Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "Lanthanum fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum Fluoride is a water insoluble Lanthanum source for use in oxygen-sensitive applications, such as metal production. Fluoride compounds have diverse applications in current technologies and science, from oil refining and etching to synthetic organic chemistry and the manufacture of pharmaceuticals.

High-antiwear cutting fluid

InactiveCN104277900AImprove anti-wear performanceLow costLubricant compositionLanthanum fluoridePolyethylene glycol

The invention discloses a high-antiwear cutting fluid, which comprises the following raw materials in parts by weight: 10-25 parts of soybean oil, 5-15 parts of rapeseed oil, 8-25 parts of 2-ethylhexyl oleate, 15-30 parts of fatty alcohol-polyoxyethylene ether, 3-8 parts of disodium sulphonatoacetate, 1-5 parts of copper / silica composite nano materials, 5-12 parts of citric acid-modified lanthanum fluoride nanoparticles, 20-40 parts of an imidazoline-ammonium salt corrosion inhibitor, 3-15 parts of glycerin, 2-15 parts of triethanolamine, 2-6 parts of borax, 0.5-1.5 parts of benzotriazole, 8-20 parts of polyethylene glycol and 30-50 parts of water. The high-antiwear cutting fluid is excellent in antiwear, cooling, lubrication, cleaning and antirust functions, and is low in cost and strong in stability.

Owner:CHAOHU GUANGFENG METAL PROD

Optical element equipped with lanthanum fluoride film

InactiveUS20030227670A1Reduce optical loss of opticalSmall surface areaVacuum evaporation coatingSputtering coatingLanthanum fluorideCrystal growth

An optical element of the present invention comprises a fluorite substrate 1, and a lanthanum fluoride film 2 formed directly on the substrate 1. The substrate 1, on which the lanthanum fluoride film 2 is formed, has a plane which is a (111) plane or a plane inclined by an angle within ±30 degrees, preferably within 15 degrees from the (111) plane. Therefore, the lanthanum fluoride film undergoes the crystal growth subjected to the C-axis orientation on the optical substrate. Since the lanthanum fluoride film is dense and has a small surface area, it scarcely involves the oxidation and hydroxylation areas as well as the structural defect. Therefore, it is possible to reduce the optical loss of the optical element in the vacuum ultraviolet region.

Owner:NIKON CORP

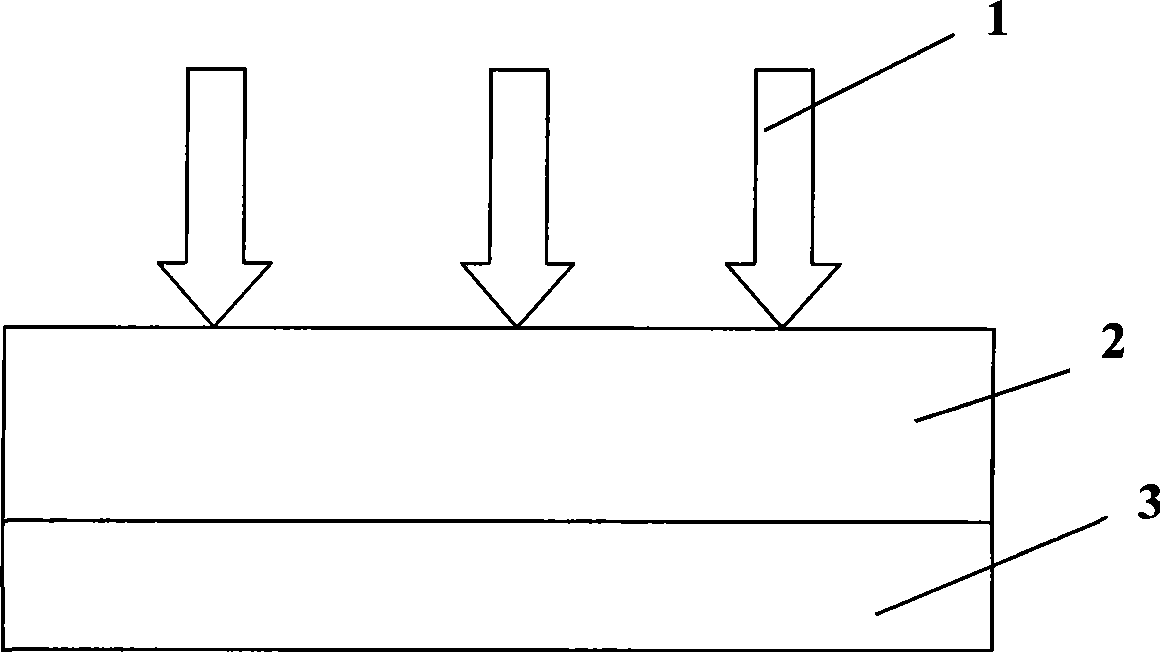

Up-conversion solar cell

InactiveCN101488533AWide spectral response rangeConvert morePhotovoltaic energy generationSemiconductor devicesSpectral responseLanthanum fluoride

The invention discloses an up-conversion solar cell, relating to a solar cell. The up-conversion silicon solar cell is a nano up-conversion luminescence layer (3) prepared with nano up-conversion luminescent materials by the method of carrying out spin coating or screen printing on the back surface of the silicon solar cell (2); sunlight (1) comes in from the front of the silicon solar cell (2). The materials of the nano up-conversion luminescence layer (3) are silicon dioxide-lanthanum fluoride nanocrystalline glass ceramics doped with erbium ions, or silicon dioxide-lanthanum fluoride nanocrystalline glass ceramics doped with both erbium ions and ytterbium ions or zinc sulfide doped with erbium ions. The nano luminescence layer is 0.5-2um thick. The up-conversion silicon solar cell can convert the low-energy photons which can not be effectively absorbed by the silicon solar cells to the high-energy photons which the silicon solar cells can respond to, thus expanding the spectral response range of the solar cells, improving the service efficiency of sunlight in unit area and lowering the cost.

Owner:BEIJING JIAOTONG UNIV

Preparation method of rare earth polishing powder

InactiveCN104017500AReduce consumptionReduce manufacturing costPolishing compositions with abrasivesLanthanum fluorideRare earth

The invention discloses a preparation method of rare earth polishing powder. The preparation method comprises the following steps of (1) precipitating mixed rare earth through an ammonium hydrogen carbonate and ammonia water mixed solution, ageing, and then, adding mixed fluorine-contained acid to fluorinate to obtain fluorinated alkaline rare earth carbonate, wherein mixed rare earth is cerium lanthanum chloride rare earth or cerium lanthanum chloride rare earth, and mixed fluorine-contained acid is mixed acid of hydrofluoric acid and fluosilicic acid; (2) carrying out multi-stage roasting on fluorinated alkaline rare earth carbonate obtained in the step (1) to obtain a mixed rare earth oxide, wherein the mixed rare earth oxide is an oxygen cerium fluoride and cerium oxide mixture or an oxygen cerium lanthanum fluoride and cerium oxide mixture; (3) smashing the mixed rare earth oxide obtained in the step (2), and grading to obtain the rare earth polishing powder with the particle size of 0.3-0.5mu m. The preparation method can be used for preparing ultrafine rare earth polishing powder which is capable of reaching the angstrom grade on a glass polished surface, uniform in dispersion and small in particle size.

Owner:山东麦丰新材料科技股份有限公司

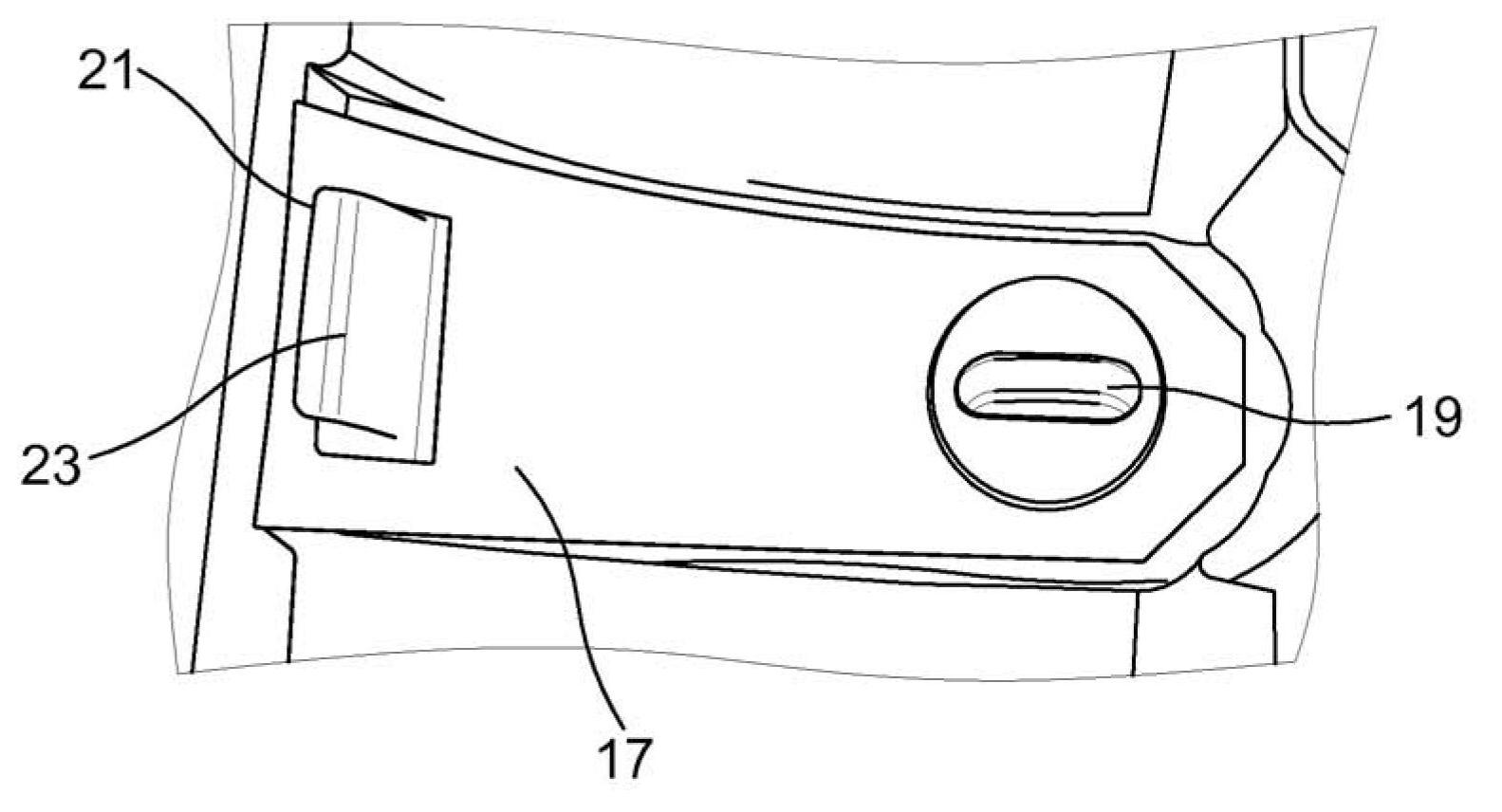

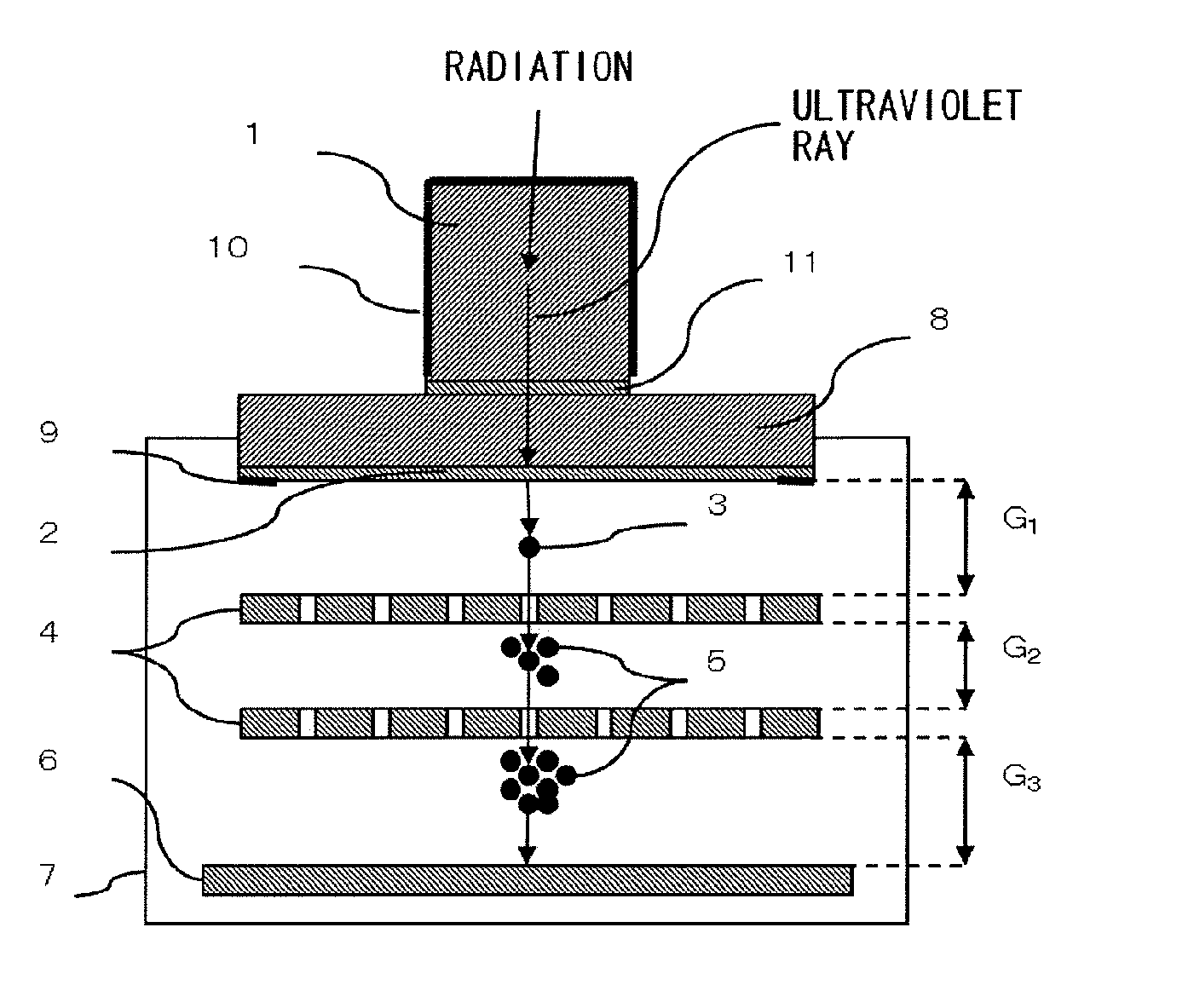

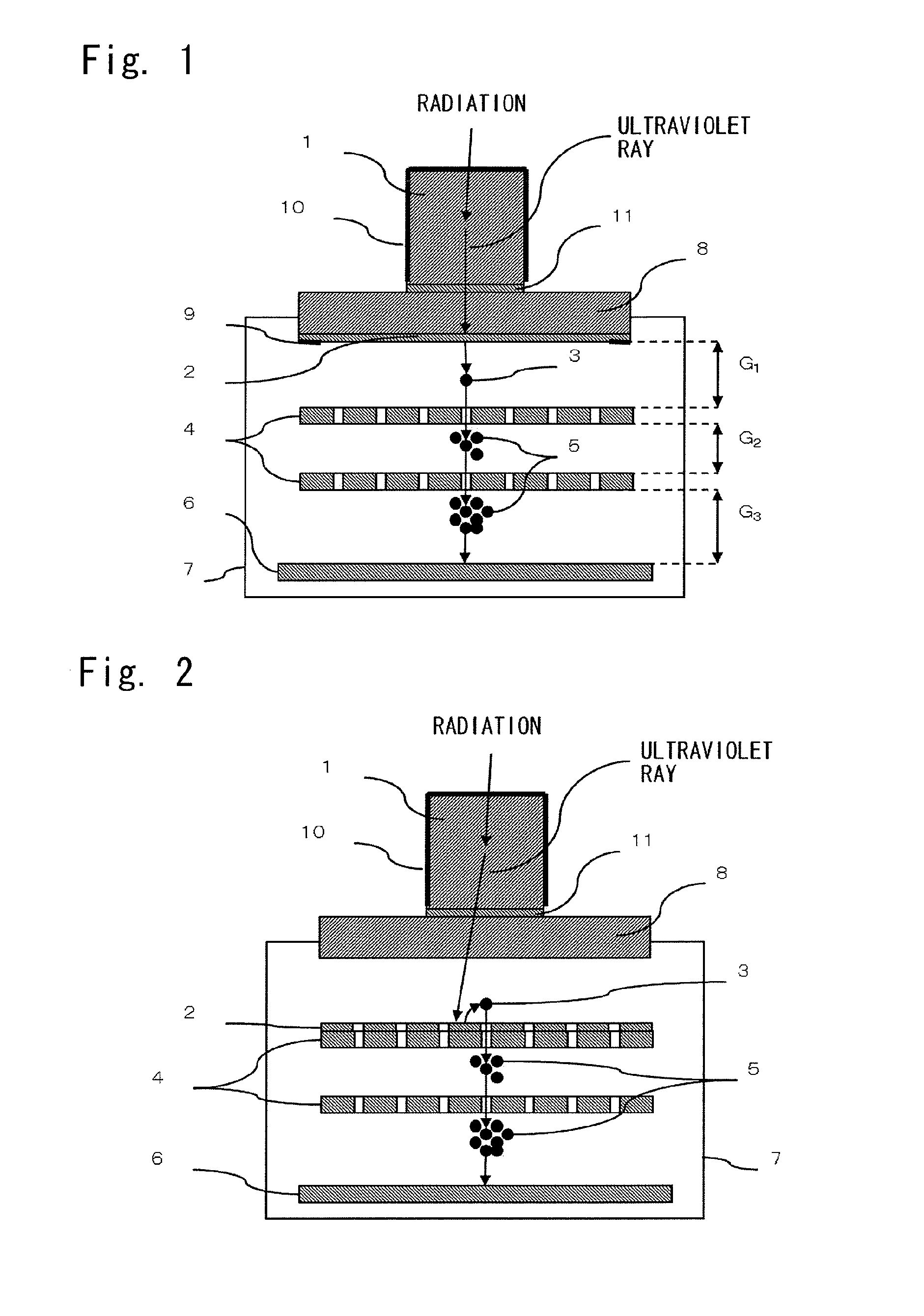

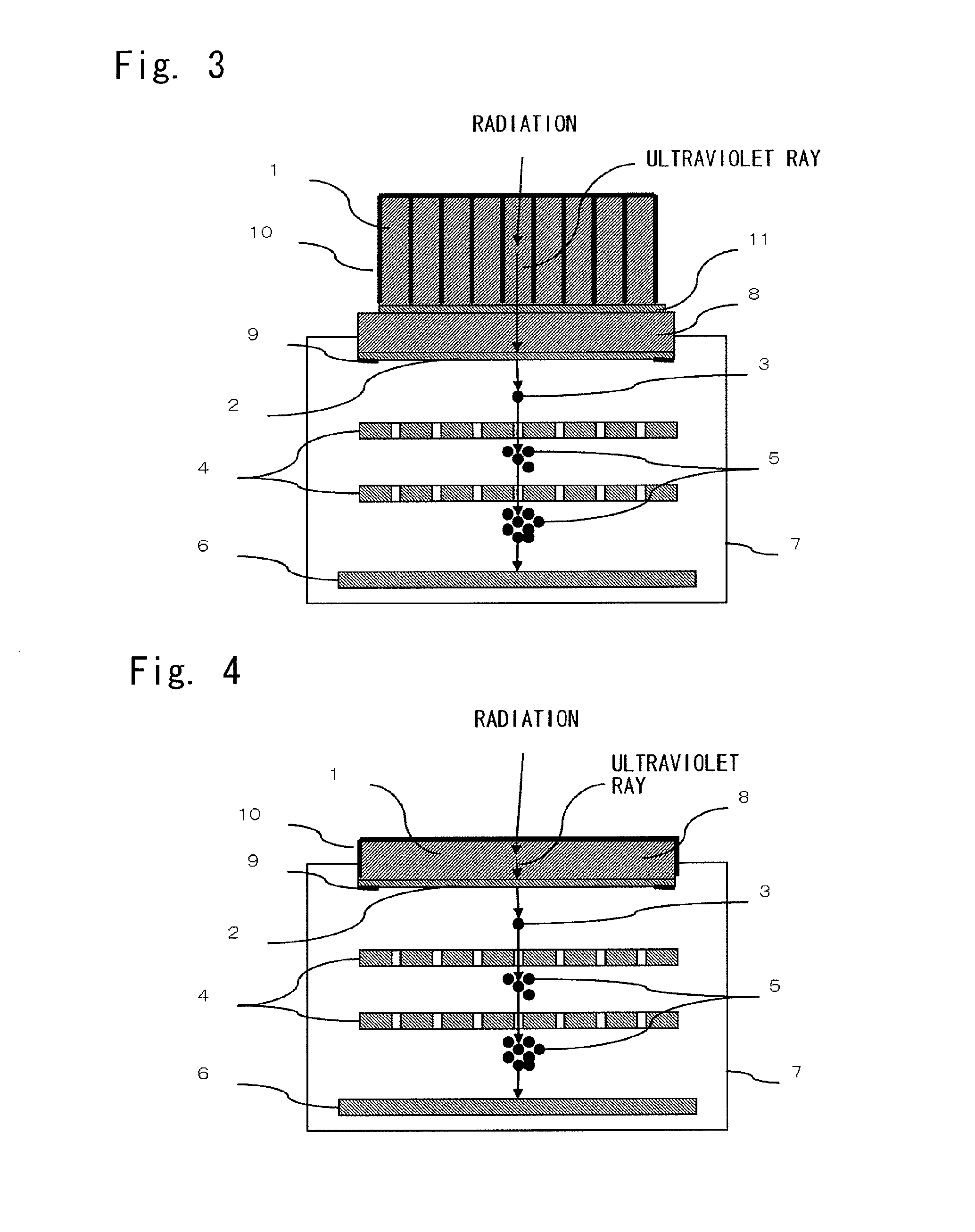

Radiographic image detector

InactiveUS20120018642A1High sensitivityExcellent in position resolutionCathode ray tubes/electron beam tubesSolid-state devicesHard X-raysLanthanum fluoride

[Problems to be Solved] It is an object of the present invention to provide a novel radiographic image detector which can detect radiation, such as hard X-rays or γ-rays, with high sensitivity and which is excellent in position resolution and count rate characteristic.[Means to Solve the Problems] A radiographic image detector comprises a combination of a scintillator, such as a lanthanum fluoride crystal containing neodymium, for converting incident radiation into ultraviolet rays; and a gas multiplication ultraviolet image detector for converting ultraviolet rays into electrons, amplifying such electrons by use of a gas electron avalanche phenomenon, and detecting the electrons. The radiographic image detector is characterized in that the gas multiplication ultraviolet image detector is basically constituted by a photoelectric conversion substance, such as cesium iodide or cesium telluride, for converting ultraviolet rays into electrons; a gas electron multiplier for amplifying electrons by use of the gas electron avalanche phenomenon; and a pixel electrode having an amplification function and a detection function.

Owner:TOKUYAMA CORP +3

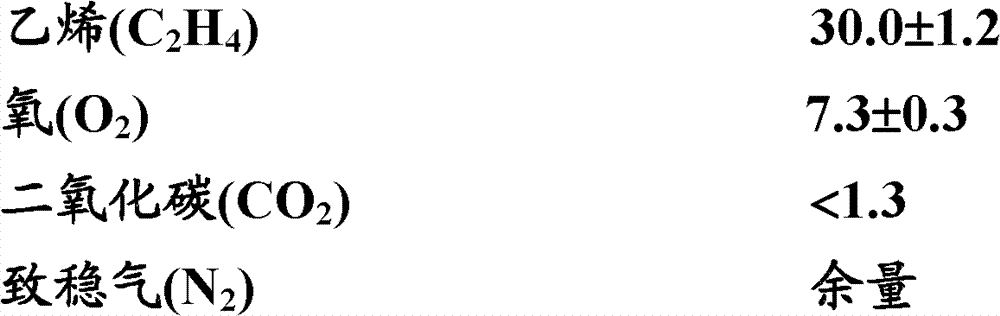

Modified alumina carrier, its preparation method, silver catalyst prepared from it, and its application in production of ethylene oxide

ActiveCN102950029AHigh activityImprove stabilityCatalyst carriersOrganic chemistryLanthanum fluorideEthylene Dibromide

The invention relates to a porous alumina carrier for a silver catalyst used in the production of ethylene oxide through ethylene epoxidation. The porous alumina carrier comprises 90wt% or more of alpha-alumina, and 0.01-1.0wt%, preferably 0.05-0.6wt% and most preferably 0.15-0.4wt% of a metallic lanthanum fluoride (by lanthanum) deposited on the surface of the carrier and the tunnel surfaces of the carrier. A supported silver catalyst prepared from the porous alpha-alumina carrier has a high catalytic activity and a high stability when the supported silver catalyst is used in the production of ethylene oxide through ethylene epoxidation. The invention also relates to a preparation method of the porous alumina carrier, the silver catalyst prepared from the porous alumina carrier, and an application of the porous alumina carrier in the production of ethylene oxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dense homogeneous fluoride films for DUV elements and method of preparing same

The invention is directed to optical elements that are coated with dense homogeneous fluoride films and to a method of making such coated elements. The coatings materials are a high (''H'') refractive index fluoride material and a low (''L'') refractive index material that are co evaporated to form a coating layer of a L-H coating material (a co deposited coating of L and H materials). Lanthanidemetal fluorides (for example, neodymium, lanthanum, dysprosium, yttrium and gadolinium, and combinations thereof) are preferred metal fluorides for use as the high refractive index materials with lanthanum fluoride (LaF3)and gadolinium fluoride (GdF3) being particularly preferred. Aluminum fluoride (AlF3) and alkaline earth metal fluorides (fluorides of calcium, magnesium, barium and strontium) are the preferred low refractive index materials, with magnesium fluoride (MgF2) being a preferred alkaline earth metal fluoride.

Owner:CORNING INC

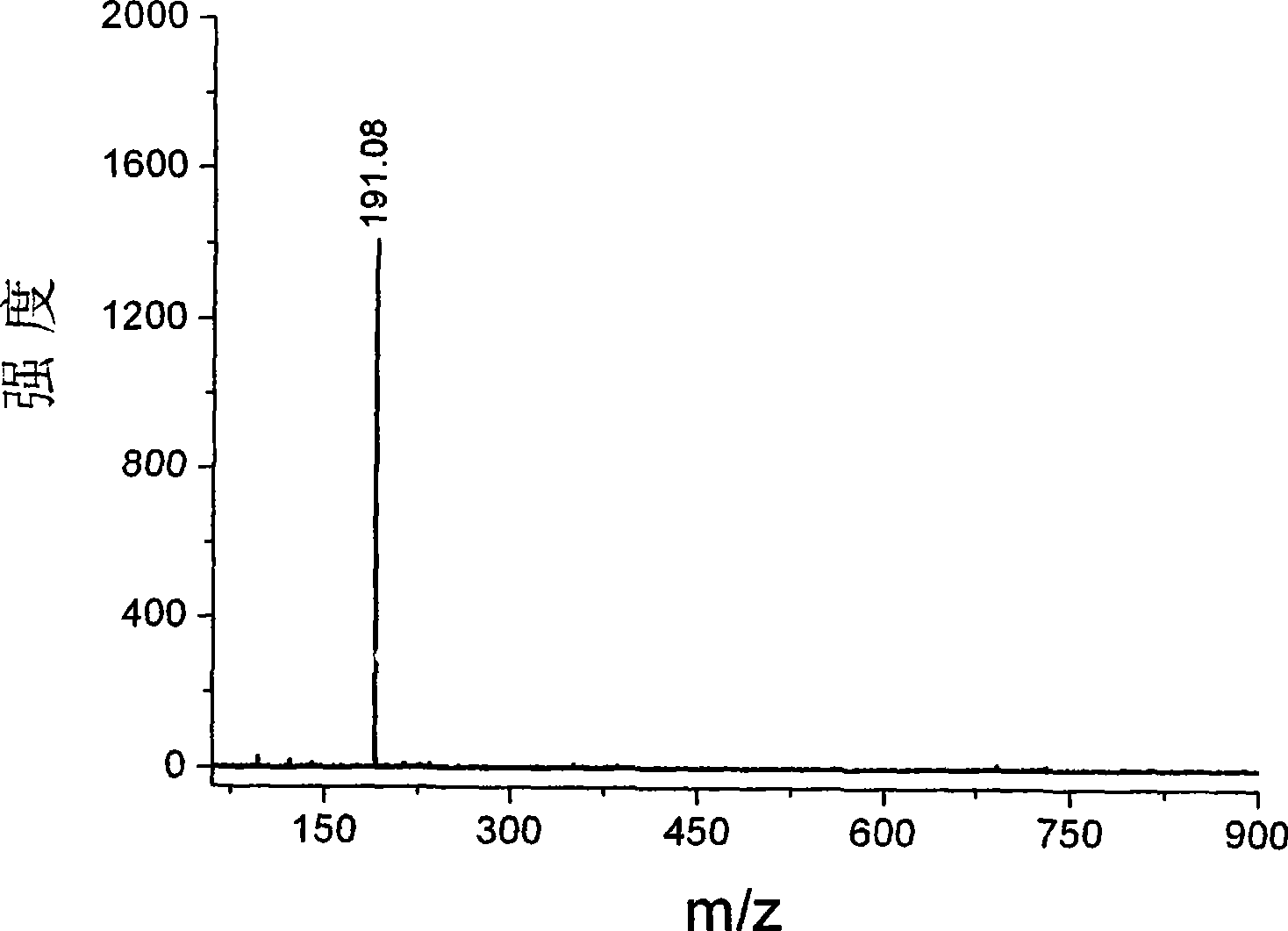

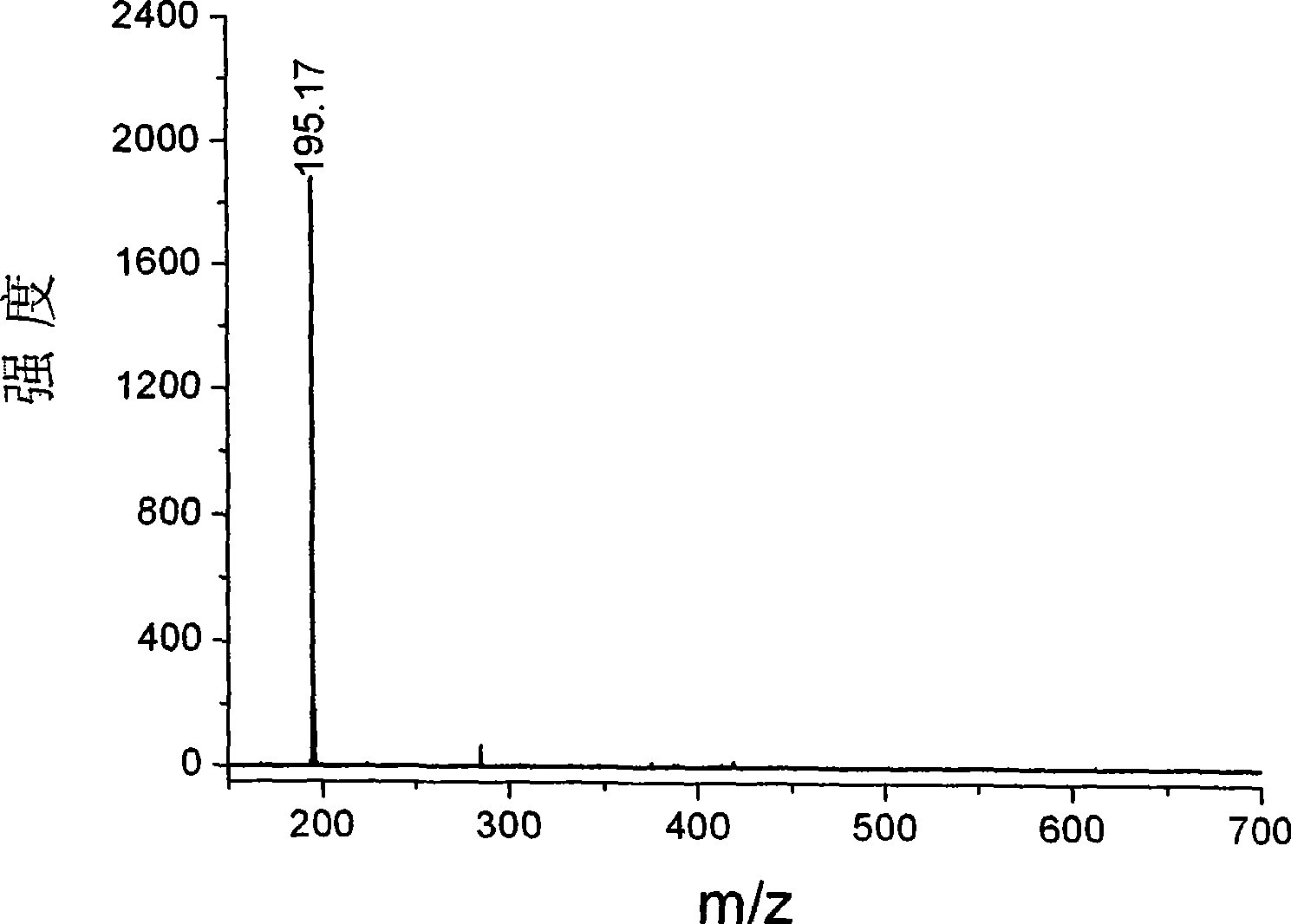

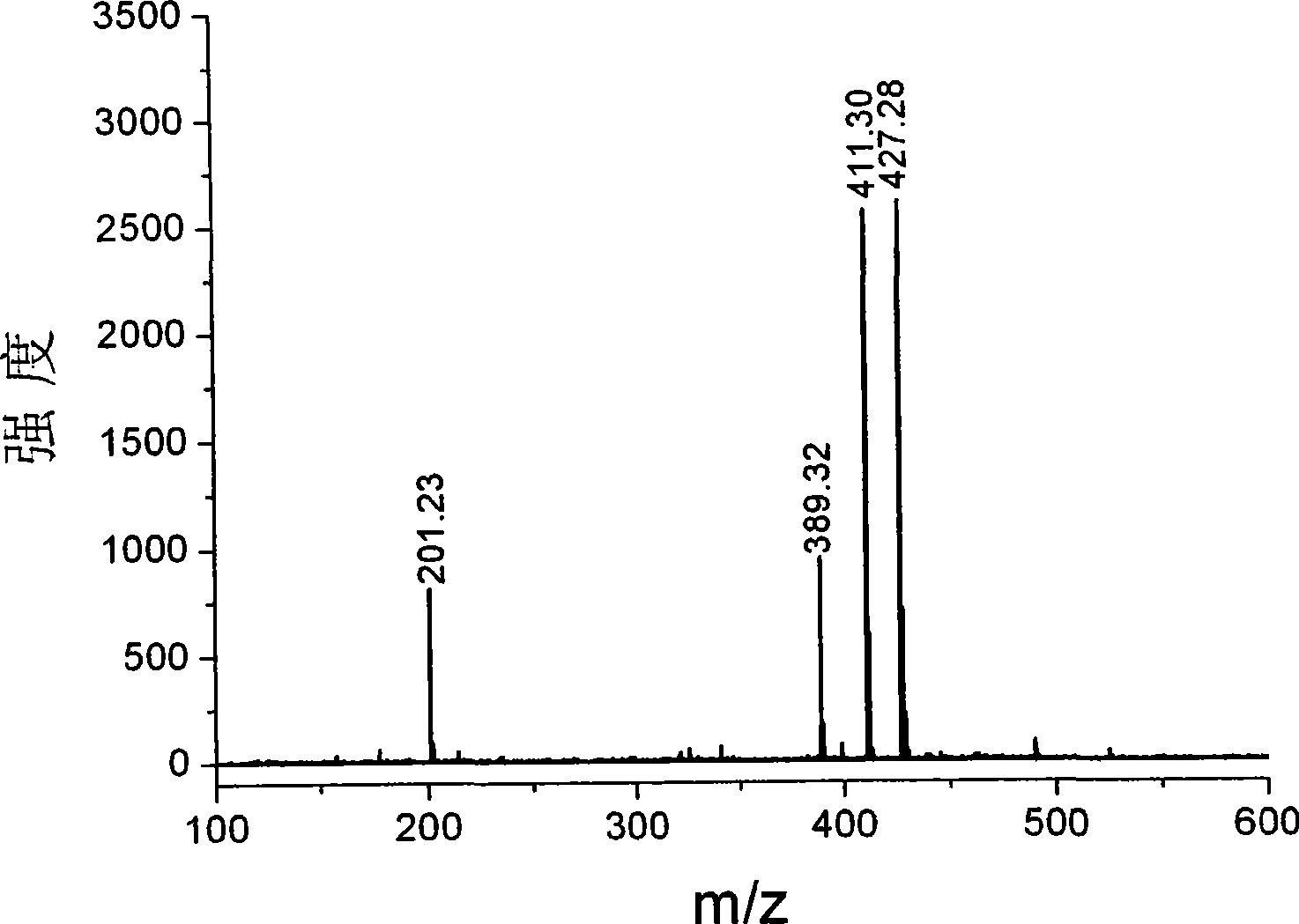

Use of rare earth fluoride nano material in MALDI-MS

InactiveCN101504387AEasy to prepareHigh yieldMaterial analysis by electric/magnetic meansCeriumTrifluoride

The invention relates to a matrix material for MALDI, in particular to application of fluoride nanometer materials as a matrix in MALDI-MS. The fluoride nanometer materials are nano-particles with various shapes of ytterbium trifluoride, lanthanum trifluoride, cerium trifluoride, praseodymium trifluoride, neodymium trifluoride, samarium trifluoride, europium trifluoride, gadolinium trifluoride, terbium trifluoride, dysprosium trifluoride, holmium trifluoride, erbium trifluoride, thulium trifluoride, ytterbium trifluoride or lutetium trifluoride, or nano-particles of trifluorides compounded byany two or more of ytterbium, lanthanum, cerium, praseodymium, neodymium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium or lutetium in any proportion. The invention takes rare earth fluoride nanometer materials as the matrix of the MALDI-MS for the first time, develops the matrix of the MALDI-MS with simple and convenient operation and strong universality, and realizes the quick and accurate analysis of the MALDI-MS.

Owner:NANJING UNIV

Method for preparing rare earth doped lanthanum fluoride luminous hollow nano powder by using multi-element solvothermal method

InactiveCN102093892AHigh degree of crystallizationUniform size distributionNanoopticsLuminescent compositionsFluorescenceLanthanum fluoride

The invention provides a method for preparing rare earth doped lanthanum fluoride luminous hollow nano powder by using a multi-element solvothermal method, belonging to the technical field of rare earth ion doped luminous nano powder preparation technology. The method is characterized by comprising the following steps: through preparing multi-element type solution of rare earth aurum nitrate, preparing a mixed polar solvent of deionized water, glycol and oleic acid at a mole ratio of 1:3:1; dissolving the rare earth oxides in nitric acid so as to obtain a nitrate mixture, wherein the rare earth oxides such as lanthana and any of teribium oxide or neodymium oxide are weighed according to the stoichiometry rate of a chemical molecular formula La(1-x)RExF3, and x is equal to 0.01-0.1; and adding the multi-element polar solvent in the nitrate mixture, and dropwise adding ammonium fluoride in the nitrate mixture, so as to obtain precursor turbid liquid, subsequently putting the precursor turbid liquid in a high pressure kettle for solvothermal treatment reaction, thus lanthanum fluoride luminous hollow nano powder is generated through a dissolution-recrystallization process of precursor rare earth fluoride. A test indicates that the powder has good fluorescent characteristic spectrum.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

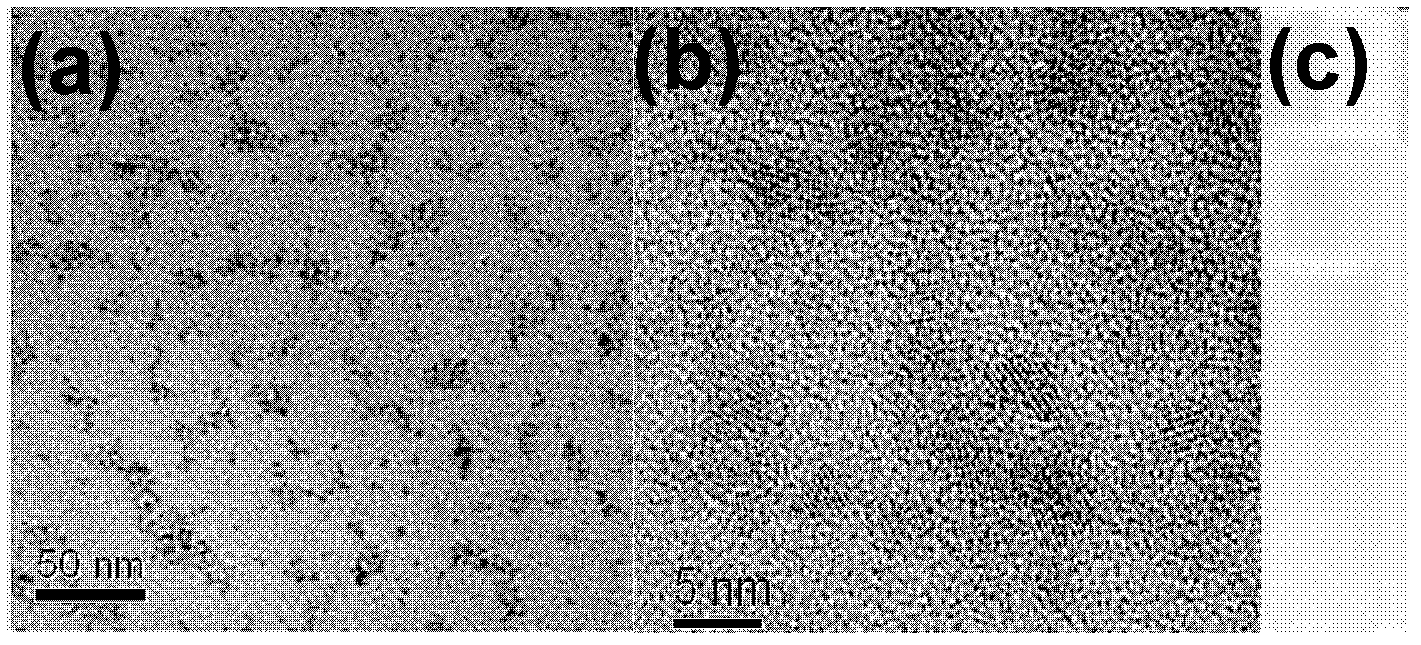

Method for synthesizing amino functionalized rare earth-doped lanthanum fluoride nano fluorescent marker material

InactiveCN102676171AGood water solubilitySimple preparation equipmentFluorescence/phosphorescenceLuminescent compositionsLanthanum fluorideActive agent

The invention relates to a method for synthesizing an amino functionalized rare earth-doped lanthanum fluoride nano fluorescent marker material, which comprises the steps of: with phosphorylethanolamine as a surface active agent, mixing sodium fluoride, lanthanum nitrate and rare earth nitrate in distilled water, carrying out heat preservation at the temperature of 30-90 DEG C, and stirring for a period of time, washing and drying to obtain the aminated rare earth-doped lanthanum fluoride nanocrystalline with the component of xLn<3+>-(1-x) LaF3, wherein Ln<3+>=Ce<3+>, Yb<3+>, Er<3+>, Tm<3+>, Ho<3+>, Eu<3+>, Gd<3+>, Tb<3+>, Dy<3+>, Sm<3+>, Nd<3+> and Pr<3+>, and x=0-50mol%. The rare earth-doped LaF3 nano fluorescent marker material prepared by the method has the advantages that the size of nanoparticles can be controlled to be about 5nm, water solubility is good and the surface amino can be used to realize the connection with biomolecule. Furthermore, different rare earth ions can be doped into the nanoparticles, so that the specific fluorescence emission can be realized so that the biological connection can be detected sensitively; and the nano fluorescent marker material prepared by the method has the potential in application in the biological marking field.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

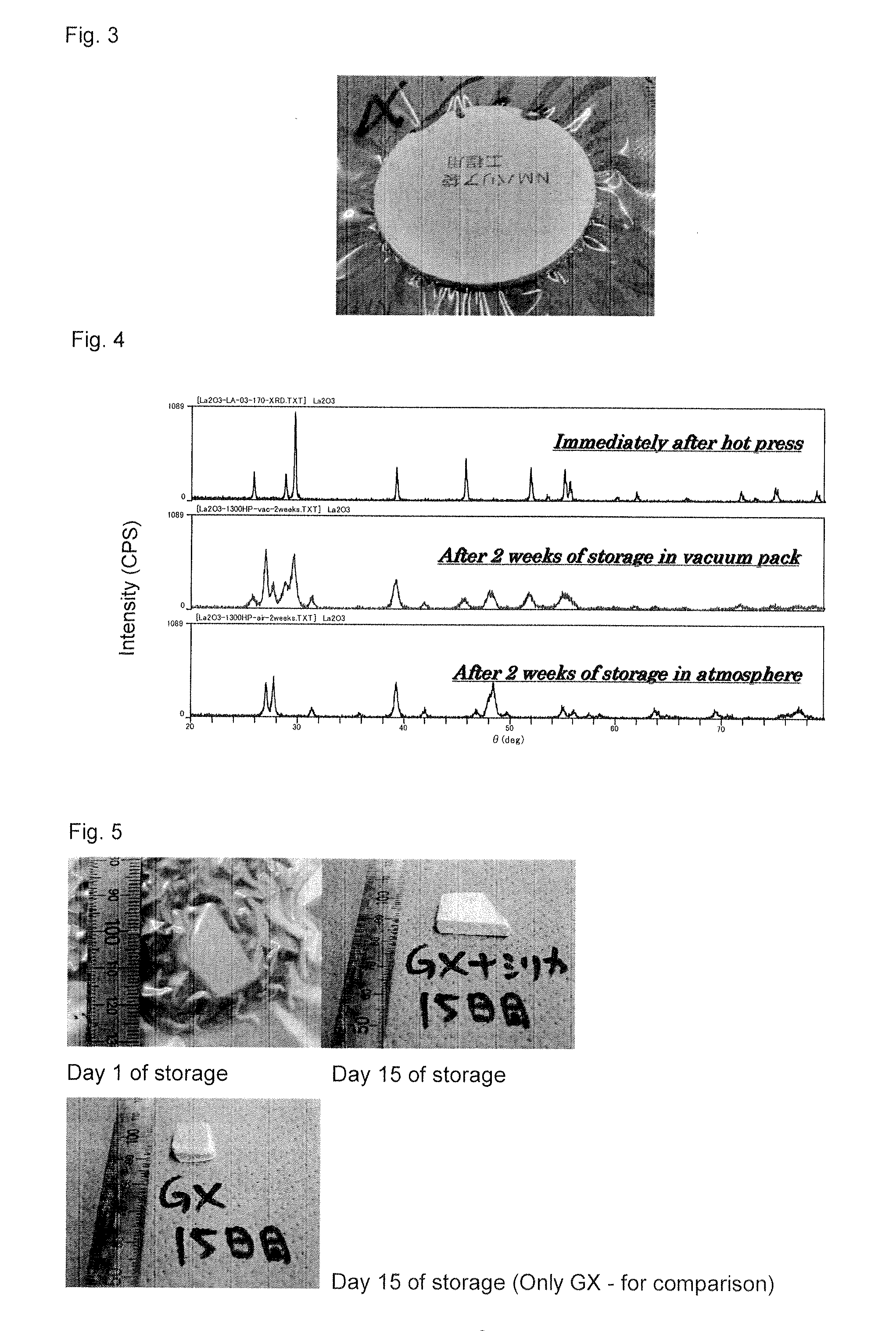

Method of Storing Lanthanum Oxide Target, and Vacuum-Sealed Lanthanum Oxide Target

A method of storing a sputtering target made of lanthanum oxide, wherein a lanthanum oxide target to which a lanthanum fluoride film was formed and lanthanum oxide powder are charged in a vacuum pack with an oxygen transmission rate of 0.1 cm3 / m2 per 24 h at 1 atm or less and a moisture vapor transmission rate of 0.1 g / m2 per 24 h or less, and, after charging the target and the powder, the vacuum pack is subject to vacuum suction and sealing for storage. This invention aims to provide technology for enabling the long-term storage of a sputtering target in a usable state by devising the method of storing a target made of an oxide of lanthanum as a rare earth metal, and thereby inhibiting the pulverization phenomenon of the target caused by the hydration (hydroxylation) of such target due to residual air or the inclusion of air, and the pulverization phenomenon caused by the formation of carbonate.

Owner:JX NIPPON MINING & METALS CO LTD

Self-lubricating friction-reducing ceramic coated ring and preparation process thereof

InactiveCN108866697AReduce coefficient of frictionHigh surface hardnessMolten spray coatingElectrophoretic coatingsEpoxyLanthanum fluoride

Disclosed are a self-lubricating friction-reducing ceramic coated ring and a preparation process thereof. The self-lubricating friction-reducing ceramic coated ring is composed of a metal ring body, a100-200 mu m internal reinforcing layer, a 350-400 mu m heat-resistant thermal insulating layer and a 500-600 mu m external friction-reducing layer, wherein the internal reinforcing layer is composedof 40-60% of tungsten carbide, 30-40% of boron carbide and 10-20% of chromium carbide; the heat-resistant thermal insulating layer is composed of 35-50% of silicon dioxide hollow microspheres, 30-35%of zirconium oxide hollow microspheres and 20-25% of liquid silicon rubber; the external friction-reducing layer is composed of 50-60% of polytetrafluoroethylene, 10-20% of silicone-modified epoxy resin, 1-5% of polyoxymethylene, 12-18% of silicon nitride, 4-8% of graphene fluoride, 2-6% of molybdenum disulfide and 1-3% of lanthanum fluoride. By means of a three-layer coating structural design, the self-lubricating friction-reducing ceramic coated ring achieves ultrahigh surface hardness and coating-ring bonding strength, improves surface self-lubricating properties, is low in friction coefficient in high-speed spinning and well meets the use requirements of high-end compact spinning and siro compact spinning.

Owner:无锡市求实纺织专件有限公司

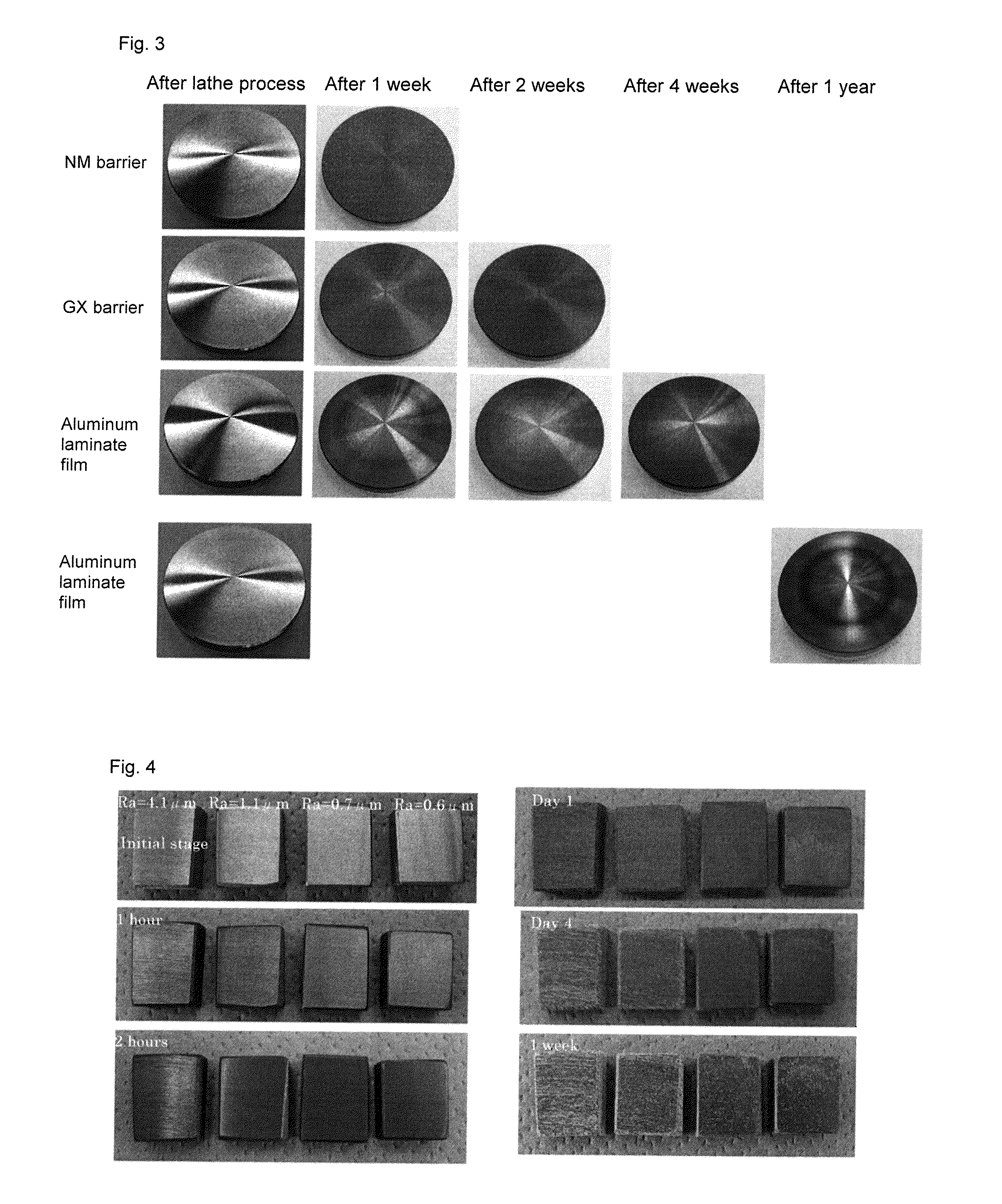

Method of Storing Metal Lanthanum Target, Vacuum-sealed Metal Lanthanum Target, and Thin Film Formed by Sputtering the Metal Lanthanum Target

A method of storing a metal lanthanum sputtering target, wherein a surface of a metal lanthanum target to be stored is processed so as to achieve a roughness Ra of 1 μm or less, a lanthanum fluoride coating is formed on the surface thereof, the metal lanthanum target to which the lanthanum fluoride coating was formed is subsequently charged in a vacuum pack with an oxygen transmission rate of 0.1 cm3 / m2 per 24 h at 1 atm or less and a moisture vapor transmission rate of 0.1 g / m2 per 24 h or less, and the vacuum pack is thereafter subject to vacuum suction and sealing for storage. This invention aims to provide technology for enabling the long-term storage of a sputtering target in a usable state by devising the method of storing a metal lanthanum target as a rare earth metal, and thereby inhibiting the degradation phenomenon caused by the oxidation of the target due to residual air or the inclusion of air.

Owner:JX NIPPON MINING & METALS CORP

Optical waveguide[[s]] and optical fiber perform including gallium, lanthanum, sulfur, oxygen, and fluorine

InactiveUS7016593B2Improve thermal stabilityImprove propertiesGlass making apparatusCladded optical fibreGallium sulfideLanthanum fluoride

An optical waveguide includes a clad of clad glass and a core of core glass. The clad glass includes gallium, lanthanum, and sulfur. The clad glass may include gallium sulfide and lanthanum oxide. The clad glass may also include lanthanum fluoride. The core glass includes gallium, lanthanum, sulfur, oxygen, and fluorine. The core glass may include gallium sulfide, lanthanum oxide, and lanthanum fluoride. An optical fiber perform is also disclosed.

Owner:UNIV OF SOUTHAMPTON

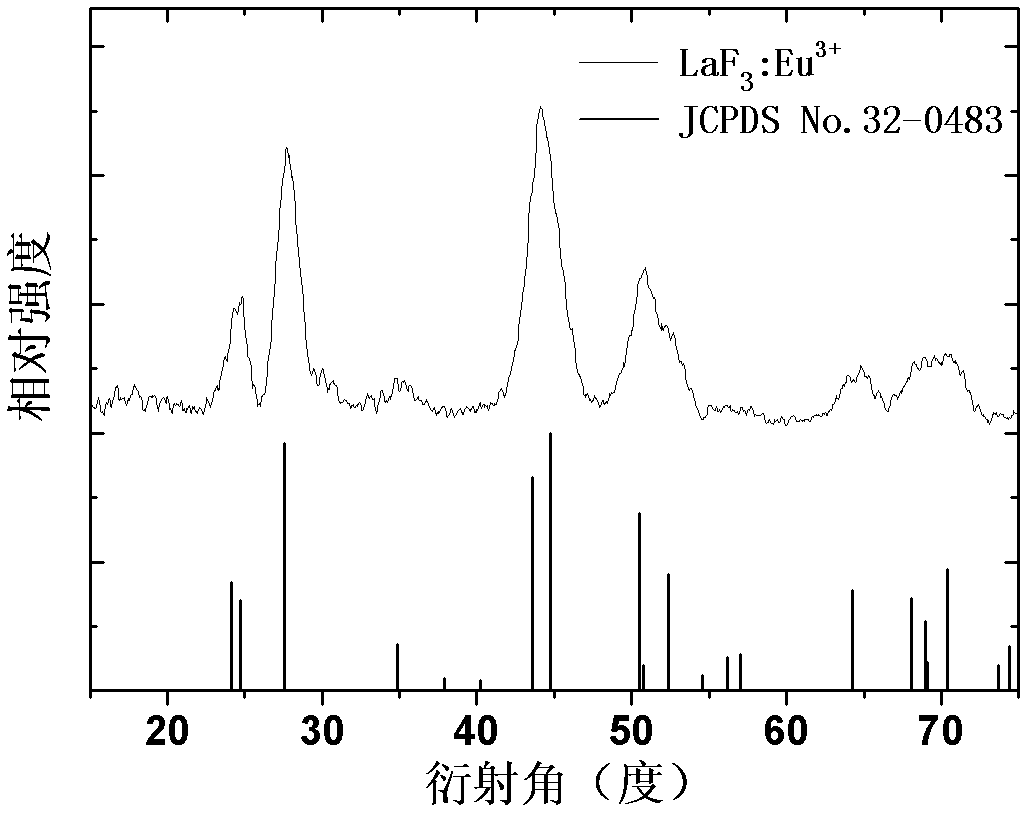

Method for preparing europium-doped lanthanum fluoride porous nanospheres by using herring sperm deoxyribonucleic acid (DNA) as template

InactiveCN102078785AMicroballoon preparationMicrocapsule preparationHerring sperm DNALanthanum fluoride

The invention relates to a method for preparing europium-doped lanthanum fluoride porous nanospheres by using herring sperm deoxyribonucleic acid (DNA) as a template, and belongs to the technical field of nano material preparation. The method comprises the following three steps of: (1) preparing mixed solution, namely dissolving Eu2O3 in nitric acid, evaporating to obtain a Eu(NO3)3 crystal, adding deionized water and La(NO3)3.6H2O to obtain mixed solution of La(NO3)3 and Eu(NO3)3 (the europium nitrate accounts for 5 mole percent), and dripping herring sperm DNA aqueous solution into the mixed solution of La(NO3)3 and Eu(NO3)3 to form mixed solution of La(NO3)3, Eu(NO3)3 and herring sperm DNA; (2) preparing LaF3:5 percent Eu<3+> precipitates, namely dripping NH4F aqueous solution into the mixed solution to obtain the LaF3:5 percent Eu<3+> precipitates; and (3) preparing LaF3:5 percent Eu<3+> porous nanospheres, namely transferring the LaF3:5 percent Eu<3+> precipitates to a hydrothermal reaction kettle, reacting at the temperature of 160 DEG C for 12 hours, performing centrifugal separation on precipitates, washing by using absolute ethanol, and performing vacuum drying at the temperature of 60 DEG C for 24 hours to obtain the LaF3:5 percent Eu<3+> porous nanospheres with good crystal forms and the diameter of 40 to 70nm. The method is simple, practicable, economic and environmental-friendly, and has a wide application prospect.

Owner:CHANGCHUN UNIV OF SCI & TECH

Metal parts wear surface on-line strengthening repair material and preparation thereof

InactiveCN101348908BImprove wear resistanceHigh hardnessMetallic material coating processesAdditivesLanthanum fluorideRare earth

The invention relates to an on-line strengthening repair material for the worn surfaces of metal parts, as well as a preparation method thereof. The components in percentage by weight of the repair material consist of 30 to 60 percent of serpentine mineral micro-powder, 5 to 10 percent of ulexite mineral micro-powder, 5 to 10 percent of lanthanum fluoride rare earth, 2 to 5 percent of iron oxide micro-powder, 2 to 5 percent of alumina micro-powder and 40 to 50 percent of sorbitan mono-palmitate. The preparation method comprises the following steps that: the well proportioned raw materials areput into a high-speed stirrer to be stirred for one hour, and then is ground for four hours by a high-speed ball mill so as to acquire powder with the particle size less than one micron, thus the on-line strengthening repair material for the worn surfaces of metal parts is formed. The invention also discloses a method for using the material. The on-line strengthening repair material for the worn surface of metal parts can form high-hardness surface modified strengthening repair layers on the worn surfaces of metal parts, realize the non-disassembly maintenance of machinery, remarkably improvethe wear resistance of parts and prolong the life span of equipment.

Owner:海秋(北京)新材料技术股份有限公司

Infrared colorful false proof material and preparation method thereof

InactiveCN101058707AWide spectral rangeHigh fluorescence brightnessOther chemical processesInorganic pigment treatmentFluorescenceLanthanum fluoride

The invention discloses an infrared colorful false proof material and making method, which comprises the following steps: selecting certain proportional alumina, lead fluoride, beryllium fluoride, calcium fluoride, strontium fluoride, lanthanum fluoride, europium trioxide, samarium trioxide, thulium trioxide and gadolinium trioxide as raw materal; blending these raw materials; grinding; heating; insulating; heating again; quenching; cooling; grinding; packing. The spectral scale is broad to form 3-6 different colorful fluorescences stimulated by laser at 960nm, which is fit for falseproof marking material.

Owner:龙彪

Novel hermetically-coated optical fiber

The invention discloses a novel hermetically-coated optical fiber. The novel hermetically-coated optical fiber comprises an optical fiber body and a coated layer, wherein the outer surface of the optical fiber body is coated with the coated layer. The optical fiber body is prepared from the following materials in parts by mass: 100 parts of silicon dioxide, 20 to 30 parts of germanium dioxide, 5 to 8 parts of sodium oxide, 5 to 8 parts of boric oxide, 5 to 8 parts of potassium oxide, 5 to 8 parts of aluminum oxide, 5 to 8 parts of magnesium oxide, 5 to 8 parts of calcium oxide, 3 to 6 parts of zirconium fluoride, 3 to 6 parts of barium fluoride, 3 to 6 parts of lanthanum fluoride, 3 to 6 parts of aluminum fluoride, 3 to 6 parts of sodium fluoride, 2 to 10 parts of silicon hydroxide and 2 to 7 parts of phosphorus pentoxide. Thus, the novel hermetically-coated optical fiber has the advantages of novel structure, sturdiness, durability, rapid transmission rate, small loss, good heat resistance, good environmental adaptability, safety, reliability, long service life and the like. The novel hermetically-coated optical fiber has a wide market prospect for popularization.

Owner:徐州博创建设发展集团有限公司

Abrasion-resistant, anti-drag and damaged surface repair agent for metal and preparation method thereof

The invention belongs to the field of repair agents for surface of metal and in particular relates to an abrasion-resistant, anti-drag and damaged surface repair agent for metal and a preparation method thereof. The repair agent includes, by mass, 2-40% of abrasion-resistant repair powder, 45-95% of lubricating oil and 3-20% of random polyether, and a hexahydric composite emulsifier can also be added, wherein the abrasion-resistant repair powder comprises, by mass, 5-35% of organic molybdenum, 20-60% of lanthanum fluoride, 2-28% of nickel powder, 5-30% of silicon dioxide powder and 3-15% of boron nitride powder. The preparation method includes grinding the lubricating oil, the abrasion-resistant repair powder and the random polyether according to the ratio after even mixing, adding the hexahydric composite emulsifier, and evenly mixing to obtain the repair agent. According to the repair agent, abrasion due to friction can be reduced, the repair function of damaged surfaces is provided, using accuracy and reliability of equipment can be improved, energy and electricity can be saved, and the service life of the equipment can be prolonged.

Owner:兴友新材料科技(山东)有限公司

Metal parts wear surface on-line strengthening repair material and preparation thereof

InactiveCN101348908AImprove wear resistanceHigh hardnessMetallic material coating processesAdditivesLanthanum fluorideRare earth

The invention relates to an on-line strengthening repair material for the worn surfaces of metal parts, as well as a preparation method thereof. The components in percentage by weight of the repair material consist of 30 to 60 percent of serpentine mineral micro-powder, 5 to 10 percent of ulexite mineral micro-powder, 5 to 10 percent of lanthanum fluoride rare earth, 2 to 5 percent of iron oxide micro-powder, 2 to 5 percent of alumina micro-powder and 40 to 50 percent of sorbitan mono-palmitate. The preparation method comprises the following steps that: the well proportioned raw materials are put into a high-speed stirrer to be stirred for one hour, and then is ground for four hours by a high-speed ball mill so as to acquire powder with the particle size less than one micron, thus the on-line strengthening repair material for the worn surfaces of metal parts is formed. The invention also discloses a method for using the material. The on-line strengthening repair material for the worn surface of metal parts can form high-hardness surface modified strengthening repair layers on the worn surfaces of metal parts, realize the non-disassembly maintenance of machinery, remarkably improve the wear resistance of parts and prolong the life span of equipment.

Owner:海秋(北京)新材料技术股份有限公司

Production Method for High-Purity Lanthanum, High-Purity Lanthanum, Sputtering Target Composed of High-Purity Lanthanum, and Metal Gate Film Containing High-Purity Lanthanum as Main Component

ActiveUS20130241010A1Effect of stably providingImprove stabilityCellsVacuum evaporation coatingRare-earth elementLanthanum fluoride

A method for producing high-purity lanthanum having a purity of 4N or more excluding rare earth elements other than lanthanum and gas components, wherein lanthanum having a purity of 4N or more is produced by reducing, with distilled calcium, a lanthanum fluoride starting material that has a purity of 4N or more excluding rare earth elements other than lanthanum and gas components, and the obtained lanthanum is subjected to electron beam melting to remove volatile substances. The method for producing high-purity lanthanum, in which Al, Fe, and Cu are respectively contained in the amount of 10 wtppm or less. The method for producing high-purity lanthanum, in which total content of gas components is 1000 wtppm or less. The present invention aims to provide a technique capable of efficiently and stably providing high-purity lanthanum, a sputtering target composed of high-purity lanthanum, and a thin film for metal gate that contains high-purity lanthanum as a main component.

Owner:JX NIPPON MINING& METALS CORP

Praseodymium-holmium-codoped lanthanum fluoride up-conversion luminescence material, and preparation method and application thereof

InactiveCN103571491ASolid-state devicesSemiconductor/solid-state device manufacturingHolmiumLanthanum fluoride

The invention provides a praseodymium-holmium-codoped lanthanum fluoride up-conversion luminescence material. The chemical formula of the praseodymium-holmium-codoped lanthanum fluoride up-conversion luminescence material is LaF3:xPr3+,yHo<3+>, wherein x is 0.002-0.06, and y is 0.002-0.04. The praseodymium-holmium-codoped lanthanum fluoride up-conversion luminescence material can be excited through long wave radiation to emit blue light. The invention also provides a preparation method of the praseodymium-holmium-codoped lanthanum fluoride up-conversion luminescence material, and an application of the praseodymium-holmium-codoped lanthanum fluoride up-conversion luminescence material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Full-spectrum response double-doped lanthanum fluoride/attapulgite upconverting composite photocatalytic material and preparation method and application thereof

ActiveCN109158117AReduce compoundingBroaden the photoresponse rangePhysical/chemical process catalystsWater/sewage treatment by irradiationMicrowaveLight irradiation

The invention belongs to the field of photocatalytic materials, and particularly relates to a double-doped lanthanum fluoride / attapulgite upconverting composite photocatalytic material and a preparation method and application thereof. The preparation method comprises the following steps: adding La(NO3)3.6H2O, Tm(NO3)3.6H2O, Yb(NO3)3.5H2O, NH4F and hydrochloric acid-modified ATP into deionized water respectively for dissolving, magnetically stirring for 30min for fully mixing, and adjusting the pH value of a system to 4-5; then, transferring to a microwave hydrothermal kettle for a reaction, reacting for 1-2h at the set power of 400W and the set temperature of 160-200 DEG C, centrifuging a prepared sample, washing by using deionized water, then drying the sample, and grinding to obtain a ytterbium-doped and thulium-doped lanthanum fluoride / attapulgite upconverting composite photocatalytic material. The composite photocatalytic material is applied to simulation of photocatalytic gasolinedenitrification, and the denitrification rate can reach 85% after 3h light irradiation.

Owner:CHANGZHOU UNIV

Optical element equipped with lanthanum fluoride film

InactiveUS6809876B2Reduce optical loss of opticalSmall surface areaVacuum evaporation coatingSputtering coatingLanthanum fluorideCrystal growth

An optical element of the present invention comprises a fluorite substrate 1, and a lanthanum fluoride film 2 formed directly on the substrate 1. The substrate 1, on which the lanthanum fluoride film 2 is formed, has a plane which is a (111) plane or a plane inclined by an angle within ±30 degrees, preferably within 15 degrees from the (111) plane. Therefore, the lanthanum fluoride film undergoes the crystal growth subjected to the C-axis orientation on the optical substrate. Since the lanthanum fluoride film is dense and has a small surface area, it scarcely involves the oxidation and hydroxylation areas as well as the structural defect. Therefore, it is possible to reduce the optical loss of the optical element in the vacuum ultraviolet region.

Owner:NIKON CORP

Use of specific composite materials as extinguishing material for electric arcing in electric apparatuses

InactiveCN102696086AHigh-tension/heavy-dress switchesAir-break switchesLanthanum fluoridePhysical chemistry

The present invention relates to the use of a composite material including a polymer matrix and at least one metal fluoride charge selected from among cerium fluorides CeF3 and / or CeF4, lanthanum fluoride LaF3, magnesium fluoride MgF2, barium fluoride BaF2 or mixtures of same, as extinguishing material for electric arcing in an electric apparatus.

Owner:SCHNEIDER ELECTRIC ENERGY FRANCE

Dual wavelength antireflection film for excimer laser and optical film thickness monitoring system

The invention discloses a dual wavelength antireflection film for excimer laser and an optical film thickness monitoring system that are applied to an excimer laser device compatible with 193 nm and 248 nm deep ultraviolet. The dual wavelength antireflection film for the excimer laser comprises a substrate and a multilayer film arranged on the substrate, wherein the multilayer film is formed by alternating stacking high refractive index films and low refractive index films, each high refractive index film is made of lanthanum fluoride, each low refractive index film is made of magnesium fluoride, and the multilayer film has 4 to 10 layers. The optical film thickness monitoring system comprises an electron-beam evaporation source, a thermal resistance evaporation source and a plated substrate; a baffle plate is arranged between the electron-beam evaporation source as well as the thermal resistance evaporation source and a plated substrate. The dual wavelength antireflection film applied to deep ultraviolet excimer laser ranges from 193 nm to 248 nm and is very low in residual reflectivity of a substrate surface, and minimum absorbing and scattering loss can be realized.

Owner:HANGZHOU KOTI OPTICAL TECH

Wear-resistant communication optical cable jacket pipe special material and preparation method thereof

InactiveCN104311964AImprove wear resistanceHigh mechanical strengthRubber insulatorsPlastic/resin/waxes insulatorsWear resistantLanthanum fluoride

The invention discloses a wear-resistant communication optical cable jacket pipe special material and a preparation method thereof. The special material is prepared from the following raw materials in parts by weight: 36-48 parts of ultra-high molecular weight polyethylene, 21-33 parts of polyformaldehyde, 10-15 parts of tantalum diselenide, 7-13 parts of fused alumina zirconia powder, 4-8 parts of vaseline, 10-15 parts of Songhua stone powder, 4-6 parts of perfluoro-polyether, 3-5 parts of lanthanum fluoride, 6-9 parts of chlorinated paraffin, 14-18 parts of acetyl tributyl citrate, 15-20 parts of high-abrasion-resistance carbon black N660, 4-8 parts of zinc oxide whisker, 17-26 parts of butadiene rubber, 2-3 parts of dibutyl thiourea, 3-6 parts of basic lead silicate, 3-5 parts of 2-phenylindole, 4-6 parts of oxidized polyethylene wax, 1-2 parts of thiodipropionic acid octadecyl dodecyl ester, 4-8 parts of cresyl diphenyl phosphate and 2.5-4.5 parts of auxiliary agent. The jacket pipe special material has strong wear resistance, high mechanical strength and good fatigue resistance and aging resistance, and can prolong the service life of optical cables.

Owner:安徽电信器材贸易工业有限责任公司

Use of specific composite materials as electric arc extinction materials in electrical equipment

InactiveUS20120228264A1Facilitate extinctionHigh-tension/heavy-dress switchesAir-break switchesExtinctionLanthanum fluoride

The present invention provides the use of a composite material comprising a polymeric matrix and at least one metal fluoride filler selected from the cerium fluorides CeF3 and / or CeF4, lanthanum fluoride LaF3 and mixtures thereof, as an electric arc extinction material in electrical equipment.

Owner:SCHNEIDER ELECTRIC ENERGY FRANCE

Lanthanum fluoride single crystal and optical component

InactiveUS20180059288A1High transparencyPolycrystalline material growthMaterial analysis by electric/magnetic meansAlkaline earth metalLanthanum fluoride

A lanthanum fluoride single crystal wherein an alkaline earth metal is added to the lanthanum fluoride single crystal, and internal transmittance of light at 9.3 μm in wavelength is no less than 85% / mm. The lanthanum fluoride single crystal and an optical component which have high transparency in an infrared region, and can be preferably used for phase plates for lasers, lenses and optical window materials for laser beam machines, gas detectors, flame detectors, infrared cameras, and so on, etc. are provided.

Owner:TOKUYAMA CORP

Cerium oxide polishing solution, preparation method and applications thereof

ActiveCN110872471AIncrease profitImprove dispersion stabilityPolishing compositions with abrasivesO-Phosphoric AcidLanthanum fluoride

The invention relates to the technical field of polishing solutions, and discloses a cerium oxide polishing solution, a preparation method and applications thereof, wherein the polishing solution contains a grinding agent, a dispersing agent, a defoaming agent and water, the grinding agent is a mixture of cerium oxide, lanthanum oxide, lanthanum fluoride, lanthanum oxyfluoride and titanium oxide,the dispersing agent is a mixture of allyl polyoxyethylene ether and / or polyoxyethylene octyl phenol ether, triethylhexyl phosphoric acid, vinyl bis stearamide and sodium p-styrenesulfonate, and the defoaming agent is a copolymer of polyoxyethylene polyoxypropylene alcohol amine ether and polyether dimethyl siloxane. With the application of the polishing solution to polish glass surface, the polishing efficiency is high, the dispersing capacity is strong, the lasting defoaming effect is good, and defoaming can be performed for a long time.

Owner:HUIZHOU BYD IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Optical waveguide[[s]] and optical fiber perform including gallium, lanthanum, sulfur, oxygen, and fluorine Optical waveguide[[s]] and optical fiber perform including gallium, lanthanum, sulfur, oxygen, and fluorine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/86095b83-535f-4d0f-8ec9-91d36fd5bd79/US07016593-20060321-D00000.png)

![Optical waveguide[[s]] and optical fiber perform including gallium, lanthanum, sulfur, oxygen, and fluorine Optical waveguide[[s]] and optical fiber perform including gallium, lanthanum, sulfur, oxygen, and fluorine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/86095b83-535f-4d0f-8ec9-91d36fd5bd79/US07016593-20060321-D00001.png)

![Optical waveguide[[s]] and optical fiber perform including gallium, lanthanum, sulfur, oxygen, and fluorine Optical waveguide[[s]] and optical fiber perform including gallium, lanthanum, sulfur, oxygen, and fluorine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/86095b83-535f-4d0f-8ec9-91d36fd5bd79/US07016593-20060321-D00002.png)