Preparation method of low-base-number and high-molecular-weight calcium alkyl benzene sulfonate antirust agent

A technology of calcium alkyl benzene sulfonate and alkyl benzene sulfonic acid is applied in the preparation of calcium sulfonate rust inhibitor, the preparation field of low base value, high molecular weight calcium alkyl benzene sulfonate rust inhibitor, and can solve the problem of preventing Poor rust performance, serious environmental pollution, small molecular weight and other problems, to achieve the effect of ensuring rust resistance and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

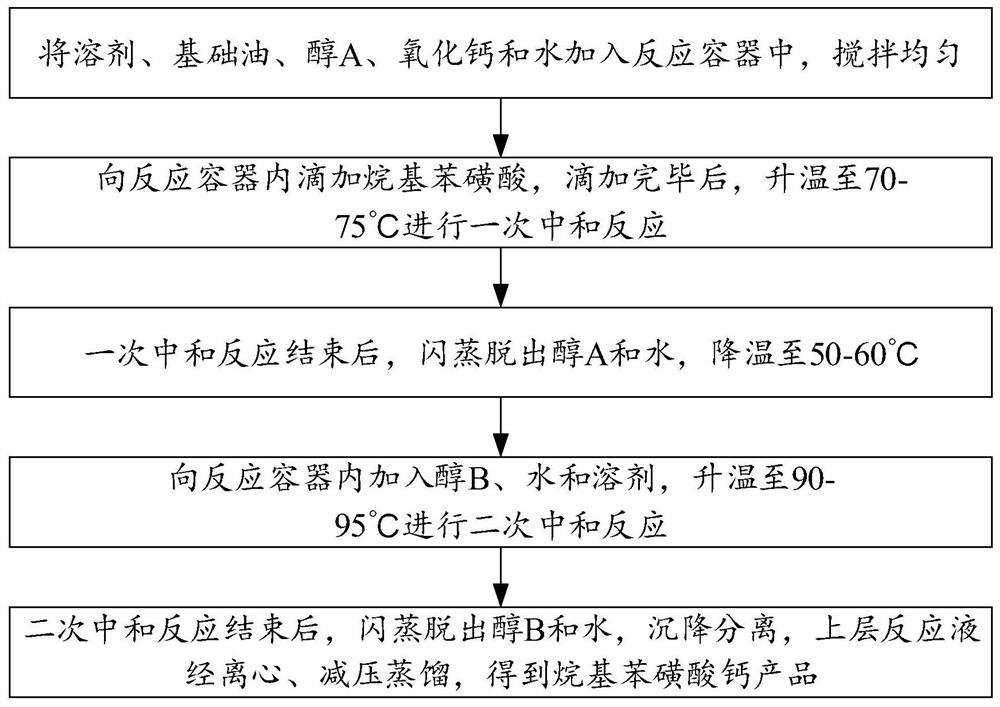

[0037] Such as figure 1 Shown, the present invention provides a kind of preparation method of low alkali value, large molecular weight alkylbenzene sulfonate calcium antirust agent, it adopts high molecular weight alkylbenzene sulfonic acid to prepare ultra-low alkali value calcium alkylbenzene sulfonate, prepares The calcium alkylbenzene sulfonate antirust agent has excellent antirust performance, and its alkali value is very low, does not contain heavy metals, has little environmental pollution, and has significant advantages in product economy and universality; including:

[0038] Step 1, adding solvent, base oil, alcohol A, calcium oxide and water into the reaction vessel, and stirring evenly;

[0039] Among them, specifically include:

[0040] Under the condition of protective gas, put the solvent, base oil, alcohol A, calcium oxide and water into the reaction kettle, raise the temperature to 50-60°C, and stir evenly;

[0041] or,

[0042] Under the condition of protec...

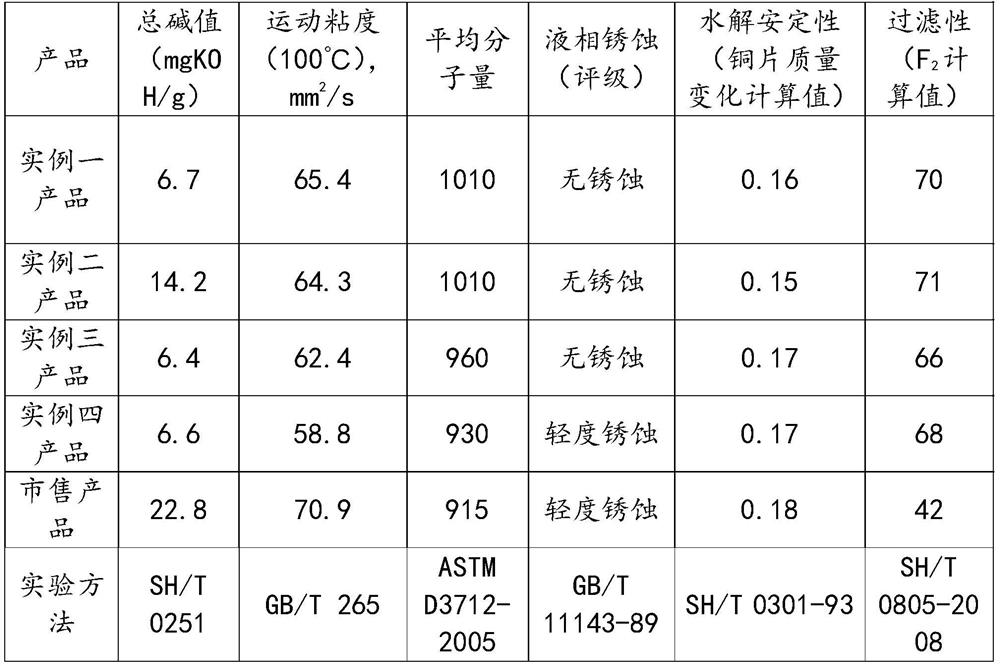

example 1

[0061]Take 300kg of solvent, 140kg of base oil, and 50kg of alcohol A into a 1000L reactor, stir for 20min to mix evenly. Finally, 8.5kg of calcium oxide and 10kg of water were added and stirred for 30 minutes. Take 150kg of alkylbenzene sulfonic acid whose carbon chain length is C22-C24, and add it dropwise at a uniform speed within 90-120 minutes, and the temperature is raised to 50-60°C. Then the temperature was raised to 70-75°C, neutralized for 2 hours, and the pH value of the neutralized reaction solution was recorded. After the first stage of neutralization, alcohol and water are removed by flash evaporation, and the temperature is lowered to 50-60°C. Add 50kg of alcohol B, 15kg of water, and 80kg of solvent, raise the temperature to 90-95°C, neutralize for 2 hours, and record the pH value of the neutralization reaction solution. After the second stage of neutralization, alcohol and water are removed by flash evaporation. After the dealcoholization is completed, the ...

example 2

[0063] Take 300kg of solvent, 140kg of base oil, and 50kg of alcohol A into a 1000L reactor, stir for 20min to mix evenly. Finally, 10kg of calcium oxide and 10kg of water were added and stirred for 30 minutes. Take 150kg of alkylbenzene sulfonic acid whose carbon chain length is C22-C24, and add it dropwise at a uniform speed within 90-120 minutes, and the temperature is raised to 50-60°C. Then the temperature was raised to 70-75°C, neutralized for 2 hours, and the pH value of the neutralized reaction solution was recorded. After the first stage of neutralization, alcohol and water are removed by flash evaporation, and the temperature is lowered to 50-60°C. Add 50kg of alcohol B, 15kg of water, and 80kg of solvent, raise the temperature to 90-95°C, neutralize for 2 hours, and record the pH value of the neutralization reaction solution. After the second stage of neutralization, alcohol and water are removed by flash evaporation. After the dealcoholization is completed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com