Graphite enamel material and production method thereof

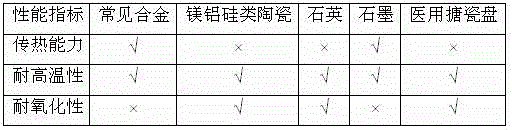

A production method and graphite technology, applied in the field of new materials, can solve problems such as heat transfer capacity, high temperature resistance, oxidation resistance defects, etc., and achieve the effect of temperature uniformity, oxidation resistance atmosphere, and good heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of graphite enamel material, comprising the steps of:

[0032] 1) Making graphite matrix: choose a density of 1.8g / cm 3 Above, graphite rods with a thermal conductivity above 90W / mK are used as matrix materials, which are processed into corresponding shapes by sawing and grinding according to requirements to obtain graphite matrix;

[0033] 2) Titanium coating on the surface of graphite matrix: Coating a layer of metal titanium on the surface of graphite matrix by evaporation method, the specific operation is as follows:

[0034] A. Wet the surface of the graphite matrix with an adhesive; ) mixed;

[0035] B. Sprinkle the coating powder on the surface of the wetted graphite matrix; the coating powder is composed of TiO with a mass ratio of 37:53:20 2 , MgCl 2 Mixed with Al powder;

[0036] C. Place the graphite matrix in a vacuum furnace at 850°C for 3 hours under a vacuum of 3Pa;

[0037] D. Cool to below 100°C and take out of the oven. When ...

Embodiment 2

[0044] A preparation method of graphite enamel material, comprising the steps of:

[0045] 1) Making graphite matrix: choose a density of 1.8g / cm 3 Above, graphite rods with a thermal conductivity above 90W / mK are used as matrix materials, which are processed into corresponding shapes by sawing and grinding according to requirements to obtain graphite matrix;

[0046] 2) Titanium coating on the surface of graphite matrix: Coating a layer of metal titanium on the surface of graphite matrix by evaporation method, the specific operation is as follows:

[0047] A. Wet the surface of the graphite matrix with an adhesive; ) mixed;

[0048] B. Sprinkle the coating powder on the surface of the wetted graphite matrix; the coating powder is composed of TiO with a mass ratio of 37:53:20 2 , MgCl 2 Mixed with Al powder;

[0049] C. Place the graphite matrix in a vacuum furnace at 750°C for 6 hours under a vacuum of 3Pa;

[0050] D. Cool to below 100°C and take out of the oven. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com