High-purity aluminum fluoride production technology

A technology of pure aluminum fluoride and production process, which is applied in the direction of aluminum fluoride and aluminum halide, etc. It can solve the problems of substandard fluorite ore raw materials, excessive SiO2 content in aluminum fluoride, and being on the verge of going out, so as to reduce fluorine pollution Emissions, low combustion loss, and the effect of reducing the consumption of aluminum fluoride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

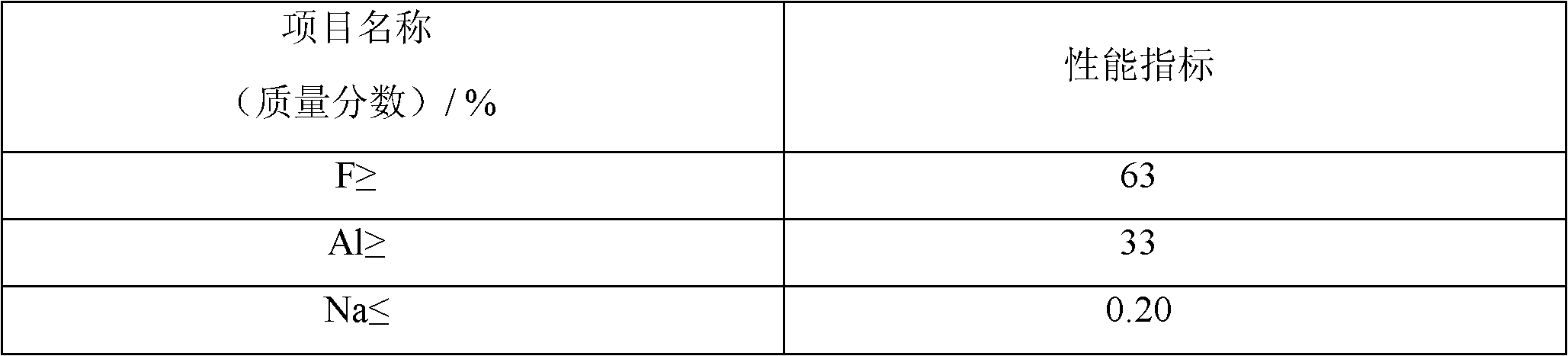

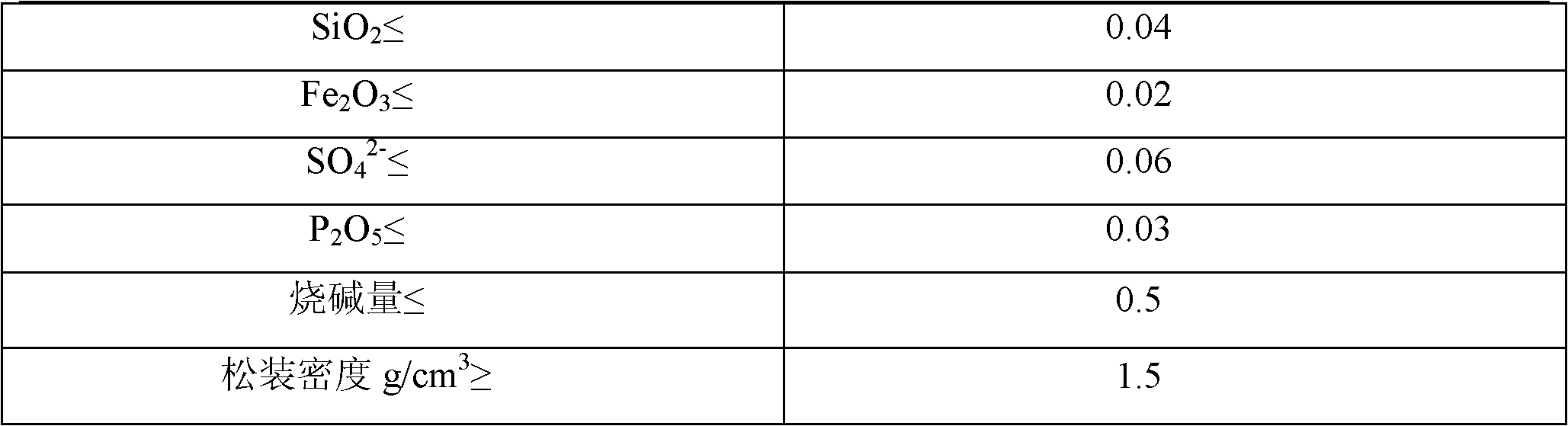

Embodiment 1

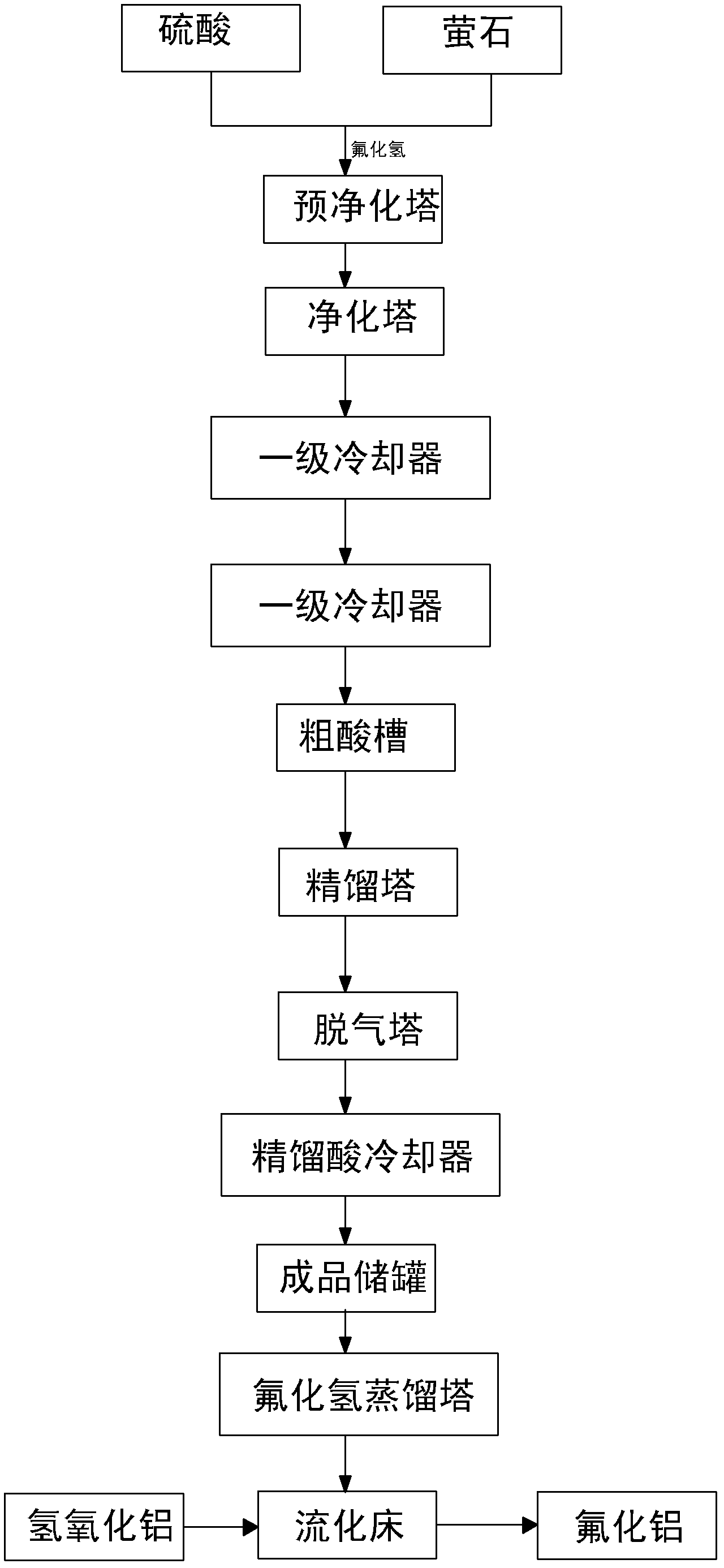

[0045] A kind of high-purity aluminum fluoride production process comprises the steps:

[0046] (1) Desiliconization of hydrogen fluoride gas: fluorite and sulfuric acid react to generate hydrogen fluoride gas; hydrogen fluoride gas is washed by sulfuric acid in the pre-purification tower and sulfuric acid in the purification tower, and then enters the primary and secondary coolers; the condensed acid enters the crude acid tank , the crude acid tank overflows to the rectification tower for desiliconization, and then enters the degassing tower for degassing; finally enters the rectification acid cooler, and overflows from the rectification acid cooler to the finished product storage tank;

[0047] (2) Evaporation of anhydrous hydrogen fluoride: The finished acid from the finished product storage tank is pumped into the hydrogen fluoride distillation tower kettle by the submerged pump, evaporated by the evaporator in the tower kettle, and the evaporated hydrogen fluoride gas pass...

Embodiment 2

[0057] A kind of high-purity aluminum fluoride production process comprises the steps:

[0058](1) Desiliconization of hydrogen fluoride gas: fluorite and sulfuric acid react to generate hydrogen fluoride gas; hydrogen fluoride gas is washed by sulfuric acid in the pre-purification tower and sulfuric acid in the purification tower, and then enters the primary and secondary coolers; the condensed acid enters the crude acid tank , overflows from the crude acid tank to the rectification tower for desiliconization, then enters the degassing tower for degassing; finally enters the rectification acid cooler, overflows from the rectification acid cooler to the finished product storage tank;

[0059] (2) Evaporation of anhydrous hydrogen fluoride: The finished acid from the finished product storage tank is pumped into the hydrogen fluoride distillation tower kettle by the submerged pump, evaporated by the evaporator in the tower kettle, and the evaporated hydrogen fluoride gas is then ...

Embodiment 3

[0069] A kind of high-purity aluminum fluoride production process comprises the steps:

[0070] (1) Desiliconization of hydrogen fluoride gas: fluorite and sulfuric acid react to generate hydrogen fluoride gas; hydrogen fluoride gas is washed by sulfuric acid in the pre-purification tower and sulfuric acid in the purification tower, and then enters the primary and secondary coolers; the condensed acid enters the crude acid tank , overflows from the crude acid tank to the rectification tower for desiliconization, then enters the degassing tower for degassing; finally enters the rectification acid cooler, overflows from the rectification acid cooler to the finished product storage tank;

[0071] (2) Evaporation of anhydrous hydrogen fluoride: The finished acid from the finished product storage tank is pumped into the hydrogen fluoride distillation tower kettle by the submerged pump, evaporated by the evaporator in the tower kettle, and the evaporated hydrogen fluoride gas is then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com