High-power half-medium-low-grade silicon-calcium phosphorite combined separation process

A kind of phosphorite, low-grade technology, applied in the field of combined separation of high-semi-medium-low-grade siliceous calcareous phosphorite, can solve the problems of high production cost, stagnant mines, complicated processes, etc., and achieve comprehensive utilization of phosphorous resources. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

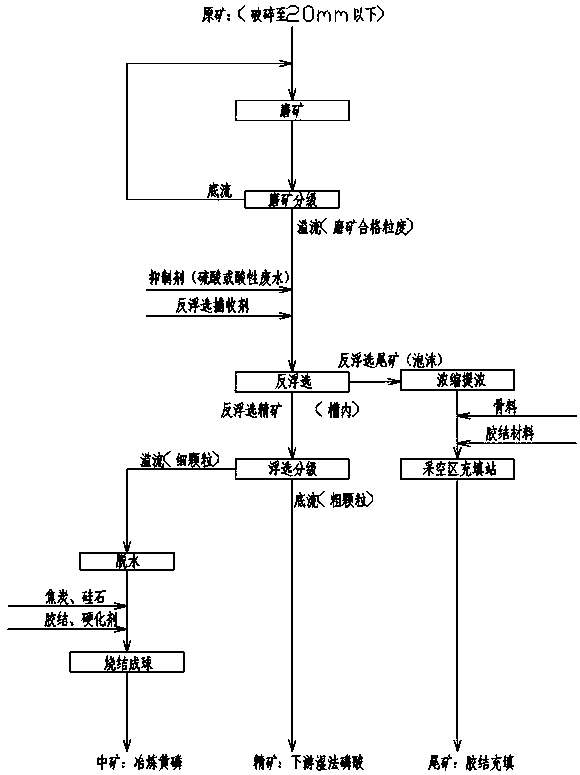

[0034] Example: refer to figure 1 .

[0035] A collophosite raw ore in Southwest China was crushed (particle size ≤ 15mm) and then wet-milled in a closed circuit, with a grinding fineness of -200 mesh 62%.

[0036] Phosphoric acid is added to the flotation pulp to wash the acid wastewater, the pH value of the flotation pulp is 5, and the reverse flotation collector (WF-01) is added according to 450g / t raw ore. The reverse flotation process of one roughing and one open-circuit sweeping is adopted: the product in the roughing tank is used as the flotation concentrate, and the roughing foam product flows to the sweeping operation by itself; the sweeping foam is used as the final flotation tailings, and the The product is as a sweep concentrate.

[0037] The flotation concentrate is classified by the hydrocyclone group, and the classification particle size is -400 mesh (38um). The cyclone underflow (wt65%) is sent to the phosphoric acid plant in the form of slurry. The slag po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com