Production technique of large common-substance molybdenum plate

A production process and large unit weight technology, which is applied in the production process field of large unit weight molybdenum plates, can solve the problems of difficult processing of large unit weight molybdenum plates, achieve quick results, reduce environmental pollution, achieve feasibility and temperature uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

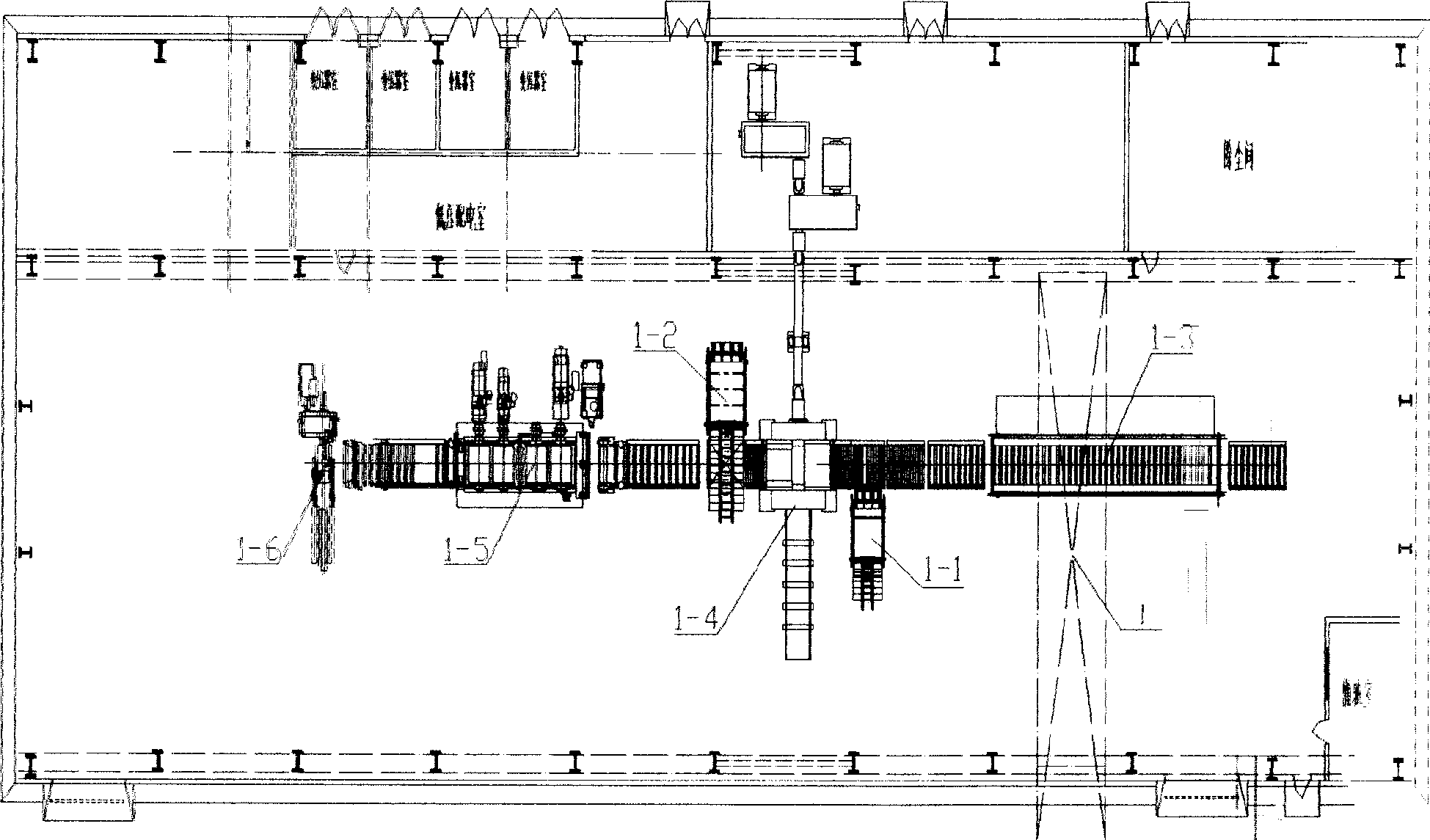

[0038] Process flow of the present invention is as follows:

[0039] Mixing - pressing - sintering - heating - hot rolling.

[0040] Mixing is to put various alloy component powders into a large mixer for mixing, and put the mixed powder into a plastic sleeve with a support frame, and seal the plastic sleeve:

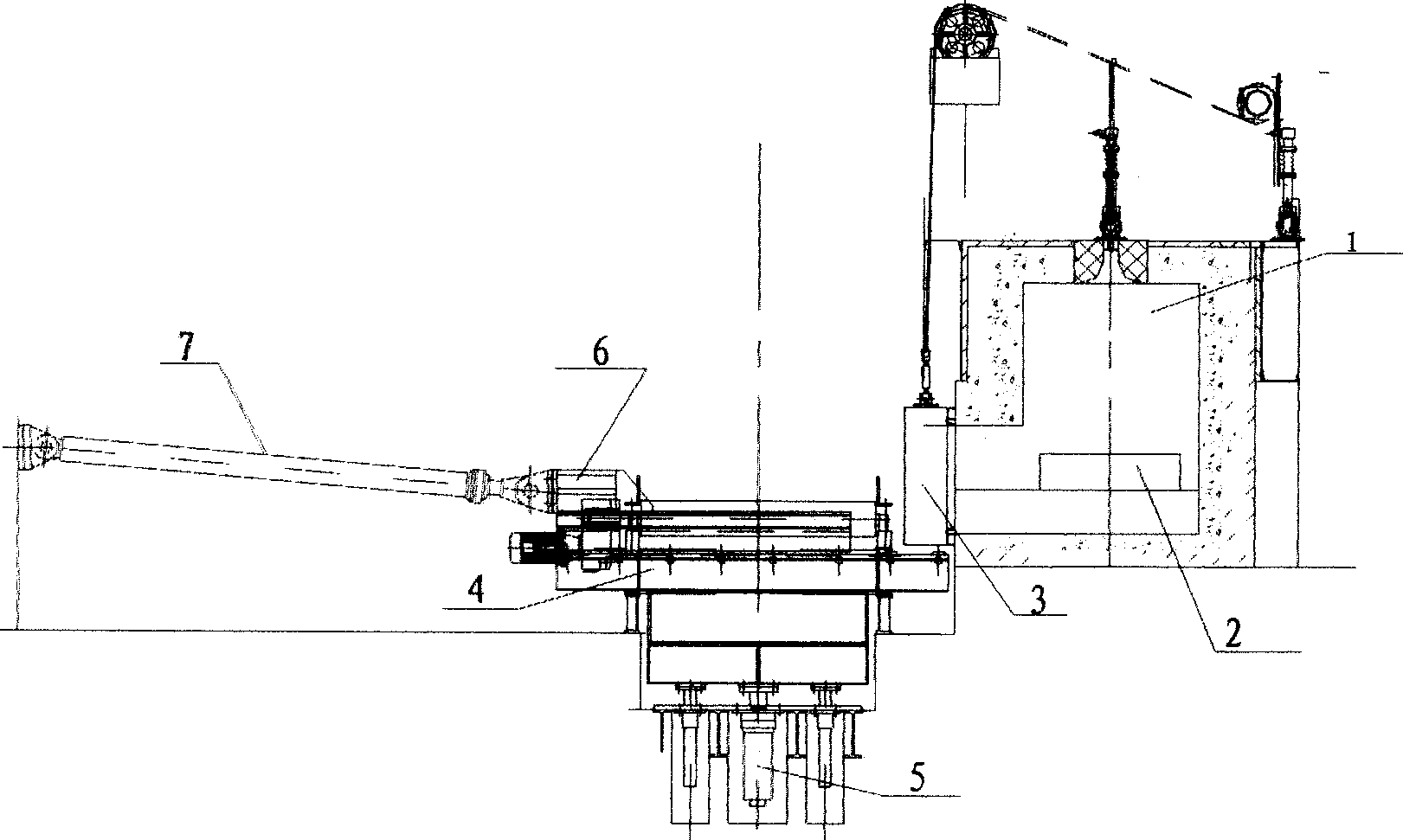

[0041] Pressing is done in large isostatic presses. Put the plastic sleeve together with the support frame into a large isostatic press and press it into a slab;

[0042] Sintering is to sinter hot-rolled blanks in a large sintering furnace, pre-sintering in the furnace, and then high-temperature sintering;

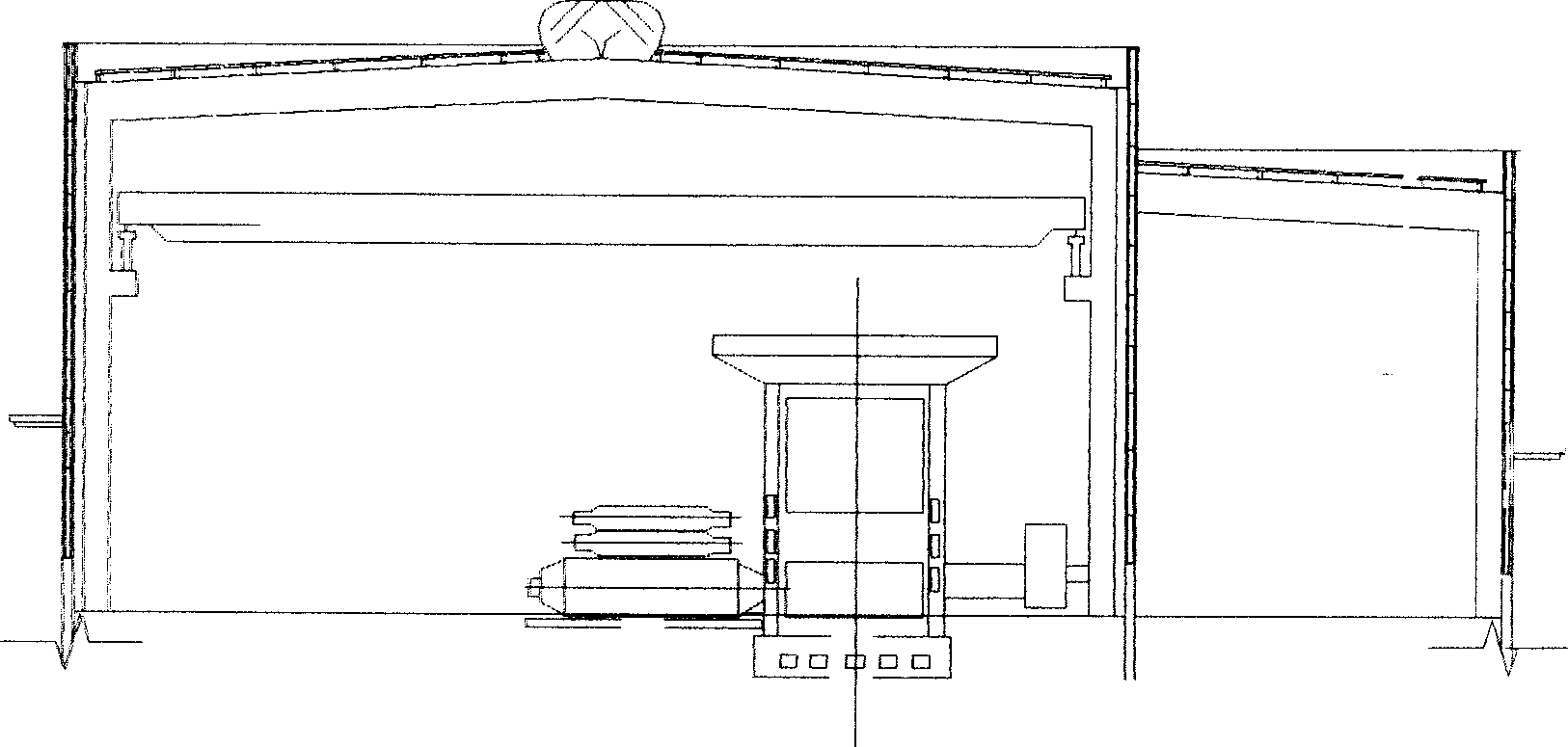

[0043] In order to meet the temperature requirements for billet opening and hot rolling of large molybdenum billets, three different furnace types, No. 1, No. 2 and No. 3, are selected for online heating to meet the temperature required for hot rolling.

[0044] The sintered molybdenum plate is heated from room temperature to 1400-1500°C. If a traditional molybd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com