Emulsion type carbon fiber sizing agent containing graphene oxide and preparation method thereof

An emulsion-type carbon fiber and graphene technology, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of influence, sizing agent particle size distribution and unfavorable stability, etc., and achieve the effect of superior fiber performance and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Epoxy resin EP-44: 50g;

[0033] Polyethylene glycol (PEG6000): 100g;

[0034] Toluene diisocyanate: 7g;

[0035] Alkylphenol polyoxyethylene ether: 50g;

[0036] Graphene oxide aqueous solution (2 wt%): 375g;

[0037] Toluene: 50g.

[0038]Add 50g of epoxy resin EP-44, 100g of polyethylene glycol and 50g of toluene into the reaction kettle, heat until completely dissolved and stir evenly, add 7g of toluene diisocyanate at reflux temperature, react for 2 hours, add 50g of alkylphenol poly Oxyethylene ether, stirred for 1h, and then vacuumed to extract the solvent. Reduced to room temperature to obtain epoxy emulsifier. Add 520g of epoxy resin EP-44 on the basis of the obtained emulsion epoxy oxidant, mix thoroughly at 60°C, then slowly add 375g, 2wt% graphene oxide aqueous solution, and use deionized water to add emulsion-type carbon fiber sizing to 50% solid content agent.

Embodiment 2

[0040] Epoxy resin EP-44: 55g;

[0041] Polyethylene glycol (PEG6000): 90g;

[0042] Toluene diisocyanate: 6.5g;

[0043] Alkylphenol polyoxyethylene ether: 50g;

[0044] Graphene oxide aqueous solution (2 wt%): 375g;

[0045] Butanone: 60g.

[0046] Add 55g of epoxy resin EP-44, 90g of polyethylene glycol and 60g of methyl ethyl ketone into the reaction kettle, heat until completely dissolved and stir evenly, add 6.5g of toluene diisocyanate at reflux temperature, react for 2 hours, add 50g of alkyl Phenol polyoxyethylene ether, stirred for 1h, then vacuumed, the solvent was drawn out, and the epoxy emulsifier was obtained by lowering to room temperature. On the basis of the obtained epoxy emulsifier, add 522g of epoxy resin EP-44, mix thoroughly at 60°C, then slowly add 375g, 2wt% graphene oxide aqueous solution, and add deionized water to the emulsion carbon fiber with a solid content of 50% Sizing agent.

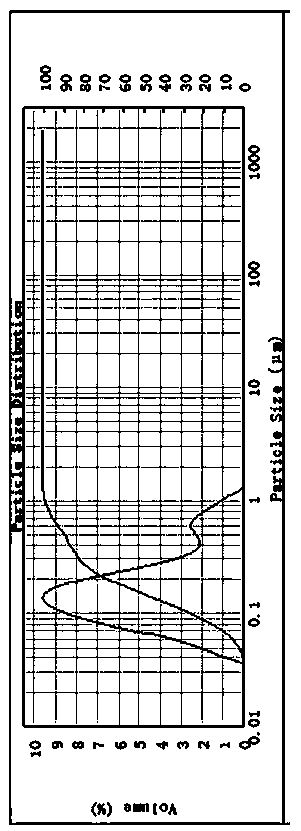

[0047] From figure 1 It can be found...

Embodiment 3

[0054] Epoxy resin EP-20: 57g;

[0055] Polyethylene glycol (PEG6000): 100g;

[0056] Toluene diisocyanate: 7.5g;

[0057] Alkylphenol polyoxyethylene ether: 50g;

[0058] Graphene oxide aqueous solution (2 wt%): 400g;

[0059] Butanone: 65g.

[0060] Add 57g of epoxy resin EP-20, 100g of polyethylene glycol and 65g of methyl ethyl ketone into the reaction kettle, heat until completely dissolved and stir evenly, add 6.5g of toluene diisocyanate at reflux temperature, react for 2 hours, add 50g of alkyl Phenol polyoxyethylene ether, stirred for 1h, then vacuumed, the solvent was drawn out, and the epoxy emulsifier was obtained by lowering to room temperature. On the basis of the obtained epoxy emulsifier, add 600g of epoxy resin EP-44, mix thoroughly at 60°C, then slowly add 400g, 2wt% graphene oxide aqueous solution, and add deionized water to the emulsion carbon fiber with a solid content of 50% Sizing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com