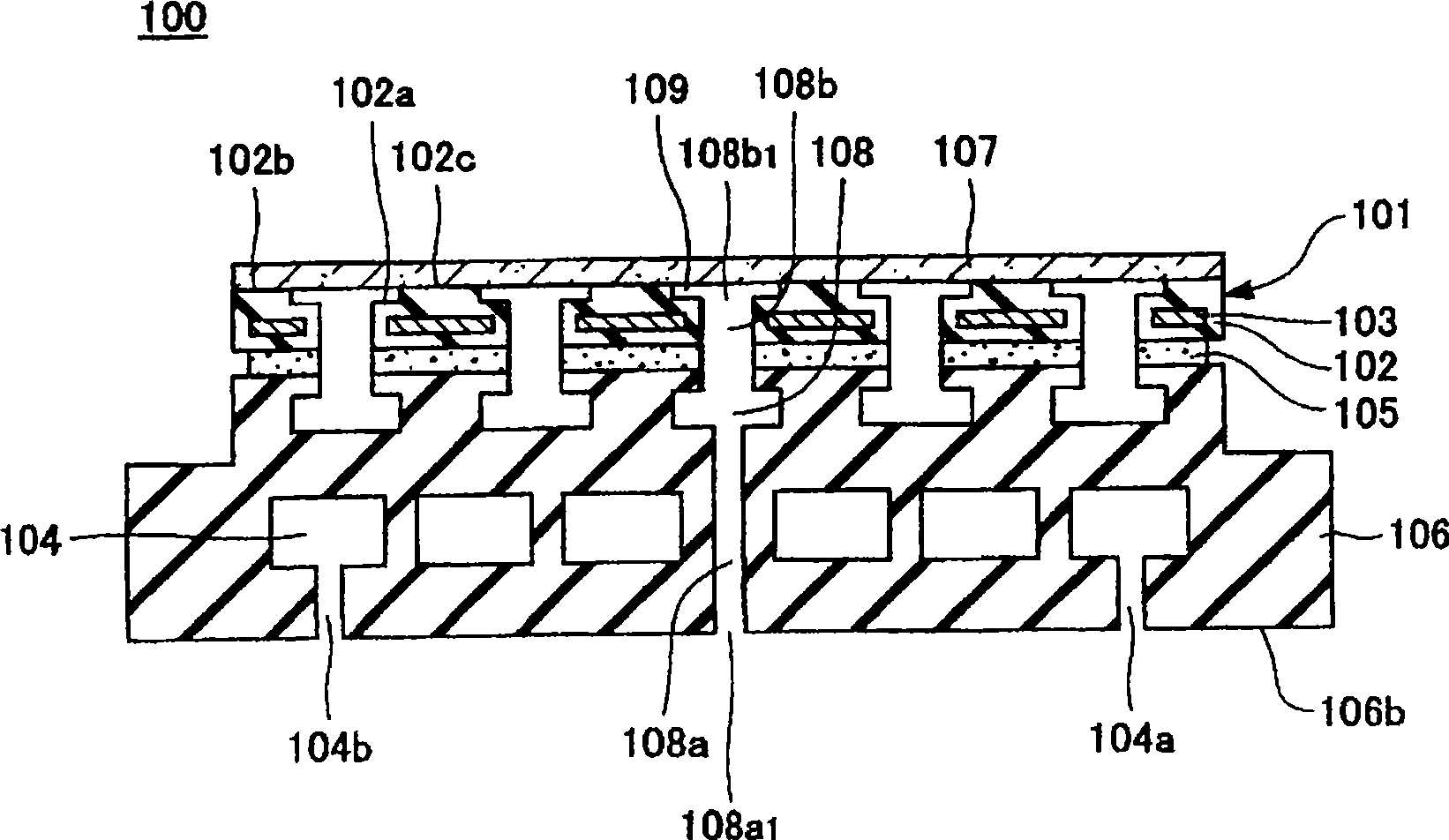

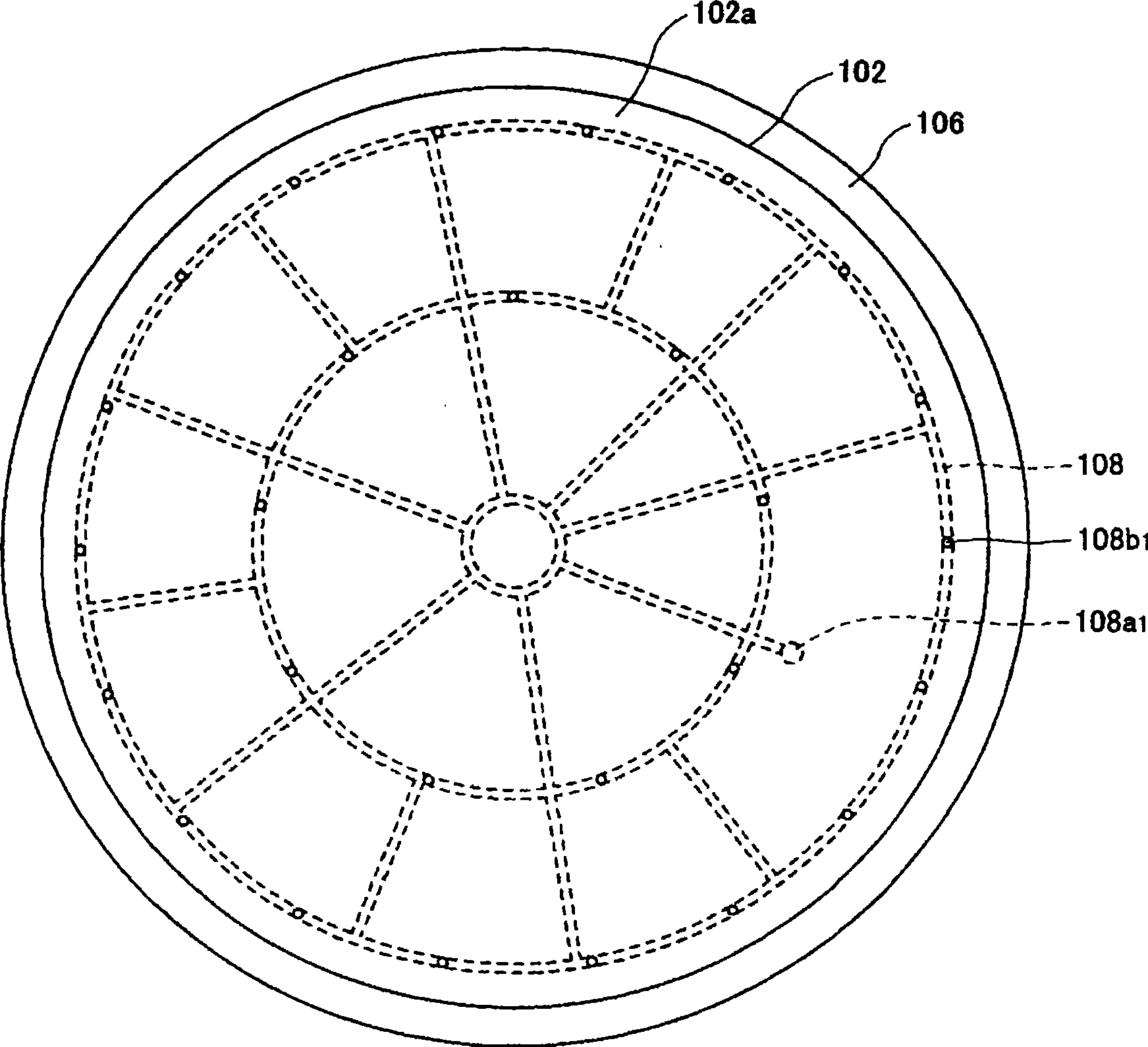

Substrate Processing Apparatus and Substrate Mount Table Used in the Apparatus

InactiveUS20100162956A1Achieving temperature uniformityEliminate the effects ofElectric discharge tubesSemiconductor/solid-state device manufacturingInternal pressureSusceptor

Disclosed is a susceptor which achieves uniform temperature distribution of a wafer placed on the susceptor, and also disclosed is a substrate processing apparatus provided with the susceptor. An annular recess 12a is formed in an intermediate portion between the central portion and the peripheral portion of a wafer support surface of the susceptor 12. Due to the provision of the recess, the substrate heating effect by thermal radiation from the susceptor is suppressed in the intermediate portion. The geometrical dimension of the recess is determined taking the chamber internal pressure into consideration.

Owner:TOKYO ELECTRON LTD

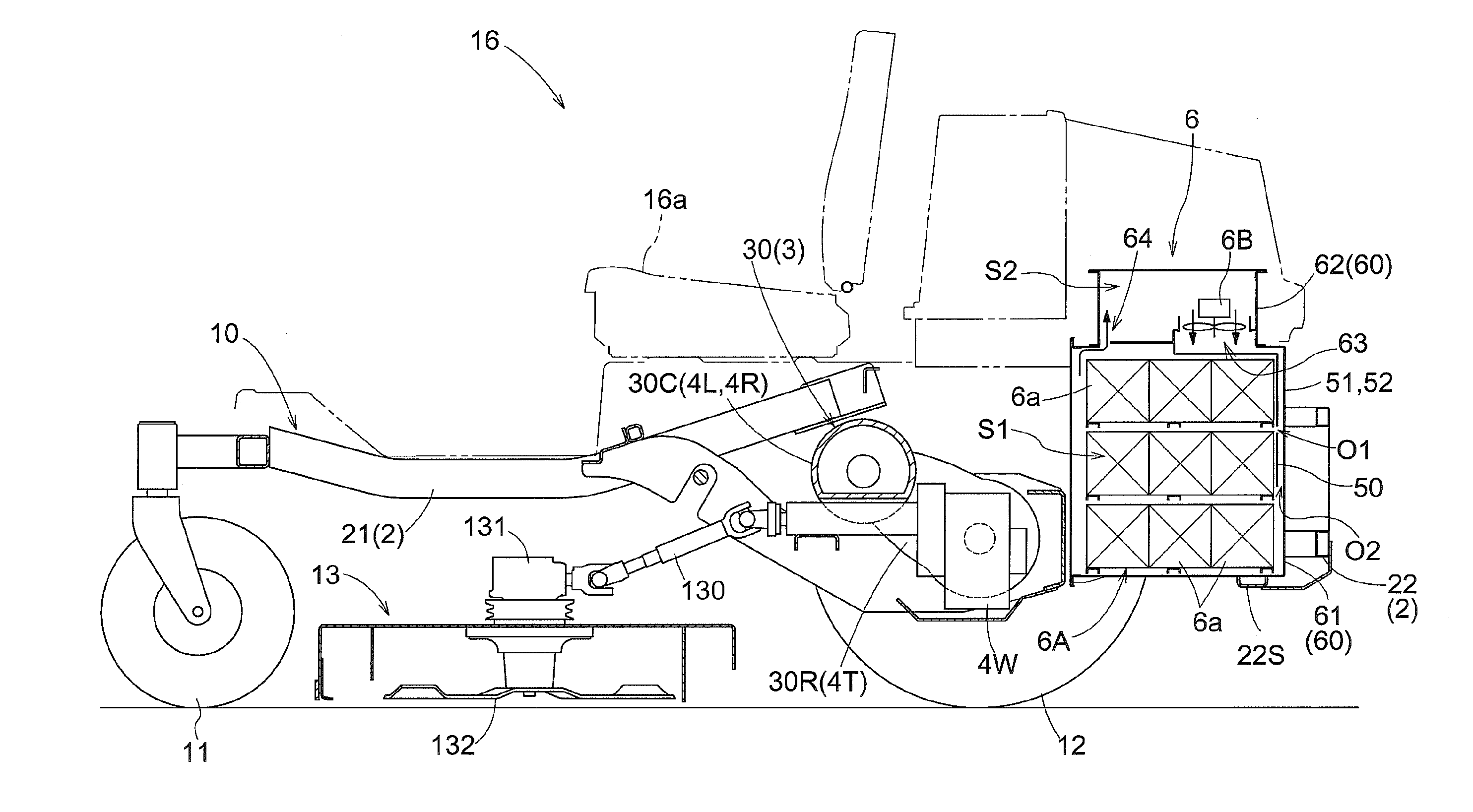

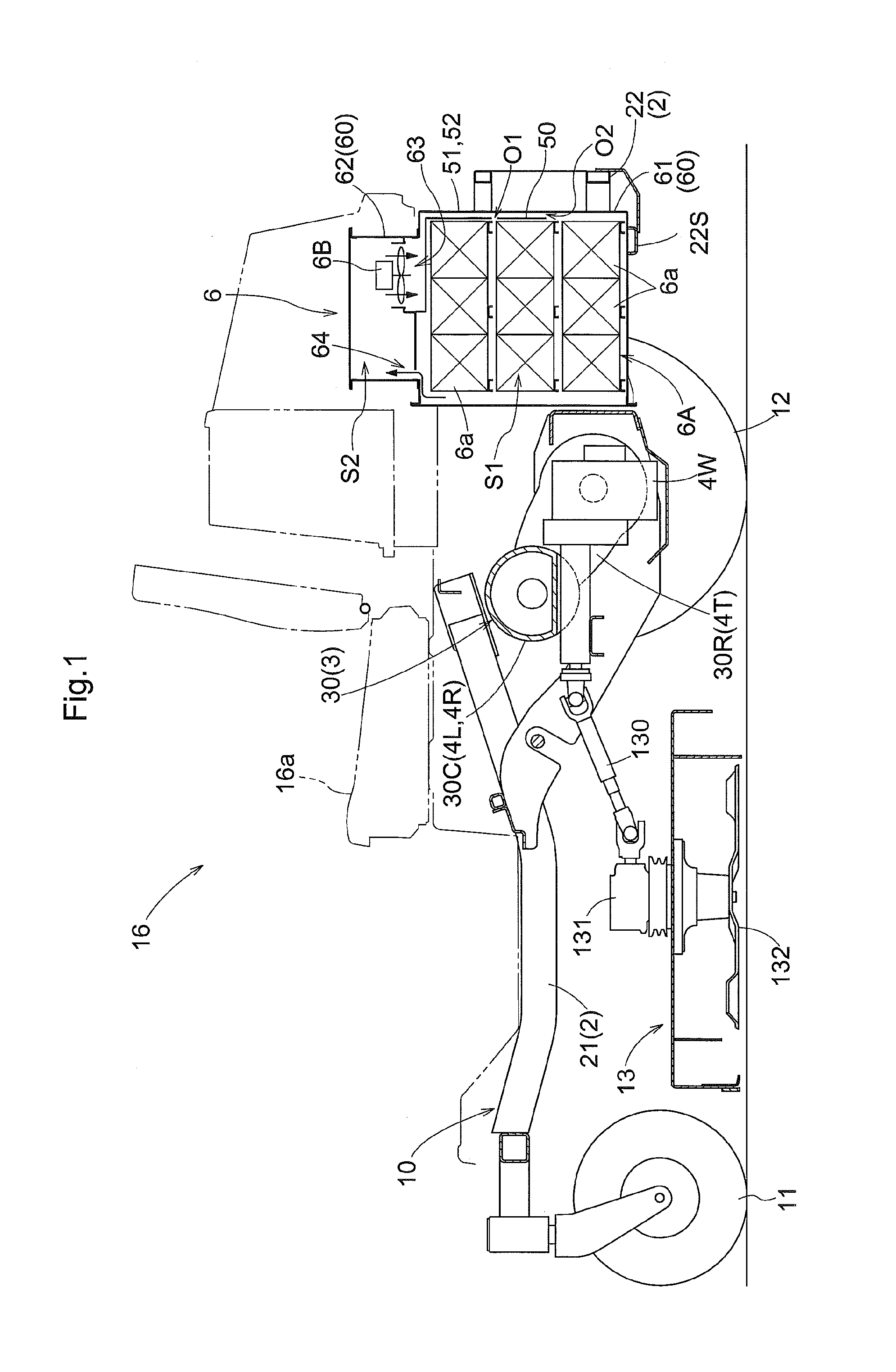

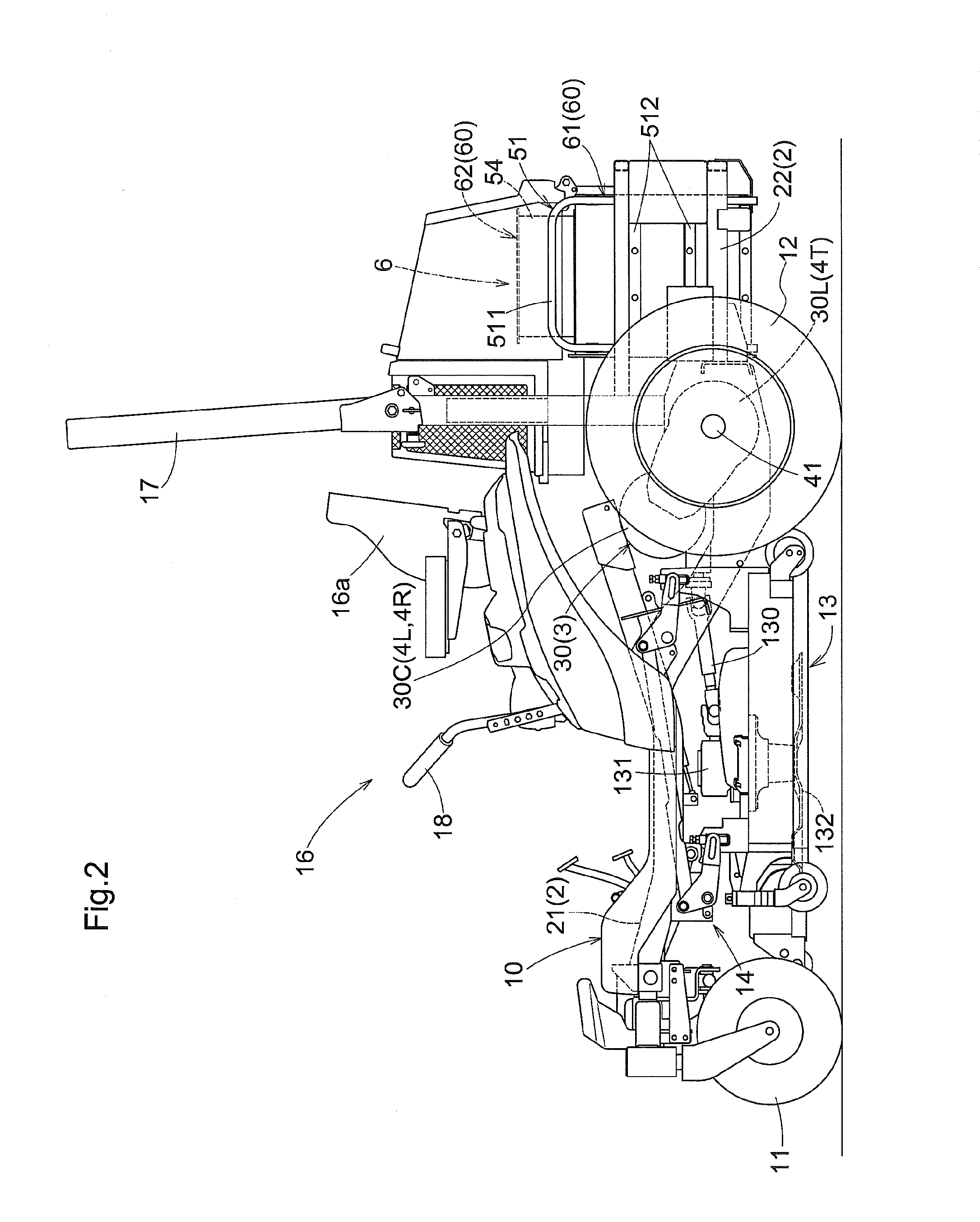

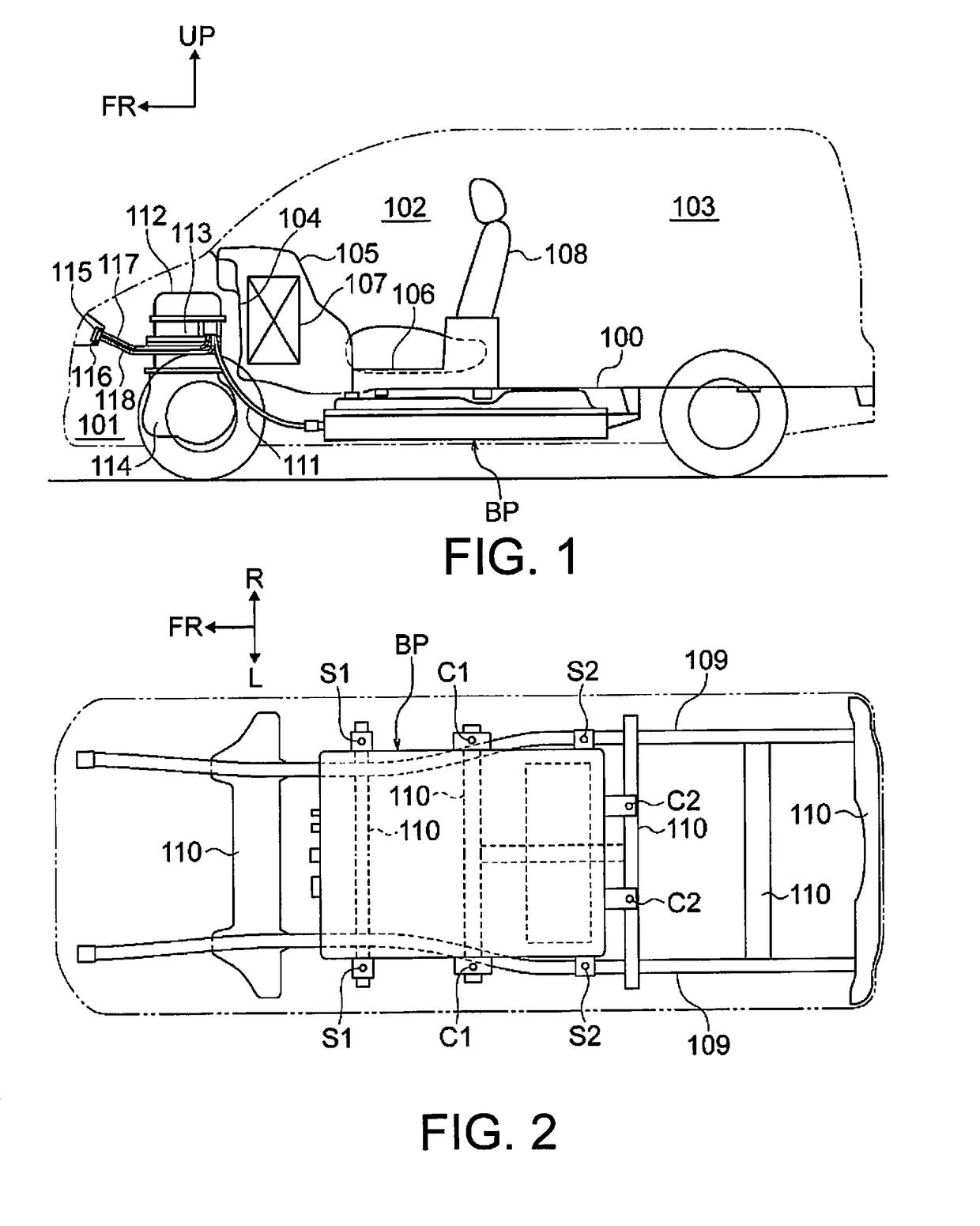

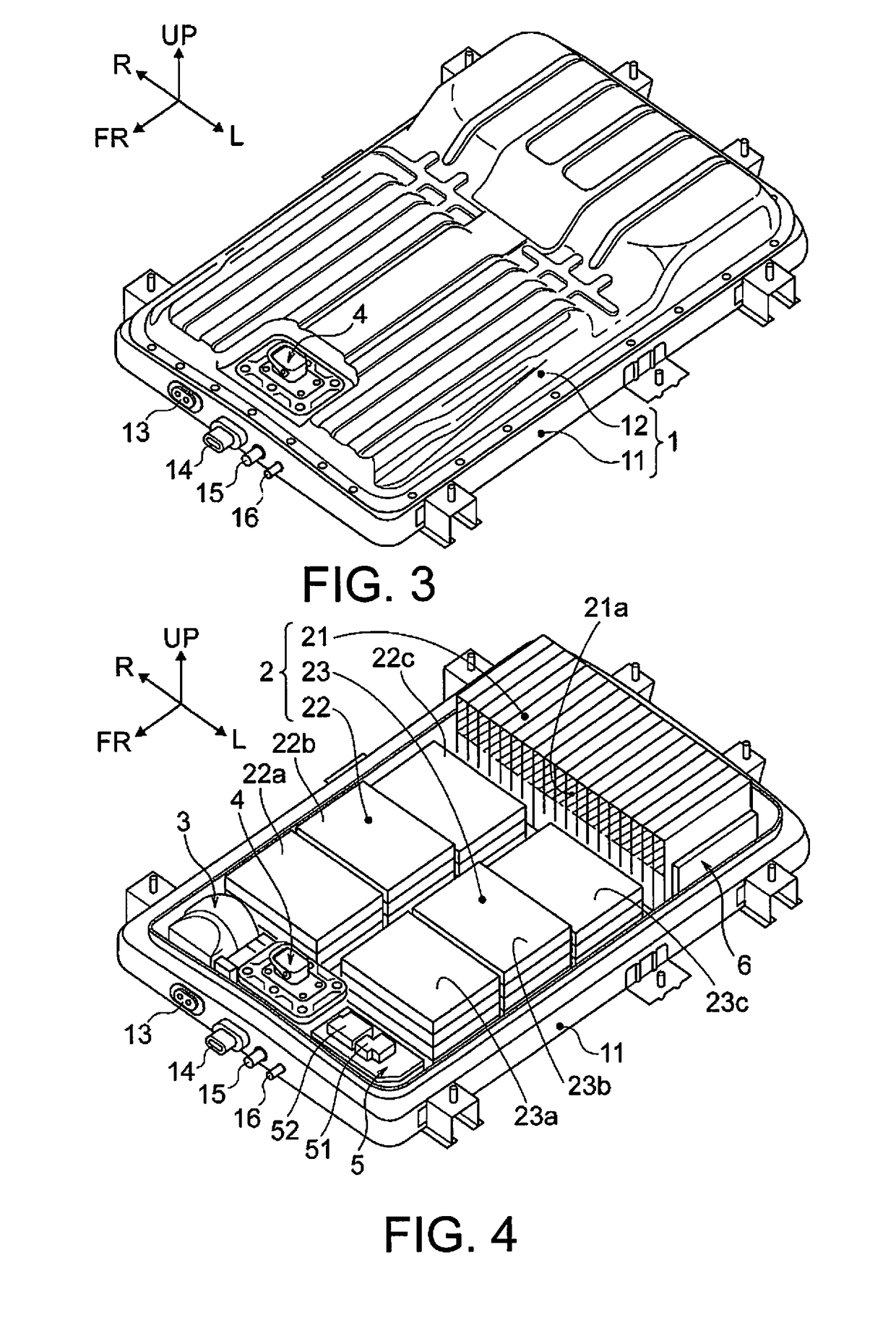

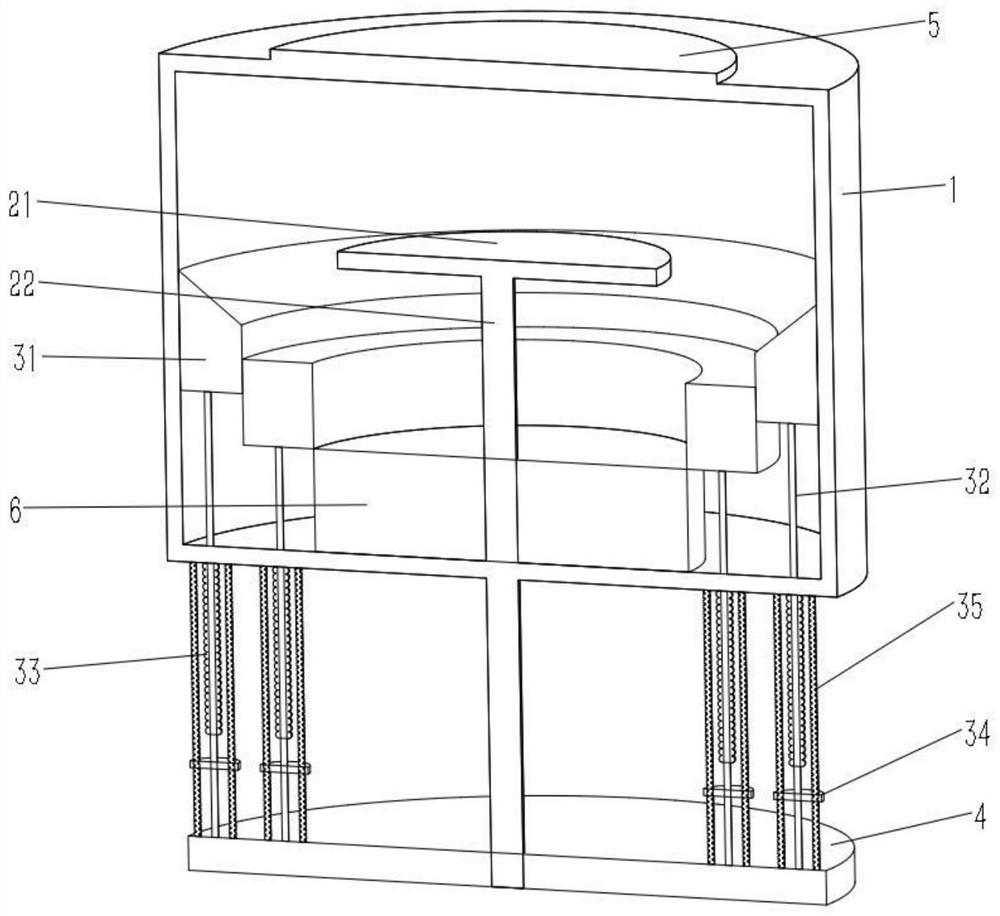

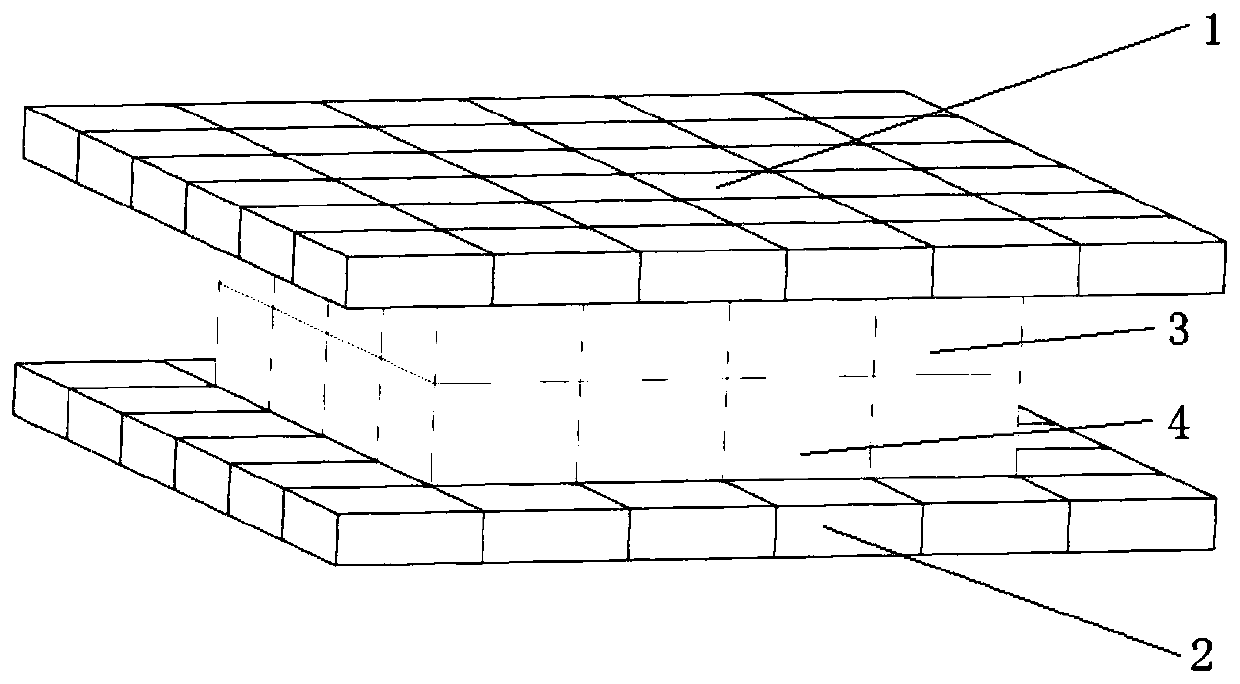

Battery Pack and Electric Work Vehicle

ActiveUS20160293906A1Easy to useAvoid enteringMowersElectric propulsion mountingBattery packAutomotive engineering

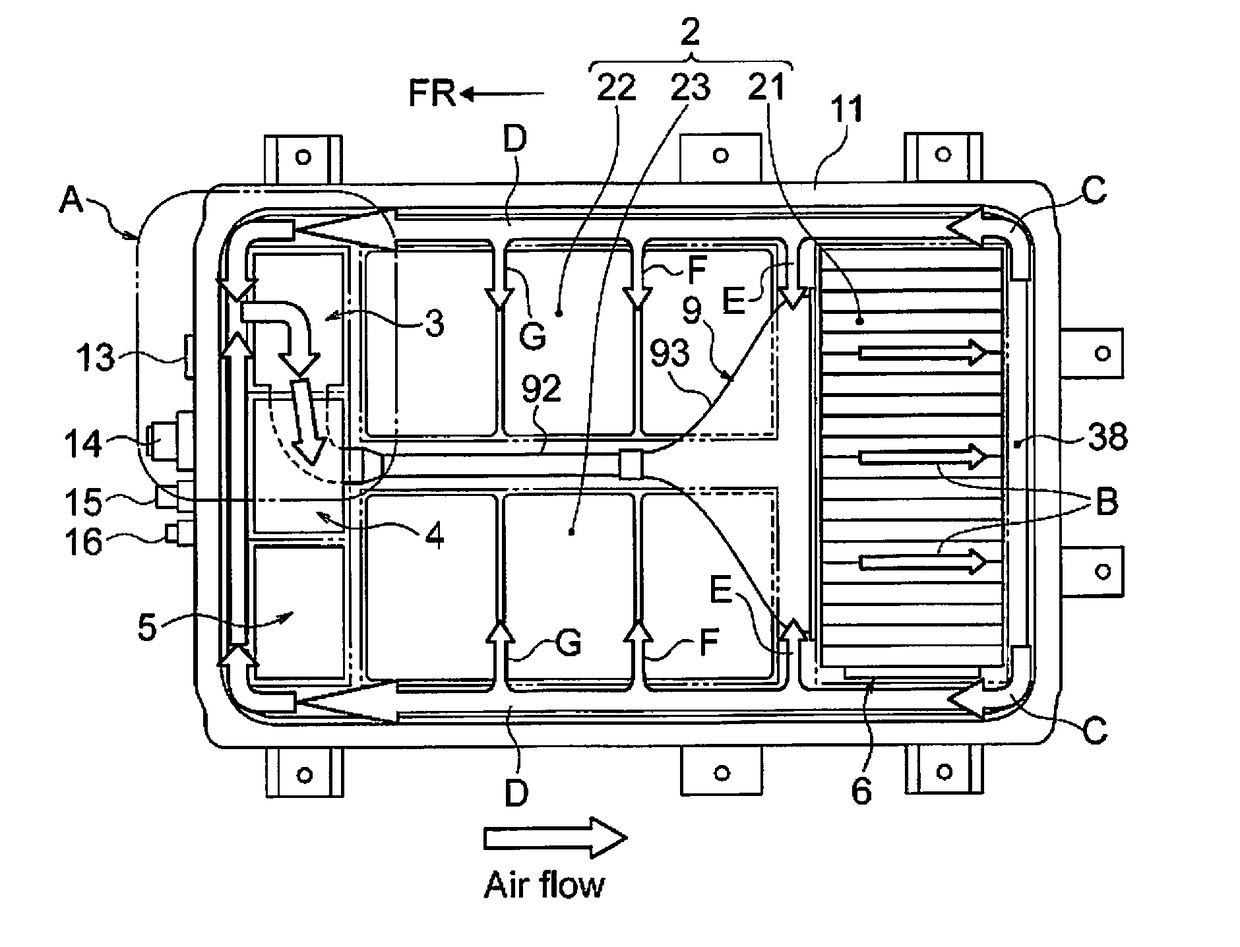

A battery pack (6) for an electric work vehicle includes a battery unit (6A), a casing (60) for tightly housing the battery unit (6A), a circulation fan (6B) mounted in an inner space of the casing (60), and an air guide (50) provided in the casing (60) to direct cooling air produced by the circulation fan (6B) to the battery unit (6A).

Owner:KUBOTA LTD

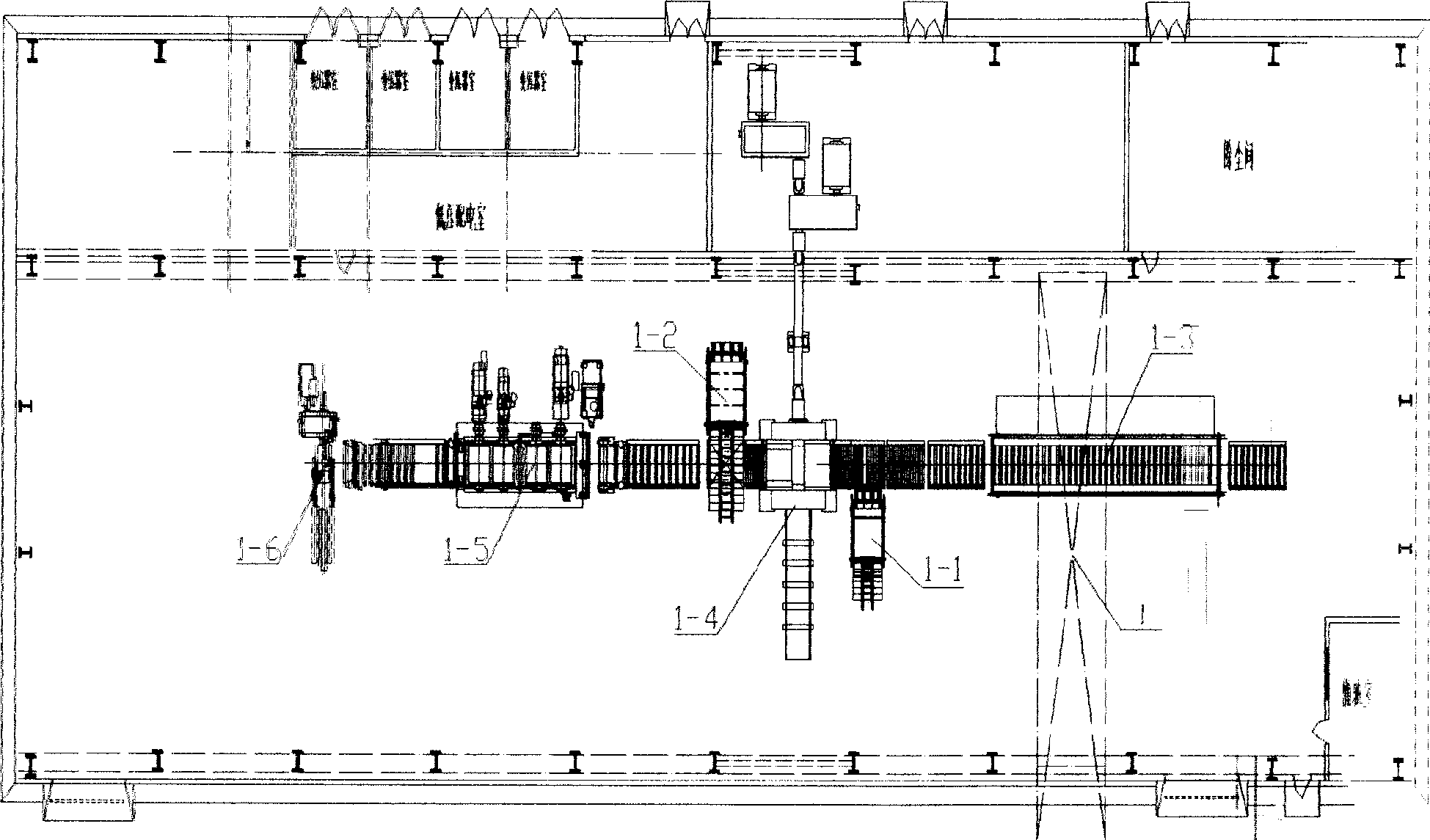

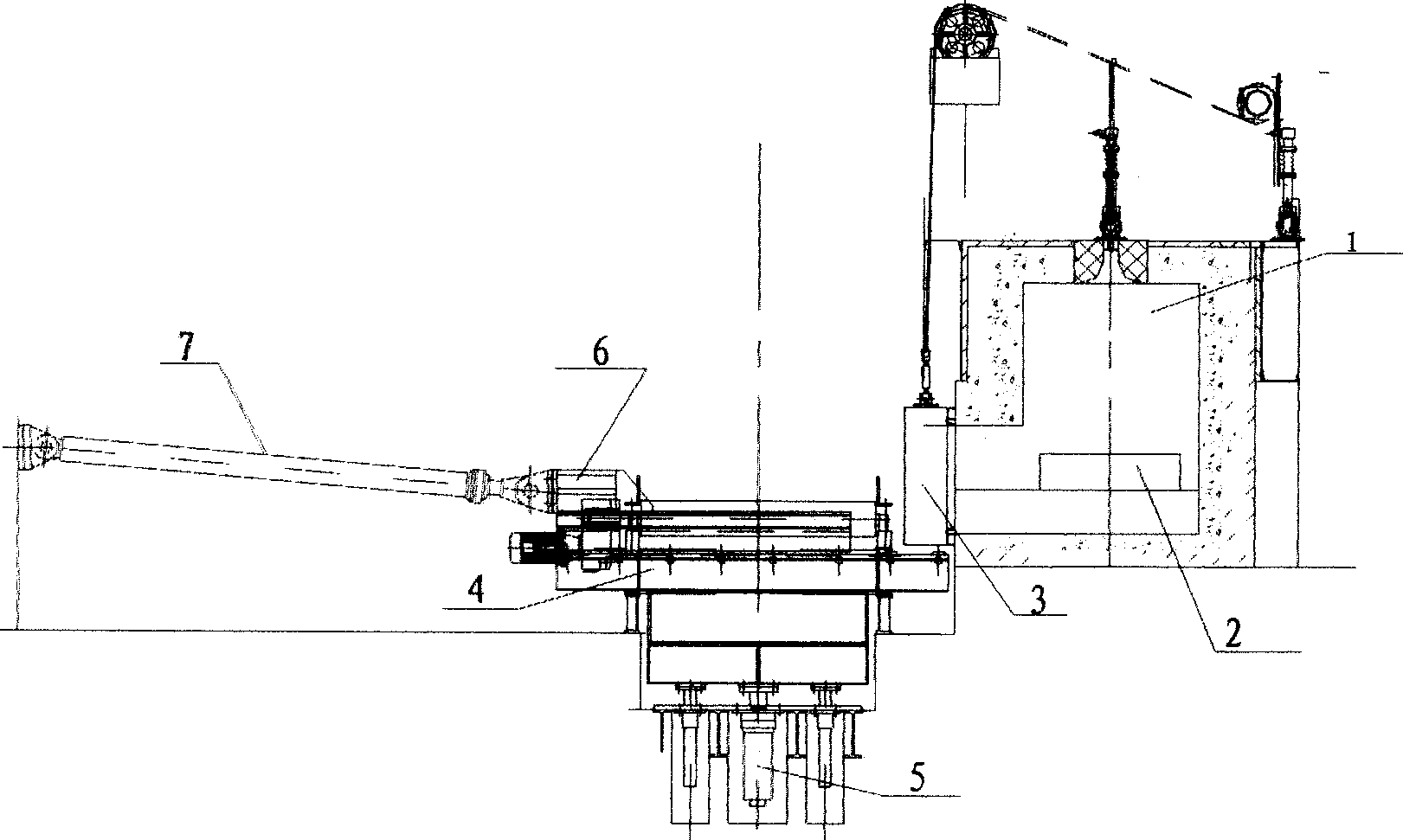

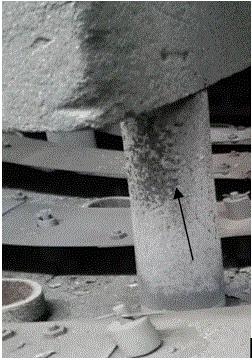

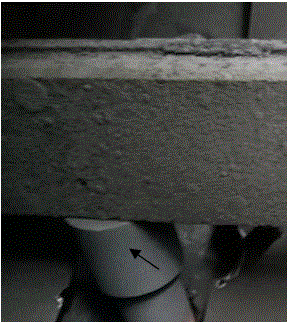

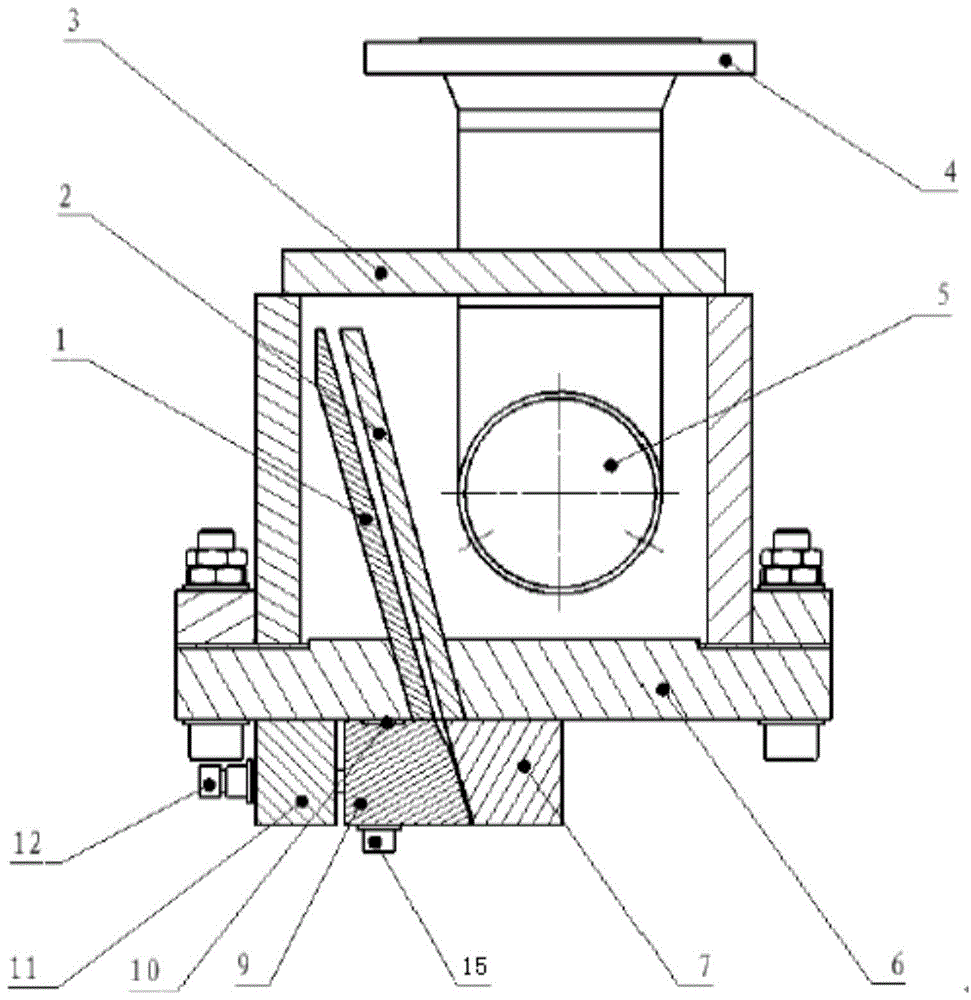

Production technique of large common-substance molybdenum plate

The invention relates to a production process of a large single heavy molybdenum plate in the rare metal press manufacturing field. The process of mixing-pressing-sintering-heating-hot rolling-variable speed shot blasting is adopted; the needed alloy ingredient powder material is loaded into a large mixing machine for mixing, the mixed powder material is loaded into a garment bag with a support frame and the mouth of the garment bag is sealed; the garment bag and the support frame are pressed into plate blank in a large isostatic pressing machine; hot rolling blank is sintered in a large sintering furnace, presintering is firstly carried out in the furnace, and then high-temperature sintering is carried out; heating is carried out by selecting three heating furnaces of different types, namely, an induction heating furnace, a radiation heating furnace and a roller-hearth type heating furnace sequentially; and a reversible hot rolling mill is automatically controlled for hot rolling by adopting four-roll and two-roll and four-roll type special hydraulic thickness, and the molybdenum plate after the hot rolling is treated with variable speed shot blasting. The method not only can effectively solve the problem of difficult production of the large big single heavy molybdenum plate, but also has low cost, small energy consumption, and is environment-friendly. The method is mainly used for plate rolling equipment.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

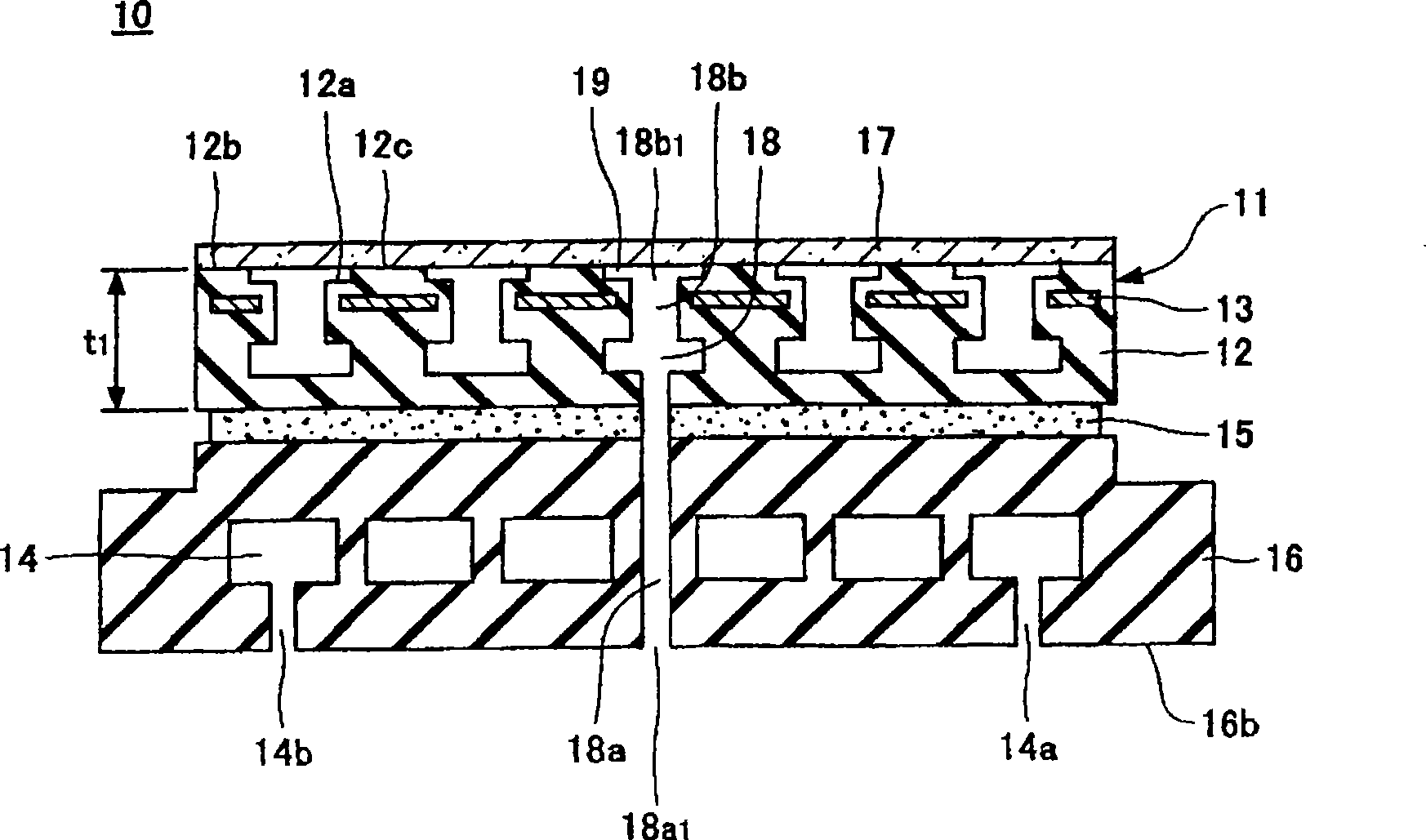

Electrostatic chuck and substrate temperature adjusting-fixing device

InactiveCN101471279AAchieving temperature uniformityReduce manufacturing costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

There is provided an electrostatic chuck for adsorbing and holding an adsorption object placed on an upper surface of a base body having an electrostatic electrode embedded therein and for filling inert gas of which a pressure is adjusted into a space formed between the upper surface of the base body and a lower surface of the adsorption object, wherein the base body includes a gas discharge portion embedded therein so as to discharge the inert gas to the space and a gas path embedded therein so as to introduce the inert gas into the gas discharge portion while communicating with the gas discharge portion.

Owner:SHINKO ELECTRIC IND CO LTD

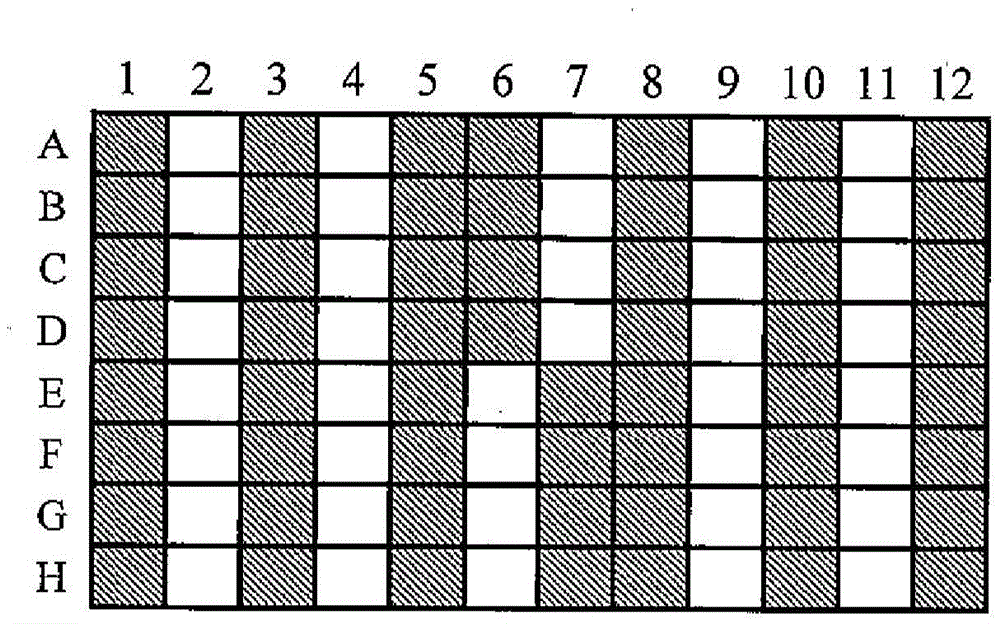

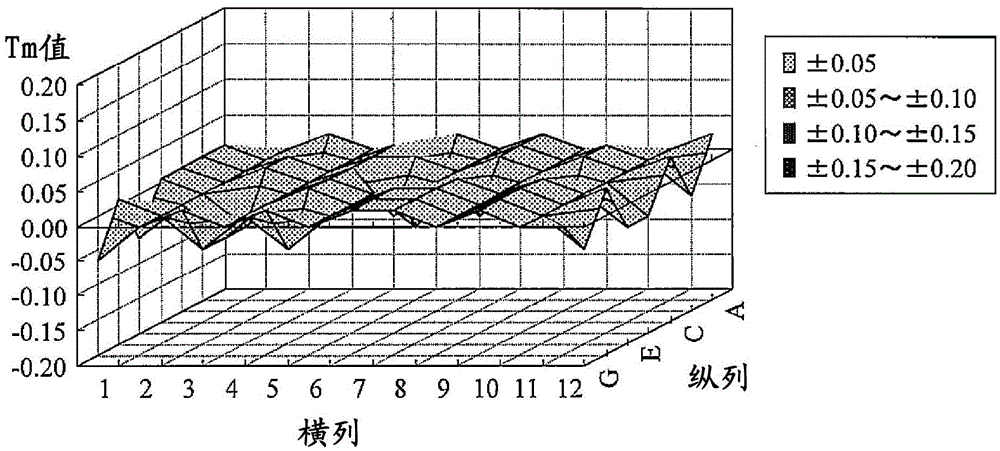

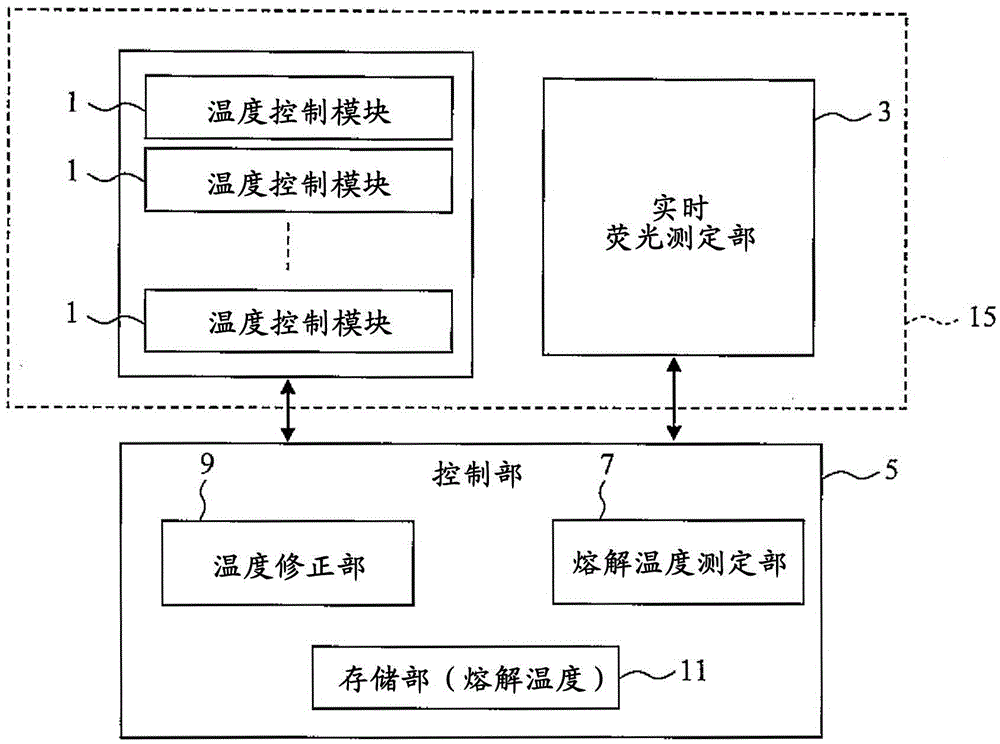

Nucleic acid amplification apparatus and nucleic acid analysis apparatus

ActiveCN103635568AAchieving temperature uniformityConstitute clearBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlTemperature difference

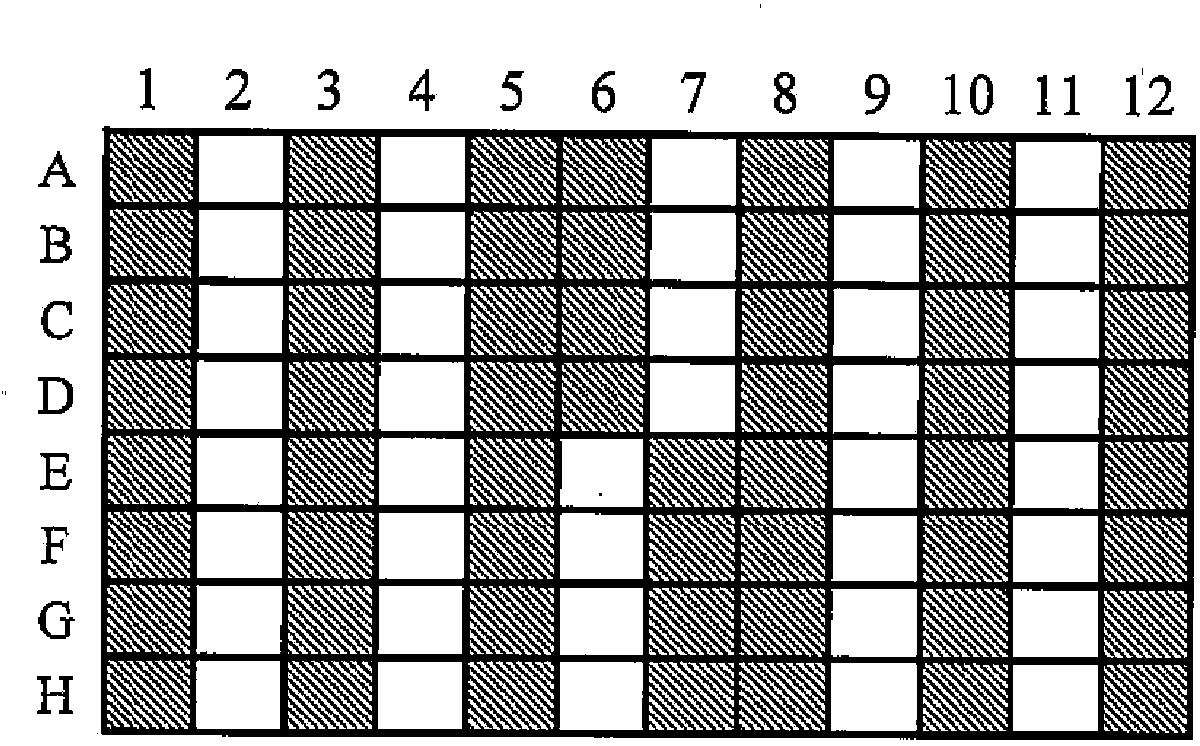

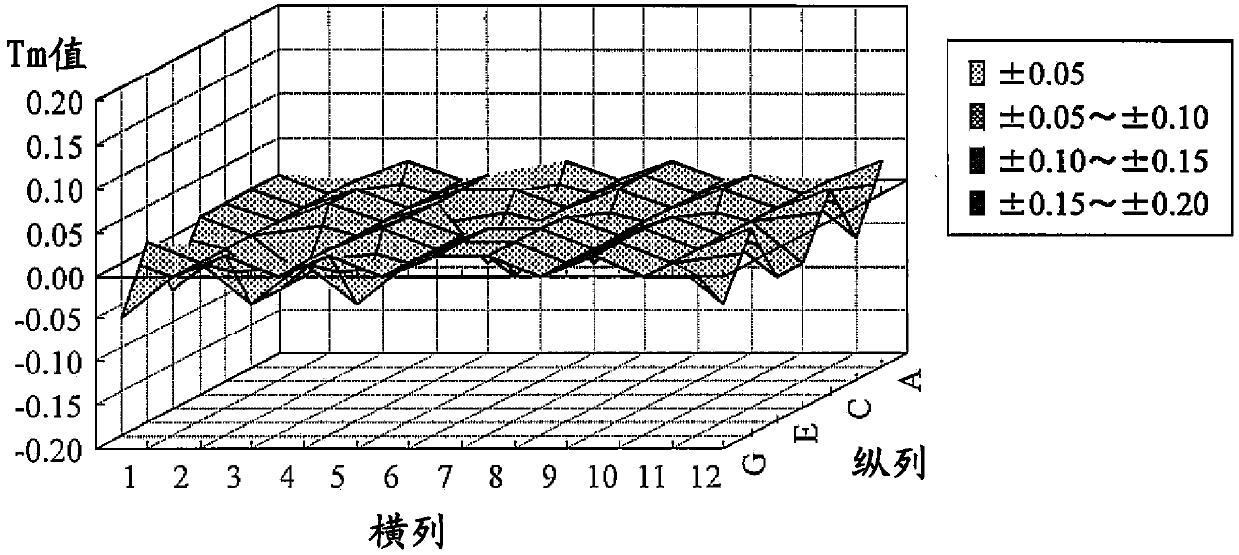

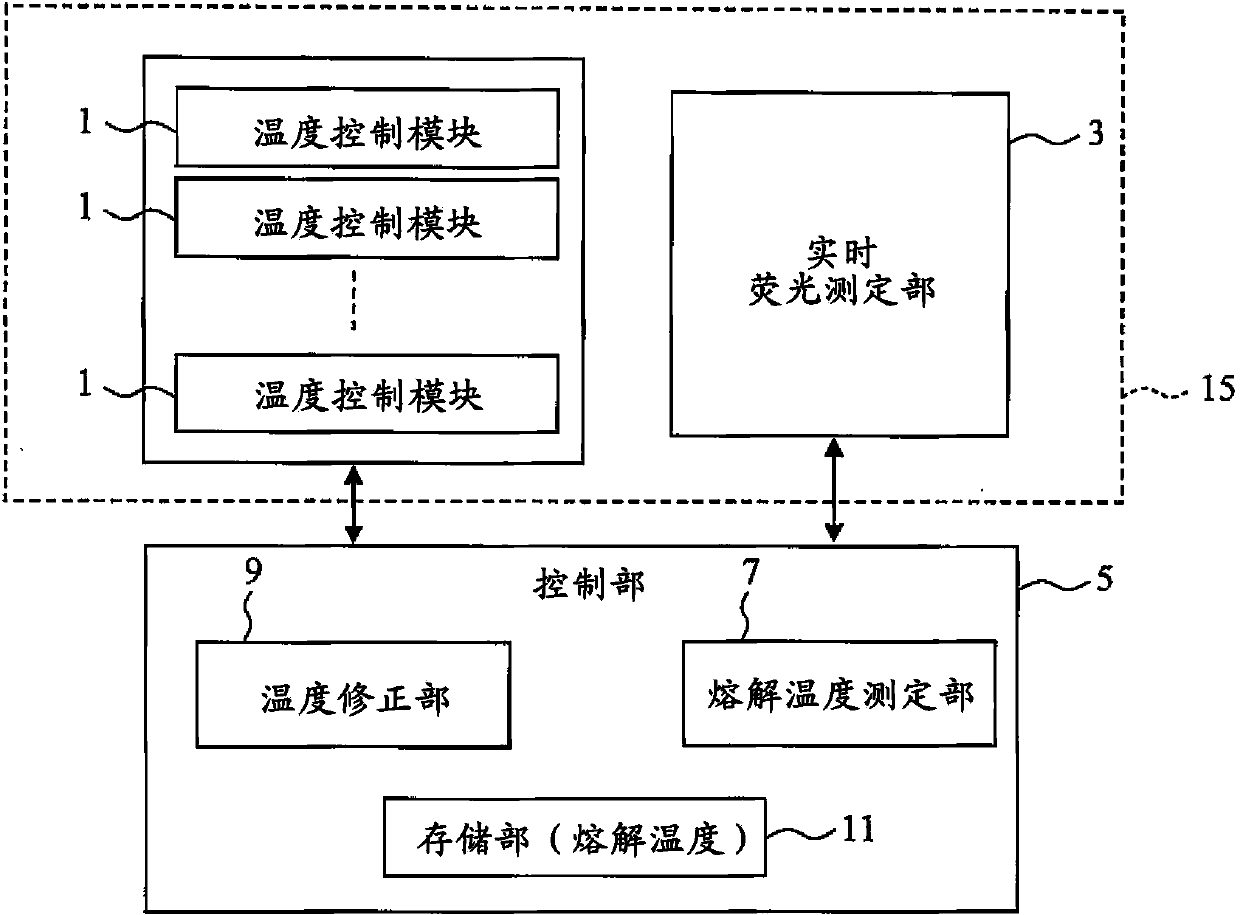

In conventional techniques, when a temperature measurement probe that has been corrected is used for the correction of absolute values of temperatures of temperature control blocks of which the temperatures can be controlled individually, there are temperature differences of up to 0.5 DEG C among the temperature control blocks. In the present invention, in contrast, a melting temperature of a temperature correction sample that is housed in each of reaction vessels corresponding to the temperature control blocks is measured as a measurement melting temperature. Subsequently, comparison is made between the measurement melting temperature corresponding to each of the temperature control blocks and a reference melting temperature for the temperature correction sample, and the absolute value of the temperature of each of the temperature control blocks is corrected on the basis of the value of the resultant difference.

Owner:HITACHI HIGH-TECH CORP

Battery pack temperature control structure for electric vehicles

ActiveUS9742043B2Large heightAchieving temperature uniformitySecondary cellsCell component detailsTemperature controlComputer module

Owner:NISSAN MOTOR CO LTD

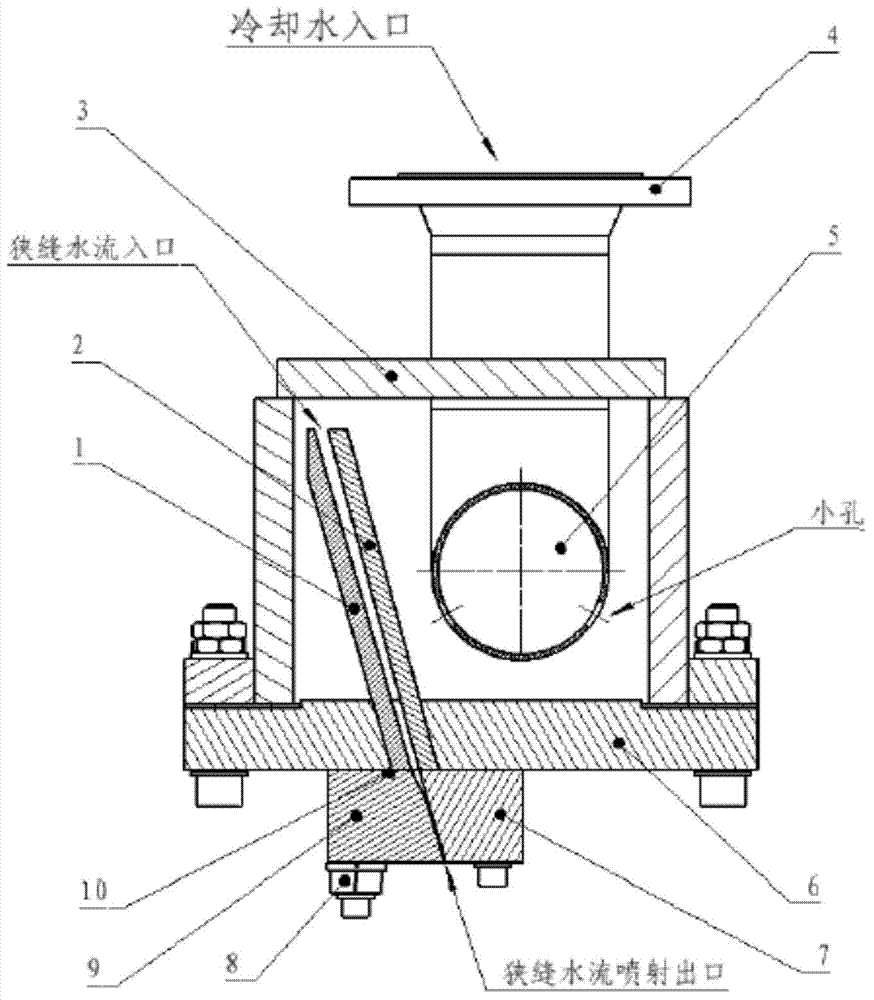

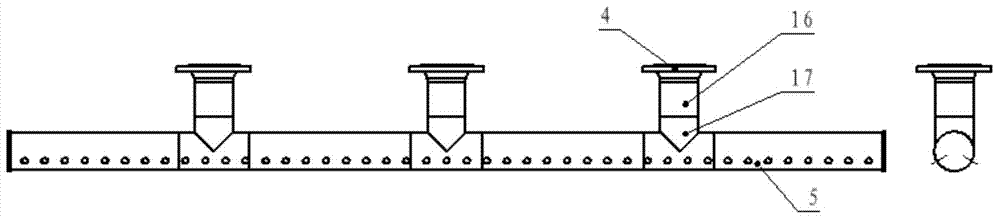

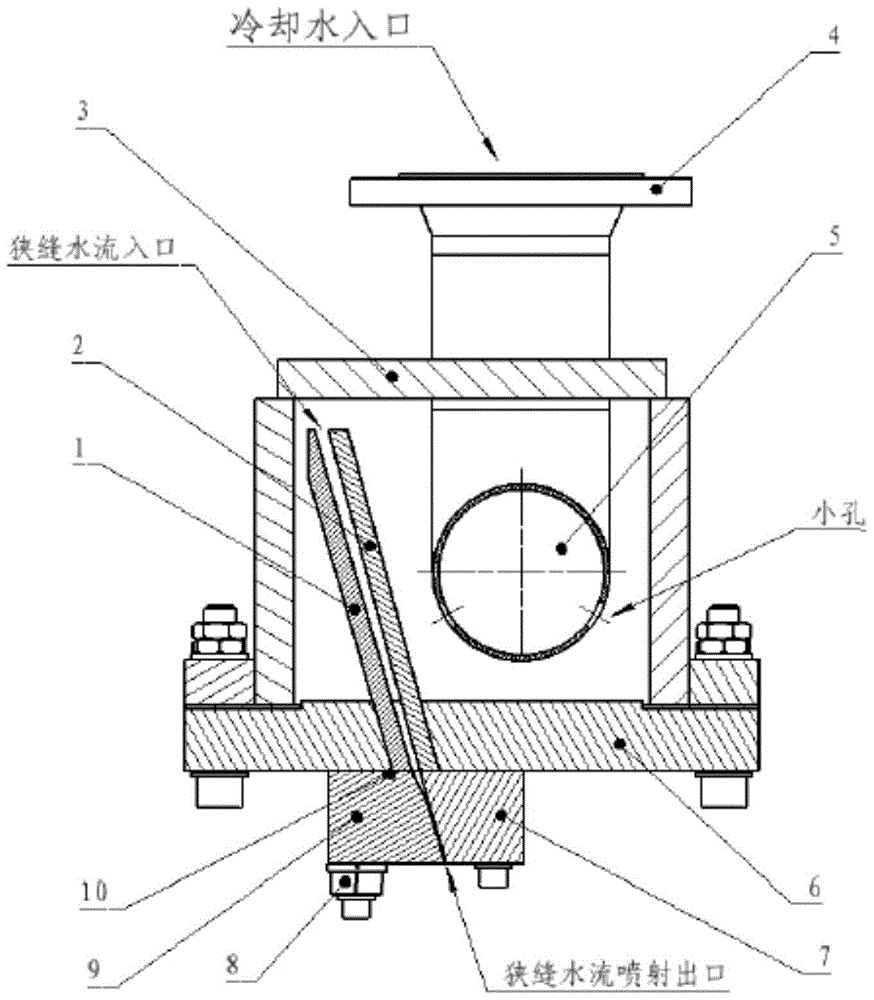

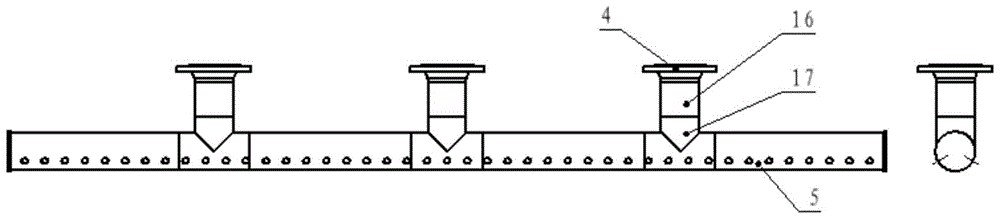

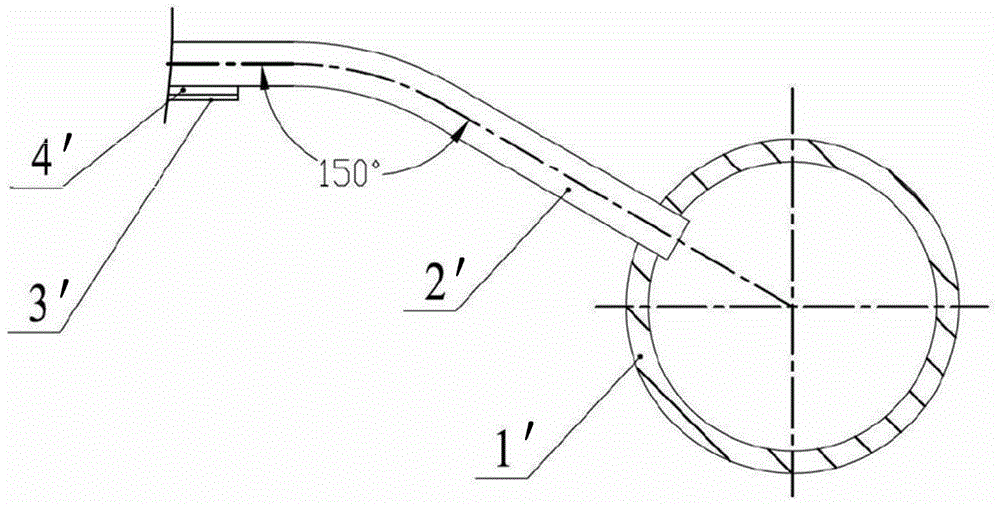

Cooling device for generating flat spraying jet

ActiveCN104741394AShorten the timeQuick start responseWork treatment devicesMetal rolling arrangementsHeat resistanceWater flow

The invention relates to a cooling device for generating a flat spraying jet. The cooling device comprises a tank for storing cooling water, and a slot for forming a spraying jet, wherein the slot is communicated with the tank through a drainage channel arranged in the tank. The cooling device further comprises a water inlet pipe component; the upper end of the water inlet pipe component is a cooling water inlet; the cooling water inlet is positioned rightly above the external of the tank; the lower end of the water inlet pipe component is a horizontal round pipe horizontally arranged in the tank; multiple small holes are formed in the two sides of the horizontal round pipe; the upper end of the drainage channel is a spraying jet inlet; the spraying jet inlet is positioned near the top of the tank; the drainage channel is communicated with the slot; the slot is formed by a fixed plate and an adjustable plate; and the width of the slot can be adjusted. The cooling device solves the problems of slow water current opening, slow water current closing and weak heat resistance in a traditional cooling device.

Owner:BAOSHAN IRON & STEEL CO LTD

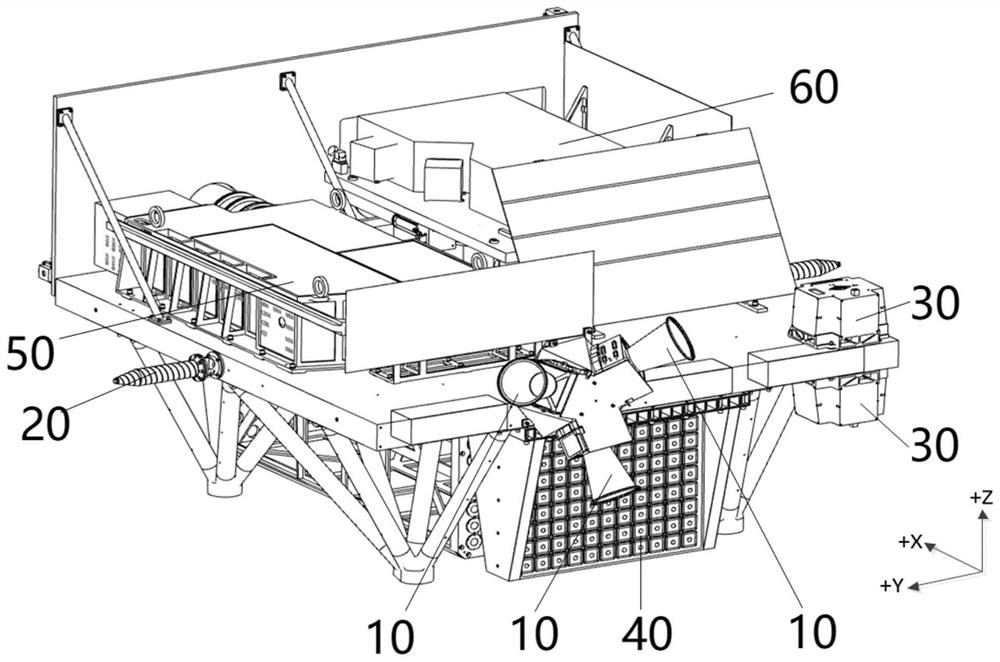

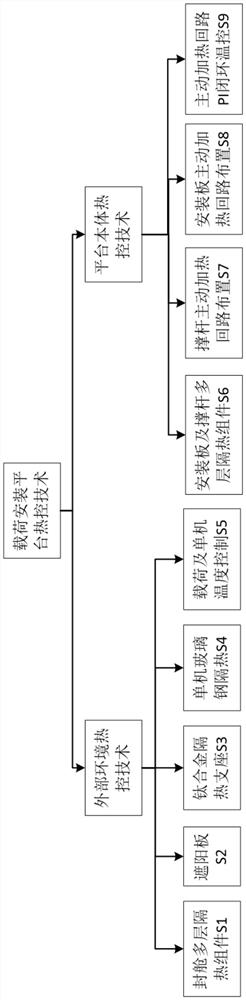

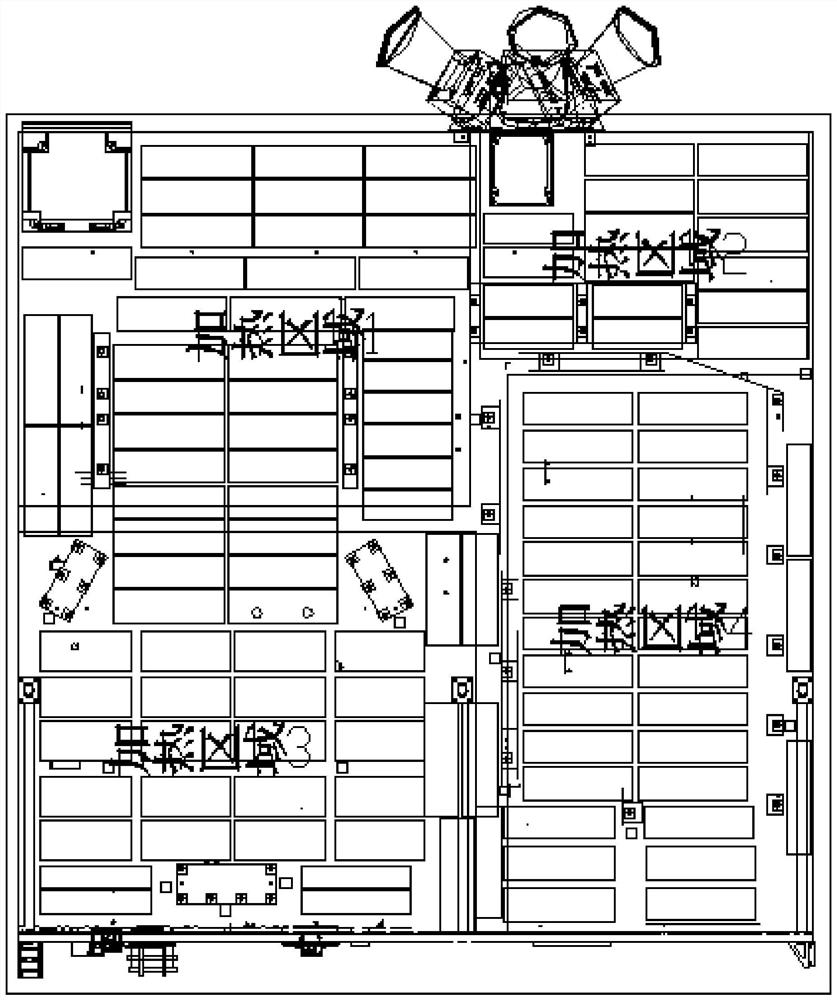

Satellite high-precision optical load installation platform thermal control system and method

ActiveCN111959830AMinimizes the effects of temperature uniformityAchieving temperature uniformityCosmonautic environmental control arrangementCosmonautic thermal protectionTemperature controlHeat flow

The invention provides a satellite high-precision optical load installation platform thermal control system and method. The system comprises an external environment thermal control module configured to reduce the influence of the external environment on the temperature uniformity of a satellite high-precision optical load installation platform body through an external heat flow shielding unit, a boundary temperature control unit and an installation part heat insulation unit; and a platform body thermal control module configured to equalize the temperature thereof through a surface thermal insulation unit, a heating loop arrangement unit and a PI closed-loop temperature control unit.

Owner:INNOVATION ACAD FOR MICROSATELLITES OF CAS +1

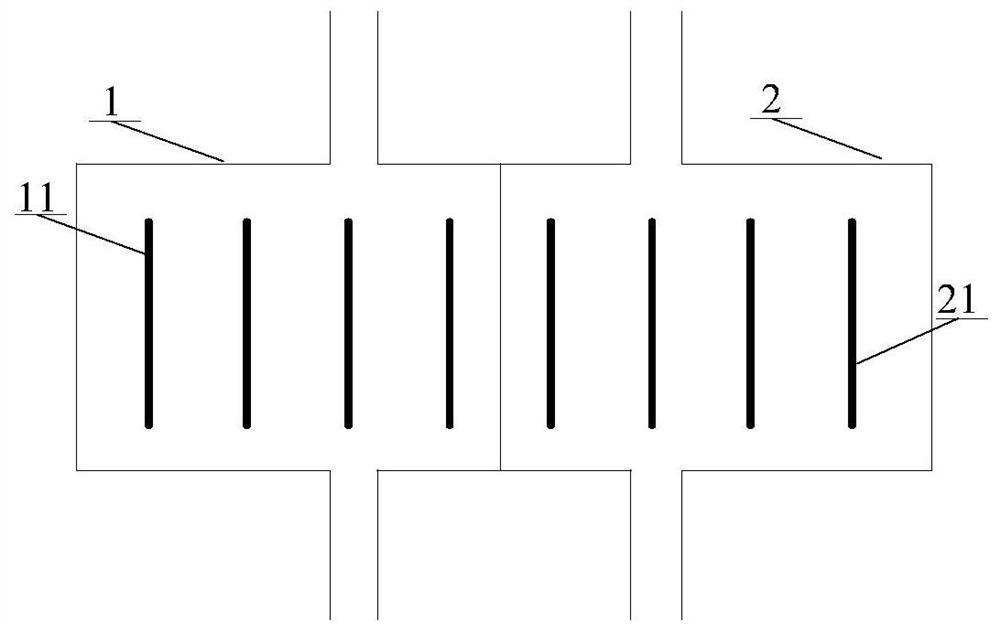

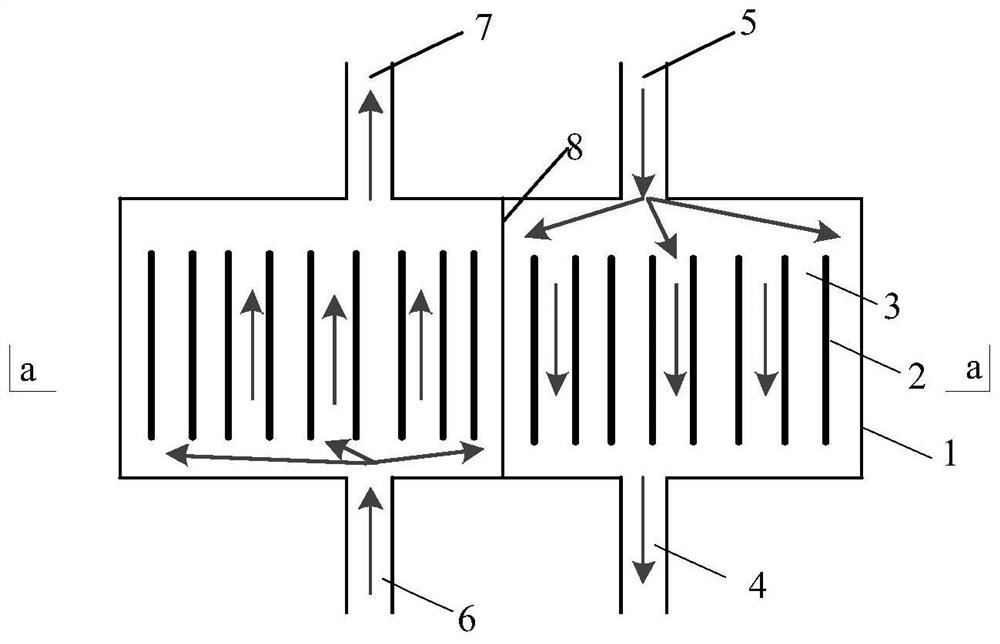

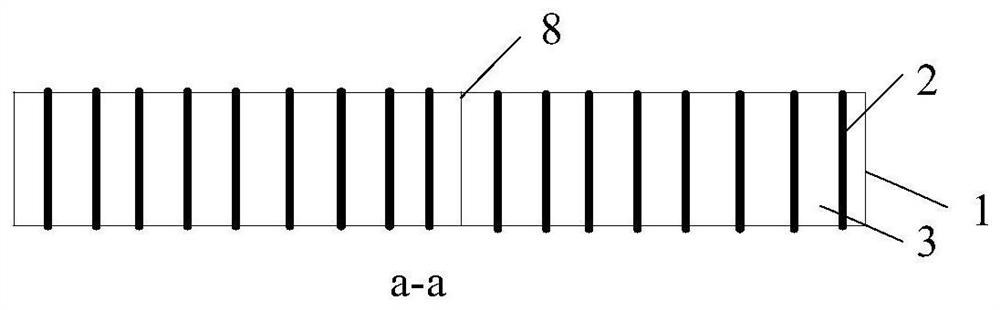

Liquid cooling plate and heat dissipating equipment

PendingCN112902715AAchieving temperature uniformityReduce convection heat transfer thermal resistanceSemiconductor/solid-state device detailsIndirect heat exchangersSingle phaseEngineering

The invention provides a liquid cooling plate and heat dissipating equipment. The liquid cooling plate comprises a single-phase channel and a two-phase channel. First fins are arranged at an interval in the single-phase channel, and second fins are arranged at an interval in the two-phase channel. A liquid state cooling liquid exchanged in heat by the first fins in the single-phase channel becomes a gas-liquid two phase cooling liquid and is then output by the second fins in the two-phase channel after heat exchange. According to the technical scheme, the gas-liquid two phase cooling liquid is exchanged in heat again via the two phase channel, so that the temperature difference between a heat dissipating object and the cooling liquid is reduced, the convection heat exchange heat resistance is reduced, the cooling effect is improved, and a supercooling problem in the heat dissipating process can be prevented.

Owner:ZTE CORP

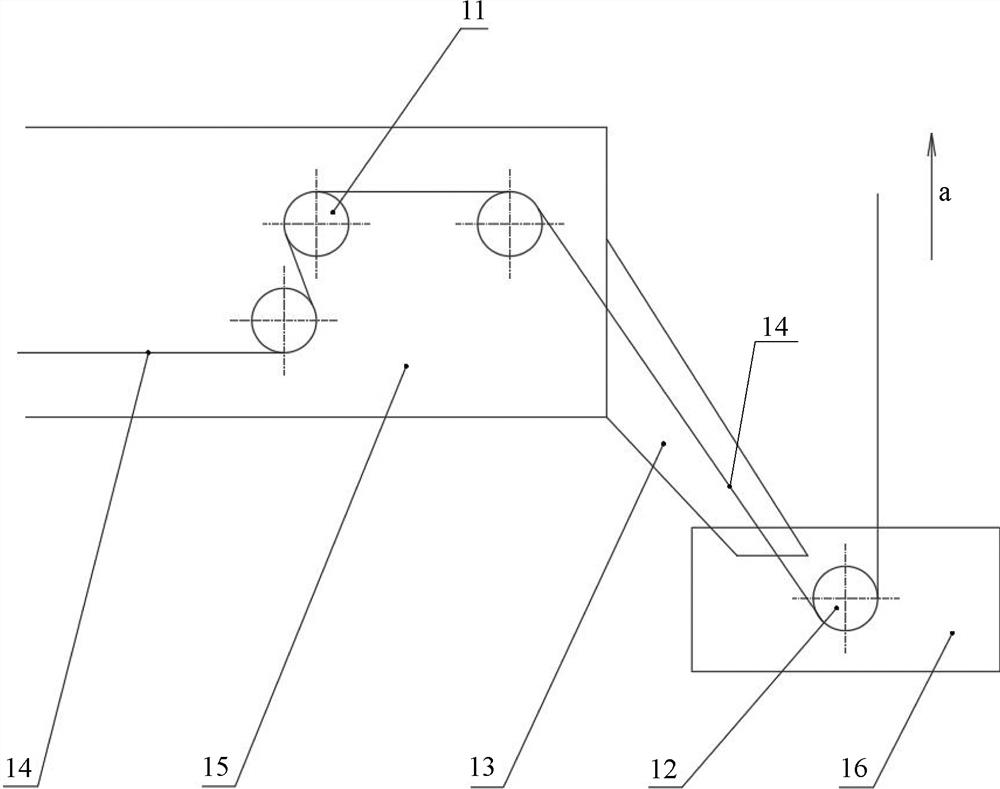

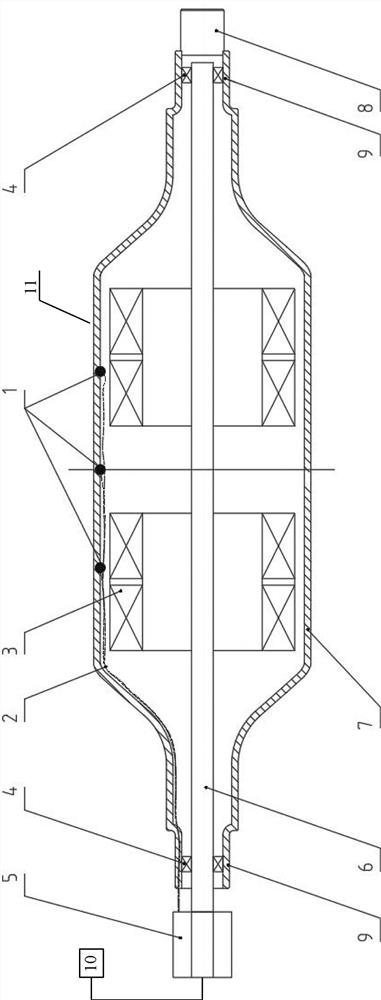

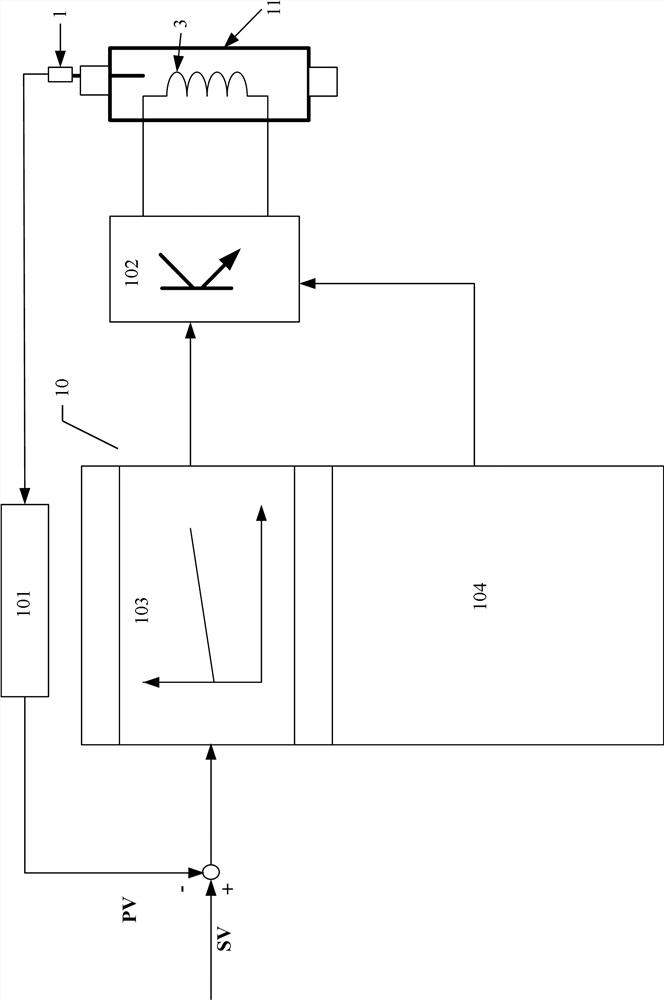

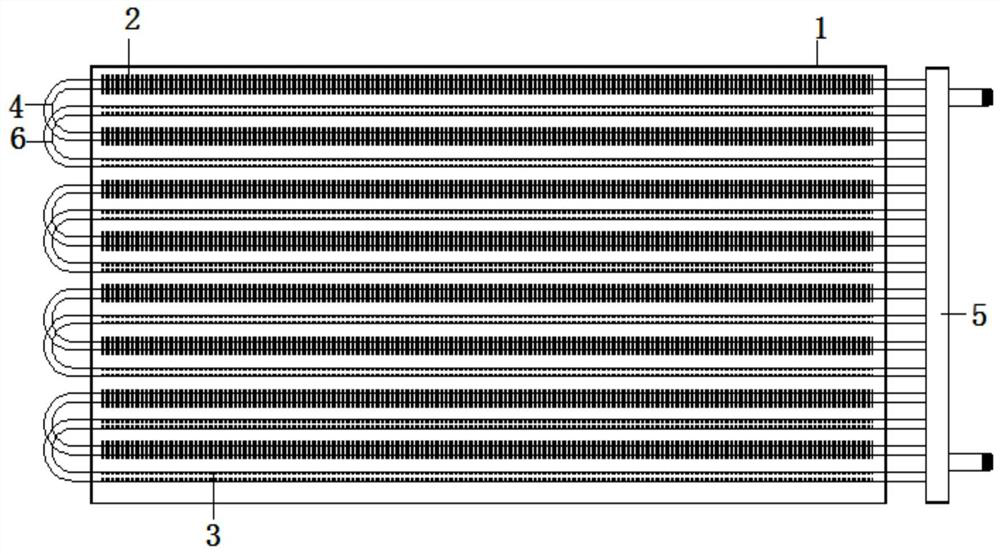

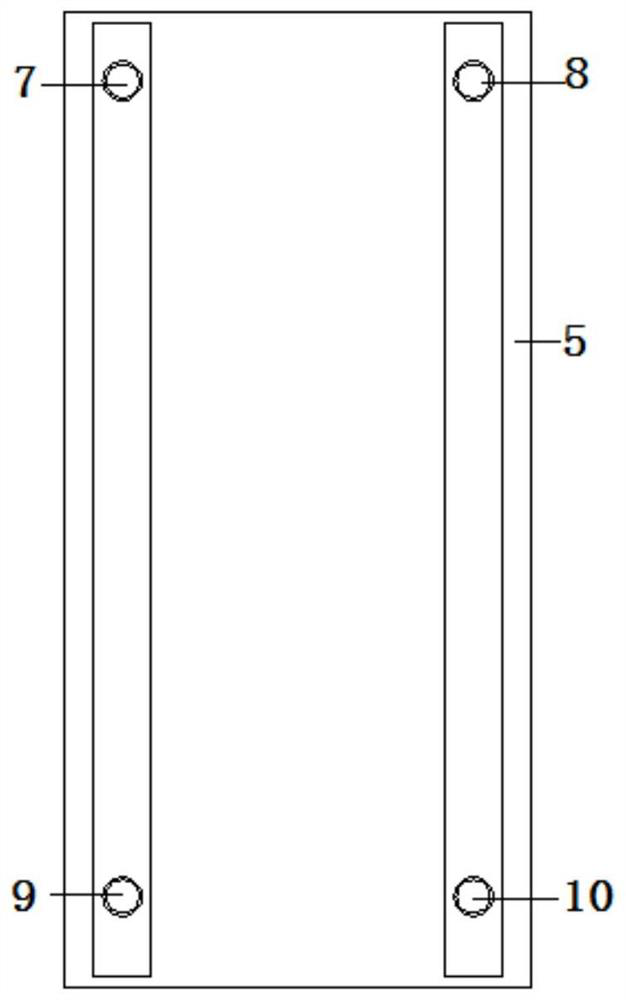

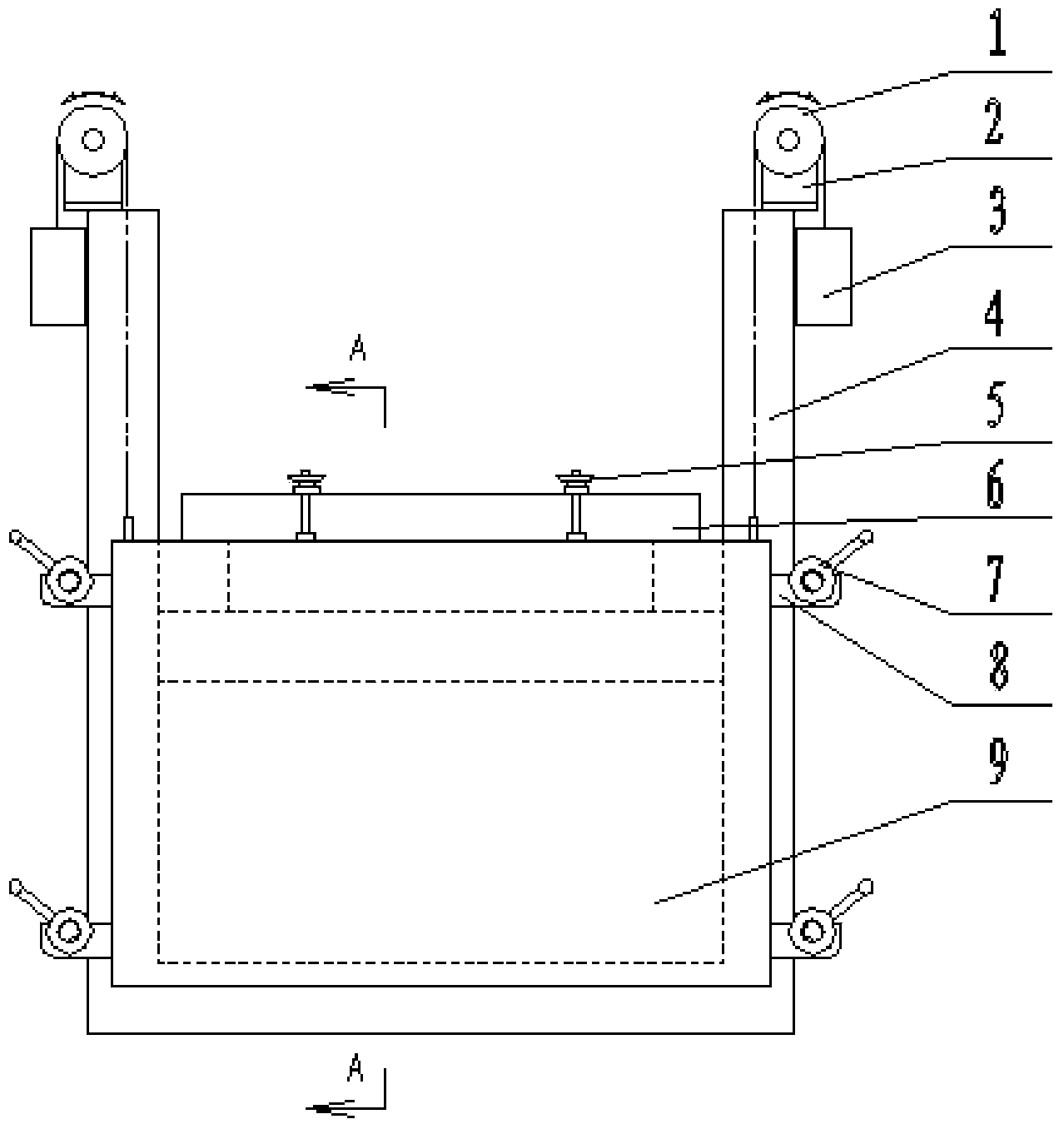

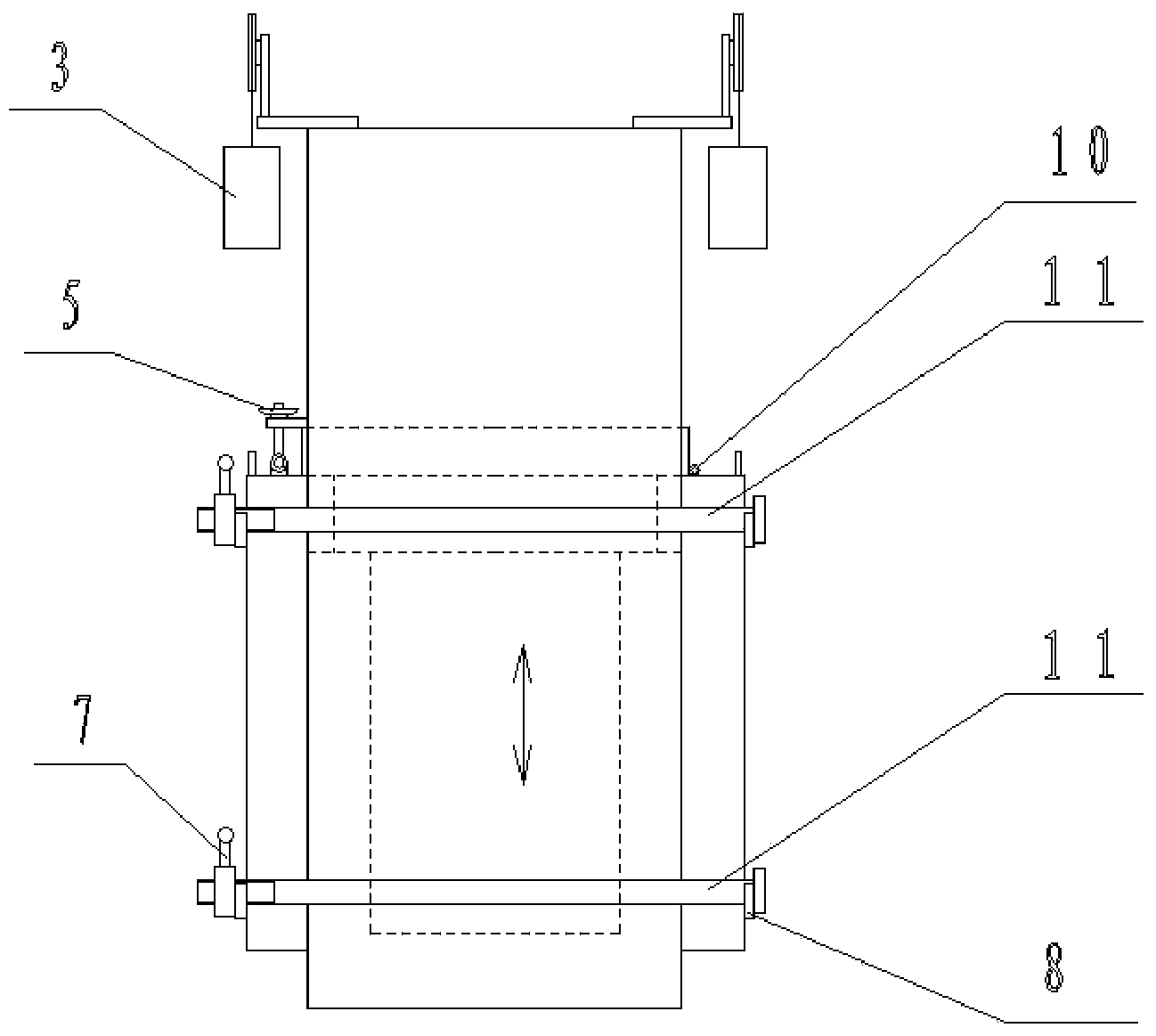

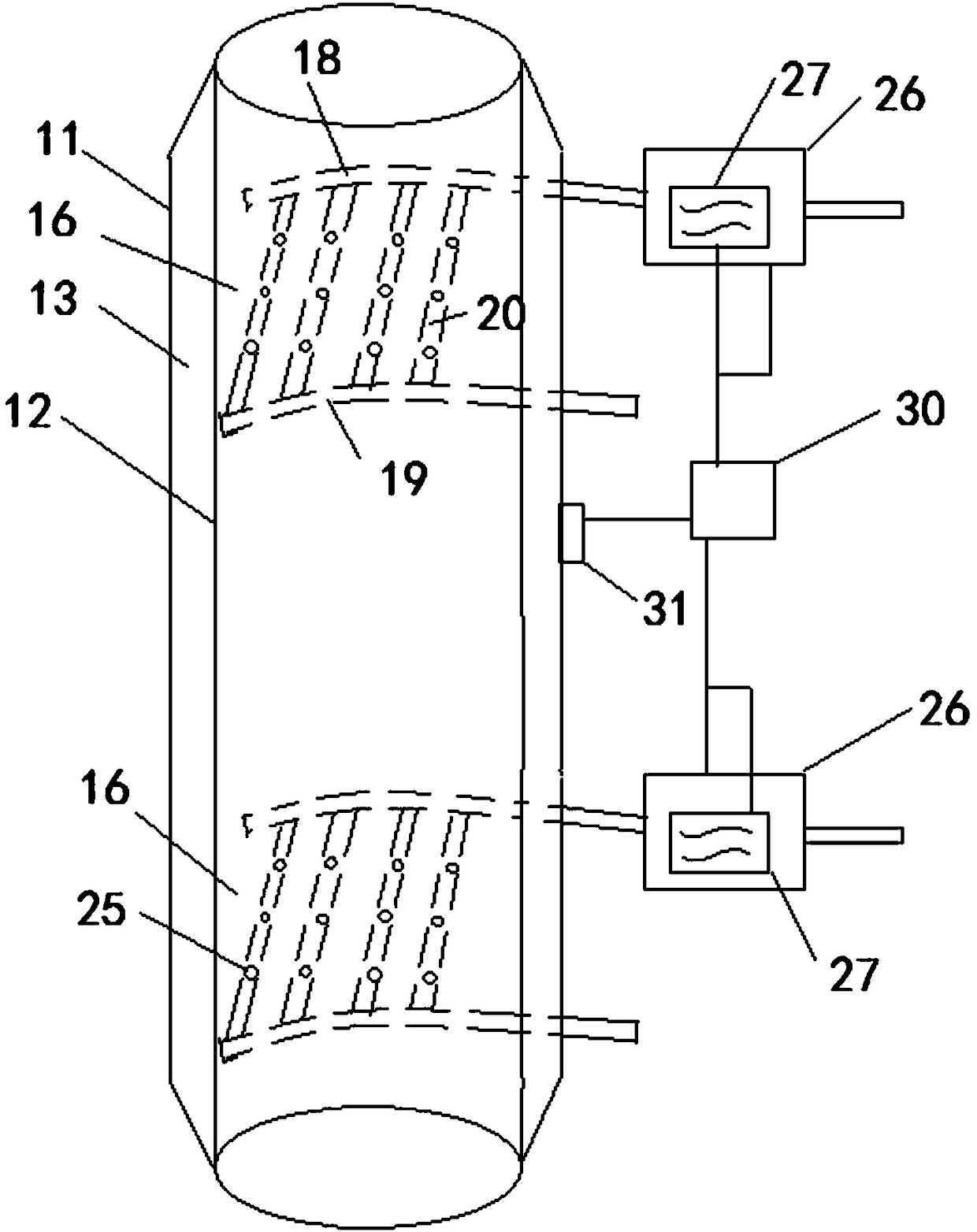

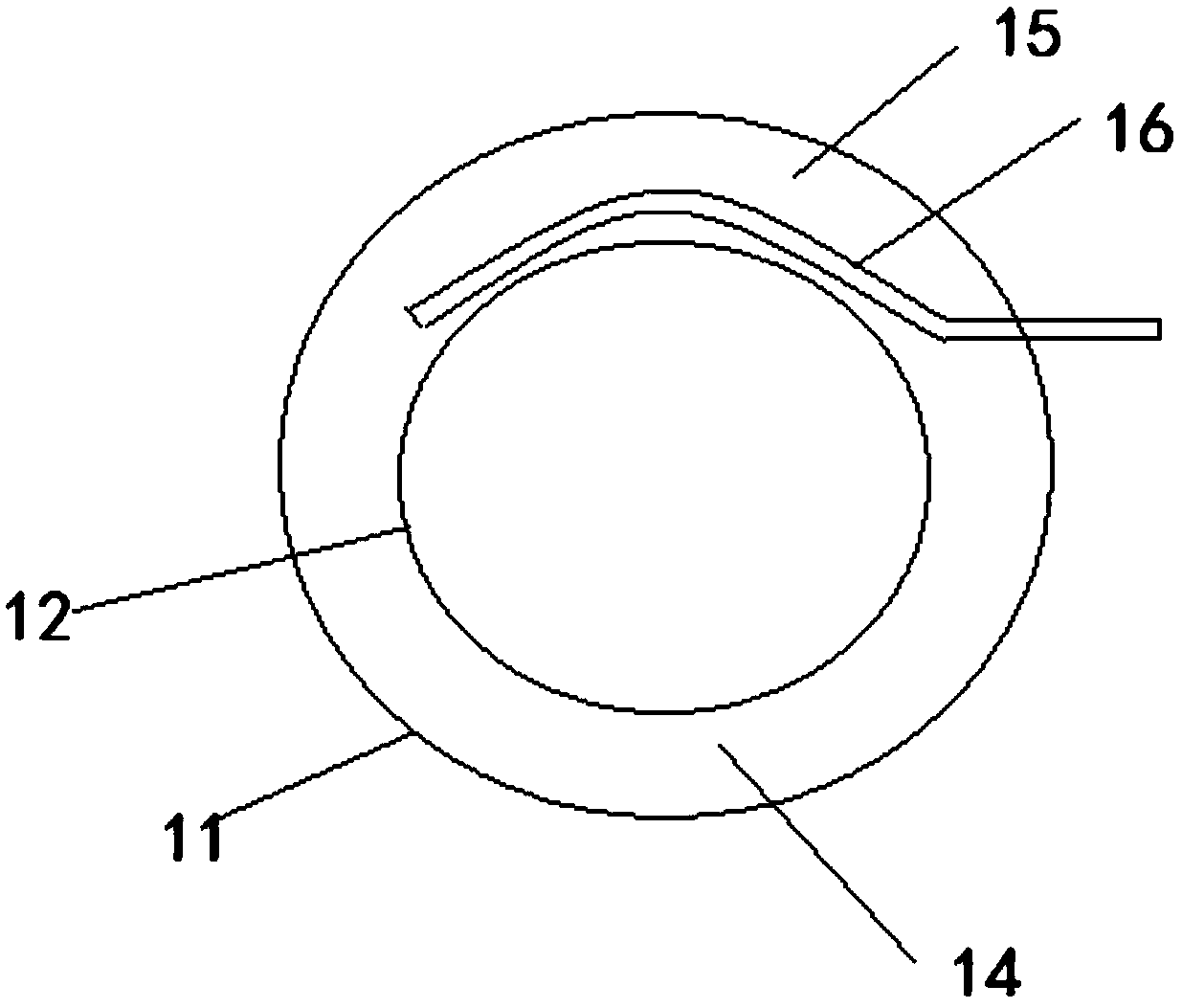

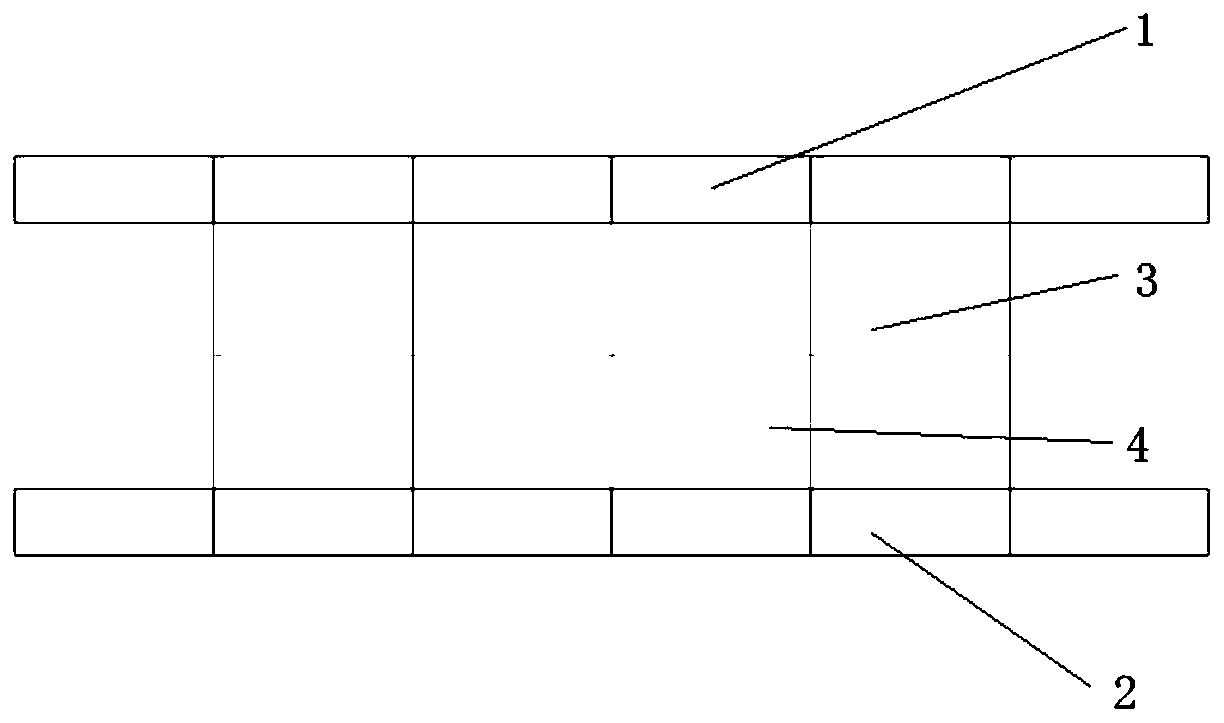

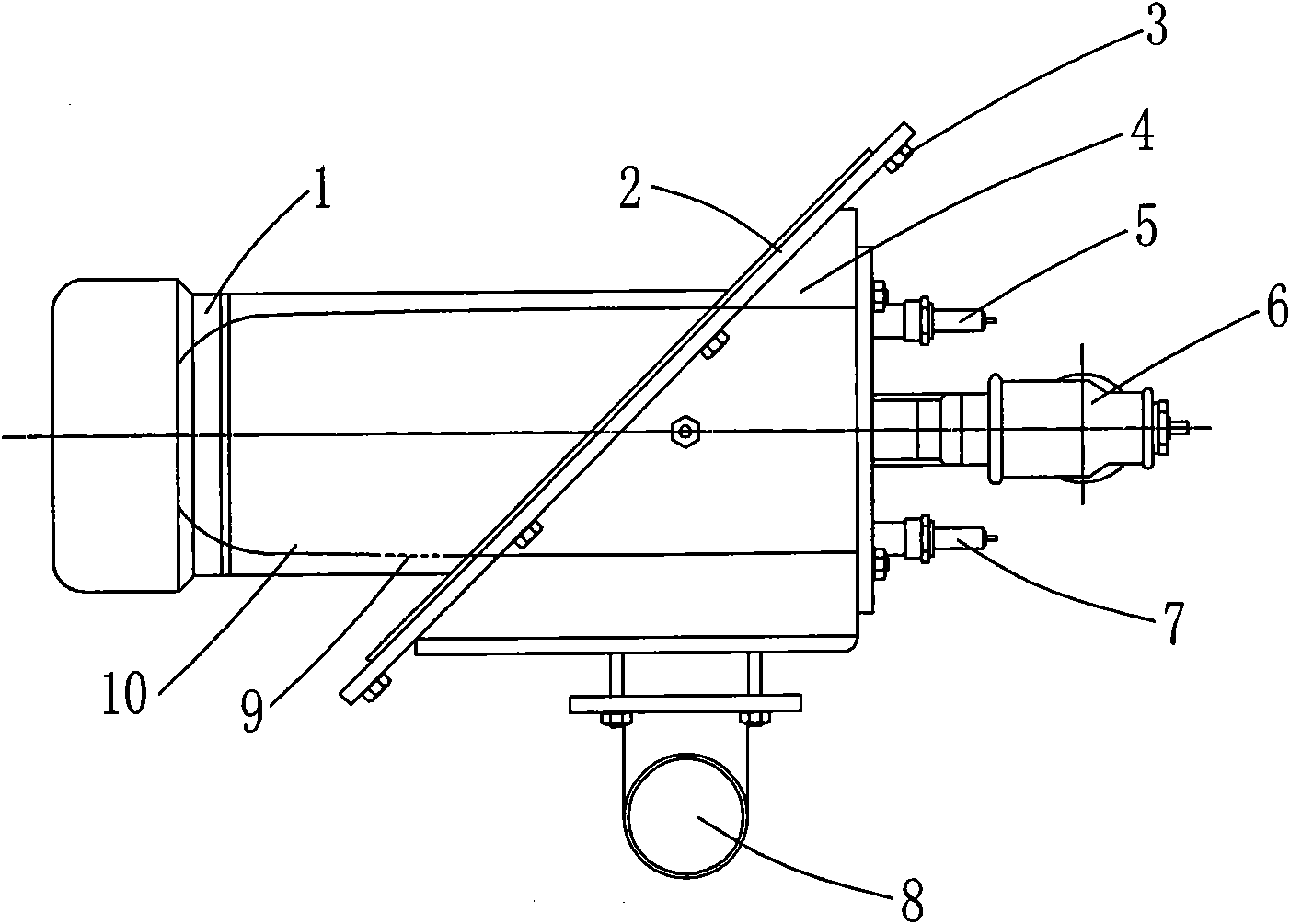

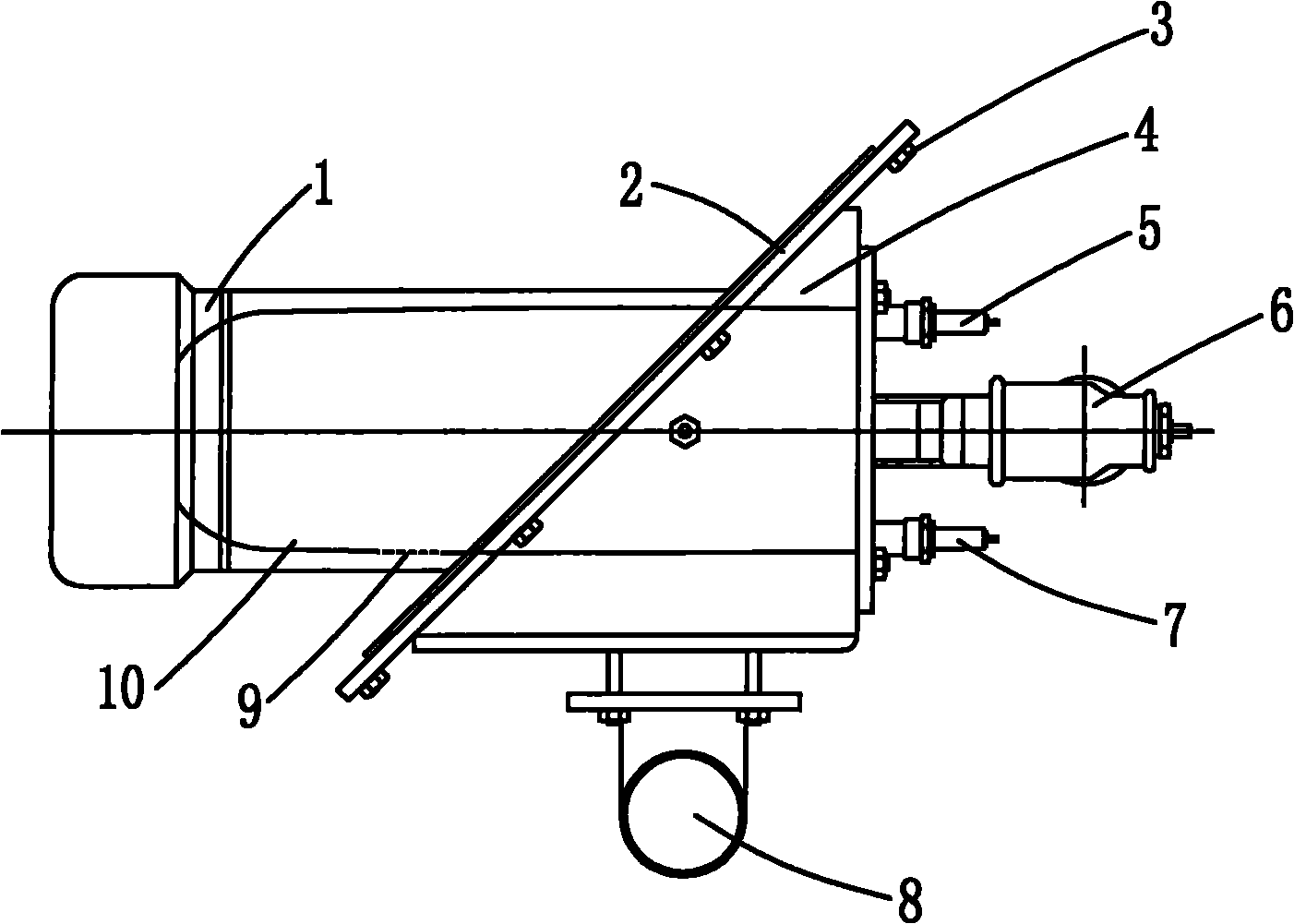

Device for controlling temperature uniformity of strip steel before entering zinc pot and using method of device

InactiveCN113122698AAchieving temperature uniformityUniform temperature controlHot-dipping/immersion processesFurnace typesMolten stateSafety control

The invention relates to the field of a hot dipping process which uses molten zinc or cadmium or an alloy coating material based on the molten zinc or cadmium and does not influence the shape, in particular to a device for controlling temperature uniformity of strip steel before entering a zinc pot and a using method of the device. The device for controlling the temperature uniformity of the strip steel before entering the zinc pot comprises a heating roller (11), a sink roller (12), a furnace nose (13), the strip steel (14), a heat treatment furnace (15) and the zinc pot (16), and is characterized in that the heating roller (11) comprises a temperature thermocouple (1), a thermocouple compensation lead wire (2), an induction heating body (3), a bearing (4), a slip ring (5), a mandrel (6), a roller body (7), a driving shaft (8), a middle shaft sleeve (9) and a temperature control device (10). The using method of the device for controlling the temperature uniformity of the strip steel before entering the zinc pot is characterized by comprising the following steps of (1) measuring, (2) calculating, (3) adjusting, and (4) safety control. By means of the device and method, the temperature control is made uniform.

Owner:BAOSTEEL ENG & TECH GRP +1

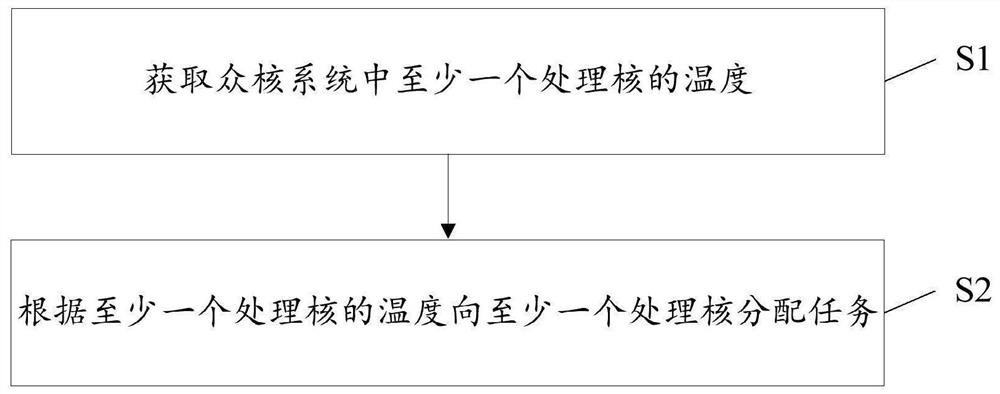

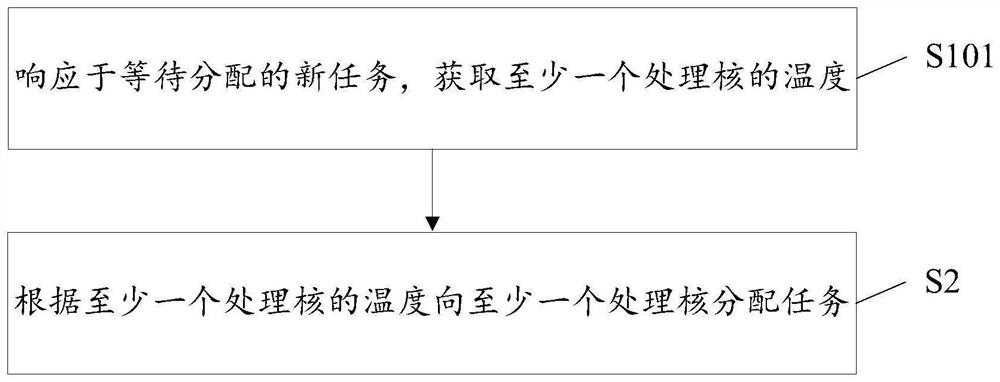

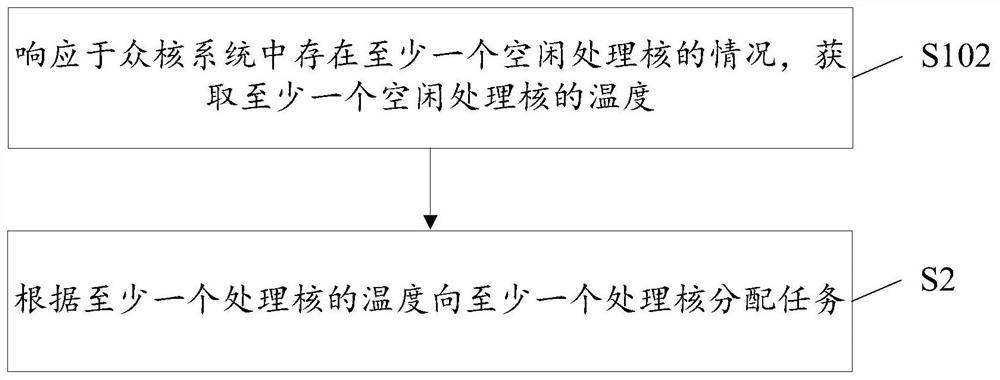

Task allocation method, processing core, electronic equipment and computer readable medium

PendingCN112416586AAchieving temperature uniformityEasy to understandResource allocationReal-time computingCore system

The invention provides a task allocation method. The task allocation method comprises the steps: acquiring the temperature of at least one processing core in a many-core system; and allocating tasks to at least one processing core according to the temperature of at least one processing core. The invention further provides a processing core, electronic equipment and a computer readable medium.

Owner:LYNXI TECH CO LTD

Preparation method of heating pipe for water radiating pipe detection device

InactiveCN111186156ASolve the problem of local uneven temperatureAchieving temperature uniformityCoatingsTubular articlesViscous liquidFiber

The invention discloses a preparation method of a heating pipe for a water radiating pipe detection device. The preparation method comprises the following steps of uniformly spraying acid fluid on theinner surface of a metal steel pipe, washing and drying to obtain a roughened steel pipe; adding phenolic resin into absolute ethyl alcohol, and uniformly stirring to form viscous fluid, so as to obtain phenolic resin viscous fluid; uniformly coating the rough surface of the steel pipe with the phenolic resin viscous liquid, and then extruding and flatly paving a phenolic foam board on the roughsurface at constant temperature to obtain a heat-insulating coated steel pipe; adding aluminum oxide into the phenolic resin viscous liquid in the step 2, and carrying out ultrasonic dispersion to obtain suspended viscous liquid; and flatly paving a graphene fiber net on the inner surface of the steel pipe, and then coating the surface of the graphene fiber net with the suspension viscous liquid to obtain heating pipe through constant-temperature extrusion reaction for 2 to 4h. According to the preparation method of the heating pipe for the water radiating pipe detection device, the problem ofnon-uniform local temperature is solved, the graphene is used as a heating layer to form a uniform discharge net, and meanwhile, the temperature uniformity is realized by using the high heat conductivity coefficient of the graphene.

Owner:SHAOXING UNIVERSITY

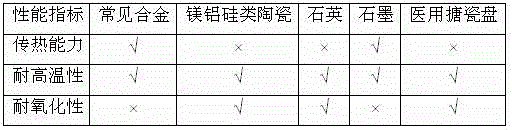

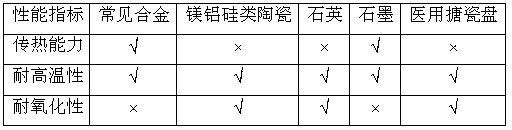

Graphite enamel material and production method thereof

The invention relates to a production method of a graphite enamel material. The method concretely comprises the following steps: 1, producing a graphite matrix body: selecting a graphite bar or board as a matrix body material, and processing the matrix body material into a corresponding shape according to demands to obtain the graphite matrix body; 2, plating titanium on the surface of the graphite matrix body: A, wetting the surface of the graphite matrix body by using an adhesive; B, sprinkling plating powder to the wetted surface of the graphite matrix body; C, performing heat preservation on the graphite matrix body for 3-6h under conditions of the vacuum degree being 0.5-5Pa and the temperature being 600-850 DEG C; and D, performing cooling to the temperature of 100 DEG C or less, discharging the processed material from a furnace, performing cooling to a room temperature, and brushing away redundant powder by using a hair brush; and 3, preparing a titanium nitride layer: putting the graphite matrix body of which the surface is plated with the titanium in the step 2 to a vacuum furnace, performing vacuumizing to 0.1Pa or less, and starting heating; when the temperature is raised to 950-1200 DEG C, introducing nitrogen to 0.05+ / -0.02MPa, and performing heat preservation for 20-200min; and performing cooling to the temperature of 100 DEG C or less, and discharging the finished material from the vacuum furnace. The graphite enamel material has the advantages of high heat transmission, oxidation resistance, high-temperature resistance, temperature shock resistance and the like, and can be made into a furnace body supporting material, a material frame, a material plate and the like.

Owner:ZHONGNAN DIAMOND CO LTD

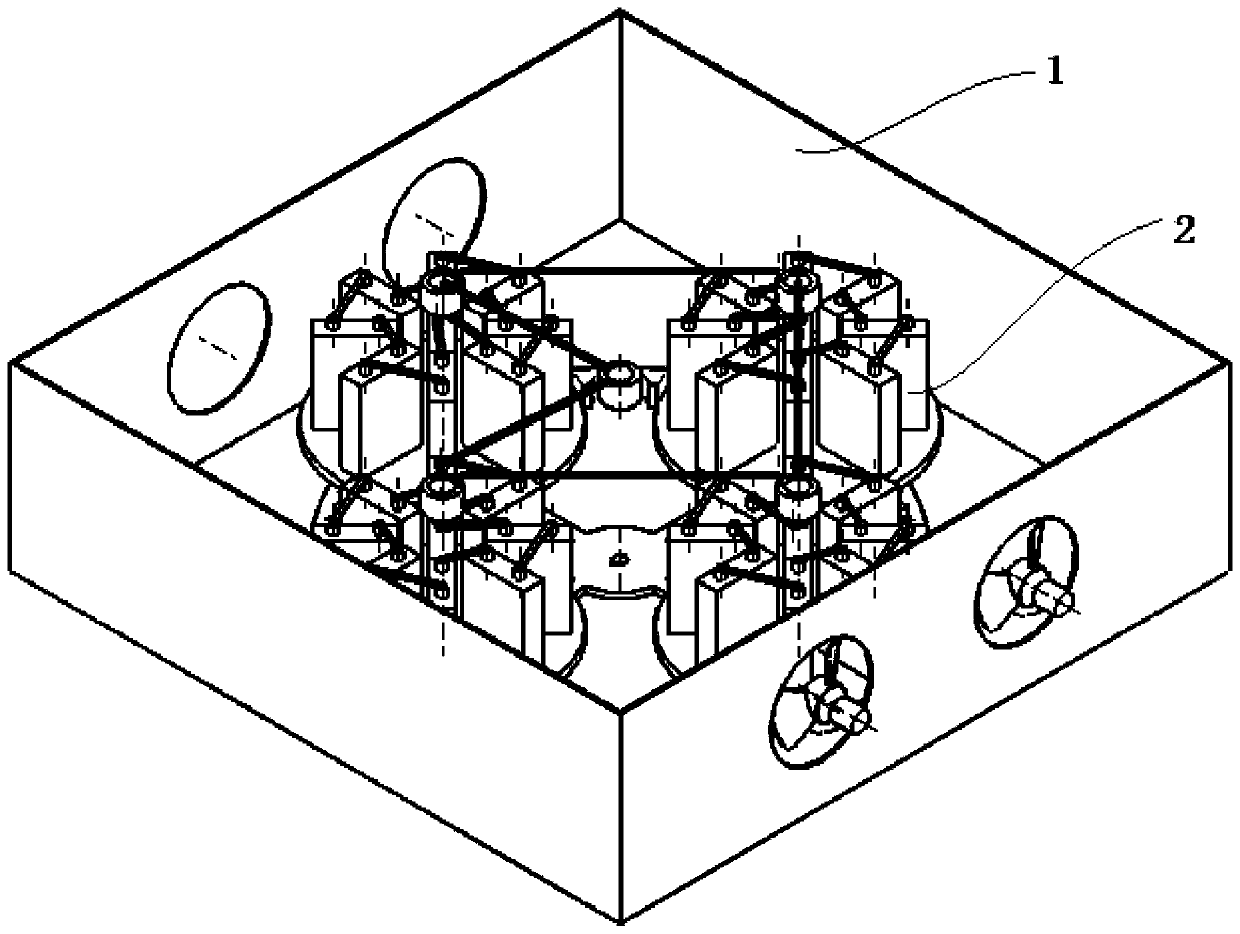

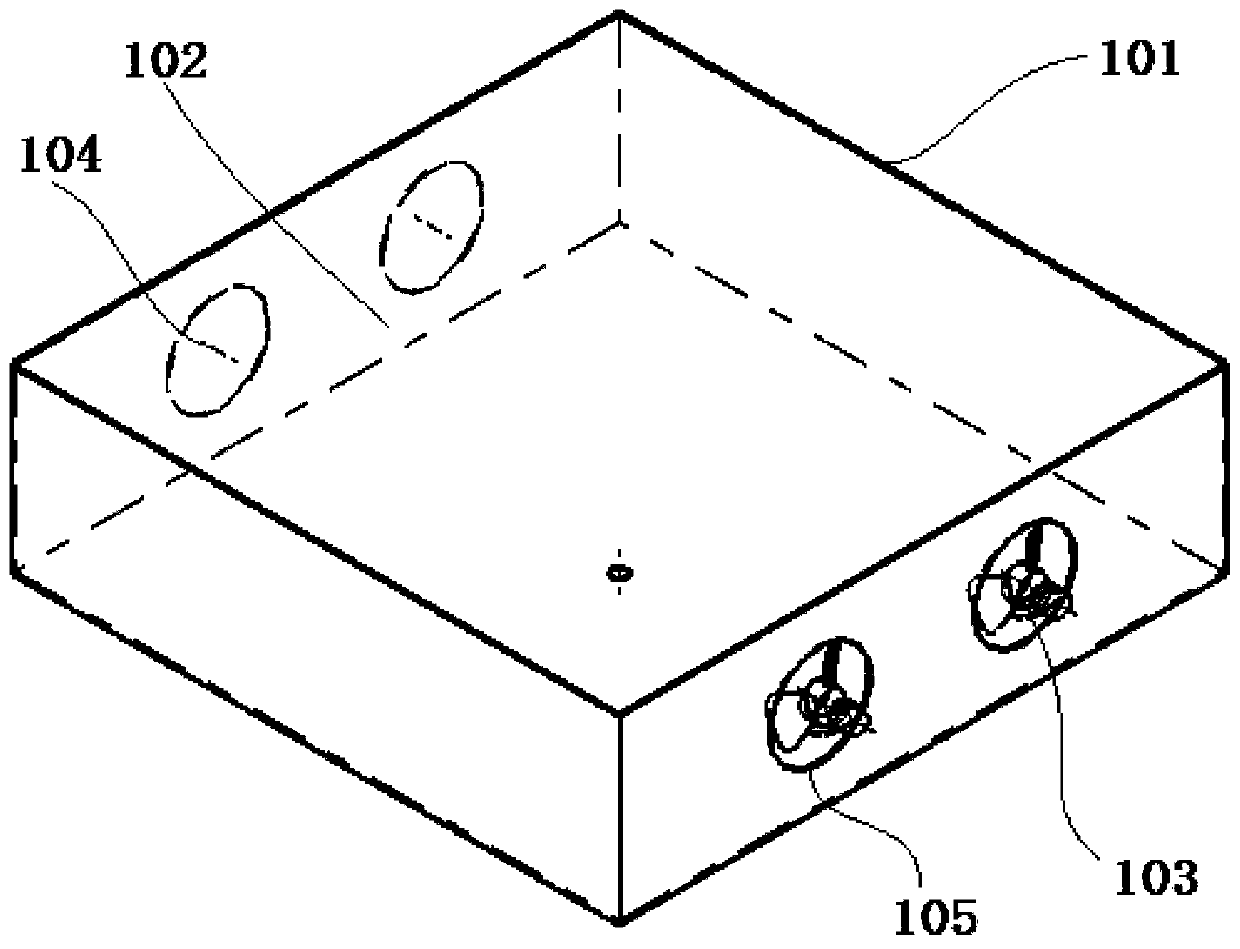

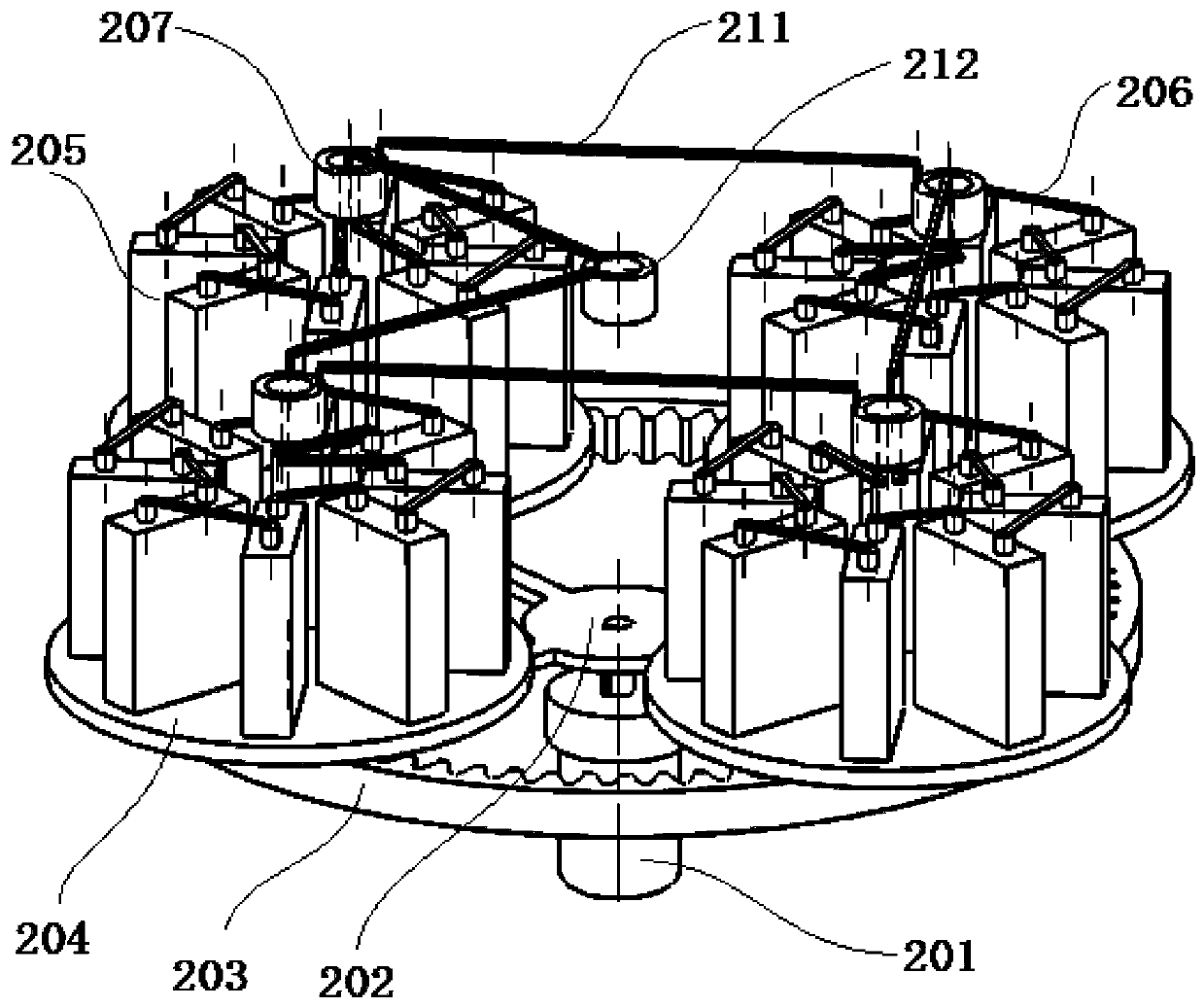

Rotary battery pack thermal management system based on air-cooling uniform temperature control

PendingCN110571496AGuaranteed temperature uniformityImprove uniformitySecondary cellsCell component detailsTemperature controlLow speed

The invention discloses a rotary battery pack thermal management system based on air-cooling uniform temperature control. The rotary battery pack thermal management system comprises a box body and a battery pack rotating module. The battery pack rotating module comprises a low-speed motor, a rigid rib plate, a large inner gear, discs, single batteries and a plurality of small outer gears. The rigid rib plate is composed of a center plate and a plurality of ribs. The low-speed motor is connected with the center plate. The tail end of each rib is connected with one small outer gear in a revolutepair form. The large inner gear and the small outer gears form a planetary gear structure and are meshed with each other. One disc is fixedly installed in the center of each set of small outer gears.A circle of battery pack composed of a plurality of annularly and evenly distributed single batteries is fixedly installed on each disc. A rotary conductive sliding ring is installed at the top of the center of each battery pack. Fans are installed on the box body. According to the invention, the batteries are driven to realize revolution and autorotation motion, and the battery packs are enabledto have the same motion condition and cooling environment under the air cooling condition, so that the batteries are ensured to have good temperature uniformity.

Owner:NANCHANG UNIV

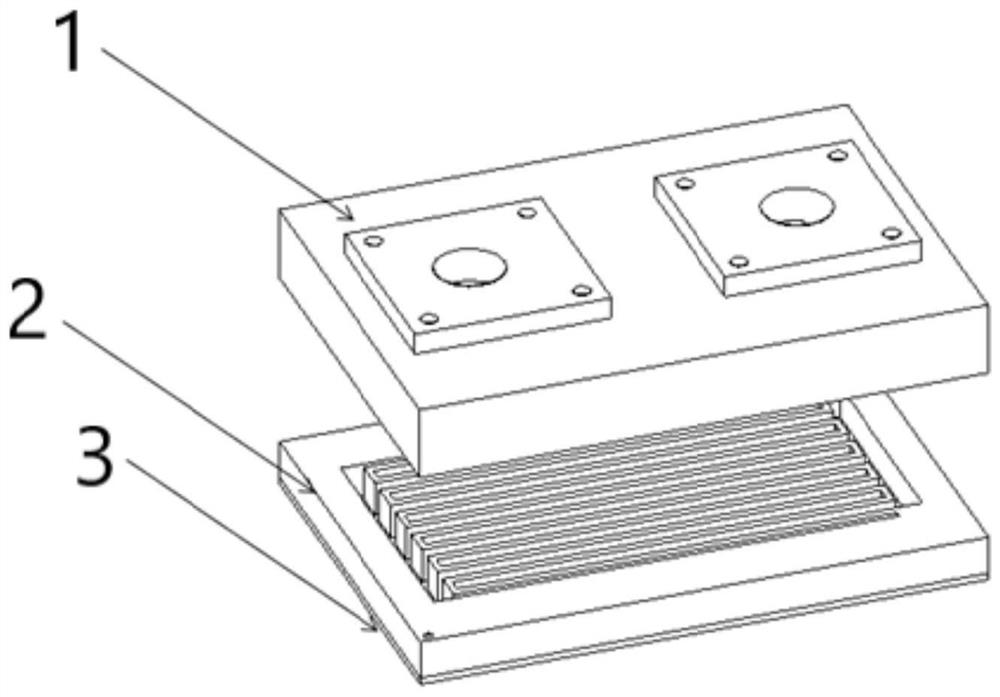

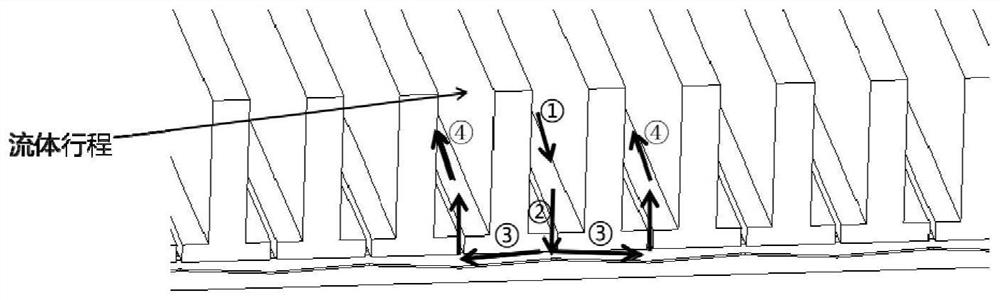

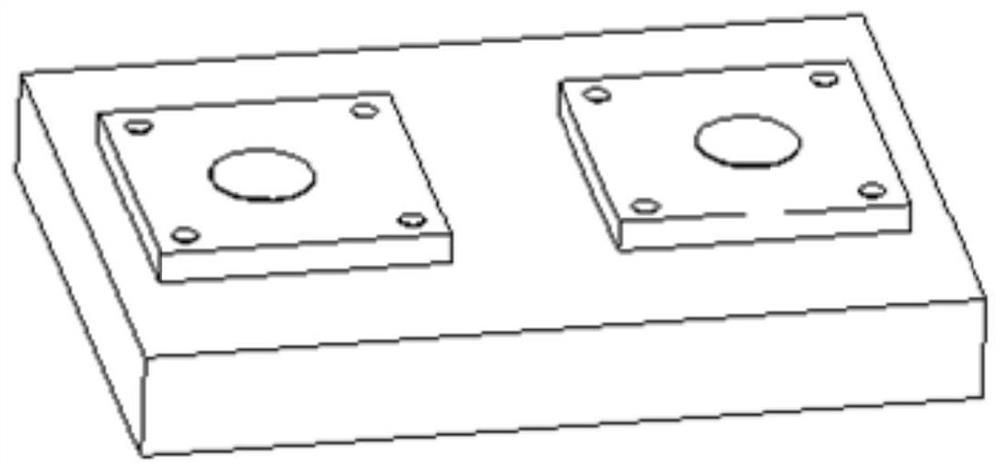

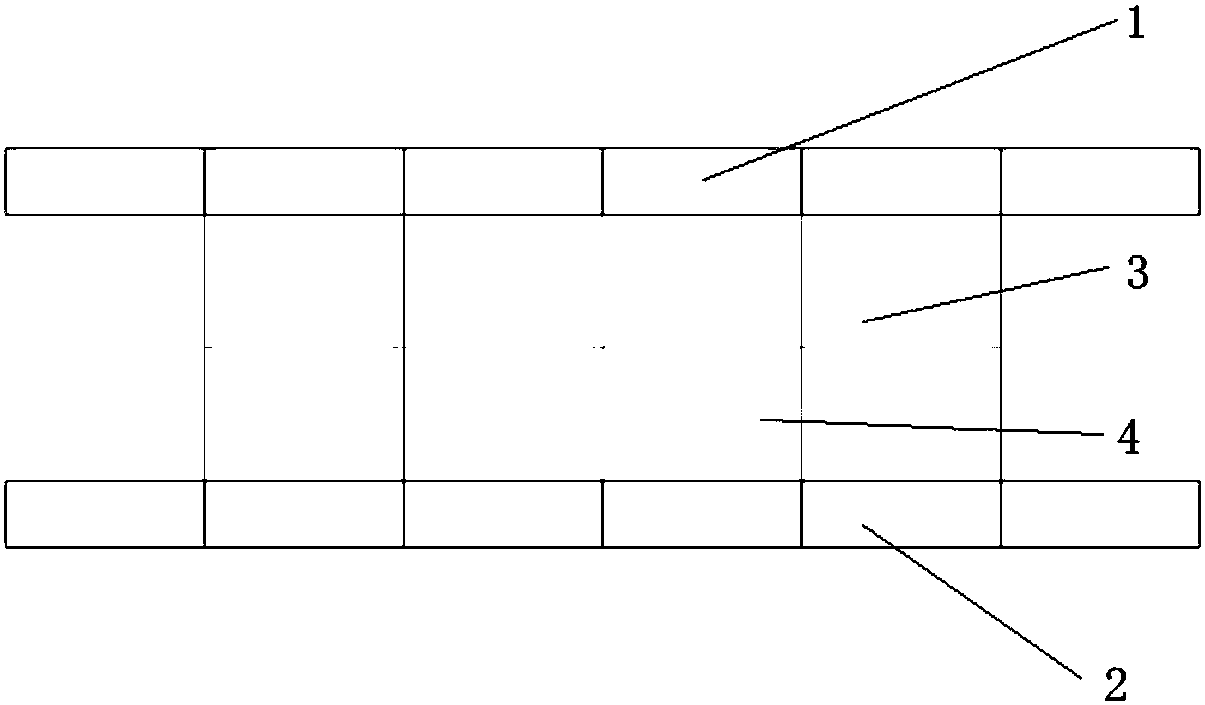

Manifold type micro-channel heat sink with boss-like structure

PendingCN112952537AAchieving temperature uniformityEvenly distributedLaser cooling arrangementsLiquid layerEngineering

The invention provides a manifold type micro-channel heat sink with a boss-like structure. The manifold type micro-channel heat sink comprises a micro-channel layer, a liquid separation layer and a liquid inlet layer, wherein the liquid separation layer is provided with an S-shaped manifold type liquid separation flow channel, a liquid inlet channel and a liquid return channel are separated, the outlet of the liquid separation layer is connected with the inlet of the micro-channel layer, after a cooling liquid enter the liquid separation layer through the liquid inlet layer and then is fed into the micro-channel layer through a manifold flow division structure, the cooling liquid enters each micro-channels through manifolds, heat exchange between fluid and crystals is completed in the micro-channels, then the fluid upwards enters a liquid return manifold through the flow path, and the cooling task is completed. According to the invention, the problem that the heat sink heat dissipation surface is low in temperature due to a manifold micro-channel heat sink micro-channel inlet impact area is solved through the ball-convex-like structure, and the temperature of the low-temperature area is adjusted by adjusting the structure size of the ball-convex-like structure, so that the purpose of uniform temperature of the heat dissipation surface is achieved; and the heat sink liquid separation layer enables the flow cooled to reach each micro-channel to be uniformly distributed, so that the temperature uniformity of the heat dissipation surface of the heat sink is further improved.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

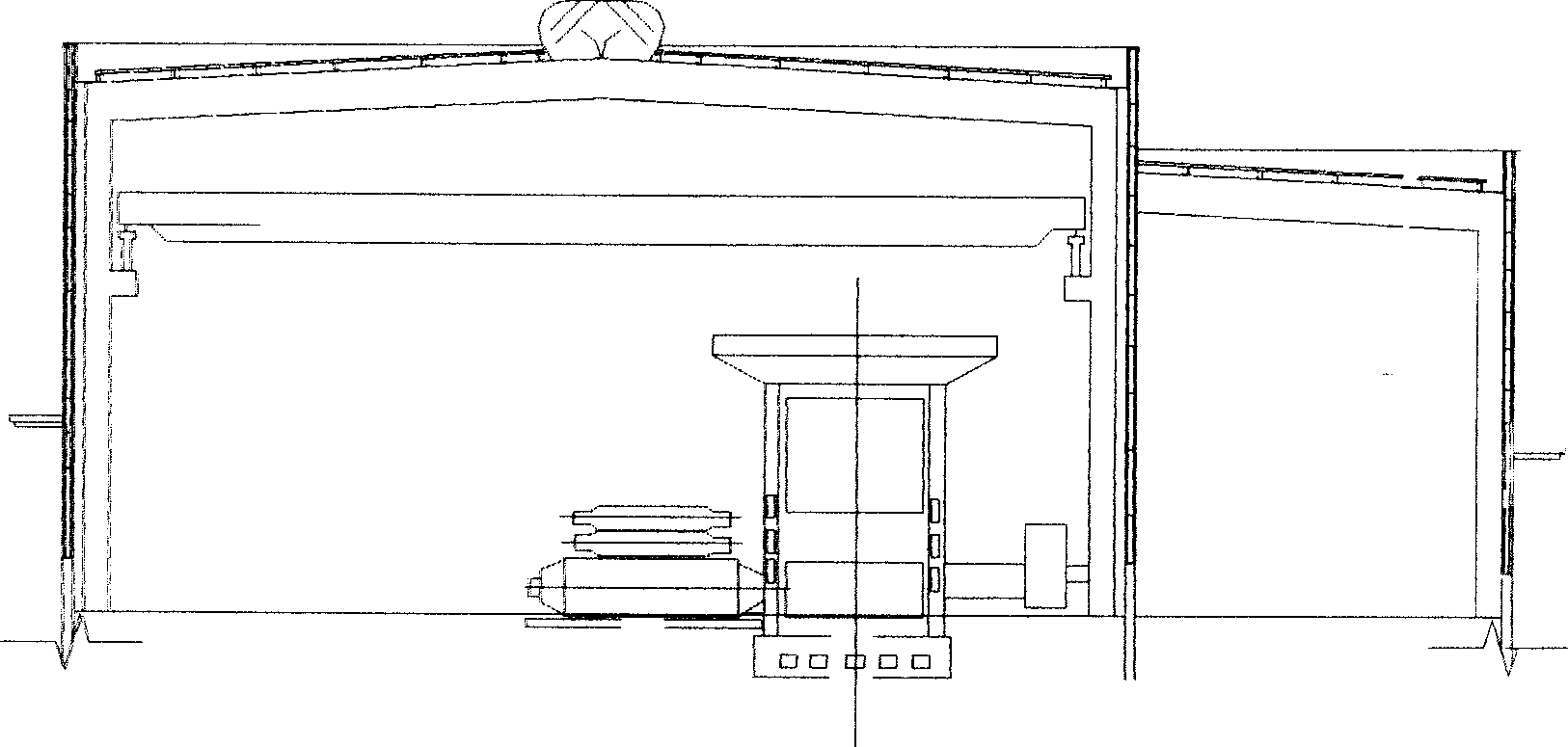

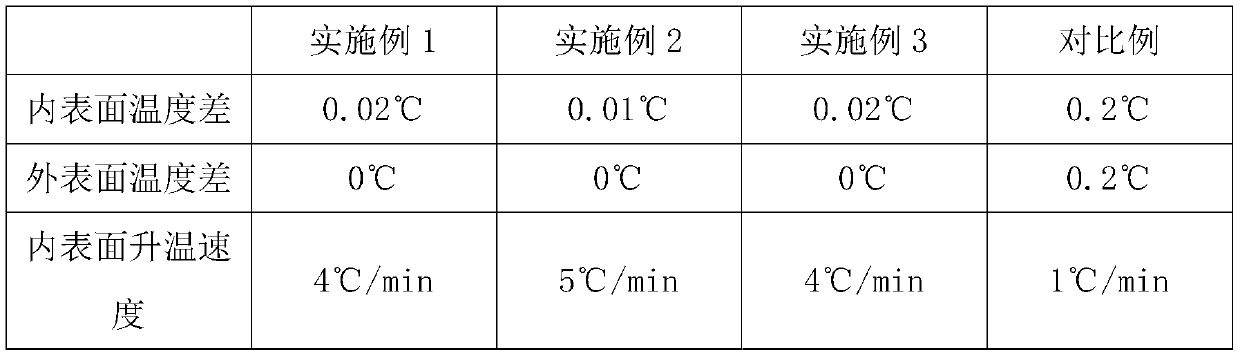

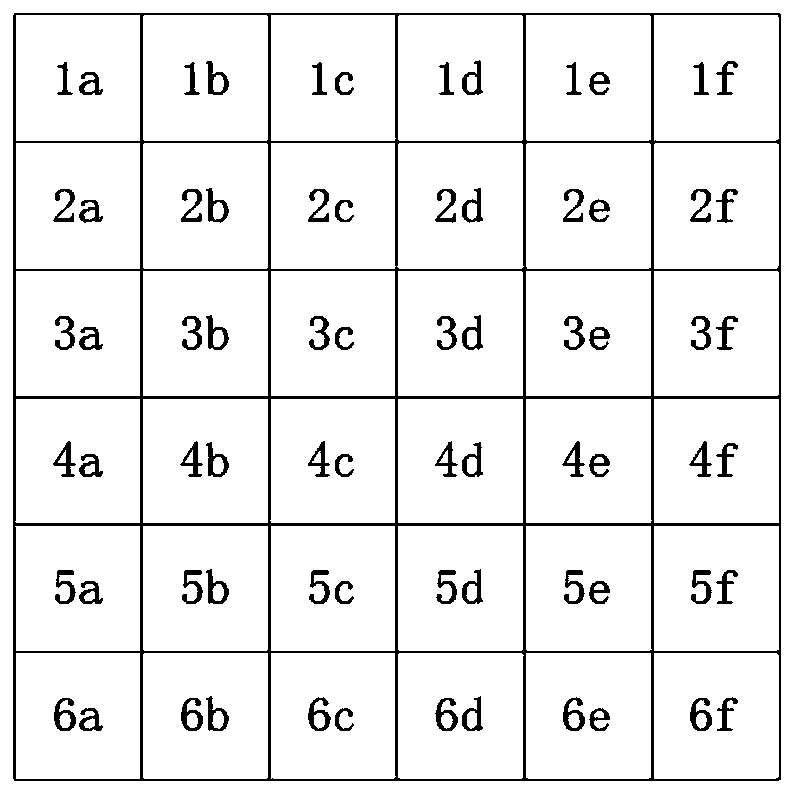

Temperature uniformity control method during aluminum alloy part superplastic forming

ActiveCN107626829ASame temperatureAchieving temperature uniformityShaping toolsMetal working apparatusMetallurgyTemperature monitoring

The invention relates to a temperature uniformity control method during aluminum alloy part superplastic forming. The method includes the following steps that firstly, superplastic forming molds are manufactured; secondly, a superplastic forming upper platform and a superplastic forming lower platform are manufactured, and heating area of the equal number are divided; thirdly, temperature monitoring areas of the same number are divided for the superplastic forming upper mold and the superplastic forming lower mold; fourthly, according to the heating areas of the superplastic forming upper platform and the superplastic forming lower platform and the temperature monitoring areas of the superplastic forming upper mold and the superplastic forming lower mold, installing and clamping are performed; fifthly, the heating areas of the superplastic forming upper platform and the superplastic forming lower platform are powered on to rise temperature for heating; sixthly, the temperature of the temperature monitoring areas of the superplastic forming upper mold and the superplastic forming lower mold is monitored in real time through a temperature monitoring device, and the temperature risingspeed of the heating areas of the superplastic forming upper platform and the superplastic forming lower platform is controlled so that it can be achieved that the temperature of the temperature monitoring areas of the superplastic forming molds can be uniform; and seventhly, aluminum alloy part superplastic forming is performed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

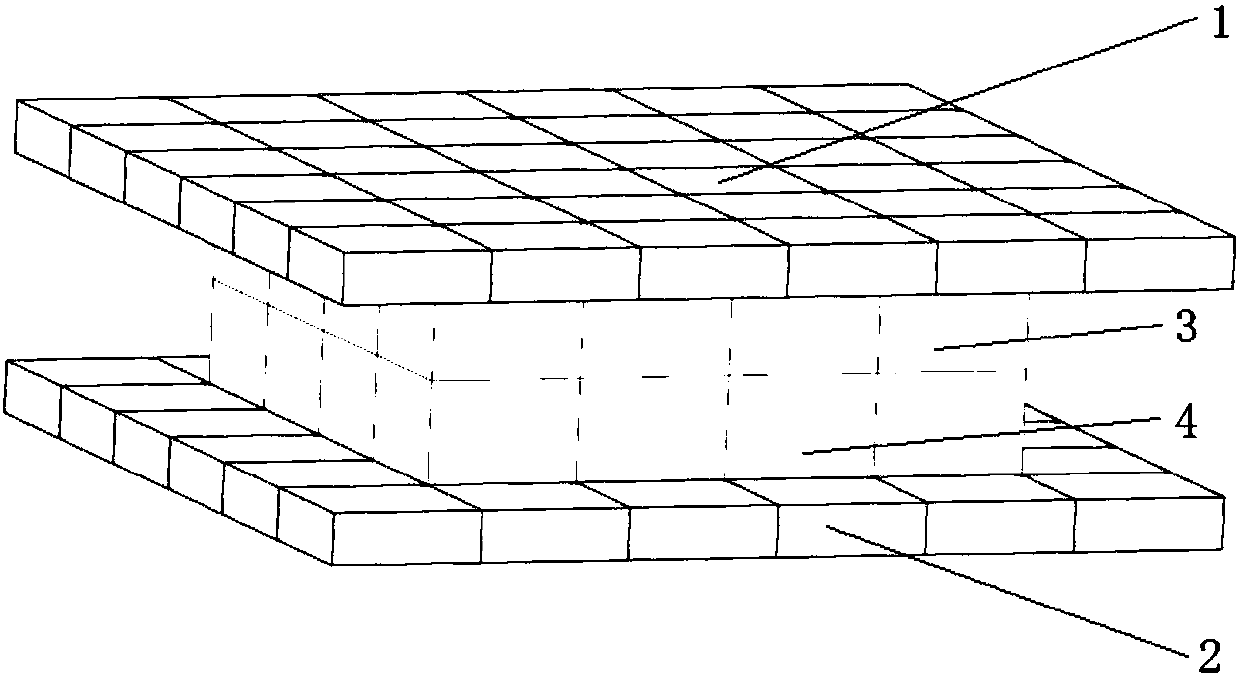

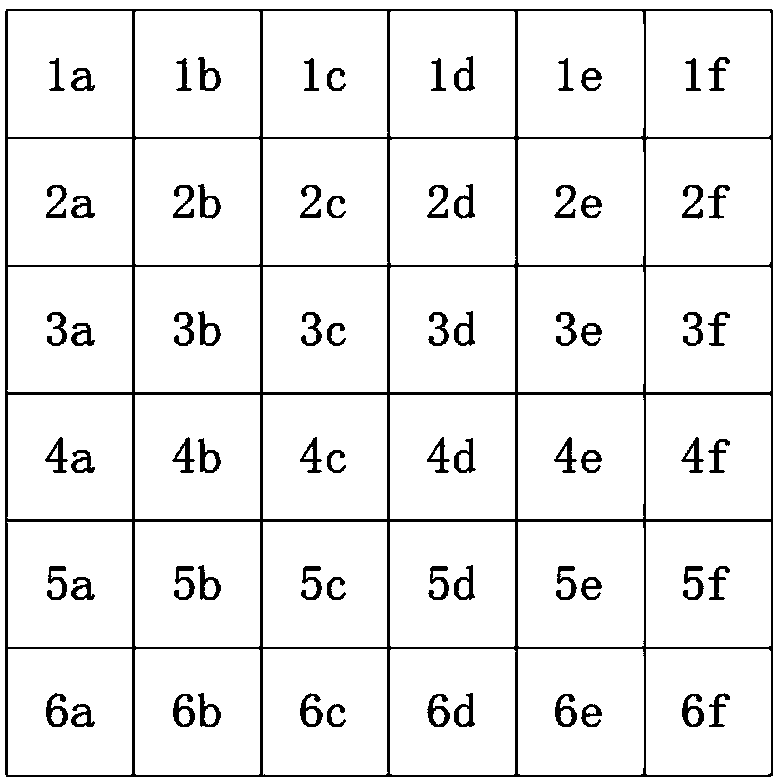

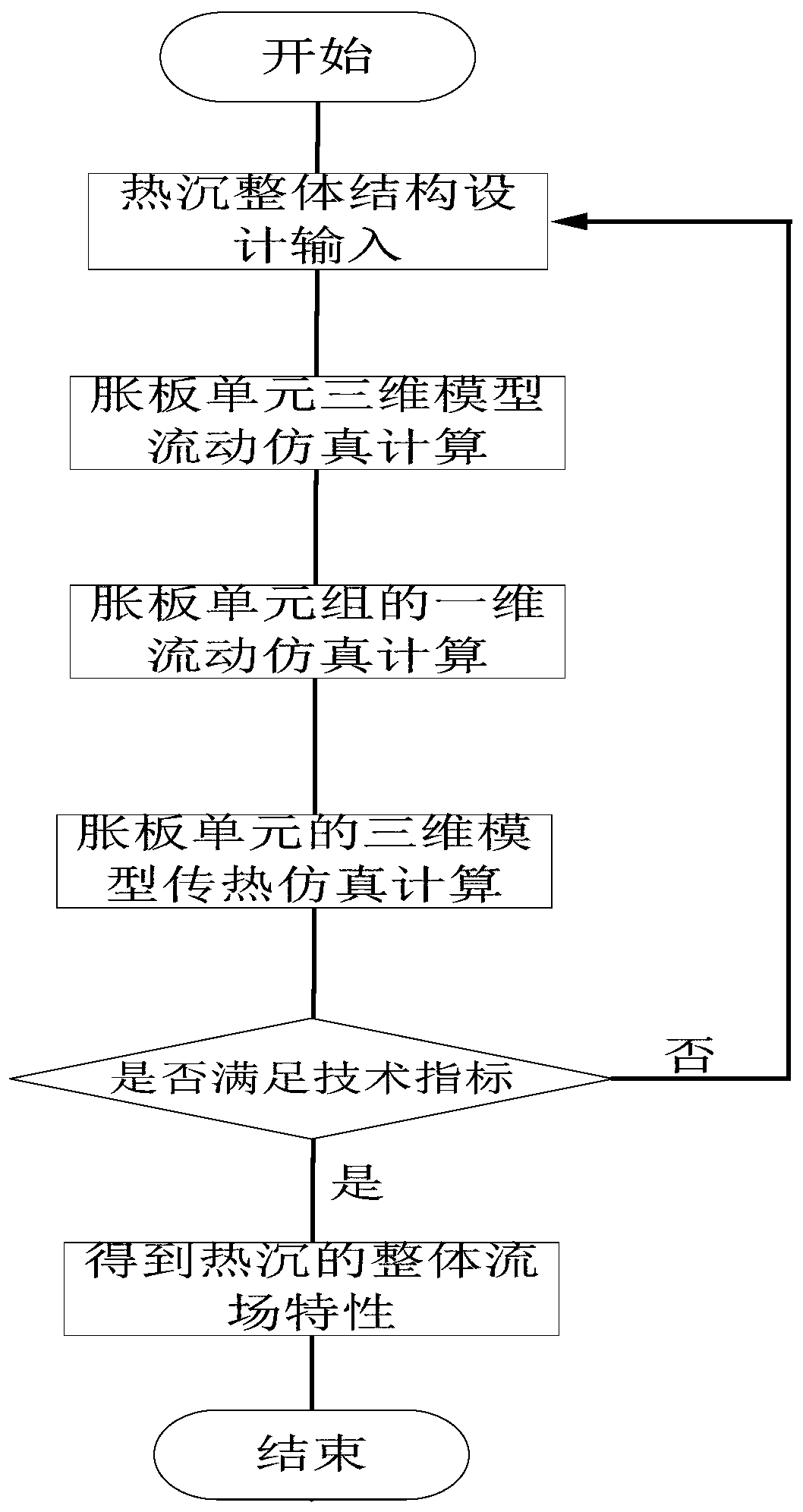

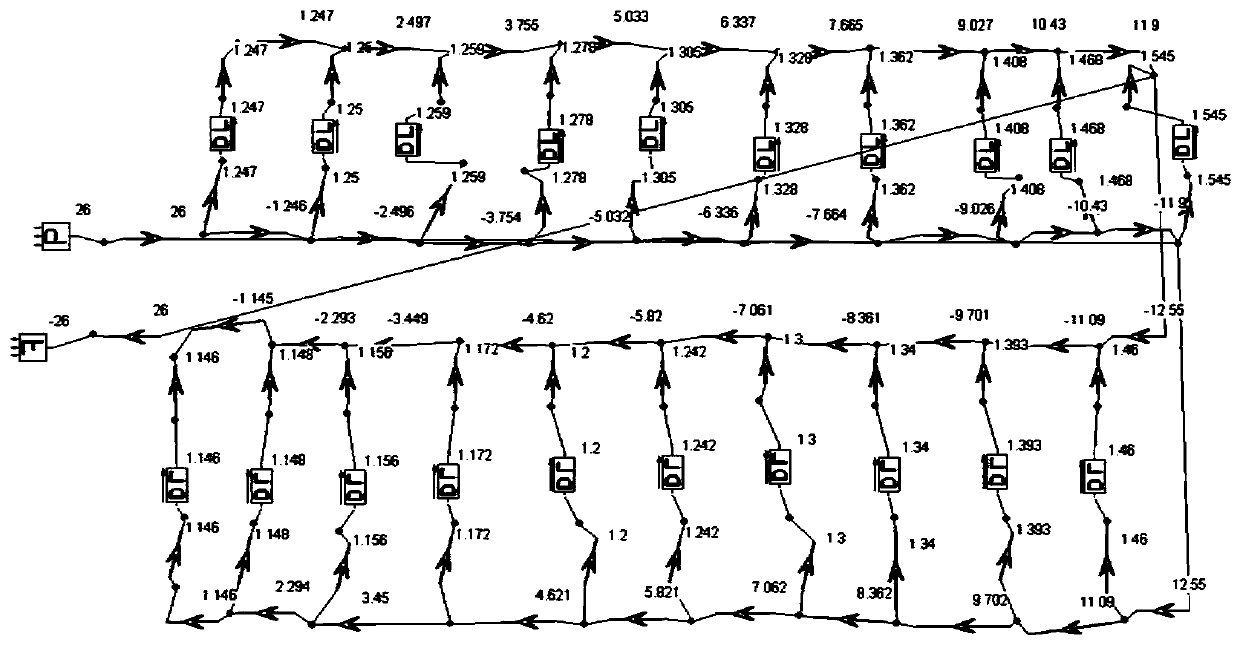

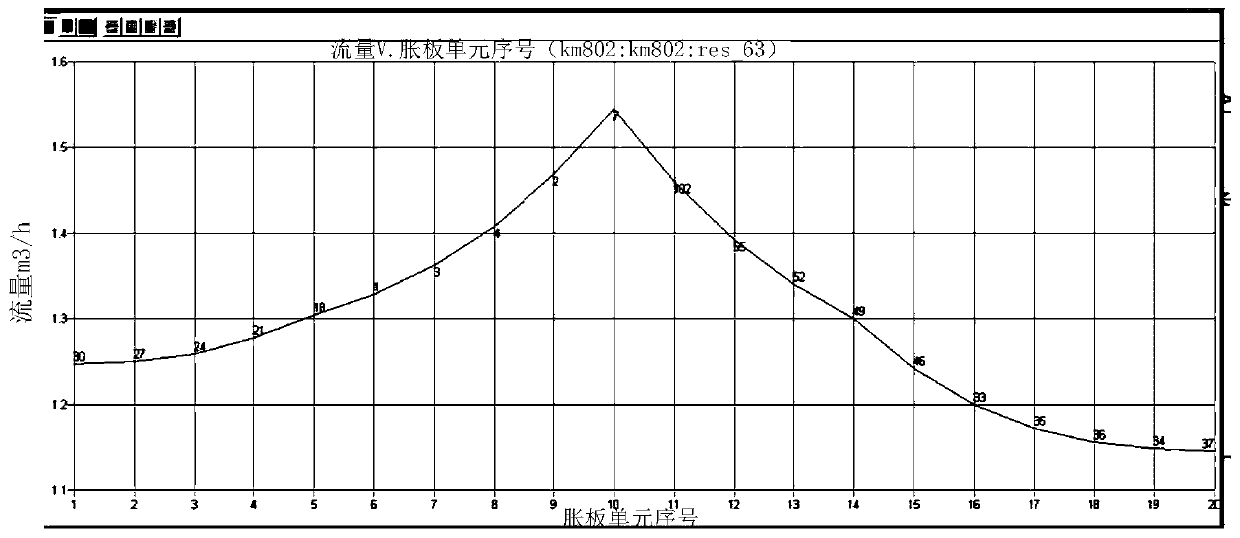

CFD structure optimization method for large plate heat sink

ActiveCN109977578BAchieving temperature uniformityTo achieve temperature requirementsGeometric CADDesign optimisation/simulationDimensional simulationEngineering

The invention discloses a large -scale hot -sinking CFD structure optimization method. This method uses the Fluent system to divide the three -dimensional modeling and grid of the swelling board unit, and then set the boundary conditions.The heat situation, through the one -dimensional simulation calculation of the thermal sink pipe network system and the three -dimensional CFD simulation calculation, obtains the flow field and temperature field of liquid nitrogen in the swelling plate, and determines the best pipeline path in the thermal sinking pipe network.The ratio is achieved, and the temperature uniformity and average temperature meet the requirements of all the swelling plates in the thermal sinking pipe network can solve the overall design and simulation computing problem of large -scale heat sinking.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

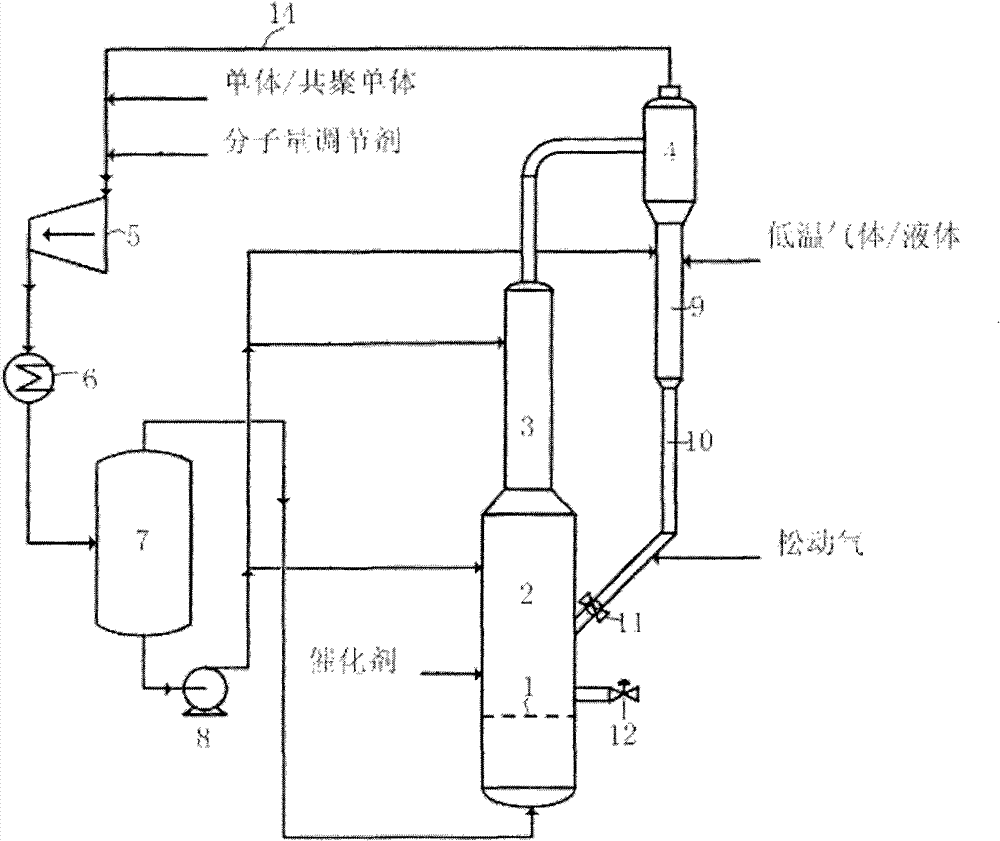

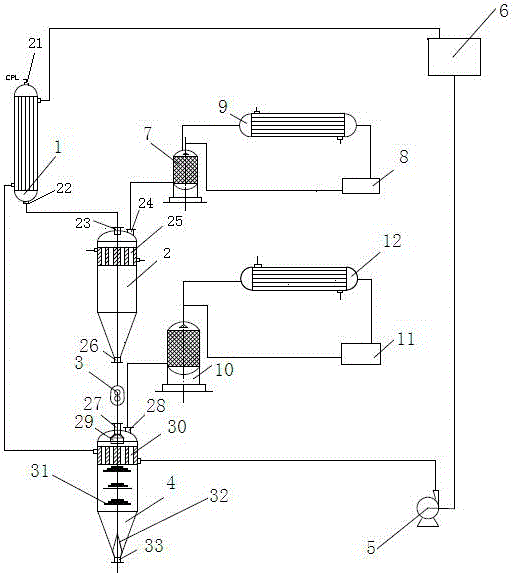

Olefin polymerization reaction apparatus and method

The invention provides an olefin polymerization reaction apparatus and method. The apparatus comprises a gas distributor, a first reactor, a second reactor, a cyclone separator, a liquid collecting tank, a gas stripping section and a material returning leg, wherein the first reactor is a bubbling fluidized bed, and the top is connected with the second reactor; and the second reactor is a fast fluidized bed, the bed diameter ratio of the first reactor to the second reactor is (1.2-3):1, and the height ratio is (0.2-2):1. The apparatus and method are suitable for the polymerization of ethylene, propylene or other gas olefins, can effectively reduce the particle entrainment, gas distributor blockage and local overheating problems during gas olefin polymerization, prolong the production period, reduce the stop frequency, save the production cost and improve economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +2

A cooling device that generates a flat jet stream

ActiveCN104741394BShorten the timeQuick start responseWork treatment devicesMetal rolling arrangementsHeat resistanceWater flow

The invention relates to a cooling device for generating a flat jet stream, which comprises a tank for storing cooling water and a slit for forming the jet stream, the slit communicates with the tank through a drainage channel arranged inside the tank, and The device also includes a water inlet pipe assembly. The upper end of the water inlet pipe assembly is a cooling water inlet. The cooling water inlet is located directly above the outside of the box. There are many small holes on both sides of the pipe; the upper end of the drainage channel is the jet water inlet, which is located near the top of the box, and the drainage channel is connected with the slit, which is composed of a fixed plate and an adjustable Plate formed with adjustable slit width. The invention solves the problems of slow opening of water flow, slow closing of water flow and poor heat resistance of the existing cooling device.

Owner:BAOSHAN IRON & STEEL CO LTD

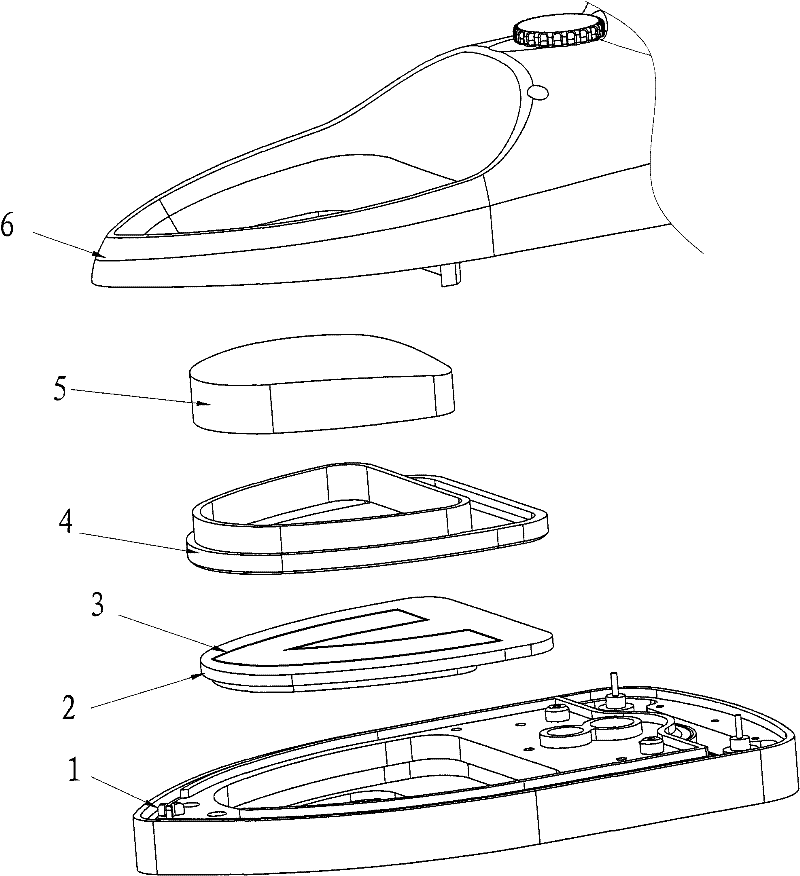

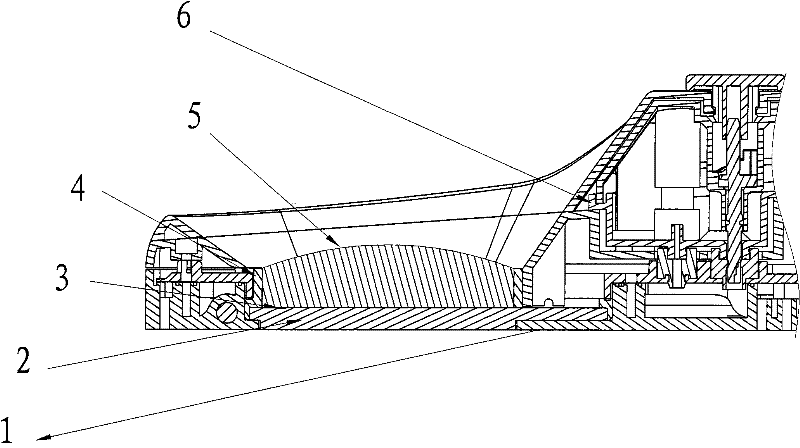

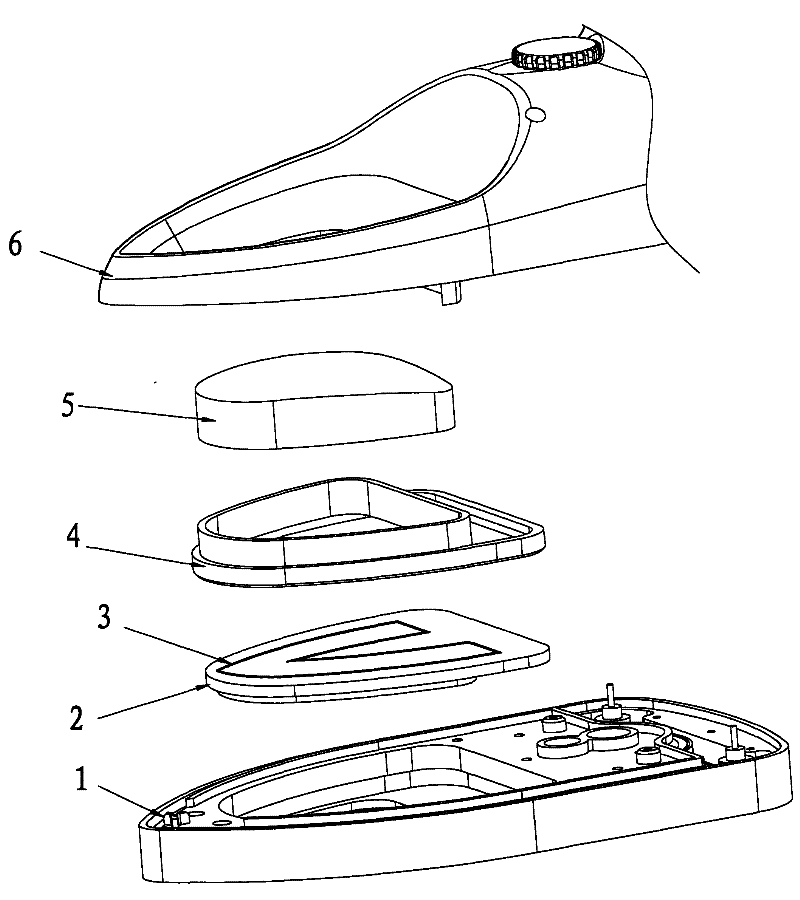

Electric iron

ActiveCN101597858BObserve the condition of ironingEasy ironingHand ironTextiles and paperMagnifying glassEngineering

The invention discloses an electric iron, comprising a heating base plate (1), an upper cover (6) and a control circuit arranged in the electric iron, wherein, a transparent observing cover (2) is embedded in the heating base plate (1), a heat-emitting source (3) is arranged on the transparent observing cover (2), and the heat-emitting source (3) is connected with the control circuit arranged in the electric iron. The upper part of the transparent observing cover (2) is also provided with a magnifying glass (5). In the invention, as the partial transparent heating base plate structure composed by embedding the transparent observing cover on the heating base plate, user can observe while ironing clothes in the ironing process, meanwhile, the heating base plate can generate vapor, thus the ironing textile has better effect. In addition, a magnifying glass is arranged on the transparent observing cover, the textile ironing can be observed well through the transparent observing cover and the magnifying glass, and the ironing process is clearer. In addition, the invention takes the transparent heating film as a heat-emitting source to conduct heat through the transparent observing cover, thus realizing temperature uniformity of the electric iron and the textile contacting surface and realizing the ironing on the clothes. The invention has simple and reasonable structure, high safety, small volume and convenient operation.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

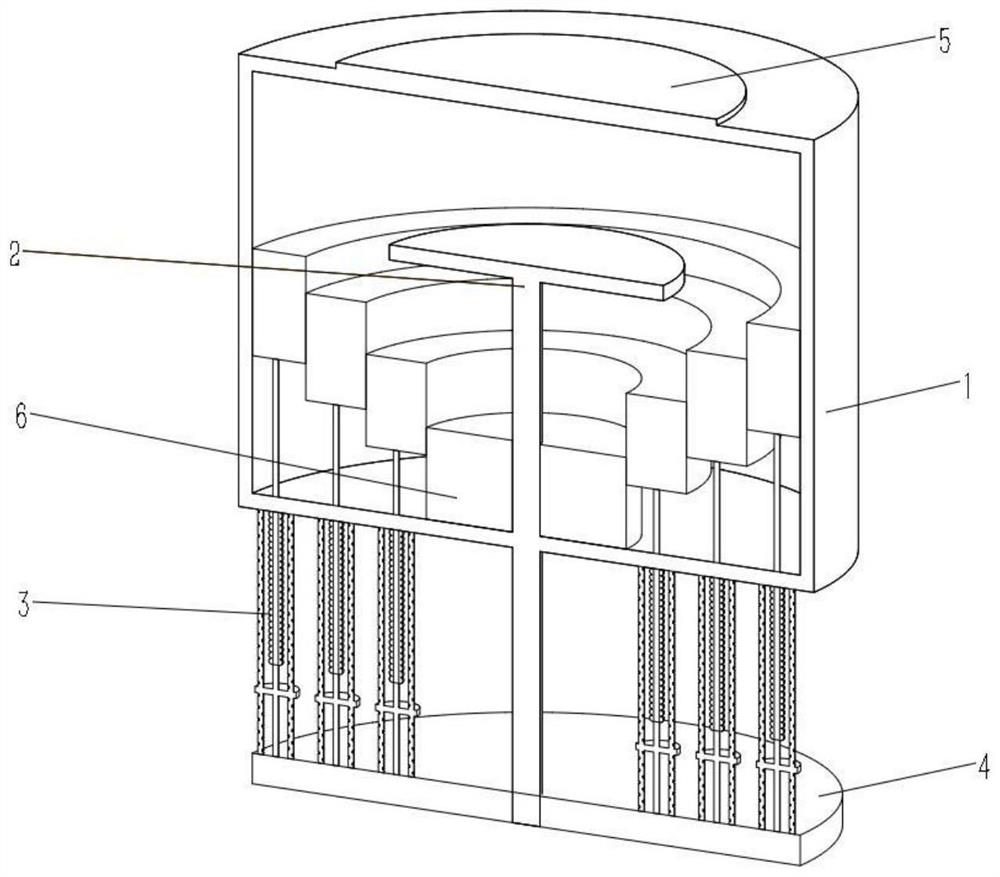

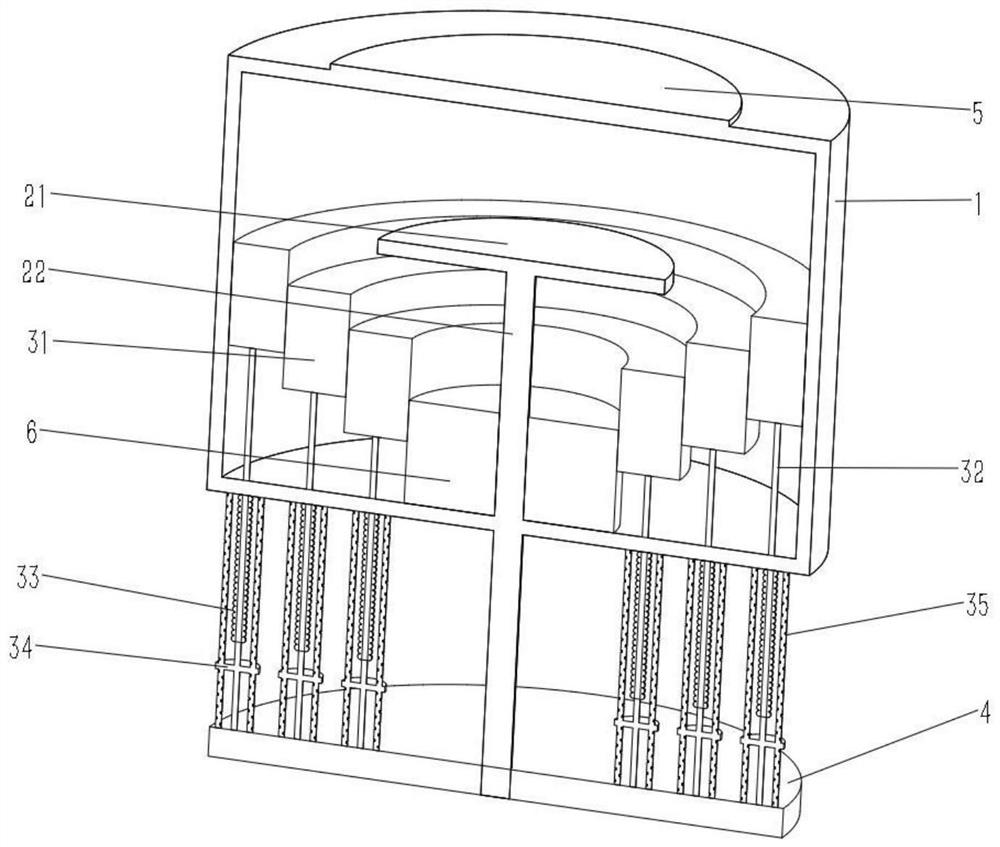

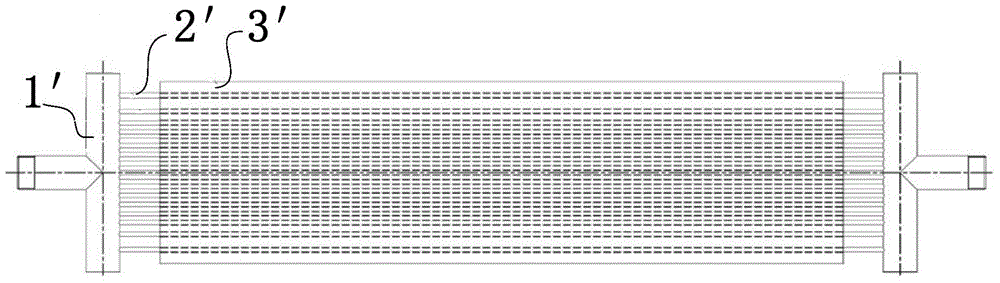

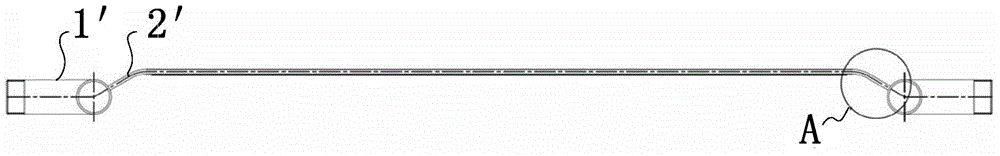

Heat dissipation and heat absorption synchronous cross type heat exchanger

PendingCN112013699ASolve the cooling problemFix workHeat storage plantsHeat exchanger casingsThermal waterMechanical engineering

The invention discloses a heat dissipation and heat absorption synchronous cross type heat exchanger. The heat exchanger comprises an outer shell. A plurality of heat dissipation pipes and heat absorption pipes are fixed to the interior of the outer shell in a crossed mode. One end of each of the heat dissipation pipes is communicated with a heat dissipation pipe connecting bent pipe, and the other end of each of the heat dissipation pipes is connected with a concentrating pipe; one end of each of the heat absorption pipes is communicated with a heat absorption pipe connecting bent pipe, the other end of each of the heat absorption pipes is connected with the concentrating pipe; the upper end of the concentrating pipe is provided with a heat-conducting oil inlet and a cold water inlet; thelower end of the concentrating pipe is provided with a hot water outlet and a heat-conducting oil outlet; and the heat-conducting oil inlet and the heat-conducting oil outlet are communicated with the heat dissipation pipes. The heat exchanger solves the problem of synchronous work of heat dissipation and heat absorption of traditional phase change energy storage; the uniform internal temperatureof a phase change energy storage material can be achieved; and the heat dissipation pipes are of an outer fin type structure, and the heat absorption pipes are of an inner fin type structure, so thatthe best heat dissipation and heat absorption effect can be achieved.

Owner:上海光秦环保科技发展有限公司

Microwave plasma reaction cavity and equipment for chemical vapor deposition

PendingCN114164418AImprove power densityLarge coverage areaChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention provides a microwave plasma reaction cavity and equipment for chemical vapor deposition. The microwave plasma reaction cavity comprises a cavity body, a quartz window, a fixed ring, a substrate table assembly, a fixed disc and at least one variable-diameter ring assembly. The variable-diameter ring assembly comprises a variable-diameter ring arranged between the substrate table assembly and the cavity, a length-variable corrugated pipe module arranged on the outer surface of the bottom of the cavity, a transmission rod fixed in the corrugated pipe module in a penetrating mode, a movable disc arranged between the cavity and the fixed disc and fixedly connected with the transmission rod, and a lead screw arranged on the movable disc in a penetrating mode. The transmission rod is fixedly connected with the variable-diameter ring, the lead screw is in threaded fit with the movable disc, and the two ends of the lead screw are movably connected with the bottom of the cavity and the fixed disc respectively. The axial and radial boundaries of the cavity are adjusted through the variable-diameter ring assembly, the purposes of increasing the power density of plasmas above the substrate table in real time, preventing generation of secondary plasmas and improving the temperature uniformity on the substrate table are achieved under the condition that the reaction cavity is not disassembled, and the growth speed and quality of diamonds are improved.

Owner:深圳优普莱等离子体技术有限公司

Continuous Caprolactam Polymerization Kettle

A continuous-processing caprolactam polymerization kettle is characterized by comprising two kettle bodies, wherein the first segment is a pressure kettle body and the second segment is a normal-pressure kettle body. The first pressure kettle body is a reactor with a taper outlet, a feed inlet and a reflux mouth are arranged at a kettle cover head, a tubular heat exchanger is arranged below the kettle cover head in the kettle, and the taper outlet is connected with the second normal-pressure kettle body via a gear melt pump. The second normal-pressure kettle body is a reactor with a taper outlet, a feed inlet and a reflux mouth are arranged at a kettle cover head, the feed inlet in connected with the first pressure kettle body via a gear melt pump, a taper slit pressure-releasing device is arranged at the inlet end in the kettle, a tubular heat exchanger and a coaxial multilayer convex perforated plate are successively arranged below the pressure-releasing device, and a inverse-taper baffle plate is arranged in the taper outlet. By employing the above structure design, the flow and the mixing of material fluid in the polymerization kettle are effectively improved, and the problems are solved that the reaction is not uniform and the synthesized product is not uniform in molecular weight and molecular weight distribution.

Owner:FUJIAN JINJIANG TECH

x-ray conversion target

The invention discloses an X-ray converting target which comprises a base body and a target layer plate. The base body comprises a base plate and a framework, wherein at least one guide plate is fixedly arranged on the upper surface of the base plate, and the guide plate, the base plate, the framework and the target layer plate form a first coolant layer. The X-ray converting target further comprises a sealing plate. At least one second guide plate is fixedly arranged on the lower surface of the base plate, and the second guide plate, the base plate, the framework and the sealing plate form a second coolant layer. The first coolant layer comprises at least one flow inlet channel and at least one flow outlet channel. The second coolant layer comprises at least one flow inlet channel and at least one flow outlet channel. One end of each flow inlet channel is used for coolants to pass through, the other end of each flow inlet channel is communicated with the corresponding flow outlet channel, and one end of each flow outlet channel is used for the coolants to flow out. The X-ray converting target guarantees high efficiency of converting large-power or super-power electronic beams into X rays and meanwhile achieves temperature evenness. Furthermore, the service life of the converting target is prolonged.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

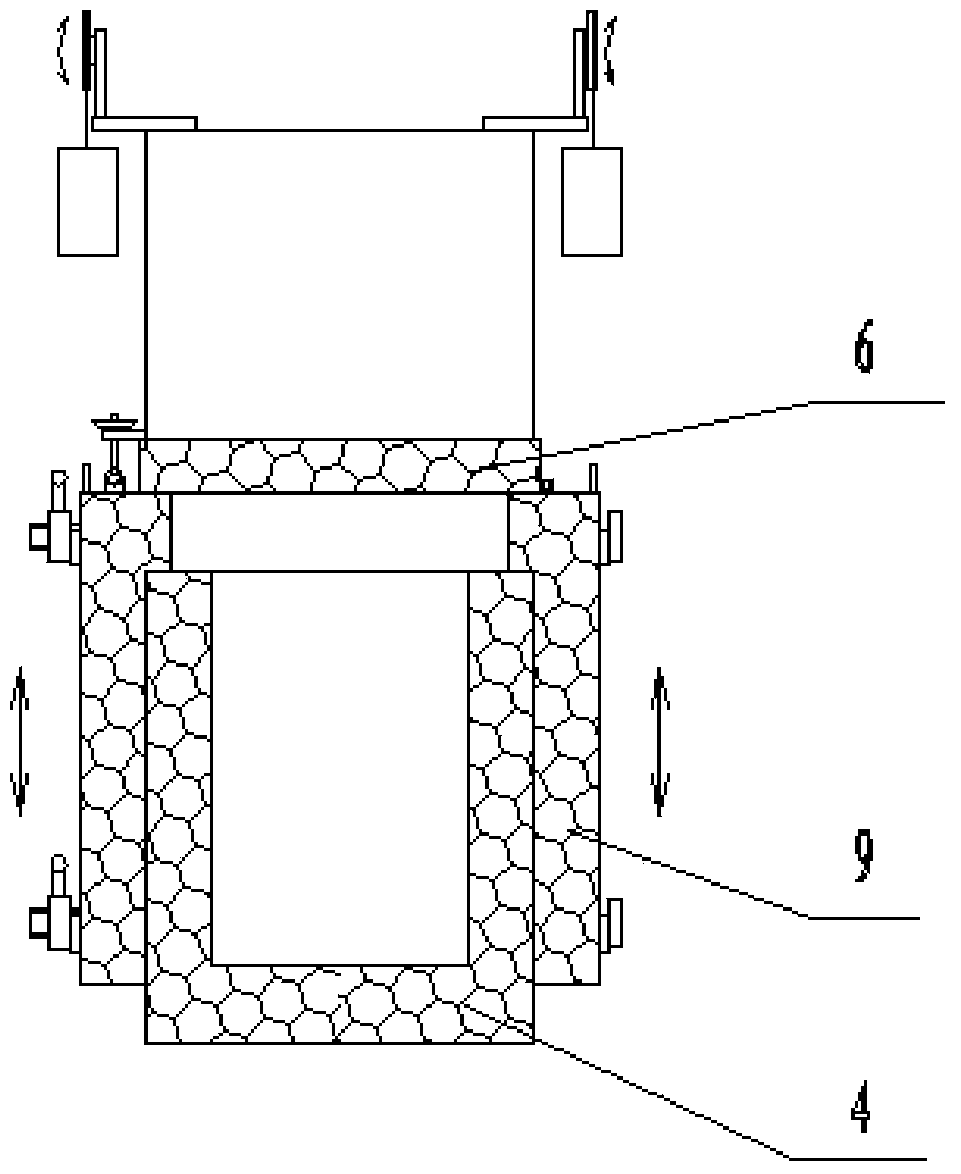

Telescopic tempering device

InactiveCN104372141AFulfilling Tempering RequirementsImprove insulation effectFurnace typesHeat treatment furnacesEngineeringClosed space

The invention provides a telescopic tempering device. The device comprises a box body A, a box body B, a locking rod and a cover, wherein the box body B can move up and down relative to the box body A; the locking rod can be used for controlling the stay position of the box body B on the box body A; the box body A, the box body B and the cover can form a closed space. The telescopic tempering device disclosed by the invention has the beneficial effects of satisfying the requirements of parts on different sizes and guaranteeing the timeliness of tempering; moreover, the device disclosed by the invention is provided with a fan, so temperature uniformity is realized; besides, a main body material of the device disclosed by the invention is a heat insulating plate, so the device has the advantages of good heat insulation performance, low manufacturing cost and simplicity and convenience in operation.

Owner:TIANJIN HEAT TREATMENT INST

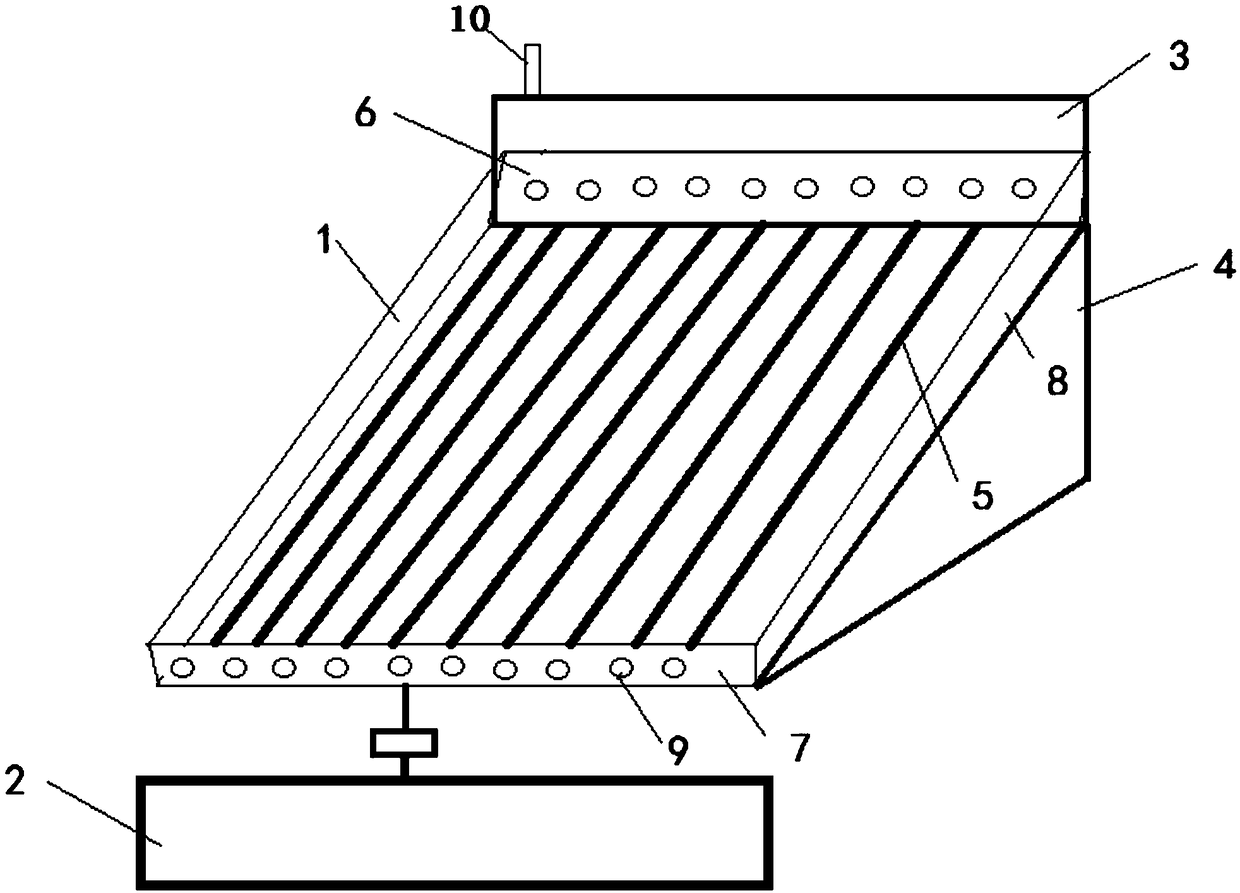

Solar water heater with auxiliary heaters

InactiveCN108426378AIncrease temperatureReduce the temperatureSolar heating energySolar heat collector controllersEngineeringThermal efficiency

The invention discloses a solar water heater with auxiliary heaters. The solar water heater with the auxiliary heaters comprises a solar heat collector, a cold water box, a hot water box and a support, and further comprises the auxiliary heaters, wherein the solar heat collector comprises a frame and a plurality of solar vacuum heat collecting tubes which are arranged in the frame and are arrangedin parallel side by side; the frame comprises a top plate, a bottom plate and side plates on two sides; and the auxiliary heaters are arranged in the solar vacuum heat collecting tubes. By the auxiliary heaters, the integral heat collecting efficiency and safety can be improved.

Owner:郑州东青信息科技有限公司

A method for controlling temperature uniformity during superplastic forming of aluminum alloy parts

ActiveCN107626829BSame temperatureAchieving temperature uniformityShaping toolsMetal working apparatusTemperature monitoringMaterials science

The invention relates to a temperature uniformity control method during aluminum alloy part superplastic forming. The method includes the following steps that firstly, superplastic forming molds are manufactured; secondly, a superplastic forming upper platform and a superplastic forming lower platform are manufactured, and heating area of the equal number are divided; thirdly, temperature monitoring areas of the same number are divided for the superplastic forming upper mold and the superplastic forming lower mold; fourthly, according to the heating areas of the superplastic forming upper platform and the superplastic forming lower platform and the temperature monitoring areas of the superplastic forming upper mold and the superplastic forming lower mold, installing and clamping are performed; fifthly, the heating areas of the superplastic forming upper platform and the superplastic forming lower platform are powered on to rise temperature for heating; sixthly, the temperature of the temperature monitoring areas of the superplastic forming upper mold and the superplastic forming lower mold is monitored in real time through a temperature monitoring device, and the temperature risingspeed of the heating areas of the superplastic forming upper platform and the superplastic forming lower platform is controlled so that it can be achieved that the temperature of the temperature monitoring areas of the superplastic forming molds can be uniform; and seventhly, aluminum alloy part superplastic forming is performed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

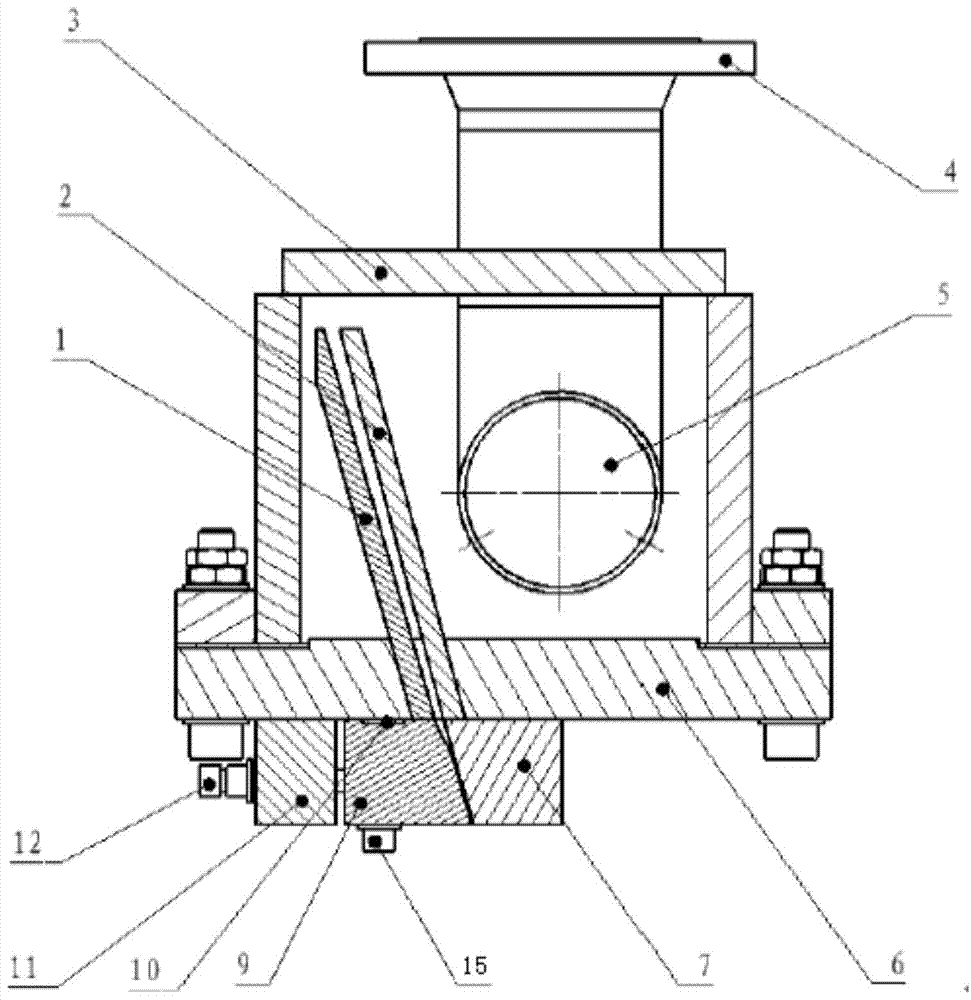

Wedge-shaped air preheating combustor

InactiveCN101949539ADoes not affect normal workStable combustionIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorFuel gas

The invention discloses a wedge-shaped air preheating combustor. The combustor is provided with a main cylindrical combustion pipe, wherein an internal combustion nozzle is coaxially arranged in the inner cavity of the main combustion pipe; the inner cavity at one end of the internal combustion nozzle is gradually retracted and the end of the inner cavity at one end of the internal combustion nozzle is communicated with the inner cavity of the main combustion pipe; the other end of the internal combustion nozzle is hermetically connected with the end part of the main combustion pipe; a gas connecting pipe communicated with the inner cavity of the internal combustion nozzle is arranged on the sealed end part; an air inlet pipe is radially communicated with the external wall of the main combustion pipe close to the closed end; a plurality of air inlet holes are reserved on the external wall of the internal combustion nozzle far away from the closed end; the air inlet pipe is communicated with the inner cavity of the internal combustion nozzle through the main combustion pipe, and an interlayer and the air inlet holes of the internal combustion nozzle; and an installation flange is obliquely connected with the external wall of the main combustion pipe. An included angle of 40 to 45 degrees is formed between the installation flange and the axis of the main combustion pipe. When the combustor is arranged on a round industrial furnace, the flame sprayed from the internal combustion nozzle can enter along the tangential direction of the internal cavity of the furnace to fully stir the air flow in the furnace cavity, so that the temperature field of the furnace is uniform.

Owner:陆守祥

A kind of graphite enamel material and preparation method thereof

The invention relates to a production method of a graphite enamel material. The method concretely comprises the following steps: 1, producing a graphite matrix body: selecting a graphite bar or board as a matrix body material, and processing the matrix body material into a corresponding shape according to demands to obtain the graphite matrix body; 2, plating titanium on the surface of the graphite matrix body: A, wetting the surface of the graphite matrix body by using an adhesive; B, sprinkling plating powder to the wetted surface of the graphite matrix body; C, performing heat preservation on the graphite matrix body for 3-6h under conditions of the vacuum degree being 0.5-5Pa and the temperature being 600-850 DEG C; and D, performing cooling to the temperature of 100 DEG C or less, discharging the processed material from a furnace, performing cooling to a room temperature, and brushing away redundant powder by using a hair brush; and 3, preparing a titanium nitride layer: putting the graphite matrix body of which the surface is plated with the titanium in the step 2 to a vacuum furnace, performing vacuumizing to 0.1Pa or less, and starting heating; when the temperature is raised to 950-1200 DEG C, introducing nitrogen to 0.05+ / -0.02MPa, and performing heat preservation for 20-200min; and performing cooling to the temperature of 100 DEG C or less, and discharging the finished material from the vacuum furnace. The graphite enamel material has the advantages of high heat transmission, oxidation resistance, high-temperature resistance, temperature shock resistance and the like, and can be made into a furnace body supporting material, a material frame, a material plate and the like.

Owner:ZHONGNAN DIAMOND CO LTD

Nucleic acid amplification device and nucleic acid analysis device

ActiveCN103635568BAchieving temperature uniformityConstitute clearBioreactor/fermenter combinationsHeating or cooling apparatusTemperature controlTemperature difference

According to a conventional technique, when a calibrated temperature measuring probe is used for correcting the temperature absolute values of individually temperature-controllable thermal control blocks, a temperature difference of a maximum of 0.5° C. remains between the thermal control blocks. According to the present invention, the melting temperature of a temperature calibration sample housed in a reaction vessel corresponding to each of the temperature control blocks is measured as a measured melting temperature. The measured melting temperature corresponding to each of the thermal control blocks and the reference melting temperature of the temperature calibration sample are compared, and the temperature absolute value of each of the thermal control blocks is corrected based on respective difference values.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com