Preparation method of macrocrystalline magnesia with low silicon dioxide content

A technology of silicon dioxide and crystalline magnesium, applied in flotation, solid separation and other directions, can solve the problems of high silicon dioxide, low product yield, affecting the high temperature erosion resistance of magnesia, and reduce the silicon dioxide content , the effect of improving the yield of large crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the large crystalline magnesia of the low silicon dioxide content of the present embodiment may further comprise the steps:

[0043] (1) selection: using low-grade magnesite as raw material, select magnesite with a magnesium oxide content of 40%;

[0044] (2) Cleaning: the magnesite after step (1) is selected, is cleaned, and the mud and fine-grained minerals on its surface are removed, and stand-by;

[0045] (3) Refining: the magnesite after step (2) is cleaned is refined, and the refining process is divided into six steps. The first step is to crush the above-mentioned magnesite, and the second step is to crush the crushed magnesite. Washing with water, the third step is to grind the washed magnesite, the fourth step is to add water to the ground magnesite to make raw ore pulp, the fifth step is to deslim the raw ore pulp, and the sixth step is to remove the Flotation is carried out on the raw ore pulp after mud to obtain concentrate powder ...

Embodiment 2

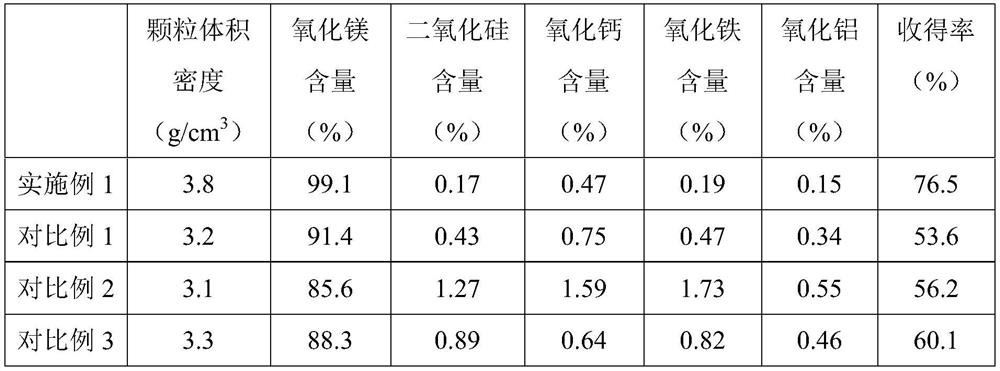

[0096]The large crystalline magnesia prepared in Example 2 and the magnesia prepared in Comparative Examples 1-3 were selected respectively, and tested with reference to QB / T 002-2016.

[0097] Table 1 Comparison of test parameters

[0098]

[0099] Compared with Comparative Examples 1-3, the large crystalline magnesia prepared in Example 1 of the present invention has good performance advantages, particle volume density, magnesium oxide content, silicon dioxide content, calcium oxide content, iron oxide content, aluminum oxide content The test parameters such as content and yield all reflect significant differences, and it is high-quality large crystal magnesia. Specifically, the present invention makes full use of the basic conditions such as magnesite tailings flotation purification and new suspension furnaces previously applied by the company, and researches and develops volume density up to 3.5g / cm 3 The above-mentioned large crystal magnesia with low silicon dioxide ...

Embodiment 3

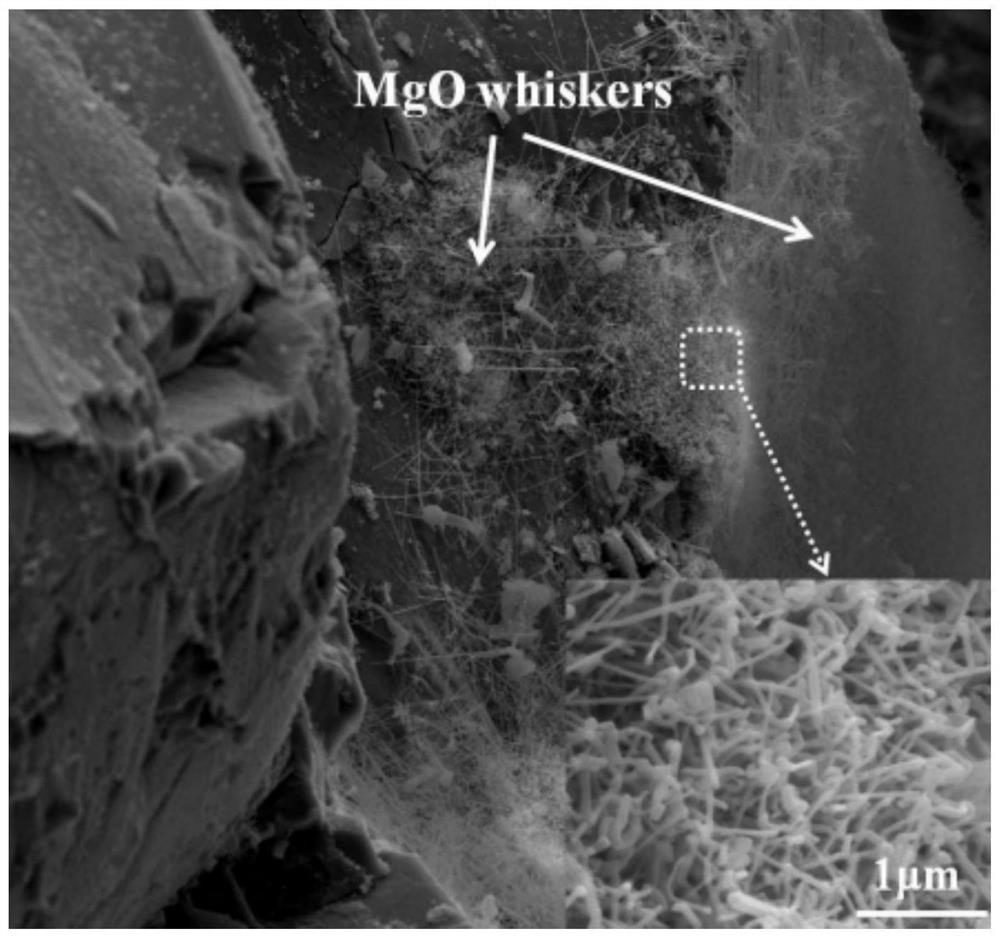

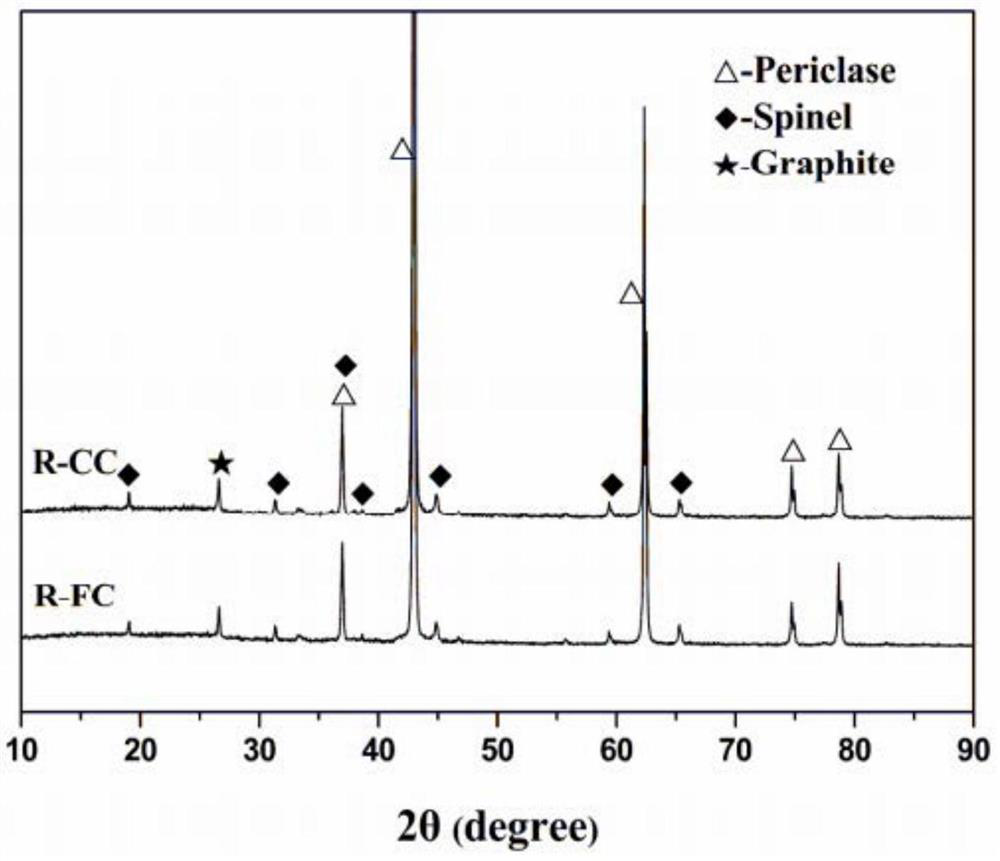

[0101] Combined with the test results of Example 2, the large crystal magnesia prepared in Example 1 was selected for SEM and XRD tests. For the specific method, refer to the following literature (Wang Chunxin. The influence of smelting process on the structure and properties of fused magnesia and magnesia-aluminum spinel [D].), combined with SEM and XRD for analysis.

[0102] Such as figure 1 with figure 2 As shown, the large crystalline magnesia prepared by the present invention has its main crystal phase as a trigonal rhombohedron without impurity peaks, indicating that the large crystalline magnesia has a high purity and almost no impurity mineral phase, which is comparable to the high-purity magnesia obtained by chemical analysis. They are consistent with each other, and the diffraction peaks are stronger at the same time, indicating that the crystal form in magnesia is relatively complete and the crystallinity is higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com