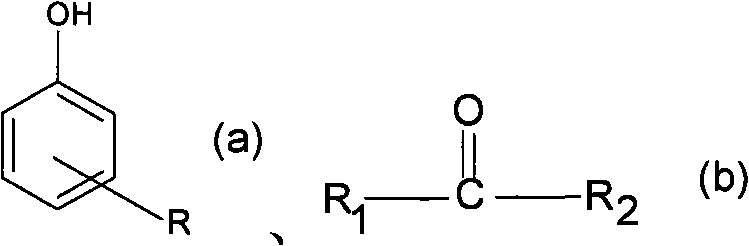

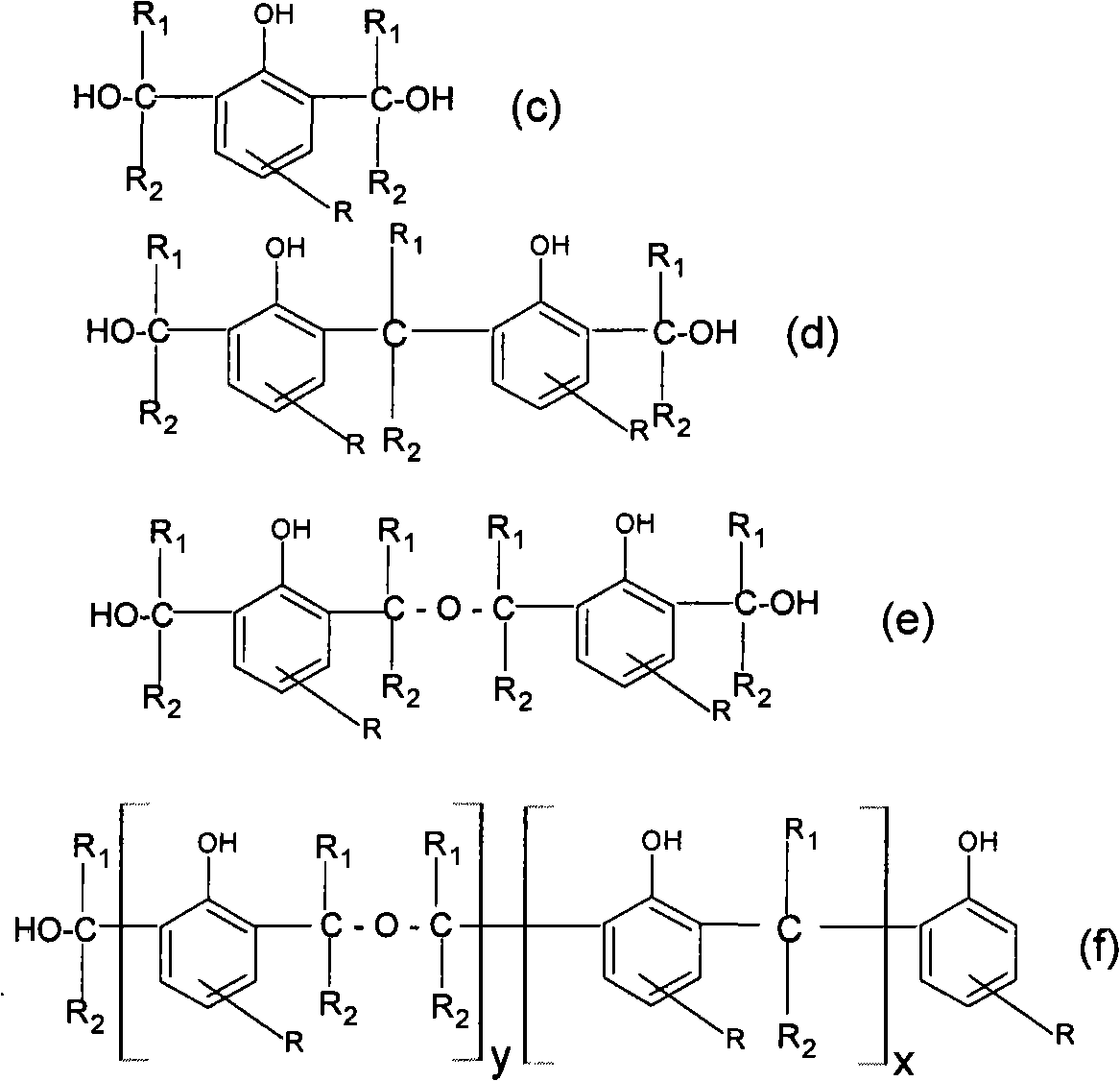

Modified phenolic tackifying resins for rubber compounding applications

A tackifying resin, resole phenolic resin technology, used in other rubber adhesives, adhesives, adhesive types, etc., to solve problems such as high cost and availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Rosin and morpholine modified p-tert-butylphenol (PTBP)-formaldehyde resin

[0056] 50 kg of p-tert-butylphenol (PTBP) and 25 kg of toluene were added to the reactor and heated to 85 to 110° C. to dissolve the phenol. Triethylamine (TEA) catalyst was then added to adjust the pH of the reaction mixture to basic conditions. Then, under reflux conditions, 32 kg of aqueous formaldehyde (37%) was slowly added over a period of about 2-3 hours. Morpholine (5 kg) and rosin (5 kg) were added to the resole mixture and refluxed for an additional 2-3 hours. Finally, the reaction mixture is first dehydrated at atmospheric pressure, and then the volatile substances present in the resin product are removed under vacuum (temperature 180-200° C. and vacuum 25-50 mm Hg).

Embodiment 2

[0058] Rosin, stearic acid and morpholine modified p-tert-butylphenol (PTBP)-formaldehyde resin

[0059] 150 kg of p-tert-butylphenol (PTBP) and 75 kg of toluene were added to the reactor and heated to 85 to 110° C. to dissolve the phenol. Triethylamine (TEA) catalyst was then added to adjust the pH of the reaction mixture to basic conditions. Then, under reflux conditions, 95 kg of aqueous formaldehyde (37%) was slowly added over a period of about 2-3 hours. Morpholine (14 kg), rosin (15 kg) and stearic acid (6 kg) were added to the resole mixture and refluxed for an additional 2-3 hours. Finally, the reaction mixture is first dehydrated at atmospheric pressure, and then the volatile substances present in the resin product are removed under vacuum (temperature 180-200° C. and vacuum 25-50 mm Hg).

Embodiment 3

[0061] Rosin, stearic acid and morpholine modified p-tert-octylphenol (PTOP)-formaldehyde resin

[0062] 225 grams of p-tert-octylphenol (PTOP) and 150 grams of toluene were added to the reaction flask and heated to 85 to 110° C. to dissolve the phenol. Triethylamine (TEA) catalyst was then added to adjust the pH of the reaction mixture to basic conditions. Then, under reflux conditions, 104 kg of aqueous formaldehyde (37%) was slowly added over a period of about 2-3 hours. Morpholine (15 grams), rosin (16 grams) and stearic acid (6 grams) were added to the resole mixture and refluxed for an additional 2-3 hours. Finally, the reaction mixture is first dehydrated at atmospheric pressure, and then the volatile substances present in the resin product are removed under vacuum (temperature 180-200° C. and vacuum 25-50 mm Hg).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com