Advanced treatment technique for brine

A kind of advanced treatment, brine technology, applied in the direction of alkali metal halide purification, alkali metal chloride and other directions, can solve the problems of large environmental pollution, high operating costs, waste of resources, etc., to reduce environmental pollution, reduce CO2 emissions, save alkali consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiment:

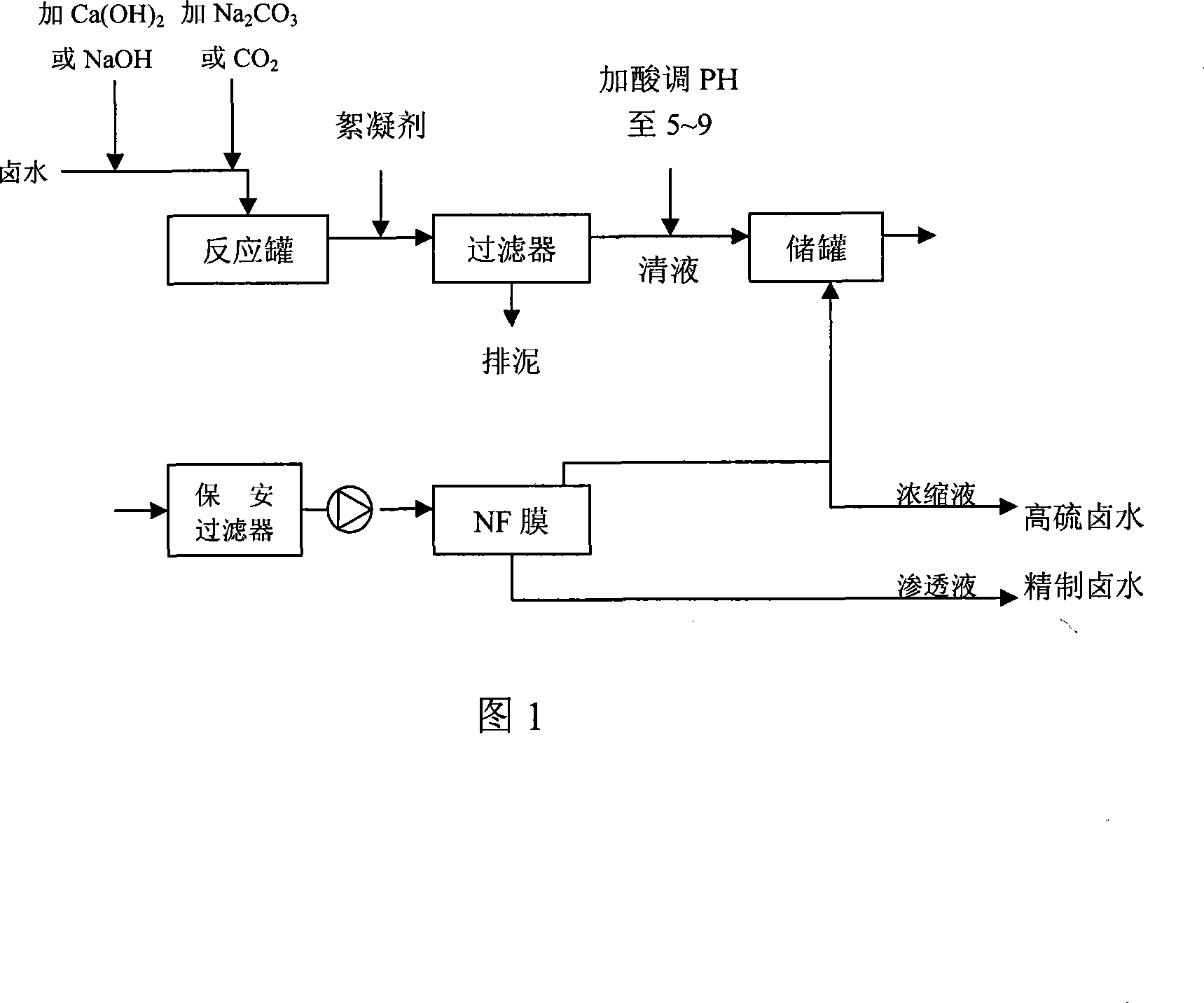

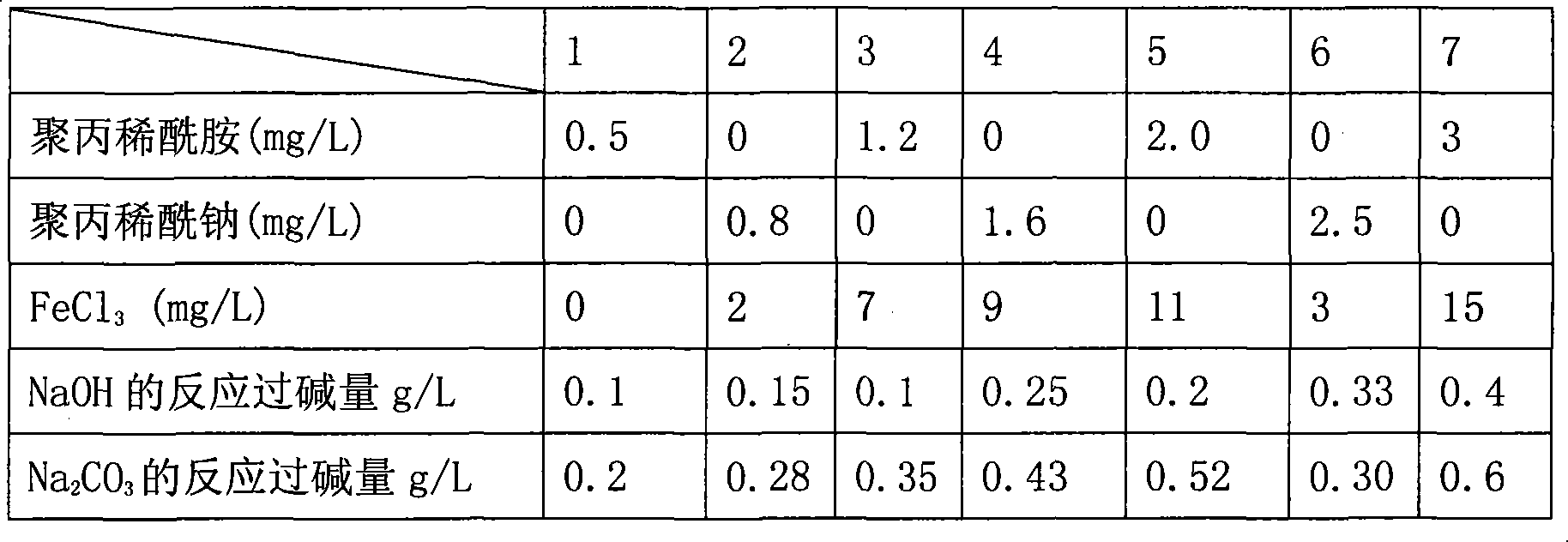

[0026] Brine advanced treatment process, the concentration of NaCl in the brine is greater than 200g / L, Na 2 SO 4 Concentration less than 50g / L, also contains Ca 2+ and Mg 2+ , Ca 2+ , Mg 2+ The concentration of the brine is 1.1-1.8g / L, 0.26-0.31g / L; the brine also contains suspended solids, and the concentration of the suspended solids is 50-500mg / L. The brine is pretreated, that is, NaOH is added to the brine and Na 2 CO 3 , the reaction overalkaline amount of NaOH is 0.1~0.4g / L, NaOH 2 CO 3 The overalkaline amount of the reaction is 0.2~0.6g / L, the reaction is complete, add sodium polyacrylate polymer flocculant and ferric chloride, the amount of polymer flocculant added is 0.5~3mg / L, FeCl 3 The amount of addition is 0-15mg / L, and the precipitate and suspended solids are removed by filtration, so that the Ca in the brine 2+ , Mg 2+ and SS concentration is less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com