Corrugated plate carrying and mounting trolley

A technology for installing trolleys and corrugated plates, which is applied in the direction of hoisting devices, hoisting devices, portable hoisting devices, etc., can solve the problems of affecting the anti-rust ability, high labor intensity, and easy scratches, so as to reduce labor intensity and ensure anti-corrosion. Anti-rust ability, anti-collision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

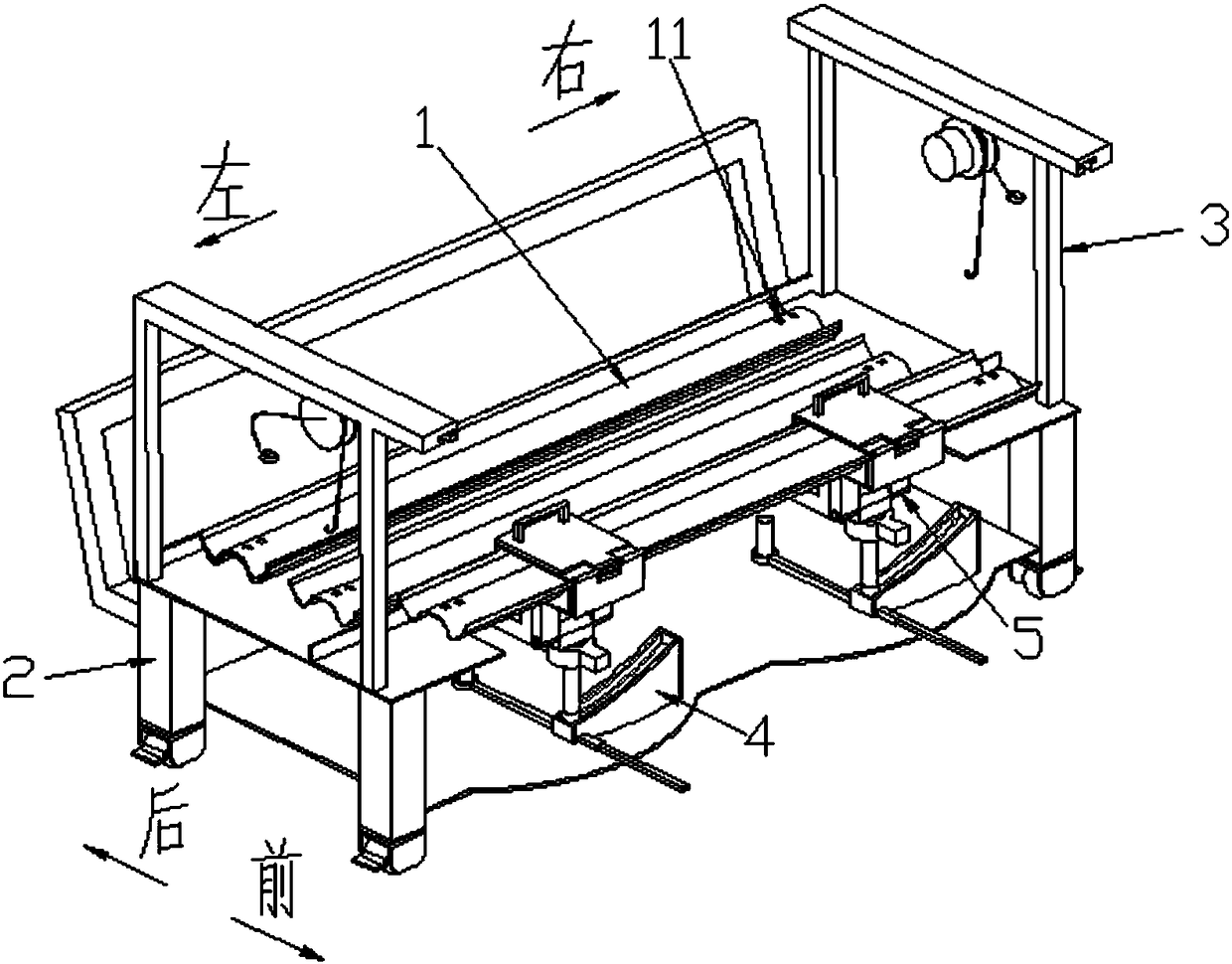

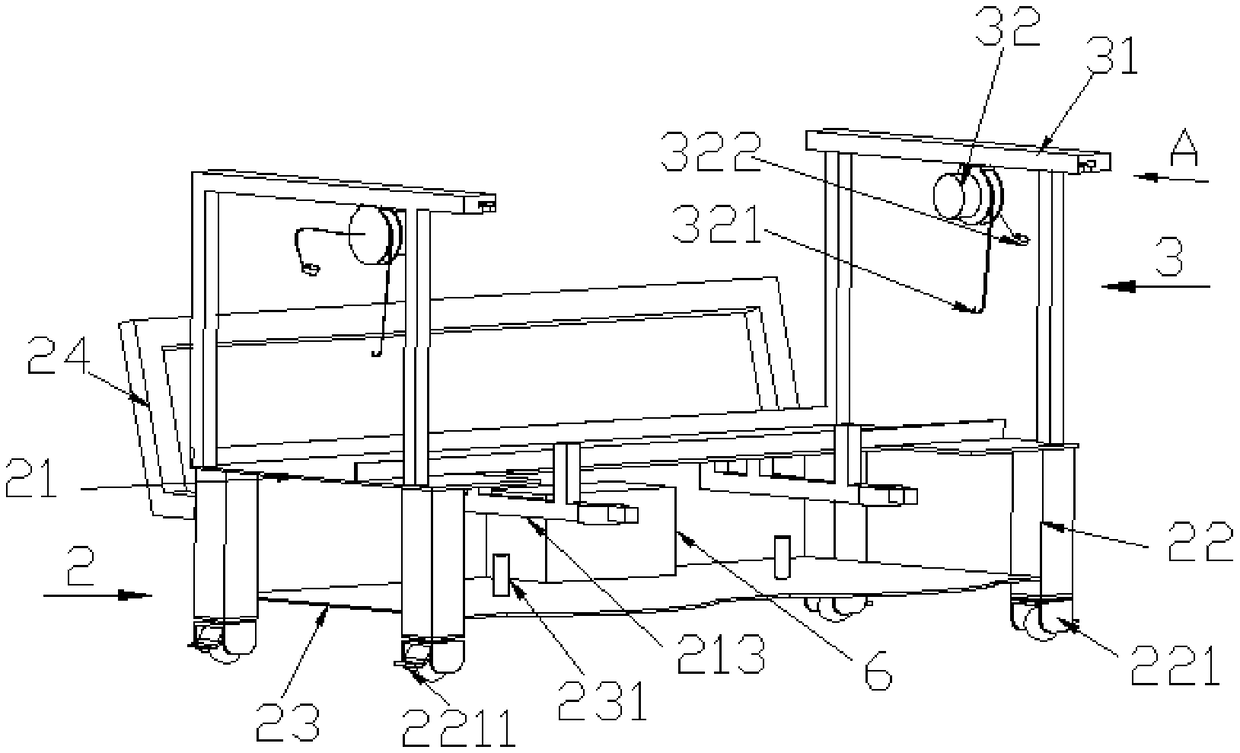

[0036] Such as Figure 1 to Figure 6 As shown, a corrugated plate handling and installation trolley includes a corrugated plate 1, a trolley frame 2, a lifting frame 3, an adjustment component 4, and a flipping component 5;

[0037] Mounting holes 11 are provided at both ends of the corrugated plate 1;

[0038] The trolley frame 2 includes a shelving platform 21, a supporting foot 22, a mounting plate 23, and a push handle 24;

[0039] The supporting feet 22 are arranged at the four corners below the shelving platform 21, the mounting plate 23 is located below the shelving platform 21 and is fixedly connected with the supporting feet 22; the push handle 24 is arranged behind the shelving platform 21 And be fixedly connected with the support foot 22;

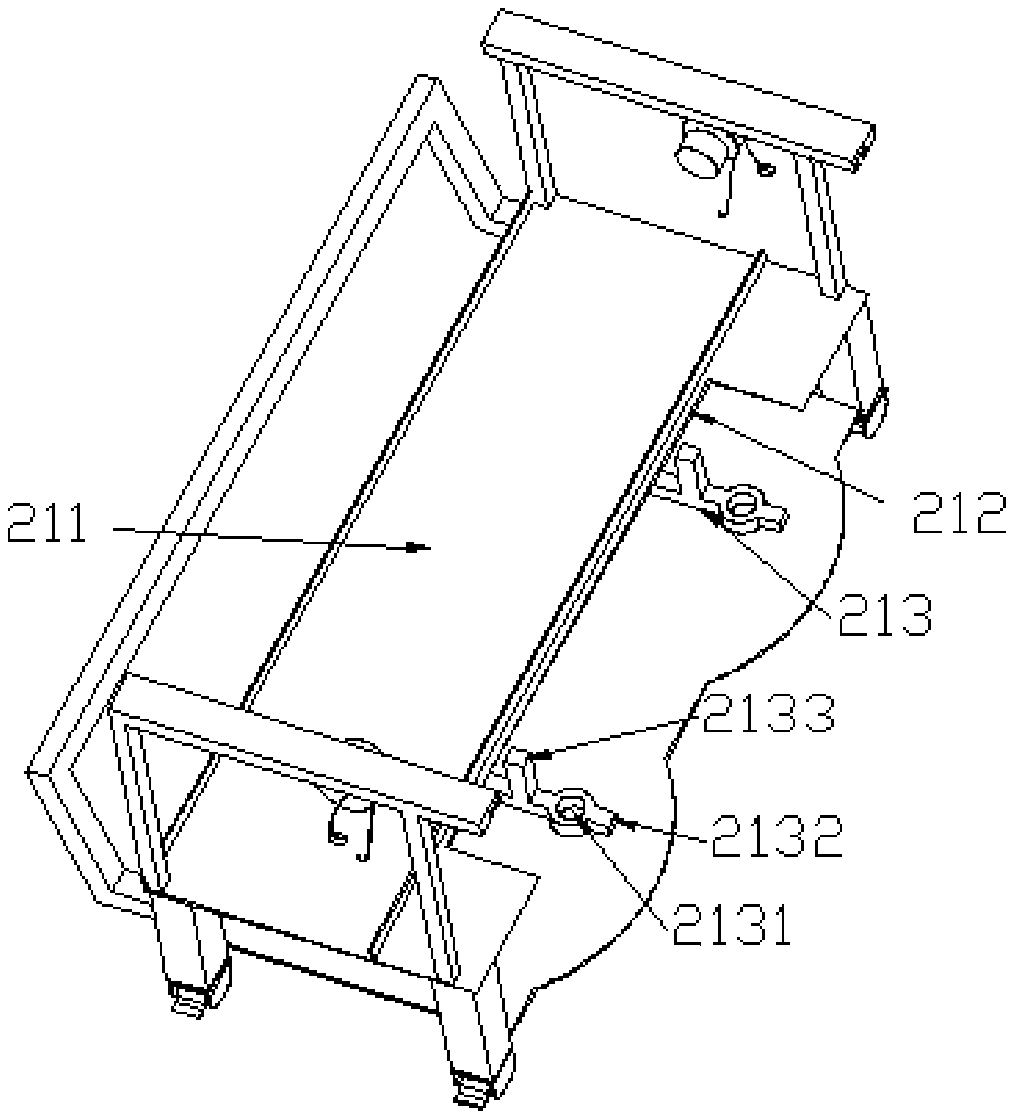

[0040] The rear part of the shelving platform 21 is a placement area 211, the corrugated board 1 is stacked in the placement area 211, and the front part of the shelving platform 21 has a notch 212; the lower part of the shelvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com