Composite impermeable cloth for salt pond and preparation method thereof

A composite anti-seepage and salt pond technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of low economic efficiency, short service life, poor salinity resistance, etc. Benefit, reduce leakage rate, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A kind of preparation method of the compound anti-seepage cloth that the present invention is used for salt pool comprises the following steps:

[0048] (1) Arrange the polyester industry on the coating machine, soak and apply the paste-like PVC coating slurry;

[0049] (2) Put the polyester industrial cloth coated with paste polyvinyl chloride coating slurry into a vertical oven and a horizontal oven in turn for high-temperature plasticization at 180-240 degrees to obtain semi-finished products;

[0050] (3) Put the semi-finished product into the laminating machine, and paste the PVC rubber modified film on both sides of the semi-finished product by means of pressure;

[0051] (4) The finished product is obtained after cooling.

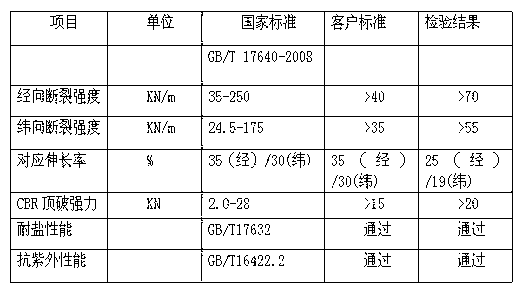

Embodiment 1

[0052] Example 1: A composite anti-seepage cloth for salt ponds, wherein the distribution ratio of polyvinyl chloride rubber modified membrane components is: 100 parts by weight of polyvinyl chloride, 20 PHR of dioctyl adipate, and dioctyl phthalate 28PHR, the liquid rubber adopts the liquid rubber Q101 produced by Taiwan Zhaoxin Enterprise Co., Ltd., the weight ratio is 12 PHR, nano calcium carbonate 5PHR, stearic acid 0.02PHR, 3PHR barium stearate is used as a stabilizer, and the ultraviolet absorber UV -531 weight proportion is 0.6PHR, uses the carbon black of 1.8PHR as pigment; Paste polyvinyl chloride coating slurry composition proportion is: polyvinyl chloride paste resin P440, weight 100 parts by weight, dioctyl adipate 28 PHR, dioctyl phthalate 60 PHR, the liquid rubber adopts the liquid rubber Q101 produced by Taiwan Zhaoxin Enterprise Co., Ltd., the weight ratio is 12 PHR, and the nano-calcium carbonate 4PHR with a diameter of 80 nanometers is selected. Barium steara...

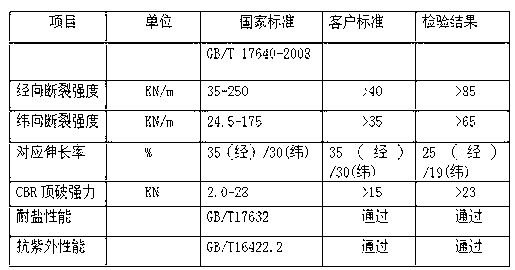

Embodiment 2

[0058] Example 2: A composite anti-seepage cloth for salt ponds, wherein the distribution ratio of polyvinyl chloride rubber modified membrane components is: 100 parts by weight of polyvinyl chloride, dioctyl adipate 18PHR, dioctyl phthalate 25PHR, the liquid rubber adopts the liquid rubber Q101 produced by Taiwan Zhaoxin Enterprise Co., Ltd., the weight ratio is 10 PHR, and the diameter is 100 nanometers of nano-calcium carbonate 0.1PHR, stearic acid 0.02PHR, and the stabilizer is zinc stearate. The weight ratio is 3PHR, the ultraviolet absorber is UV-326, the weight ratio is 0.6PHR, the pigment is phthalocyanine blue, the weight ratio is 1.8PHR; the paste polyvinyl chloride coating slurry component ratio is: polyvinyl chloride Vinyl paste resin P450, 100 parts by weight, dioctyl adipate 25 PHR, dioctyl phthalate 50 PHR, liquid rubber adopts liquid rubber Q101 produced by Taiwan Zhaoxin Enterprise Co., Ltd., and the weight ratio is 10 PHR , select the nano calcium carbonate 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com