Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Sodium fluoride product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing high-quality sodium fluoride from fluorine-containing wastewater as raw material

ActiveCN106830012ARecovery rateRecycling rate due toAlkali metal fluoridesAlkali metal halide purificationNuclear chemistryPrecipitation

The invention discloses a method for producing high-quality sodium fluoride from fluorine-containing wastewater as a raw material. The method comprises the following steps: directly adding excessive sodium carbonate into the fluorine-containing wastewater to completely crystallize and separate fluorine in the solution in a mode of sodium fluoride, or firstly, adding amino into the fluorine-containing wastewater so as to obtain an ammonium fluoride solution, or firstly, precipitating and enriching the fluorine in the fluorine-containing wastewater, secondly, converting a precipitated and enriched product into an ammonium fluoride solution by using an ammonium salt solution, adding excessive sodium carbonate into the ammonium fluoride solution to completely crystal and separate the fluorine in the mode of sodium fluoride, and filtering so as to obtain sodium fluoride filter cakes and a post fluorine precipitation liquid; and washing the sodium fluoride filter cakes by using the ammonium fluoride solution, drying so as to obtain a high-quality sodium fluoride product of which the purity is up to 99.25% or greater, crystallizing the post fluorine precipitation liquid to recycle sodium carbonate in the post fluorine precipitation liquid, further desalting a sodium carbonate crystallization mother liquid, and recycling reclaimed water. The method has the advantages of being simple and convenient to operate, high in fluorine recycling rate, low in production cost, good in sodium fluoride product quality, free of fluorine-containing waste and the like.

Owner:CENT SOUTH UNIV

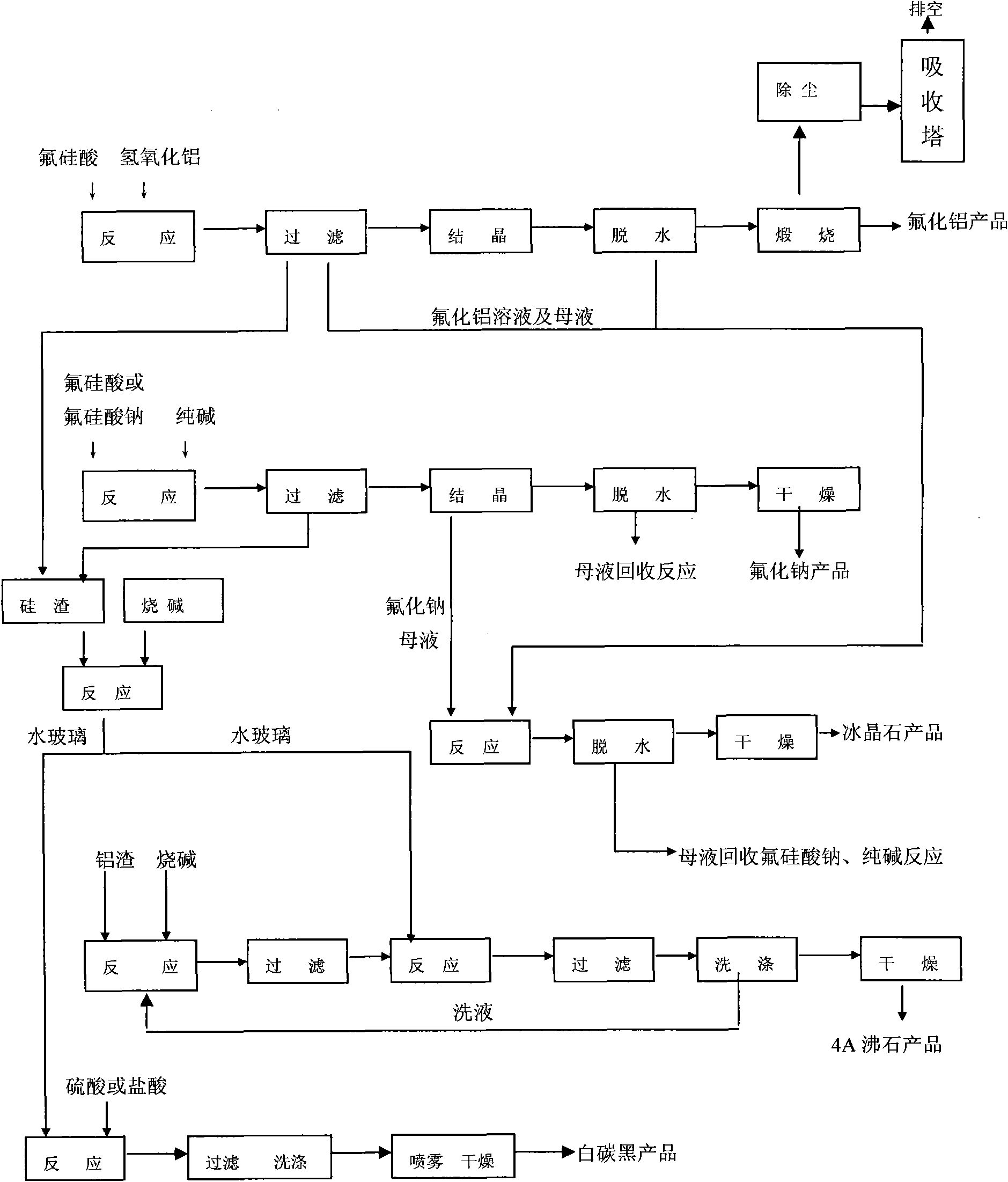

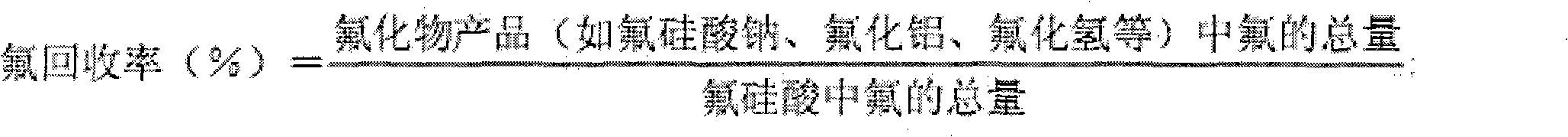

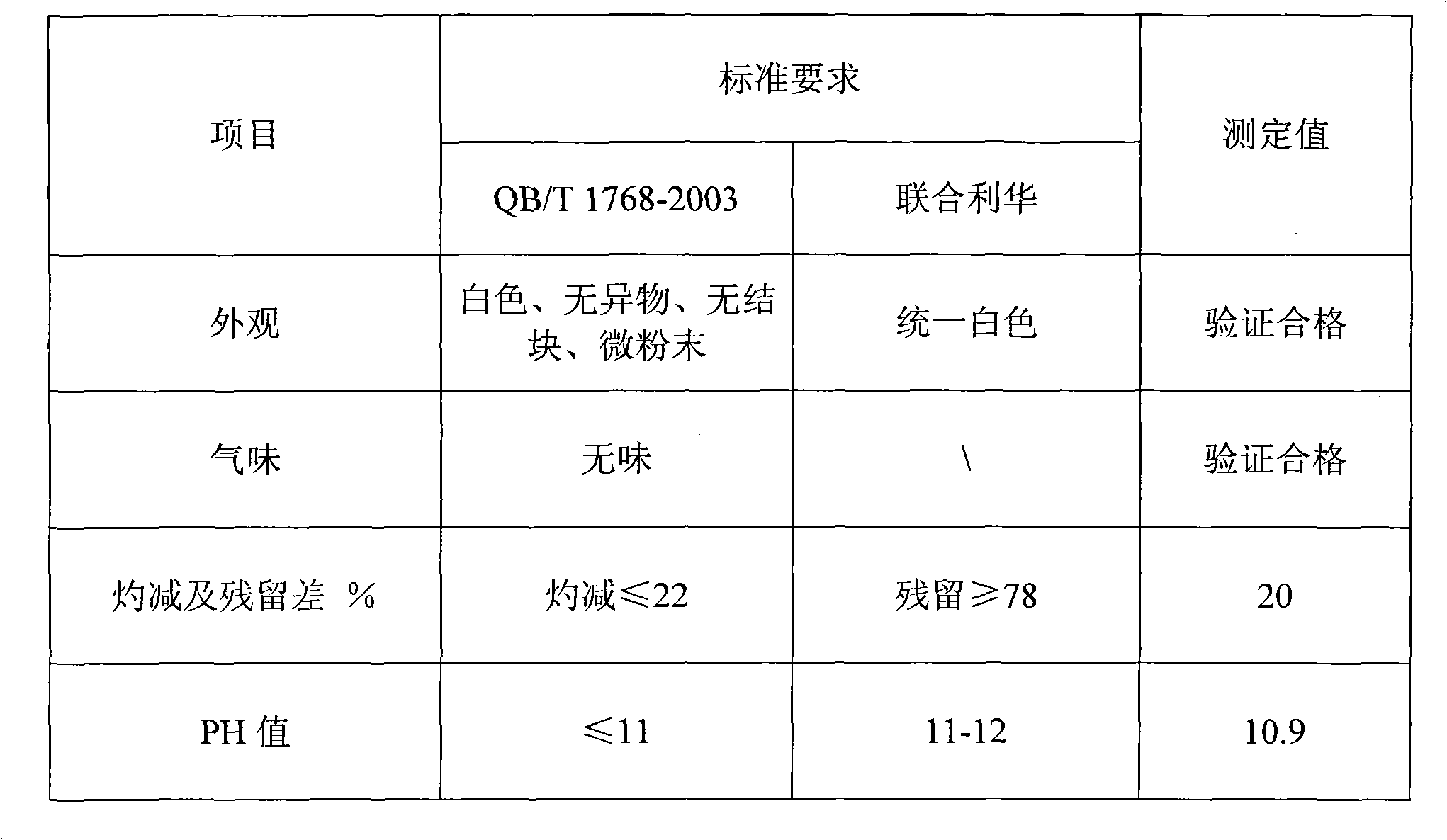

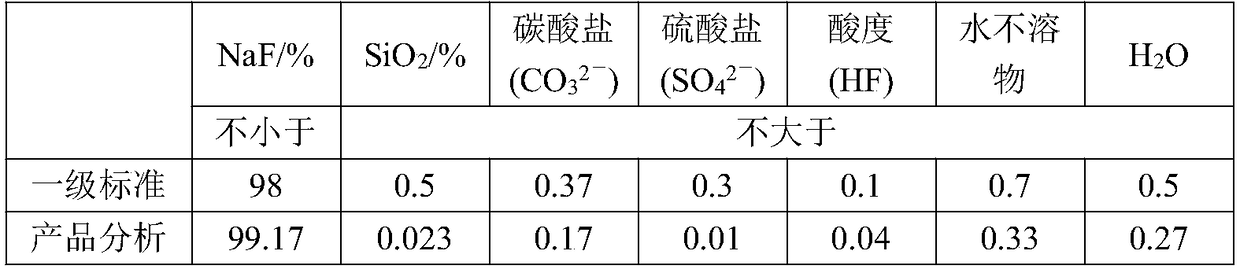

Process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid

ActiveCN101913637AHigh recovery rateTake advantage ofSilicaAlkali metal silicatesChemical industrySlag

The invention discloses a process method for producing fluorine compounds and silicon compounds by cleanly utilizing fluosilicic acid. The process method comprises the following steps of: preparing fluosilicic acid as a phosphorus chemical by-product into an anhydrous aluminum fluoride product, a sodium fluoride product and a cryolite product, and combining with other industrial waste silicon slags and aluminum slags to prepare a 4A zeolite product. The process method comprehensively utilizes the fluosilicic acid and has high resource recovery rate, wherein the recovery rate of the fluorine element reaches higher than 90 percent. Waste silicon dioxide slags generated in the process can be recycled to produce white carbon black and the 4A zeolite, and a mother liquor, a cleaning solution and waste gas which are generated in the production process are all recycled, thereby the environmental pollution is reduced, and the purposes of zero emission and no pollution are truly achieved, thus the method completely meets the requirement for clean production. The invention has the advantages of advanced production process, good product quality and high value, wherein the fluorine content of the aluminum fluoride is high and between 63-65 percent; the quality index of the obtained white carbon black meets the requirement on the standard of the chemical industry; and the quality of the 4A zeolite product meets the requirements on the national standard and the standard of European and American developed countries.

Owner:四川励志环保科技有限公司

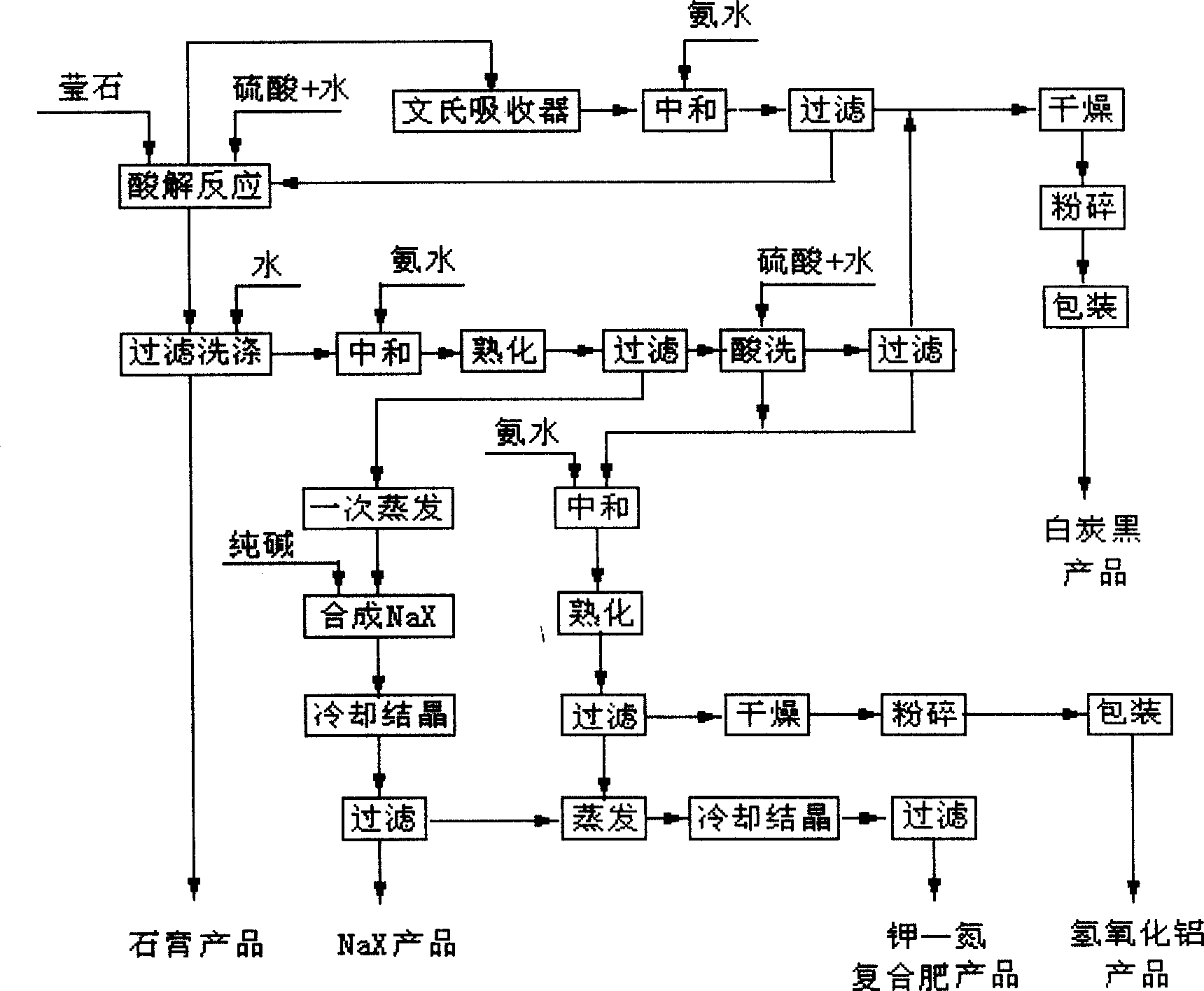

Potash feldspar wet method decomposition and production process

InactiveCN1765837AIncrease productionQuality improvementPotassium fertilisersDecompositionSodium fluoride product

The wet-way decomposition manufacturing technique for potash feldspar comprises: adding sulfuric acid into the mineral powder of potash feldspar and fluorite to mix and acidolysis at 50-80Deg, preparing white carbon black both from gas and acidolysis liquid to increase its yield as well as aluminum hydroxide and sodium fluoride and K-N compound fertilizer. This process is simple, high effect and low cost, can produce a plurality of products and byproducts with little pollution well economic benefit.

Owner:鄂州市长润农业生态技术有限公司

Method for producing sodium fluoride

InactiveCN101376507AReduced silica contentLow costAlkali metal fluoridesAmmonia preparation/separationFiltrationSodium fluoride product

The invention relates to a manufacturing method of sodium fluoride, which takes ammonium fluoride and sodium hydroxide as raw material and comprises the steps as follows: (1) an ammonium fluoride solution whose concentration is 20 to 50 percent and a sodium hydroxide solution whose concentration is 20 to 35 percent are added in a reaction kettle at the same time; the material feeding time is 15 to 30 minutes, the stirring is conducted for 15 to 30 minutes after the material feeding, and a sodium fluoride ground-paste is prepared; (2) the obtained sodium fluoride ground-paste is filtered to prepare a sodium fluoride paste which is dried for 1 to 2 hours at the temperature ranging from 100 to 300 DEG C to obtain the sodium fluoride with excellent quality; (3) a mother solution which is processed through filtration is concentrated to lead the sodium fluoride in the mother solution to be crystallized to obtain a sodium fluoride product. Compared with the neutralization method, the manufacturing method of the sodium fluoride has obvious advantage on the price; compared with the sodium fluosilicate method, the ammonium fluoride has extremely low silicon dioxide content, the product quality is easy to be controlled during the production process, the flow is short, and the product quality is better. In addition, the manufacturing method generates no three wastes during the reaction process, and has remarkable environmental protection benefit; a product which is generated during the reaction process can be recycled, thereby lowering the manufacturing cost to a certain extent.

Owner:DO FLUORIDE CHEM CO LTD

Method for producing hydrofluoric acid, waterless magnesium sulfate and sodium fluoride

The process of producing hydrofluoric acid, anhydrous magnesium sulfate and sodium fluoride with sodium fluorosilicate and magnesia as material includes the following steps: 1. decomposing sodium fluorosilicate to produce sodium fluoride product and silicon tetrafluoride gas; 2. absorbing the gas with water, filtering to prepare fluorosilicic acid solution for preparing magnesium tetrafluoride, washing silica and drying to obtain carbon white; 3. reacting fluorosilicic acid solution and magnesia, filtering to obtain magnesium fluorosilicate solution, and concentrating to obtain crystal magnesium fluorosilicate hexahydrate; 4. decomposing magnesium fluorosilicate hexahydrate to produce magnesium fluoride solid, silicon tetrafluoride gas and water vapor; 5. absorbing the gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution returned to the step 3, washing silica and drying to obtain carbon white; and 6. reacting magnesium fluoride and sulfuric acid, condensing and rectifying to obtain hydrofluoric acid, and obtaining anhydrous magnesium sulfate.

Owner:DO FLUORIDE CHEM CO LTD

Fluorine adsorbent and method for recycling fluorine from fluorine-containing water

InactiveCN108993391ALarge adsorption capacityImprove acid resistanceOther chemical processesWater contaminantsActivated carbonMixed oxide

The invention discloses a fluorine adsorbent. The adsorbent is a mixture composed of an oxide of a metal element Me, a hydrate of the oxide and activated carbon, wherein the metal element Me is selected from an element capable of forming an insoluble complex with fluorine. A method for removing and recycling fluorine from fluorine-containing water comprises the following steps: step 1, adsorbing and enriching fluorine; step 2, regenerating an adsorbent; and step 3, producing sodium fluoride. According to the invention, the adsorption capacity of the adsorbent to F is remarkably increased, andacid resistance of the adsorbent is greatly improved. The mixed oxide adsorbent containing activated carbon is adopted; the adsorbent can be used for defluorination of neutral and weakly acidic fluorine-containing groundwater, so that the groundwater achieves a drinking standard; the adsorbent can also be used for deep purification and standard emission of high-acidity fluorine-containing industrial wastewater; and the fluorine in water can be recycled in the form of a sodium fluoride product, so that waste is changed into wealth. The method has the advantages of simple process, simple and convenient operation, cleanness and environment friendliness, good fluorine removal effect and the like, and is suitable for industrial application of removing and recycling fluorine in fluorine-containing water.

Owner:长沙华盛新材料科技有限责任公司

Preparation method of sodium fluoride

InactiveCN102557079AAvoid enteringReduced corrosion protection requirementsAlkali metal fluoridesChemical industrySodium fluoride product

The invention discloses a preparation method of sodium fluoride. The preparation method comprises the following steps: adding sodium sulfate solution at the mass percentage concentration of 12 to 28 percent into ammonium fluoride solution at the temperature of between 30 and 65 DEG C to generate sodium sulfate precipitate, wherein the ammonium fluoride at the mass percentage concentration of 8 to 50 percent serves as a raw material and the adding speed of the sodium sulfate is 40 to 200 ml / min; reacting for 60 to 130 minutes by controlling the stirring speed to 130 to 400 r / min; performing solid liquid separation to obtain sodium sulfate filter cakes; washing the filter cakes by using deionized water; and drying to obtain the sodium sulfate products. Compared with the prior art, the method has the advantages of using the sodium sulfate as the raw material instead of the conventional sodium chloride, preventing chloride ions from entering a production system, reducing corrosion-resistant requirement of the equipment and saving production cost. The method is simple and practical in process route and provides technological theory support for production of the sodium fluoride in the fluorine chemical industry enterprises.

Owner:WENGFU (GRP) CO LTD

Preparation method of superior pure sodium fluoride

InactiveCN105293528AHigh purityLow impurity contentAlkali metal fluoridesHydrofluoric acidFiltration

The invention relates to a preparation method of superior pure sodium fluoride. The method comprises the steps of (1) crystallization and (2) washing. In the crystallization step, Na2CO3 is placed in a polytetrafluorine reactor; 40% hydrofluoric acid is slowly added under stirring, until the pH value is 8, wherein 40wt% of hydrofluoric acid is added, and a terminal point is reached when no carbon dioxide escapes; suction filtration is carried out such that crystals are obtained. In the washing step, the crystals are washed twice with distilled water, and are dried under a temperature of 35 DEG C, such that superior pure sodium fluoride is obtained. The preparation method provided by the invention has the advantages of simple process steps, easy-to-control reaction process, high production efficiency, low impurity content, and high superior pure sodium fluoride product purity.

Owner:TIANJIN CHEM REAGENT RES INST

Method for producing sodium fluoride

InactiveCN101134582ASilicon oxidesAlkali metal fluoridesSodium fluoride productSilicon tetrafluoride

The present invention relates to process of producing sodium fluoride with fluorosilicic acid and sodium chloride as material. The process includes the following steps: 1. reacting fluorosilicic acid solution and sodium chloride for 10-30 min, filtering to obtain solid sodium fluorosilicate and waste hydrochloric acid solution to be treated and drained; 2. decomposing sodium fluorosilicate at 300-800 deg.c for 1-5 hr to produce solid sodium fluoride product and silicon tetrafluoride gas; and 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution and solid silica, and washing and drying silica to obtain carbon white. The process utilizes fluorosilicic acid as one side product of phosphate fertilizer production as one main material, and has low cost and environment friendship.

Owner:DO FLUORIDE CHEM CO LTD

Method for producing sodium fluoride and sodium silicate by utilizing fluorine-containing silicon slag

InactiveCN111392748ASolve the problem of solid waste treatmentNo pollutionAlkali metal silicatesAlkali metal fluoridesHexafluorosilicic acidSilicon dioxide

The invention discloses a method for producing sodium fluoride and sodium silicate from fluorine-containing silicon slag, which comprises the following steps: adding silicon slag containing silicon dioxide and fluosilicic acid into a sodium carbonate solution, and reacting to generate a mixture of sodium fluoride crystals and silicon dioxide; adding a caustic soda solution into filter cake obtained by solid-liquid separation, reacting to generate sodium fluoride crystal and sodium silicate mixed slurry, and carrying out solid-liquid separation to obtain crude sodium fluoride and liquid sodiumsilicate; subjecting the liquid sodium silicate to concentration and filtration again to remove precipitated sodium fluoride impurities so as to obtain a liquid sodium silicate product with the required modulus and concentration; washing and refining the crude sodium fluoride by using dilute caustic soda liquid, removing sodium silicate impurities, and neutralizing residual sodium hydroxide attached liquid on the sodium fluoride by using hydrofluoric acid to generate sodium fluoride; drying the refined wet sodium fluoride to obtain a sodium fluoride product of which the purity is greater than98%. The method is mature in technology, good in product quality, low in cost, free of waste water and waste residues and capable of thoroughly converting fluorine-containing silicon slag solid wasteinto sodium fluoride and sodium silicate products.

Owner:石家庄东昊化工研究院有限公司

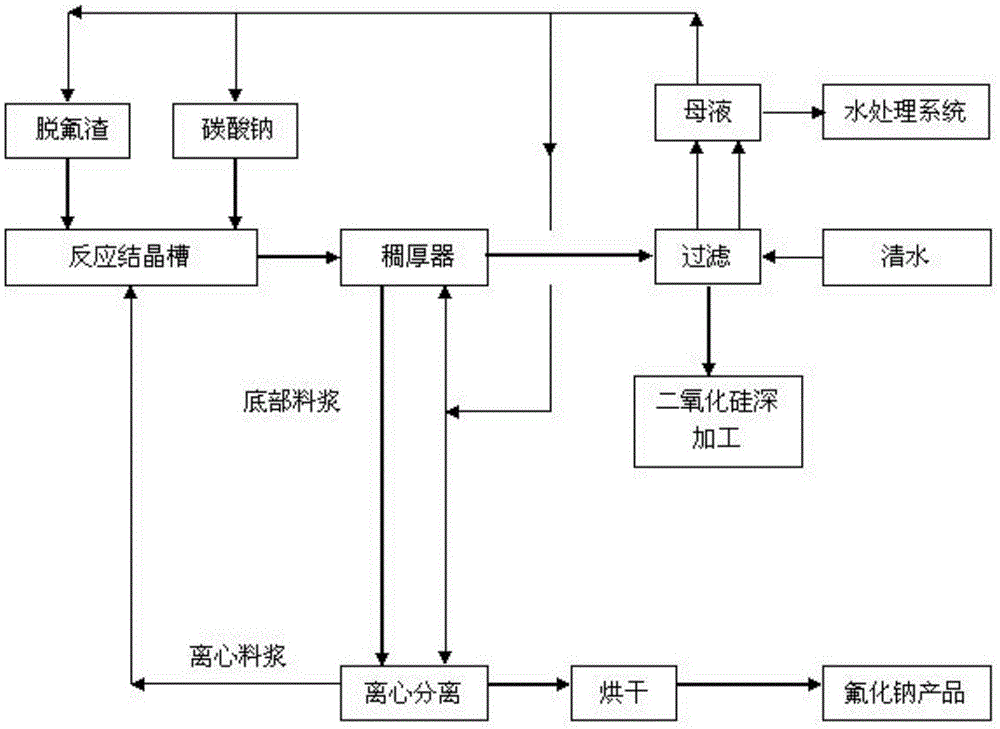

Method for preparing sodium fluoride from defluorination residue generated in production of phosphoric acid by wet process

ActiveCN104386711ACoarse crystal grain sizeIncrease the sinking speed differenceAlkali metal fluoridesSodium fluoride productPhosphoric acid

The invention discloses a method for preparing sodium fluoride from defluorination residue generated in production of phosphoric acid by a wet process. The method comprises the following steps of respectively recycling mother liquid, sodium carbonate and defluorination residue slurry, reacting and crystallizing the defluorination residue slurry and a sodium carbonate solution and simultaneously returning fine sodium fluoride particles to the system for secondary growth. By larger sinking speed difference between sodium fluoride and silicon dioxide, the separation of sodium fluoride from silicon dioxide is achieved, and the technical problem of difficulty in separation of sodium fluoride from SiO2 is effectively solved. The sodium fluoride product obtained by the method is coarse, more than 85% of the sodium fluoride product has particle diameter greater than 0.35mm and the yield of fluorine in the sodium fluoride product is above 85%. By the method, the circulation of the mother liquid is achieved, the water consumption as well as the production cost are decreased, and the method has good social and economic values and is suitable for being popularized and applied.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Method of continuously producing sodium fluoride

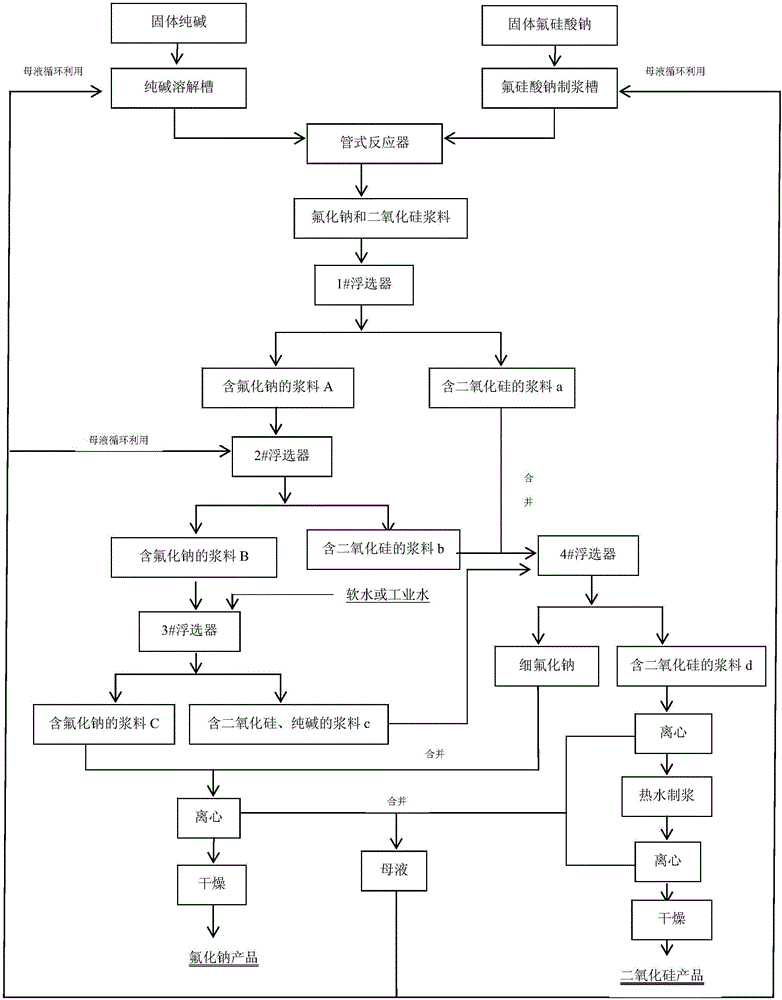

ActiveCN106517246ARealize continuous productionAdequate responseSilicaAlkali metal fluoridesAutomatic controlDecomposition

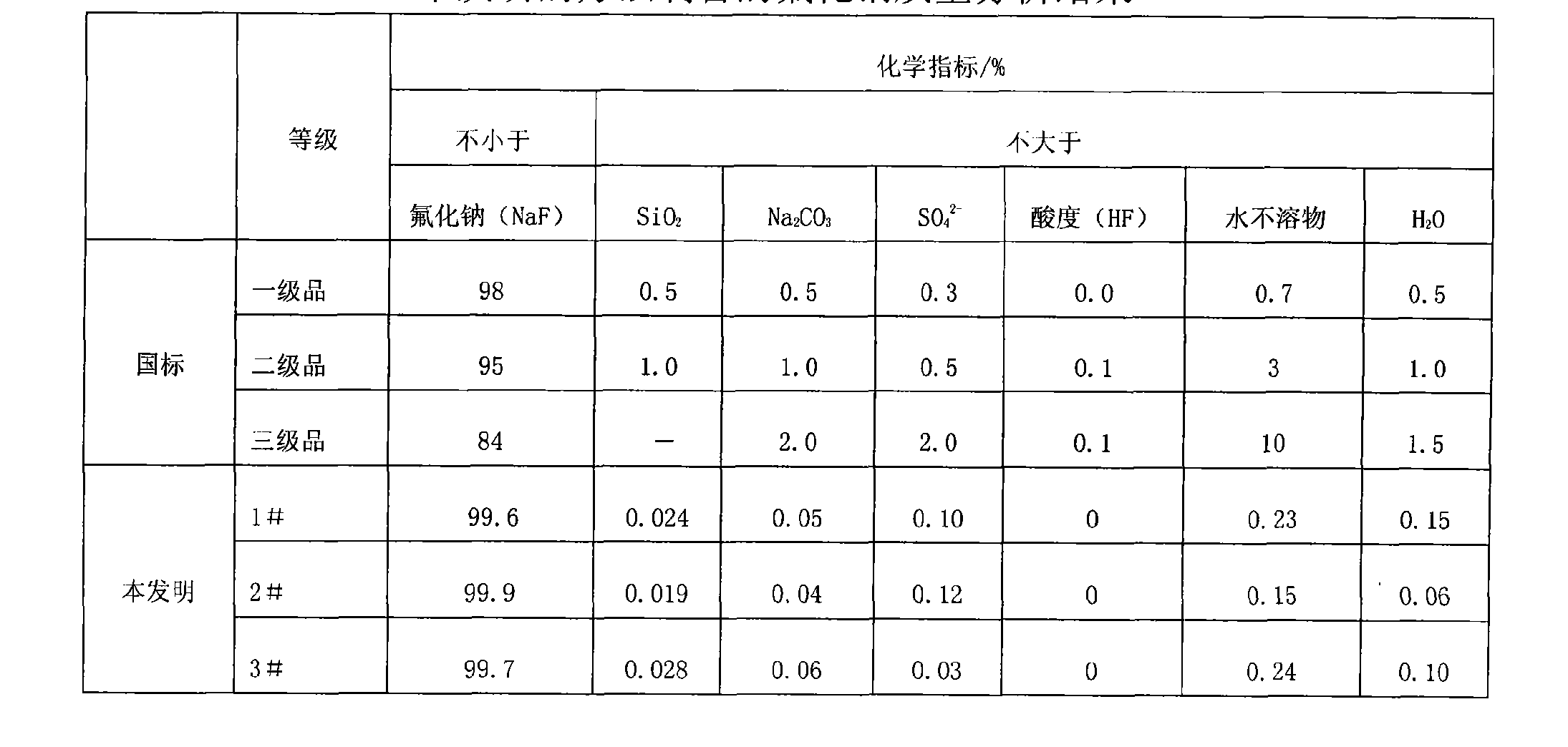

The invention discloses a method of continuously producing sodium fluoride. The method comprises the following steps of: sequentially adding a sodium fluosilicate solution with mass fraction being 20-30% and a soda pollution with mass fraction being 20-30% into a tubular type reactor, controlling a reaction temperature to 60-100 DEG C, performing double decomposition reaction to generate sodium fluoride and silicon dioxide slurry, continuously introducing sodium fluoride and silicon dioxide slurry into a multi-stage floatator to perform flotation, thereby obtaining slurry containing sodium fluoride and slurry containing silicon dioxide after floating, and separately performing centrifuging, washing and drying, thereby obtaining a sodium fluoride product and a silicon dioxide product, wherein solutions obtained by centrifuging per time are combined for being recycled as a mother solution. According to the method disclosed by the invention, soda is excessively added in a reaction process, so that sodium fluosilicate sufficiently reacts, and therefore, a conversion rate is 100%. Purity of sodium fluoride produced by the method disclosed by the invention is higher than 98.5%, and purity of silicon dioxide is higher than 98.0%. According to the method disclosed by the invention, production scale investment is less, automatic control can be realized, labor intensity of staff is relieved, product quality is excellent and raw material consumption is low.

Owner:湖南新晶富新材料有限公司

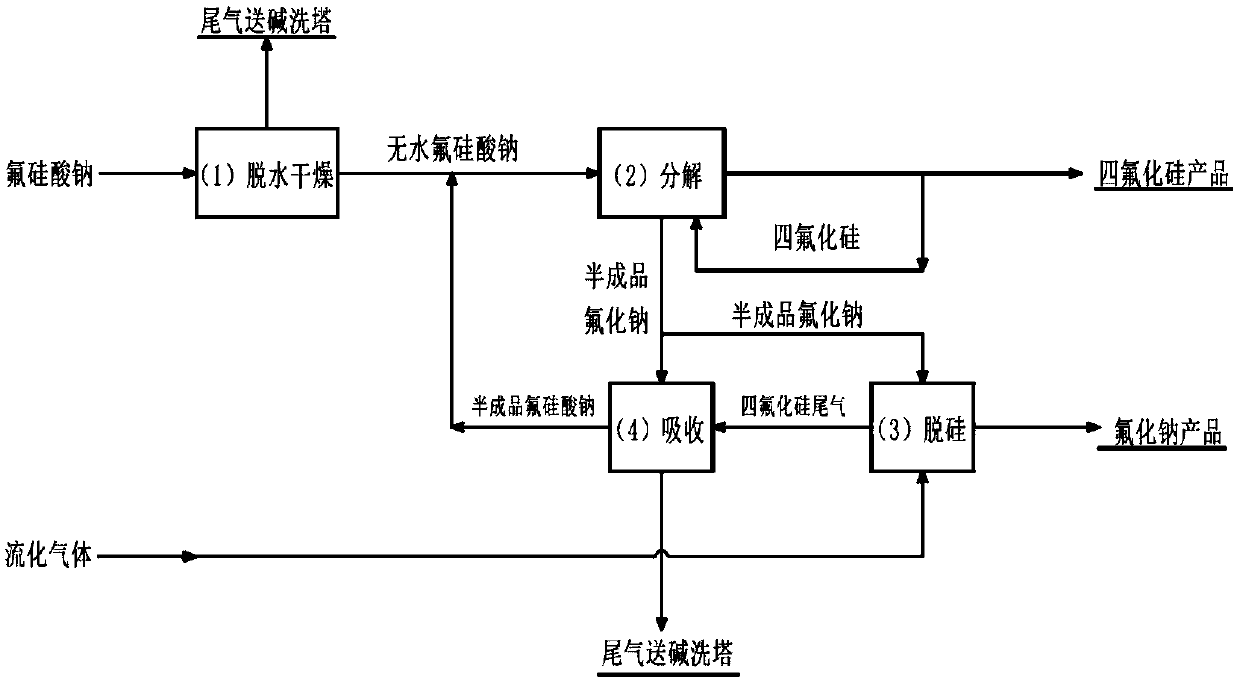

Method for efficiently producing silicon tetrafluoride and sodium fluoride by using sodium fluorosilicate

ActiveCN110683548AEnhance heat and mass transferThere is no problem of molten agglomerationAlkali metal fluoridesHalogenated silanesSodium fluoride productPhysical chemistry

The invention discloses a method for efficiently producing silicon tetrafluoride and sodium fluoride by using sodium fluorosilicate. The method includes a dehydration and drying process, a decomposition process, a desiliconization process and an absorption process. The method specifically includes the steps that sodium fluorosilicate is subjected to the dehydration and drying process to obtain anhydrous sodium fluorosilicate; then anhydrous sodium fluorosilicate enters the decomposition process to obtain silicon tetrafluoride and semi-finished sodium fluoride; a part of silicon tetrafluoride is returned to the decomposition process to be used as fluidizing gas, and the other part of silicon tetrafluoride is used as a silicon tetrafluoride product; a part of the semi-finished sodium fluoride directly enters the desiliconization process to obtain a sodium fluoride product, and silicon tetrafluoride tail gas is generated; and the other part of the semi-finished sodium fluoride is used forabsorbing silicon tetrafluoride in the desiliconized tail gas to obtain semi-finished sodium fluorosilicate, the semi-finished sodium fluorosilicate is returned to the decomposition process, and thetail gas in the absorption process is sent to an alkaline washing tower for treatment. The method is suitable for the decomposition of sodium fluorosilicate to prepare silicon tetrafluoride and sodiumfluoride, and has the advantages of short process, low energy consumption, environmental friendliness, high added value of products and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

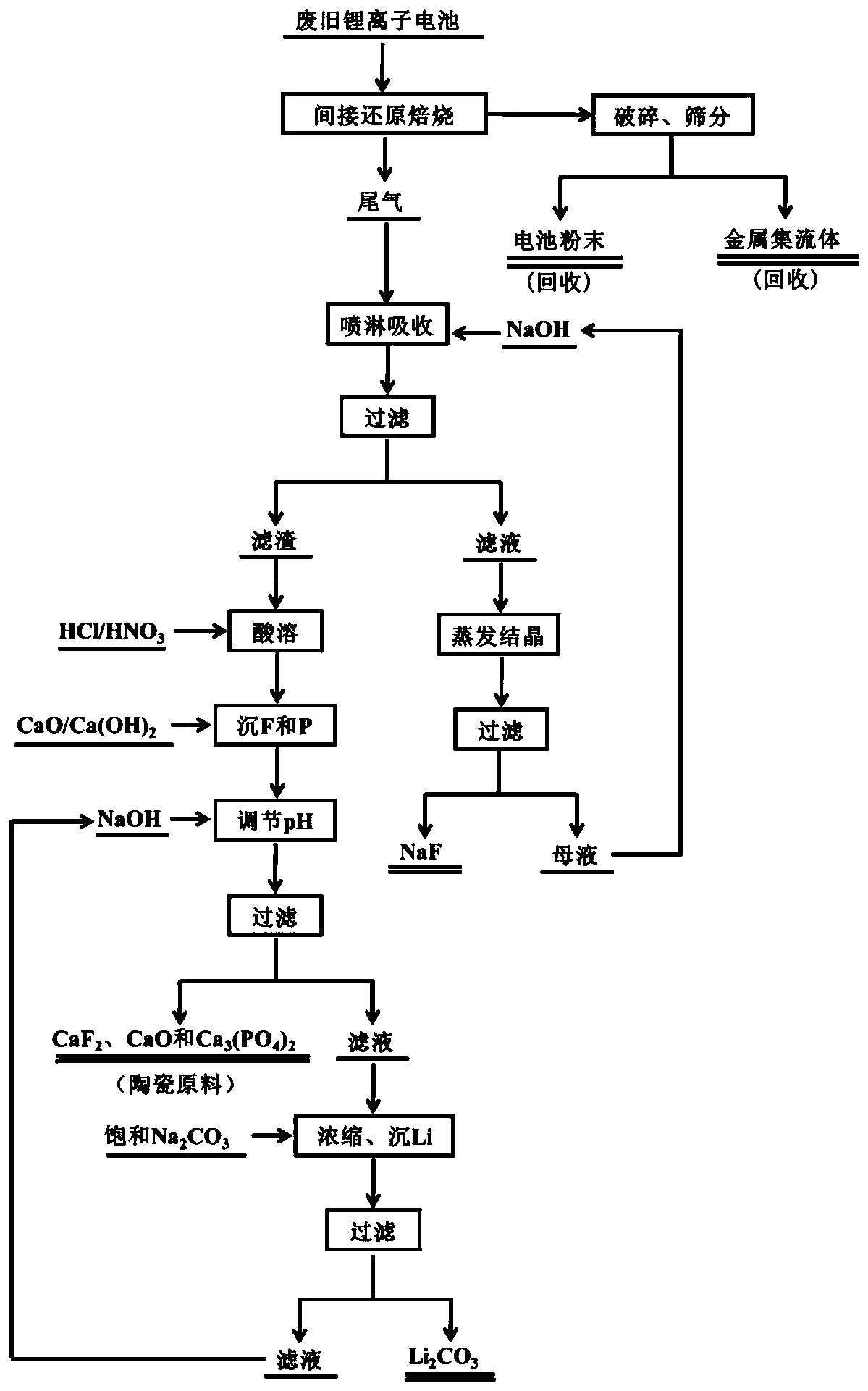

Method for resource utilization of waste lithium ion battery roasting tail gas

ActiveCN110092398AHigh purityLow costWaste accumulators reclaimingAlkali metal fluoridesResource utilizationFiltration

The invention discloses a method for the resource utilization of waste lithium ion battery roasting tail gas. Indirect reduction roasting is performed on waste lithium ion batteries in a rotary kiln,and battery powder and metal current collectors which are used for the recycling of follow-up processes after roasting, crushing and sieving; after tail gas generated during roasting is absorbed through the spraying of an alkaline solution, mixed filter residues of lithium phosphate and lithium fluoride and sodium fluoride containing filtrate can be obtained through filtering; a sodium fluoride product and crystallization mother liquor can be obtained after the evaporation, crystallization and filtration of the filtrate, and the crystallization mother liquor can return to be absorbed through spraying; calcium oxide or calcium hydroxide is added to precipitate fluorine and phosphor after the acid dissolution of the filter residues, mixed filter residues of calcium fluoride, calcium oxide and calcium phosphate which can be used as ceramic raw materials and lithium containing filtrate can be obtained after filtering; and a lithium carbonate product and alkaline filtrate are obtained afterthe concentration, lithium precipitation and filtering of the filtrate, and the alkaline filtrate can return back to the alkaline solution to adjust the pH of the solution. The method is simple in technology, short in process and low in reagent cost, and secondary pollution cannot be generated, so that the recycling problems of fluorine, phosphor and lithium in waste lithium ion battery roastingtail gas can be effectively solved.

Owner:GUANGDONG GUANGHUA SCI TECH

Comprehensive utilization method of silicon residue soil

ActiveCN106365189AShort processing timeSimple process equipmentSilicaAlkali metal fluoridesProcess equipmentResource utilization

The invention discloses a comprehensive utilization method of silicon residue soil. The comprehensive utilization method comprises the following steps: leaching and decomposing the silicon residue soil by adopting an acid solution, leaching and separating residues, separating alumsili through volatilizing leaching liquid, obtaining an aluminum fluoride product, and absorbing, acidifying and washing volatile matters to obtain white carbon black and a sodium fluoride product. The comprehensive utilization method disclosed by the invention has the characteristics of being short in process flow and processing time, simple in process equipment, and easy and safe to operate, is a process technology route for comprehensive resource utilization of high value-added chemical products produced by utilizing industrial wastes and can achieve secondary comprehensive resource utilization and realize the purposes of circular economy, energy conservation and emission reduction.

Owner:KUNMING UNIV OF SCI & TECH

A process for the comprehensive recovery of fluorine and phosphorus by alkali decomposition of mixed rare earth concentrate liquid

ActiveCN106586992BAchieve separationAchieve recyclingHydrogenAlkali metal fluoridesFiltrationDecomposition

The invention relates to a comprehensive fluorine and phosphorous recovery technology for liquid caustic soda decomposition of mixed rare earth concentrate. The comprehensive fluorine and phosphorous recovery technology is characterized by including mixing the high-grade mixed rare earth concentrate with a 60wt% sodium hydroxide solution according to a weight ratio of 1:3.5-7.5, reacting for 0.2-1 hour at 150-160 DEG C, conducting hot filtration at 80 DEG C to obtain strong liquid caustic soda and caustic soda cakes, cooling the strong liquid caustic soda to 30-70 DEG C and filtering so as to obtain a sodium phosphate product; mixing the caustic soda cakes into paste prior to washing, and filtering so as to obtain primary caustic soda washed liquid; continuing washing the caustic soda cakes until the caustic soda cakes become neutral, dissolving the neutral caustic soda cakes with 6-10 mol / L hydrochloric acid, and controlling a pH value to be 4-5 so as to obtain a rare earth chloride solution; concentrating the primary caustic soda washed liquid, and filtering so as to obtain a sodium fluoride product. The comprehensive fluorine and phosphorous recovery technology has the advantages that the comprehensive fluorine and phosphorous recovery technology is short in technological process and low in production energy consumption; fluorine and phosphorous recovery and cyclic utilization of liquid caustic soda are achieved, wastewater discharge is avoided, and clean production and comprehensive resource utilization are achieved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Method for preparing sodium fluoride

InactiveCN106745074ASimple processEasy to operateAlkali metal fluoridesSodium fluoride productTwo step

The invention discloses a method for preparing sodium fluoride. The method comprises the following steps: (1) dissolving sodium carbonate in water so as to prepare a sodium carbonate solution; (2) mixing H2SiF6 with a proper amount of mother liquor so as to prepare a suspension, stirring, heating to 85-87 DEG C, and slowly dropping the Na2CO3 solution prepared in the step (1) into a 3-neck flask by using a solution funnel; (3) starting stirring, performing heating stirring for 30-50 minutes at 85-87 DEG C, leaving to stand, performing heat-preservation aging for 0.5-1 hour, filtering, and washing so as to obtain a mixture of solid sodium fluoride and a byproduct silica; (4) separating the mixture by using a gravity settlement method, thereby obtaining a solid sodium fluoride product. The method is simple in process and convenient to operate, raw materials such as sodium hydroxide, hydrochloric acid or ammonium bicarbonate added in a two-step method are not needed, and compared with a conventional production method, the quality is ensured, pollution is reduced, and the cost is reduced.

Owner:衡阳市锦轩化工有限公司

Co-production method of sodium metasilicate and sodium fluoride

InactiveCN105883836AReduce pollutionEasy to separateAlkali metal silicatesAlkali metal fluoridesSodium metasilicateSodium fluoride product

The invention discloses a co-production method of sodium metasilicate and sodium fluoride. The method comprises the following steps: a sodium hydroxide solution with the concentration being 15%-50% in percentage by mass and fluorine-containing silicon slag are mixed in the mass ratio being (1-6):1 and stirred to have a reaction for 15-150 min; after the reaction temperature is reduced to 50-60 DEG C, the mixed solution is filtered, and a filter cake and filtrate are obtained; the filter cake is washed with a sodium hydroxide solution with the concentration being 5%-15% in percentage by mass and process water sequentially and dried until the water content is 0-1.5% after washing, and a sodium fluoride product is obtained; the molar ratio of the filtrate is adjusted to be 1 with a conventional method, evaporated and concentrated until the concentration of sodium metasilicate is 55%-60% in percentage by mass and finally cooled, crystalized and dried with the conventional method, and a sodium metasilicate product is obtained. The co-production method has the characteristics of simple process, small device and little corrosion.

Owner:福建瓮福蓝天氟化工有限公司

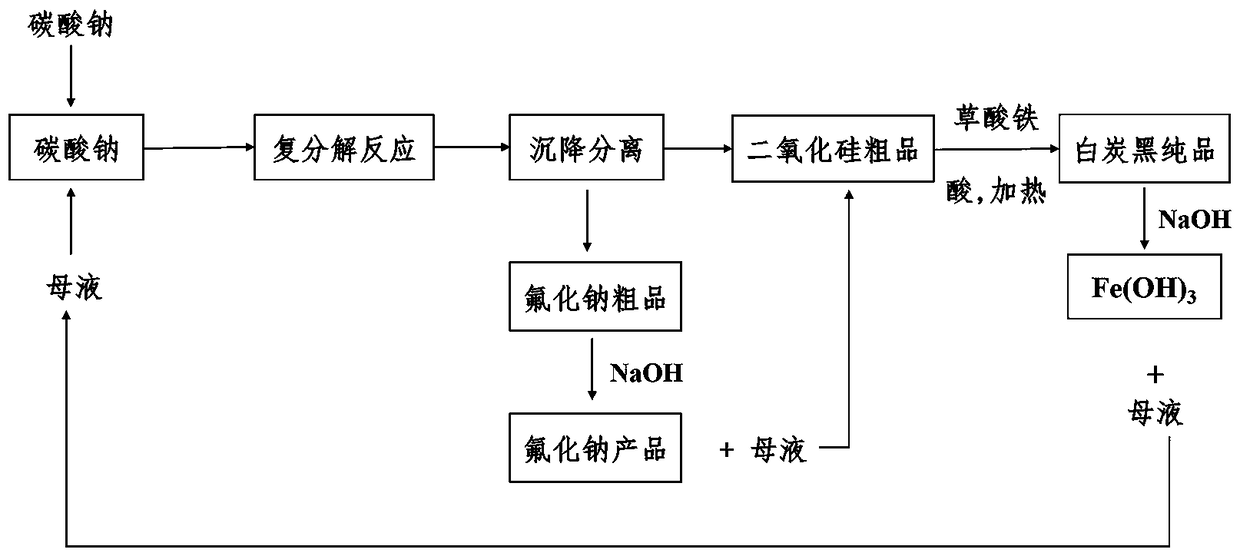

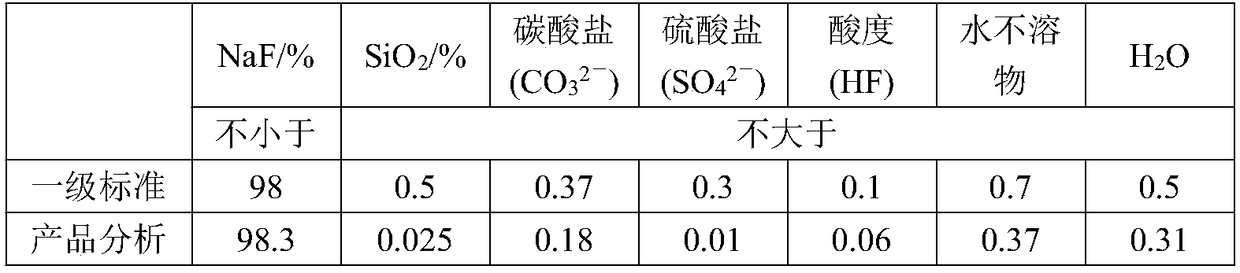

Purification process for sodium fluoride and silicon dioxide

InactiveCN108751207AGood effectHigh yieldSilicaAlkali metal fluoridesFerric oxalateSodium fluoride product

The invention relates to a separation and purification process for sodium fluoride and silicon dioxide. Sodium fluosilicate as a byproduct of phosphate fertilizer is used for producing sodium fluorideand co-producing white carbon black; the method comprises the following steps: a sodium fluoride and silicon dioxide mixed solution is subjected to settling separation in a separation scrubber, and crude sodium fluoride and crude silicon dioxide are obtained; crude sodium fluoride is dispersed in mother liquor, slightly excessive sodium hydroxide is added, so that a small quantity of silicon dioxide impurities are converted into soluble sodium silicate, filtering, washing and drying are performed, a high-purity sodium fluoride product is obtained, and the mother liquor is conveyed to a silicon dioxide purification tank continuously; silicon dioxide is dispersed in the mother liquor in the silicon dioxide purification tank, slightly excessive ferric oxalate is added, a small quantity of sodium fluoride impurities are converted into a soluble complex, filtering, washing and drying are performed, and a high-purity white carbon black product is obtained. According to the process, large quantities of acids and bases are not needed to be consumed, less mother liquor is produced in the separation and purification process, yield and purity of the sodium fluoride and white carbon black products are improved, and the mother liquor can be recycled.

Owner:HUNAN UNIV OF TECH

A method for continuous production of sodium fluoride

ActiveCN106517246BRealize continuous productionAdequate responseSilicaAlkali metal fluoridesAutomatic controlDecomposition

Owner:湖南新晶富新材料有限公司

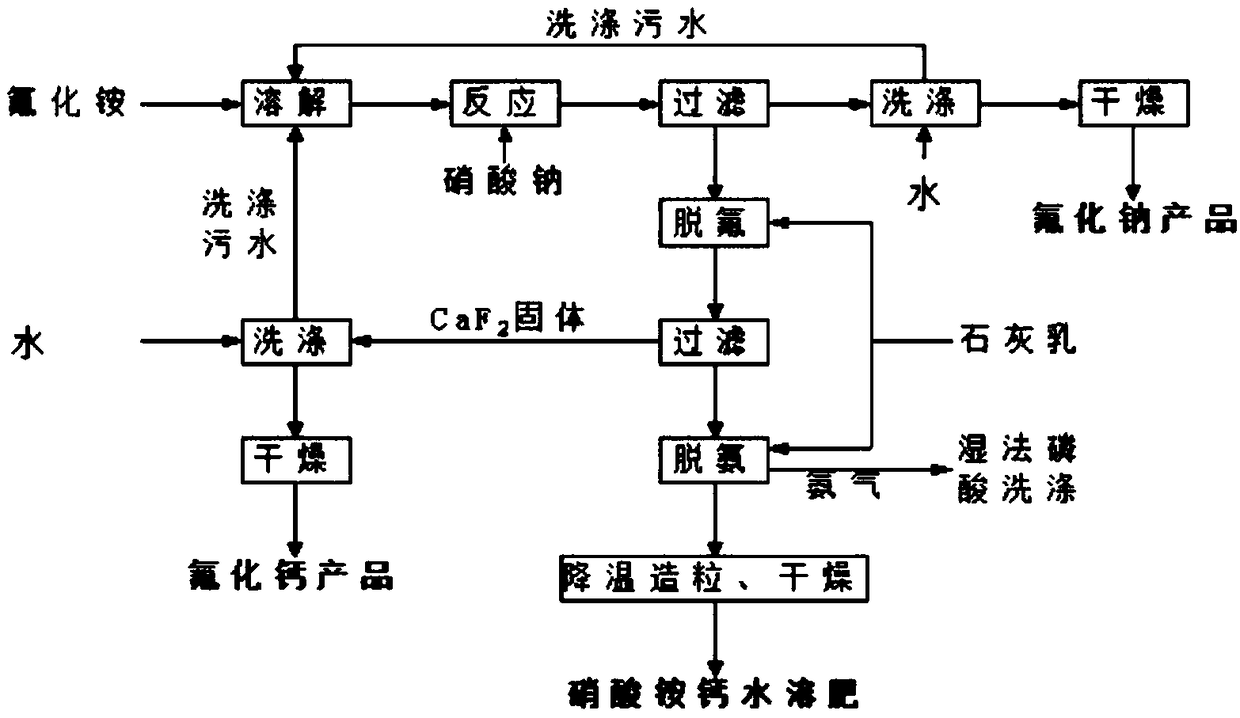

Method for preparing sodium fluoride and co-producing calcium ammonium nitrate fertilizer by using ammonium fluoride

InactiveCN109437242ALow impurity contentSolve the problem of small market capacity and difficult salesCalcium/strontium/barium fluoridesAlkali metal fluoridesPhosphoric acidSlurry

The invention relates to the technical field of inorganic chemical industry, in particular to a method for preparing sodium fluoride and co-producing a calcium ammonium nitrate fertilizer by using ammonium fluoride. The method comprises the following steps: firstly, preparing sodium fluoride: preparing the ammonium fluoride into a saturated solution, adding sodium nitrate therein to produce sodiumfluoride and an ammonium nitrate solution, filtering to obtain a sodium fluoride solid, washing, and drying to obtain an industrial sodium fluoride product; then defluorinating an ammonium nitrate filtrate: adding a small amount of lime milk into the ammonium nitrate solution, defluorinating the solution, precipitating fluoride ions in a liquid phase, then filtering the ammonium nitrate solution,precipitating, washing and drying to obtain artificial fluorite; then, preparing the fully water-soluble calcium ammonium nitrate fertilizer: adding the lime milk of lime, reacting at high temperature, enabling a reaction phase to form sub-molten salt, enabling ammonia to escape, washing by using phosphoric acid to obtain a raw material for preparing an ammonium phosphate product, cooling the sub-molten salt slurry, granulating, and drying to obtain a fully water-soluble calcium ammonium nitrate fertilizer product.

Owner:贵州开磷氟硅化工有限责任公司

Method for recovering product from waste residues containing sodium fluoride

ActiveCN103435070AHigh purityHigh recovery rateAlkali metal fluoridesSodium fluoride productLarge particle

The invention discloses a method for recovering a product from waste residues containing sodium fluoride. The method comprises the following steps of: (1) dissolving the waste residues containing sodium fluoride: (i) calculating the mass of deionized water, and (ii) dissolving, filtering, and putting a mother solution into a treatment tank; and (2) treating the mother liquid: (i) feeding, dissolving, putting a substance containing same sodium ions with sodium fluoride into the treatment tank, and stirring to ensure that the fed solid material is completely dissolved, (ii) standing after stopping stirring to ensure that precipitated product substances form a large-particle solid, and (iii) filtering and drying to obtain a sodium fluoride product. According to the method, the product recovery rate is up to 40-70%, the yield of the product is improved, the production cost is saved, and the purity of the recovered sodium fluoride product is up to 99.99%.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

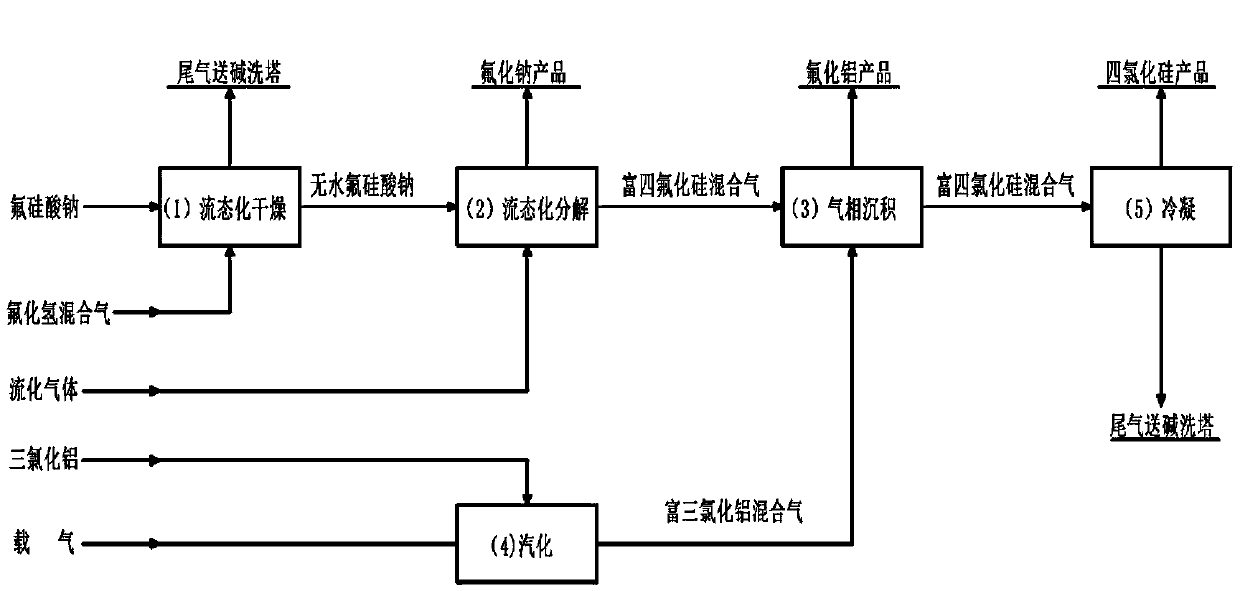

Method for efficiently producing sodium fluoride, aluminum fluoride and silicon tetrachloride by comprehensively utilizing sodium fluorosilicate

ActiveCN110683561AEnhance heat and mass transferThere is no problem of molten agglomerationAlkali metal fluoridesAluminium fluoridesAluminum fluorideCondensation process

The invention discloses a method for efficiently producing sodium fluoride, aluminum fluoride and silicon tetrachloride by comprehensively utilizing sodium fluorosilicate. The method includes a fluidized drying process, a fluidized decomposition process, a vapor deposition process, a vaporization process and a condensation process. The method includes the steps that sodium fluorosilicate is driedby fluidization to obtain anhydrous sodium fluorosilicate; then anhydrous sodium fluorosilicate enters the fluidized decomposition process to obtain a sodium fluoride product and a silicon tetrafluoride-rich gas mixture; in the vapor deposition process, the silicon tetrafluoride-rich gas mixture reacts with vaporized aluminum trichloride to obtain an aluminum fluoride product and a silicon tetrachloride-rich gas mixture; and the silicon tetrachloride-rich gas mixture is subjected to the condensation process to obtain a silicon tetrachloride product, and tail gas in the condensation process issent to an alkaline washing tower for treatment. The method has the advantages of short process, low energy consumption, environmental friendliness, high product added value and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A method for producing high-quality sodium fluoride using fluorine-containing wastewater as raw material

ActiveCN106830012BRecovery rateRecycling rate due toAlkali metal fluoridesAlkali metal halide purificationRaw materialEnvironmental chemistry

A method for producing high-quality sodium fluoride using fluorine-containing wastewater as a raw material, which includes directly adding excess sodium carbonate salt to fluoride-containing wastewater, so that the fluorine in the solution is completely crystallized in the form of sodium fluoride, or first Ammonium fluoride solution is obtained by adding ammonia to the fluorine-containing wastewater solution, or the fluorine precipitation and enrichment in the fluorine-containing wastewater is firstly enriched, and then the fluorine in the fluoride precipitation enrichment is converted into an ammonium fluoride solution with an ammonium salt solution, and then fluoride Add excess sodium carbonate salt to the ammonium solution to completely crystallize the fluorine in the form of sodium fluoride, and filter to obtain sodium fluoride filter cake and fluorine sinking liquid; the sodium fluoride filter cake is washed and dried by ammonium fluoride solution A high-quality sodium fluoride product with a purity of more than 99.25% is obtained. The sodium carbonate salt in the liquid after fluoride sinking is crystallized and recovered, and the mother liquid of sodium carbonate salt crystallization is further desalted and reused as reclaimed water. The invention has the advantages of simple operation, high recovery rate of fluorine, low production cost, good quality of sodium fluoride product, no fluorine-containing waste and the like.

Owner:CENT SOUTH UNIV

A kind of comprehensive utilization method of silicon slag

ActiveCN106365189BEfficient extractionShort processing timeSilicaAlkali metal fluoridesAluminum fluorideProcess equipment

The invention discloses a comprehensive utilization method of silicon residue soil. The comprehensive utilization method comprises the following steps: leaching and decomposing the silicon residue soil by adopting an acid solution, leaching and separating residues, separating alumsili through volatilizing leaching liquid, obtaining an aluminum fluoride product, and absorbing, acidifying and washing volatile matters to obtain white carbon black and a sodium fluoride product. The comprehensive utilization method disclosed by the invention has the characteristics of being short in process flow and processing time, simple in process equipment, and easy and safe to operate, is a process technology route for comprehensive resource utilization of high value-added chemical products produced by utilizing industrial wastes and can achieve secondary comprehensive resource utilization and realize the purposes of circular economy, energy conservation and emission reduction.

Owner:KUNMING UNIV OF SCI & TECH

Method for recovering sodium hydroxide and co-producing sodium fluoride from fluorocarbon cerium alkali transfer process

ActiveCN112725642AImprove qualityReduce handling difficultiesAlkali metal fluoridesProcess efficiency improvementSodium fluoride productProcess engineering

The invention discloses a method for recovering sodium hydroxide and co-producing sodium fluoride from a bastnaesite alkali transfer process. The method comprises the following steps: (1) roasting bastnaesite concentrate, washing and carrying out acid leaching by using a hydrochloric acid solution; (2) adding an alkaline solution into the leaching residues, stirring and heating; (3) adding a flocculating agent for solid-liquid separation after alkali transfer; (4) producing a sodium hydroxide solution with a high mass concentration or a low mass concentration and producing a sodium fluoride product by adopting solid sodium hydroxide with different contents; and (5) evaporating and concentrating the sodium hydroxide solution with low mass concentration to obtain a sodium hydroxide solution or sodium hydroxide solid with preset mass concentration. Sodium hydroxide solutions with different concentrations can be recovered and prepared by the method, and can be used in a bastnaesite concentrate alkali transfer process or other fields to obtain a sodium fluoride product with high quality and purity of more than or equal to 98%, and the sodium fluoride product can be sold as a product. The method reduces the production cost, reduces the wastewater treatment difficulty, avoids environmental pollution and fluorine resource waste, and is suitable for industrial production.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

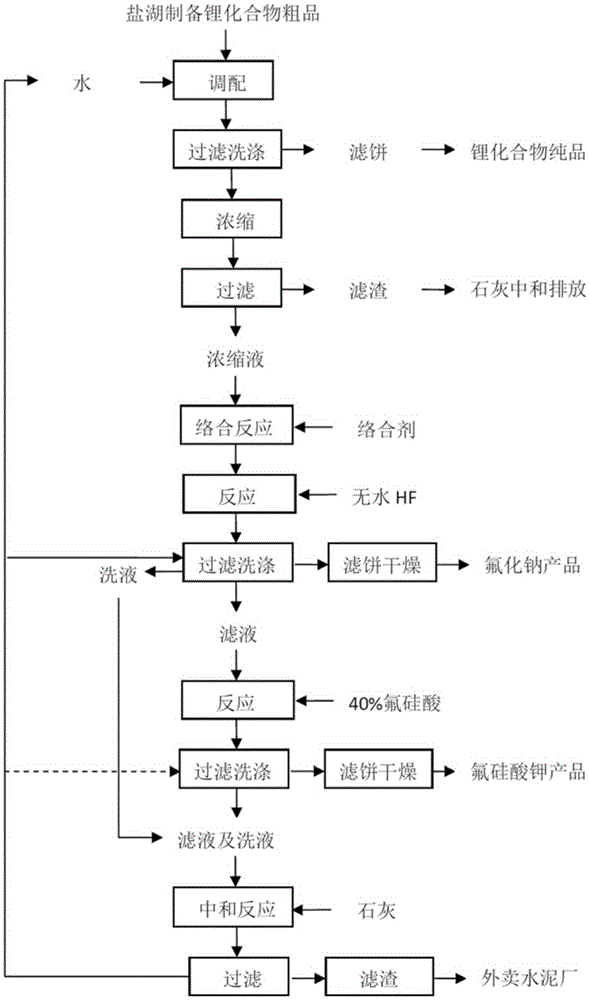

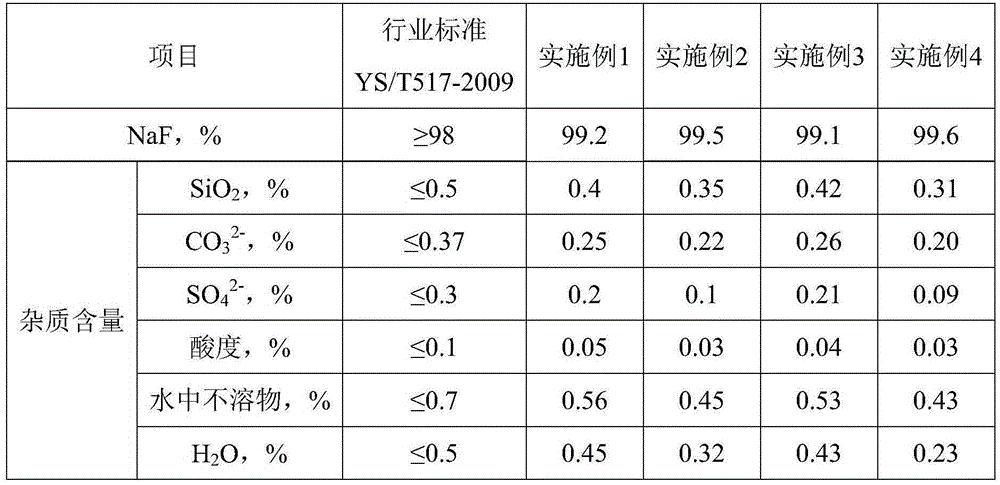

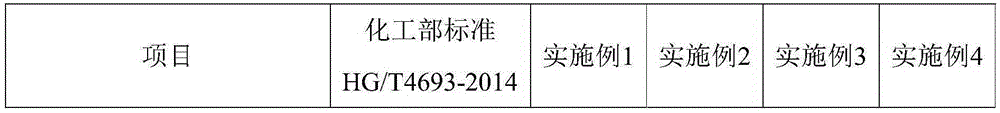

Method for producing sodium fluoride from lithium source lithium extraction waste liquid and method for co-producing sodium fluoride and potassium fluosilicate

InactiveCN105293529AEmission reductionAvoid wastingSilicon halogen compoundsAlkali metal fluoridesLithiumResource utilization

The invention discloses a method for producing sodium fluoride from a lithium source lithium extraction waste liquid and a method for co-producing sodium fluoride and potassium fluosilicate. The method for producing sodium fluoride comprises adding water into a lithium source lithium extraction crude product to obtain pulp, filtering the pulp to obtain a lithium extraction waste liquid, adding a complexing agent into the lithium extraction waste liquid or lithium extraction waste liquid concentrate, carrying out a reaction process to obtain a mixture, adding HF into the mixture according to a mole ratio of Na<+> to HF of 1: 1.05-1.1, carrying out a reaction process to obtain sodium fluoride pulp, carrying out filtration to obtain a sodium fluoride product, adding fluosilicic acid into the filtrate obtained by sodium fluoride pulp filtration, carrying out a reaction process to obtain potassium fluosilicate pulp and filtering the potassium fluosilicate pulp to obtain a potassium fluosilicate product. A lithium source lithium extraction waste liquid is used as a raw material, and lithium source concomitant metal ions are transformed into high-quality and high-added value fluoride so that a lithium source concomitant resource utilization rate is improved, resource waste is prevented, a production cost is saved, lithium extraction waste liquid discharge is reduced and good economic benefits and environment benefits are obtained.

Owner:韩甜

Method for preparing sodium fluoride from wet-process phosphoric acid defluorination slag

ActiveCN104386711BCoarse crystal grain sizeIncrease the sinking speed differenceAlkali metal fluoridesSlagSodium fluoride product

Owner:GUIZHOU CHANHEN CHEM CO LTD

A method for efficiently producing silicon tetrafluoride and sodium fluoride by utilizing sodium fluorosilicate

ActiveCN110683548BEnhance heat and mass transferThere is no problem of molten agglomerationAlkali metal fluoridesHalogenated silanesSodium fluoride productPhysical chemistry

The invention discloses a method for efficiently producing silicon tetrafluoride and sodium fluoride by using sodium fluorosilicate. The method includes a dehydration and drying process, a decomposition process, a desiliconization process and an absorption process, specifically: sodium fluorosilicate undergoes The dehydration drying process obtains anhydrous sodium fluorosilicate; then enters the decomposition process to obtain silicon tetrafluoride and semi-finished sodium fluoride; part of the silicon tetrafluoride is returned to the decomposition process as fluidizing gas, and the other part is used as a silicon tetrafluoride product; Part of the semi-finished sodium fluoride directly enters the desiliconization process to obtain sodium fluoride products and produce silicon tetrafluoride tail gas; the other part of the semi-finished sodium fluoride is used to absorb silicon tetrafluoride in the desiliconization tail gas to obtain semi-finished fluorine silicon Sodium acid is returned to the decomposition process, and the tail gas in the absorption process is sent to the alkali washing tower for treatment. The method is suitable for preparing silicon tetrafluoride and sodium fluoride by decomposing sodium fluorosilicate, and has the advantages of short process, low energy consumption, environmental friendliness and high added value of products.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of method for continuously synthesizing white carbon black and sodium fluoride

ActiveCN110606492BIncrease contentSmall particlesSilicaChemical industrySodium fluoride productPhysical chemistry

The invention provides a method for continuously synthesizing silica and sodium fluoride, comprising the following steps: synchronously pumping a soda ash solution and a sodium fluorosilicate solution into a feed port of a tubular reactor to form a mixed solution, and the mixed solution flows through the tubular reaction The reactor was reacted at 75-88°C for ≥5min, and the reacted liquid flowed out from the discharge port of the tubular reactor. After the reaction, the liquid was exhausted, and the solid-solid was separated to obtain the crude product of sodium fluoride and the slurry containing the crude product of white carbon black. , washing, purifying and drying the crude sodium fluoride product to obtain a finished product of sodium fluoride; subjecting the slurry containing the crude silica product to solid-liquid separation, washing and drying to obtain a finished silica product, the present invention provides a first A method for continuous production of high-purity, high-activity white carbon black and high-quality sodium fluoride. The indicators of the obtained silica far exceed the current requirements for the first-class precipitation method, with BET>240m 2 / g, stable quality, narrow particle size distribution, can partially replace fumed silica, is a high-end silica product.

Owner:朱志宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com