Method for rapidly building anti-seepage salt pond

A salt field and fast technology, applied in the direction of alkali metal chloride, etc., can solve the problems of long beach building time, heavy personnel load, high insoluble impurities, etc., and achieve the effect of saving beach building time, saving consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

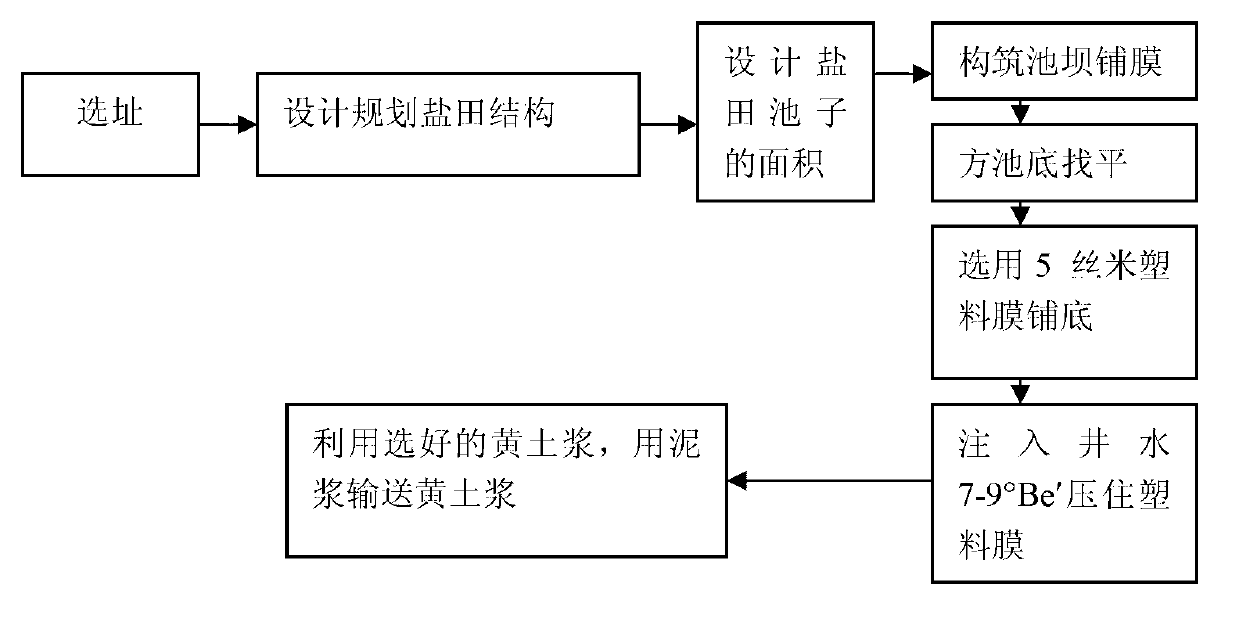

Method used

Image

Examples

Embodiment

[0021] (1) Select the underground loess slurry

[0022] Sampling the underground loess slurry and analyzing its physical and chemical indicators. Physical indicators of loess slurry: sand content is above 70%, sand particles are above 0.01mm, and soil content is ≤30%. The chemical index is that the PH value of the loess slurry is alkaline, and the metal ions, cations, and anions should be high, which is beneficial to replace Ca in the brine 2+ Precipitation, alkaline soil is conducive to SO 4 2- Precipitate.

[0023] Compared with other clays, loess slurry has its own unique characteristics. After being soaked in brine, it will become more and more firm after being pressed in the crucible, and its hardness and pressure will increase. It is suitable for mechanical salt removal. And in the rainy season or winter will not be affected by Na 2 SO 4 10H 2 The impact of O will destroy the pool plate, and it is the first choice material for beach construction. Another feature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com