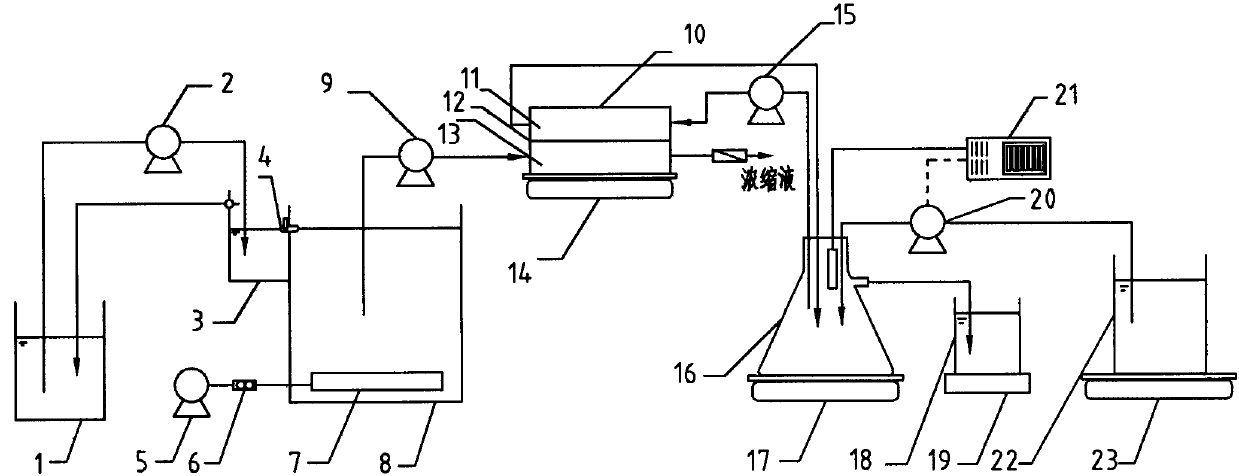

Performance test device of forward osmosis membrane

A technology of forward osmosis membrane and testing device, which is applied in the field of seawater desalination and water and wastewater treatment, can solve the problem of low water flux, and achieve the effect of accurate test results, small area, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The FO membrane used for the test is made of acetate fiber, and the effective membrane area is 0.015m 2 , the feed liquid is clear water, the flow rate is 0.13m / s, the draw liquid is 1.5M sodium chloride solution, the flow rate is 0.15m / s, and the aeration rate of the feed liquid pool 8 is 0.2m 3 / h. Under the operating condition of 20°C, the changes of the membrane flux were investigated under two modes, that is, the active layer faces the draw liquid (PRO mode) and the active layer faces the feed liquid (FO mode). After the two modes were operated stably for 8 hours, the average membrane flux in PRO mode was 9.64L / (m 2 h), the average membrane flux in FO mode is 8.39L / (m 2 h). The membrane flux of PRO mode is higher than that of FO mode, because the concentration polarization generated when the active layer faces the draw liquid (PRO mode) is smaller than that generated when the active layer faces the feed liquid (FO mode) , the membrane flux is large. When the ...

Embodiment 2

[0021] The FO membrane used for the test is made of acetate fiber, and the effective membrane area is 0.015m 2 , the feed liquid is activated sludge, the initial sludge concentration is 4.08g / L, the flow velocity is 0.13m / s, the draw liquid is 1.5M sodium chloride solution, the flow velocity is 0.15m / s, and the active layer faces the feed liquid (i.e. FO mode), the initial flux is 13L / (m 2 h), the SRT is 10d, and the aeration rate of the feed liquid tank 8 is 0.2m 3 / h. Under the operating condition of 25°C, the system was operated stably for 33 days, and the change of membrane flux and membrane fouling were investigated. With the change of time, the water flux changes from 13L / (m 2 h) down to 2L / (m 2 h). The water flux decreased rapidly within 100 hours, and then decreased slowly. After 300 hours, the membrane flux tended to be stable, and fouling on the surface of the membrane could be clearly observed. Due to the increase in the concentration of dissolved substances ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com