Preparation method of composite calcium sulfonate antirust agent

A technology of composite calcium sulfonate and rust inhibitor, applied in lubricating compositions, petroleum industry and other directions, can solve the problems of poor use economy and high cost of dinonylnaphthalene sulfonic acid, achieve low production cost, high product yield, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

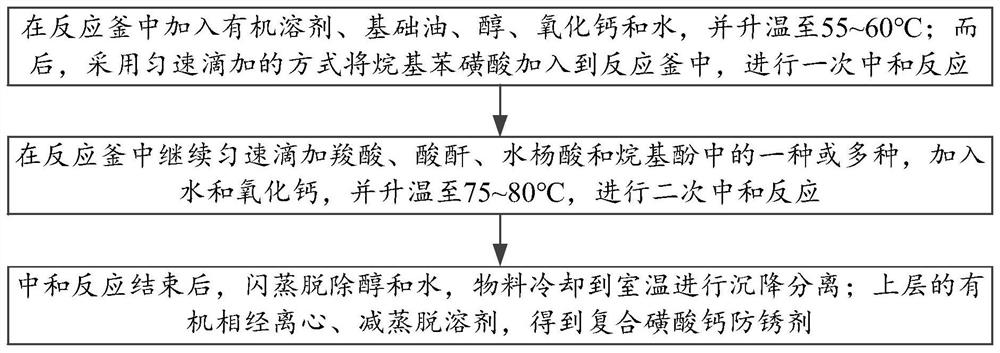

[0035] Such as figure 1 Shown, the invention provides a kind of preparation method of composite calcium sulfonate antirust agent, comprising:

[0036] Step 1. Under the condition of protective gas, add organic solvent, base oil, alcohol, calcium oxide and water into the reaction kettle, and raise the temperature to 55-60°C; then, add the alkylbenzene sulfonic acid by dropping at a constant speed In the reaction kettle, carry out a neutralization reaction; after reacting for 2 hours, use a pH meter to accurately measure the pH value of the reaction solution, so that the pH is controlled at >10;

[0037] in,

[0038] Preferably add organic solvent, base oil and alcohol to the reaction kettle first, stir and mix evenly, then add calcium oxide and water to the reaction kettle;

[0039] Preferred organic solvents include one or more of benzene, toluene, xylene, 120# solvent, 200# solvent, sherwood oil, n-hexane and n-heptane;

[0040] Preferred base oils include one or more of 1...

Embodiment 1

[0059] The present invention provides a kind of preparation method of composite calcium sulfonate antirust agent, comprising:

[0060] 1) Put 300kg of organic solvent, 140kg of base oil, and 50kg of alcohol into a 1000L reactor, stir for 20 minutes to mix evenly; then put in 10kg of calcium oxide, 10kg of water, and stir for 30 minutes; take 75kg of carbon chain length C18-C24 alkylbenzene The sulfonic acid was added dropwise at a uniform speed within 60-90min, and the temperature was raised to 55-60°C; the neutralization reaction was 2h, and the pH value of the neutralization reaction solution was recorded.

[0061] 2), after the first stage of neutralization, add 50kg of alkyl salicylic acid with a carbon chain length of C22-C24, 10kg of oleic acid, 10kg of maleic anhydride, 5kg of dodecylphenol, 5kg of water, and 2kg of calcium oxide in sequence. Raise the temperature to 75-80°C, neutralize for 2 hours, and record the pH value of the neutralization reaction solution.

[00...

Embodiment 2

[0065] The present invention provides a kind of preparation method of composite calcium sulfonate antirust agent, comprising:

[0066] 1) Put 300kg of organic solvent, 140kg of base oil, and 50kg of alcohol into a 1000L reactor, stir for 20 minutes to mix evenly; then put in 10kg of calcium oxide, 10kg of water, and stir for 30 minutes; take 75kg of carbon chain length C22~C24 alkylbenzene The sulfonic acid was added dropwise at a uniform speed within 60-90min, and the temperature was raised to 55-60°C; the neutralization reaction was 2h, and the pH value of the neutralization reaction solution was recorded.

[0067] 2), after the first stage of neutralization, add 50kg of alkyl salicylic acid with a carbon chain length of C22-C24, 10kg of oleic acid, 10kg of maleic anhydride, 5kg of dodecylphenol, 5kg of water, and 2kg of calcium oxide in sequence. Raise the temperature to 75-80°C, neutralize for 2 hours, and record the pH value of the neutralization reaction solution.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com