Technique for purifying cryolite

A cryolite and process technology, applied in the field of purification process of by-product cryolite, can solve the problems of inability to electrolyze aluminum production, waste of resources, unfavorable environment, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Add 400mL of water to a 2L reactor with stirring, and then add 200g of by-product cryolite under stirring to make a slurry; (2) Add 20g of mixed acid, in the mixed acid, HF:HCl:H 2 SO 4 The molar ratio is 1:0.3:0.3, heated to 55°C, and reacted for 30 minutes under stirring; (3) Vacuum-filter the reacted material to obtain a solid material, and dry it at 110°C for 2 hours. Obtain 193.5 grams of purified cryolite products, the rate of recovery is 96.75%. Analyze the impurity content in the product, the results are shown in Table 2.

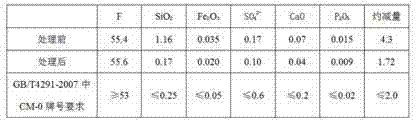

[0017] Table 2 Example 1 product chemical composition analysis results (wt%)

[0018]

Embodiment 2

[0020] (1) Add 600mL of water to a 2L reactor with stirring, and add 200g of by-product cryolite under stirring to make a slurry; (2) Add 45g of mixed acid, in which HF:HCl:H 2 SO 4 The molar ratio is 1:0.45:0.45; heated to 60°C, and reacted for 60 minutes under stirring; (3) vacuum-filtered the reacted material to obtain a solid material, dried at 110°C for 2 hours, and it was ready. 193.8g of purified cryolite product was obtained; the recovery rate was 96.9%. Analyze the impurity content in the product, and the results are shown in Table 3.

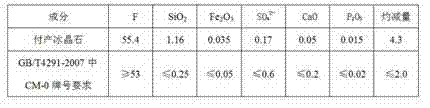

[0021] Table 3 Example 2 product chemical composition analysis results (wt%)

[0022]

Embodiment 3

[0024] (1) Add 800mL of water to a 2L reactor with stirring, and add 200g of by-product cryolite under stirring to make a slurry; (2) Add 30 grams of mixed acid, in which HF:HCl:H 2 SO 4 The molar ratio is 1:0.6:0.6, heated to 85°C, and reacted for 90 minutes under stirring; (3) Vacuum-filter the reacted material to obtain a solid material, and dry it at 110°C for 2 hours. The purified cryolite product was 192.2g; the recovery rate was 96.1%. The impurity content in the analysis sample is shown in Table 4 for the results.

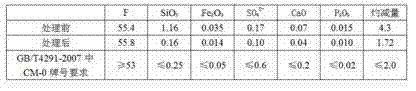

[0025] Table 4, Example 3 product chemical composition analysis results (wt%)

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com