Bridge pier column under high-concentration salt solution corrosion environment

A corrosive environment, high-concentration salt technology, used in bridges, bridge construction, bridge parts and other directions, can solve the problems of large amount of steel used for outsourcing steel casing, large maintenance workload and high cost, and achieve low overall project cost, Avoid wasting materials and have the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

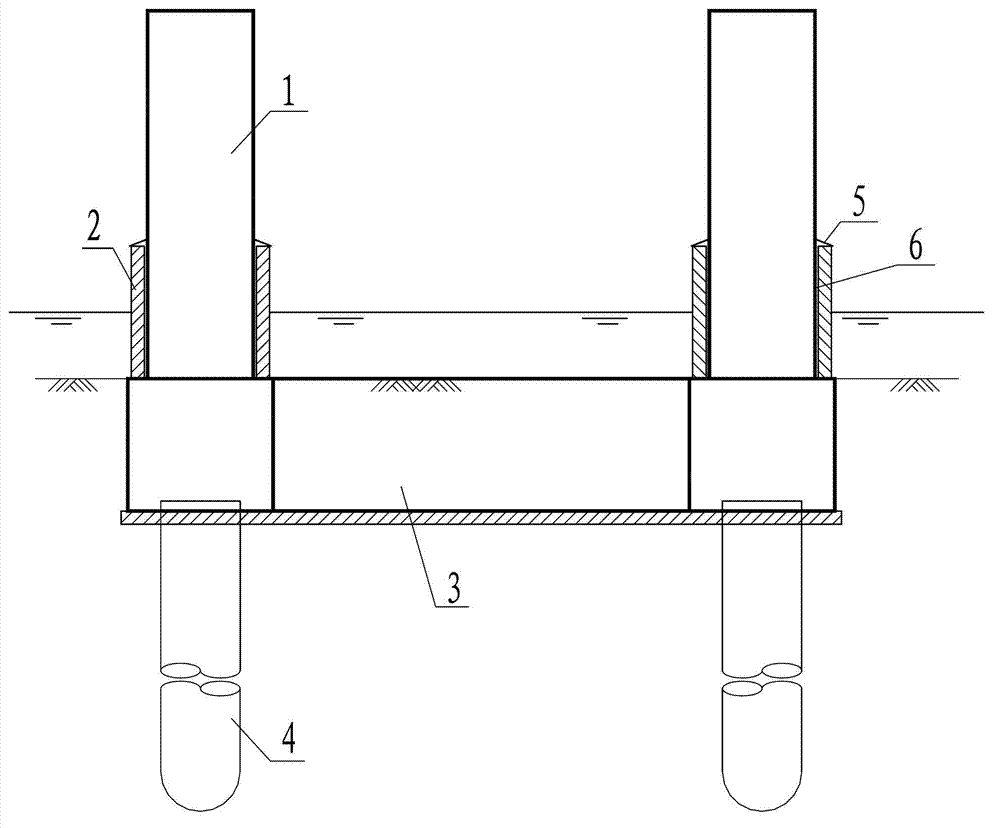

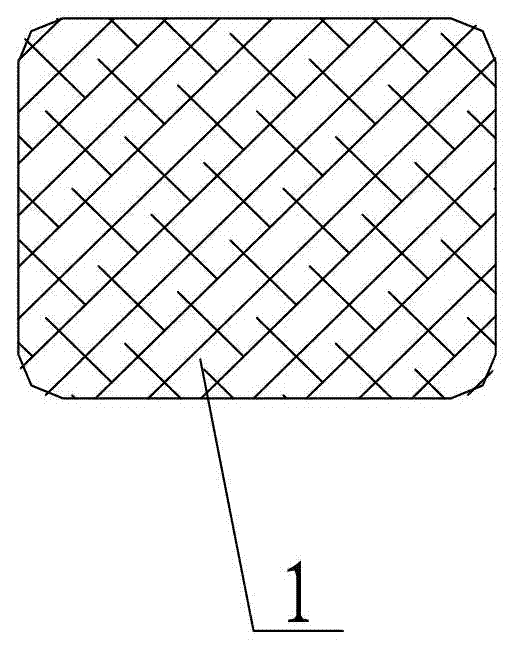

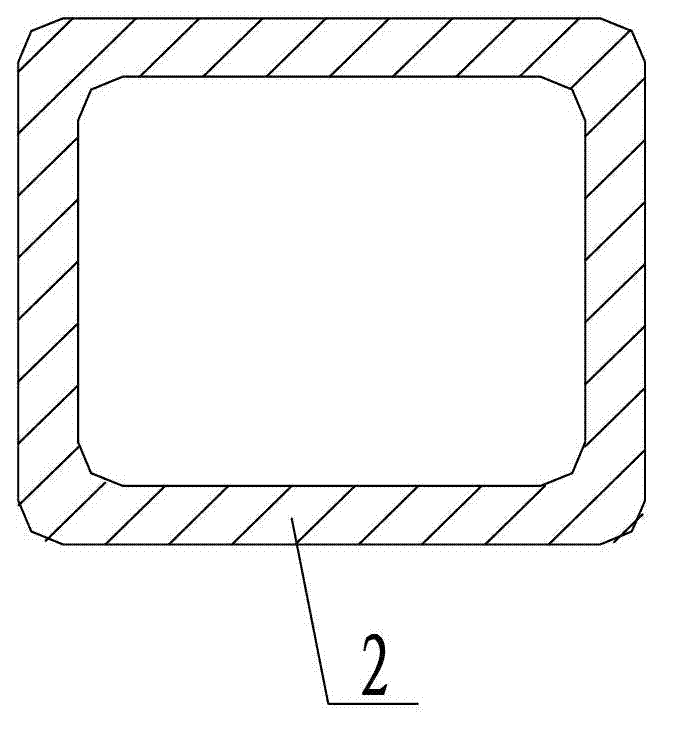

[0024] like Figure 1 to Figure 3 As shown, this embodiment discloses a bridge pier column under a high-concentration salt solution corrosion environment, including a pier column body 1 arranged on the cap 3, and the pier column body 1 is subjected to force analysis and cross-sectional configuration according to a conventional pier column. ribs. The bottom of the pier column body 1 is located in the water level change area of the salt pool. Because this part is in contact with the atmosphere and alternates between dry and wet, the salt liquid crystallizes repeatedly, which is the most serious corrosion of the structure. Set column boots 2 within the range of 1m~1.5m above the highest water level of the salt pon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com