Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Reduced silica content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

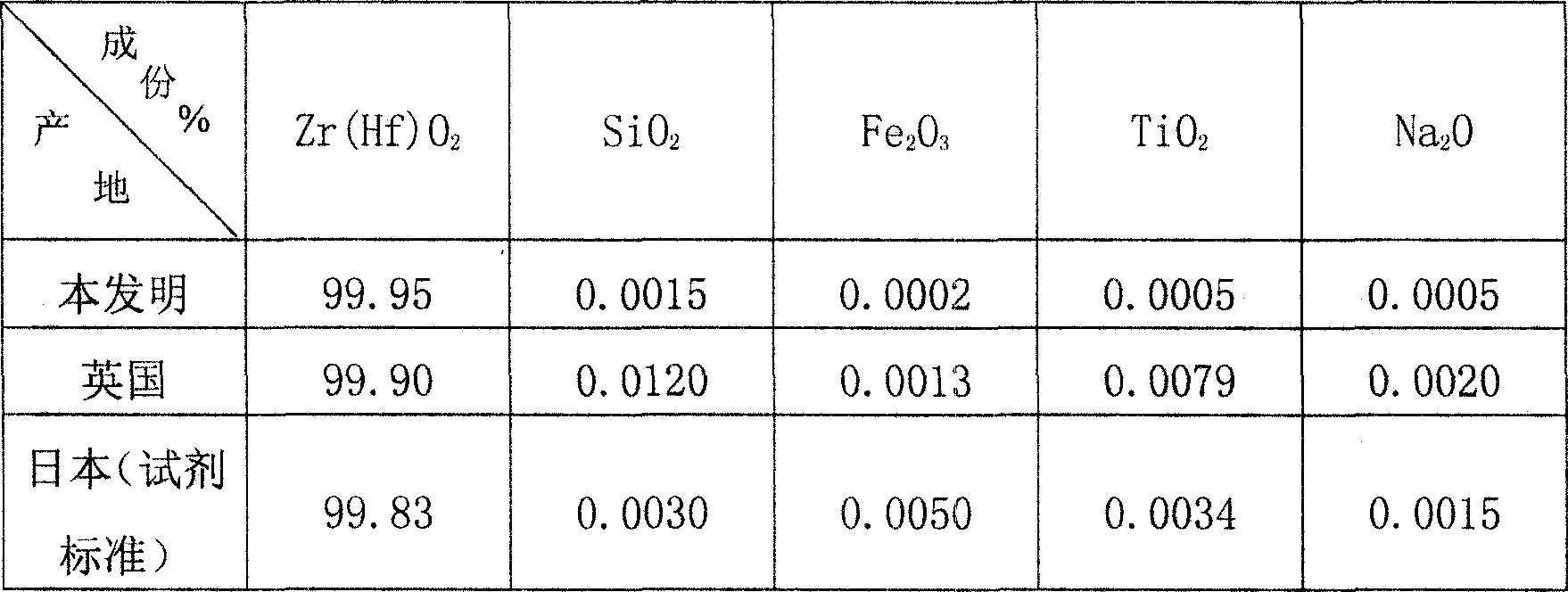

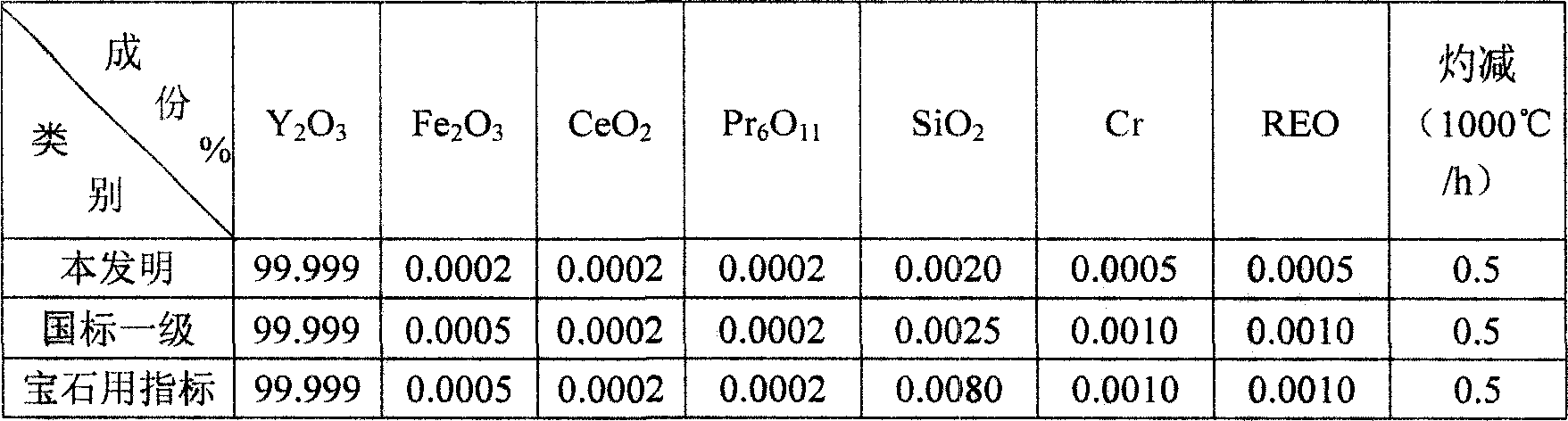

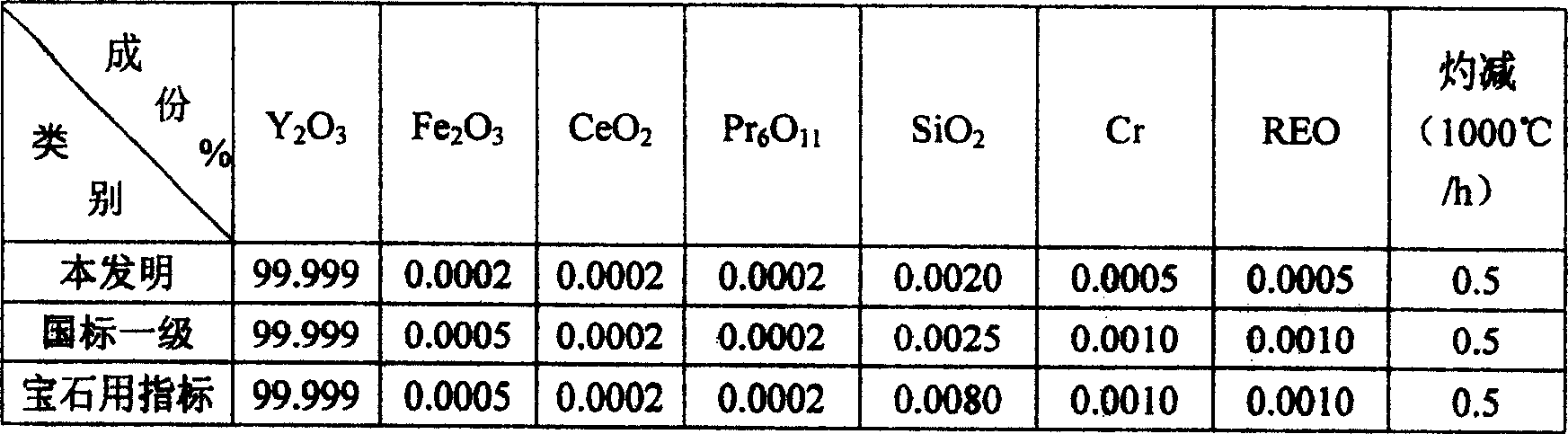

Process of preparing zirconia and yttria with Y-doped cubic zirconia powder

InactiveCN1986423AHigh metal contentLow priceRare earth metal compoundsZirconium oxidesOXALIC ACID DIHYDRATEPhysical chemistry

The process of preparing zirconia and yttria with Y-doped cubic zirconia powder includes the following steps: alkali fusing and sintering Y-doped cubic zirconia powder, water washing to eliminate sodium, acidifying and concentrating to obtain Zr crystal, oxychlorination to re-crystallize and purify, and high temperature calcining to obtain high purity jewel level zirconia; concentrating Y-containing mother liquid to crystallize zirconia, purifying high Y mother liquid, precipitating Y in oxalic acid solution, and high temperature calcining to obtain high purity jewel level yttria. The present invention has relatively low cost.

Owner:王必庆

Process for removing silica from cellulosic material

InactiveUS20060225852A1Simple and economical mannerEconomical and simplePulp liquor regenerationPretreatment with alkaline reacting compoundsCelluloseBlack liquor

A method of cellulosic raw material desilication involves the steps of impregnating the cellulosic raw material with a solution containing sodium carbonate to form a silica-containing impregnation black liquor and an at least partially desilicated raw material, separating the silica-containing impregnation black liquor from the at least partially desilicated raw material, causticizing the separated silica-containing impregnation black liquor to precipitate silica-enriched calcium carbonate and separating the precipitated silica-enriched calcium carbonate from the causticized impregnation liquor. Up to 100% of the silica contained in the cellulosic raw material can be removed before the raw material is processed by any of conventional pumping methods.

Owner:WESTERN MICHIGAN UNIVERSITY +1

High-molecular nano polymer electrolyte for lead-acid battery and its compounding method

ActiveCN1978507AIncrease capacityExtended service lifeLead-acid accumulatorsElectrical batterySilicon dioxide

The electrolyte of macromolecule nanometer polymer used in lead acid storage battery and its preparation method were related in this invention. It relates the area of lead acid storage battery. According the weight ratio, the electrolyte is mainly made up of the raw materials as following: ligand agent 0.1-1.5%, complexing agent 2.5-4%, catalytic agent 0.01-0.5%, stabilizing agent 2.3-3.8%, conditioning agent 0.1- 0.5%, antifoam agent 0.01-0.5%, sulfuric acid 36-45%, the others is water. It is characterized in that the content of silicon dioxide is low, the dosage is little and the cost is also low. And in that a steady colloid can be formed in the electrolyte which can elongate the gelatum time. Used in the minitype encapsulation lead acid storage battery, the capacity can increase greatly, the operational life can be elongated and the low temperature resistance can also be enhanced. The gel in the electrolyte can avoid the overflow of acid liquor. Otherwise, the electrolyte also has the merits of little inherent resistance, high capacity, longevity and good thixotropy and so on.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

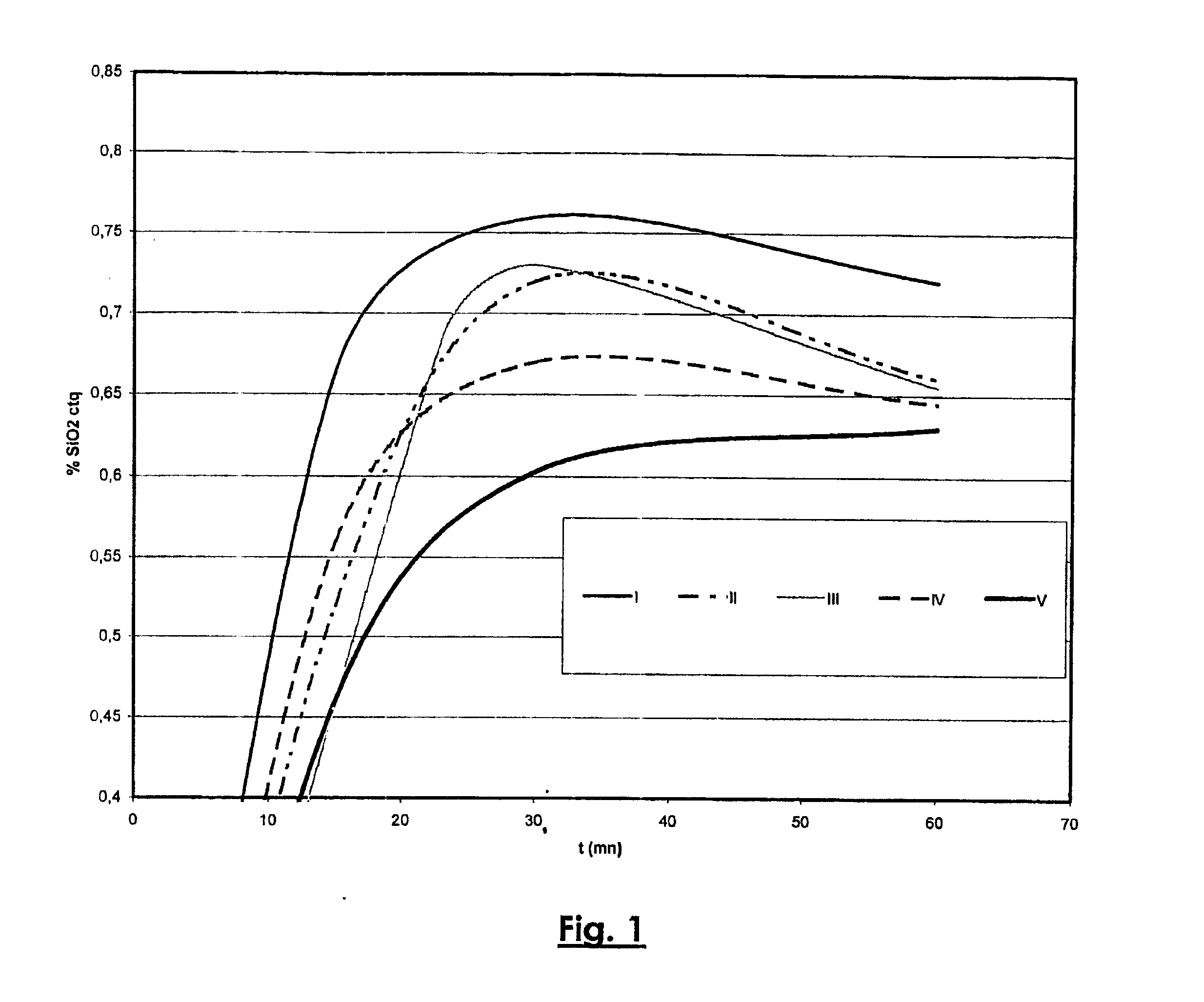

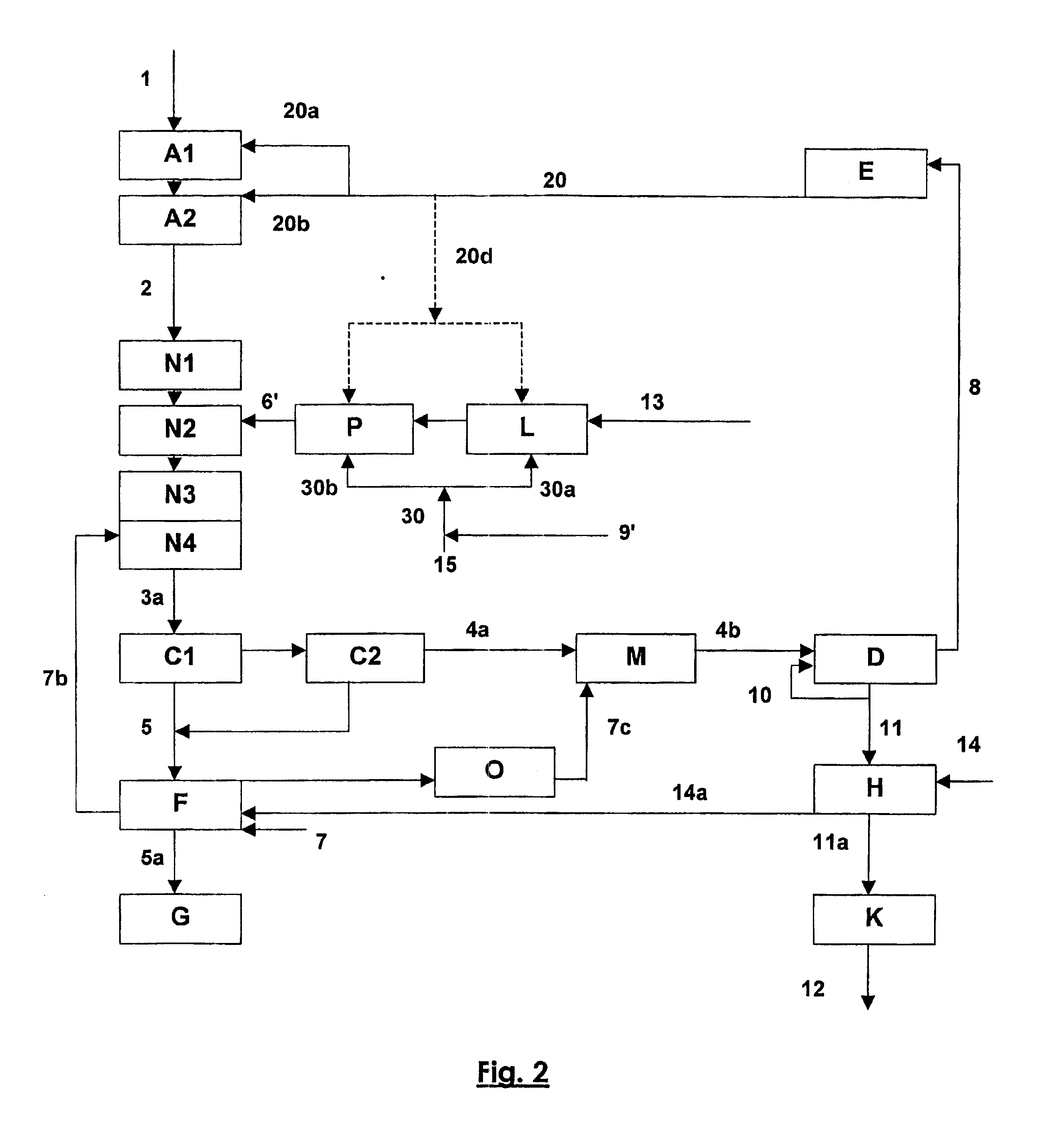

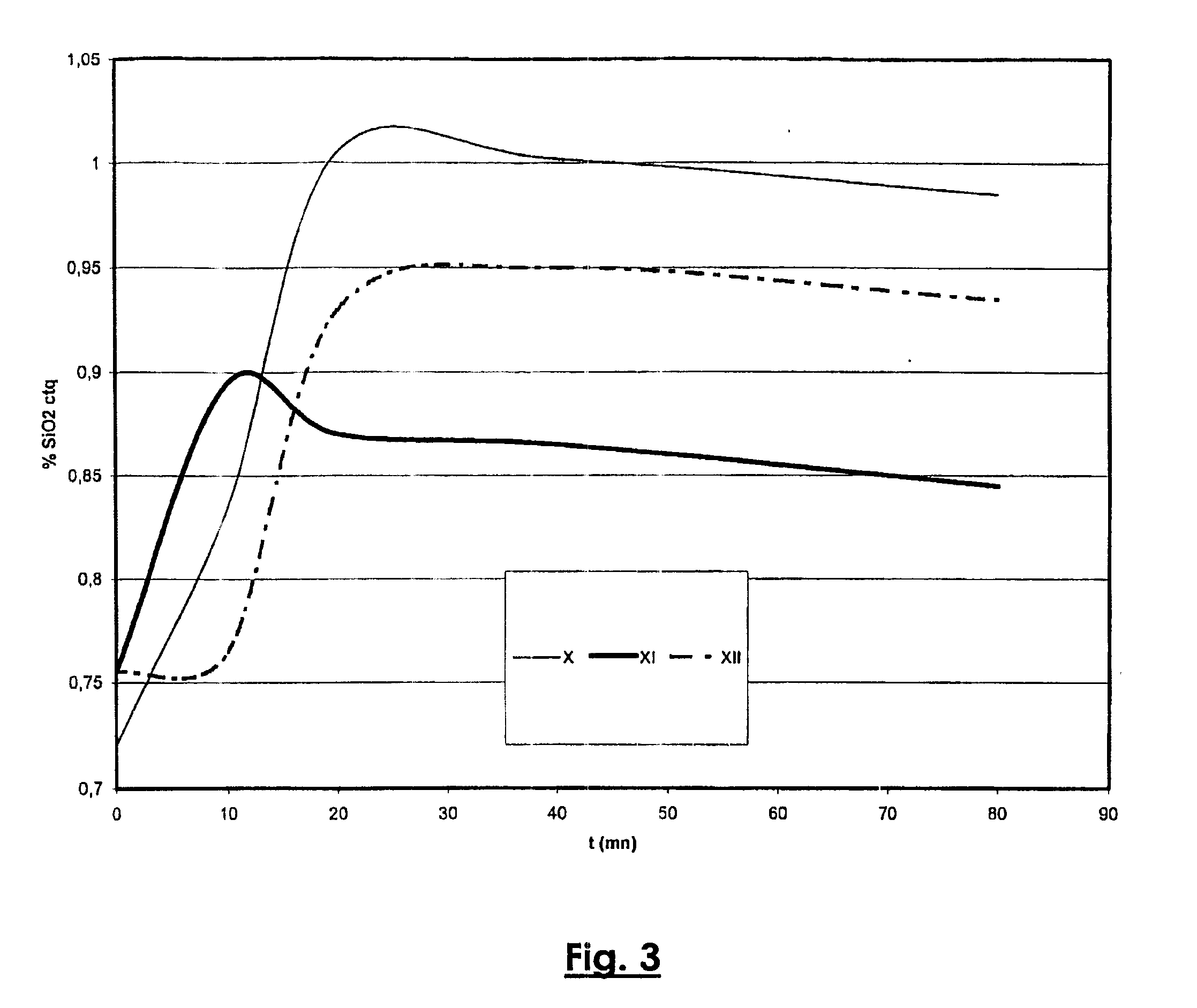

The bayer process for production of alumina trihydrate by alkaline digestion of bauxite, the process comprising a predesilication step

InactiveUS20070178041A1Reduce silica levelReduced silica contentAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationChemistryInsoluble residue

Bayer process, comprising grinding (L, B) and then digestion (N2, A) of a bauxite by bringing it into contact with a sodium aluminate liquor (20b, 120b). Digestion consists of forming a slurry (3a, 103) that is then treated to separate insoluble residues (5a, 105a) from the sodium aluminate liquor. The liquor is then crystallized (D) and recycled back to green liquor (20, 120) after having been separated from the alumina trihydrate (11, 111) precipitated during crystallization. The process comprises a predesilication treatment (P) during which the ground bauxite is brought before digestion into contact with an aqueous sodic solution that has a content of carbonates, sulphates and possibly chlorides which, expressed as a percentage related to the caustic concentration, is less than half the corresponding impurities content of the spent liquor (8, 108). Preferably, the pure caustic soda used to compensate for caustic soda losses in the Bayer circuit that was previously injected just after evaporation is now added in the aqueous sodic solution for the predesilication treatment.

Owner:ALUMINUM PECHINEY

Low-temperature co-fired ceramic material and preparation method thereof

The invention provides a low-temperature co-fired ceramic material which is prepared by sintering the following raw materials: 23.5wt%-30.5wt% of silicic acid, 28.1wt%-34.4wt% of boric acid, 34.7wt%-42.2wt% of calcium hydroxide, 0.4wt%-1.5wt% of phosphoric acid and 2.8wt%-4.1wt% of zirconium nitrate. In the low-temperature co-fired ceramic material provided by the invention, the sintering temperature can be lowered by lowering the silicon dioxide content introduced by silicic acid and enhancing the boron trioxide introduced by boric acid; and meanwhile, the introduced zirconium and phosphorus elements can promote the formation of microcrystals in microcrystalline glass to lower the dielectric loss, and the formed microcrystal can enhance the heat conductivity and mechanical properties of the low-temperature co-fired ceramic material.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Comprehensive utilization method of ferriferous fayalite material

ActiveCN103343225AIncrease response rateEasy to separateProcess efficiency improvementFayaliteLiquid state

The invention discloses a comprehensive utilization method of a ferriferous fayalite material, relates to a processing method of the ferriferous fayalite material, and in particular relates to a method for separating and utilizing iron and silicon in fayalite. The method is characterized by comprising the following steps of: grinding the ferriferous fayalite material; mixing with alkaline liquor for leaching reaction; performing solid-liquid separation on obtained reaction slurry to obtain desilicated concentrate and silicon containing alkaline liquor; and oxidizing the desilicated concentrate in air to goethite. The method disclosed by the invention enriches, separates and extracts iron and silicon elements to form two products: goethite and silicon containing alkaline liquor through alkaline liquor leaching, wherein iron and silicon in ferriferous fayalite exist in solid and liquid states, so that the comprehensive utilization ratio of resources is high and the economic benefit is better.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method of preparing light thermal insulation material by employing bauxite tailings

InactiveCN106830796ARealize resourcesHigh strengthCeramicwareThermal insulationUltimate tensile strength

The invention discloses a method of preparing a light thermal insulation material by employing bauxite tailings and relates to a comprehensive utilization method of bauxite tailings. The method is characterized by comprising the following steps of: adding the bauxite tailings into kaolin to calcined and reconstructed; and preparing the light thermal insulation material by taking the mixture as a raw material of the light thermal insulation material. The method disclosed by the invention makes full use of industrial solid wastes such as bauxite tailings, coal ash and flue gas desulfurization gypsum, and the material is low in cost, high in strength and good in thermal insulation property, and meanwhile, the requirement on SiO2 content is relatively low. The solid waste bauxite tailings can be scientifically utilized to realize reclamation of wastes, so that the method has far-reaching environmental-friendly meaning.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

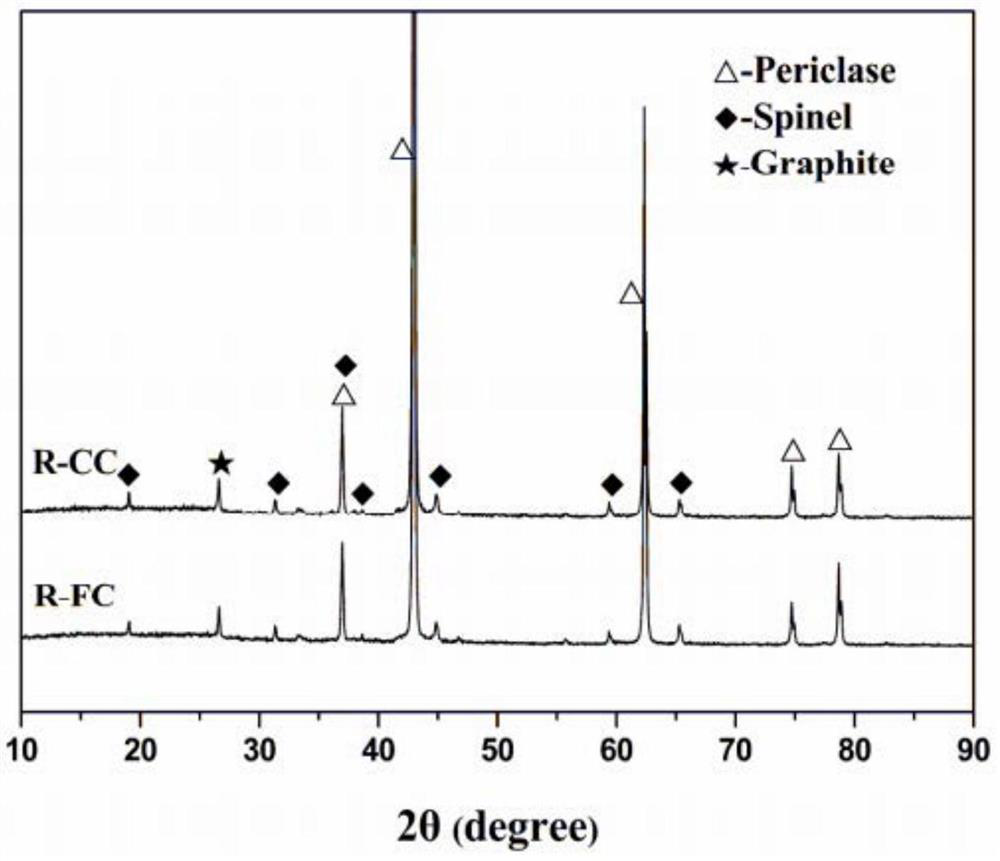

Continuous casting mould powder for high-aluminium steel, and preparation method thereof

The invention discloses continuous casting mould powder for high-aluminium steel, and a preparation method thereof. The continuous casting mould powder for high-aluminium steel is prepared through taking calcium aluminate, limestone, bauxite, lithium carbonate, barium carbonate, strontium carbonate, magnesia, sodium carbonate and a carbonaceous material as raw materials, and comprises the following composition element components in percentage by weight: 30-45% of calcium oxide CaO, 20-30% of aluminium oxide Al2O3, not greater than 3% of silicon dioxide SiO2, 3-8% of lithium oxide LiO2, 1-3% of strontium oxide SrO, 5-10% of sodium oxide NaO2, 3-6% of barium oxide BaO, not greater than 3% of magnesium oxide MgO, 2-4% of carbon C, not greater than 2% of fluorine F and the balance impurities. The continuous casting mould powder for high-aluminium steel, which is disclosed by the invention, suppresses the abovementioned elements with strong reducing property from being oxidized and then entering slag to denature the slag, and achieves the purpose of continuous casting of steel containing Al, Ti and elements with strong reducing property, such as rare-earth elements, thus smooth continuous casting of the steel is ensured, and good surface quality of casting blanks is achieved.

Owner:ZHANJIANG SHENGBAO TECH CO LTD

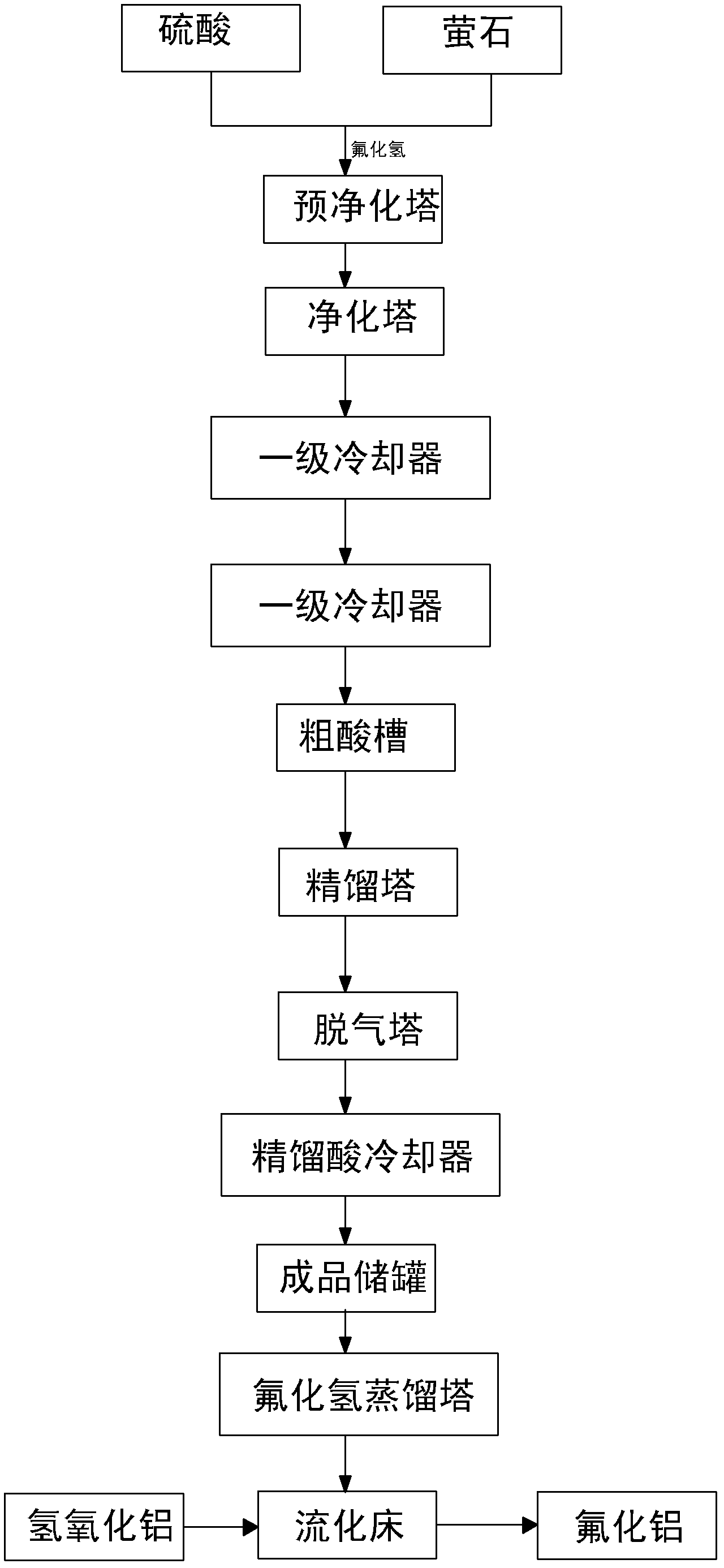

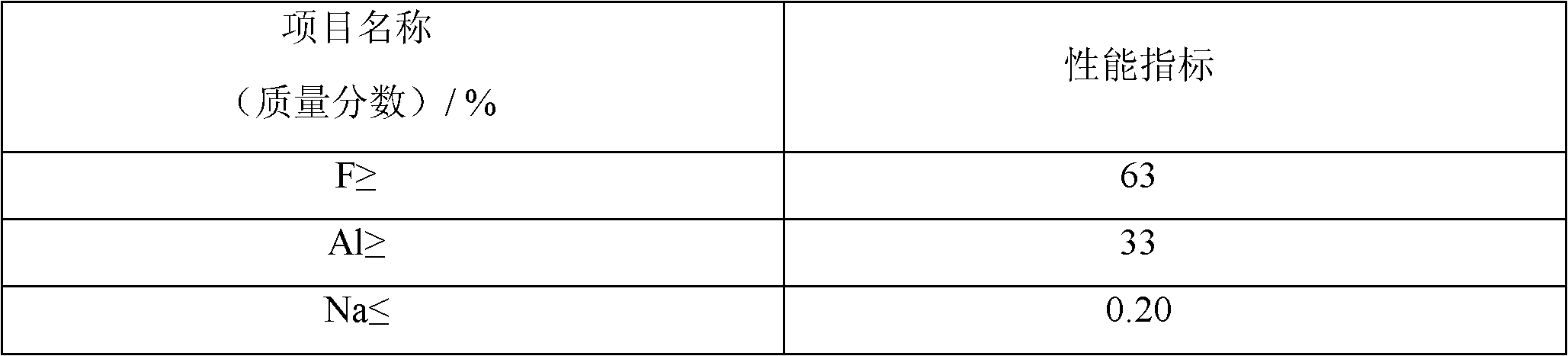

High-purity aluminum fluoride production technology

The invention belongs to the technical field of aluminum fluoride production, and relates to a production technology of high-purity aluminum fluoride. The technology comprises the steps that: (1) hydrogen fluoride gas desiliconization is carried out, wherein fluorite and sulfuric acid are subjected to a reaction; produced hydrogen fluoride gas sequentially passes through a pre-purification tower and a purification tower, such that sulfuric acid washing and condensation are carried out; condensed acid overflows to a rectification tower through a crude acid tank, and is subjected to desiliconization; degassing is carried out in a degassing tower; and the obtained product overflows to a finished product tank through a rectified acid cooling device; (2) anhydrous hydrogen fluoride evaporation is carried out, wherein the finished product acid is pumped into a hydrogen fluoride distillation tower kettle by using a submerged pump; evaporation is carried out by using an evaporator in the tower kettle; hydrogen fluoride gas after evaporation is delivered through an integral superheater in the tower kettle, and directly flows into a fluidized bed; and (3) aluminum fluoride is produced, wherein the hydrogen fluoride gas enters the fluidized bed and is subjected to a reaction with aluminum hydroxide, such that aluminum fluoride is produced. According to the invention, because anhydrous hydrogen fluoride is adopted as a raw material, and the desiliconization treatment is carried out in the preparation process, the produced aluminum fluoride has the advantages of high purity, low silicon dioxide content, low discretionary reduction amount, and simple and feasible production process.

Owner:SHANDONG BOFENG LIZHONG CHEM

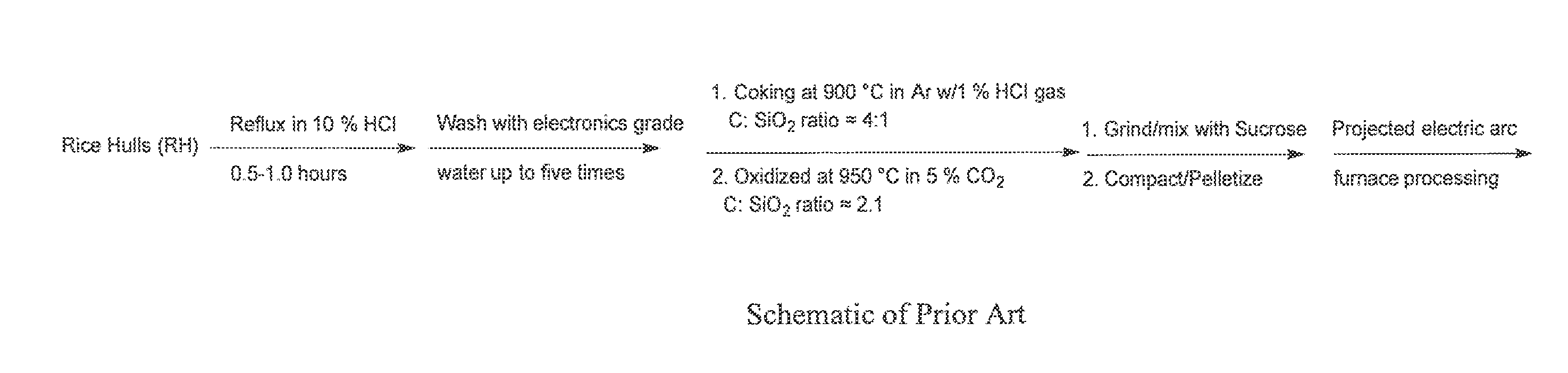

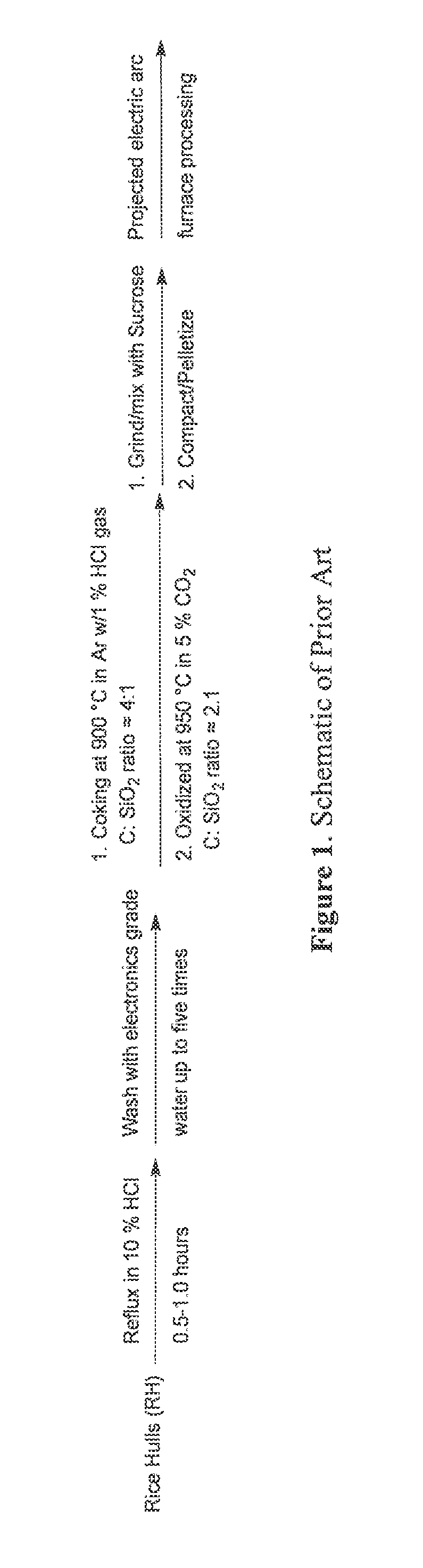

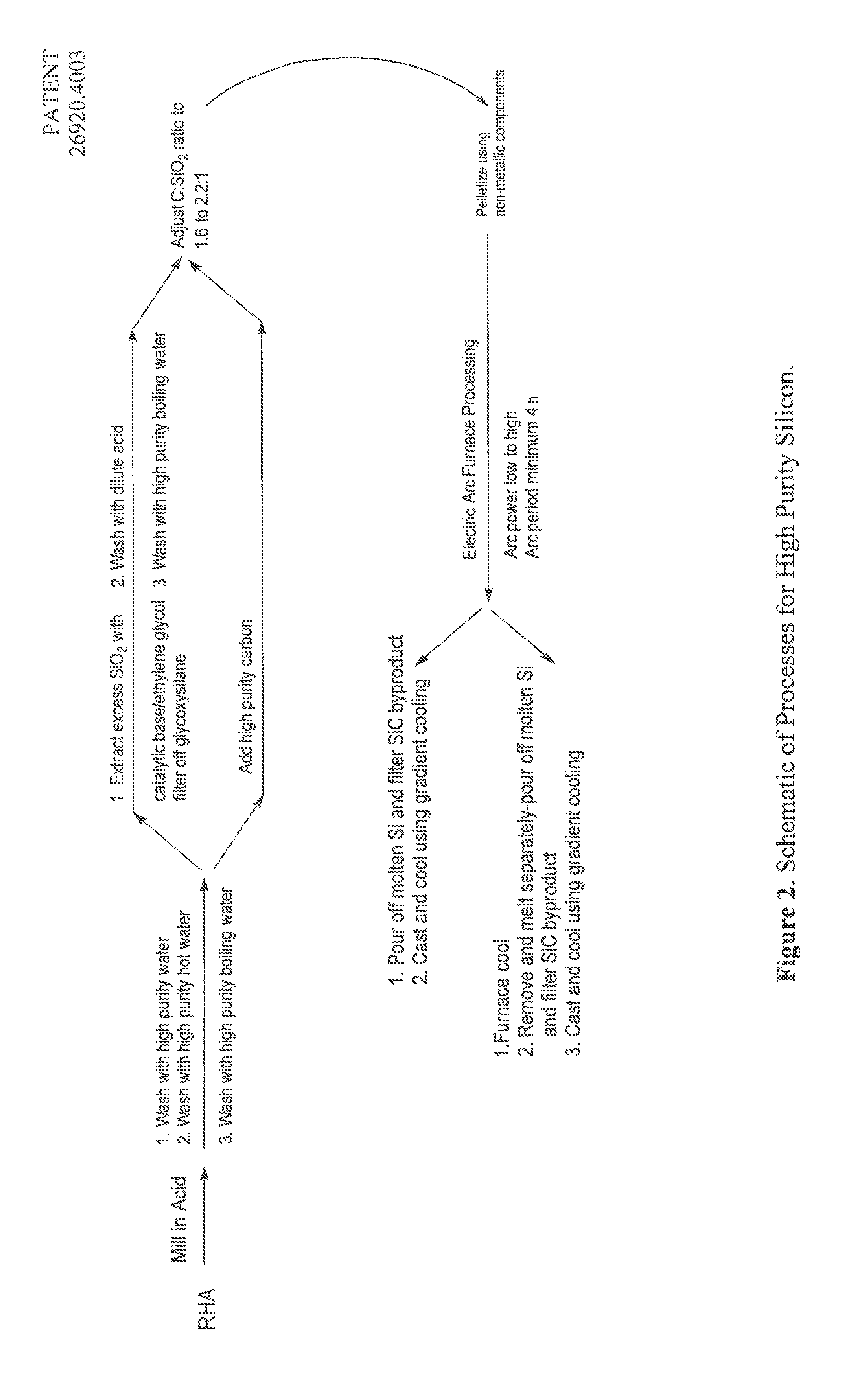

Biogenic silica as a raw material to create high purity silicon

InactiveUS20150110701A1Weaken energyReduce material costsSiliconGlass tempering apparatusBiogenic silicaSilicon dioxide

A low cost process is provided for creating high purity silicon from agricultural waste, particularly rice hull ash. The process uses a series of chemical and thermal steps to yield high purity silica while using less energy and more efficient chemical processes. The high purity silicon features fewer impurities that negatively affect the use of high purity for PV cells and reduces capital and operating costs of processes to yield ultra-pure silicon.

Owner:WADHAM ENERGY +1

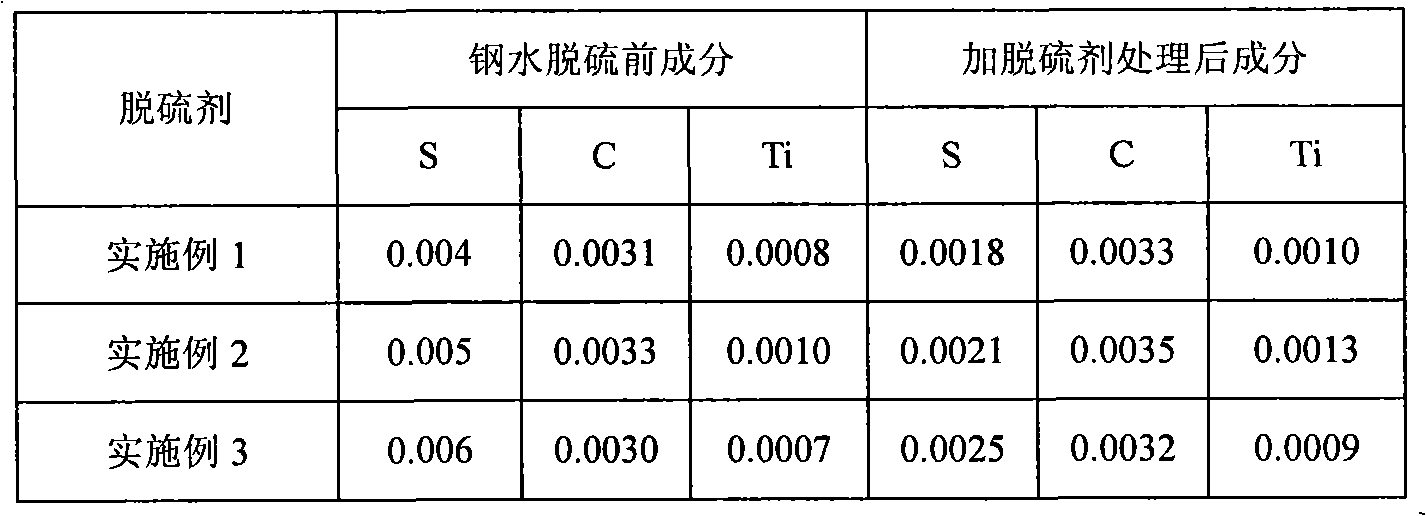

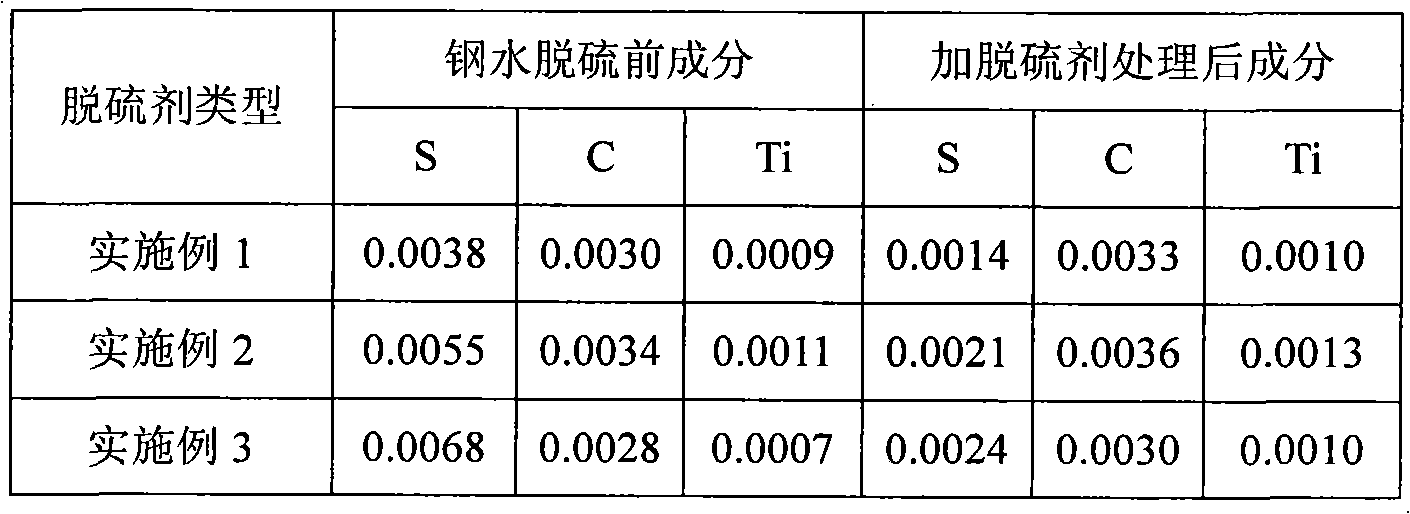

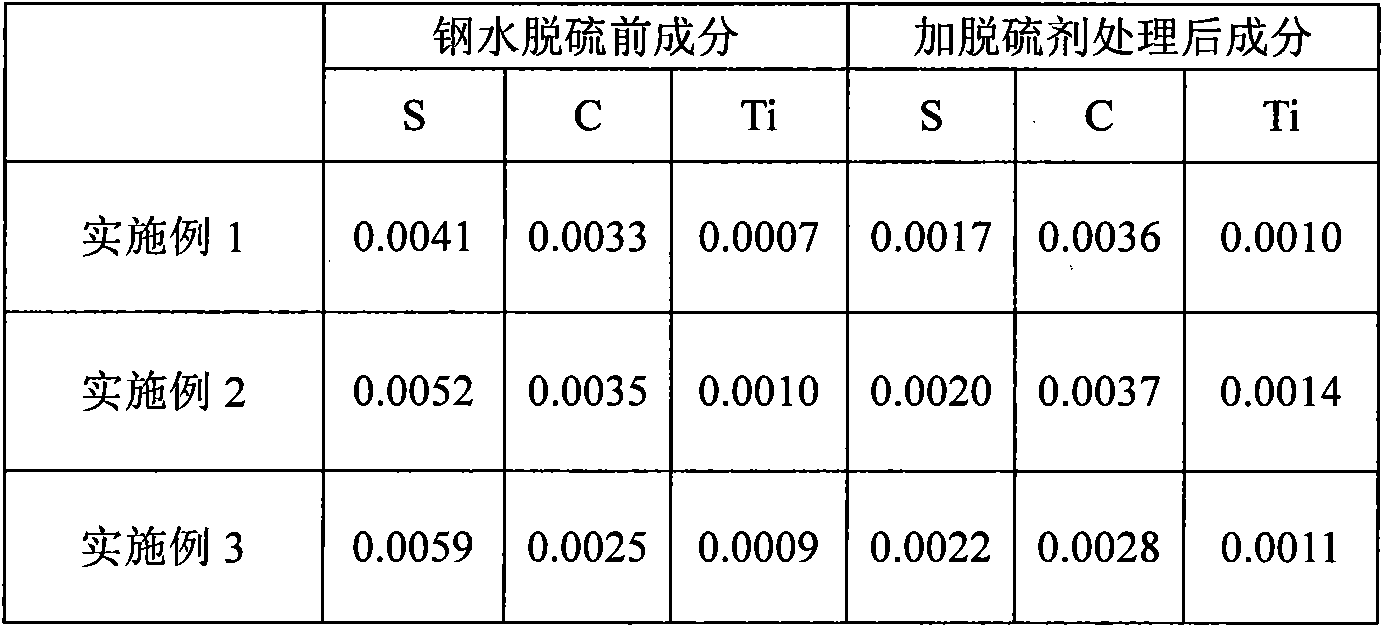

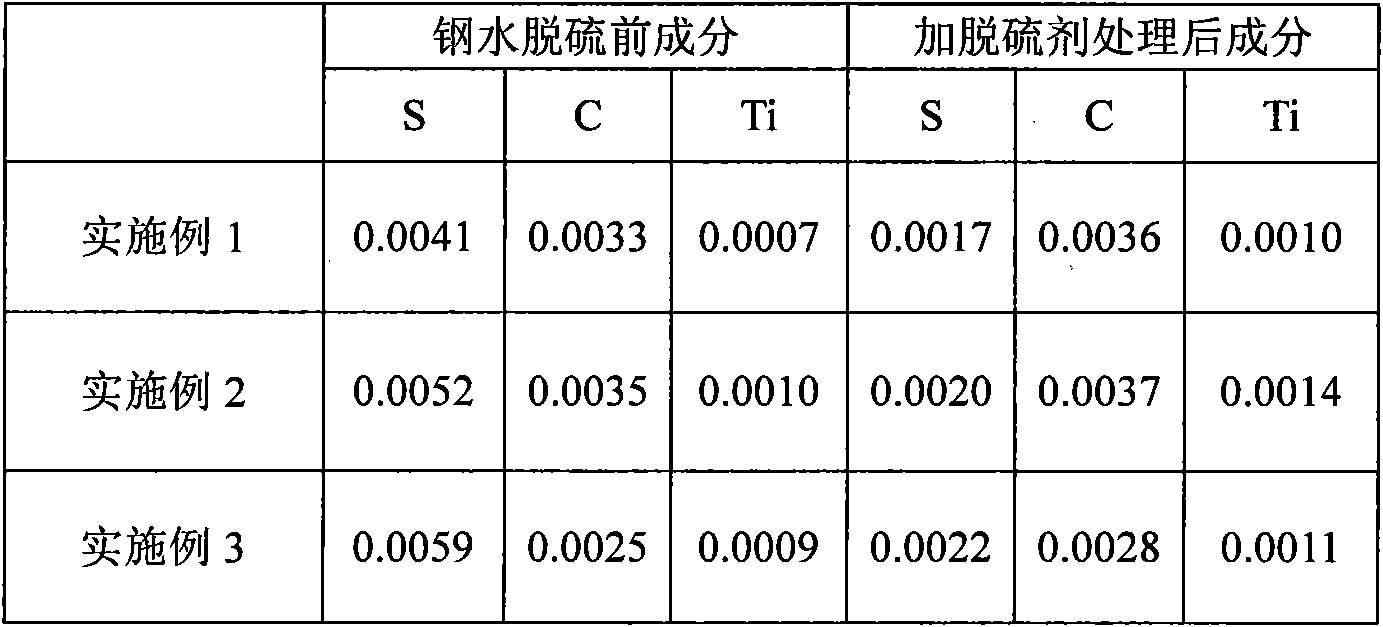

Desulfurizing agent suitable for high-aluminum silicon steel and preparation method thereof

The invention provides a desulfurizing agent suitable for high-aluminum silicon steel and a preparation method thereof. The desulfurizing agent comprises the following components: 75-80 percent of calcium oxide (CaO), 10-15 percent of aluminum oxide (Al2O3), 3-6 percent of magnesium oxide (MgO), 3-6 percent of magnesium chloride (MgCl2), not greater than 1.5 percent of silicon dioxide (SiO2), not greater than 0.02 percent of all titanium (Ti) and not greater than 0.02 percent of all carbon (C). The preparation method comprises the following steps: (1) weighing the raw materials: 72-77 percent of CaO, 8-13 percent of Al2O3 and 10-20 percent of binder; (2) respectively crushing the CaO and the Al2O3 into particles of which the particle sizes are less than 0.1mm; (3) heating the CaO to 120-150 DEG C, and carrying out spray treatment on the CaO particles by using silicone oil so as to form a protective film; (4) mixing the CaO and the Al2O3 with the binder; and (5) pressing into balls by using a ball press, and drying and packaging. The desulfurizing agent provided by the invention is easy to store, has high desulfurizing rate and low environmental pollution and has low corrosion on the refractory of a vacuum slot body; in the desulfurizing process, the molten steel carburetion and titanizing can be controlled to be under 5ppm; and the desulfurizing rate can reach at least 50 percent on the premise of not increasing the refining time.

Owner:ANGANG STEEL CO LTD

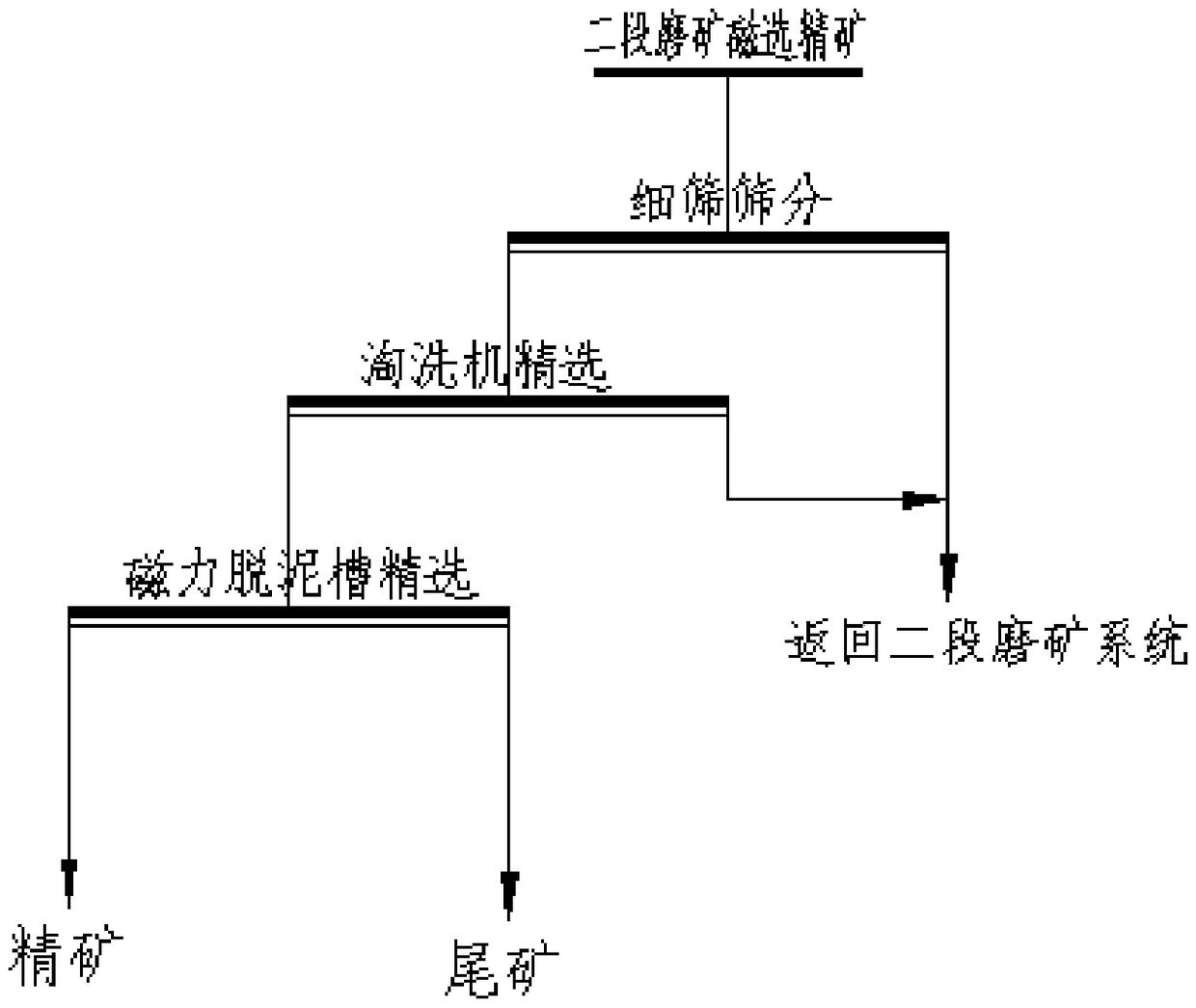

Ore dressing process for reducing content of silicon dioxide in iron ore concentrate

ActiveCN108970800AImprove the grade of all ironReduced silica contentSolid separationLower gradeLow graded

The invention belongs to the technical field of ore dressing and discloses an ore dressing process for reducing the content of silicon dioxide in iron ore concentrate. The ore dressing process includes: step one, crushing, to be more specific, crushing low-grade magnetic iron ore into size smaller than 20mm, and performing high-pressure rolling, superfine grinding and sieving and full-closed wet pre-separation to obtain rough concentrate in size smaller than 3mm; step two, ore grinding and magnetic separation, to be more specific, to be more specific, performing two-stage ore grinding, gradingand low-intensity magnetic separation; step three, fine sieving, to be more specific, feeding the magnetically separated rough concentrate into a fine sieve for sieving, and then returning materialson the sieve to a two-stage grinding system, wherein the sieve mesh size is 0.075-0.1mm; step four, feeding sieved powder into a wash mill, and concentrating to obtain washed concentrate; step five, magnetic desliming, to be more specific, subjecting the washed concentrate to concentration in a magnetic desliming tank to obtain final concentrate, wherein the SiO2 content is reduced to 3.5% or below. After two-stage grinding and low-intensity magnetic separation, two-stage continuous concentration is performed through the wash mill and the magnetic desliming tank, so that the problem of high SiO2 content of the ore concentrate is solved while quality improvement and impurity reduction of the ore concentrate are realized.

Owner:马钢集团设计研究院有限责任公司

Fluorite beneficiation and separation method

InactiveCN109821660AImprove flotation efficiencySimple processFlotationGrain treatmentsWastewaterOleic Acid Triglyceride

The invention discloses a fluorite beneficiation and separation method, and relates to the technical field of beneficiation process. The fluorite beneficiation and separation method includes the stepsof primary grinding, primary grading, primary roughing, senary refining and secondary scavenging, and specifically includes feeding flotation concentrates into a concentration tank, dehydrating the concentrated concentrates by a filter, drying the filtered concentrates by a roller dryer, putting the dried concentrates into jumbo bags to obtain finished products, feeding flotation tailings into atailings pond, recycling wastewater, collecting fluorite by oleic acid, taking water glass as a quartz inhibitor, and adjusting the pH of ore pulp to 8-9 by calcium carbonate. The fluorite beneficiation and separation method has the advantages of high flotation efficiency, simple process and low cost.

Owner:高台县宏源矿业有限责任公司

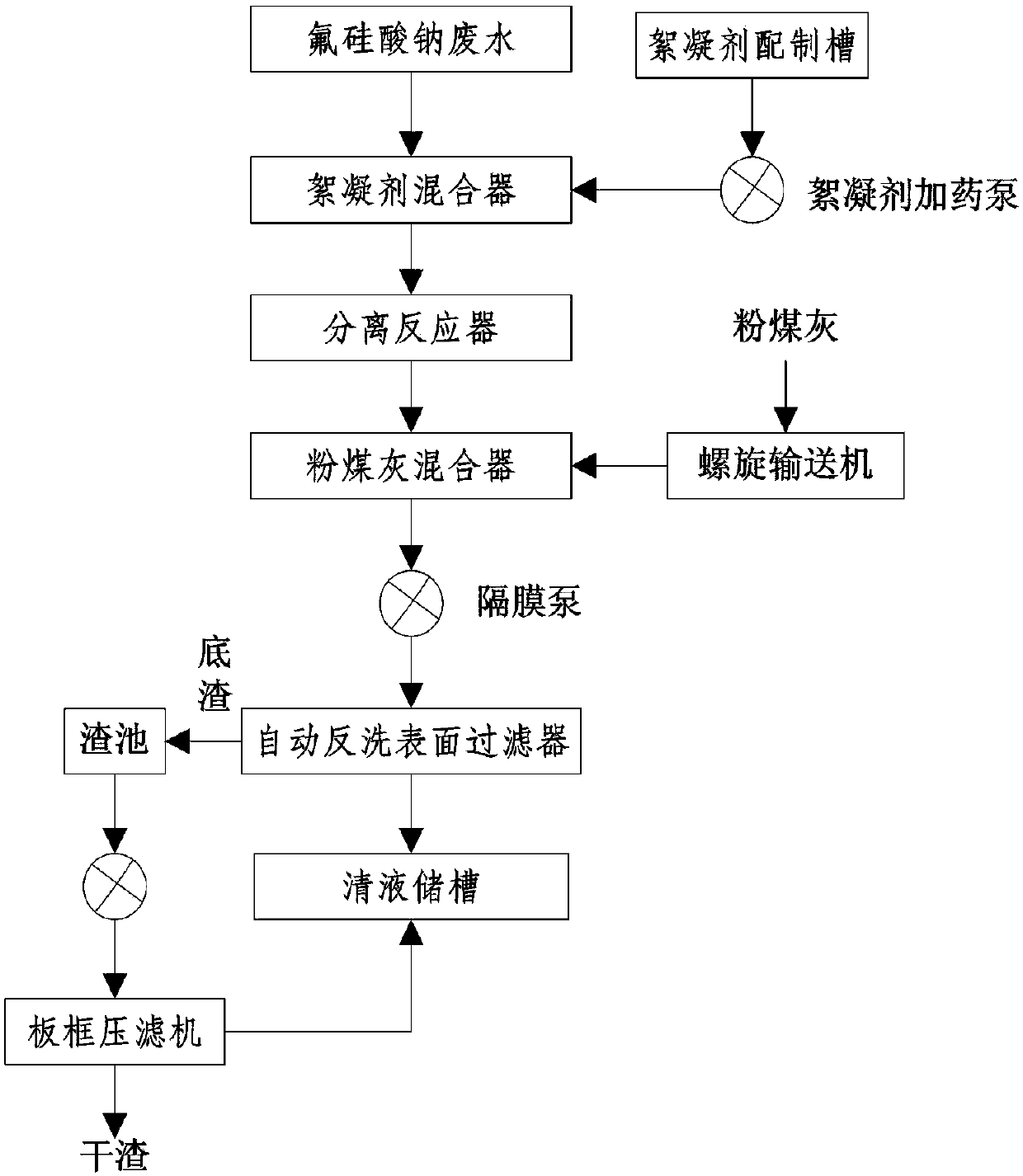

Sewage purification method during sodium fluosilicate production

ActiveCN107651781AReduce dosageReduce usageSludge treatmentSpecific water treatment objectivesChemistryCarbon source

The invention relates to the technical field of sewage treatment, and particularly relates to a sewage purification method during sodium fluosilicate production. The method comprises the steps of adjusting the Na+ content in sewage and conducting flocculant precipitation, flyash mixing and membrane separation. According to the sewage purification method during the sodium fluosilicate production, silicon dioxide removal in the sewage during the sodium fluosilicate production is and a flocculant are researched, finally a composite flocculant is obtained through compounding on the condition of acheap carbon source and nitrogen source, silicon dioxide in the sewage can effectively precipitate, it is found through an experiment that the content of the silicon dioxide in the sewage can reach 4.77 mg / L to the lowest degree after treatment, the using amount of the flocculant is little and reduced, cyclic utilization of workshop production water is achieved, and the production cost is reduced.Besides, the flocculant researched in the method has the same good flocculation effect on sewage in other fields.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

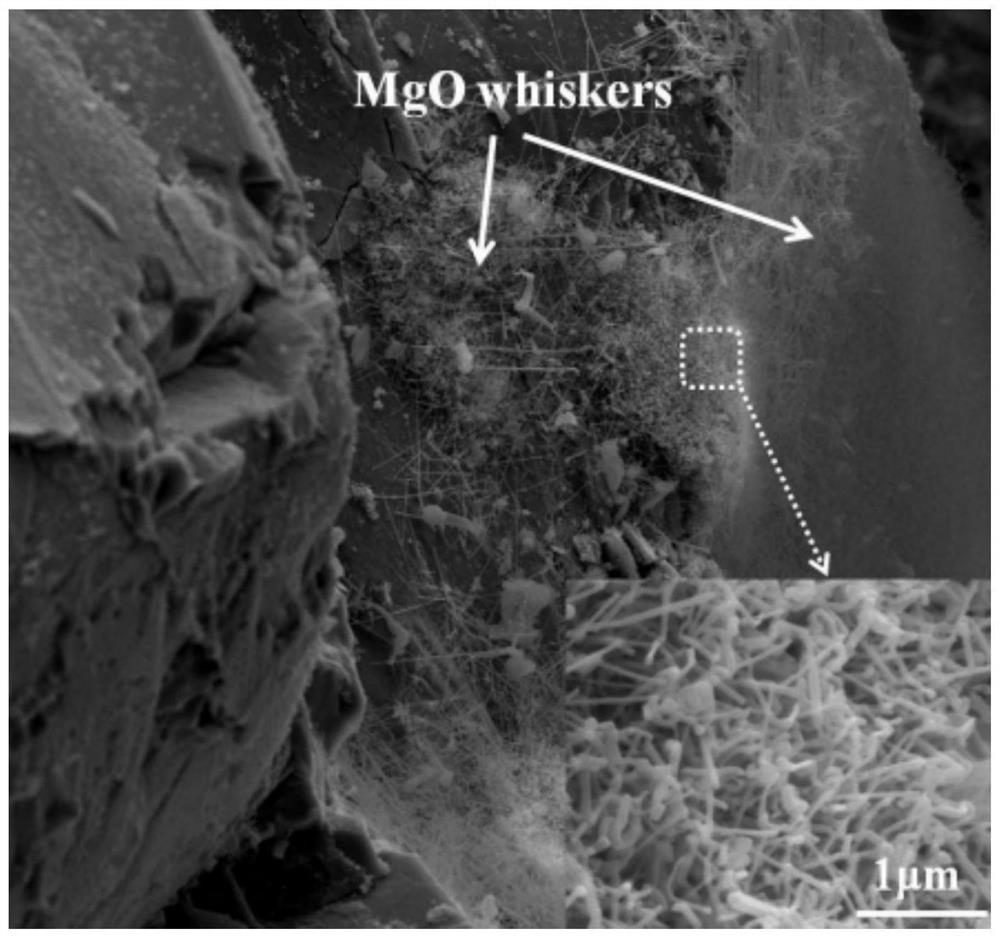

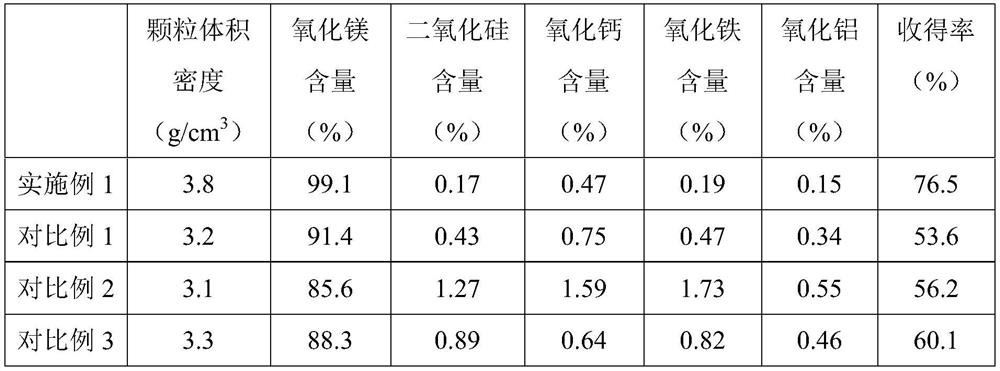

Preparation method of macrocrystalline magnesia with low silicon dioxide content

InactiveCN112094106AObvious performance advantageHigh in silicaFlotationElectric arc furnaceMacrocrystalline

The invention discloses a preparation method of macrocrystalline magnesia with low silicon dioxide content, and belongs to the technical field of mineral resource processing. The method comprises thefollowing steps: (1) fine selection: taking low-grade magnesite as a raw material, and finely selecting magnesite with the magnesium oxide content of 40%-45%; (2) cleaning: cleaning magnesite; (3) refining: refining the magnesite; (4) roasting: feeding the concentrate powder into a rotary kiln or a fluidized bed furnace for roasting, and cooling to room temperature to obtain light calcined magnesia; (5) dry pressing: feeding the light calcined magnesia into a ball press machine for dry pressing to obtain balls; and (6) electric melting: feeding the spheres prepared in the step (5) into an electric arc furnace for electric melting, and carrying out heat preservation, cooling and crystallization. The prepared macrocrystalline magnesia has good performance advantages, the test parameters suchas the particle volume density, the magnesium oxide content, the silicon dioxide content, the calcium oxide content, the iron oxide content, the aluminum oxide content and the yield show significantdifferences, and the macrocrystalline magnesia is high-quality macrocrystalline magnesia.

Owner:LIAONING DONGHE NEW MATERIAL CO LTD

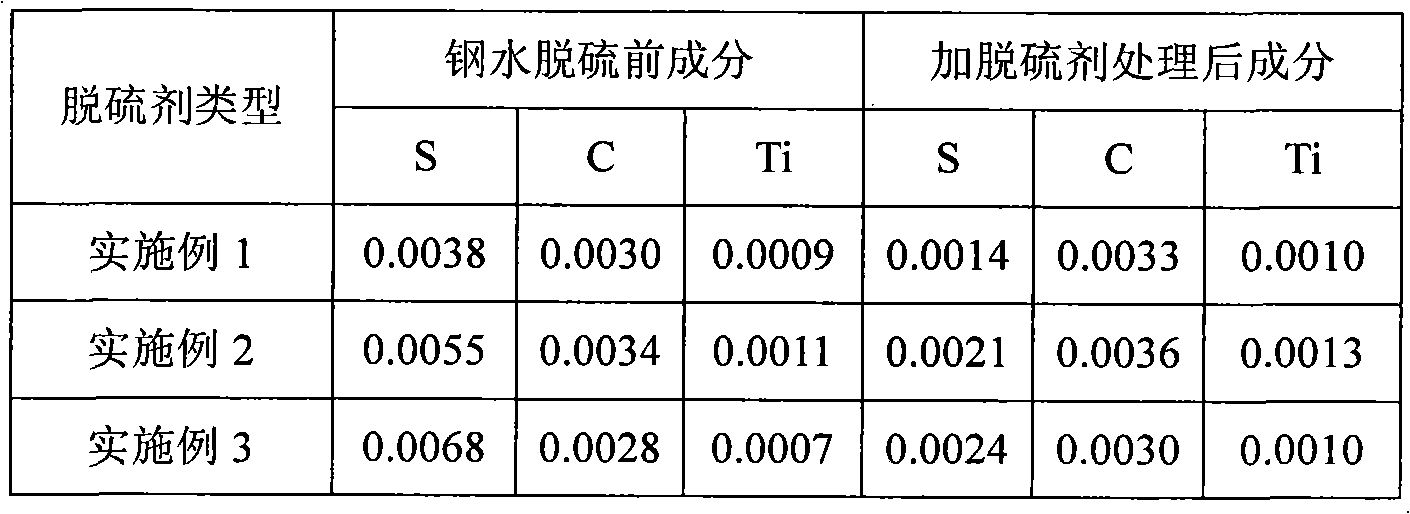

Premelting type desulfurizing agent suitable for high-aluminum silicon steel and preparation method thereof

The invention provides a premelting type desulfurizing agent suitable for high-aluminum silicon steel and a preparation method thereof. The desulfurizing agent comprises the following components by weight percent: 80-85 percent of calcium oxide (CaO), 13-18 percent of aluminum oxide (Al2O3), not greater than 1.5 percent of magnesium oxide (MgO), not greater than 1.5 percent of silicon dioxide (SiO2), not greater than 0.02 percent of all titanium (Ti) and not greater than 0.02 percent of all carbon (C). The preparation method comprises the following steps: (1) weighing 87-90 percent of limestone of which the granularity is not greater than 10mm and 10-13 percent of Al2O3 of which the granularity is not greater than 10mm by weight percent; (2) putting the raw materials in a mixer and evenly mixing; (3) adding a mixture to a smelting furnace, then, blowing fuel oil for heating, and smelting; and (4) discharging, cooling and crushing for later use. The desulfurizing agent provided by the invention is easy to store, has high desulfurizing rate and has low erosion on the refractory of a vacuum slot body; and in the desulfurizing process, molten steel carburetion and titanizing can be controlled to be under 5 parts per million (ppm), and the desulfurizing rate can reach at least 60 percent on the premise of not increasing the refining time.

Owner:ANGANG STEEL CO LTD

Comprehensive utilization method of ferriferous fayalite material

ActiveCN103343225BIncrease response rateEasy to separateProcess efficiency improvementFayaliteLiquid state

The invention discloses a comprehensive utilization method of a ferriferous fayalite material, relates to a processing method of the ferriferous fayalite material, and in particular relates to a method for separating and utilizing iron and silicon in fayalite. The method is characterized by comprising the following steps of: grinding the ferriferous fayalite material; mixing with alkaline liquor for leaching reaction; performing solid-liquid separation on obtained reaction slurry to obtain desilicated concentrate and silicon containing alkaline liquor; and oxidizing the desilicated concentrate in air to goethite. The method disclosed by the invention enriches, separates and extracts iron and silicon elements to form two products: goethite and silicon containing alkaline liquor through alkaline liquor leaching, wherein iron and silicon in ferriferous fayalite exist in solid and liquid states, so that the comprehensive utilization ratio of resources is high and the economic benefit is better.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

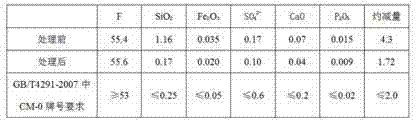

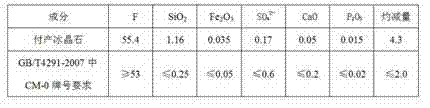

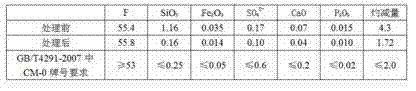

Technique for purifying cryolite

The invention relates to a technique for purifying cryolite, and the technique comprises the following steps: (1) adding water and the cryolite into a reactor, wherein the mass ratio of the water to the cryolite is (0.5-6.0):1, and stirring, thus obtaining slurry; (2) adding HF-HCl-H2SO4 mixed acid into the slurry obtained in the step (1) while stirring, wherein the molar ratio of HF to HCl to H2SO4 is 1:(0.1-1):(0.1-1) in the mixed acid, and the mass ratio of the mixed acid to the raw material cryolite is (0.04-0.30):1; (3) heating the material obtained in the step (2) to 20-100 DEG C, and stirring for reaction for 10-150 minutes; and (4) carrying out vacuum filtration or centrifugal separation on a liquid-solid mixed material obtained in the reaction of the step (3), obtaining a solid material, and drying, thus obtaining the purified cryolite. The technique used for purifying the byproduct of cryolite is simple and low in energy consumption, and the recovery rate reaches more than 96%, so that the content of silicon dioxide in the cryolite and the ignition loss can be greatly reduced, and the treatment cost is low.

Owner:湖南有色金属投资有限公司

Calcium aluminate for desulfurization of ultralow titanium and carbon steel and preparation method thereof

The invention relates to calcium aluminate for desulfurization of ultralow titanium and carbon steel and a preparation method thereof. The calcium aluminate comprises more than or equal to 94% of Ca12Al14O33, less than or equal to 2% of Ca3Al2O6, less than or equal to 2% of Ca2SiO4, less than or equal to 1.5% of MgO, less than or equal to 0.01% of pure Ti and less than or equal to 0.02% of pure carbon. The preparation method comprises the following steps of: (1) preparing materials according to the following proportions: 60-65% of CaO and 35-40% of Al; (2) mixing the proportioned raw material particles in a material mixer; (3) adding the mixed materials into a smelting furnace, and blowing fuel to heat the furnace to make furnace temperature achieve 950-1050 DEG C; (4) blowing oxygen into the furnace, heating the furnace body to 1450-1500 DEG C; and (5) cooling and crushing premelted slag into 5-30 mm blocks. The desulfurizing agent provided by the invention has the advantages of low production cost, easy for storage, low melting point, high slag melting speed, high desulfurization effect and small corrosion to refractory materials, and the carbon increase amount and the titanium increase amount of liquid steel can be effectively controlled.

Owner:ANGANG STEEL CO LTD

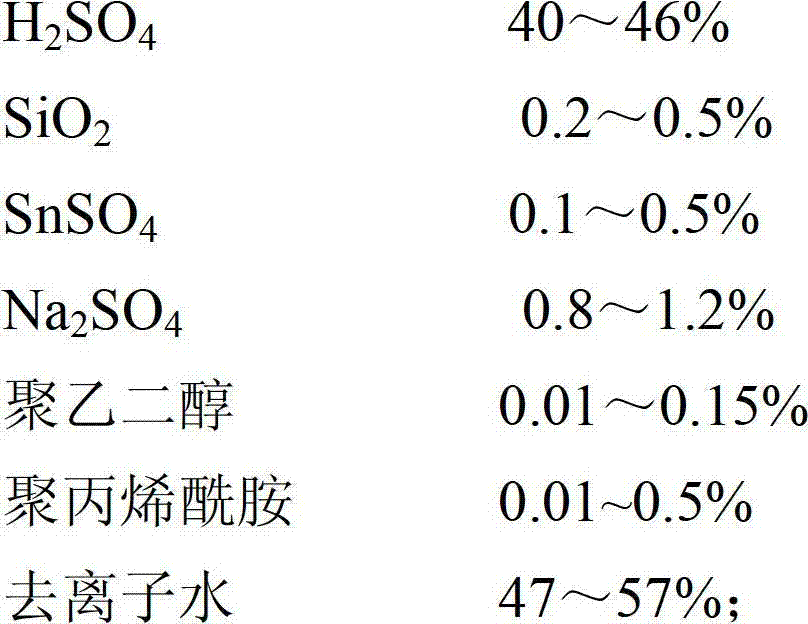

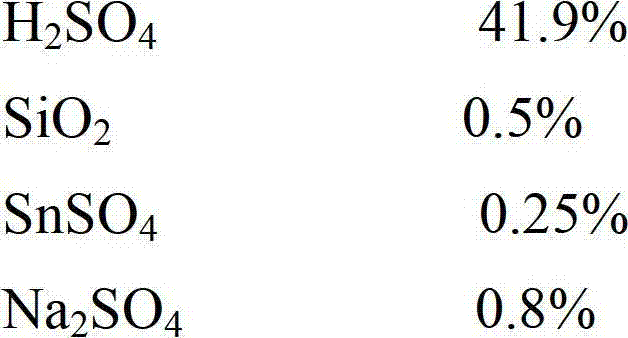

Gel electrolyte of power lead-acid storage battery

ActiveCN101908650BReduced silica contentLower impedanceFinal product manufactureSemi-lead accumulatorsPolyethylene glycolColloid

Owner:TIANNENG BATTERY GROUP

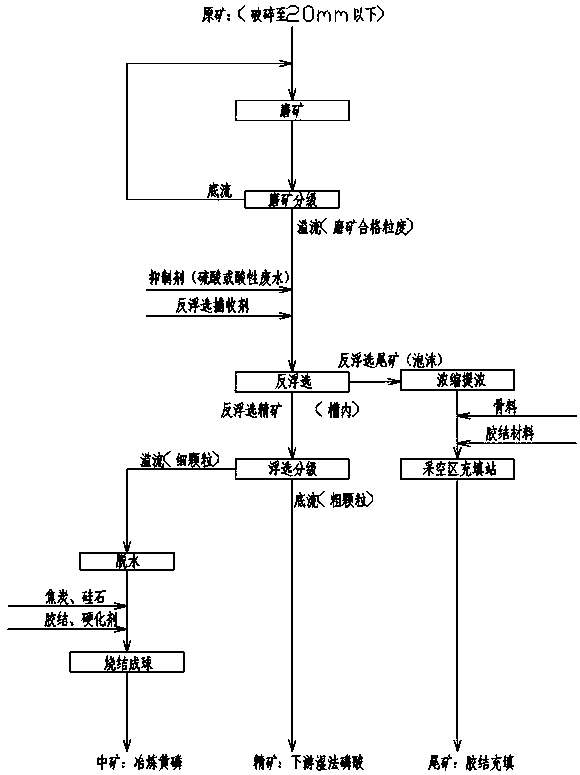

High-power half-medium-low-grade silicon-calcium phosphorite combined separation process

ActiveCN111570082AIncrease profitReduced concentrate sesquioxideFlotationRaw phosphate material treatmentO-Phosphoric AcidMaterials science

The invention discloses a high-power half-medium-low-grade silicon-calcium phosphorite combined separation process, and belongs to the field of phosphorite separation. The process specifically comprises the following steps that a high-power half-medium-low-grade silicon-calcium phosphorite is subjected to wet grinding and then reverse flotation is carried out to obtain flotation concentrate and tailings, the flotation concentrate is subjected to graded desliming, low-magnesium and low-half graded coarse-grained materials are final concentrate, and fine-grained materials are taken as middlings;and the concentrate product is allowed to be subjected to downstream wet-process phosphoric acid, middling smelting yellow phosphorus and tailing cemented filling treatment. According to the process,the content of concentrate metal ion oxide and silicon dioxide is reduced through reverse flotation and grading desliming combined separation. The middlings with certain phosphorus content and high silicon content are used for smelting yellow phosphorus, and the comprehensive utilization rate of phosphorus resources is high; the tailings cemented filling treatment is carried out, and no three wastes are discharged by a system.

Owner:WENGFU (GRP) CO LTD +1

High-molecular nano polymer electrolyte for lead-acid battery and its compounding method

ActiveCN100439438CIncrease capacityExtended service lifeLead-acid accumulatorsElectrical batterySilicon dioxide

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

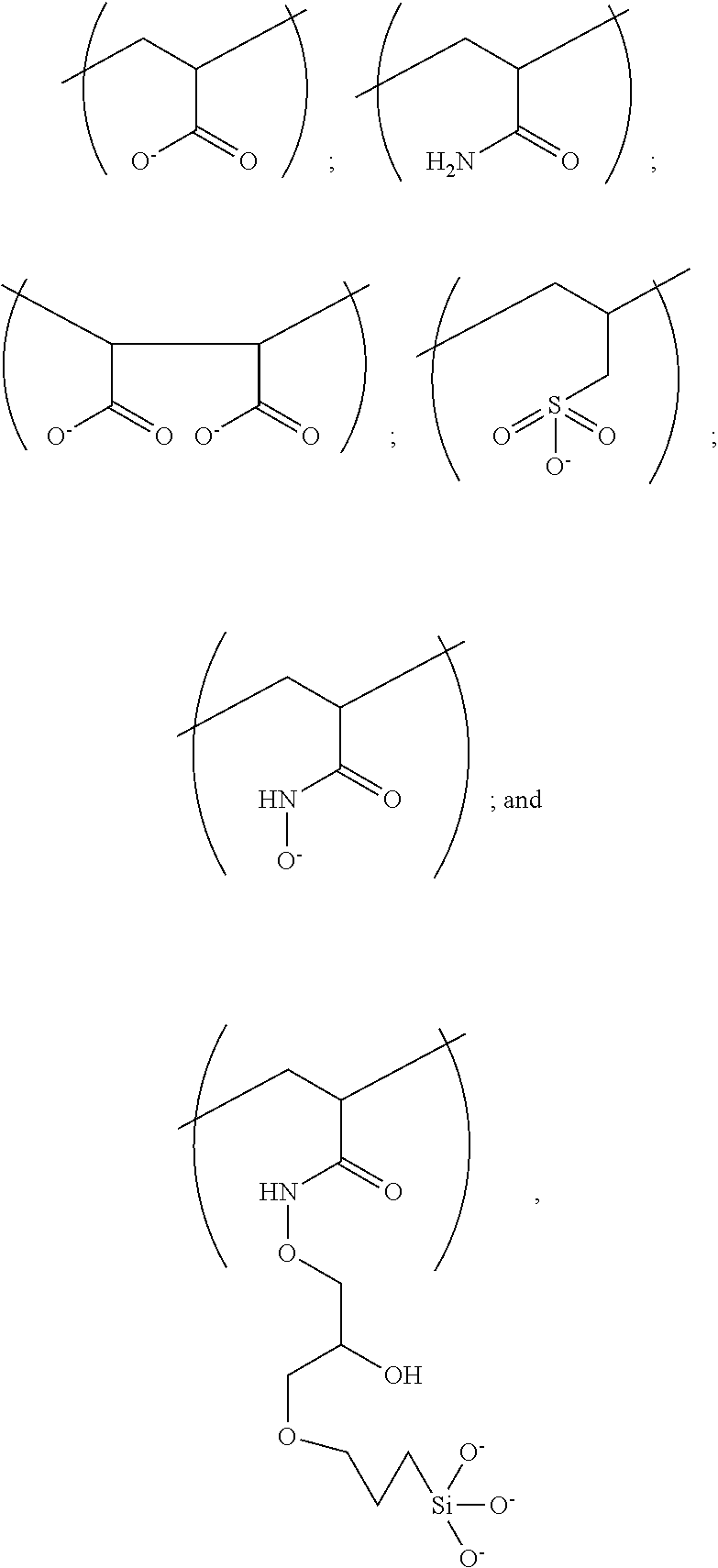

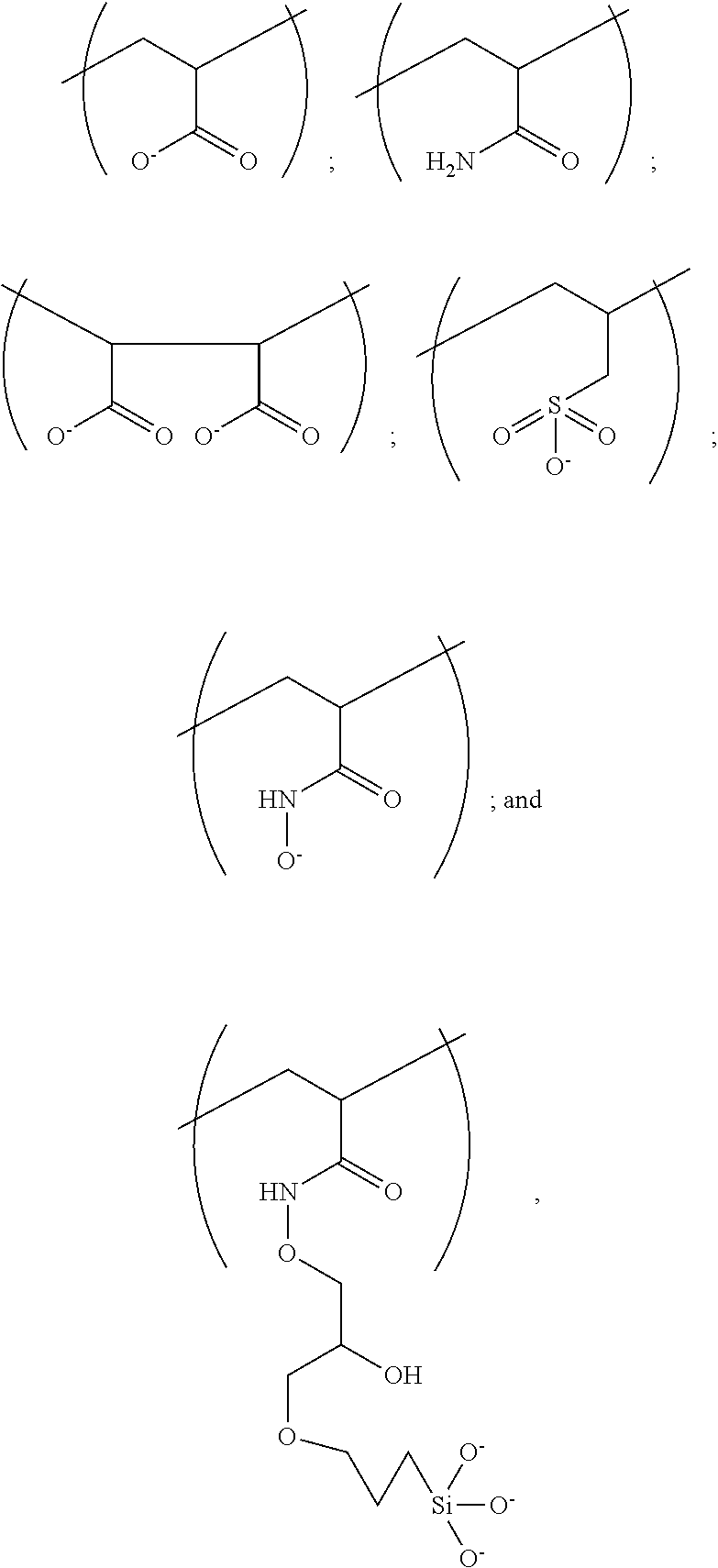

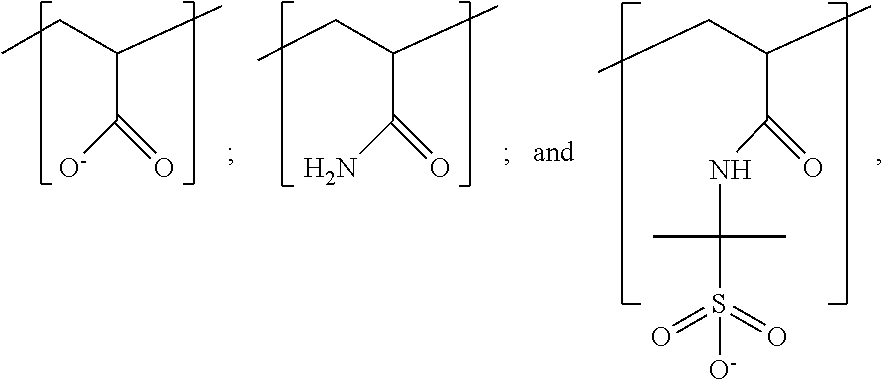

Binder formulations and uses thereof for forming agglomerated products of particulate material

InactiveUS20180230061A1High porosityReduced silica contentGranulation with special binding agentsParticulatesSulfonate

Agglomerated products formed from particulate materials and binder formulations having low molecular weight polymers (of 500 g / mol to 50,000 g / mol) in an aqueous or emulsion form, or having a blend of low molecular weight aqueous polymer and high molecular weight (of 500,000 g / mol to 50,000,000 g / mol) emulsion polymers, wherein the polymers are formed from water soluble ethylenically unsaturated monomers, or monomer blends, chosen from one or more of acrylic acid, acrylamide, maleic acid, allyl sulfonate, silanated and / or hydroxamated acrylamide, or 2-acrylamido-2-methylpropane sulfonic acid (AMPS), are disclosed herein as well as processes for agglomerating a particulate materials, and use of the binding agents for forming same.

Owner:CYTEC IND INC

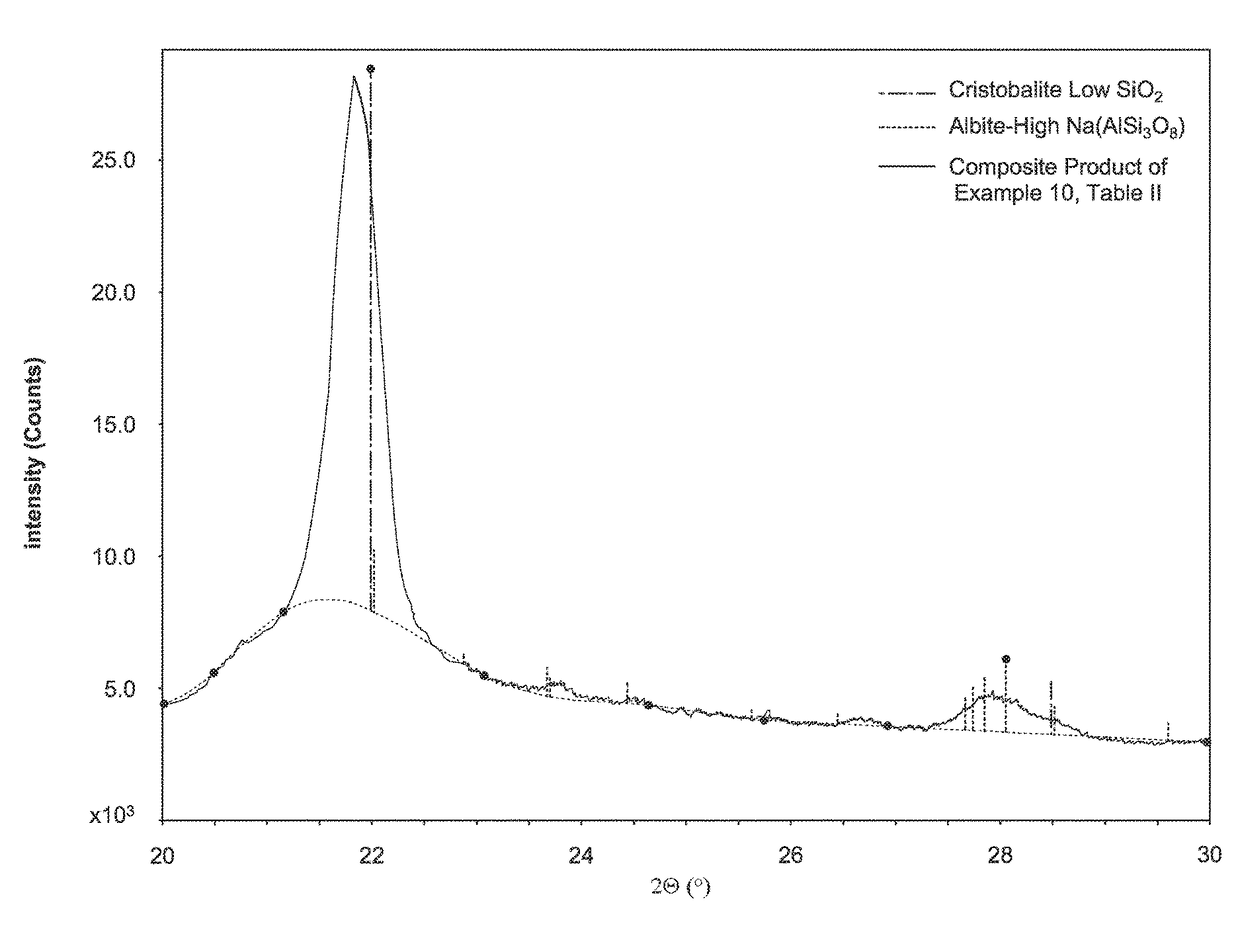

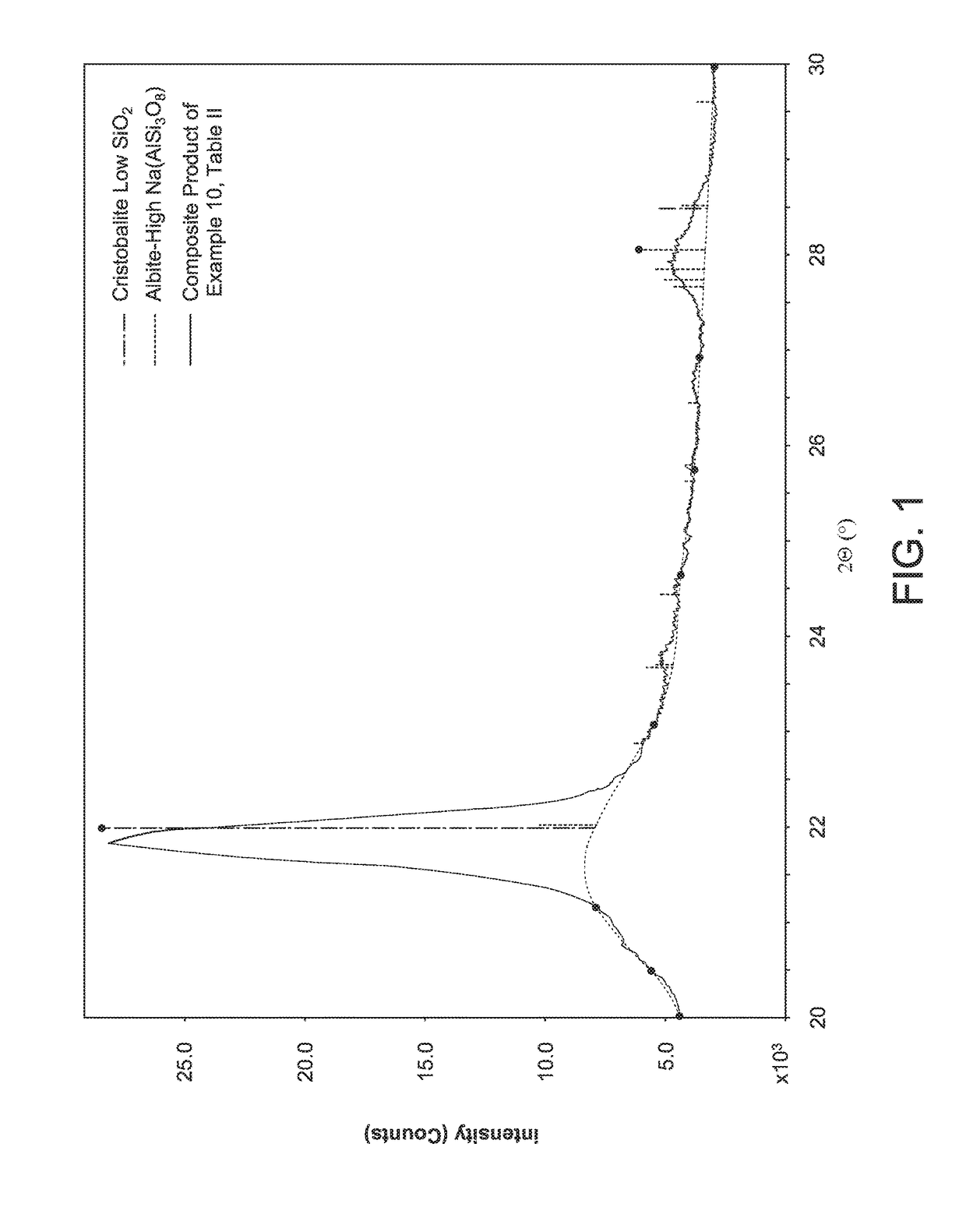

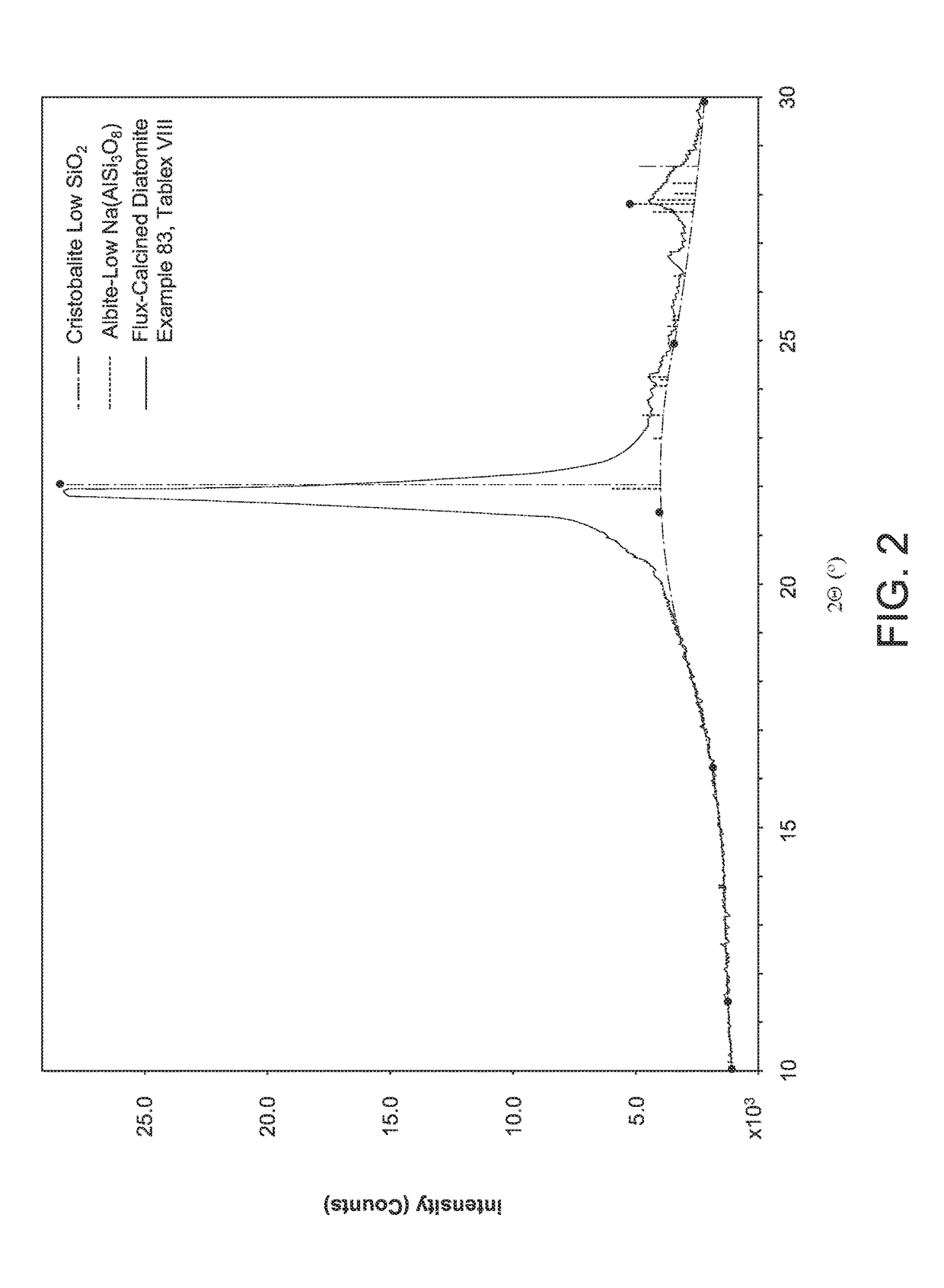

Opaline biogenic silica/expanded perlite composite products

ActiveUS20170368486A1Improve levelPromote transformationWater/sewage treatmentFiltration separationPerliteBiogenic silica

A powdered composite filtration medium includes composite particles that include at least one diatomite particle and at least one expanded perlite particle sintered together. The composite powdered filtration medium may include from about 7 wt % to about 90 wt % diatomite, from about 93 wt % to about 10 wt % expanded perlite. Less than about 1% total crystalline silica may be present in the medium. The medium may have a permeability of at least 0.25 darcy. The diatomite and expanded perlite may be sintered or calcined with or without a fluxing agent.

Owner:EP MINERALS LLC +1

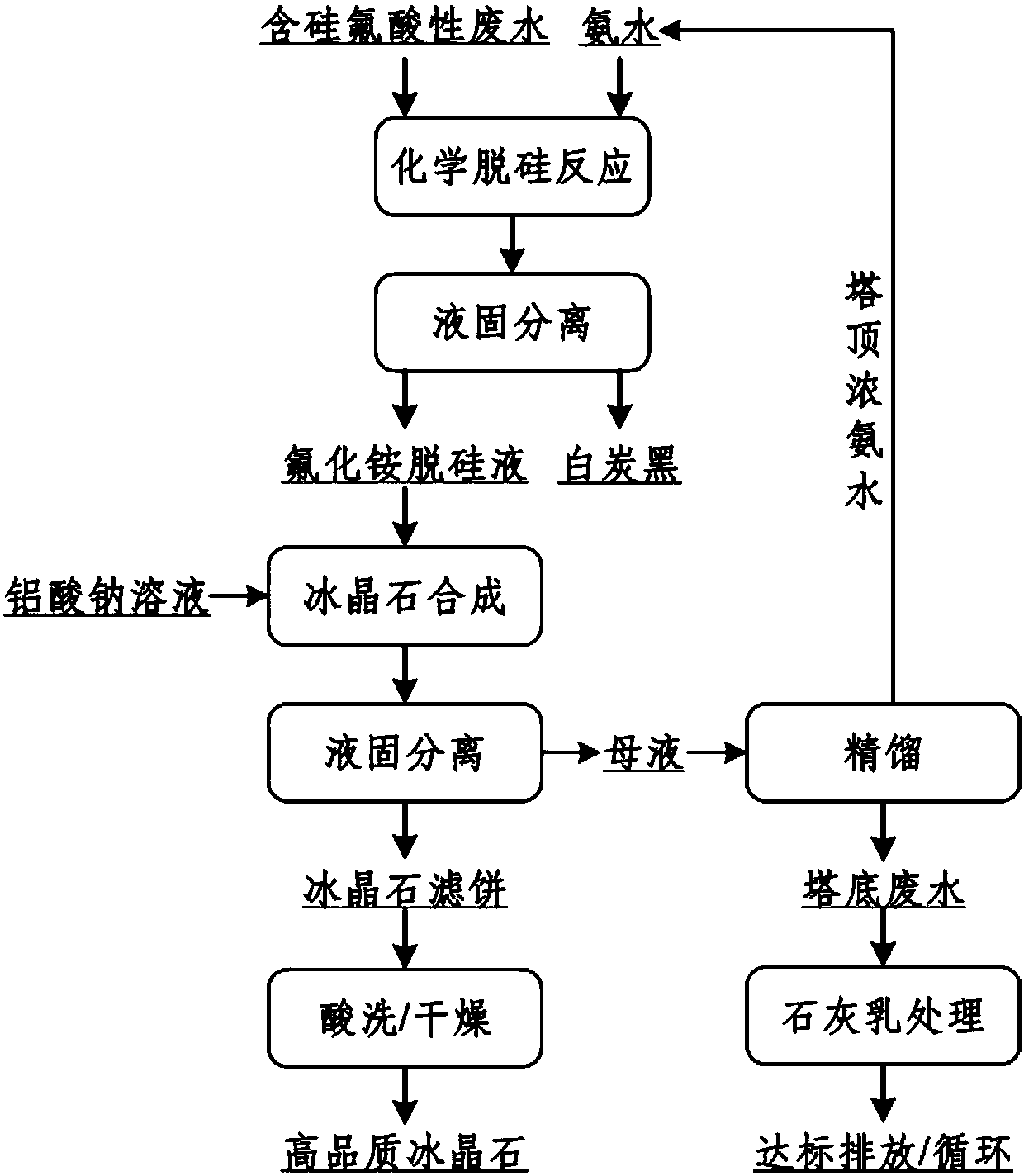

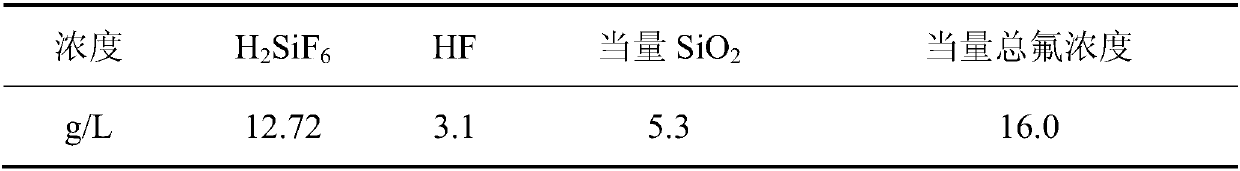

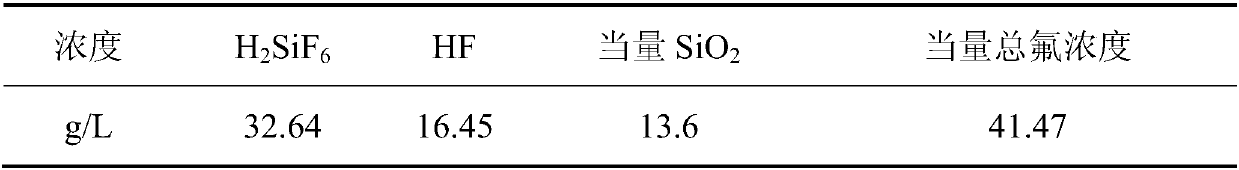

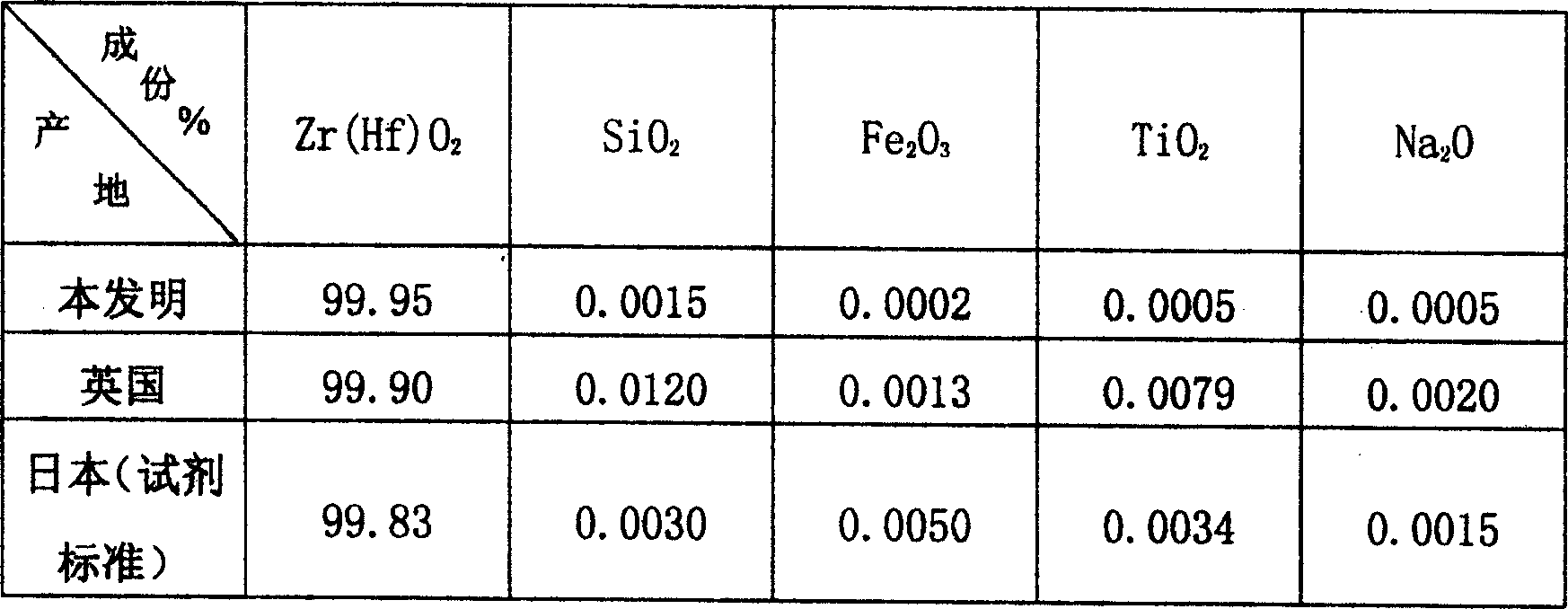

Method for preparing cryolite

ActiveCN109796034ARealize resource recyclingComprehensive recovery rate is highSilicaAluminium fluoridesAmmonium hydroxideCarbon black

The invention relates to a method for preparing cryolite. The method comprises the steps that 1) wastewater containing silicon and fluorine is mixed with ammonium hydroxide, and a chemical desiliconization reaction is carried out; 2) liquid-solid separation is carried out to obtain white carbon black and an ammonium fluoride desiliconized liquid; 3) the ammonium fluoride desiliconized liquid is mixed with a sodium aluminate solution, and a synthesis reaction is carried out; 4) liquid-solid separation is carried out to obtain the cryolite. The method for preparing the cryolite has the advantages that a high-quality cryolite product is obtained by recycling from the wastewater containing the silicon and fluorine and a white carbon black byproduct is also obtained; the recovery rate of fluorine resources in the wastewater is 90% or above, the obtained cryolite has high purity and good fluidity, and the mass fraction of SiO2 is less than 0.1%; the raw material can be acidic fluorine-containing wastewater discharged from the aluminum fluoride industry, fluorosilicic acid discharged from the phosphate fertilizer industry or ammonium fluoride alkaline wastewater discharged from the niobium and tantalum industry, and the resource recovery rates of fluorine and silicon are not affected; the process conditions are mild, high-efficiency circulation of the medium is easily achieved, the industrial operability is strong, and the economic benefits are outstanding.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process of preparing zirconia and yttria with Y-doped cubic zirconia powder

InactiveCN100463862CHigh metal contentLow priceRare earth metal compoundsZirconium oxidesRare earthSilicon dioxide

The process of preparing zirconia and yttria with Y-doped cubic zirconia powder includes the following steps: alkali fusing and sintering Y-doped cubic zirconia powder, water washing to eliminate sodium, acidifying and concentrating to obtain Zr crystal, oxychlorination to re-crystallize and purify, and high temperature calcining to obtain high purity jewel level zirconia; concentrating Y-containing mother liquid to crystallize zirconia, purifying high Y mother liquid, precipitating Y in oxalic acid solution, and high temperature calcining to obtain high purity jewel level yttria. The present invention has relatively low cost.

Owner:王必庆

Barium Sulfate Particles with Low α-Ray Dose, Utilization and Manufacturing Method

ActiveCN108473333BReduce trimmingReduced silica contentHydrogen cyanide stabilisationInorganic pigment treatmentChemical synthesisBarium sulphide

Owner:SAKAI CHEM IND CO LTD

Calcium aluminate for desulfurization of ultralow titanium and carbon steel and preparation method thereof

The invention relates to calcium aluminate for desulfurization of ultralow titanium and carbon steel and a preparation method thereof. The calcium aluminate comprises more than or equal to 94% of Ca12Al14O33, less than or equal to 2% of Ca3Al2O6, less than or equal to 2% of Ca2SiO4, less than or equal to 1.5% of MgO, less than or equal to 0.01% of pure Ti and less than or equal to 0.02% of pure carbon. The preparation method comprises the following steps of: (1) preparing materials according to the following proportions: 60-65% of CaO and 35-40% of Al; (2) mixing the proportioned raw material particles in a material mixer; (3) adding the mixed materials into a smelting furnace, and blowing fuel to heat the furnace to make furnace temperature achieve 950-1050 DEG C; (4) blowing oxygen into the furnace, heating the furnace body to 1450-1500 DEG C; and (5) cooling and crushing premelted slag into 5-30 mm blocks. The desulfurizing agent provided by the invention has the advantages of low production cost, easy for storage, low melting point, high slag melting speed, high desulfurization effect and small corrosion to refractory materials, and the carbon increase amount and the titanium increase amount of liquid steel can be effectively controlled.

Owner:ANGANG STEEL CO LTD

Premelting type desulfurizing agent suitable for high-aluminum silicon steel and preparation method thereof

Owner:ANGANG STEEL CO LTD

A method for purifying sewage in the production of sodium fluorosilicate

ActiveCN107651781BEffective settlementReduced silica contentSludge treatmentSpecific water treatment objectivesFlocculationPurification methods

The invention relates to the technical field of sewage treatment, and particularly relates to a sewage purification method during sodium fluosilicate production. The method comprises the steps of adjusting the Na+ content in sewage and conducting flocculant precipitation, flyash mixing and membrane separation. According to the sewage purification method during the sodium fluosilicate production, silicon dioxide removal in the sewage during the sodium fluosilicate production is and a flocculant are researched, finally a composite flocculant is obtained through compounding on the condition of acheap carbon source and nitrogen source, silicon dioxide in the sewage can effectively precipitate, it is found through an experiment that the content of the silicon dioxide in the sewage can reach 4.77 mg / L to the lowest degree after treatment, the using amount of the flocculant is little and reduced, cyclic utilization of workshop production water is achieved, and the production cost is reduced.Besides, the flocculant researched in the method has the same good flocculation effect on sewage in other fields.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com