Up-conversion solar cell

A technology for solar cells and silicon solar cells, applied in the field of solar cells, can solve problems such as unfavorable large-area production, insufficient light absorption, complex structure, etc., and achieve the effects of reducing heat conversion, reducing consumption, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] An up-conversion solar cell whose structure is:

[0015] Directly on the backlight surface of the silicon solar cell 2, the nano upconversion luminescent material is erbium ion-doped silica-lanthanum fluoride nanocrystalline glass ceramics by spin coating to prepare the nano upconversion luminescent layer 3; It absorbs the sunlight transmitted by the silicon solar cell and emits the corresponding light absorbed by the silicon solar cell.

[0016] The thickness of the nanometer up-conversion light-emitting layer 3 is 0.5 micrometers.

Embodiment 2

[0018] An up-conversion solar cell 2, which is directly on the backlight surface of the silicon solar cell, using the method of screen printing, and the nano-upconversion luminescent material is erbium ion and ytterbium ion co-doped silicon dioxide-lanthanum fluoride nano Crystal glass ceramics prepare the nanometer up-conversion light-emitting layer 3.

[0019] The thickness of the nanometer up-conversion light-emitting layer 3 is 2 micrometers.

Embodiment 3

[0021] An up-conversion solar cell whose structure is:

[0022] Directly on the backlight surface of the silicon solar cell 2, the nano upconversion luminescent layer 3 is prepared using the nano upconversion luminescent material which is zinc sulfide doped with erbium ions by spin coating.

[0023] The thickness of the nanometer up-conversion light-emitting layer 3 is 1 micron.

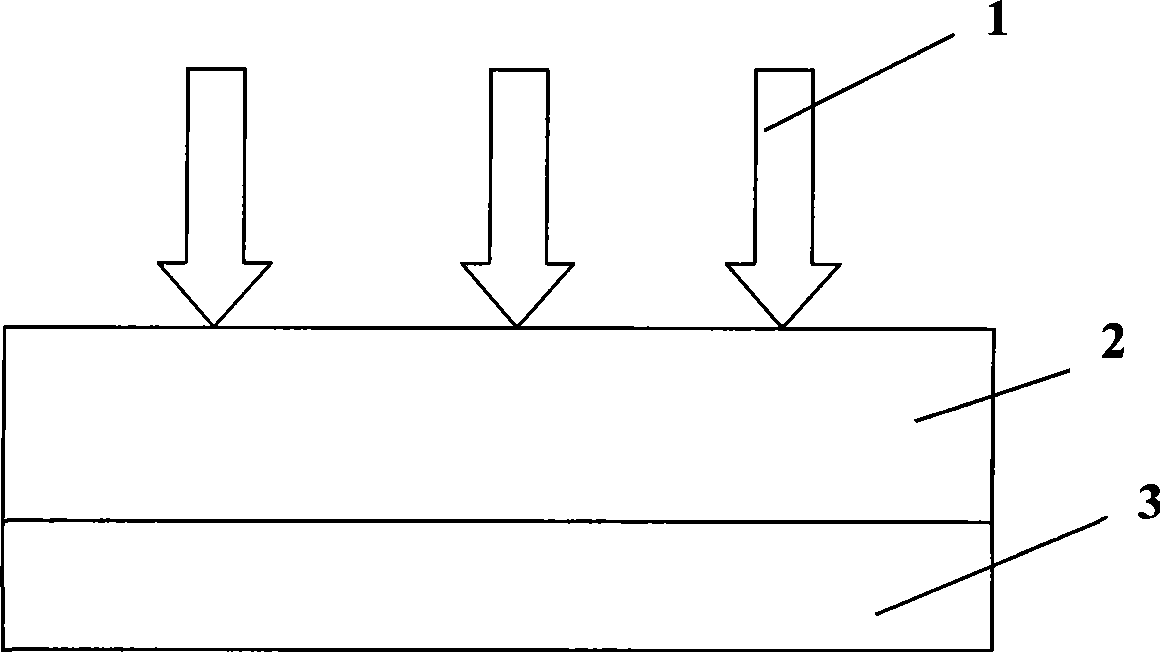

[0024] Such as figure 1 As shown, sunlight 1 is incident from the front of a silicon solar cell 2, and a nano-upconversion luminescent layer 3 made of nano-upconversion luminescent materials converts long-wavelength light that silicon cannot absorb into light that silicon can absorb, thereby enhancing silicon solar energy. The battery's utilization of long-wavelength sunlight.

[0025] Nano up-conversion luminescent material substances used in the present invention:

[0026] Erbium ion-doped silica-lanthanum fluoride nanocrystalline glass ceramics or erbium ion and ytterbium ion co-doped silica-lanthanum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com