Non-emulsion type pure oiling agent for high speed spinning of polyamide-6 filaments

A high-speed spinning, emulsion-type technology, applied in fiber types, textiles and papermaking, fiber processing, etc., can solve the problems of no public specific reports on components, more spinning smoke, poor diffusivity, etc., and achieve strength loss Low, high oil film strength, good permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

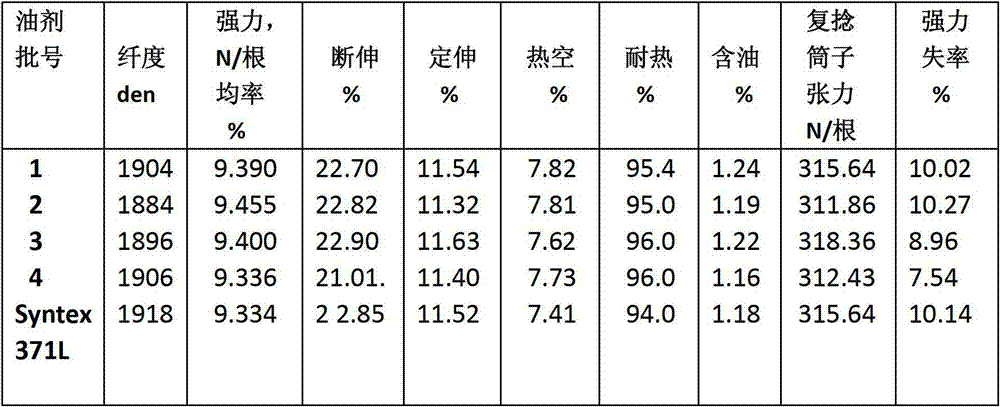

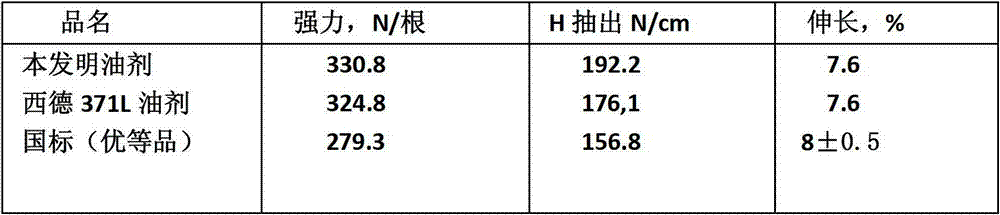

[0035] Nylon 6 filament high-speed spinning pure oil agent composition of the present invention, as table 1

[0036] Table 1 Composition of pure oil agent for nylon 6 filament high-speed spinning

[0037] components

content

Trimethylhexanol ethylene oxide propylene oxide polyether

40%

Lauryl alcohol polyoxyethylene ether C 12 O(EO)n

25%

Nonylphenol polyoxyethylene ether

20%

Polyoxyethylene laurate PEG-400 ether ester

10%

Fatty alcohol polyoxyethylene ether phosphate or alkyl phosphate amine (potassium) salt,

1%

conditioner water

2%

Adhesive Additive Ac

2%

[0038] Preparation process of pure oil agent for high-speed spinning of nylon 6 filament

[0039] This process is suitable for the preparation of pure oil agent for nylon 6 filament high-speed spinning. The process equipment includes heat preservation reaction kettle, stirring motor, water circulation vacuum pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com