Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "High precision cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

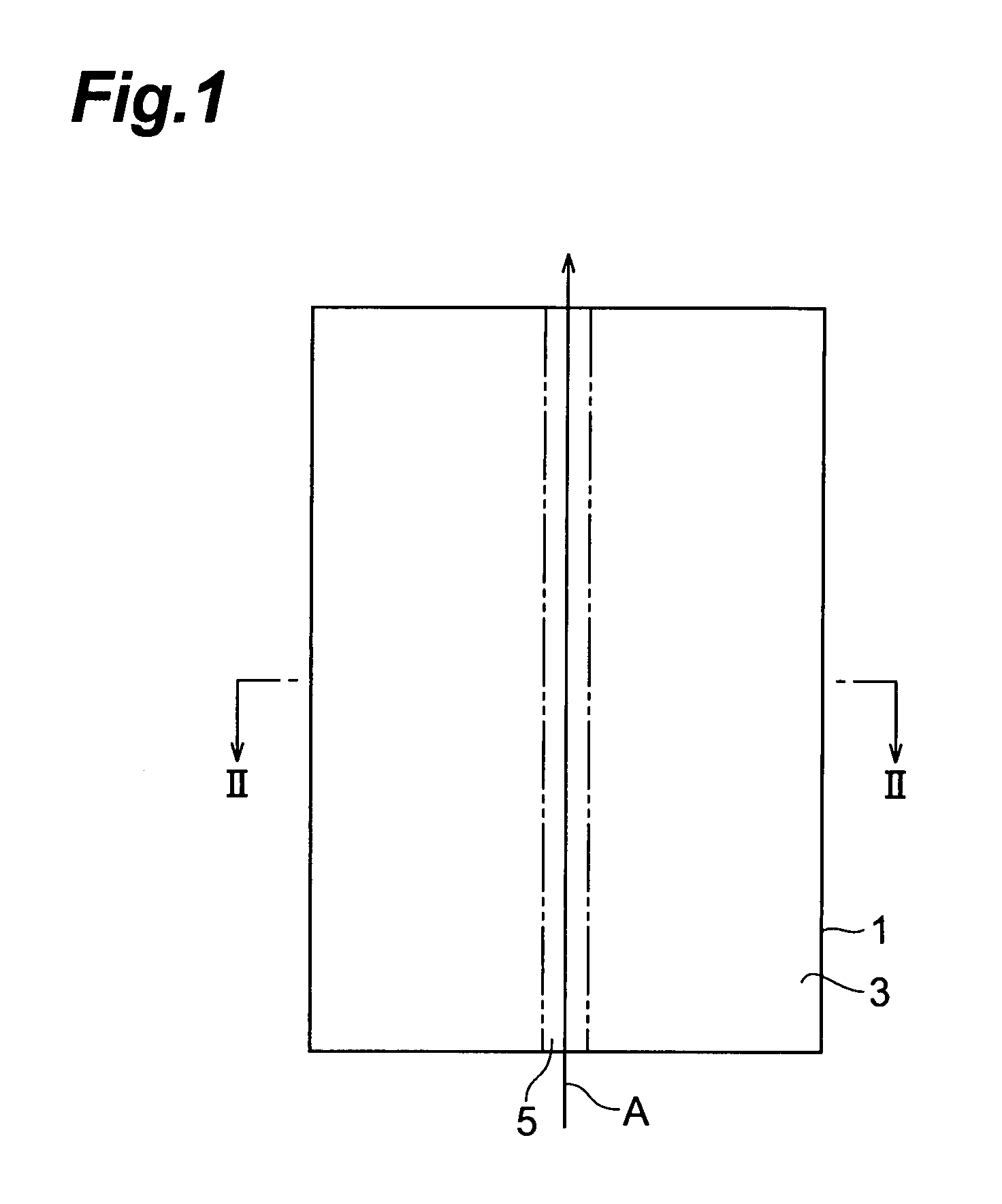

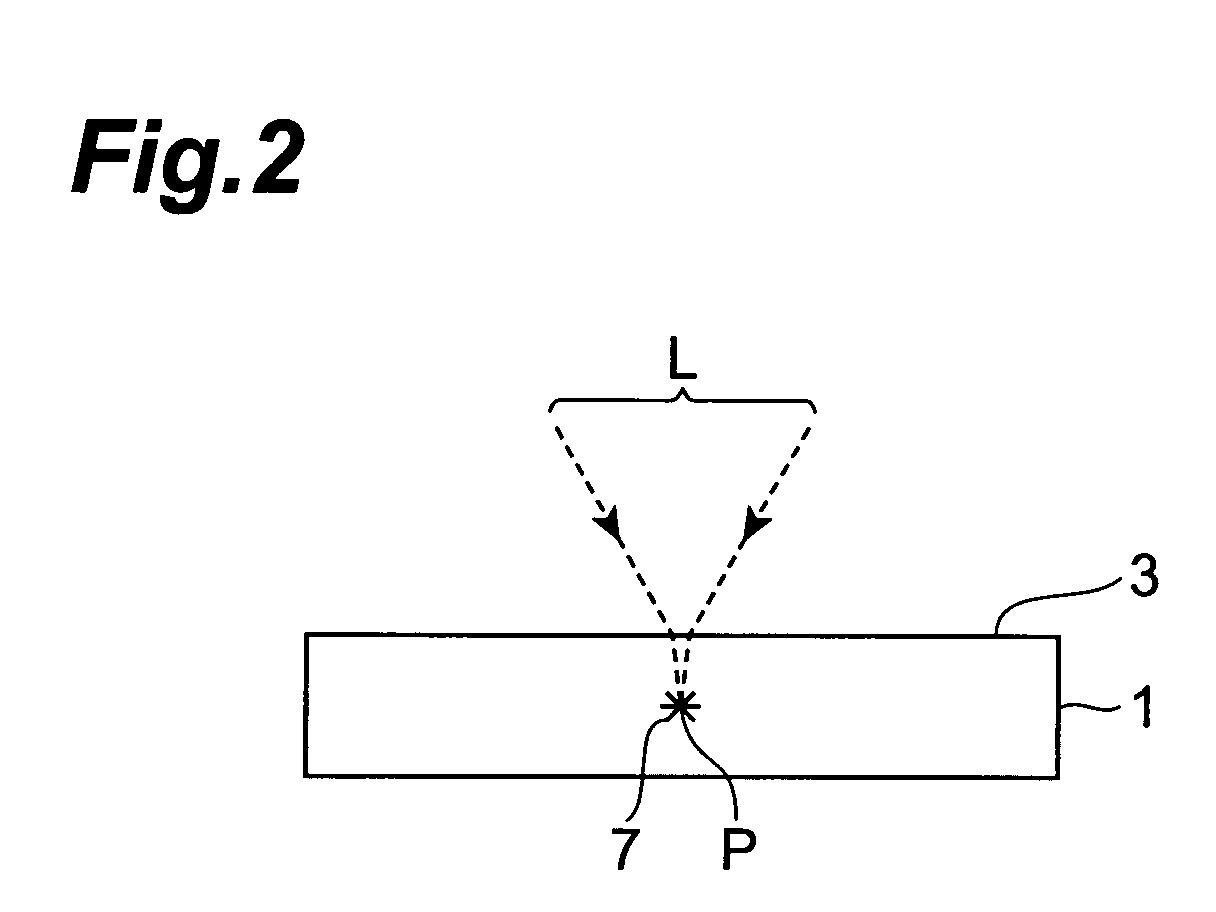

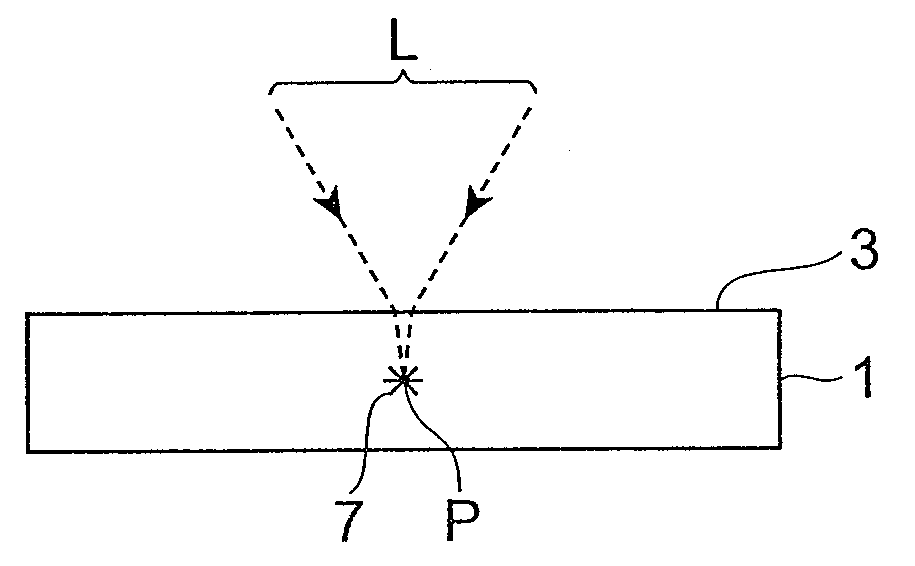

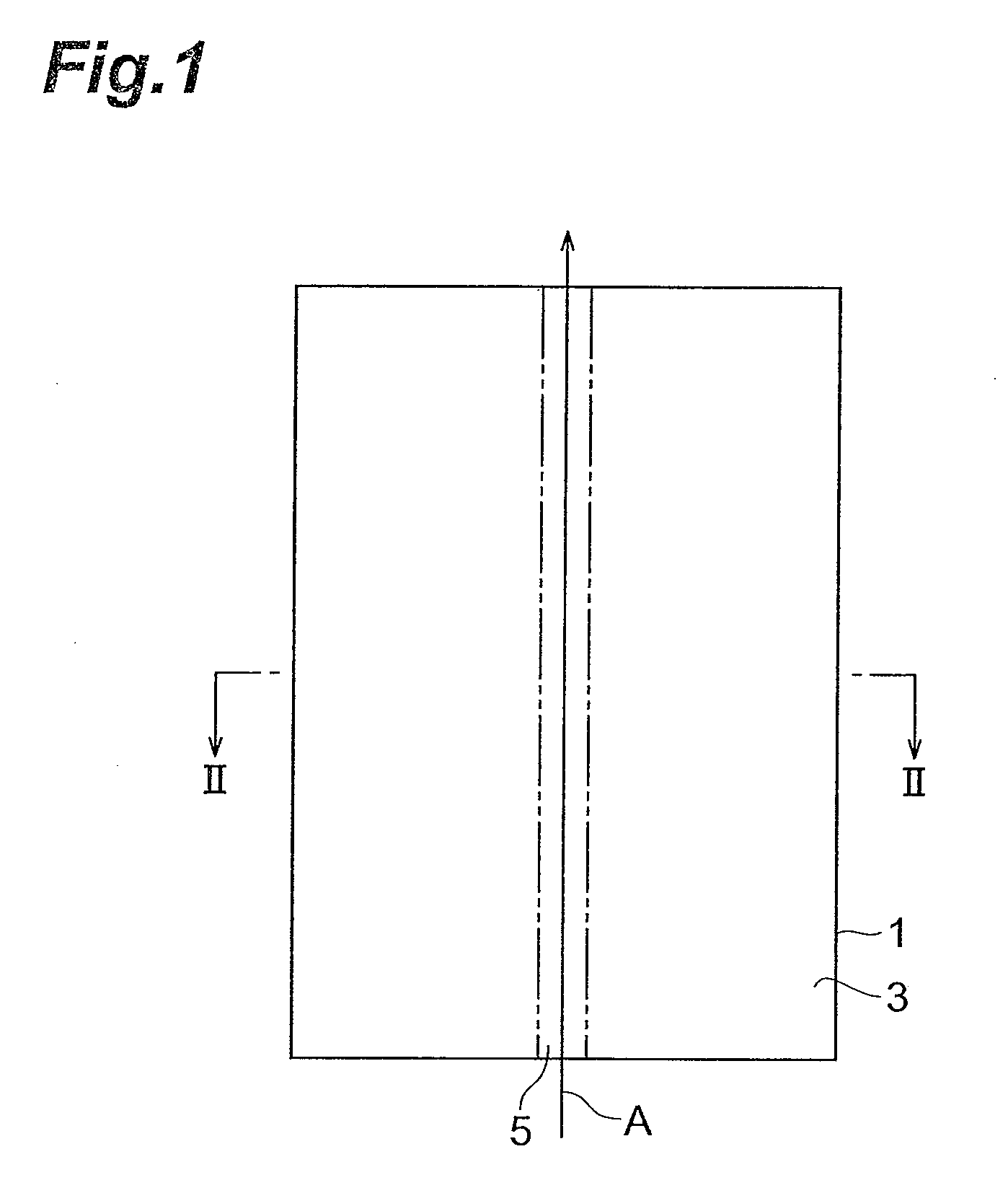

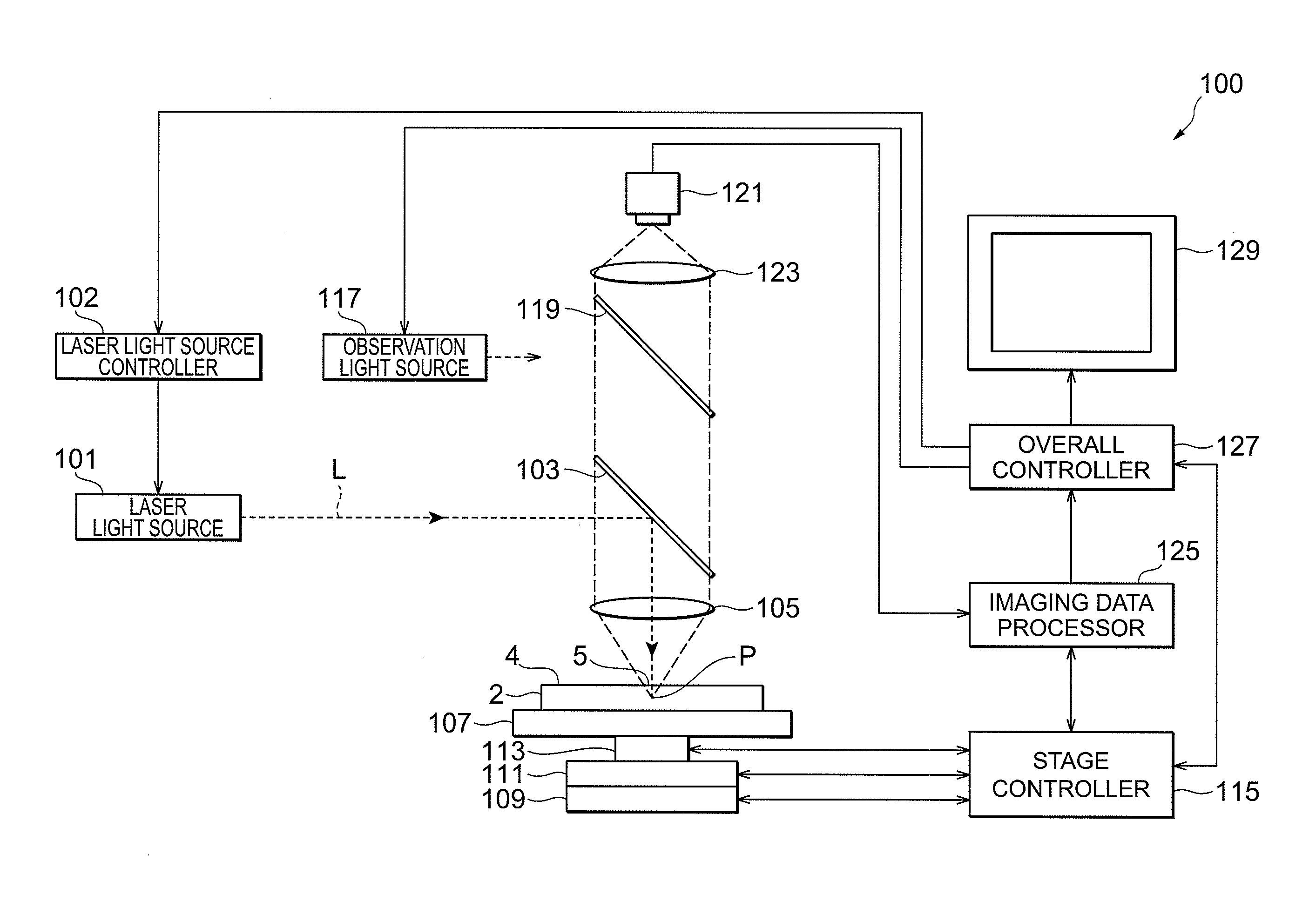

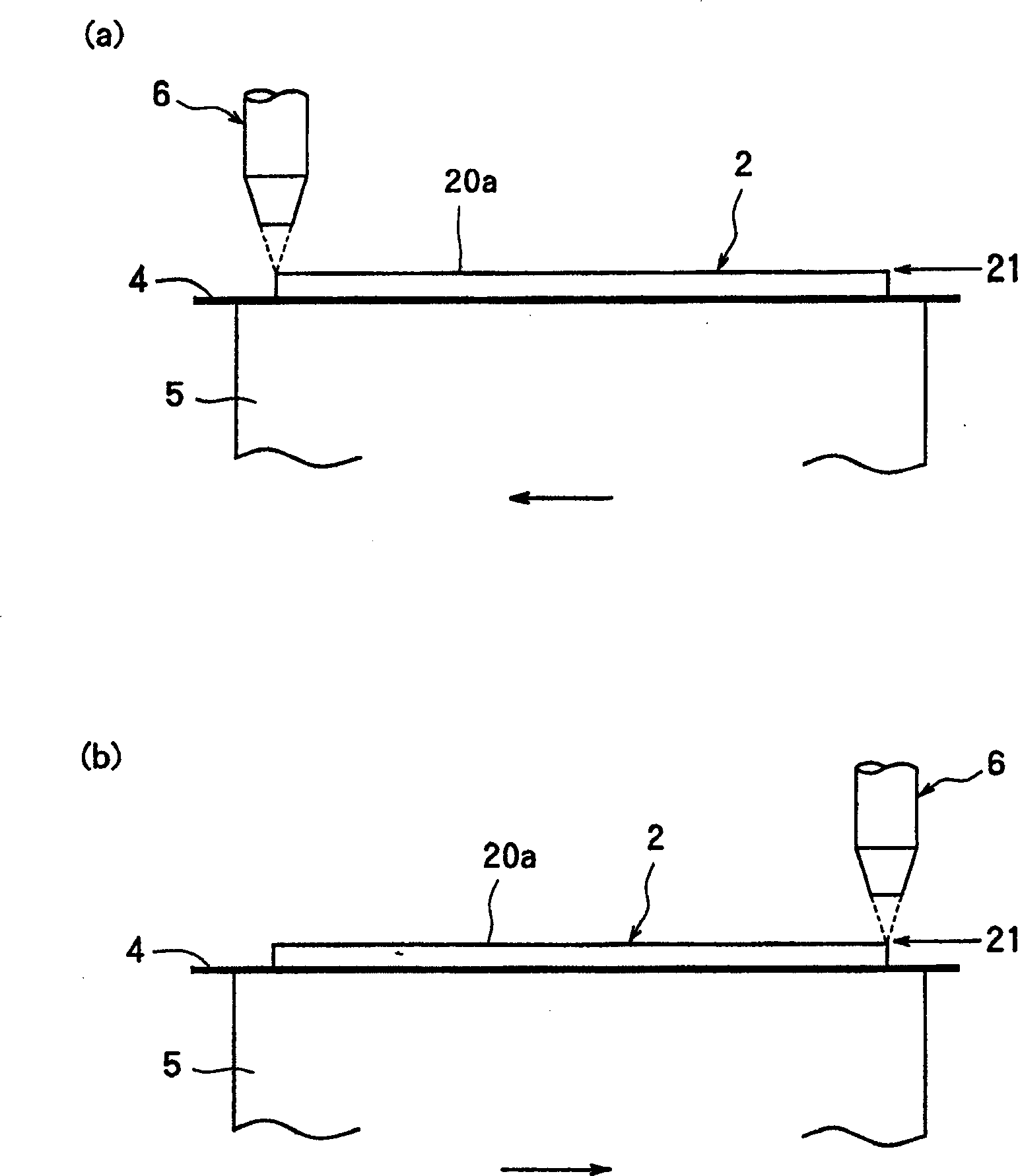

Laser processing method

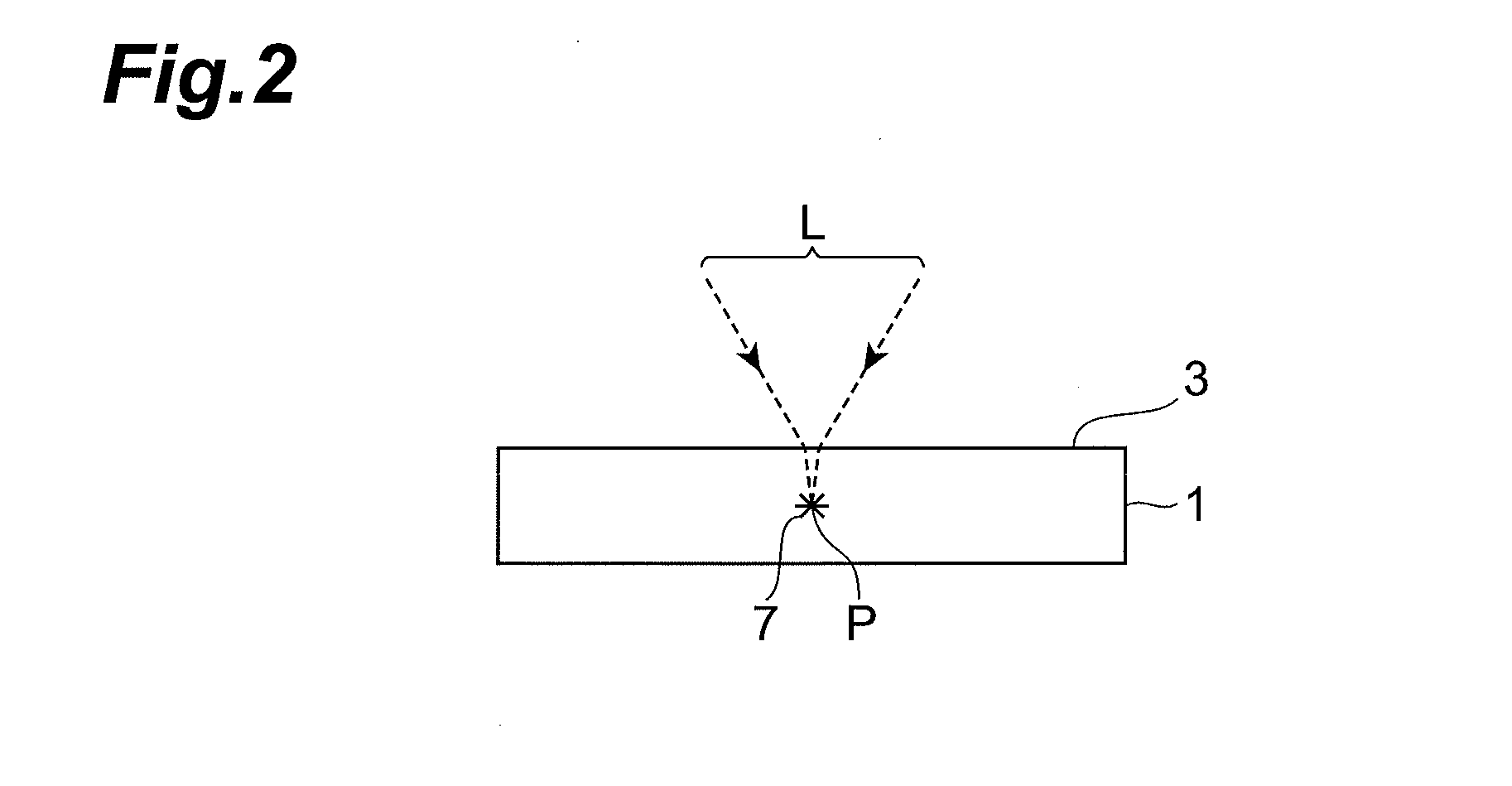

ActiveUS20070158314A1Reduce manufacturing stepsImprove accuracyFine working devicesWelding/soldering/cutting articlesLaser processingProcess region

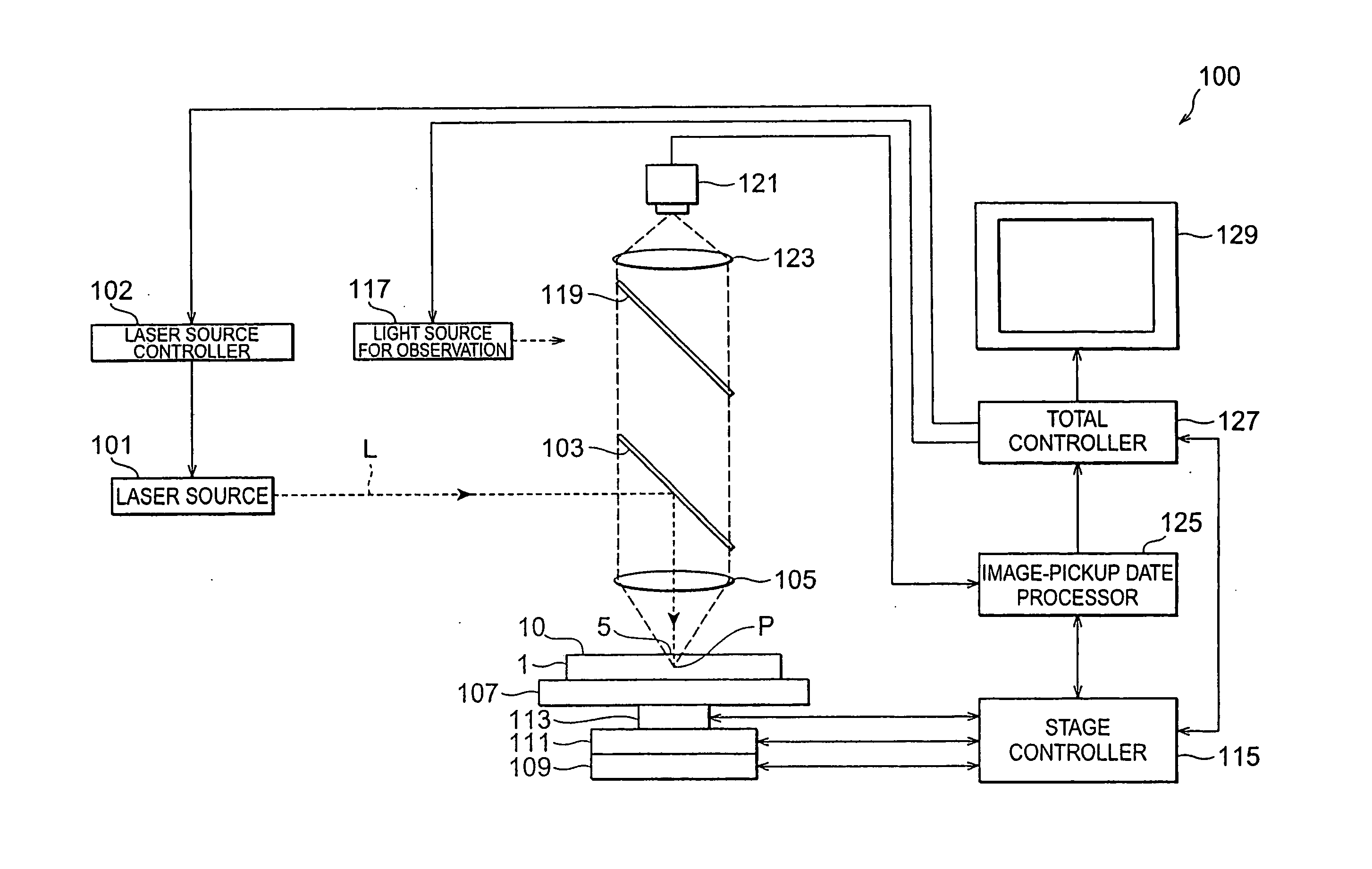

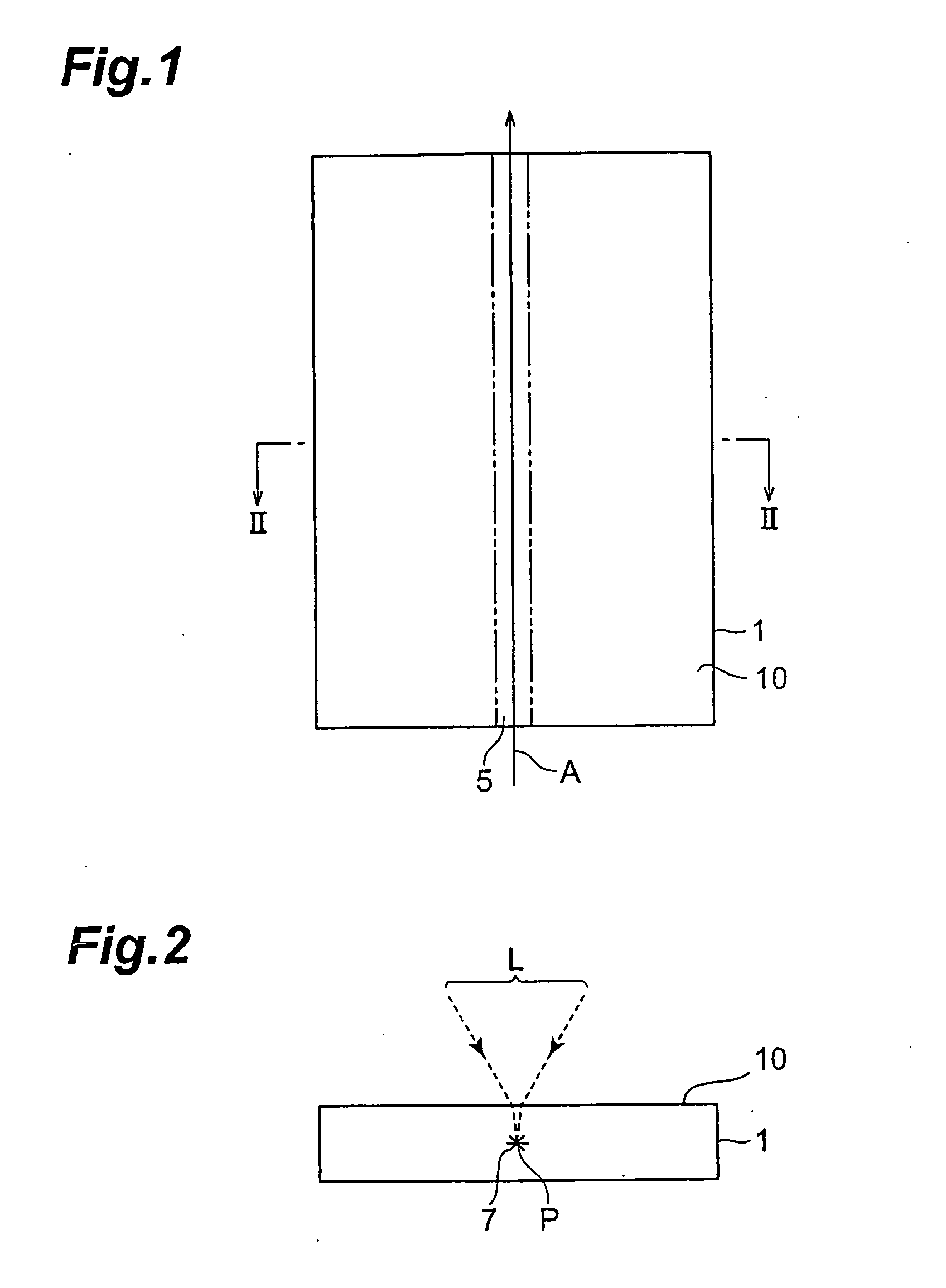

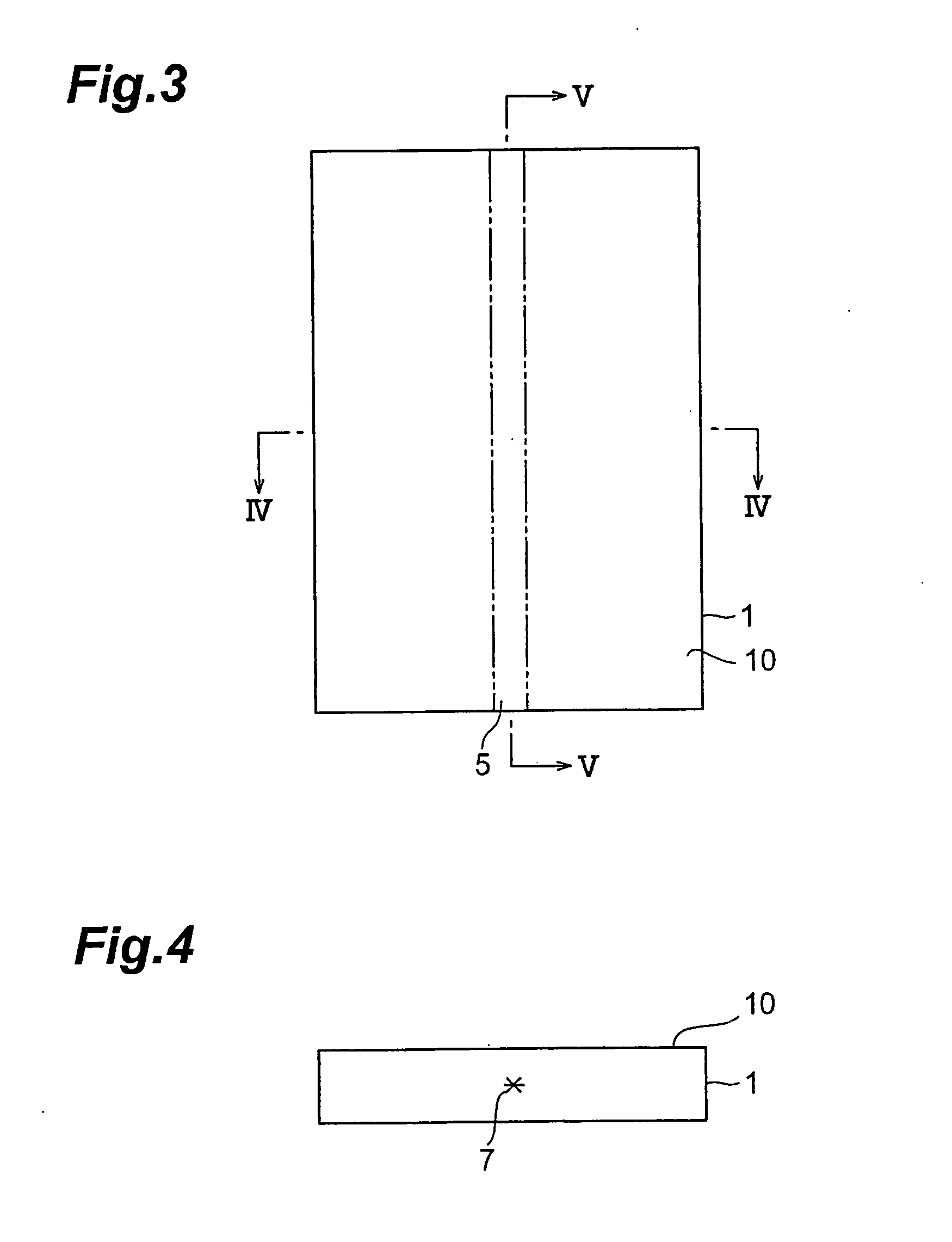

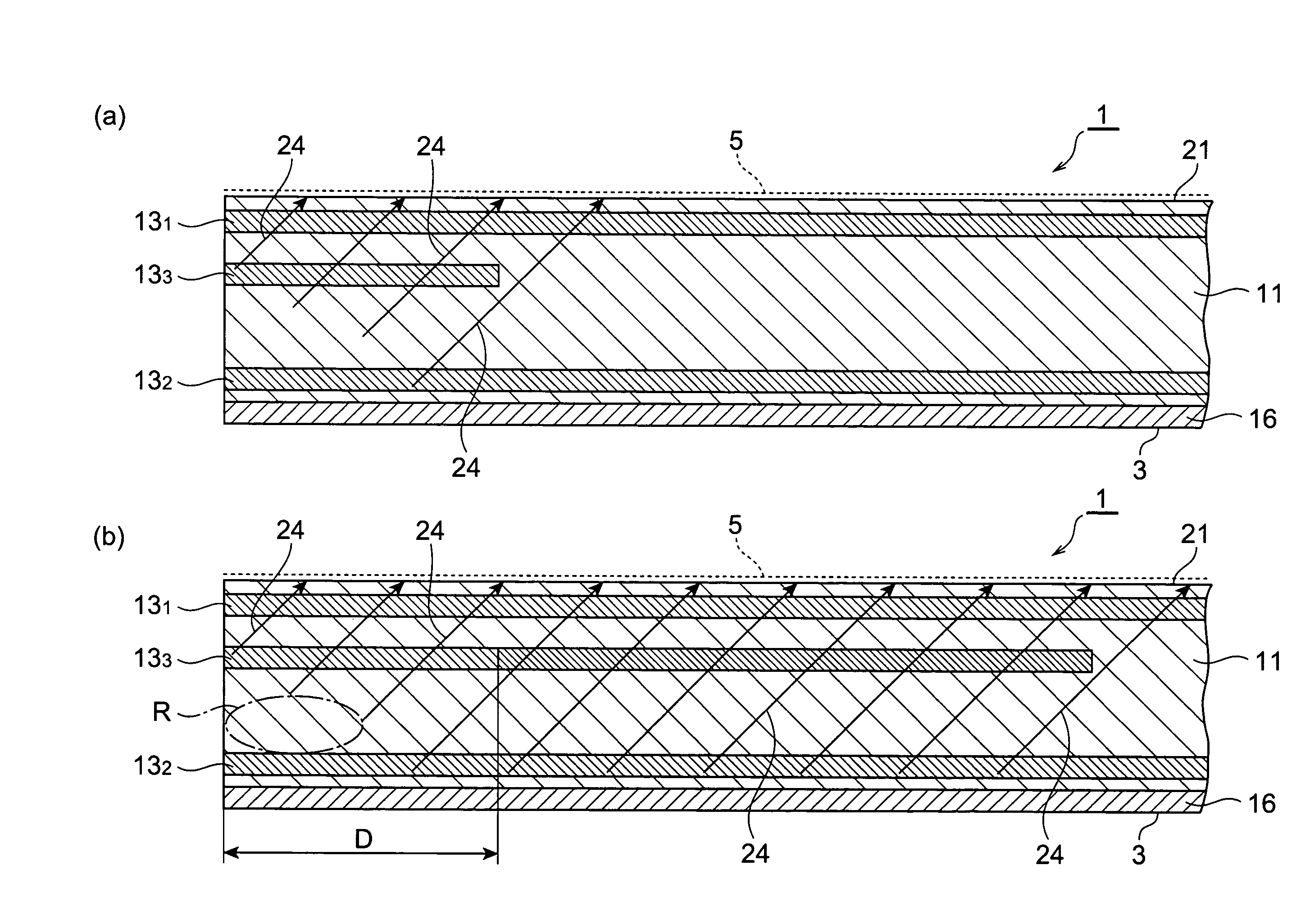

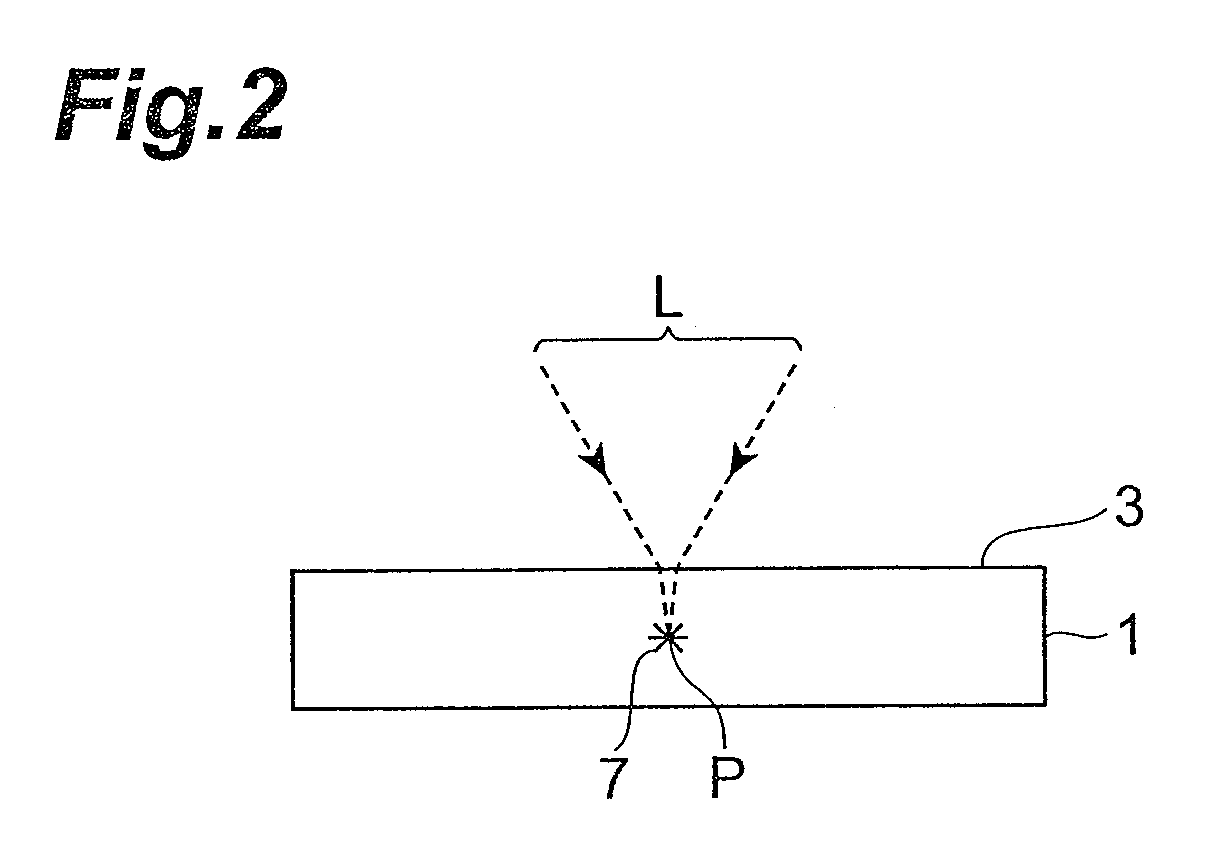

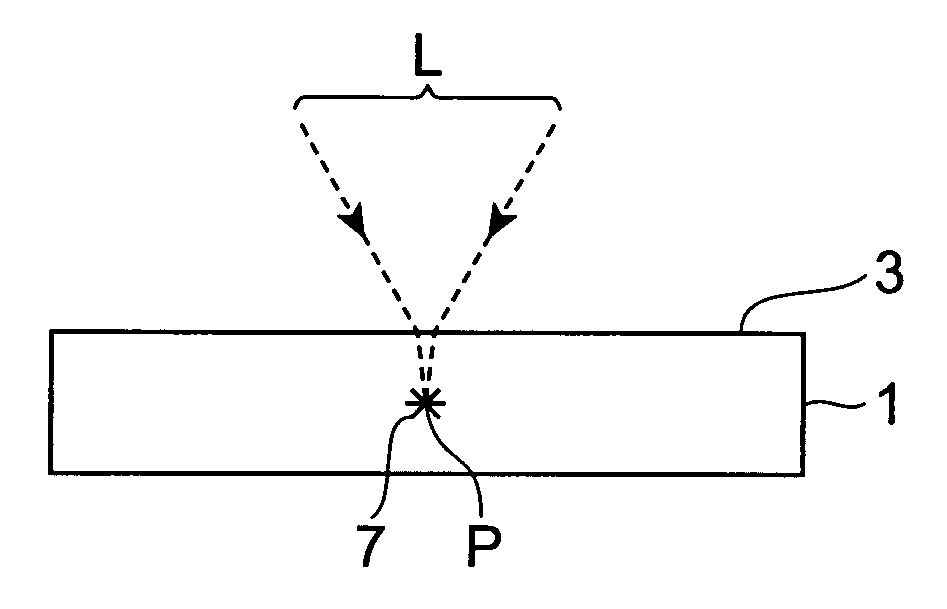

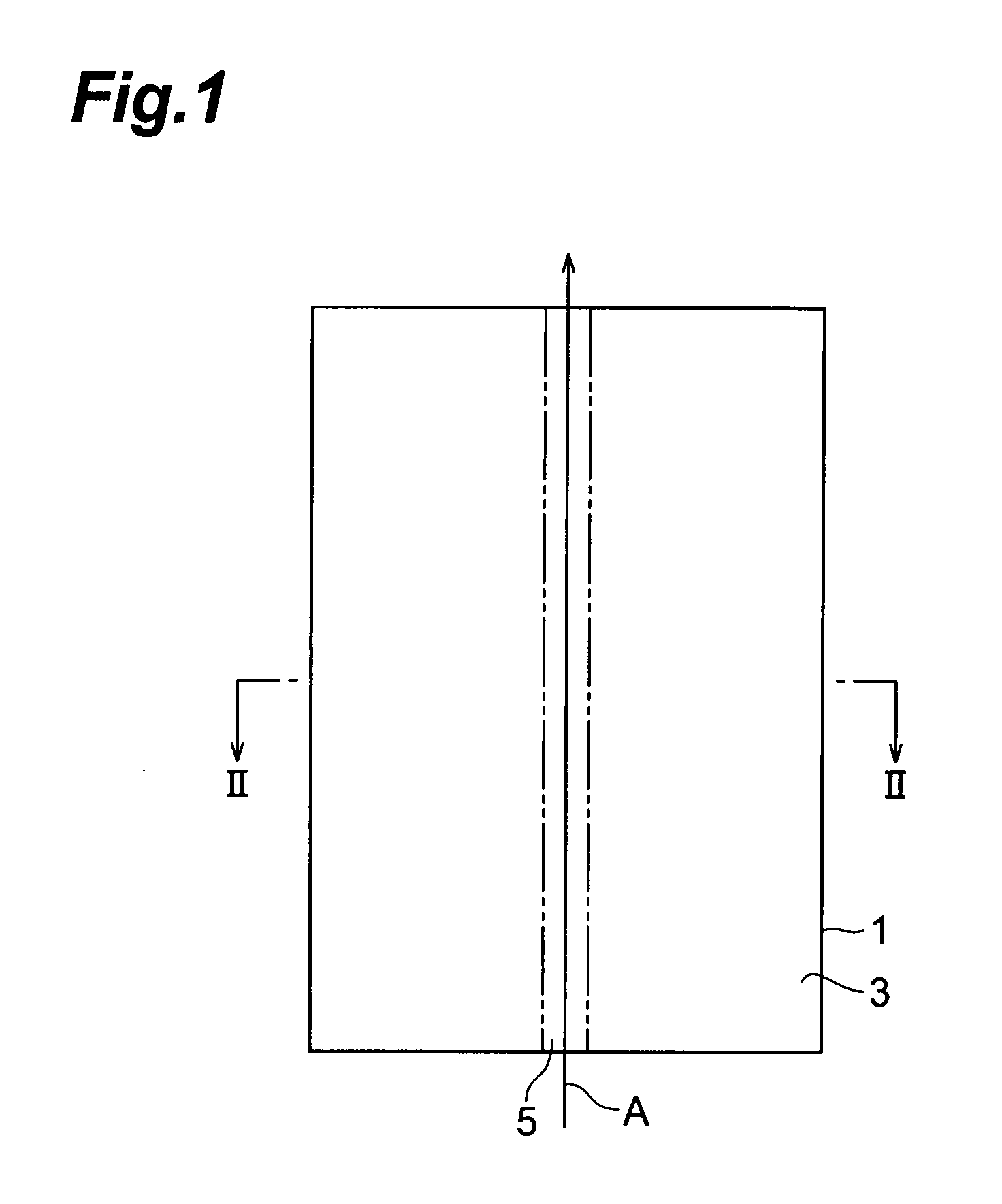

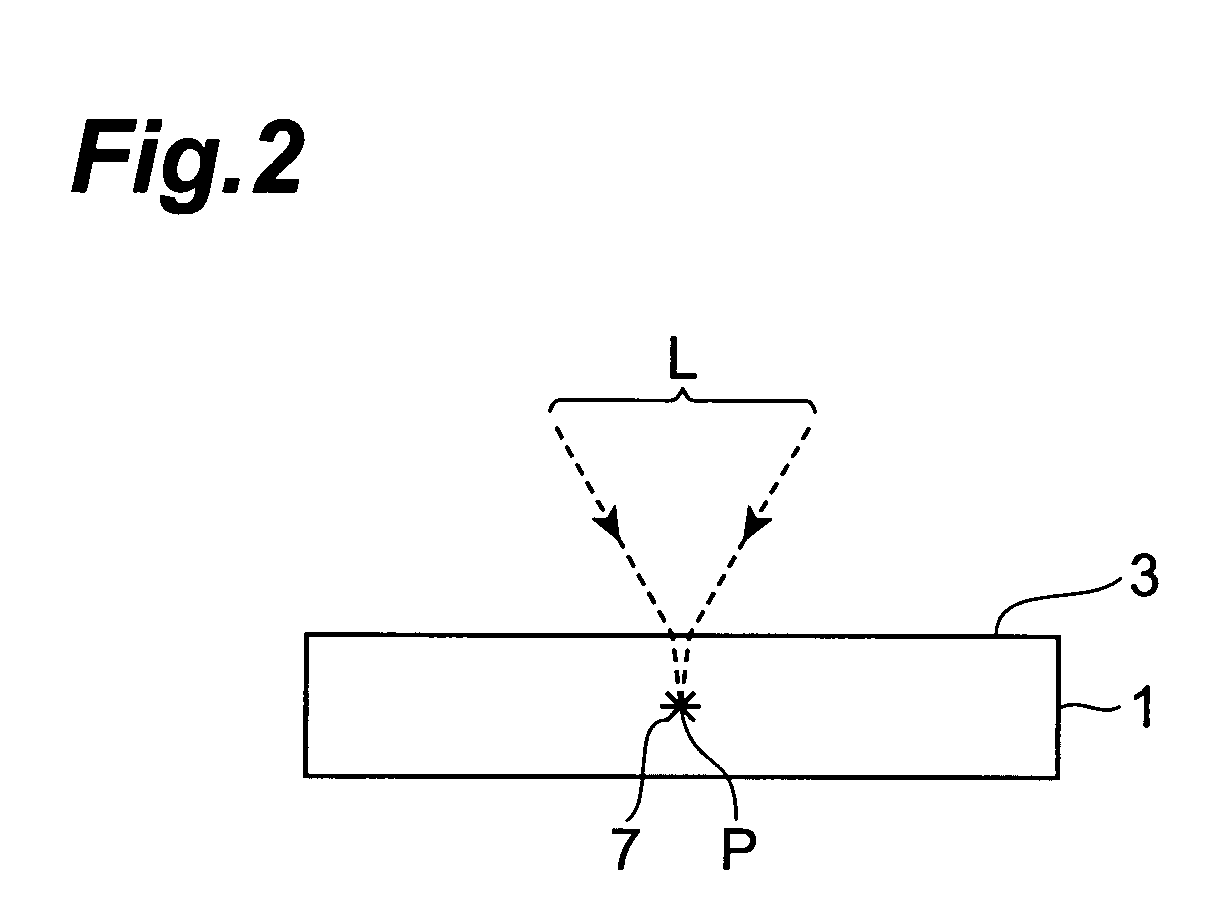

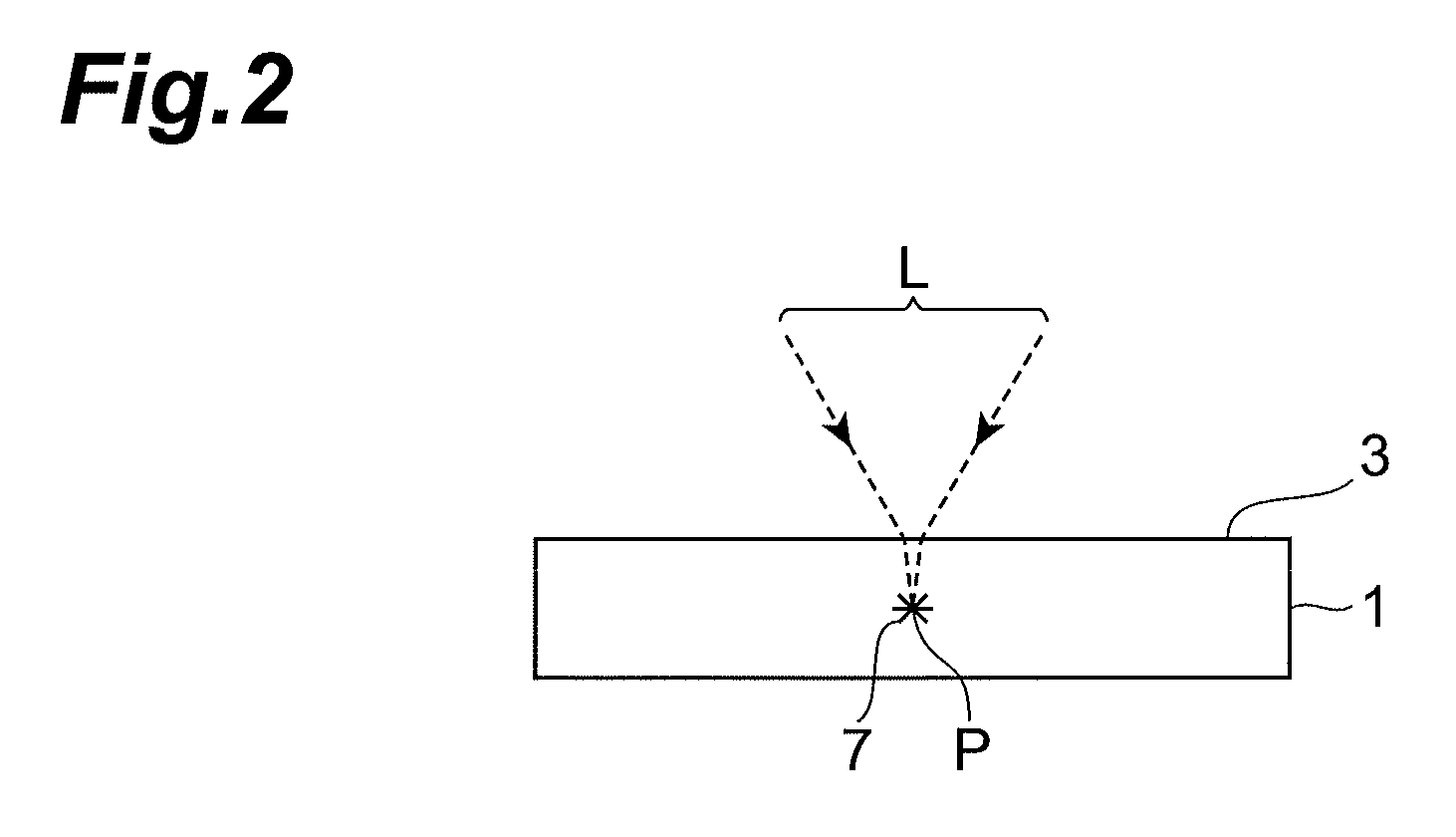

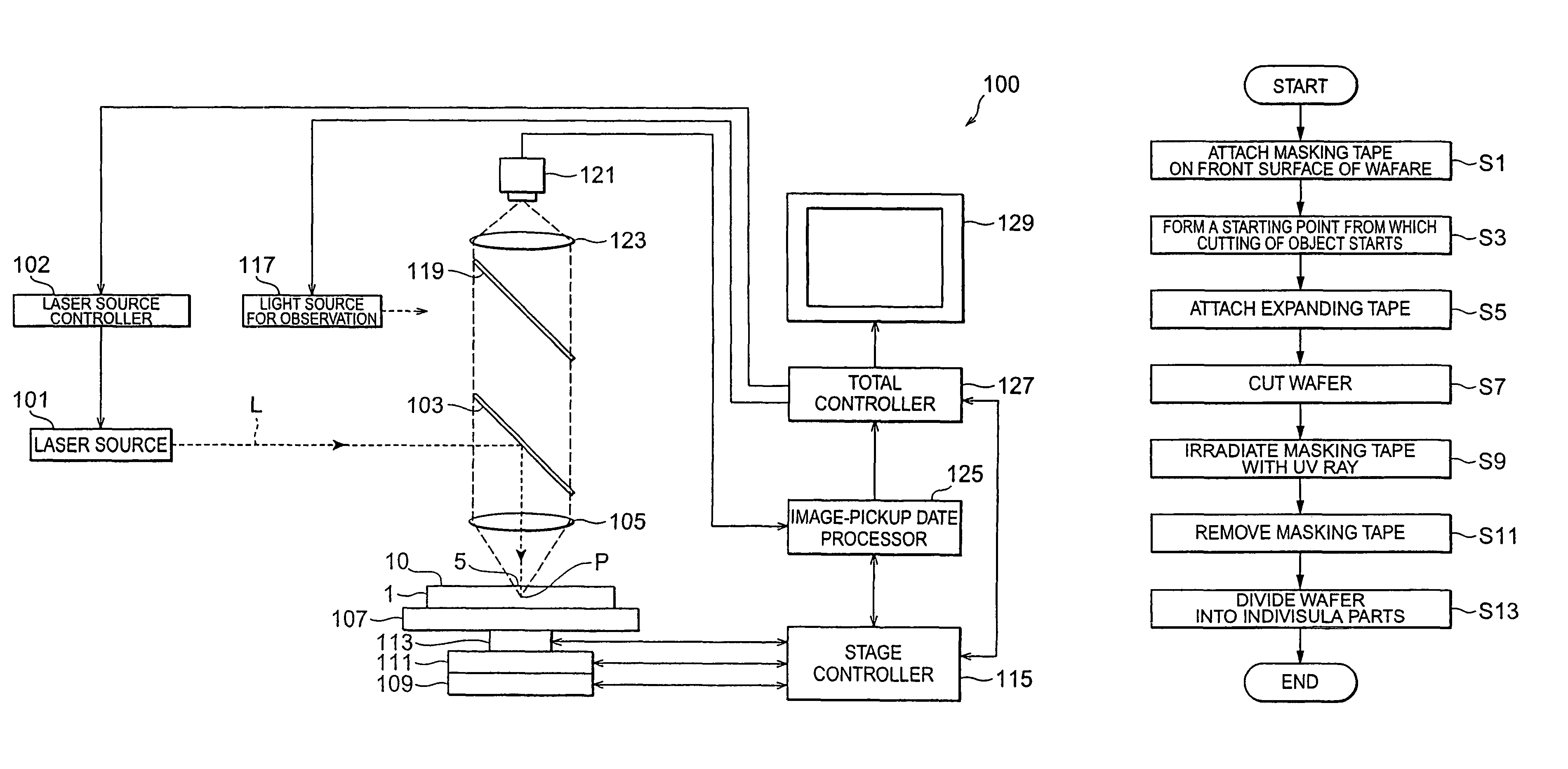

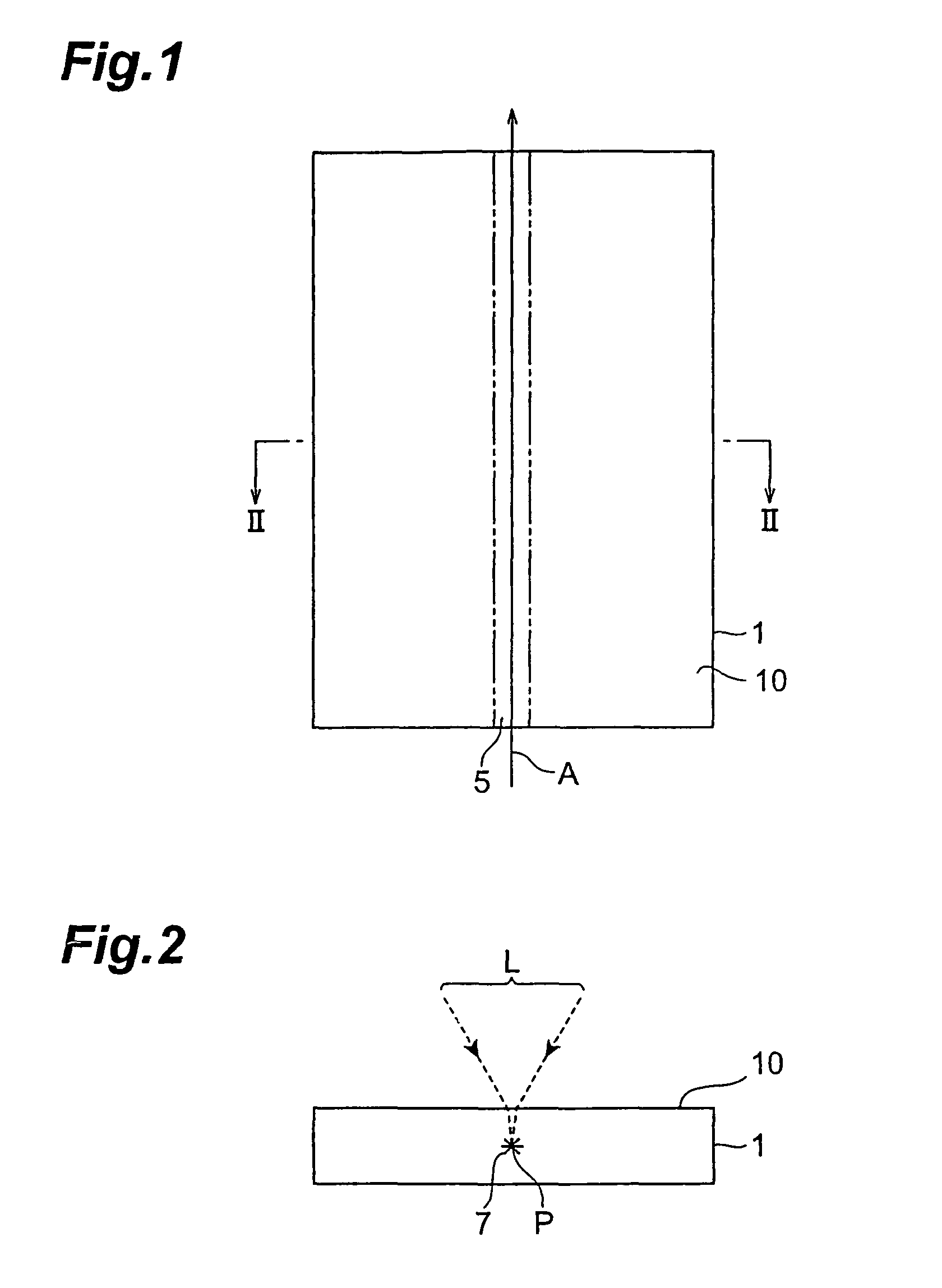

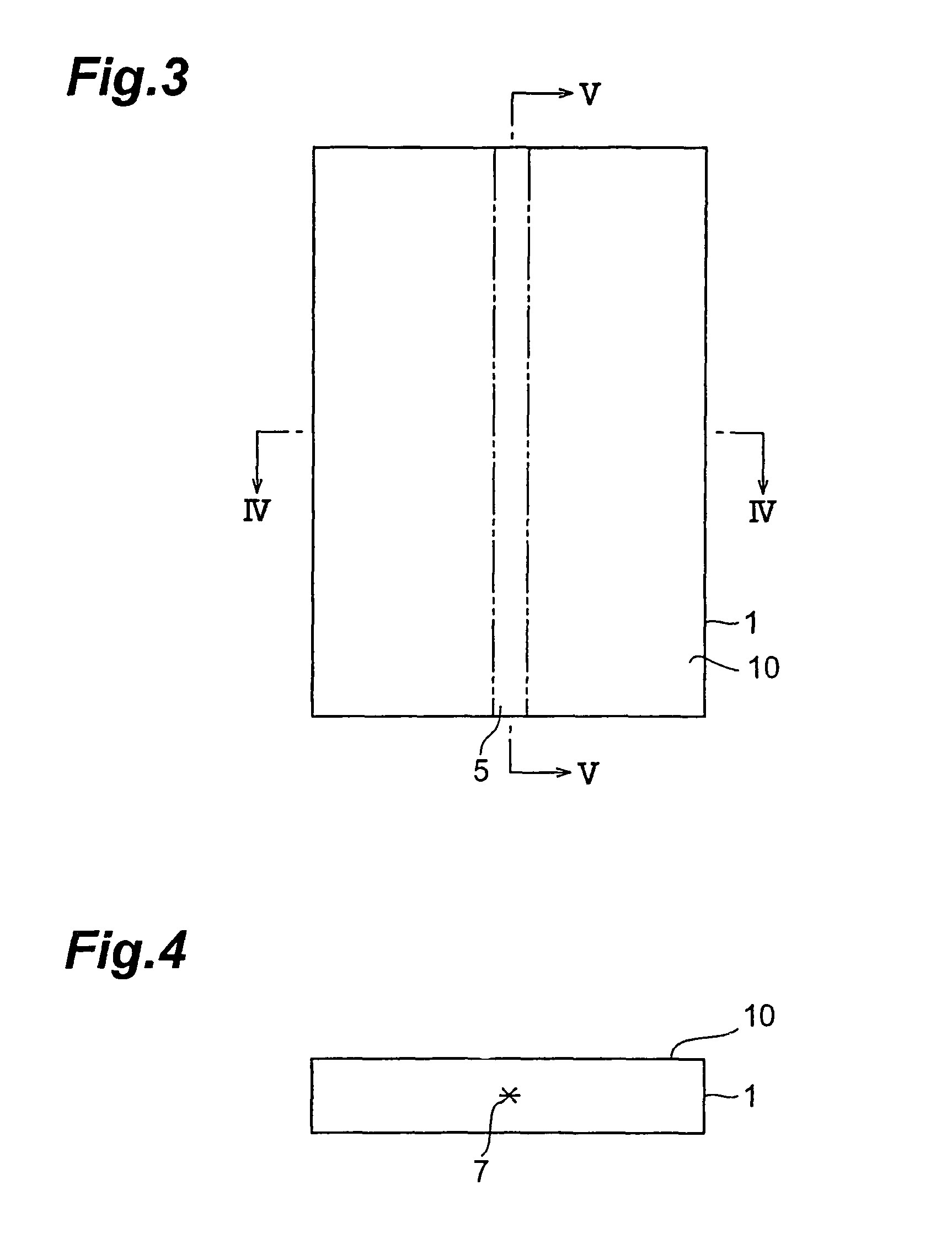

The present invention provides a laser processing method comprising the steps of attaching a protective tape 25 to a front face 3 of a wafer 1a, irradiating a substrate 15 with laser light L while employing a rear face of the wafer 1a as a laser light entrance surface and locating a light-converging point P within the substrate 15 so as to form a molten processed region 13 due to multiphoton absorption, causing the molten processed region 13 to form a cutting start region 8 inside by a predetermined distance from the laser light entrance surface along a line 5 along which the object is intended to be cut in the wafer 1a, attaching an expandable tape 23 to the rear face 21 of the wafer 1a, and expanding the expandable tape 23 so as to separate a plurality of chip parts 24 produced upon cutting the wafer 1a from the cutting start region 8 acting as a start point from each other.

Owner:HAMAMATSU PHOTONICS KK

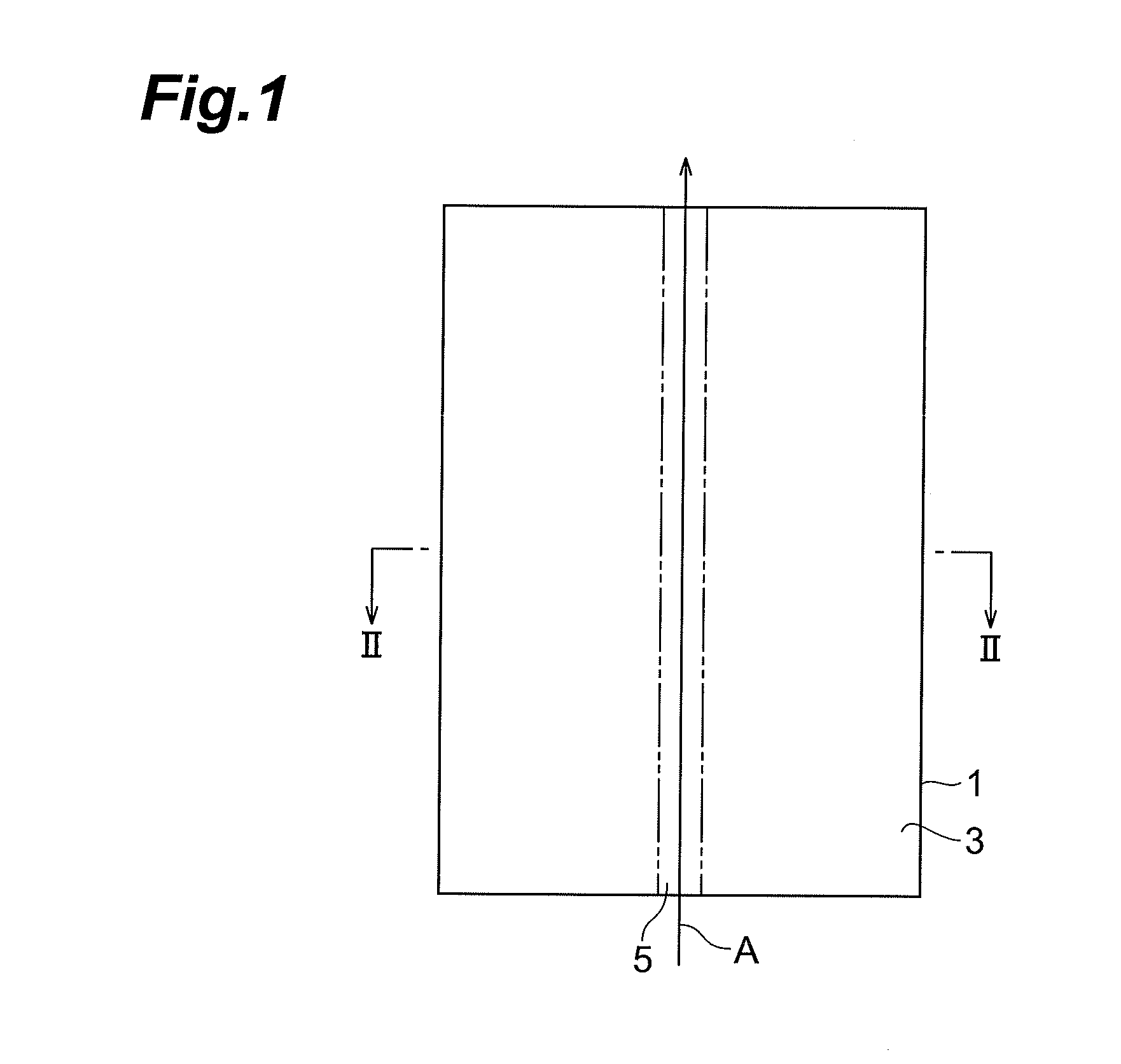

Laser processing method and chip

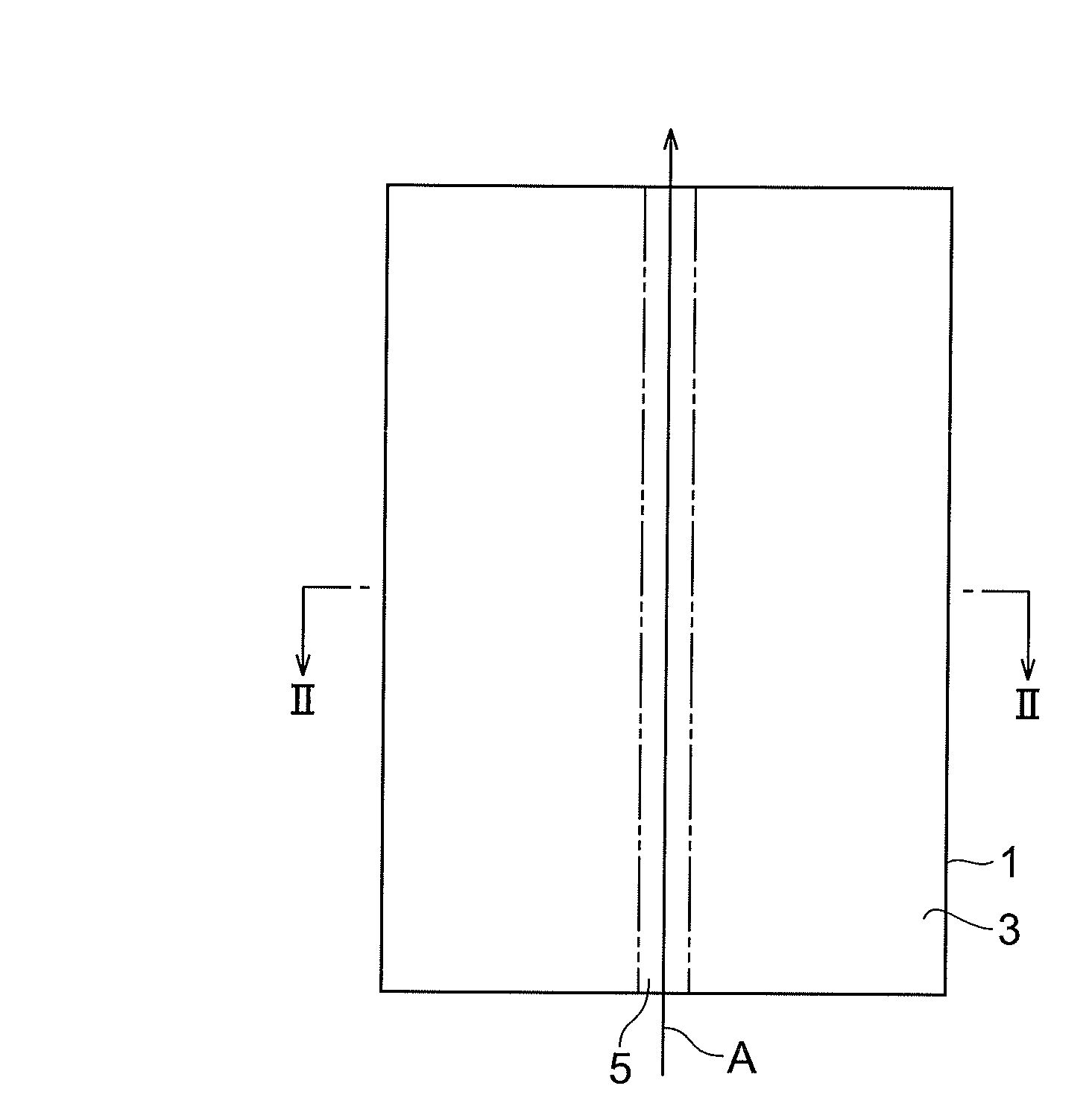

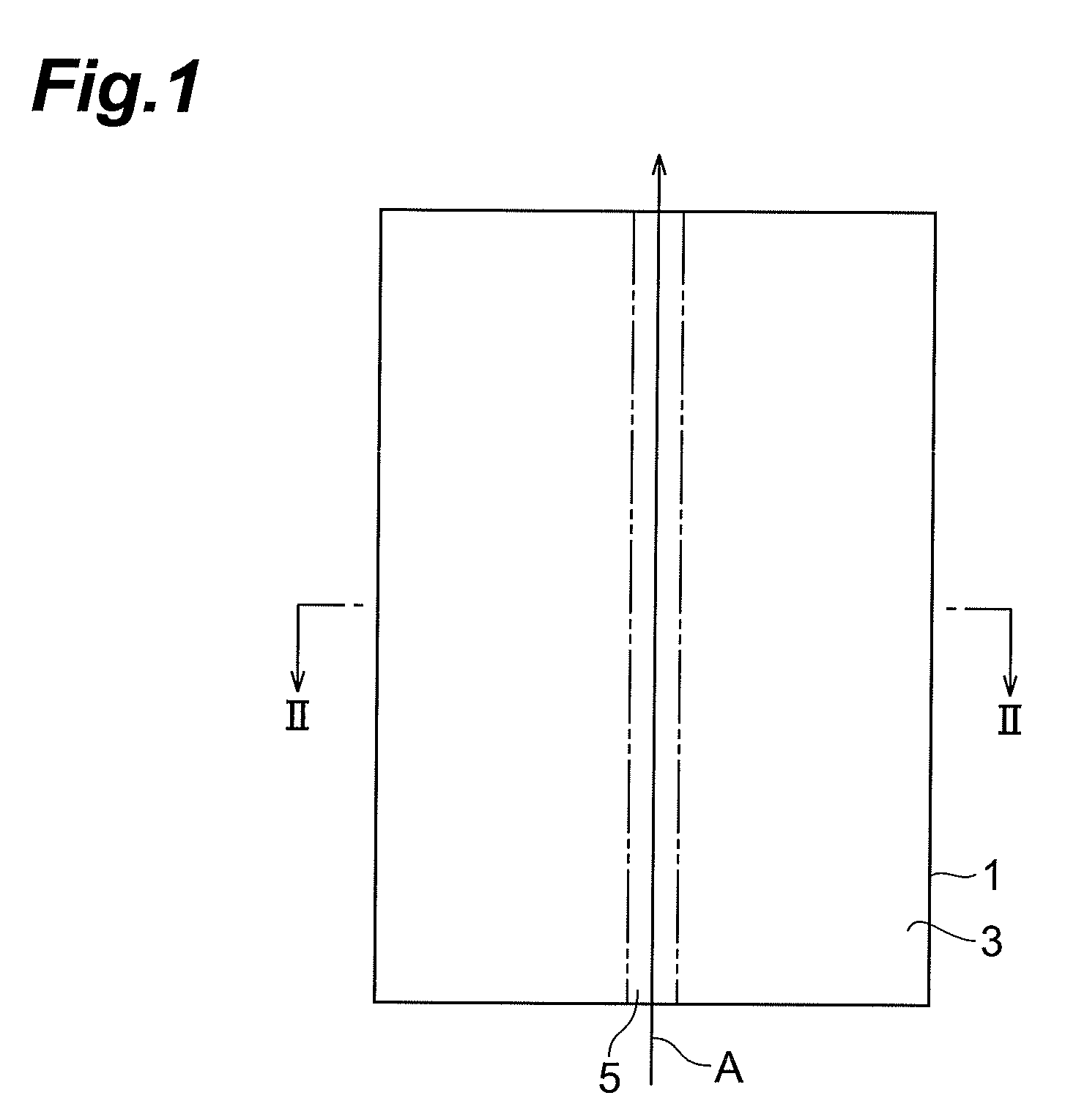

ActiveUS7897487B2High precision cuttingPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

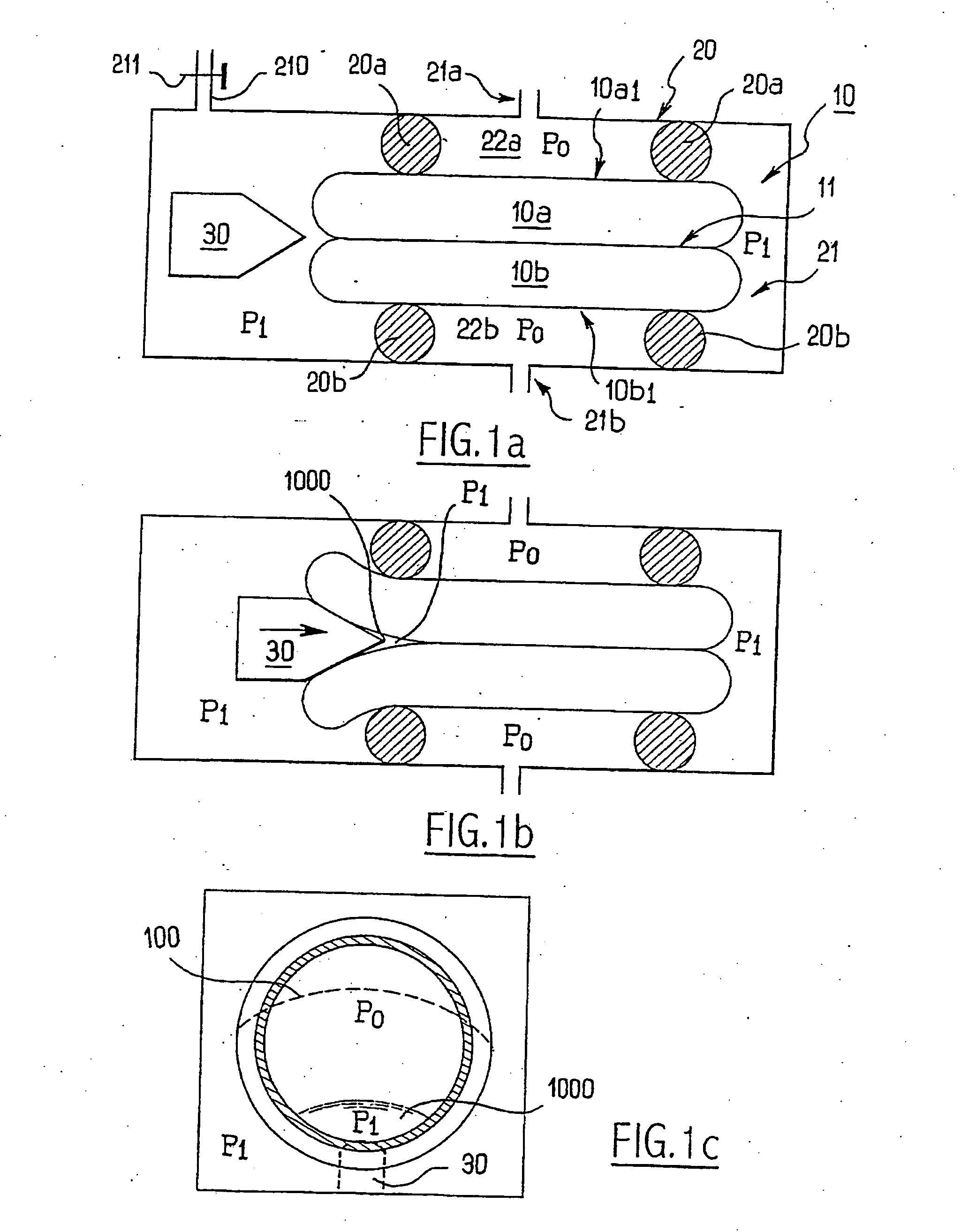

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

Laser processing method and chip

ActiveUS20100184271A1High precision cuttingPrecise cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

Laser processing method and chip

ActiveUS20080000884A1Avoid fracturesShorten the timeSemiconductor/solid-state device manufacturingFine working devicesLaser processingLaser light

An object to be processed can be cut highly accurately along a line to cut.An object to be processed 1 is irradiated with laser light while locating a converging point within a silicon wafer 11, and the converging point is relatively moved along a line to cut 5, so as to form modified regions M1, M2 positioned within the object 1 along the line to cut 5, and then a modified region M3 positioned between the modified regions M1, M2 within the object 1.

Owner:HAMAMATSU PHOTONICS KK

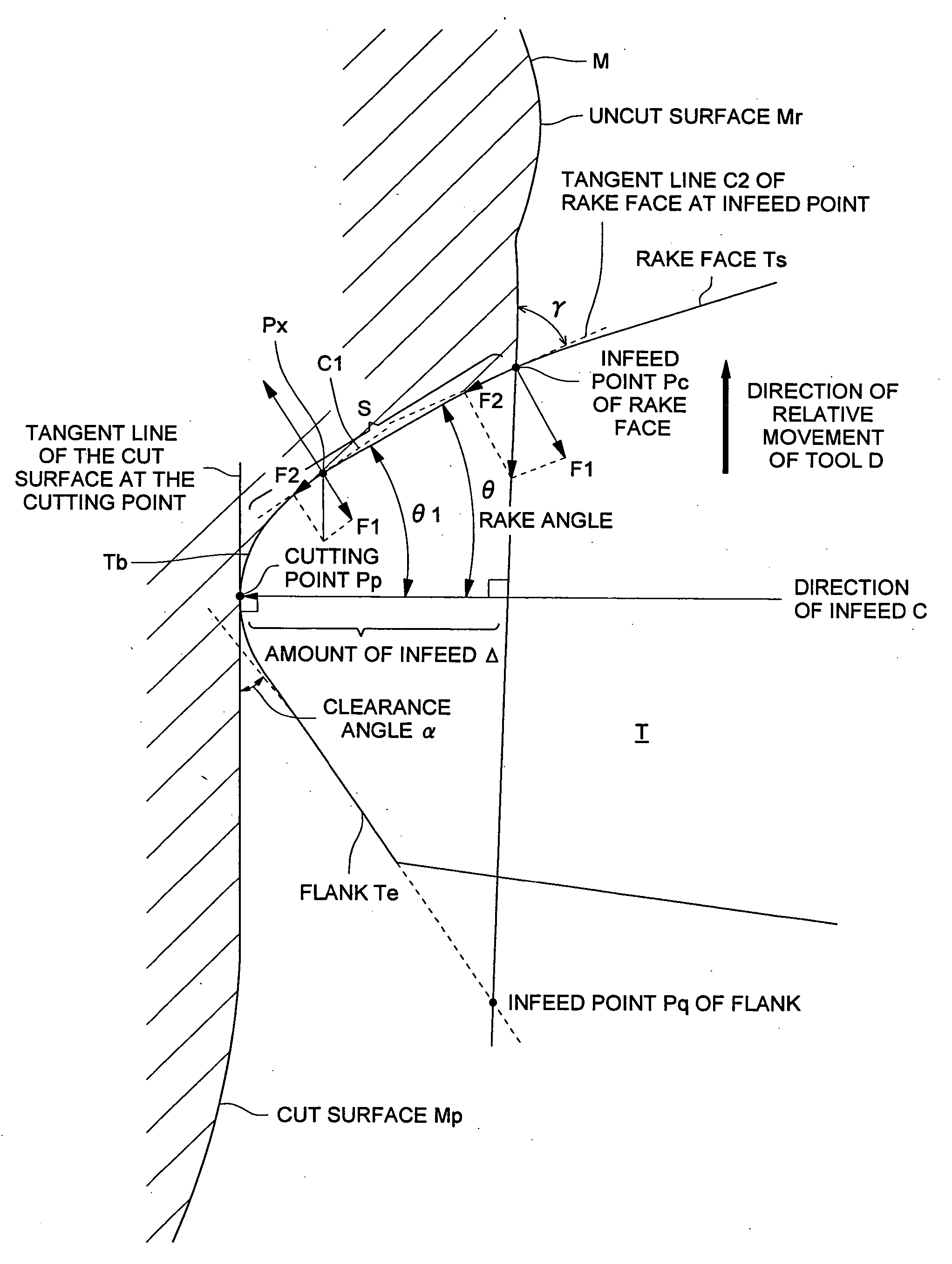

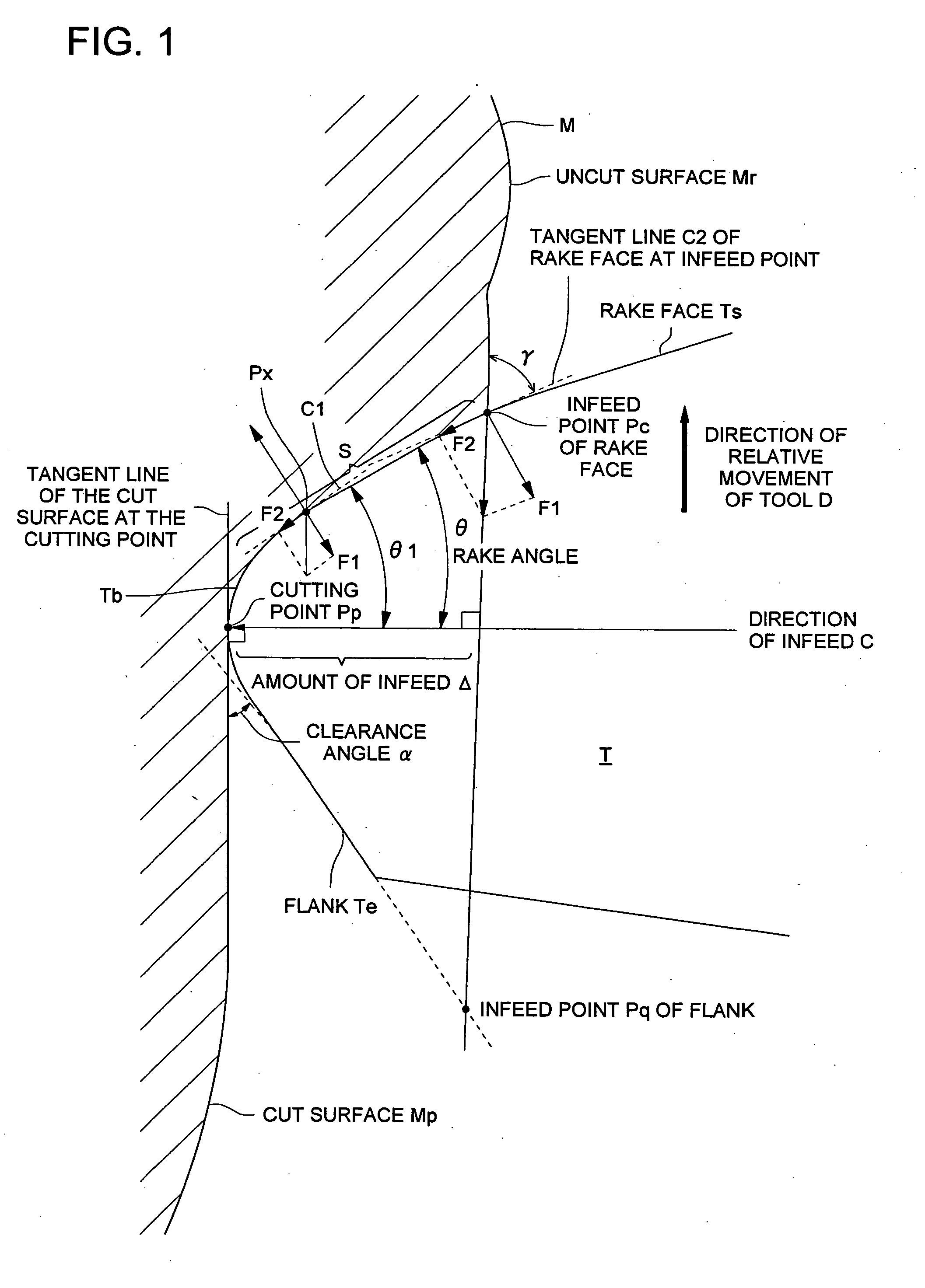

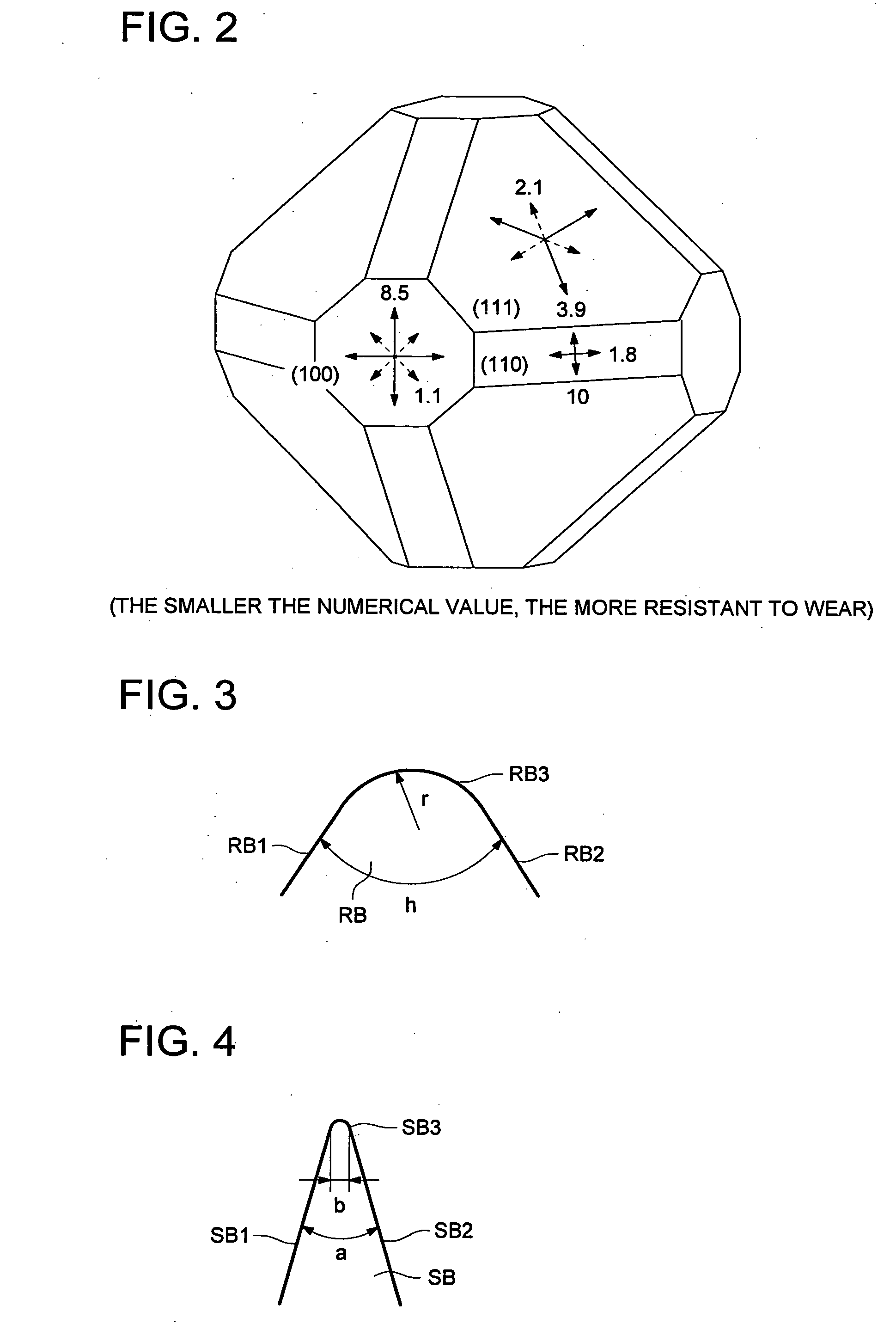

Transfer optical surface machining method, optical device producing mold and optical device

A machining method of machining a transfer optical surface on a optical element producing die having the transfer optical surface made of a material having Vickers hardness of Hv1500 or more, comprising: machining the transfer optical surface on the optical element producing die by cutting with a cutting tool, wherein a rake face of a tip of a blade of the cutting tool is set with an angle of minus values at an incising point on a surface to be machined.

Owner:KONICA MINOLTA INC

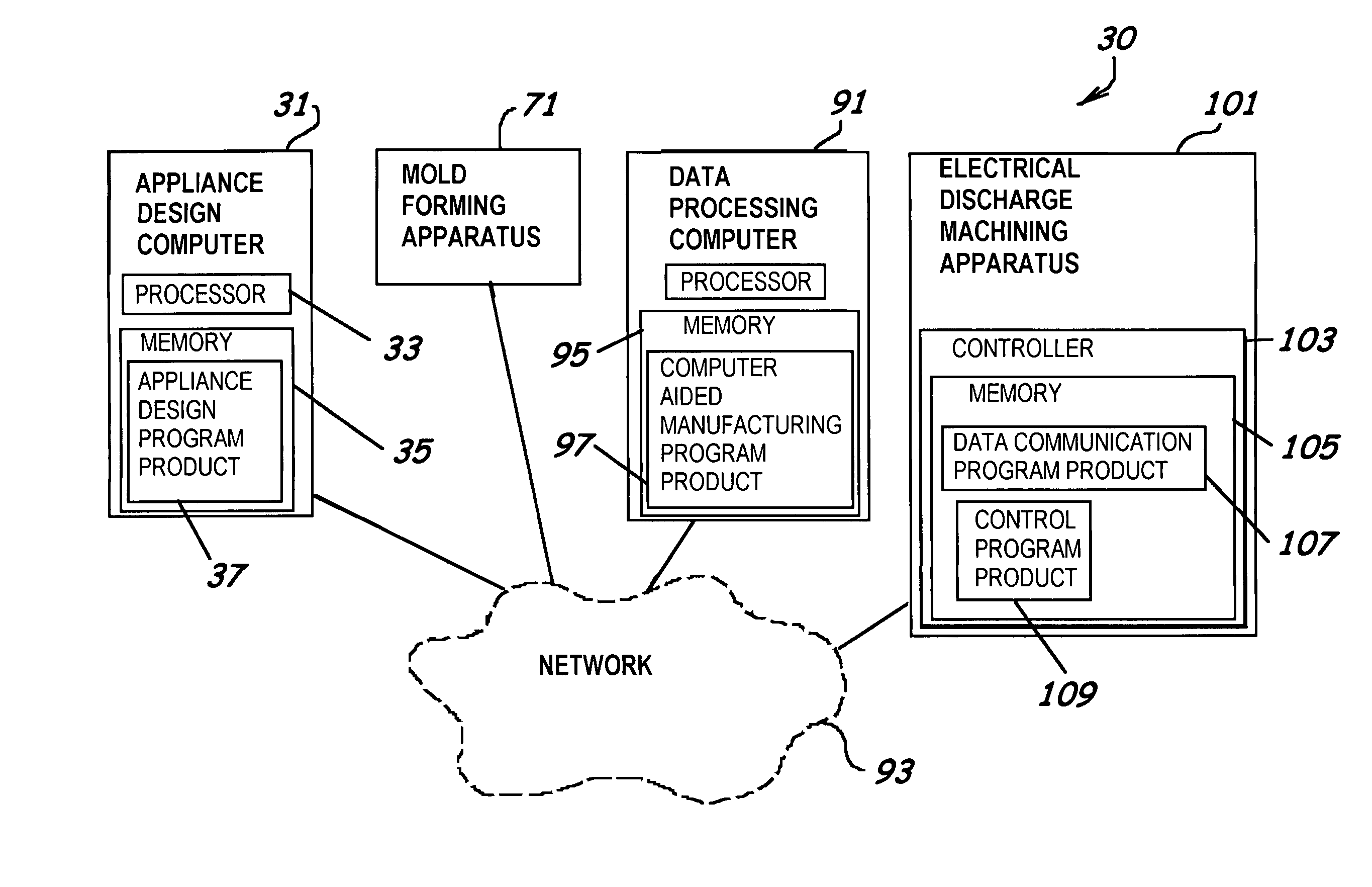

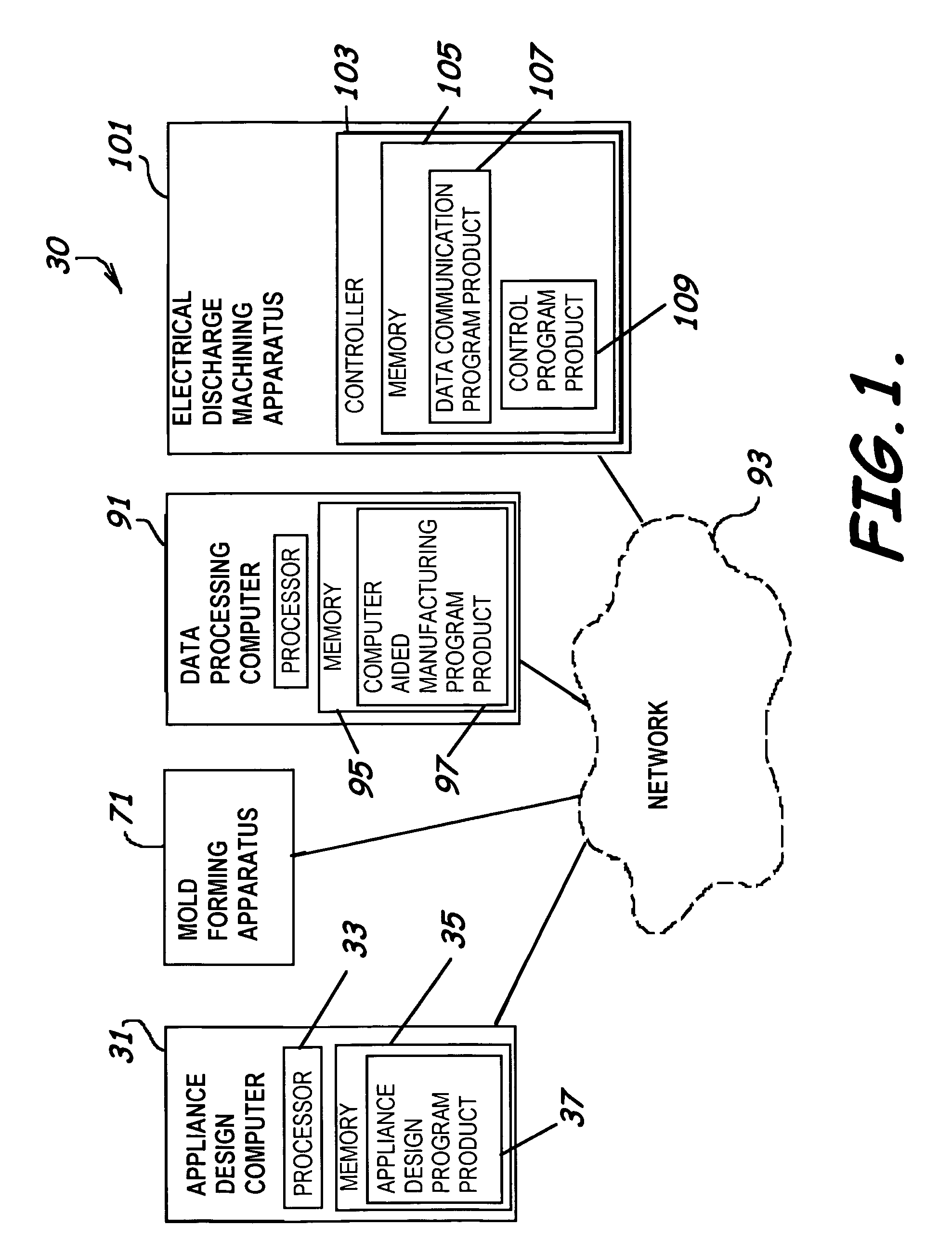

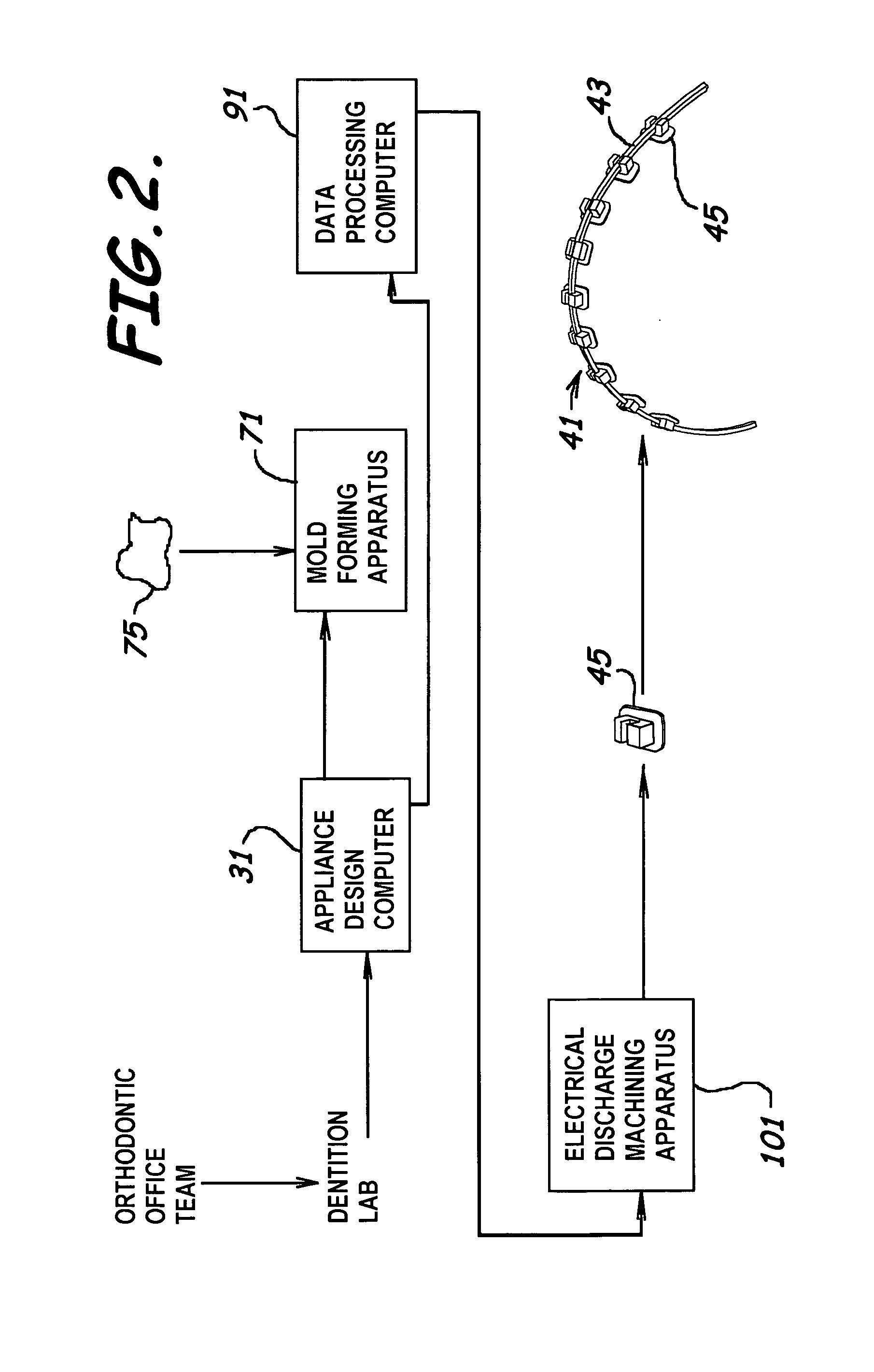

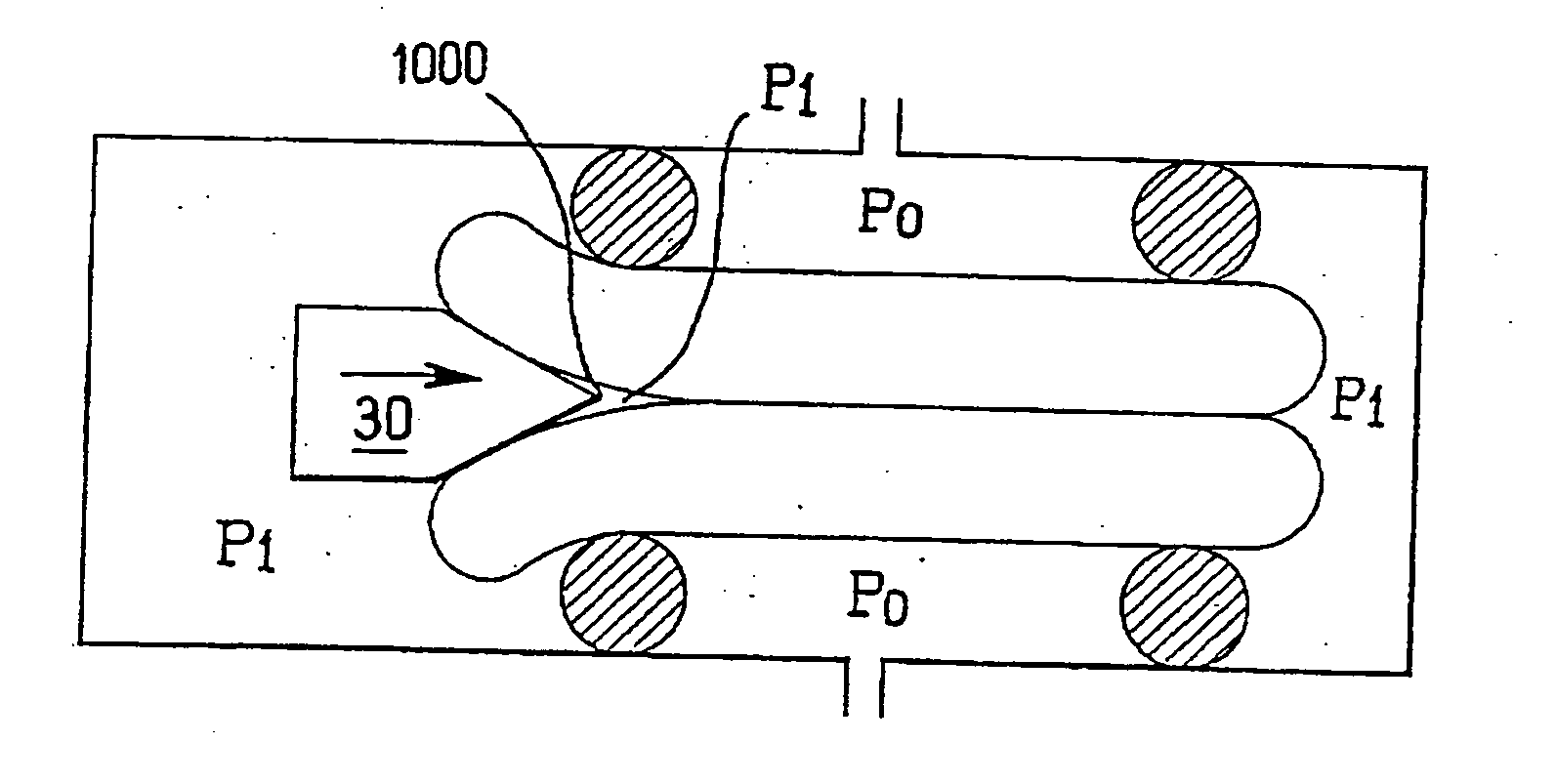

System to manufacture custom orthodontic appliances, program product, and related methods

ActiveUS20070178423A1High precision cuttingLevel of precision and efficiencyAdditive manufacturing apparatusBracketsControl signalComputer-aided

A system to manufacture orthodontic appliances, program product, and associated methods are provided. An embodiment of a system can include a virtual orthodontic appliance design computer having orthodontic appliance design program product provided to design a virtual dimensional representation of an orthodontic appliance including bracket bodies and bracket pads, and a mold apparatus positioned to form each bracket body and bracket pad. The system also includes a data processing computer including computer-aided manufacturing program product provided to derive electrical discharge device control instructions including a virtual dimensional representation of a bracket slot in the bracket, and an electrical discharge machining apparatus. The electrical discharge machining apparatus can include a controller including control program product to derive a control signal carrying the electrical discharge device control instructions and an electrical discharge device.

Owner:3M INNOVATIVE PROPERTIES CO

Laser processing method and method for manufacturing light-emitting device

ActiveUS20120077296A1Little strengthHigh precisionSemiconductor/solid-state device manufacturingFine working devicesLaser processingSingle crystal

A plurality of modified parts are formed at a first formation pitch for a line arranged along the M-plane of a single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach a principal surface of the single-crystal sapphire substrate. A plurality of modified parts are formed at a second formation pitch narrower than the first formation pitch for a line arranged along the A-plane of the single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach the principal surface of the single-crystal sapphire substrate. Along the lines, a knife edge is pressed against a wafer from the side of the single-crystal sapphire substrate opposite from the principal surface of the single-crystal sapphire substrate where the fractures have reached, to cut the wafer along the lines.

Owner:HAMAMATSU PHOTONICS KK

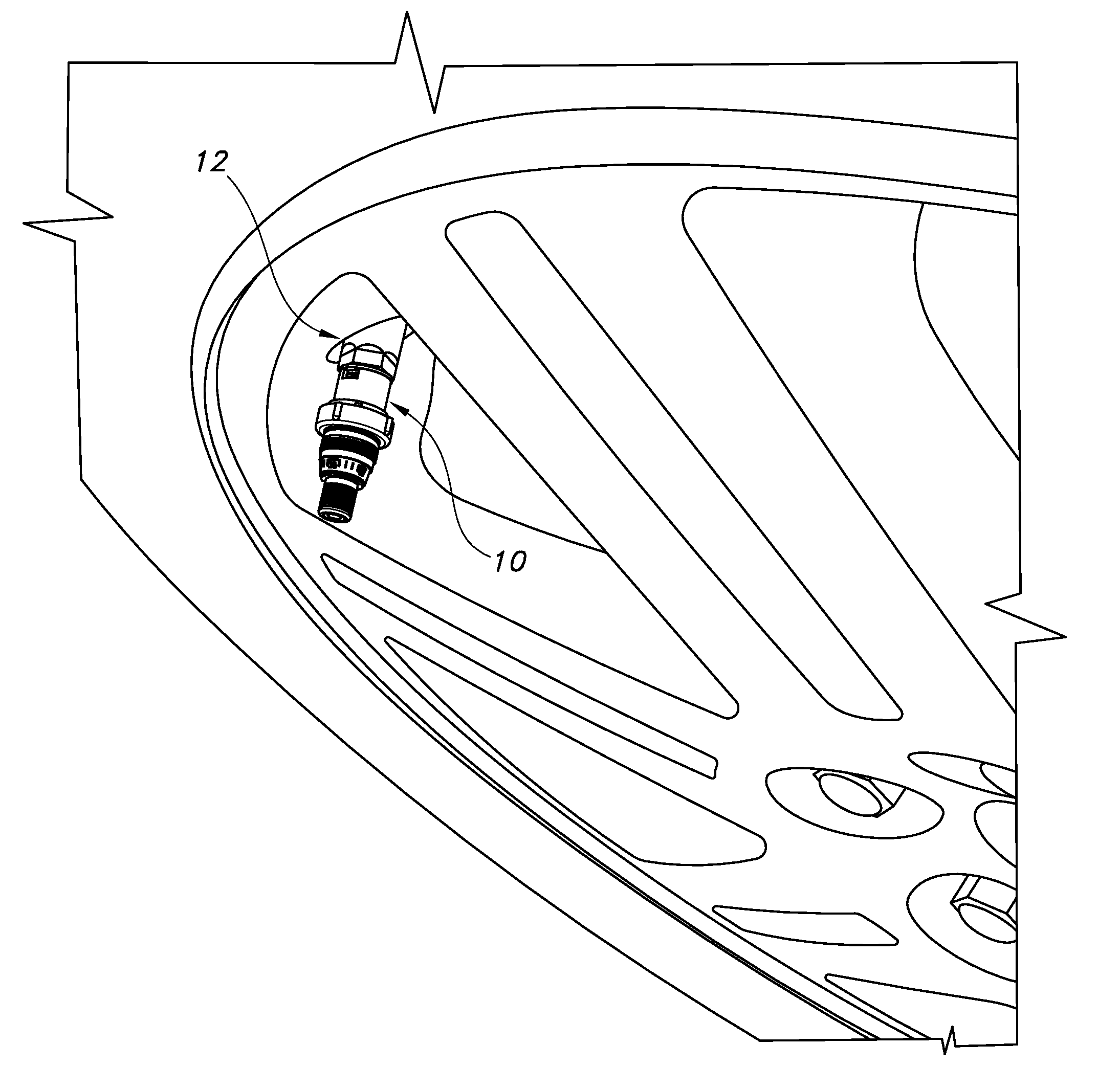

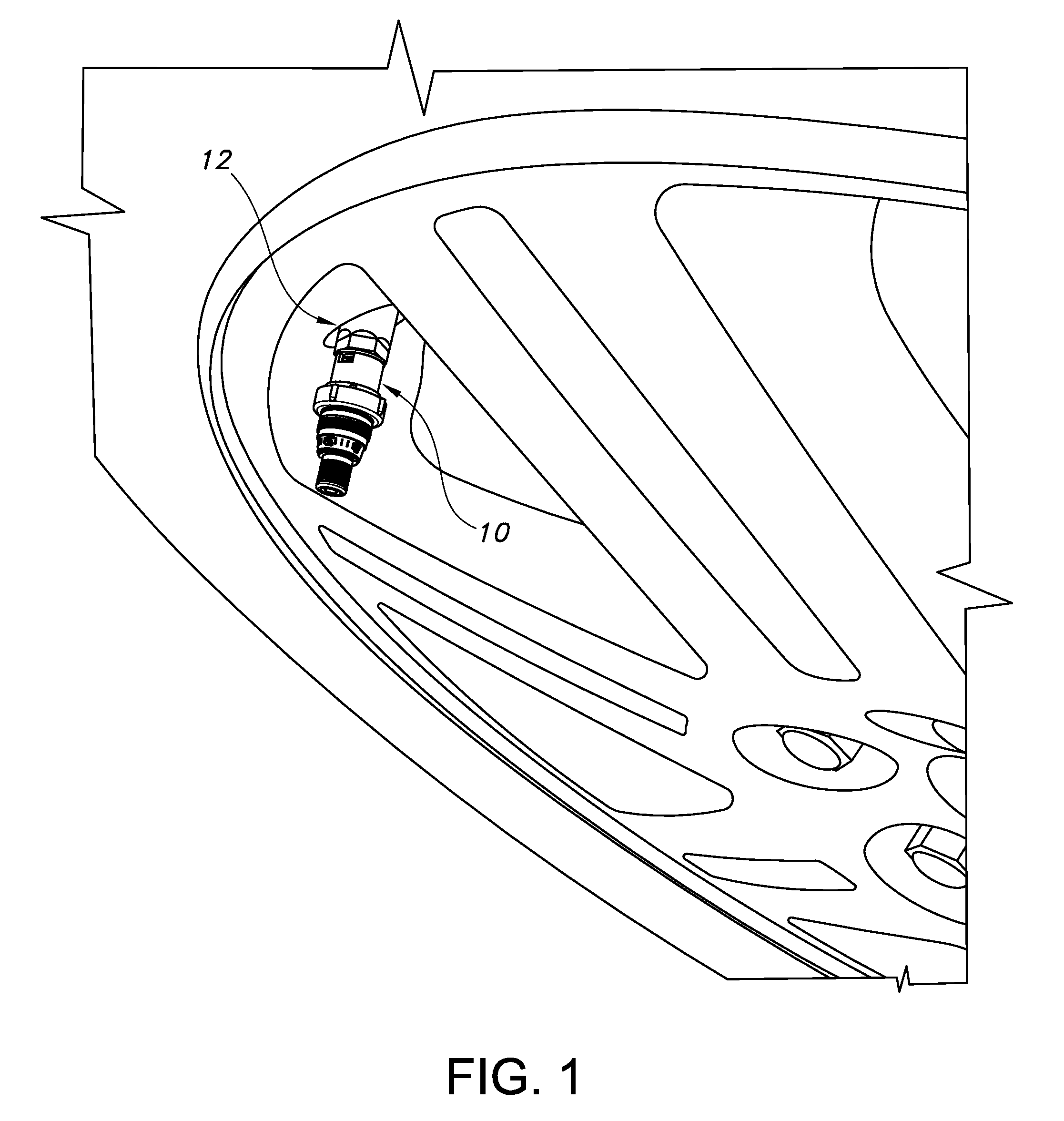

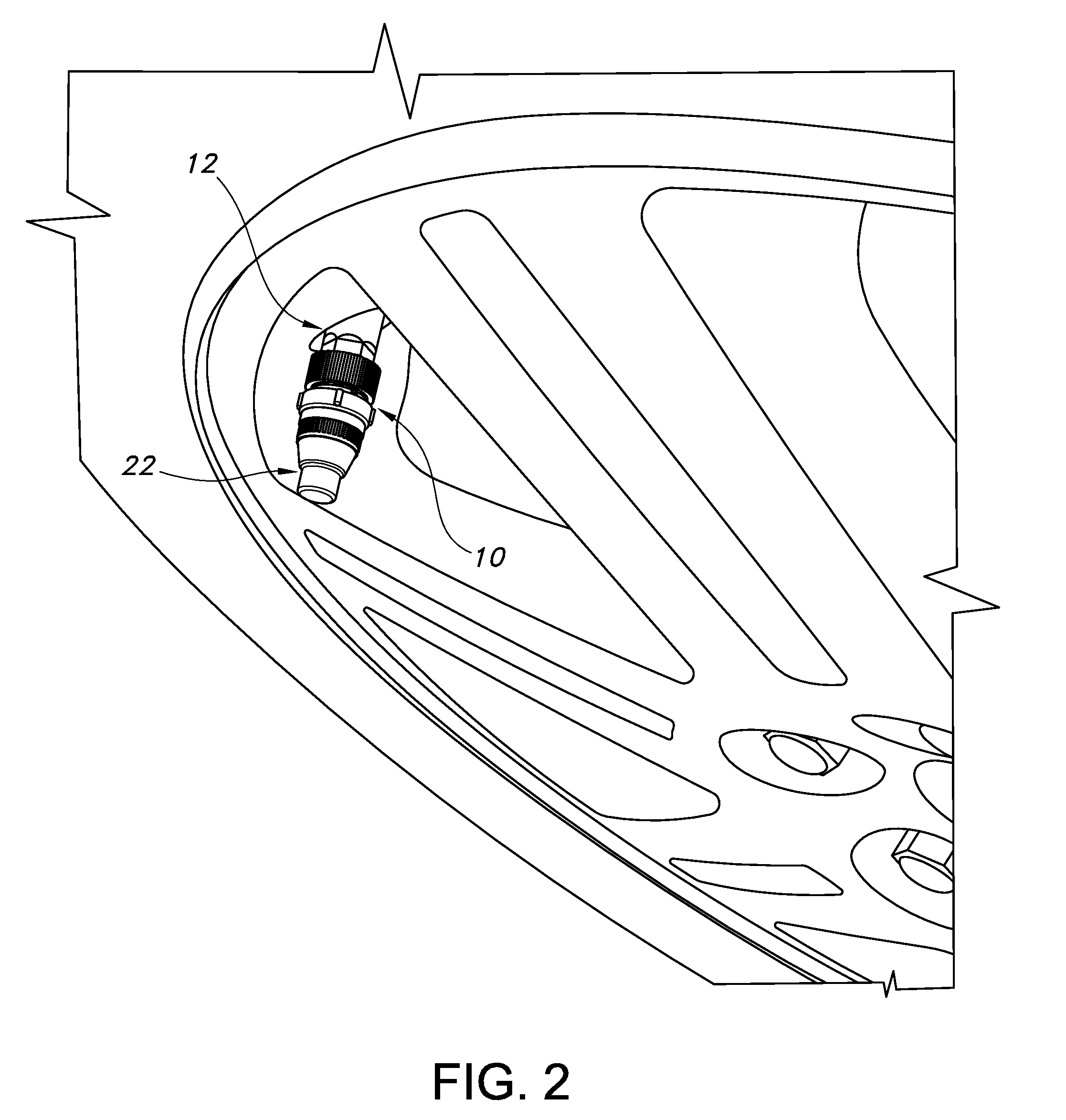

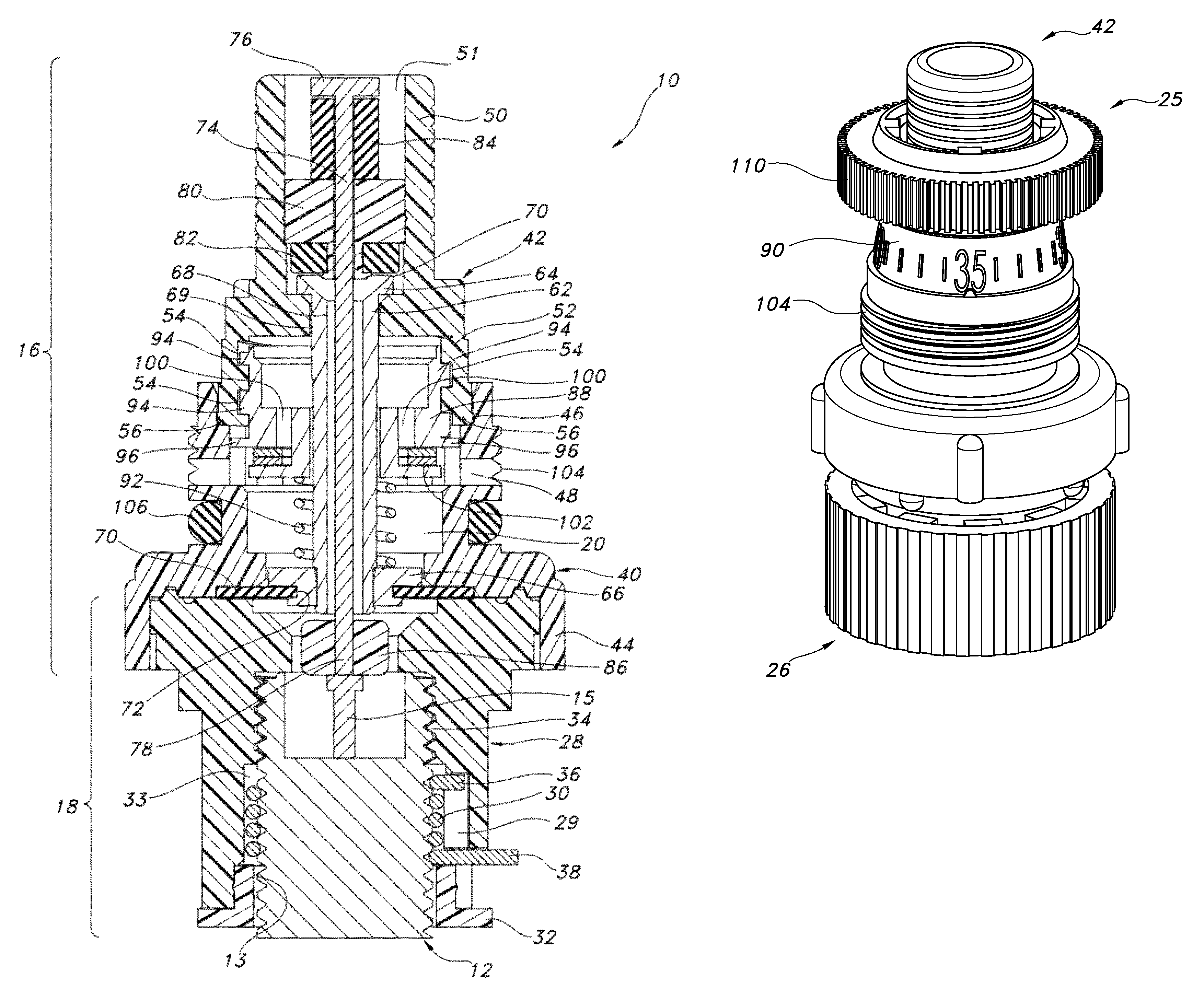

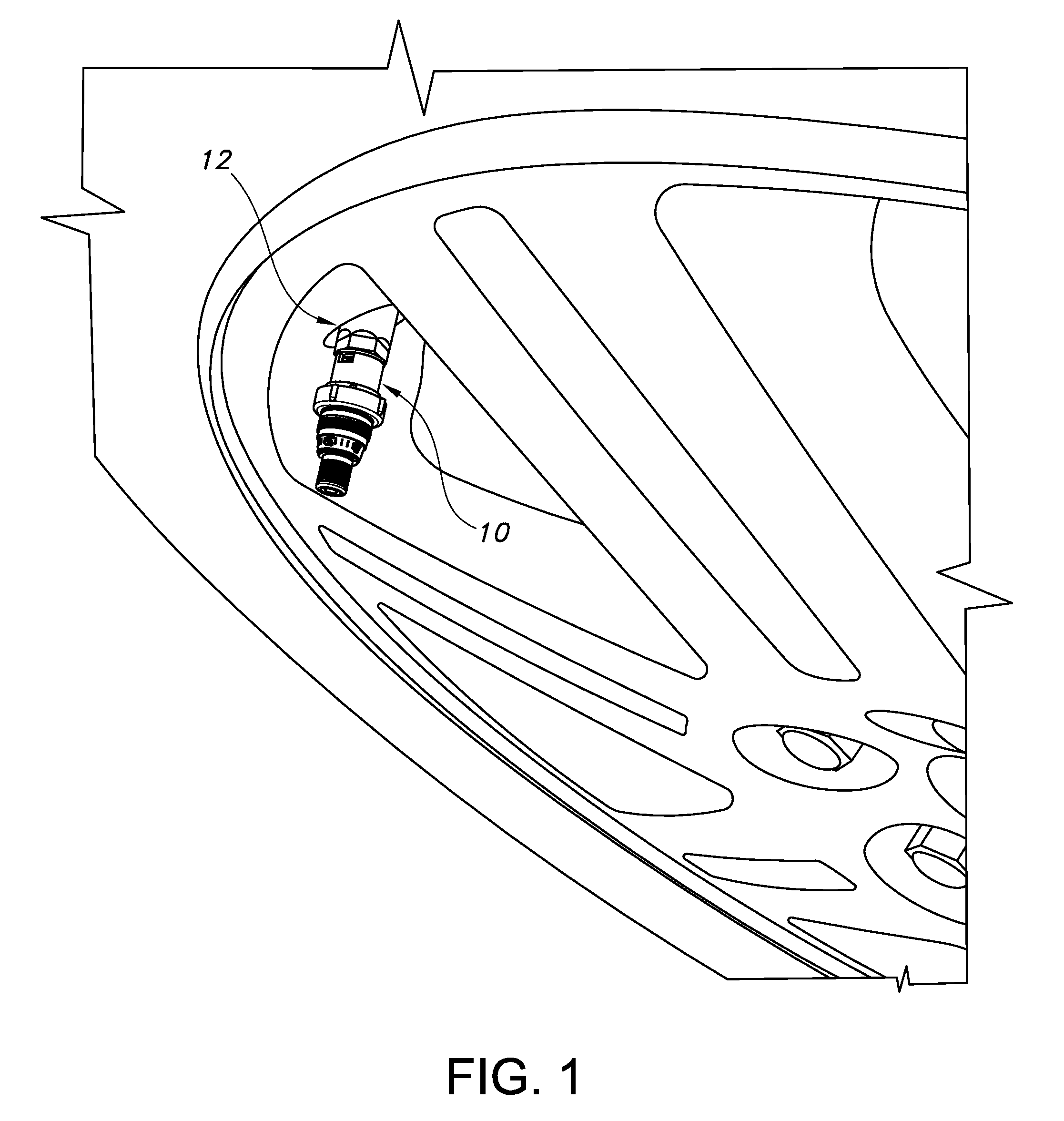

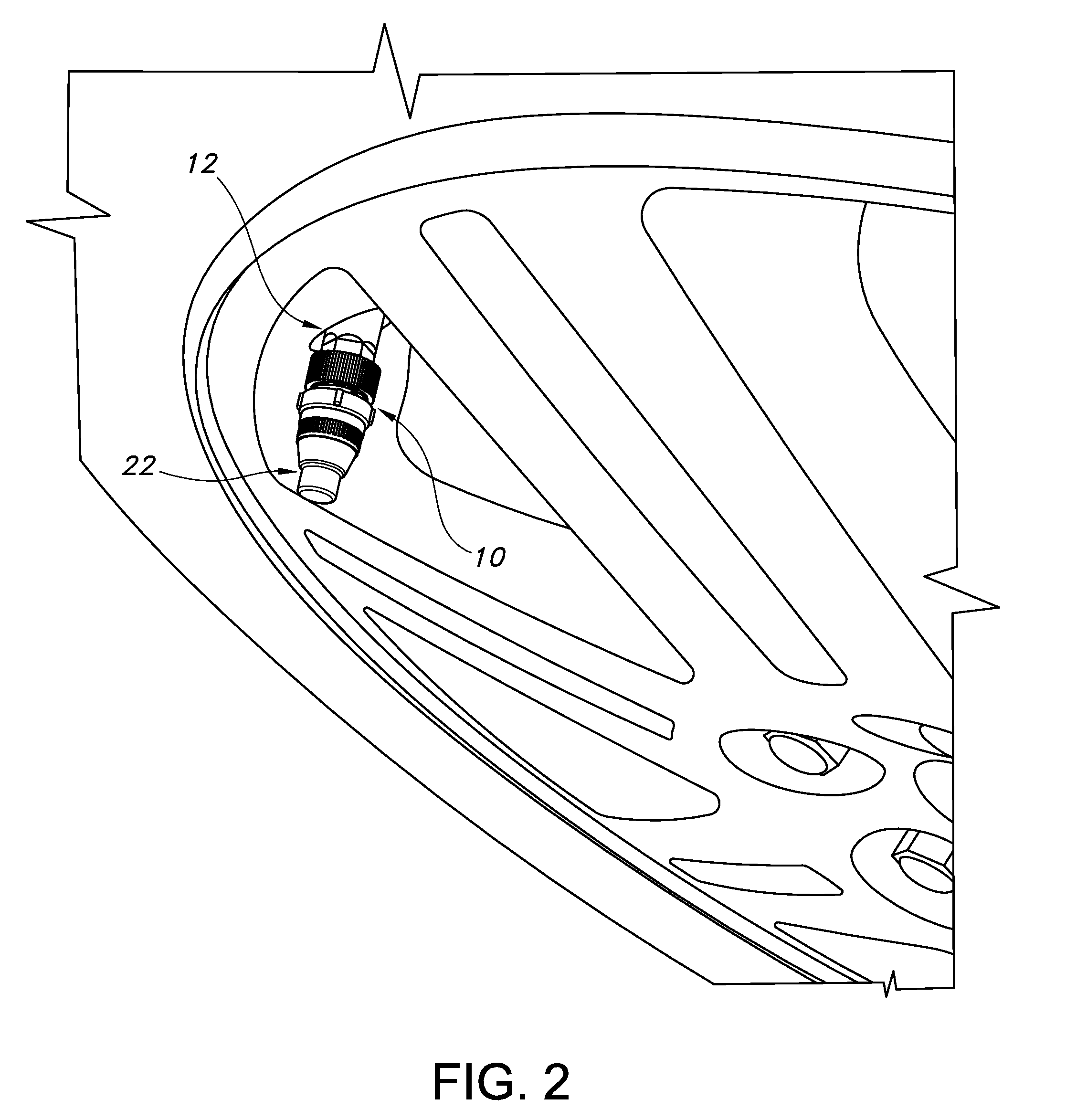

Stem-mounted tire inflation pressure regulator

InactiveUS20090095359A1Easily removeSame protective functionOperating means/releasing devices for valvesCheck valvesPressure regulatorTire pressure

The specification discloses a tire inflation pressure regulator facilitating precise tire inflation. The regulator includes a body, a two-position valve within the body, and a rotational lock. The body includes an air inlet, an air outlet, and an air vent. In one position, the valve directs air from the air inlet to the air outlet when the tire pressure is below a preset level; and, in a second position, the valve directs air from the air inlet to the air vent when the tire pressure exceeds the preset level to prevent overfilling. The valve moves rapidly between the two positions, and is unstable between the two positions. The valve includes a regulator enabling the preset level to be adjusted. The rotational lock enables the regulator to be screwed onto a tire stem, but prevents removal of the regulator from the tire stem without a key. The regulator preferably includes a cap removably sealed over the air inlet and the air vent to prevent the undesired loss of air.

Owner:FLOW RITE CONTROLS

Laser processing method and method for manufacturing light-emitting device

ActiveUS8722516B2Improve accuracyEfficient cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingSingle crystal

A plurality of modified parts are formed at a first formation pitch for a line arranged along the M-plane of a single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach a principal surface of the single-crystal sapphire substrate. A plurality of modified parts are formed at a second formation pitch narrower than the first formation pitch for a line arranged along the A-plane of the single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach the principal surface of the single-crystal sapphire substrate. Along the lines, a knife edge is pressed against a wafer from the side of the single-crystal sapphire substrate opposite from the principal surface of the single-crystal sapphire substrate where the fractures have reached, to cut the wafer along the lines.

Owner:HAMAMATSU PHOTONICS KK

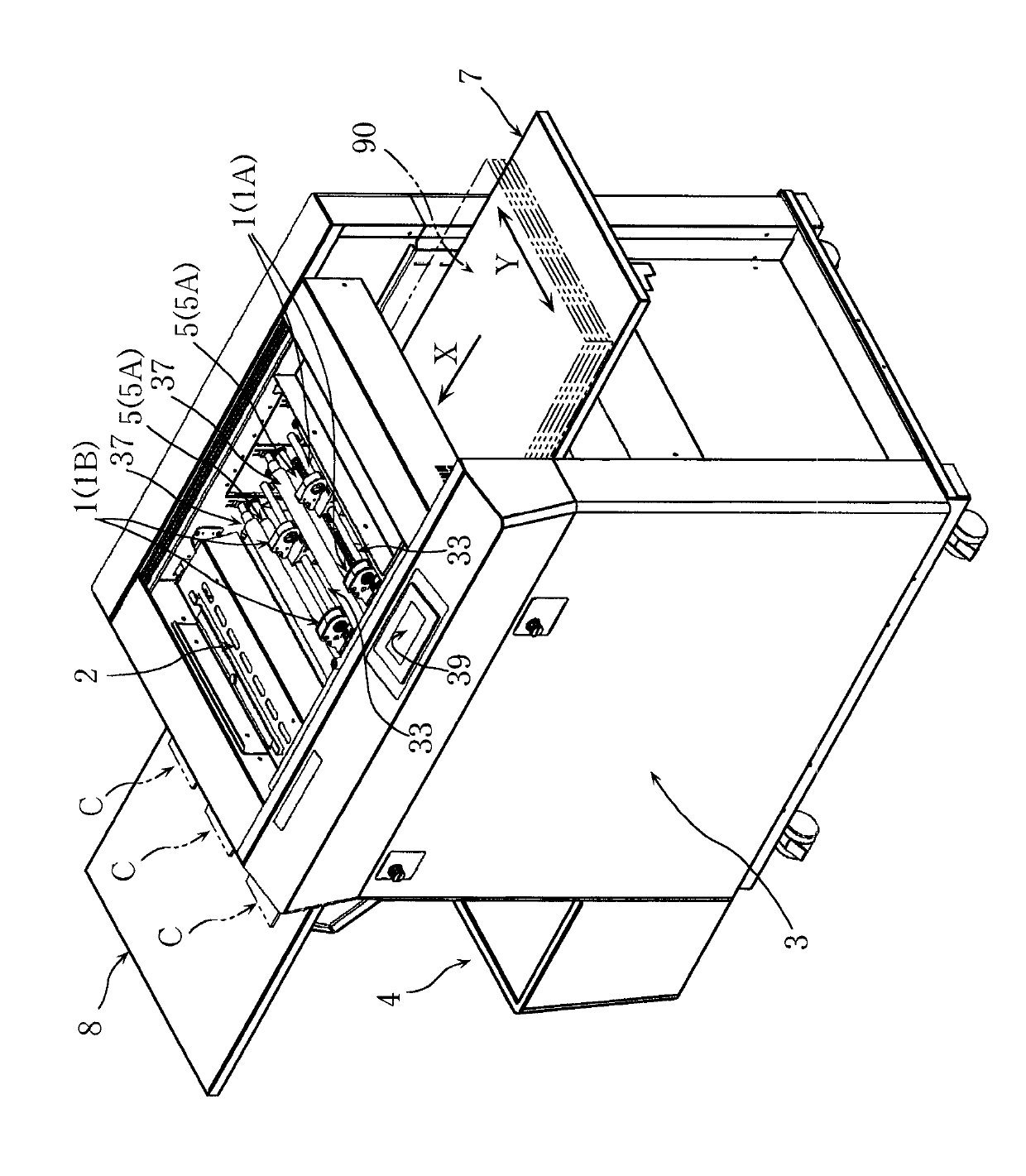

Digital control working machine with grinder

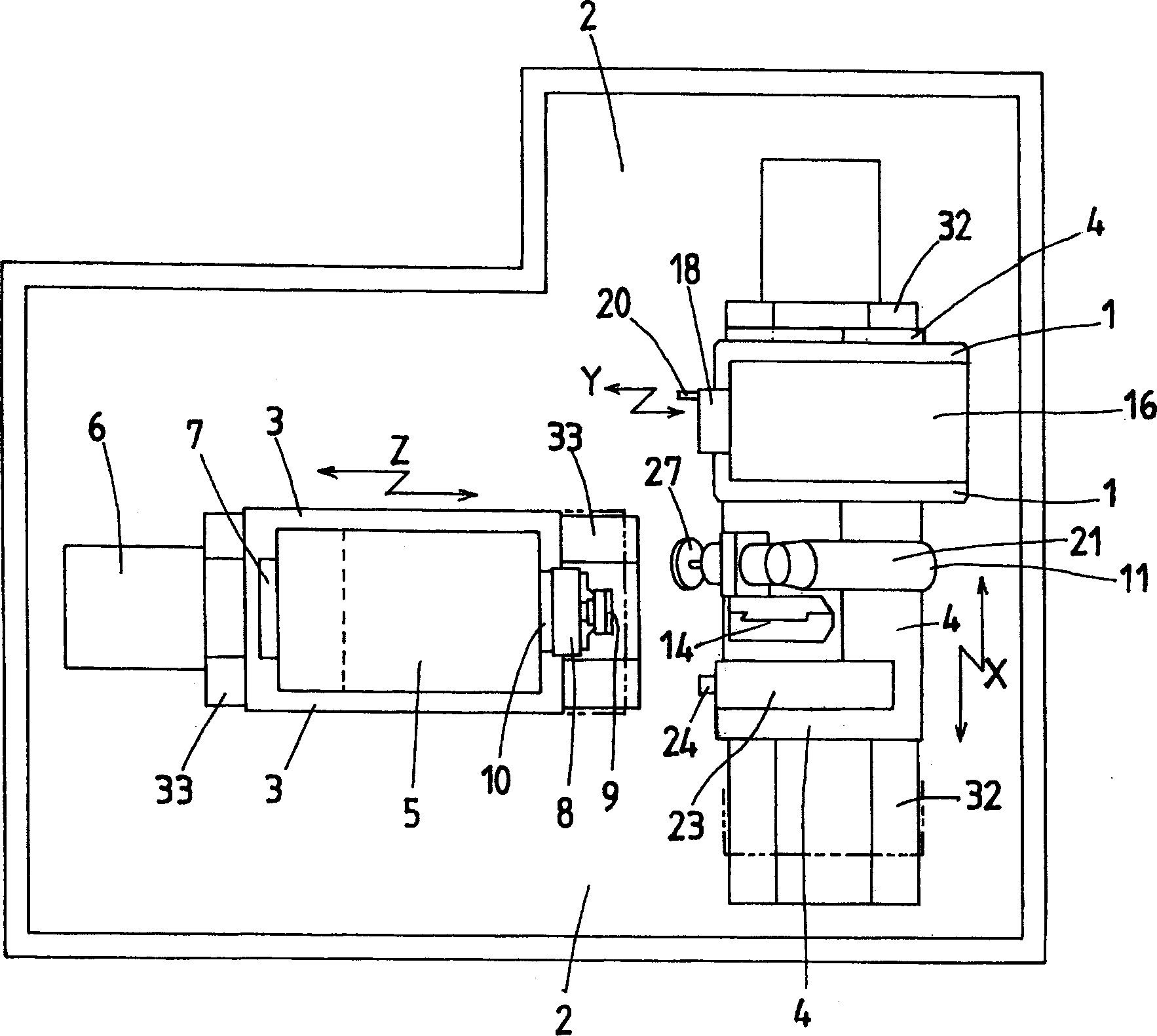

InactiveCN1491764ASmall inertia forceImprove responsivenessProgramme controlAutomatic control devicesEngineeringDigital control

The NC processing machine has the Y-axial cutting tool mounted on a slider which is arranged in a sliding base on a X-axial table and reciprocates in the Y-axial direction. This NC processing machine cuts the work into the prescribed processing configuration with the Y-axial cutting tool while the slider is reciprocating in synchronism with rotation of a main shaft 10, and then polishes a processing surface of the work by a buff of the polishing unit in accordance with configuration of a program surface of the work without change in a grasping state of the work with a chuck device .

Owner:WEST ELECTRIC CO LTD

Method and device for weight precise cutting of a food strand

ActiveUS8758099B2Easy to detectImprove accuracyMeat processing plantsPoultry processingData controlMechanical engineering

Owner:REIFENHAEUSER UWE

Laser processing method

ActiveUS8969752B2Improve accuracyHigh precision cuttingOptical radiation measurementOptical articlesLaser processingProcess region

The present invention provides a laser processing method comprising the steps of attaching a protective tape 25 to a front face 3 of a wafer 1a, irradiating a substrate 15 with laser light L while employing a rear face of the wafer 1a as a laser light entrance surface and locating a light-converging point P within the substrate 15 so as to form a molten processed region 13 due to multiphoton absorption, causing the molten processed region 13 to form a cutting start region 8 inside by a predetermined distance from the laser light entrance surface along a line 5 along which the object is intended to be cut in the wafer 1a, attaching an expandable tape 23 to the rear face 21 of the wafer 1a, and expanding the expandable tape 23 so as to separate a plurality of chip parts 24 produced upon cutting the wafer 1a from the cutting start region 8 acting as a start point from each other.

Owner:HAMAMATSU PHOTONICS KK

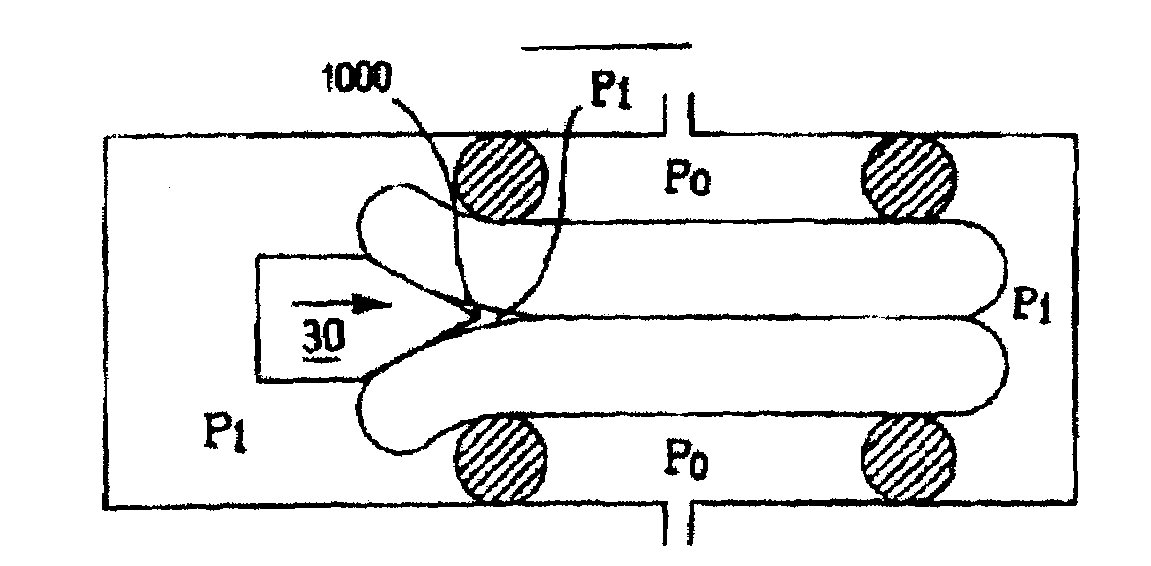

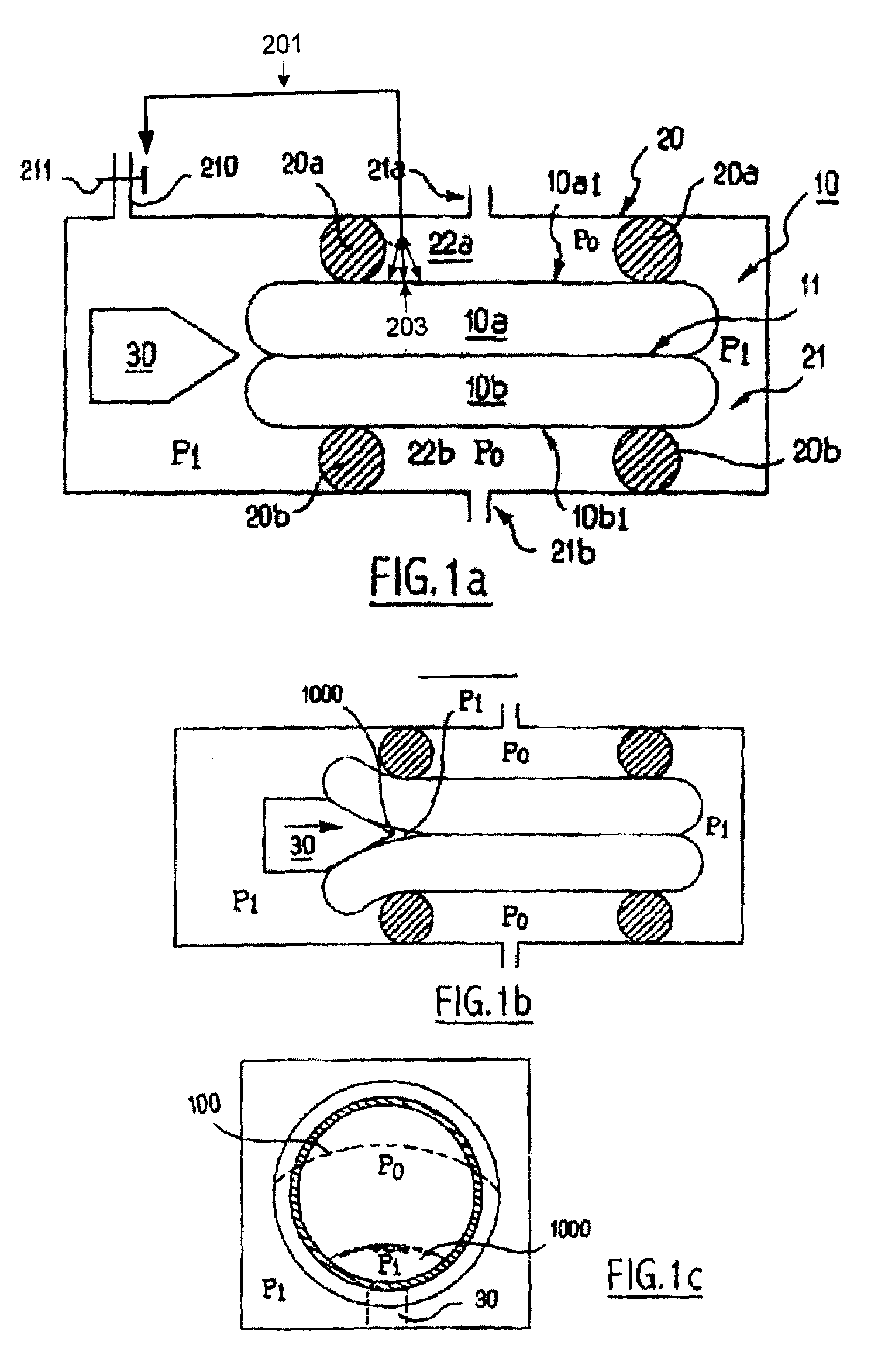

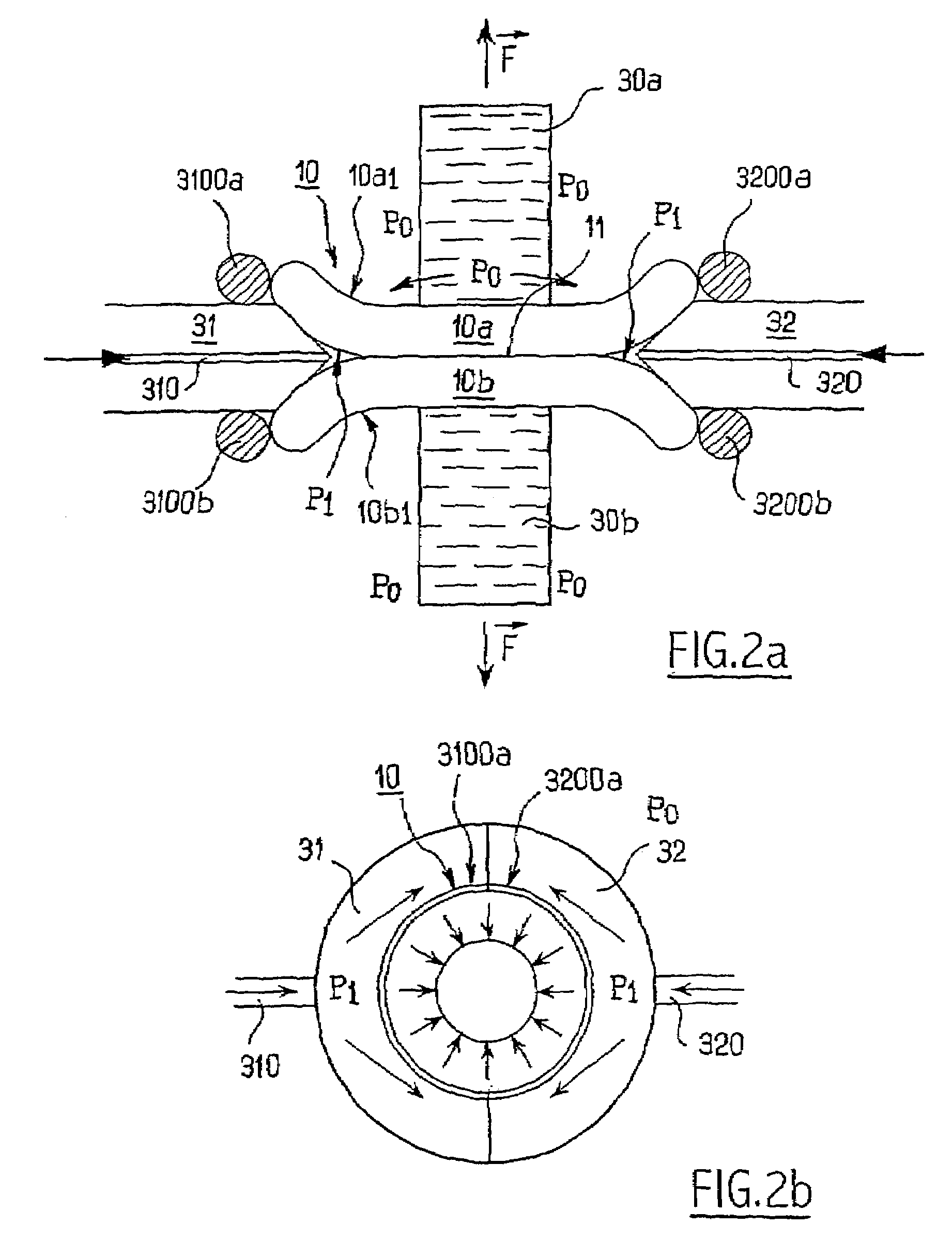

Device and method for cutting an assembly

ActiveUS20050009297A1High precision cuttingSurface/boundary effectSemiconductor/solid-state device manufacturingHigh pressureBiomedical engineering

A method is presented for cutting an assembly that includes two layers of material having a first surface and a second surface. The method includes providing a weakened interface between the two layers that defines an interface ring about the periphery of the assembly, providing a high-pressure zone at the interface ring, and providing at least one controllable low-pressure zone in the vicinity of at least one of the first surface and the second surface. The technique also includes supplying the high-pressure zone with a controllable high-pressure force, and attacking the interface ring with at least one mechanical force in combination with the high-pressure force to cut the assembly.

Owner:SOITEC SA

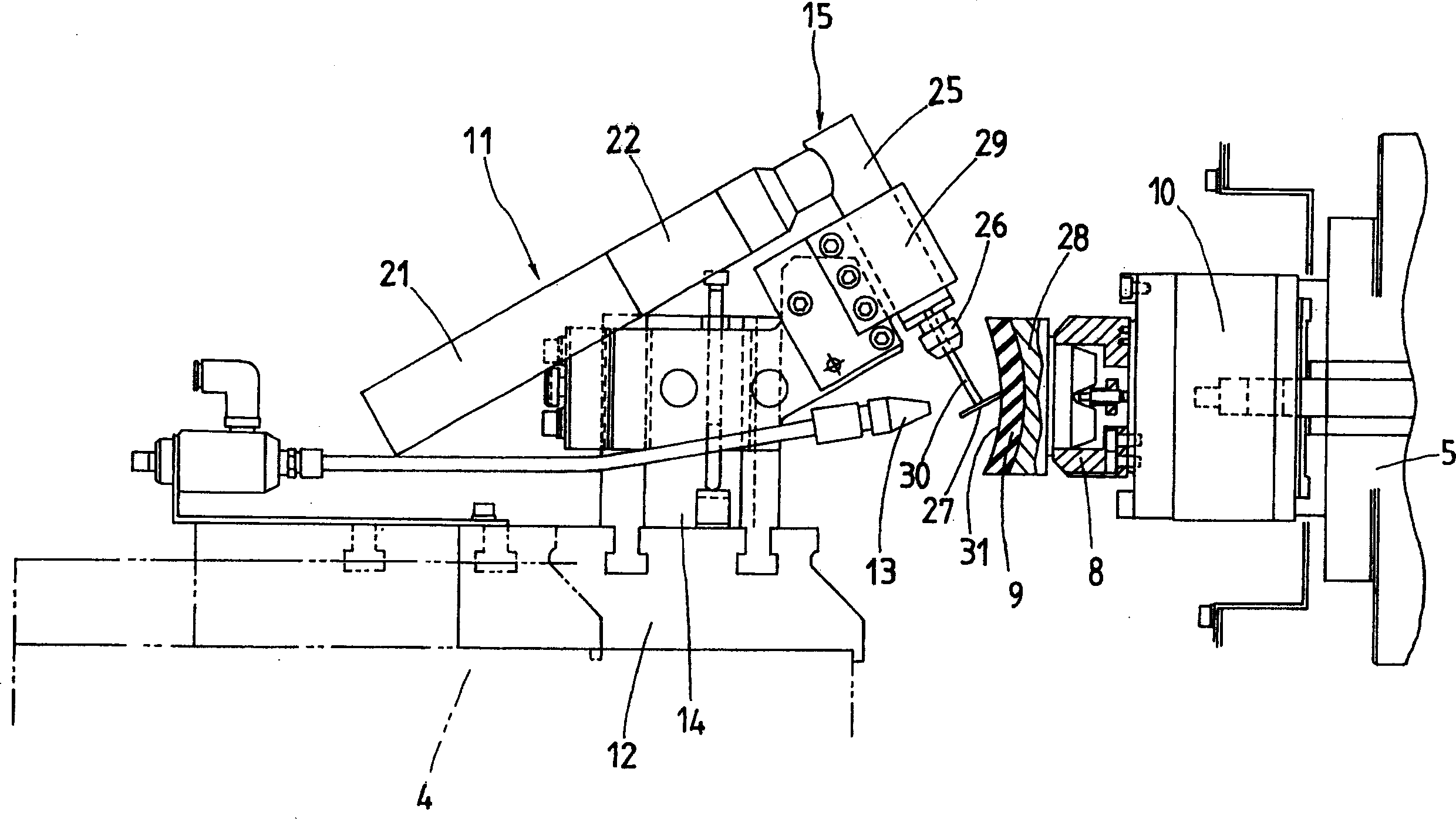

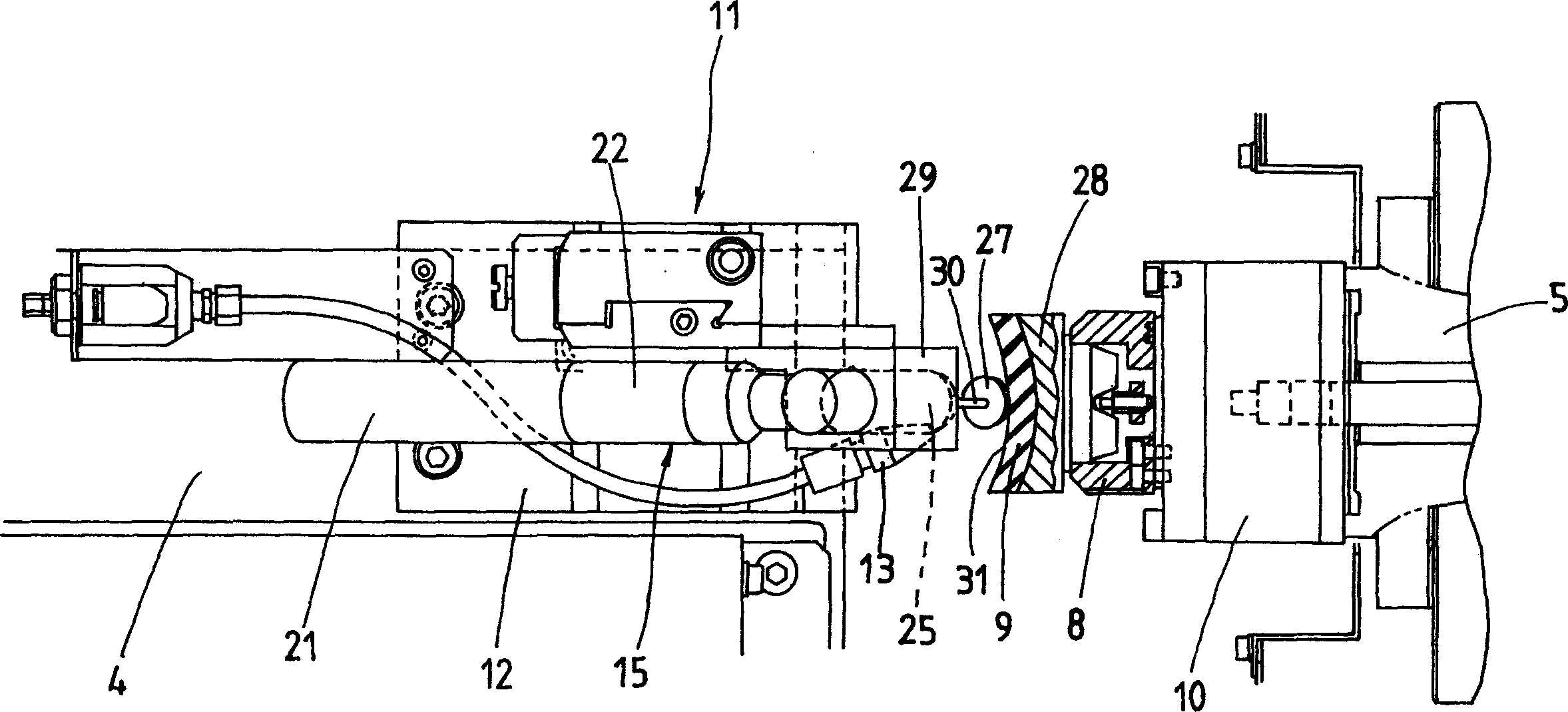

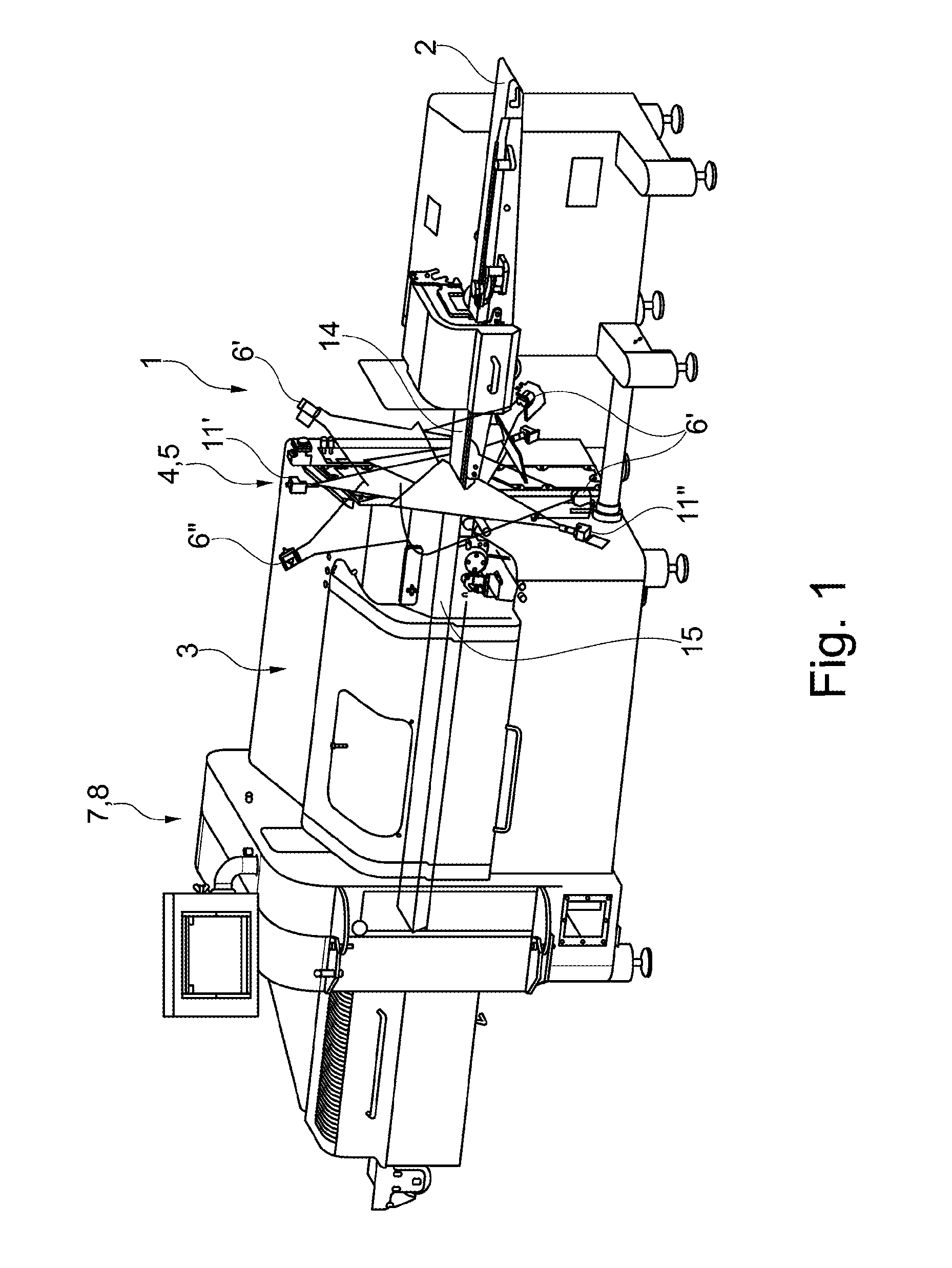

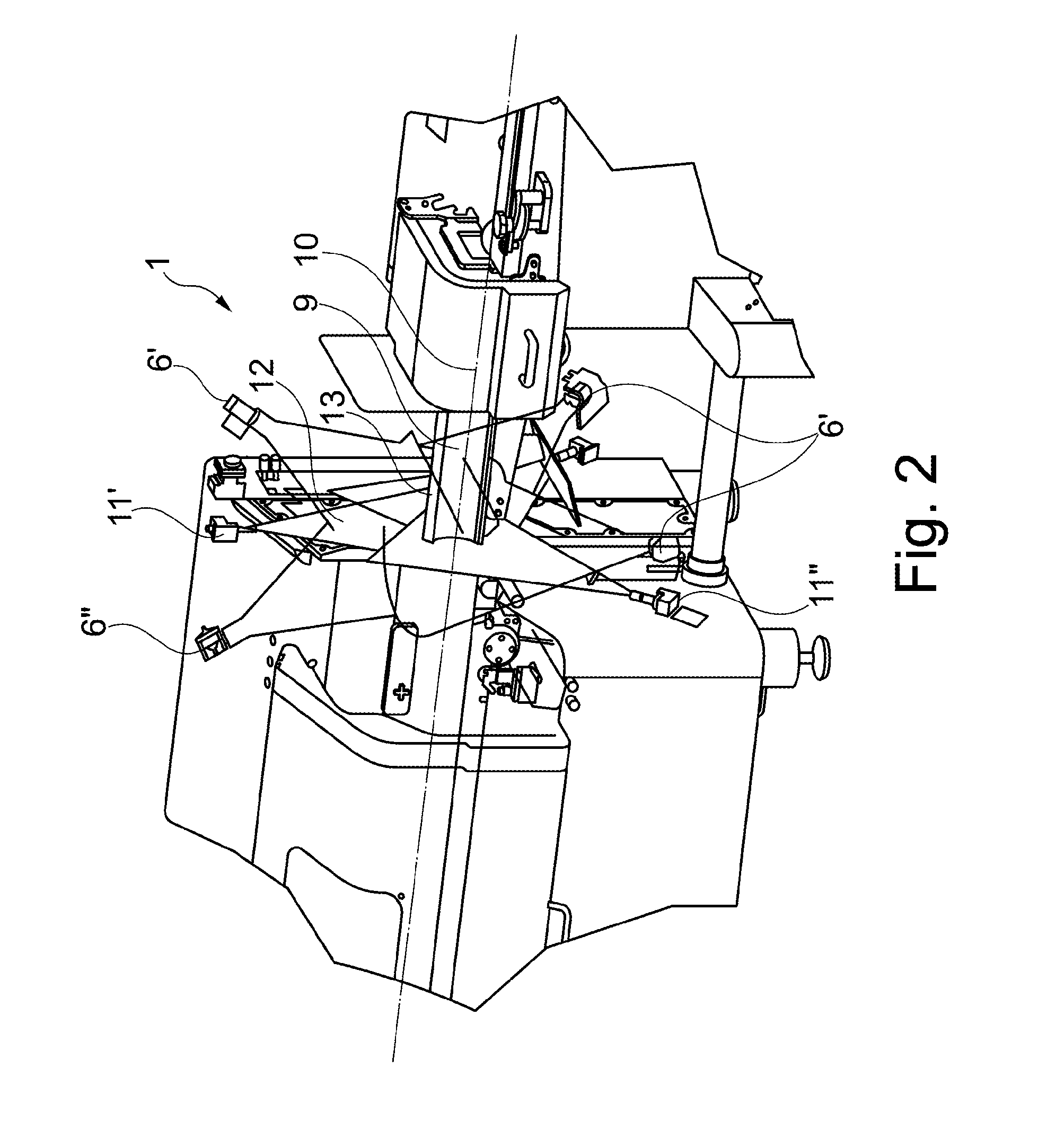

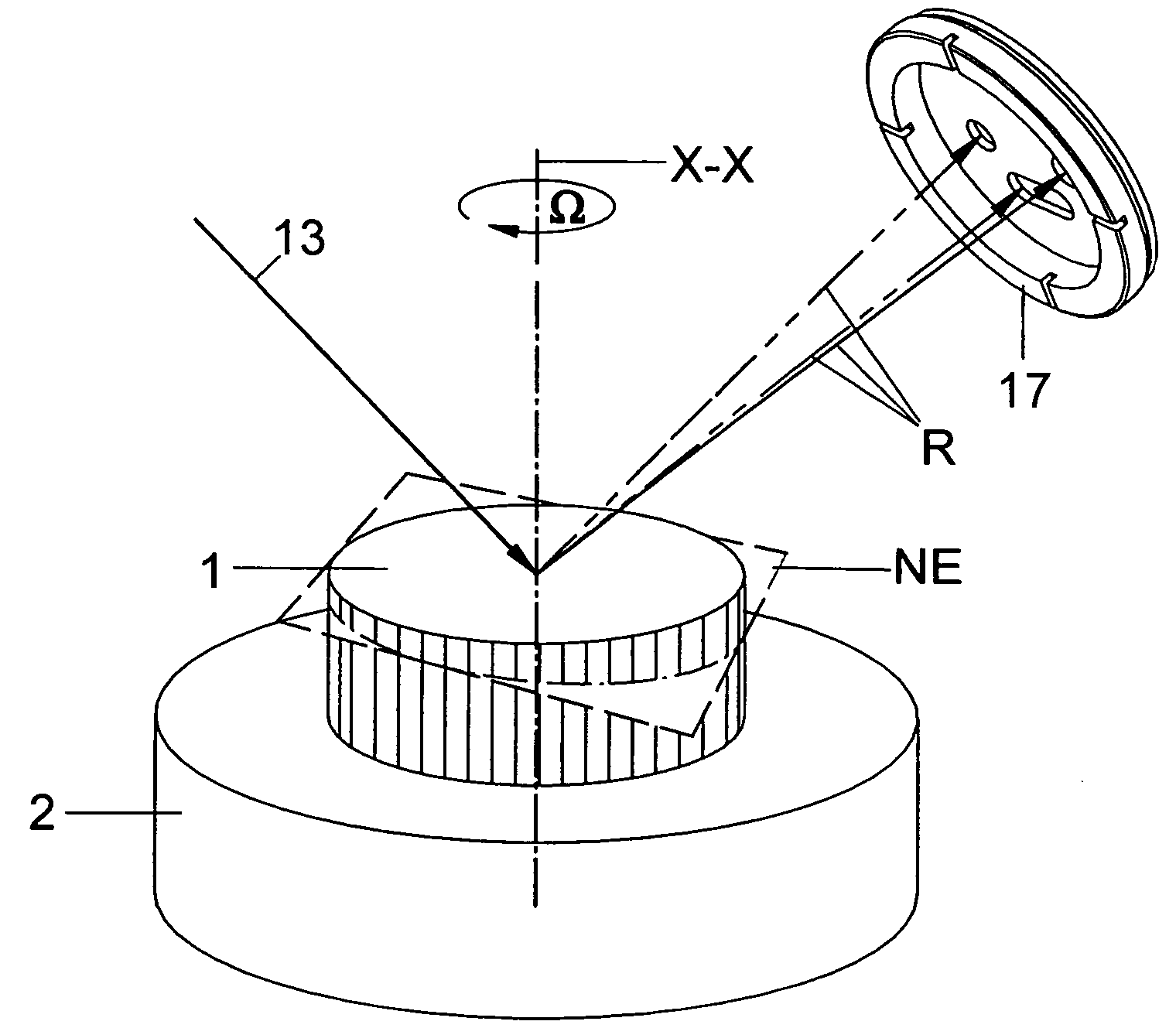

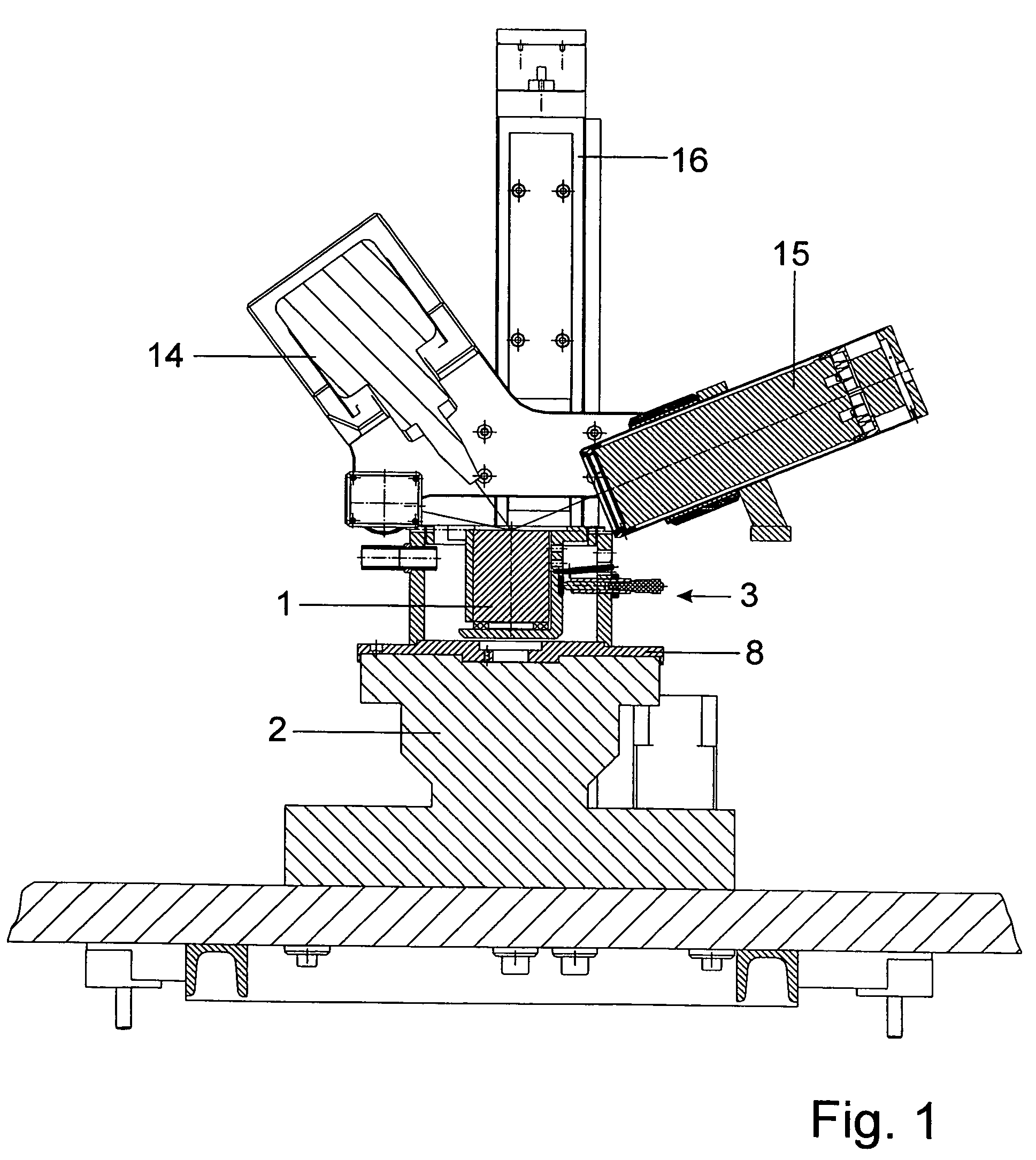

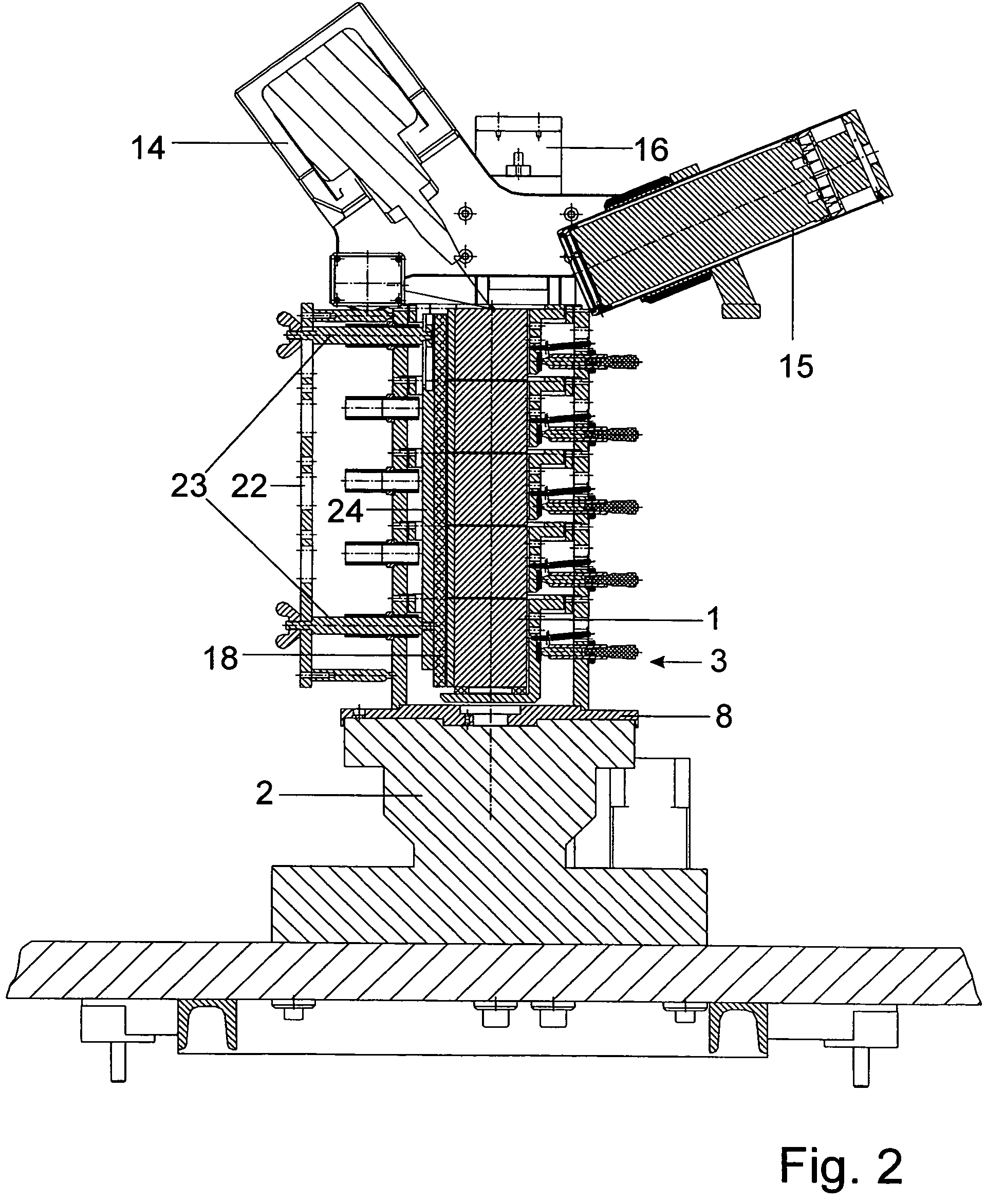

Method and apparatus for the measurement, orientation and fixation of at least one single crystal

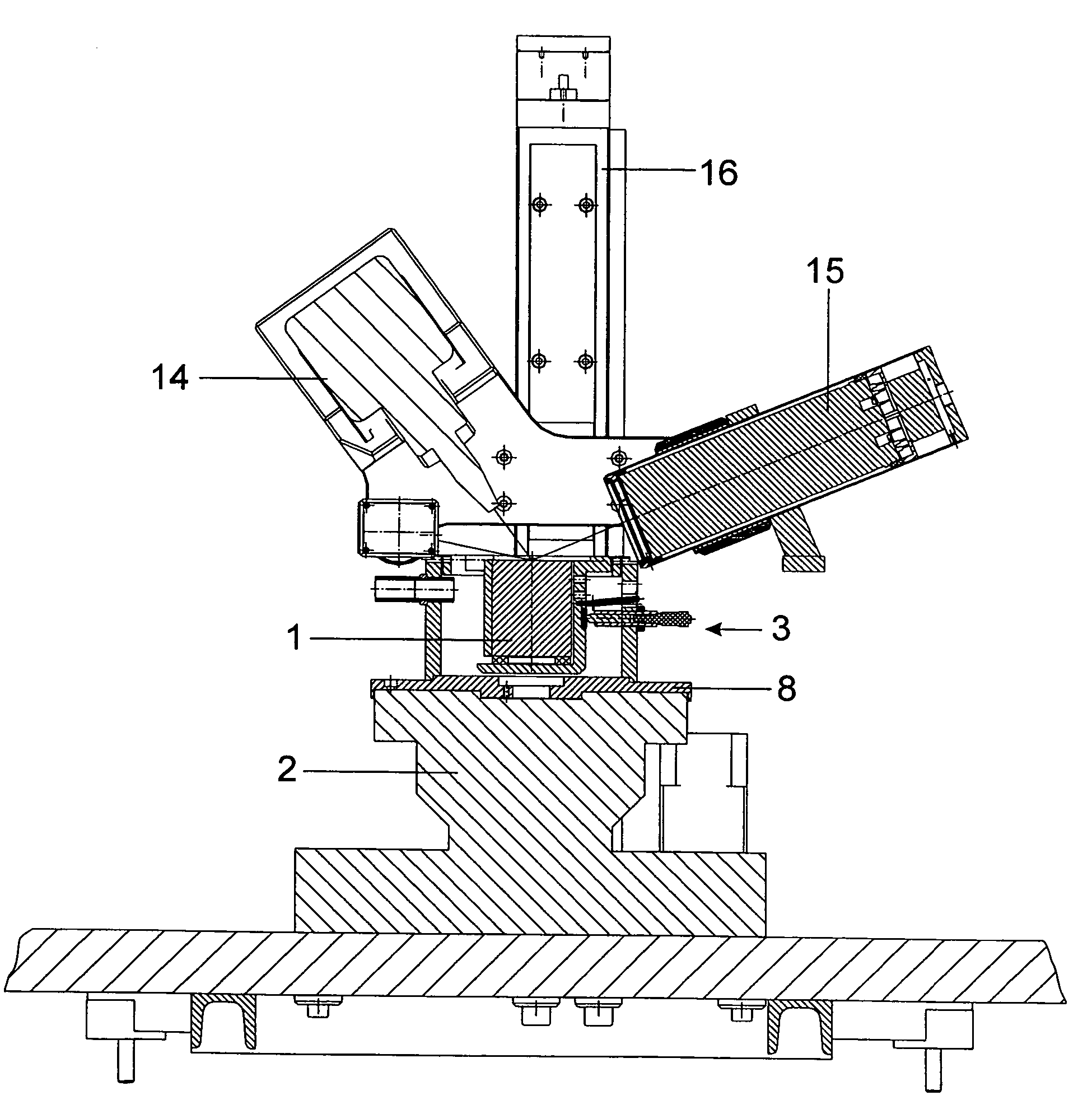

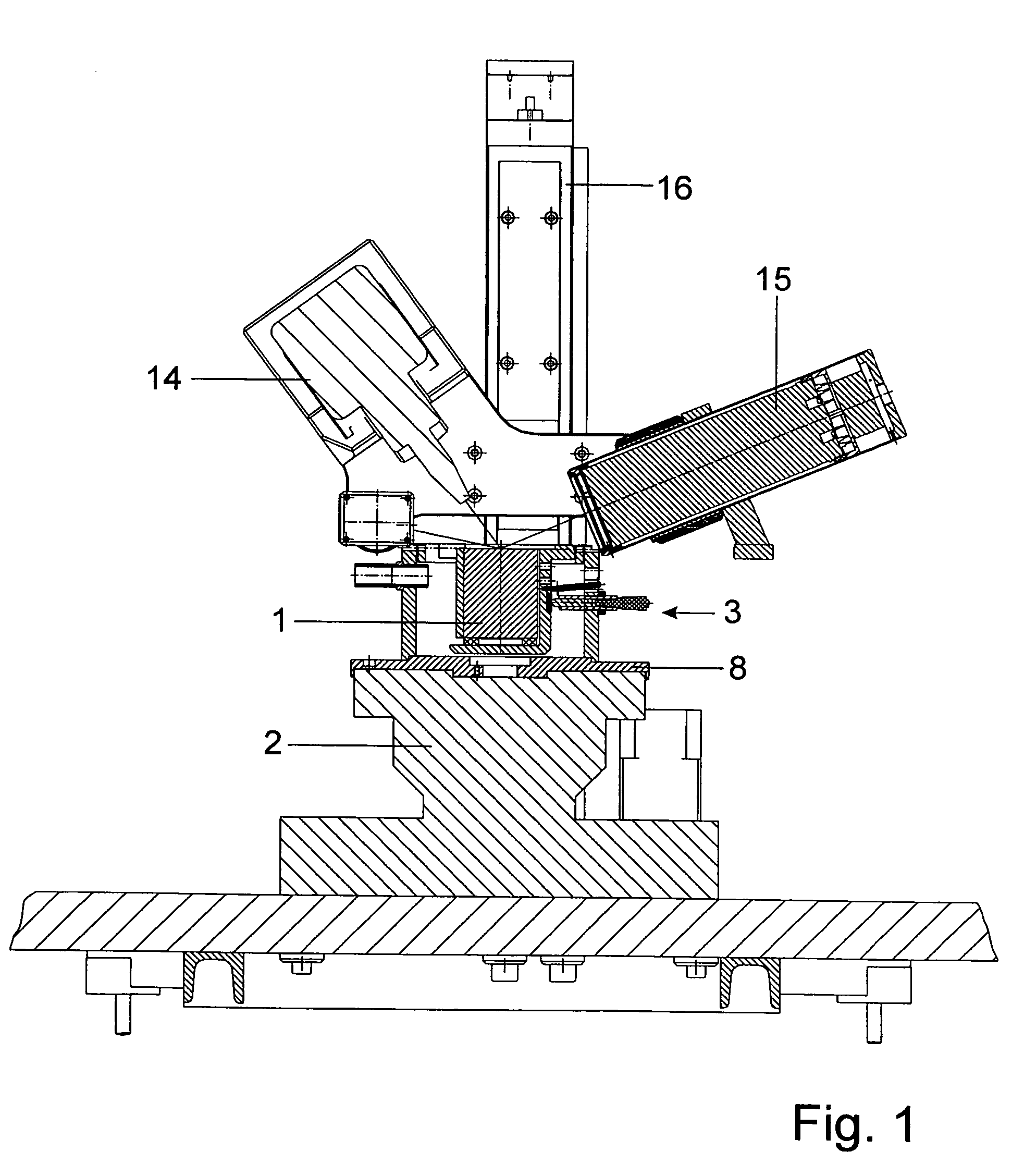

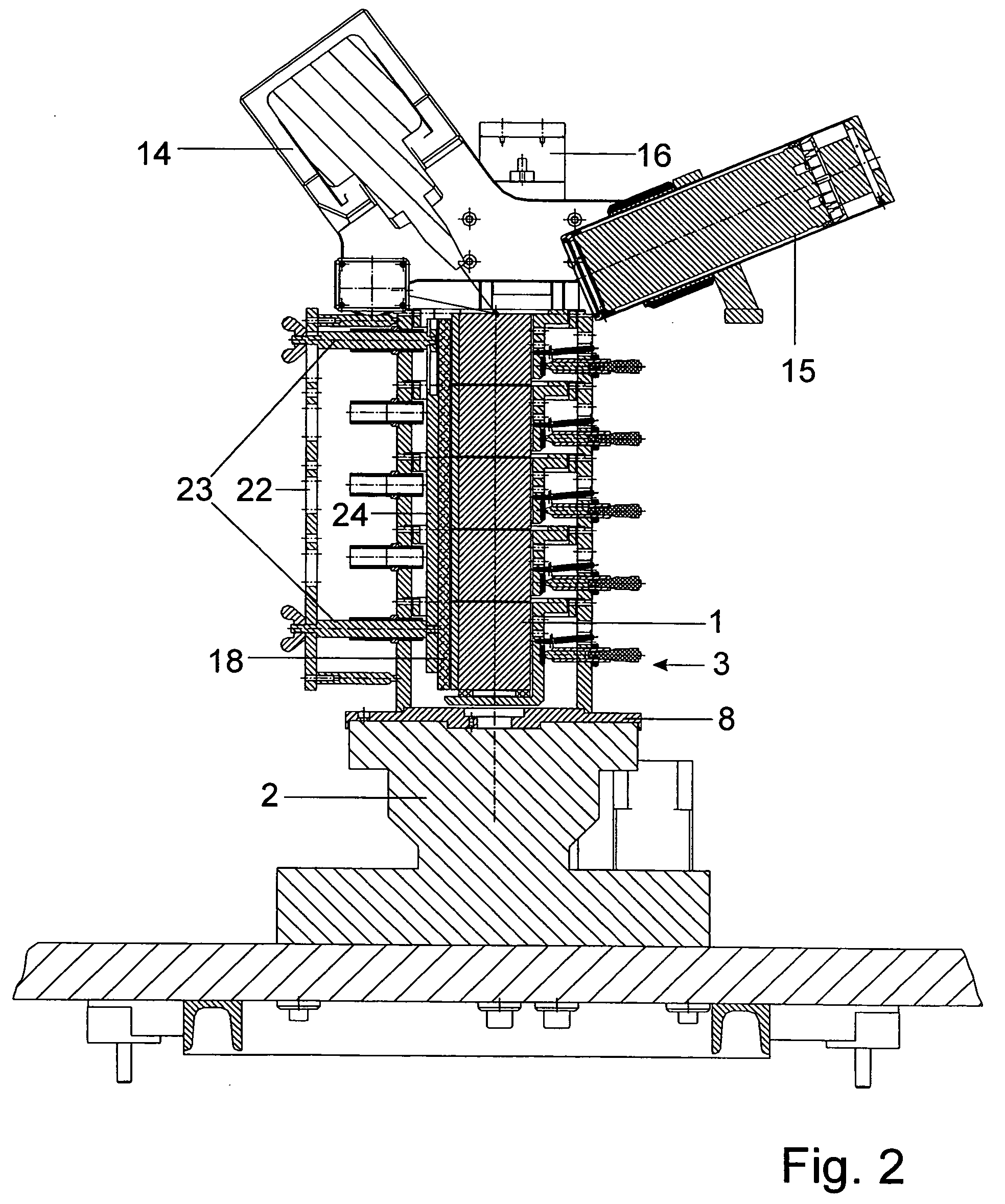

InactiveUS20060032430A1Improve accuracyHigh precision cuttingPolycrystalline material growthFrom normal temperature solutionsRotary stageLattice plane

For the measurement, orientation and fixation of at least one single crystal, it is the object of the invention to ensure increased accuracy in the determination of crystallographic orientation and oriented fixation regardless of the outer geometry of the single crystals, and the fixation should guarantee a highly accurate cutting also with very hard materials such as sapphire or silicon carbide. The single crystal is adjustably positioned on a revolving table for determining the crystal lattice orientation, wherein the crystal lattice orientation is determined during at least one revolution of the revolving table based on a plurality of x-ray reflections. The orientation of the crystal lattice is carried out with reference to the determined angles of the normal of the lattice plane relative to the axis (X-X) of the revolving table as reference direction before carrying out the fixation of the single crystal and the fastening on a support oriented in reference direction. By virtue of the invention, a plurality of single crystals can be oriented, fixated, stacked one on top of the other and connected to one another and subsequently connected simultaneously to a common support. Further, the invention makes it possible to monitor the orientation of every single crystal after fastening to the common support.

Owner:EFG ELEKTROTECHN FABATIONS & GROSHANDELSGMBH

Stem-mounted tire inflation pressure regulator

InactiveUS8113234B2High precision cuttingEasy to disassembleOperating means/releasing devices for valvesCheck valvesEngineeringPressure regulator

The specification discloses a tire inflation pressure regulator facilitating precise tire inflation. The regulator includes a body, a two-position valve within the body, and a rotational lock. The body includes an air inlet, an air outlet, and an air vent. In one position, the valve directs air from the air inlet to the air outlet when the tire pressure is below a preset level; and, in a second position, the valve directs air from the air inlet to the air vent when the tire pressure exceeds the preset level to prevent overfilling. The valve moves rapidly between the two positions, and is unstable between the two positions. The valve includes a regulator enabling the preset level to be adjusted. The rotational lock enables the regulator to be screwed onto a tire stem, but prevents removal of the regulator from the tire stem without a key. The regulator preferably includes a cap removably sealed over the air inlet and the air vent to prevent the undesired loss of air.

Owner:FLOW RITE CONTROLS

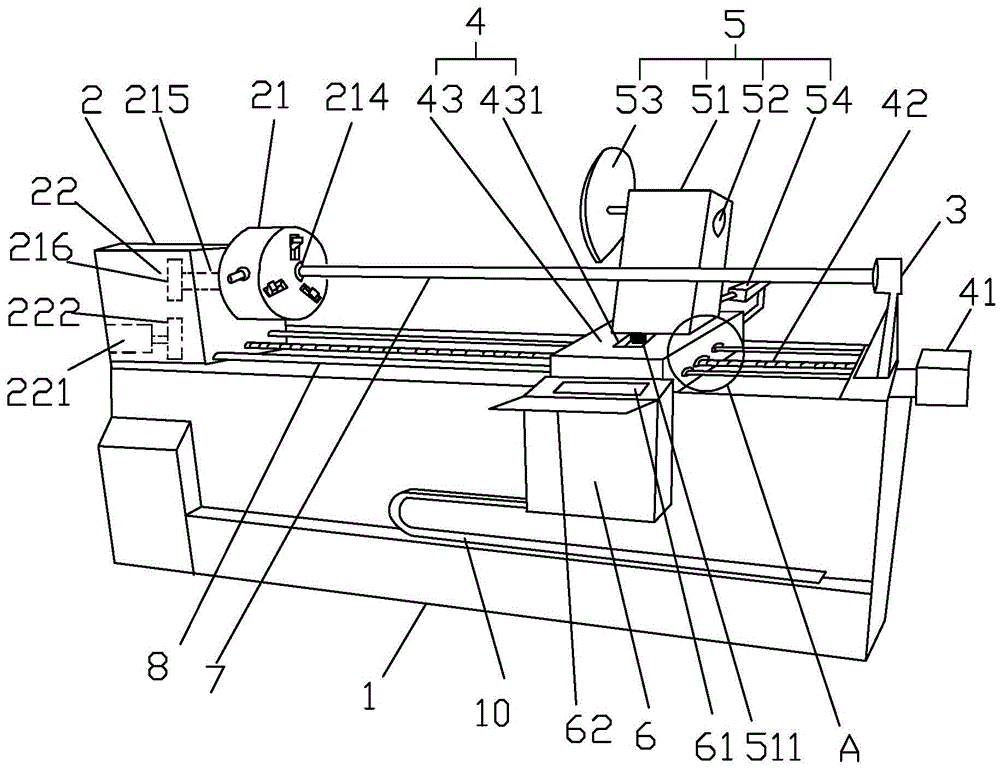

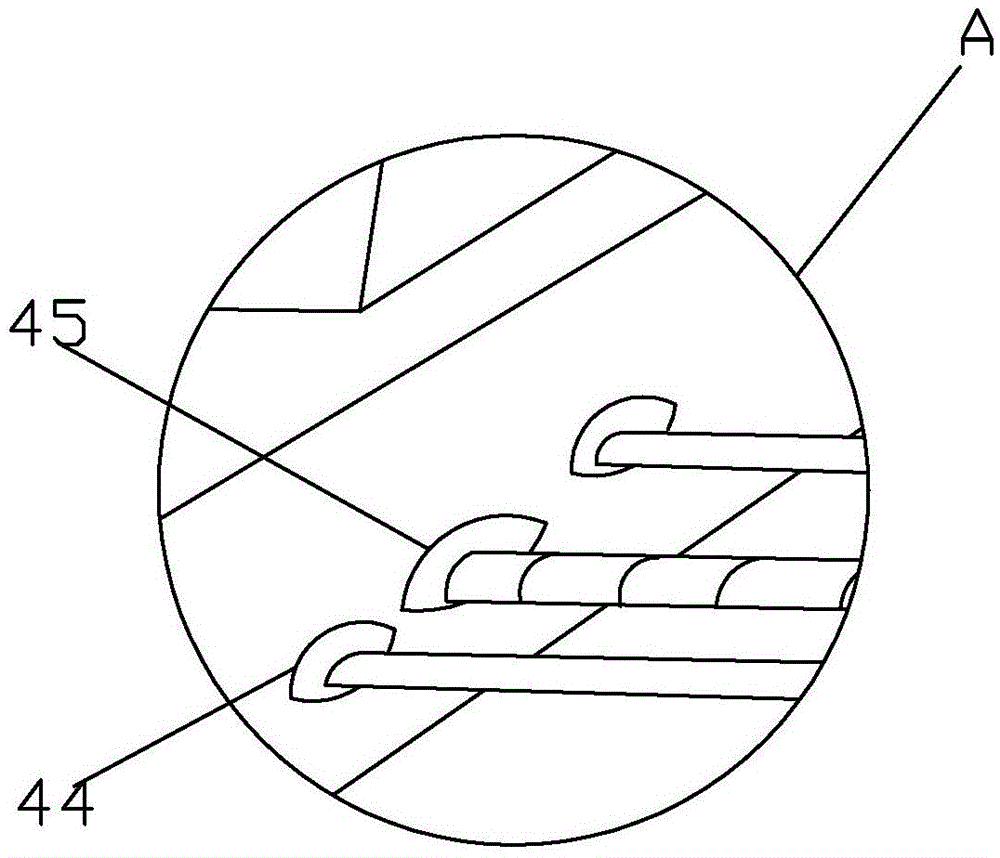

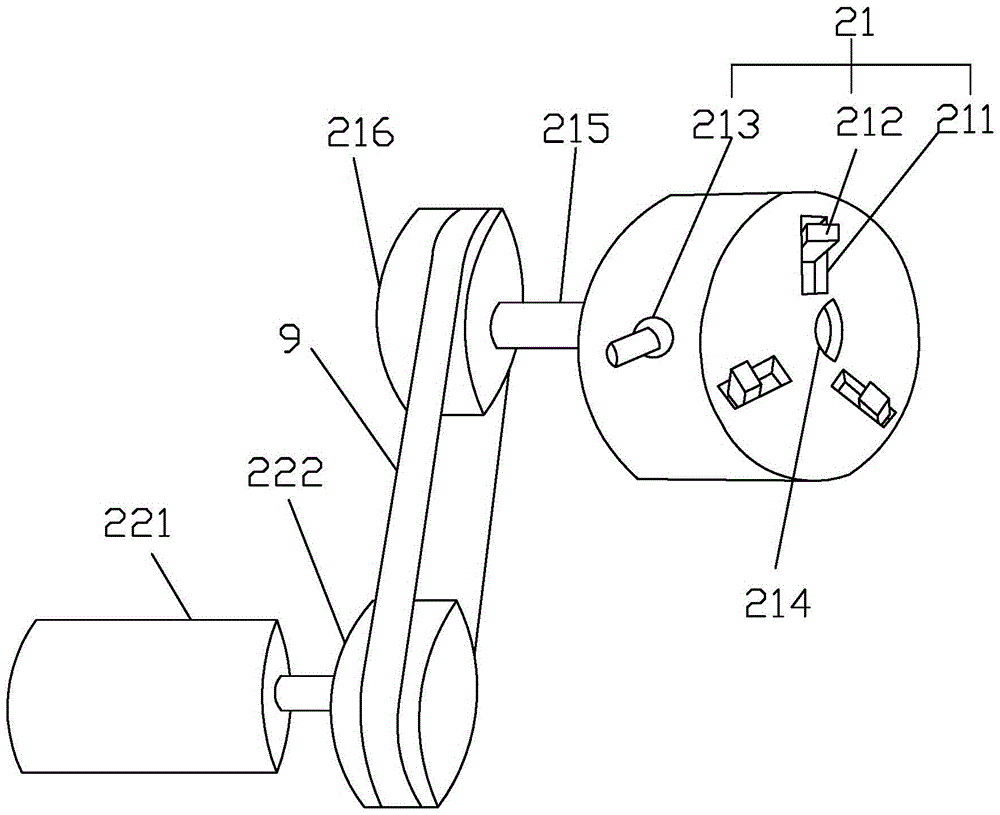

Automatic strip-cutting machine

InactiveCN105479518AHigh precision cuttingSimple structureMetal working apparatusElectric machineryMotor drive

The invention mainly discloses an automatic strip-cutting machine. The technical scheme thereof is as follows: the automatic strip-cutting machine comprises a rack, a head, a tail, a moving device, a cutting device and a PLC control cabinet, wherein the head and the tail are located at the two sides of the rack respectively; the head comprises a clamping chuck and a driver driving the clamping chuck to rotate; a sleeve rod is arranged between the clamping chuck and the tail; the moving device comprises a variable-frequency motor connected to one side of the tail, a screw rod connected with the variable-frequency motor, and a slide plate matching with the screw rod; two guide rails are arranged on the rack, and located between the head and the tail; the screw rod is installed between the guide rails; the variable-frequency motor drives the screw rod to rotate, thus driving the slide plate to move; the cutting device is connected to the top of the slide plate; the cutting device comprises a cutting frame, a first motor, a cutting knife and a cylinder; and a piston rod on the cylinder drives the cutting frame to move back and forth on the slide plate. The automatic strip-cutting machine disclosed by the invention has the advantages of being simple in structure, high in cutting efficiency, convenient to operate, and accurate in cutting.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

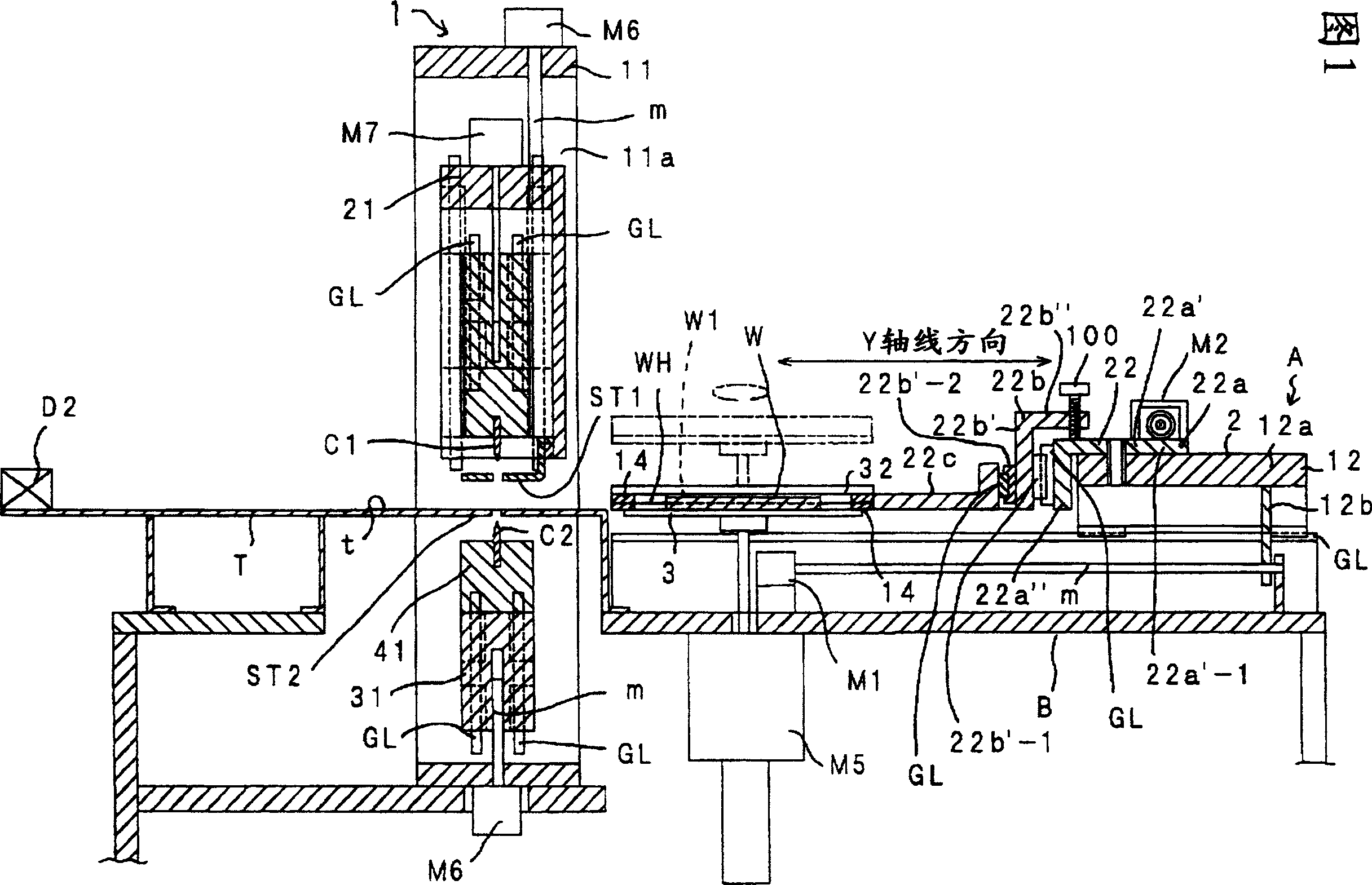

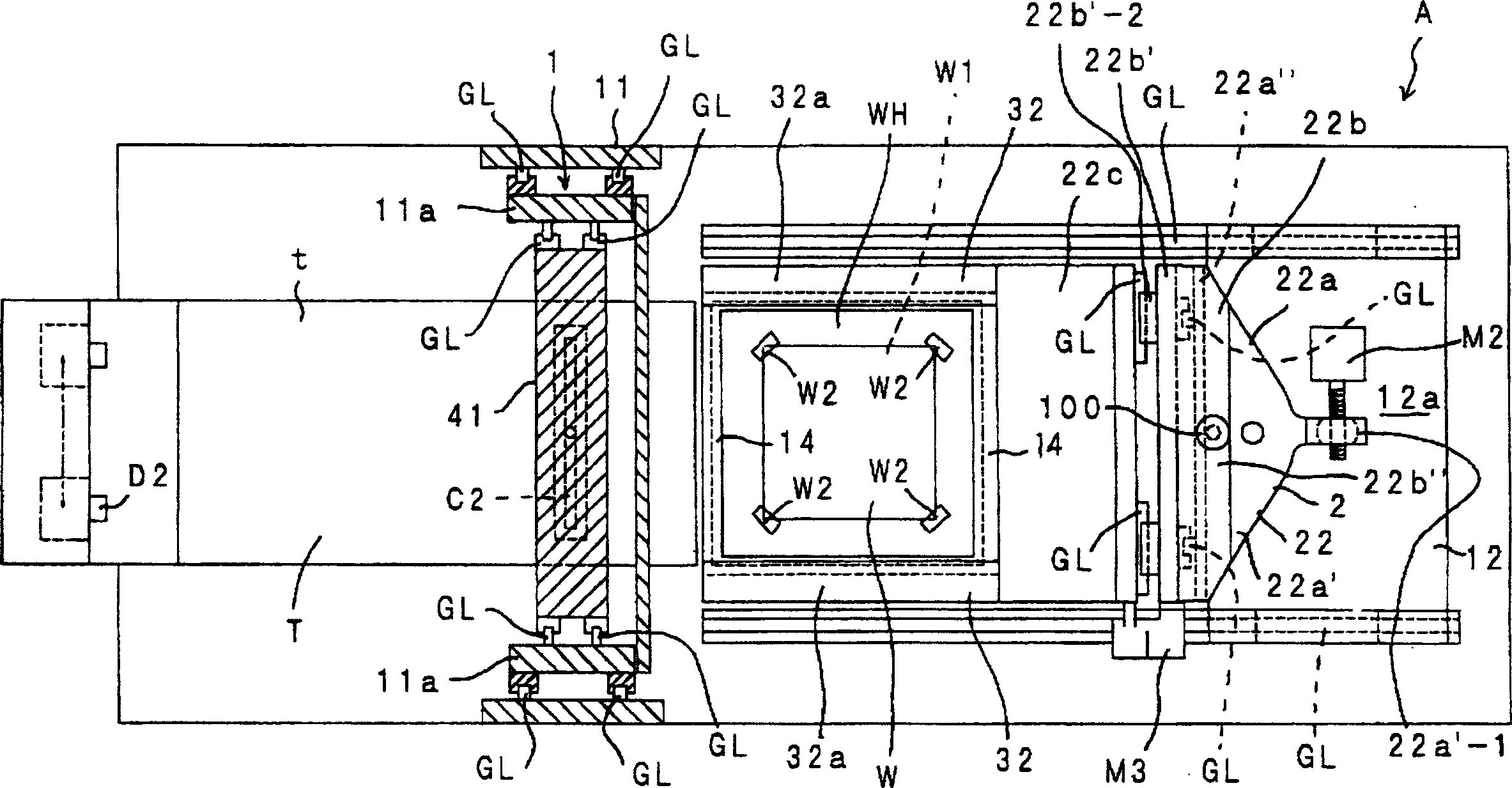

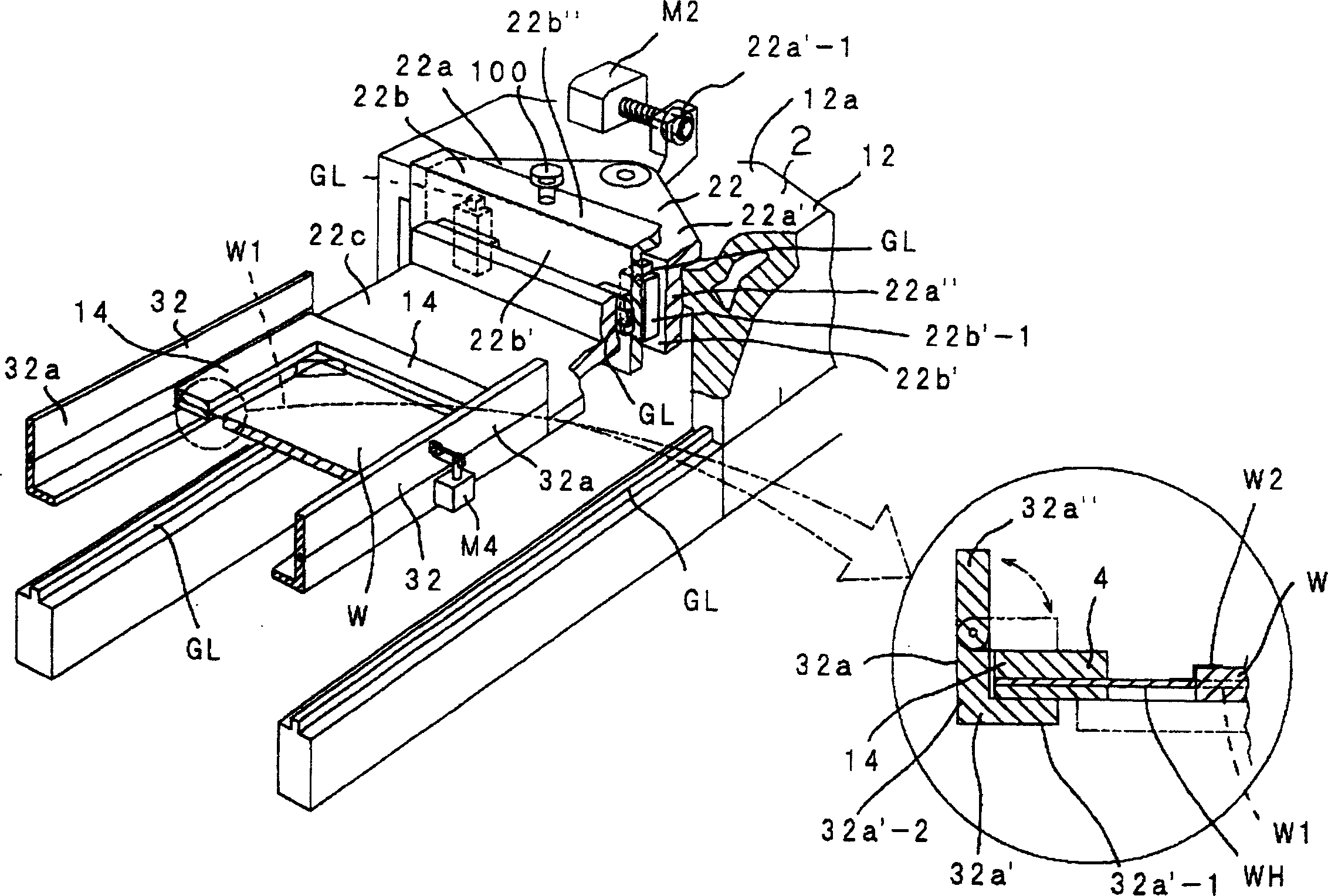

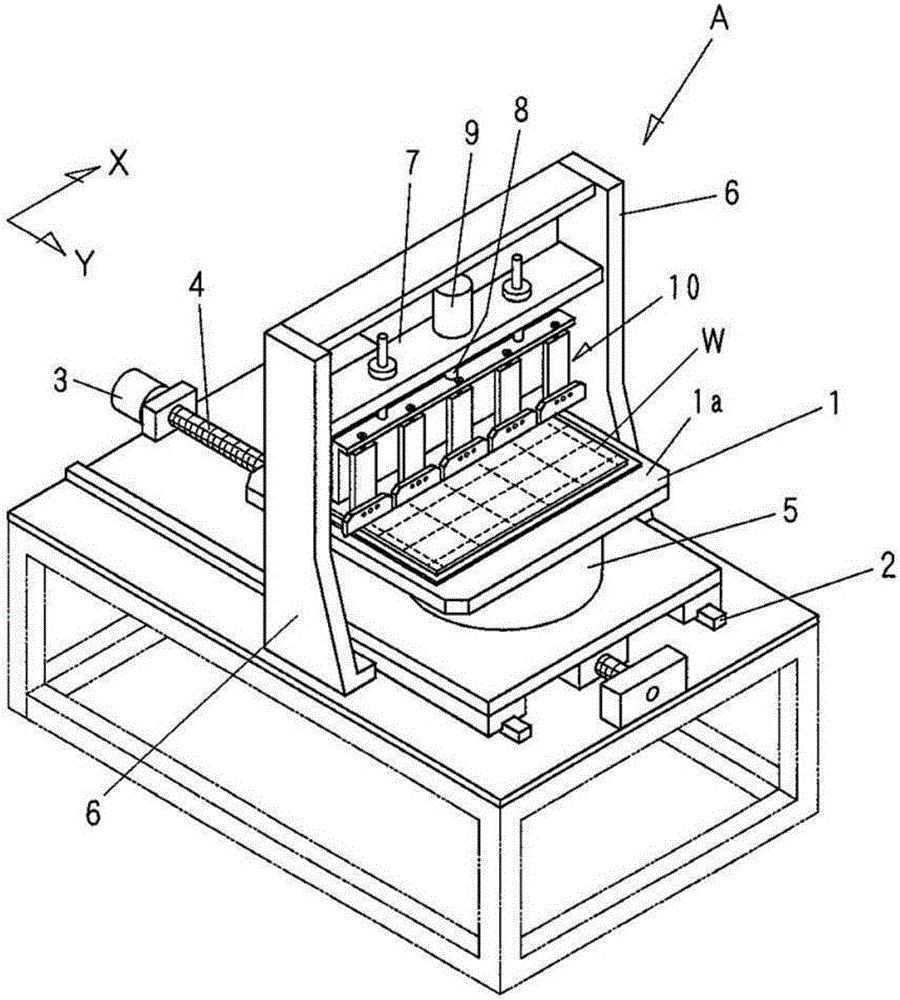

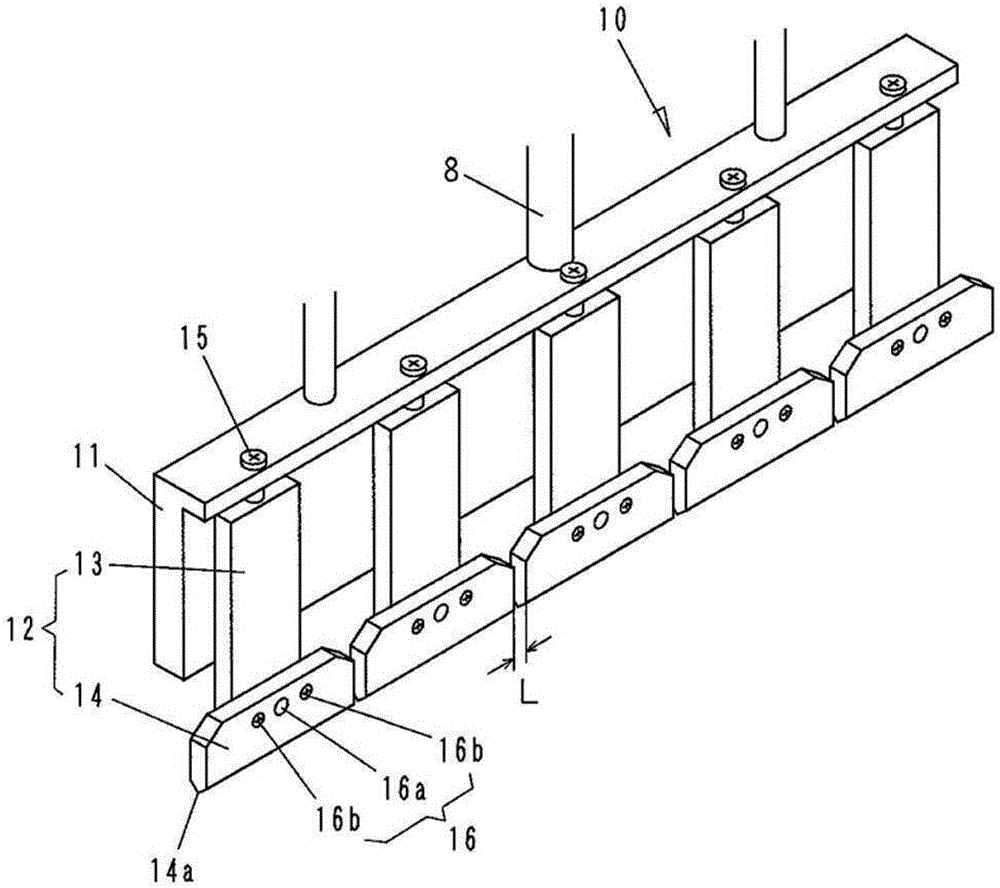

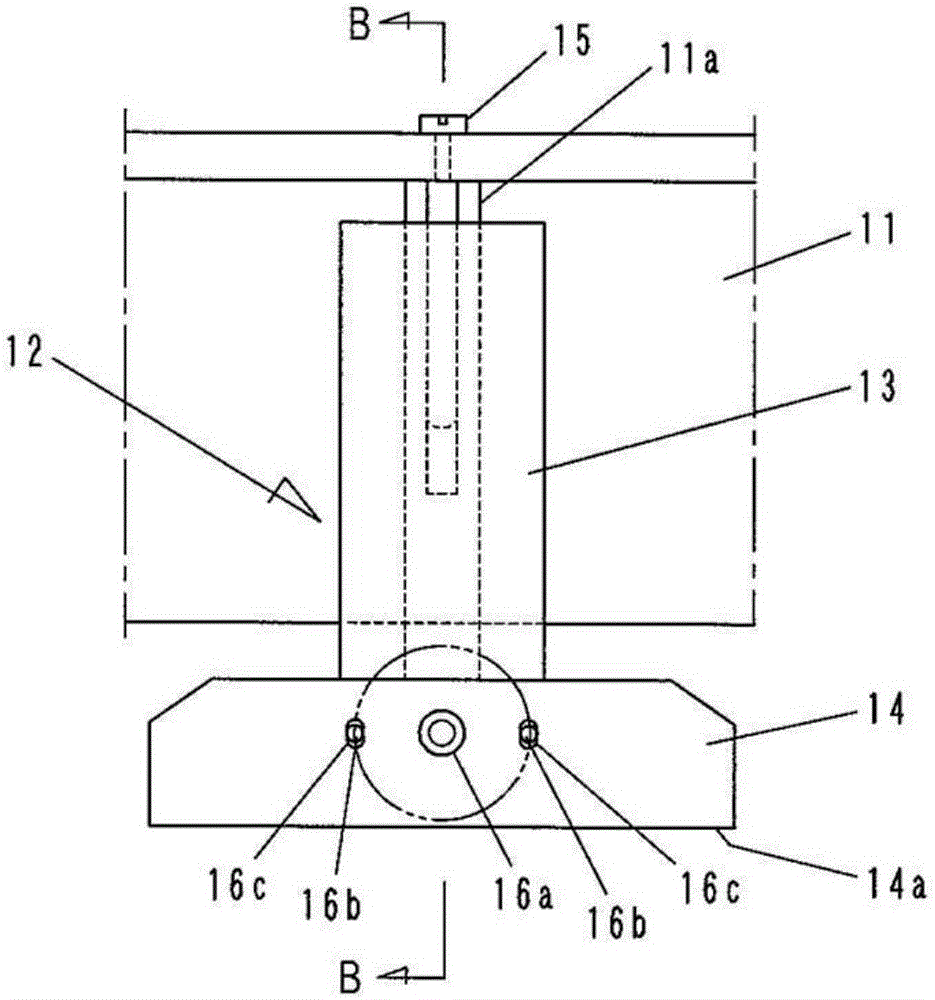

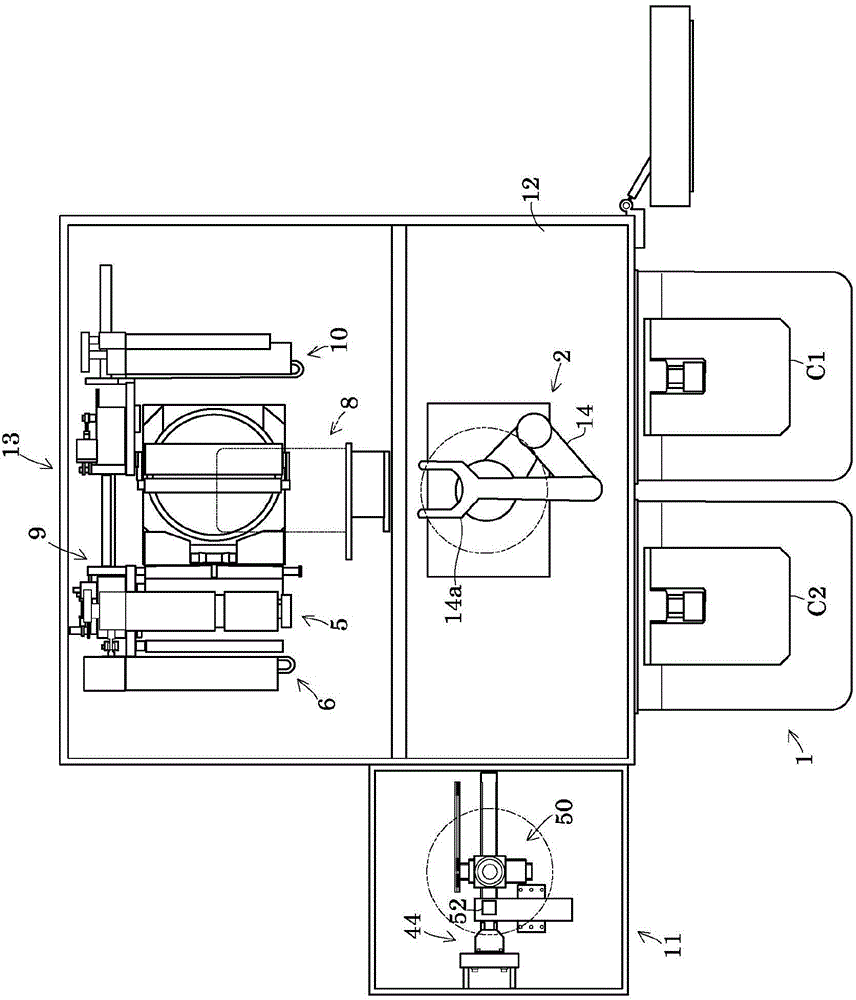

Cut processing method, cut processing apparatus and work-piece supporting construction used with said apparatus

ActiveCN1796062AAvoid deformationHigh precision cuttingShearing machinesMetal working apparatusPush upsEngineering

To provide a cutting method and a cutting device for improving cutting accuracy by preventing deformation by preventing the push-down of a workpiece by an upper cutting blade at the time of cutting (full cut or half cut) of the upper cutting blade. The workpiece W inserted into a hole W1 opened in a sheet WH for a thin work holder is temporarily fastened to the sheet WH for the work holder by being located in a middle region of the thickness of the workpiece W not to be in contact with the upper and lower cutting blades C1 and C2 for the half cut. The workpiece W is half-cut by being shared over the whole width without cutting the sheet WH for the work holder by the upper and lower cutting blades C1 and C2 of required lengths which are longer than the whole width of the workpiece W and shorter than the sheet WH for the work holder. The push-down of the workpiece W by the upper cutting blade C1 at the time of the half-cut is prevented by a lower stripper ST2 fixedly provided in the table surface height of cutting machine 1. The push-up of the workpiece W by the lower cutting blade C2 is prevented by an upper stripper ST1.

Owner:UHT CORP

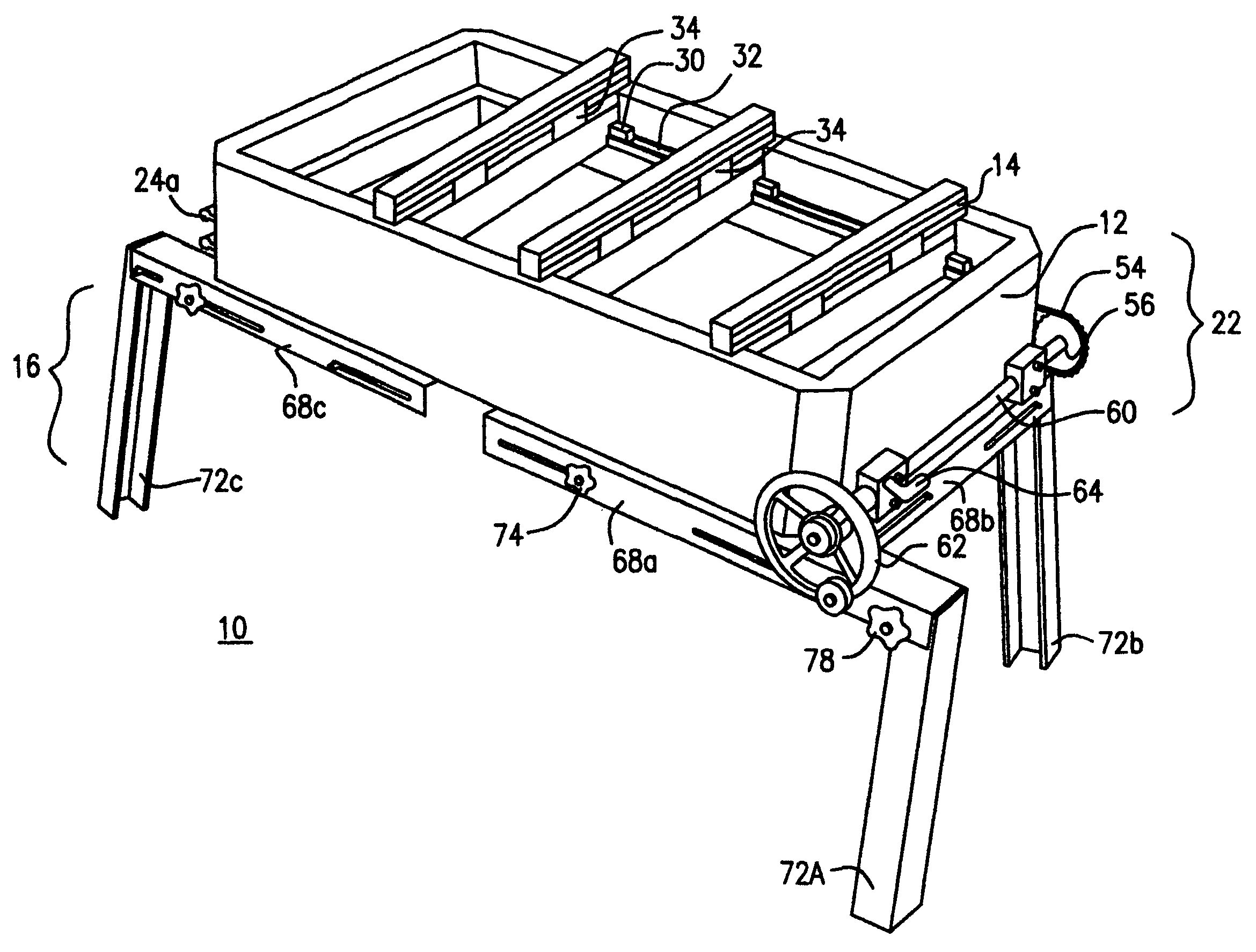

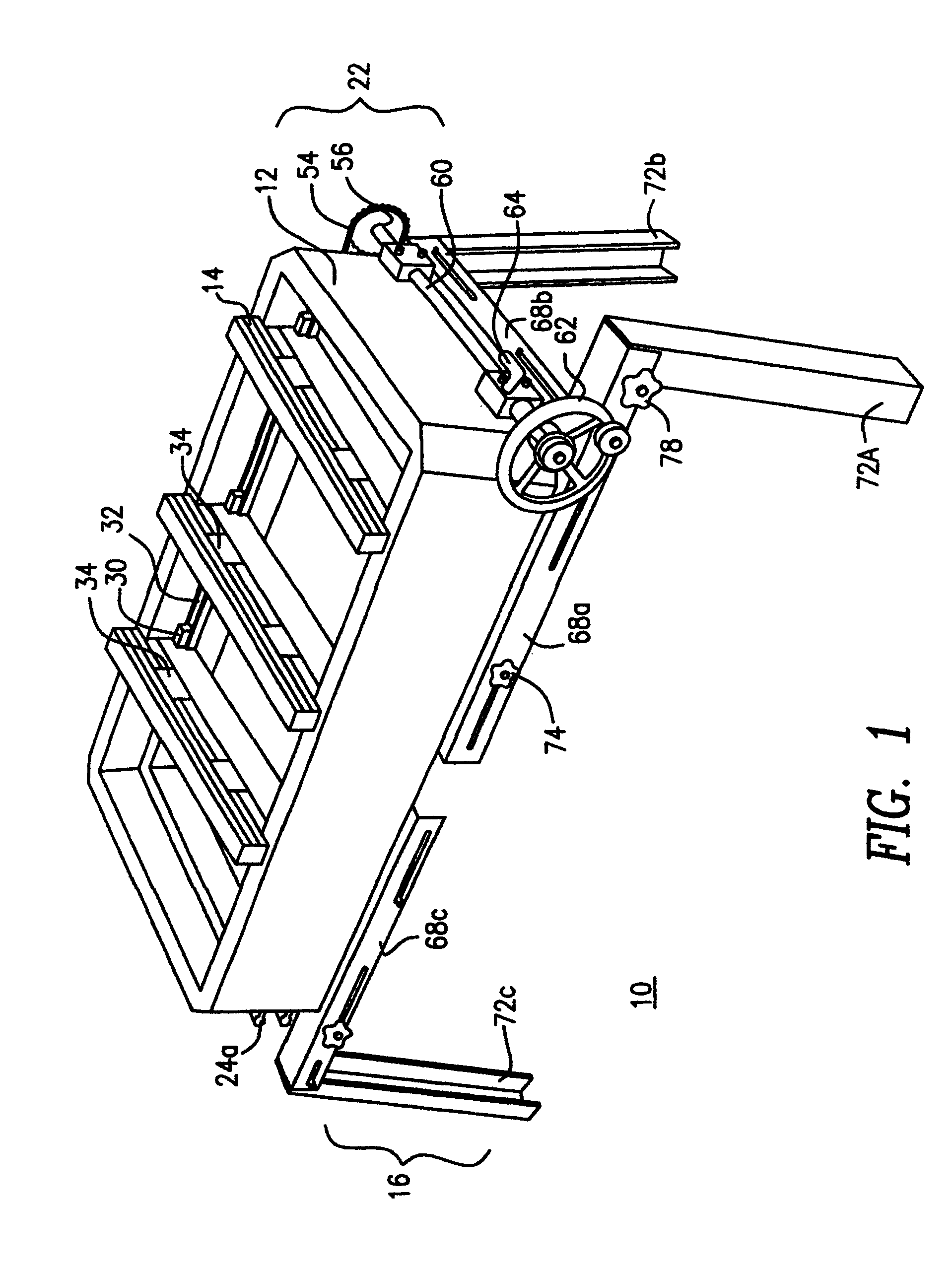

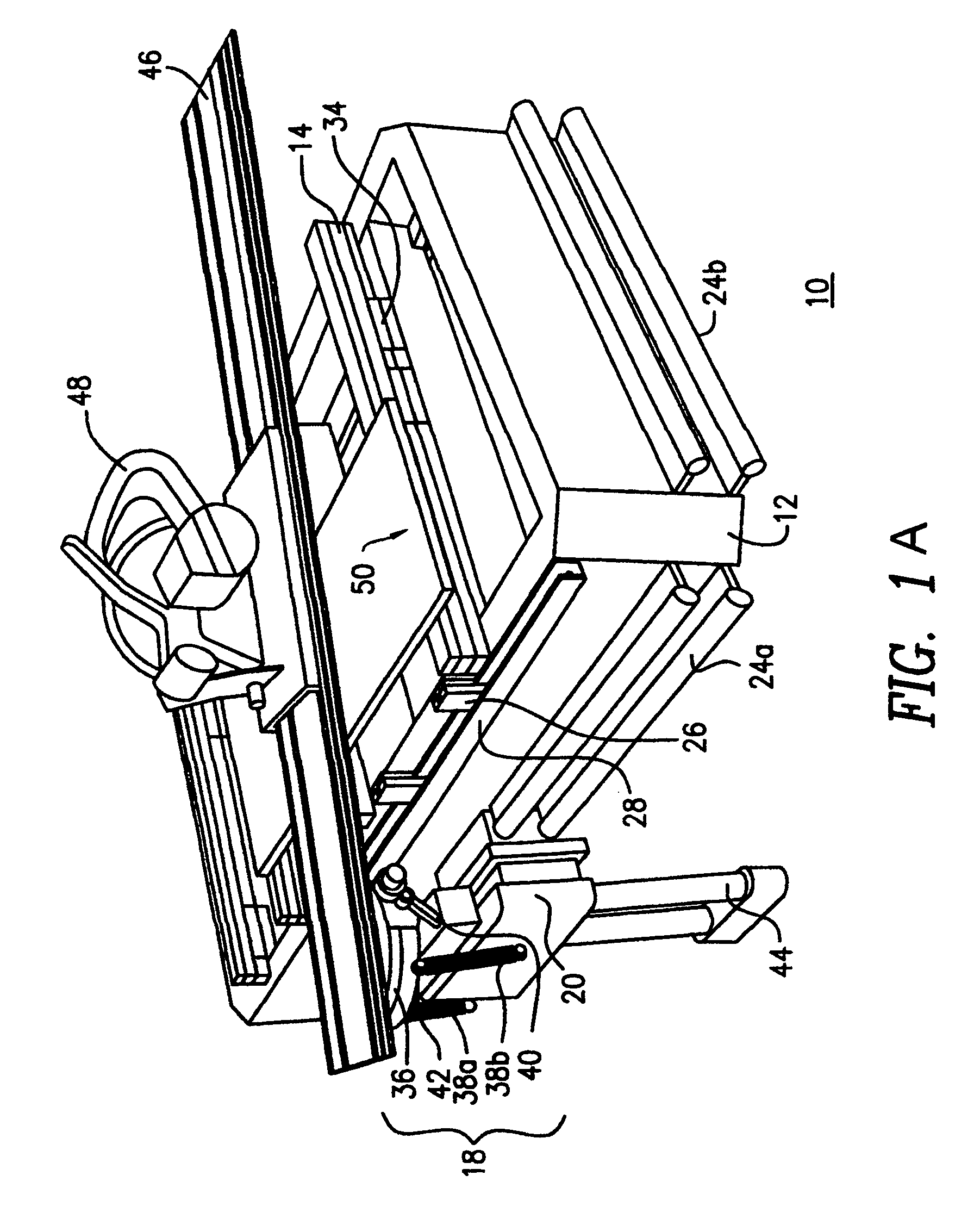

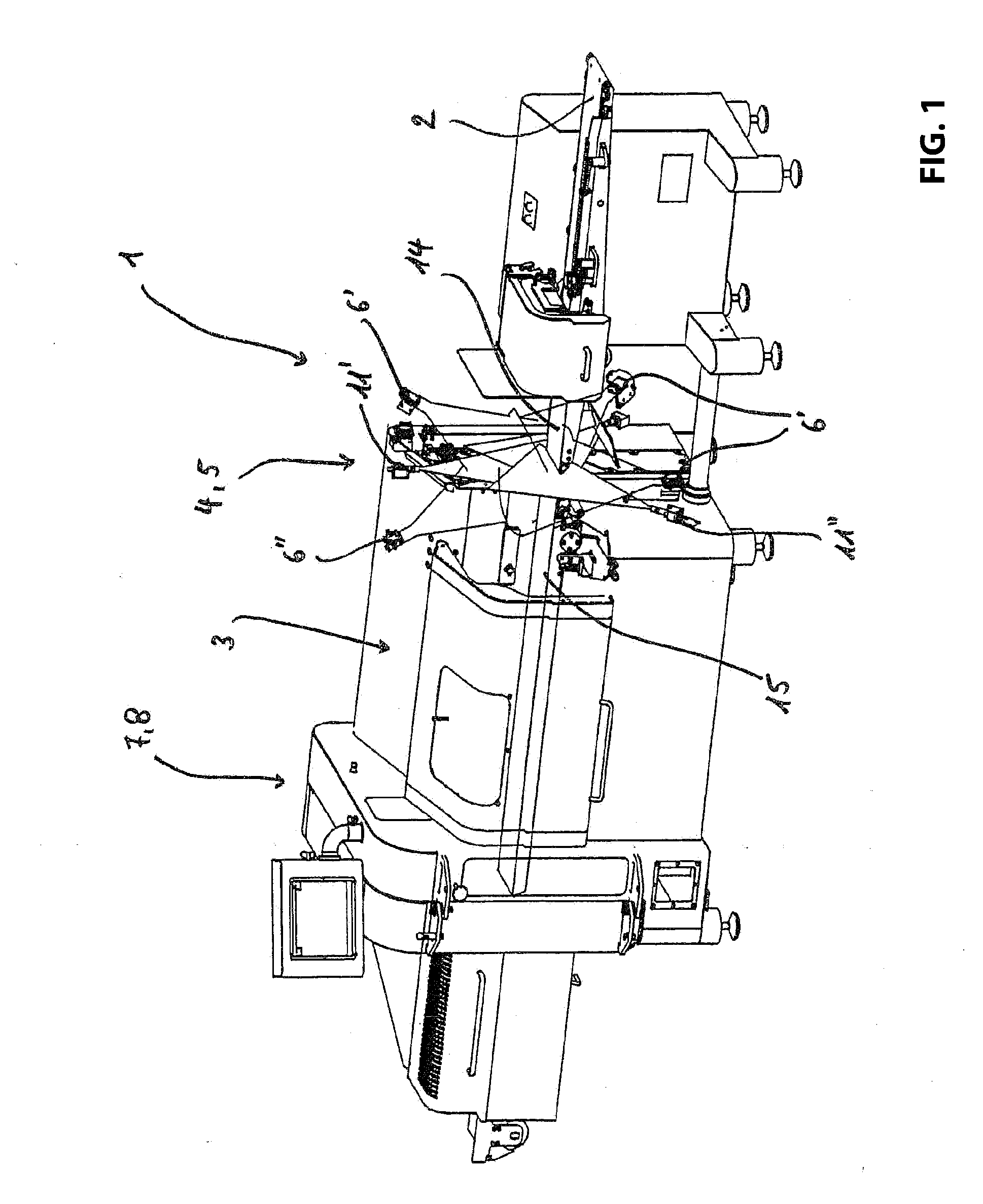

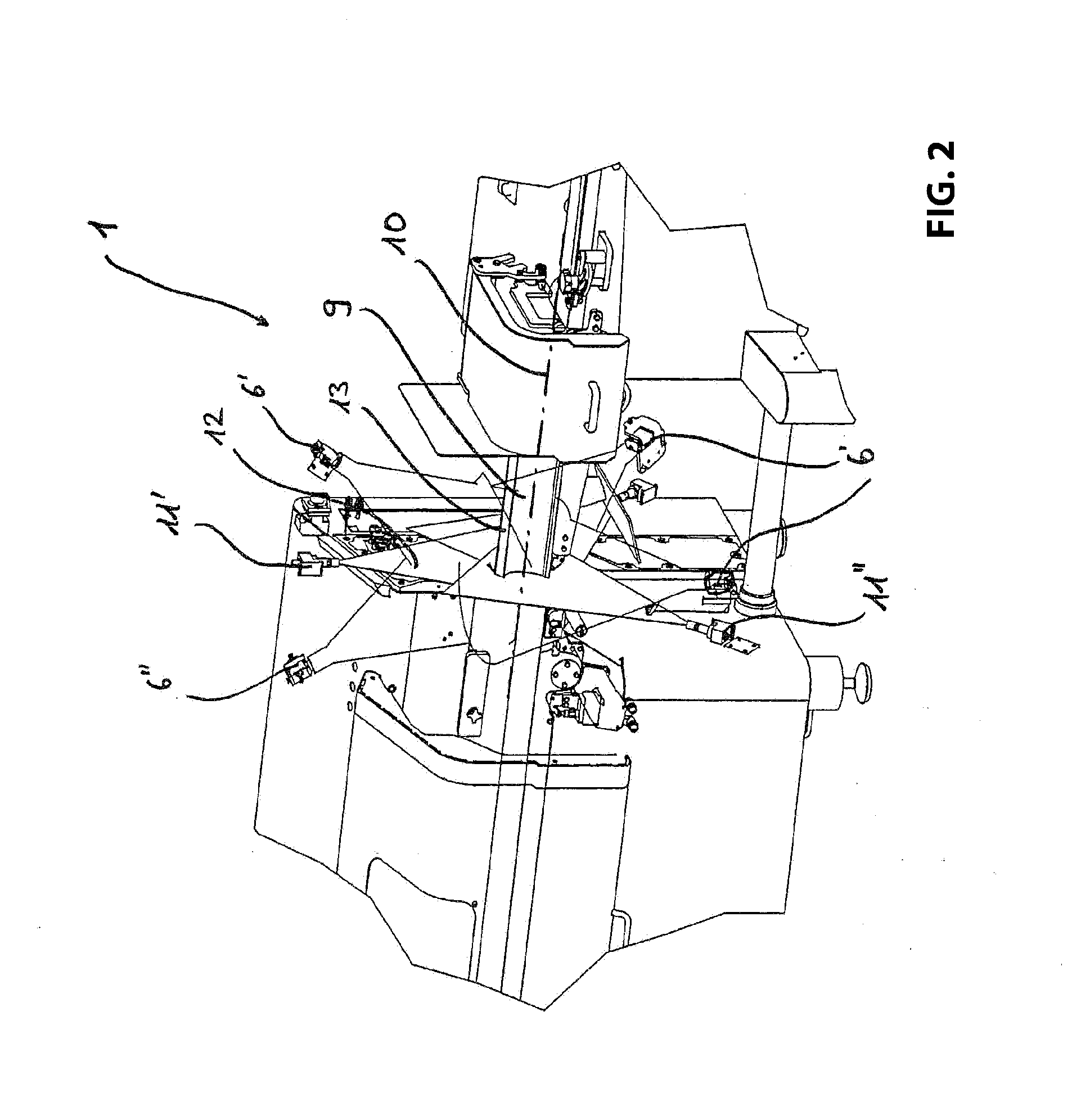

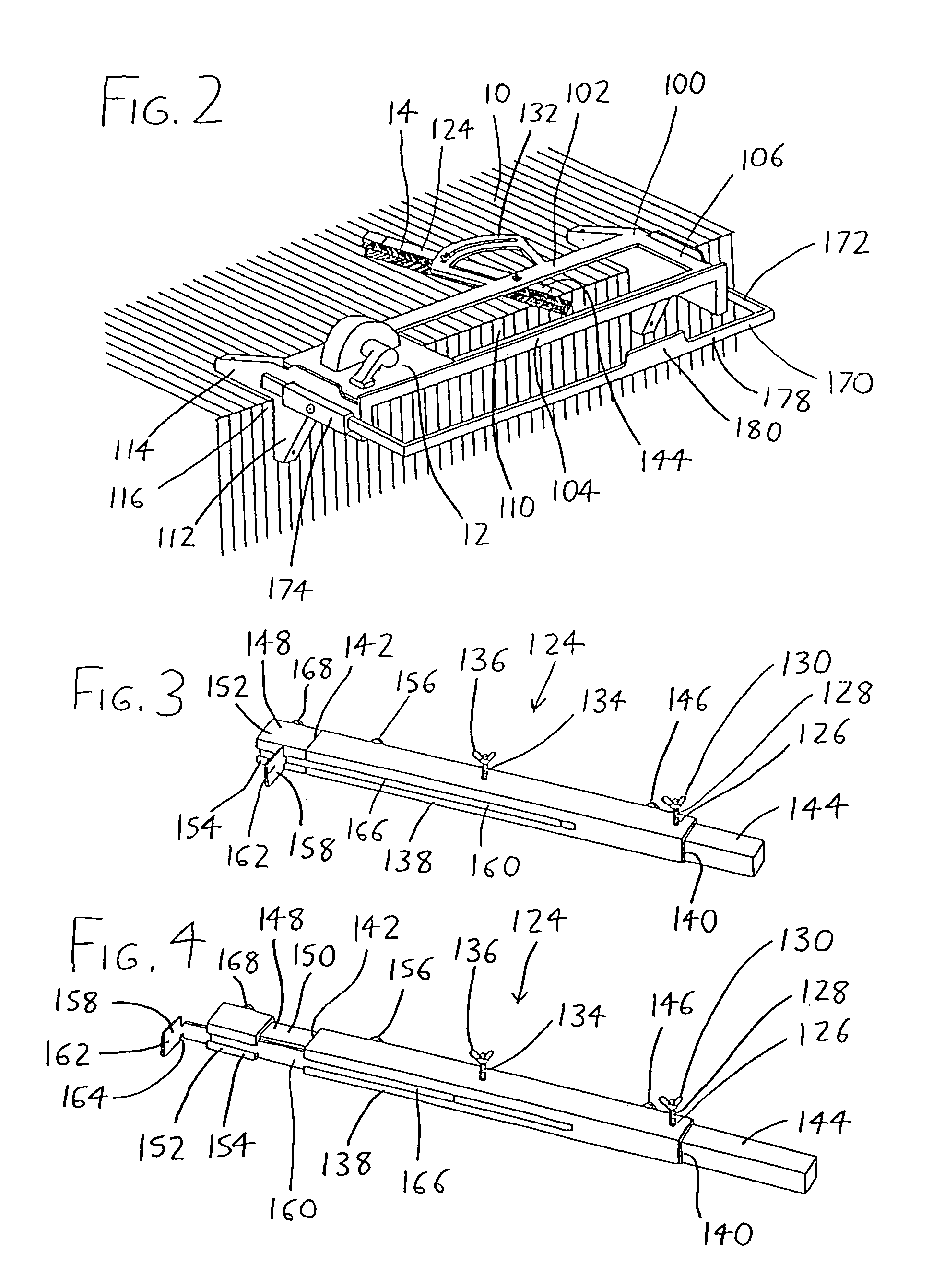

Extendable woodworking system

InactiveUS7201192B2Safe and accurateLarge capacityMetal sawing devicesShearing machinesWoodworkingElectrical and Electronics engineering

A horizontal portable miter panel saw system that is capable of utilizing a wide range of power hand tools and processing plywood panels and other oversized materials. The apparatus is designed to provide safety, accuracy, mobility, capacity, ease of use, and affordability. Four extendable multi-adjustable legs allow the table to be leveled on almost any surface. An adjustable guide control unit is movable in the x, y, and z planes via a chain drive trolley that allows a tool to make any type of cut accurately and without the need for complex measurements. A plurality of tabletop members form the table top, these are extendable and adjustable to allow for plywood panels to be supported by the table.

Owner:MAKROPOULOS DINO

Method and apparatus for the measurement, orientation and fixation of at least one single crystal

InactiveUS7285168B2Improve accuracyHigh precision cuttingAfter-treatment apparatusPolycrystalline material growthRotary stageLattice plane

For the measurement, orientation and fixation of at least one single crystal, it is the object of the invention to ensure increased accuracy in the determination of crystallographic orientation and oriented fixation regardless of the outer geometry of the single crystals, and the fixation should guarantee a highly accurate cutting also with very hard materials such as sapphire or silicon carbide. The single crystal is adjustably positioned on a revolving table for determining the crystal lattice orientation, wherein the crystal lattice orientation is determined during at least one revolution of the revolving table based on a plurality of x-ray reflections. The orientation of the crystal lattice is carried out with reference to the determined angles of the normal of the lattice plane relative to the axis (X-X) of the revolving table as reference direction before carrying out the fixation of the single crystal and the fastening on a support oriented in reference direction. By virtue of the invention, a plurality of single crystals can be oriented, fixated, stacked one on top of the other and connected to one another and subsequently connected simultaneously to a common support. Further, the invention makes it possible to monitor the orientation of every single crystal after fastening to the common support.

Owner:EFG ELEKTROTECHN FABATIONS & GROSHANDELSGMBH

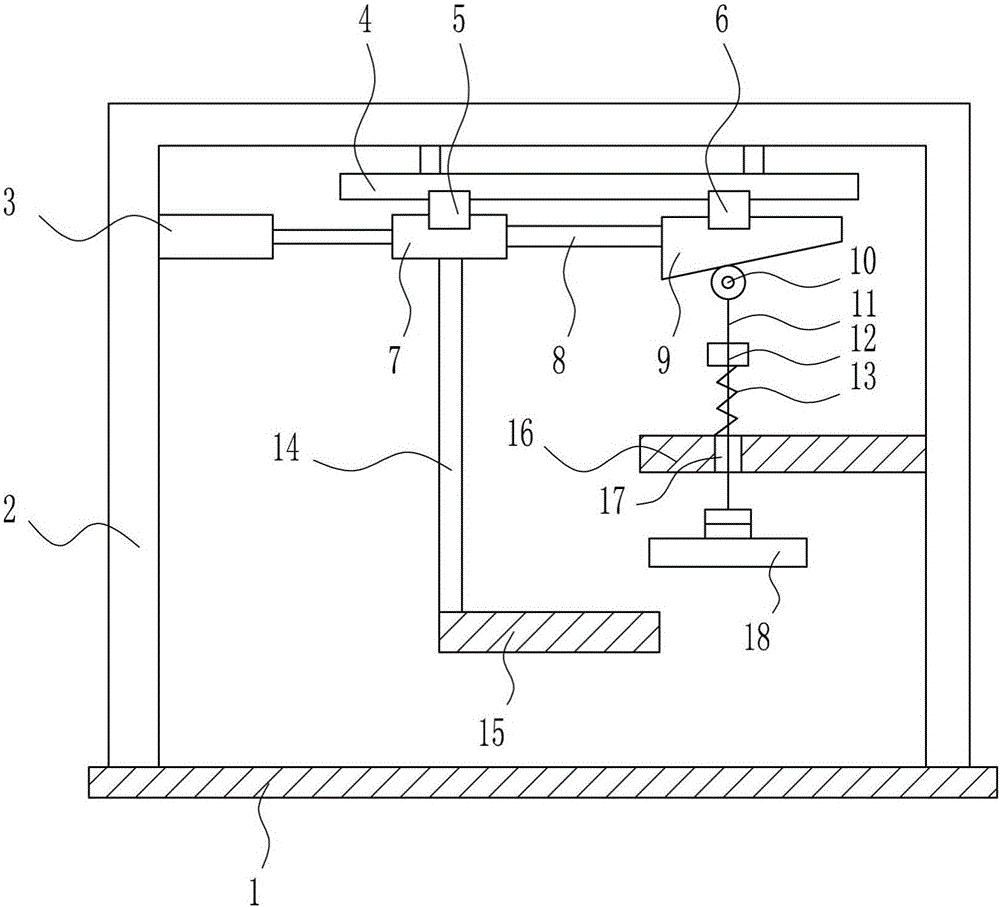

High precision cutting device for photo studios

ActiveCN106346554AHigh precision cuttingConducive to manual operationMetal working apparatusEngineeringMechanical engineering

The invention relates to a cutting device, especially to a high precision cutting device for photo studios. The technique aims to provide is the high precision for cutting device of photo studios. The cutting device adopts the following components to achieve the technical requirements: baseplate, stand, power-driven pusher, sliding rail, the first sliding block, the second sliding block, connecting block, the first connecting rod, wedge block, contact roller, lifting rod, fixed stop, spring, the second connecting rod, cutting table, guide plate and cut-off knife. The baseplate is equipped with stand, the upper inside of left arm of which is installed with power-driven pusher and middle inside of right arm with guide plate. There're guide holes on the guide plate. Sliding rails are provided at the inner top of the stand. The cutting device achieves the cutting device requirements for high precision. The device is simple and efficient but novelty, and convenient for staff in photo studios to operate.

Owner:山东港投投资发展有限公司

Method for dividing disc-like workpiece

InactiveCN1579728AHigh precision cuttingSemiconductor/solid-state device manufacturingFine working devicesSplit linesEngineering

A method of dividing a plate-like workpiece having a layer that is made of a different material from that of a substrate and is formed on the front surface of the substrate along predetermined dividing lines, comprising a laser beam application step for applying a laser beam along the dividing lines formed on the plate-like workpiece to form a plurality of grooves deeper than the layer and a cutting step for cutting the plate-like workpiece with a cutting blade along the plurality of grooves formed in the laser beam application step, wherein a length between the outer sides of grooves on both sides formed in the laser beam application step is set to be larger than the thickness of the cutting blade and the cutting blade cuts the area between the outer sides of the grooves on both sides in the cutting step.

Owner:DISCO CORP

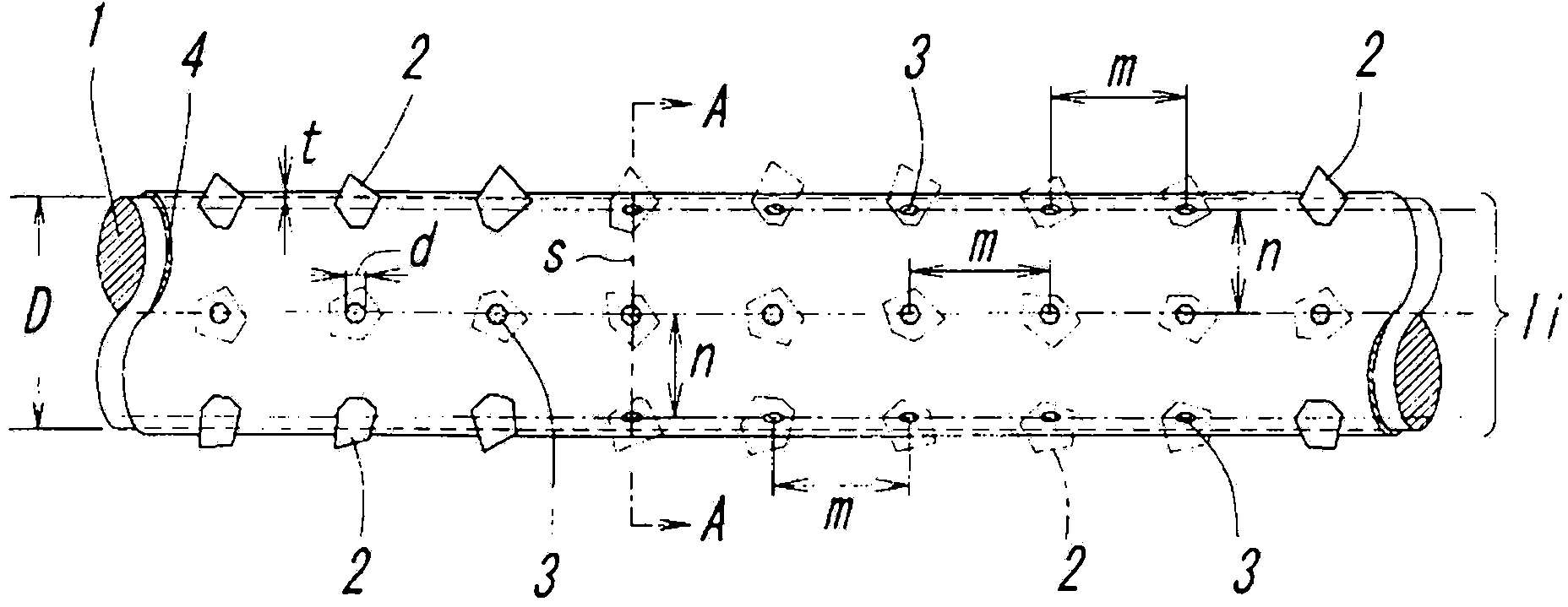

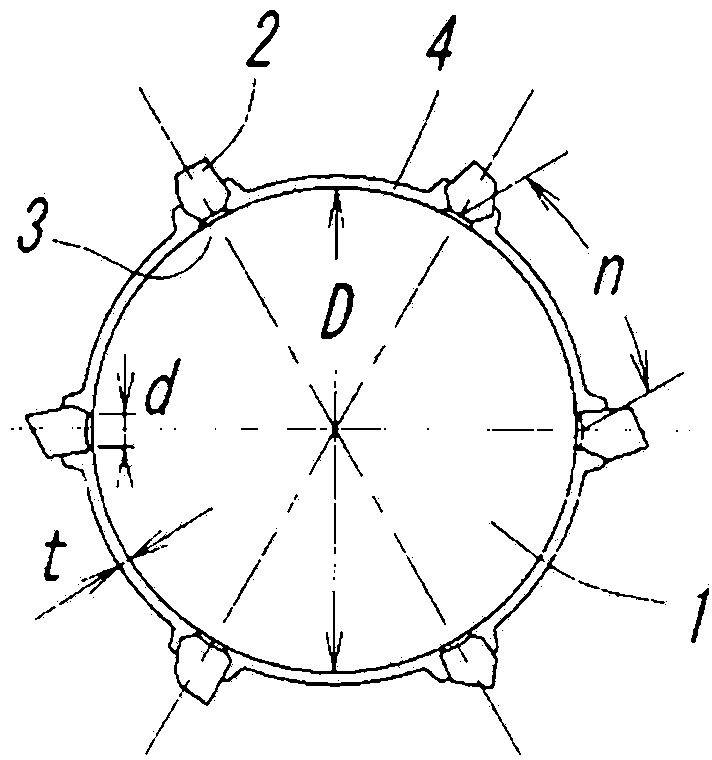

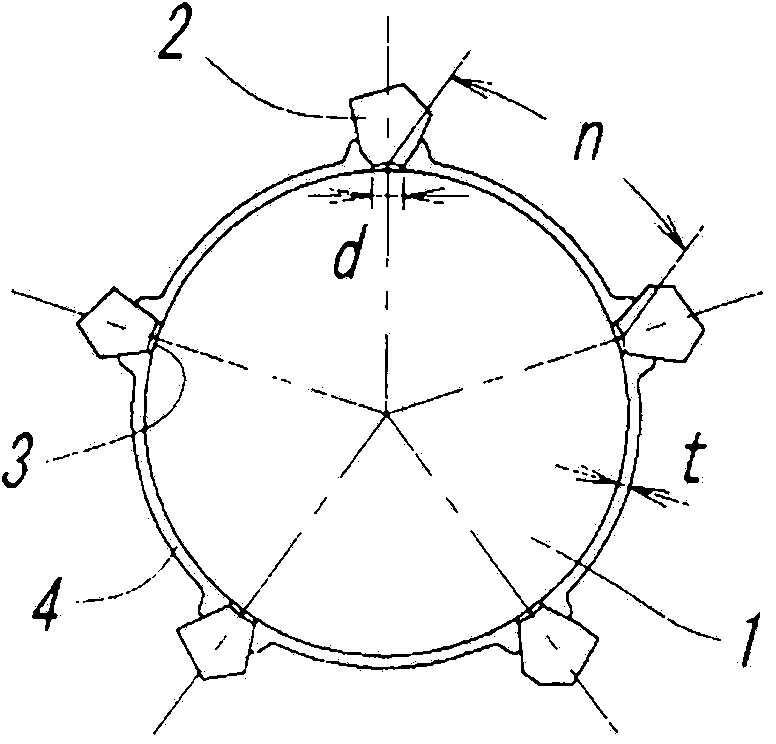

Fixed-abrasive-grain wire-saw, method for manufacturing same, and method for cutting workpiece using same

InactiveCN104136169AEffectively cut offHigh precision cuttingAbrasion apparatusMetal sawing toolsMetallurgyAdhesive

[Problem] To provide a fixed-abrasive-grain wire-saw that enables improved workpiece cutting plane accuracy and grinding efficiency and further allows for a longer product service life, a method for manufacturing the fixed-abrasive-grain wire-saw, and a method for cutting a work piece using the fixed-abrasive-grain wire-saw. [Solution] When abrasive grains (2) are to be affixed to the external peripheral surface of a metallic core wire (1), a plurality of transfer rollers (18) provided with a plurality of very small holes (18a) filled with an adhesive (3a) are used to transfer the adhesive (3a) onto the external peripheral surface of the metallic core wire, whereby a plurality of lines (li) of a punctate adhesive layer (3) axially arranged in straight lines at a regular pitch are formed on the metallic core wire; and, after being provisionally bonded to the adhesive layer, the abrasive grains are permanently bonded by electrodeposition on a metallic plating layer (4).

Owner:RIIDO

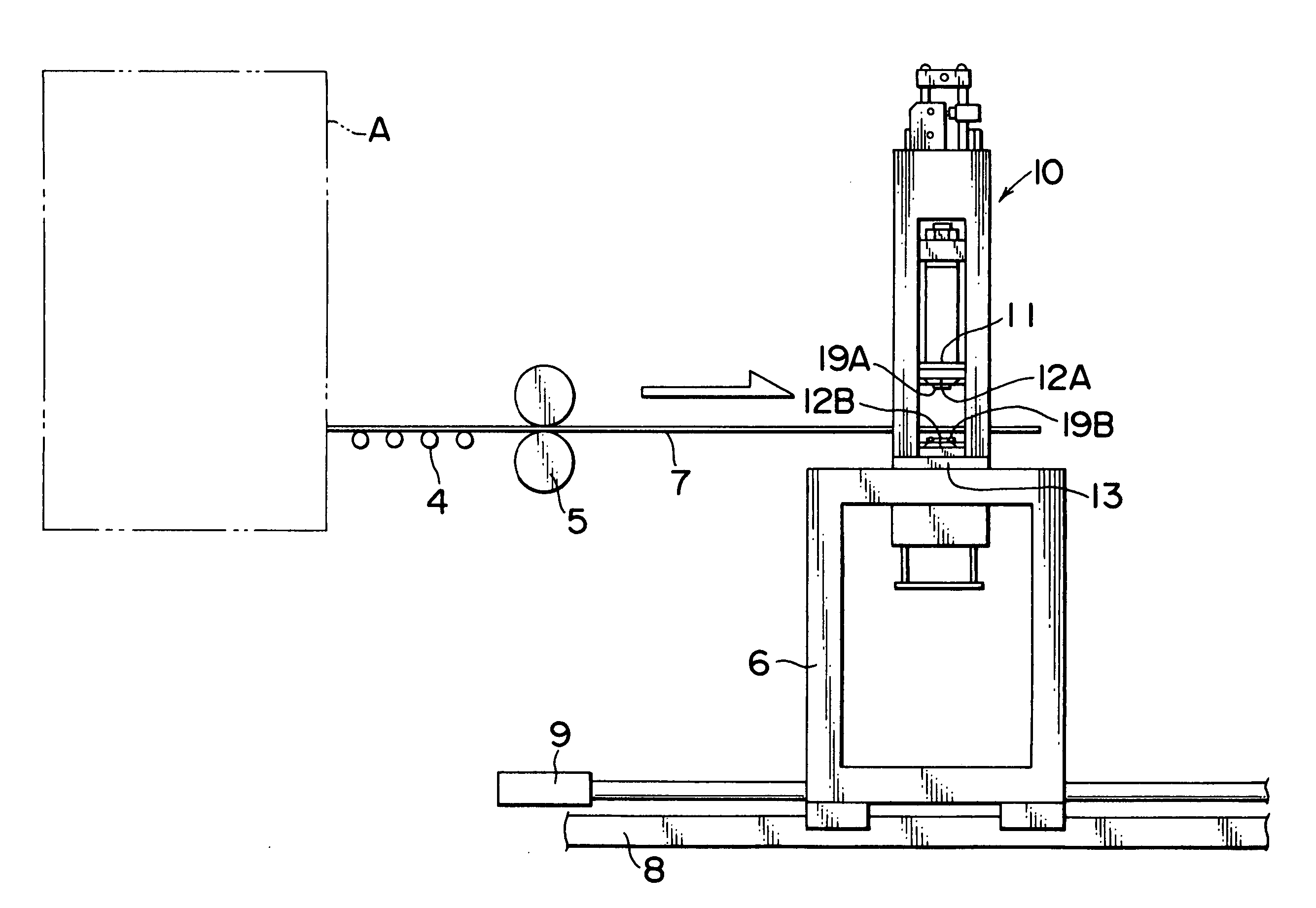

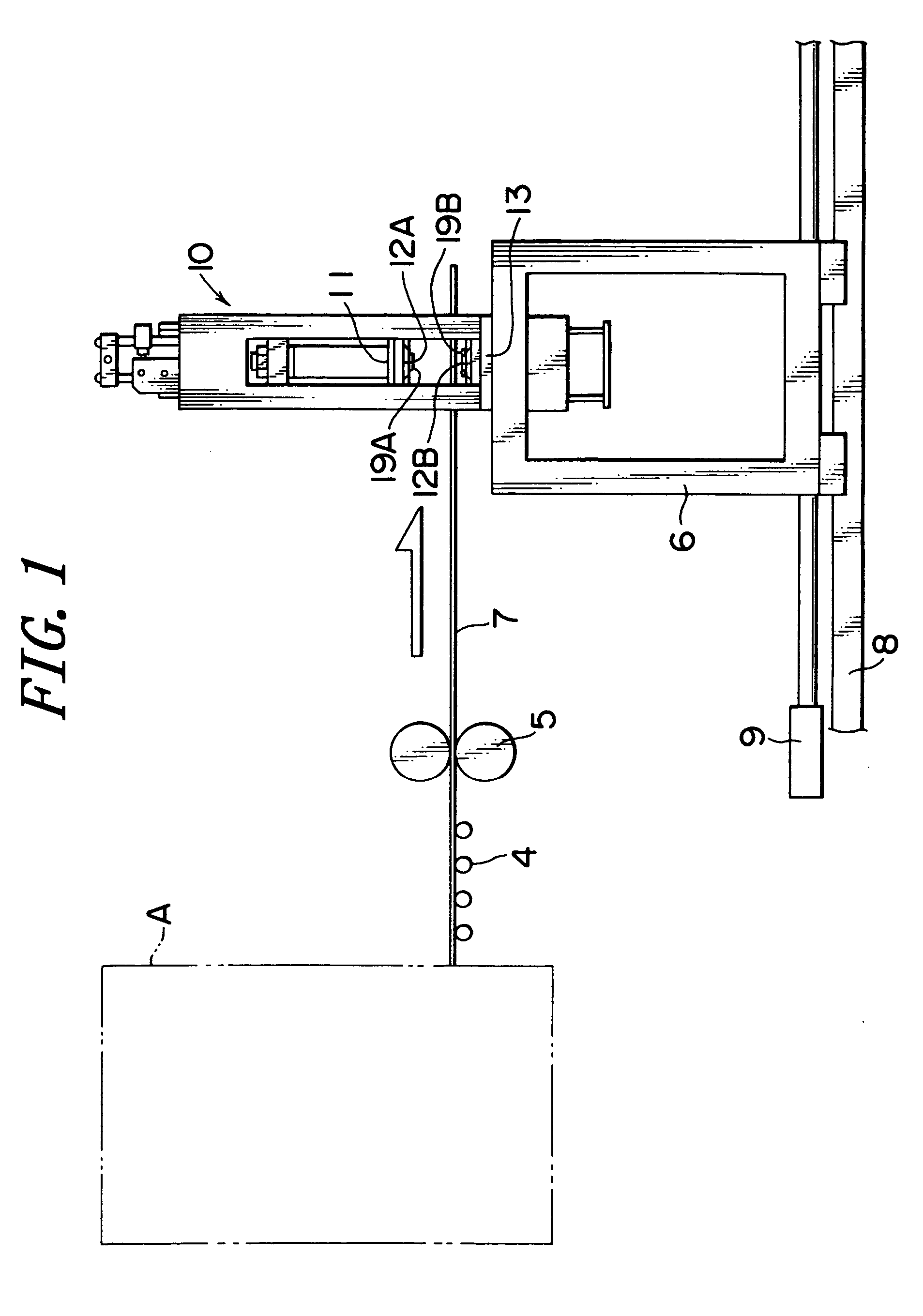

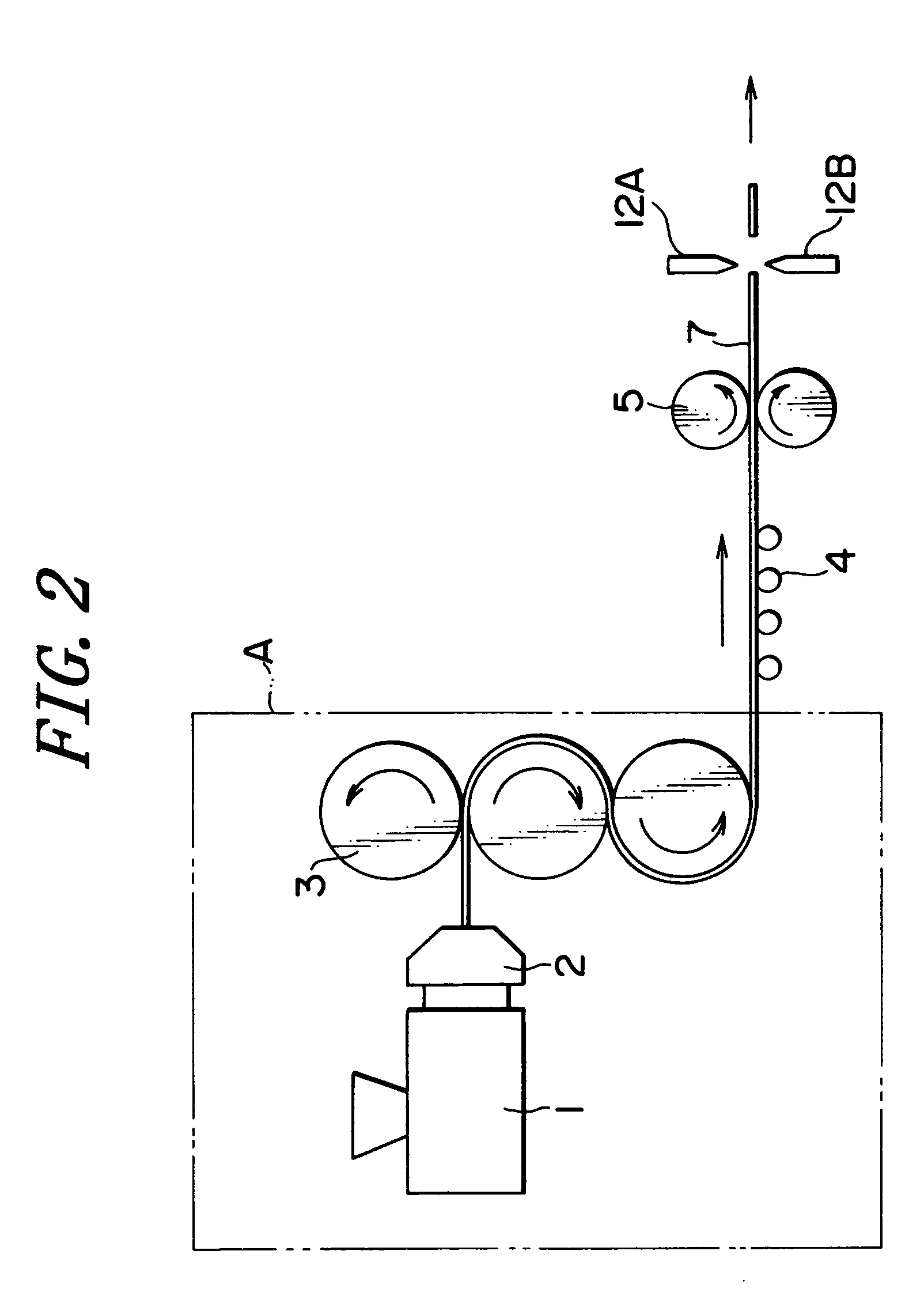

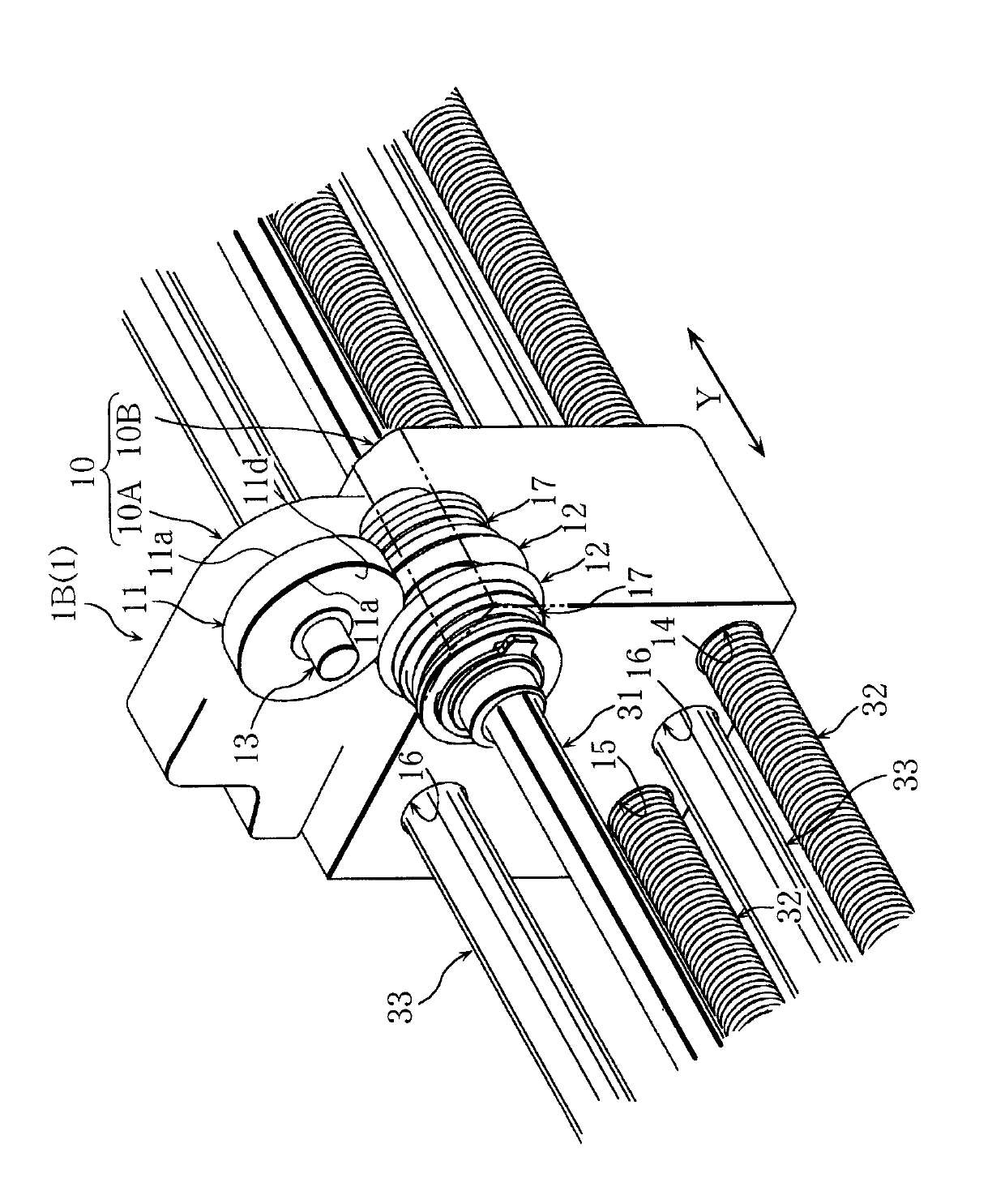

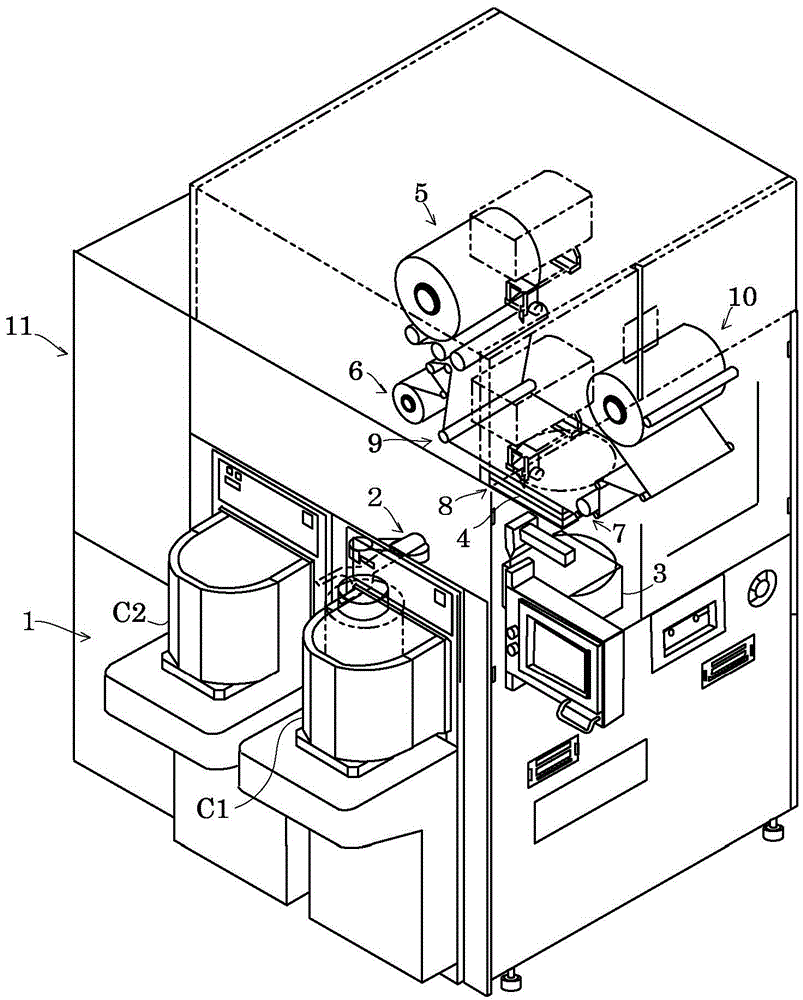

Cutting machine and manufacturing system for fixed size sheet

InactiveUS20060075863A1High precision cuttingShort cutting timeMetal working apparatusEngineeringHardness

A cutting machine 10 includes an upper blade 12A and a lower blade 12B installed at upper and lower positions, and resilient members 19A, 19B installed on both sides of the blades and protruding more than the blades for supporting a hard plastic sheet 7 during cutting. The resilient members installed on both sides of either of the upper and lower blades include a resilient member at a section near the blade and a resilient member at a section far from the blade, and the hardness of the resilient member at a section near the blade is different from the hardness of the resilient member at a section far from the blade.

Owner:TEIPI THERMAL ENG +2

Method and device for weight precise cutting of a food strand

ActiveUS20130260660A1Easy to detectImprove accuracyMeat processing plantsPoultry processingFood chainEngineering

A method for cutting a food strand into portions including the steps:feeding the food strand through a feed device towards a cutting device;continuously measuring a cross section of the food strand during feeding with a measuring device;continuously generating a marking on the food strand through a marking device;continuously detecting the marking through three first detectors arranged on identical sides of the marking with respect to the feed direction;continuously determining a size of a cross sectional surface of the food strand through a processing device from image data generated by the first detectors and a fourth detector;controlling the cutting device and / or the feed device through a control device using data of the size of the cross sectional surface; andcontinuously detecting the marking through a fourth detector arranged on another side of the marking than the three first detectors.

Owner:REIFENHAEUSER UWE

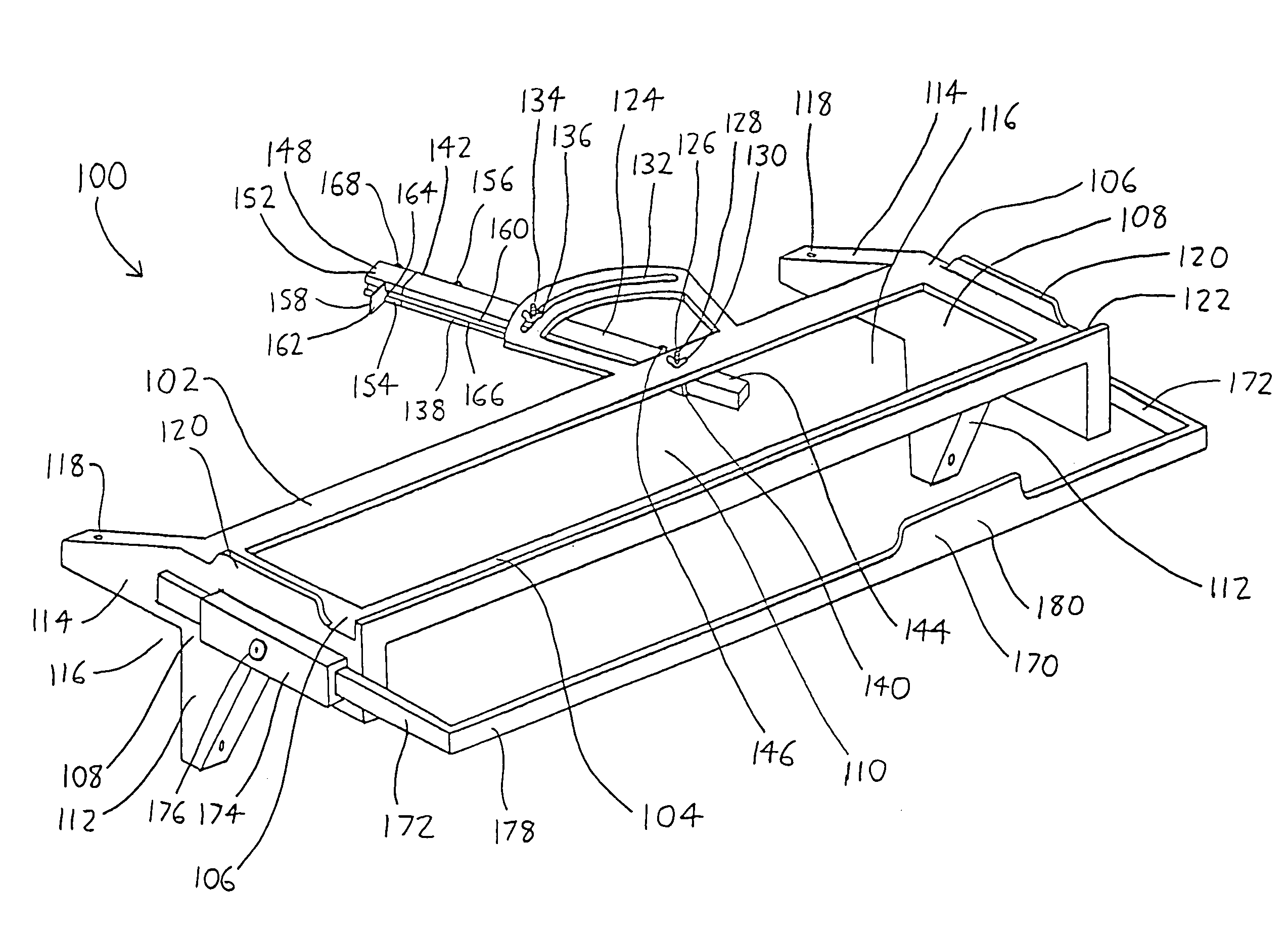

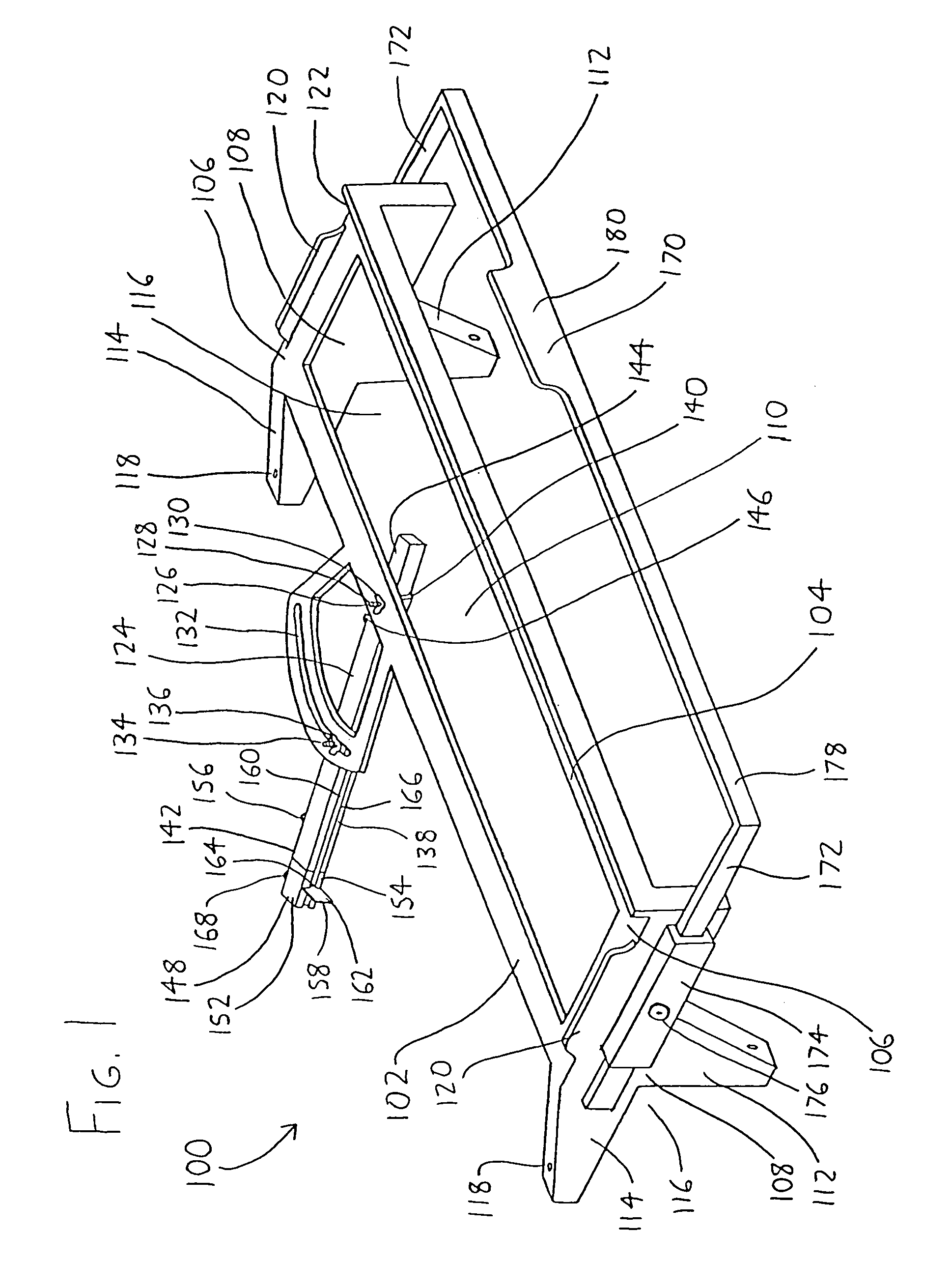

Work surface guide for power tools

InactiveUS6991009B1High precision cuttingConvenient to accommodateGuide fencesMulti-purpose machinesPower toolEngineering

A work surface guide for portable hand-operated power tools allows their adaptation to a fixed-bed form (for example, a circular saw may be used as a radial arm saw or sliding miter saw). A pair of parallel rails are spaced laterally outwardly and above a table or other work surface so that the power tool may slide along these rails to cut matter located in a cutting area situated below and beneath the rails (and protruding from the edge of the work surface beneath the rails). A board fence is pivotally attached to one of the rails to extend onto the work surface, thereby allowing the board fence to be adjusted to some desired angle, a board to be situated against the board fence to protrude beneath the rails and into the cutting area, and the power tool to be run along the rails to cut the board.

Owner:SANDS WEDEWARD SUSAN A

Device and method for cutting an assembly

InactiveUS7232738B2High precision cuttingSemiconductor/solid-state device manufacturingFine working devicesHigh pressureBiomedical engineering

A method is presented for cutting an assembly that includes two layers of material having a first surface and a second surface. The method includes providing a weakened interface between the two layers that defines an interface ring about the periphery of the assembly, providing a high-pressure zone at the interface ring, and providing at least one controllable low-pressure zone in the vicinity of at least one of the first surface and the second surface. The technique also includes supplying the high-pressure zone with a controllable high-pressure force, and attacking the interface ring with at least one mechanical force in combination with the high-pressure force to cut the assembly.

Owner:SOITEC SA

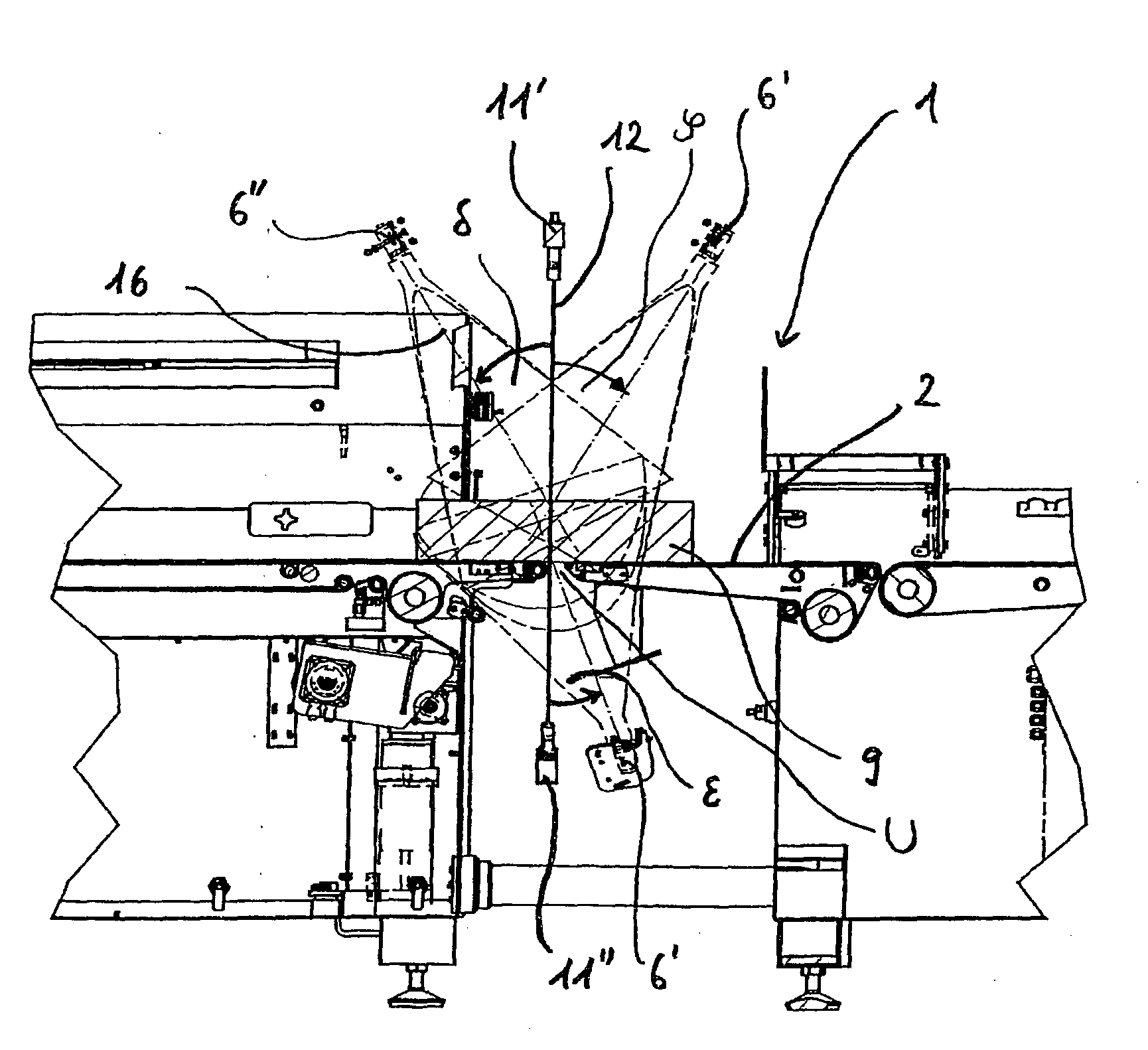

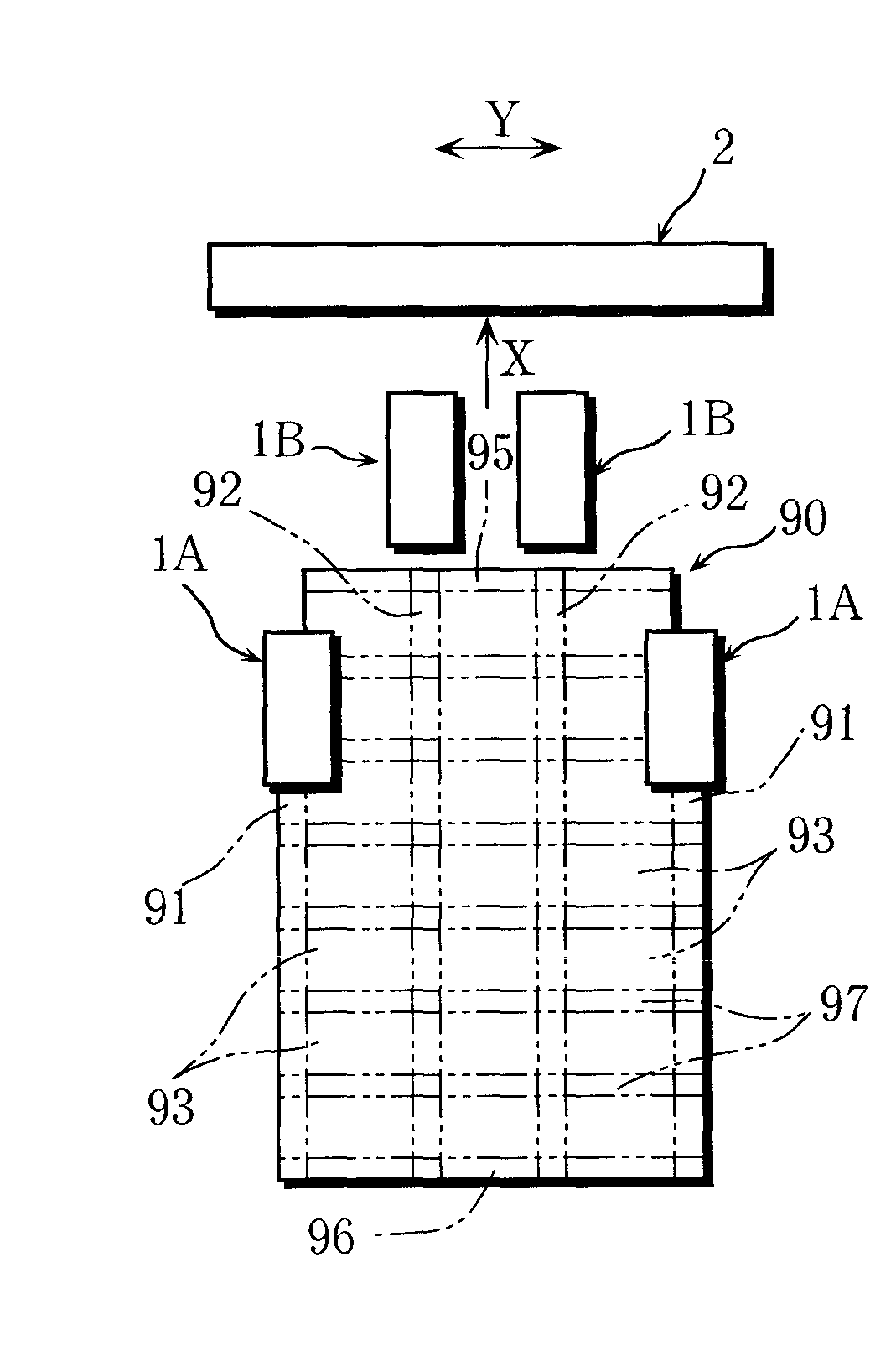

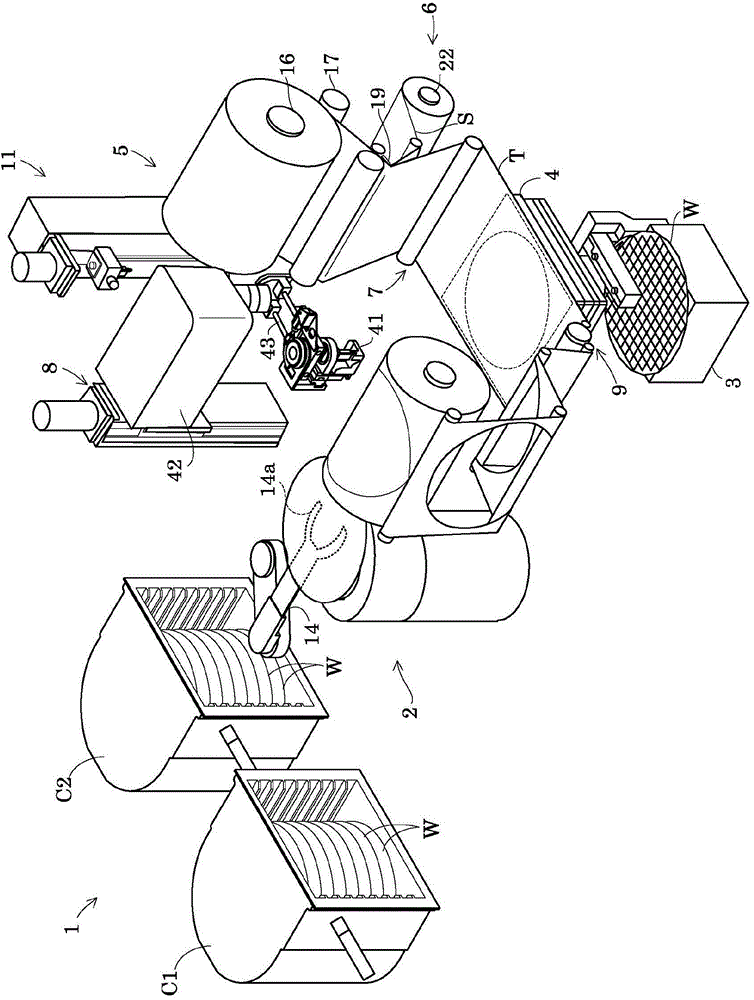

Automatic card cutting device

An automatic card cutting device comprises a plurality of convey rollers (5) for conveying paper (90), a plurality of cutting machine heads (1) for cutting the paper (90) in a conveying direction (X), and a transverse cutting machine part (2) used for cutting the paper (90) in a transverse direction (Y) at a right angle with the conveying direction (X) so as to cut the paper (90) into a plurality of cards (C). Each cutting machine head (1) comprises side heads (1A) and middle heads (1B), wherein the side heads (1A) are arranged in a manner that the positions can be adjusted freely in the transverse direction so as to cut lateral border parts (91) of the paper (90) into a strip shape; and each middle head (1B) is provided with a disc-shaped upper blade (11) and a pair of lower blades (12), each lower blade is contacted with the left border part and the right border part (11d) of the upper blade (11) respectively, and the middle head is arranged in a manner that the position can be adjusted freely in the transverse direction so as to cut a longitudinal middle waste part (92) of the paper (90) into a strip shape.

Owner:UCHIDA YOKO LTD +2

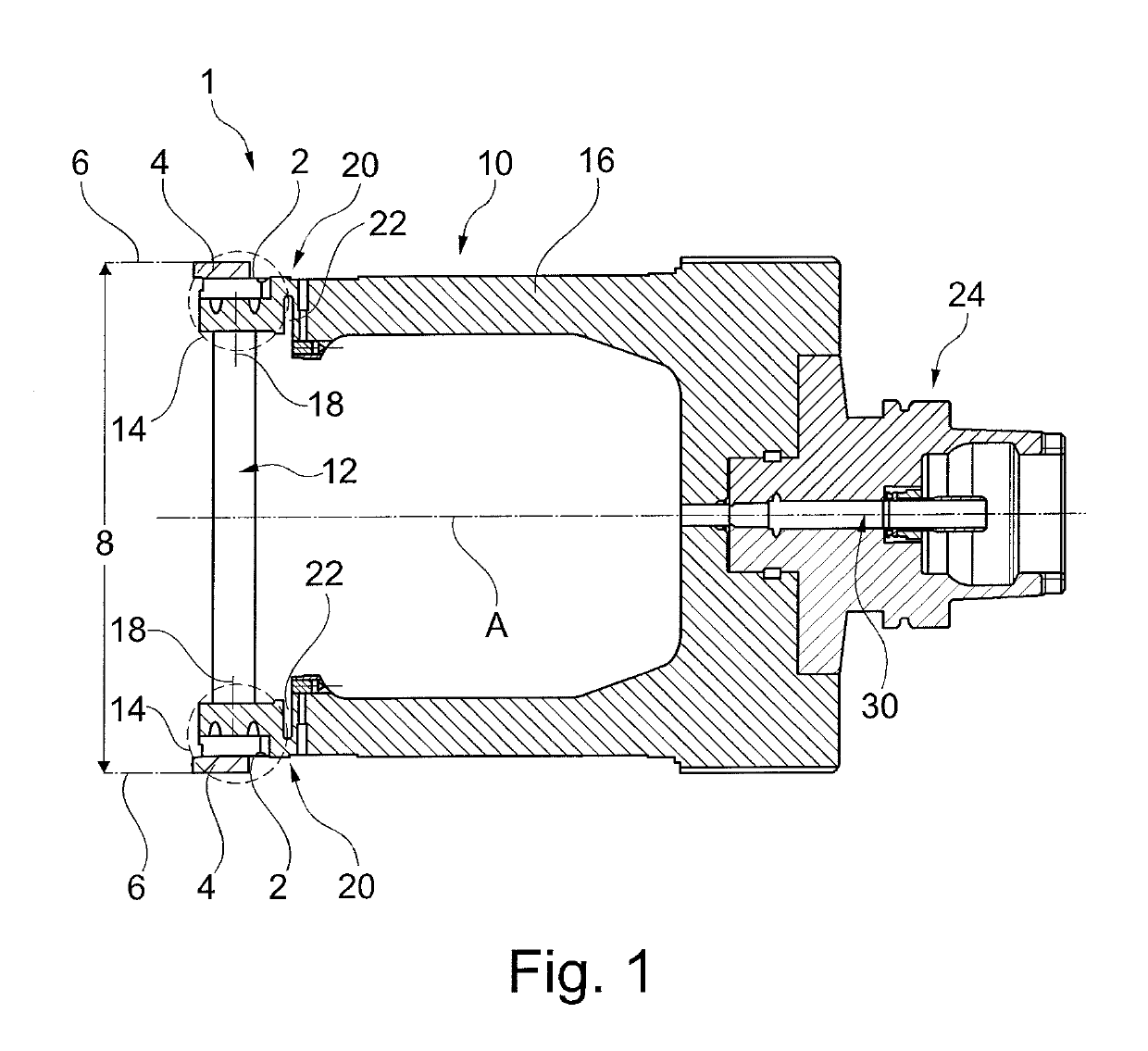

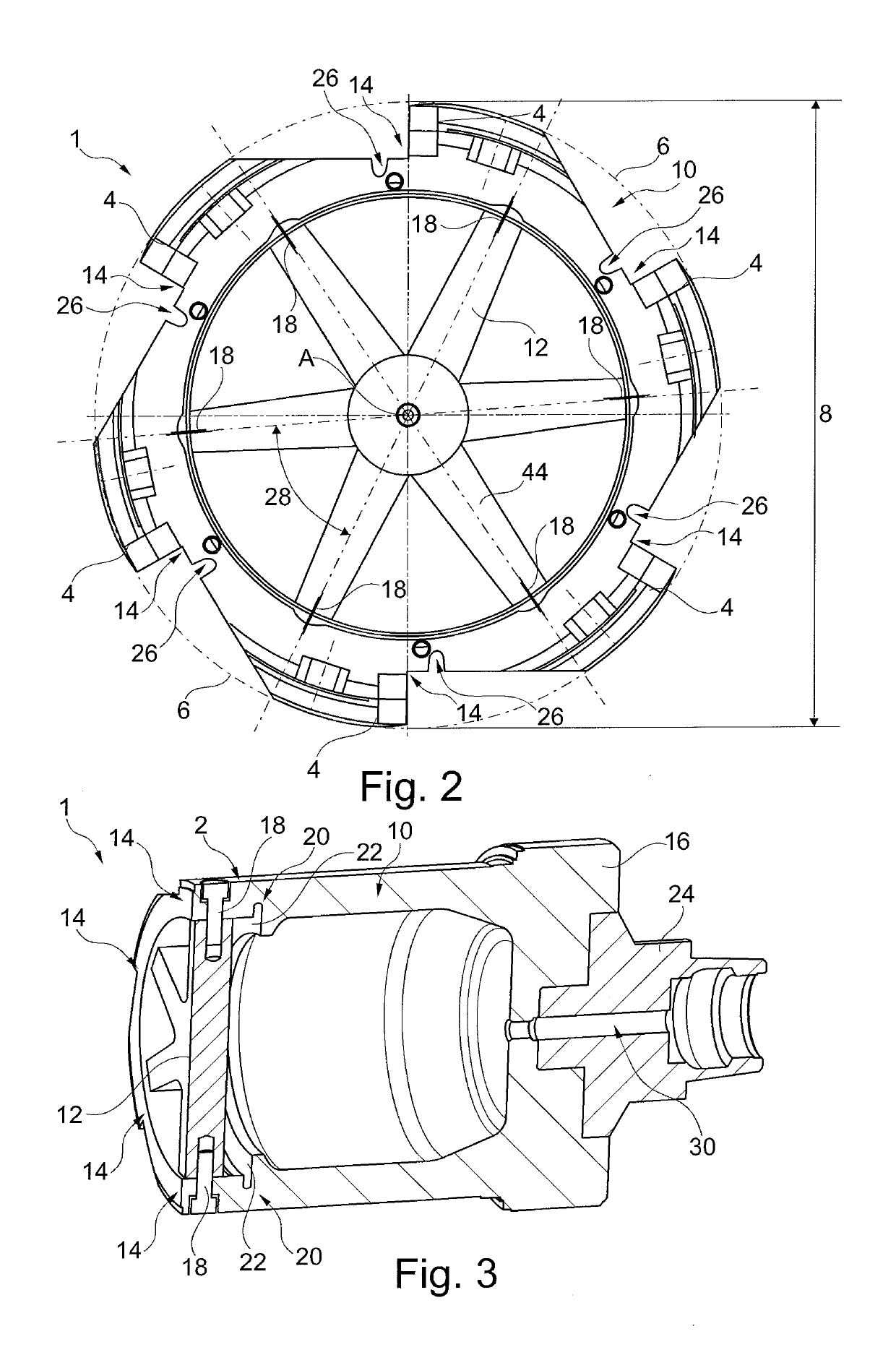

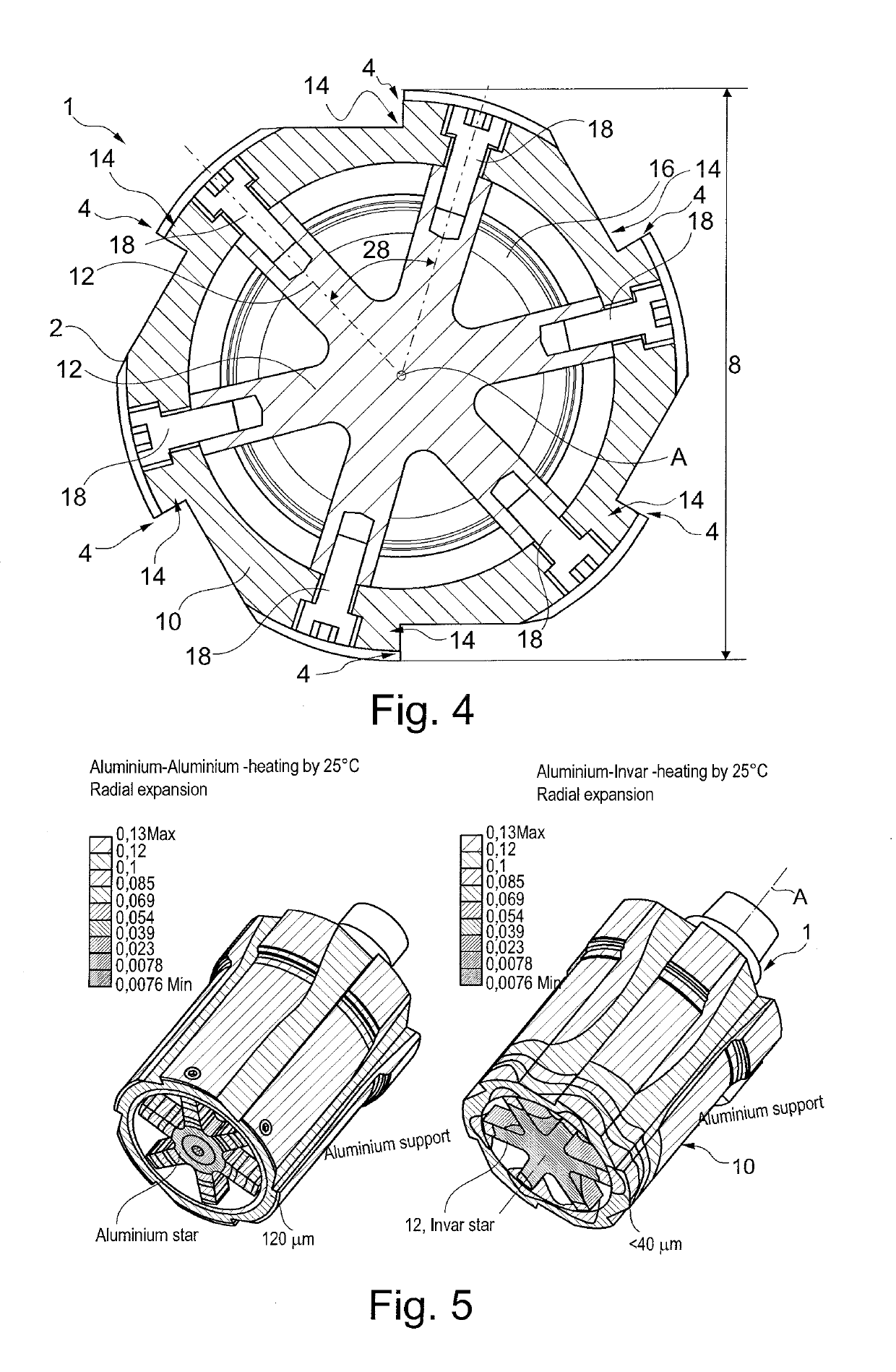

Rotary tool

ActiveUS20190314904A1High thermal expansionMinimize inertiaMilling cuttersWorkpiecesThermal expansionKnife holder

The invention relates to a rotary tool (1; 101; 201; 301; 401) for cutting large inside diameters at the outer circumference (2) of which at least one cutting edge (4; 104; 204) is arranged, comprising a support structure (10; 110; 210; 310; 410) which includes a supporting area (14; 114; 214) which indirectly or directly supports the cutting edge (4; 104; 204), and comprising a chucking portion (24; 124; 224; 324; 424) for coupling to a tool holder, wherein the support structure (10; 110; 210; 310; 410) is designed in light-weight construction and the area (14; 114; 214) of the support structure (10; 110; 210; 310; 410) indirectly or directly supporting the cutting edge (4; 104; 204) is limited regarding thermal expansion by a corset structure (12; 112; 212; 312; 412).

Owner:GUEHRING OHG

Cut-off device

InactiveCN106466887AIncrease or decrease quantityAccurate and easy to correctSemiconductor/solid-state device manufacturingWorking accessoriesEngineeringMechanical engineering

The invention provides a cut-off device. The cut-off device has a cutting-off bar capable of simply adjusting the parallelism of the top edge ridge of a pressing edge and the surface of a substrate without using a pad or the like. The cut-off device (A) includes a workbench (1), a mounting substrate (W), and a cut-off bar (10) arranged above the workbench (1), wherein the cut-off bar (10) has a plurality of pressing plates (14) arranged in a linear mode and gaps provided between the pressing plates (14).

Owner:MITSUBOSHI DIAMOND IND CO LTD

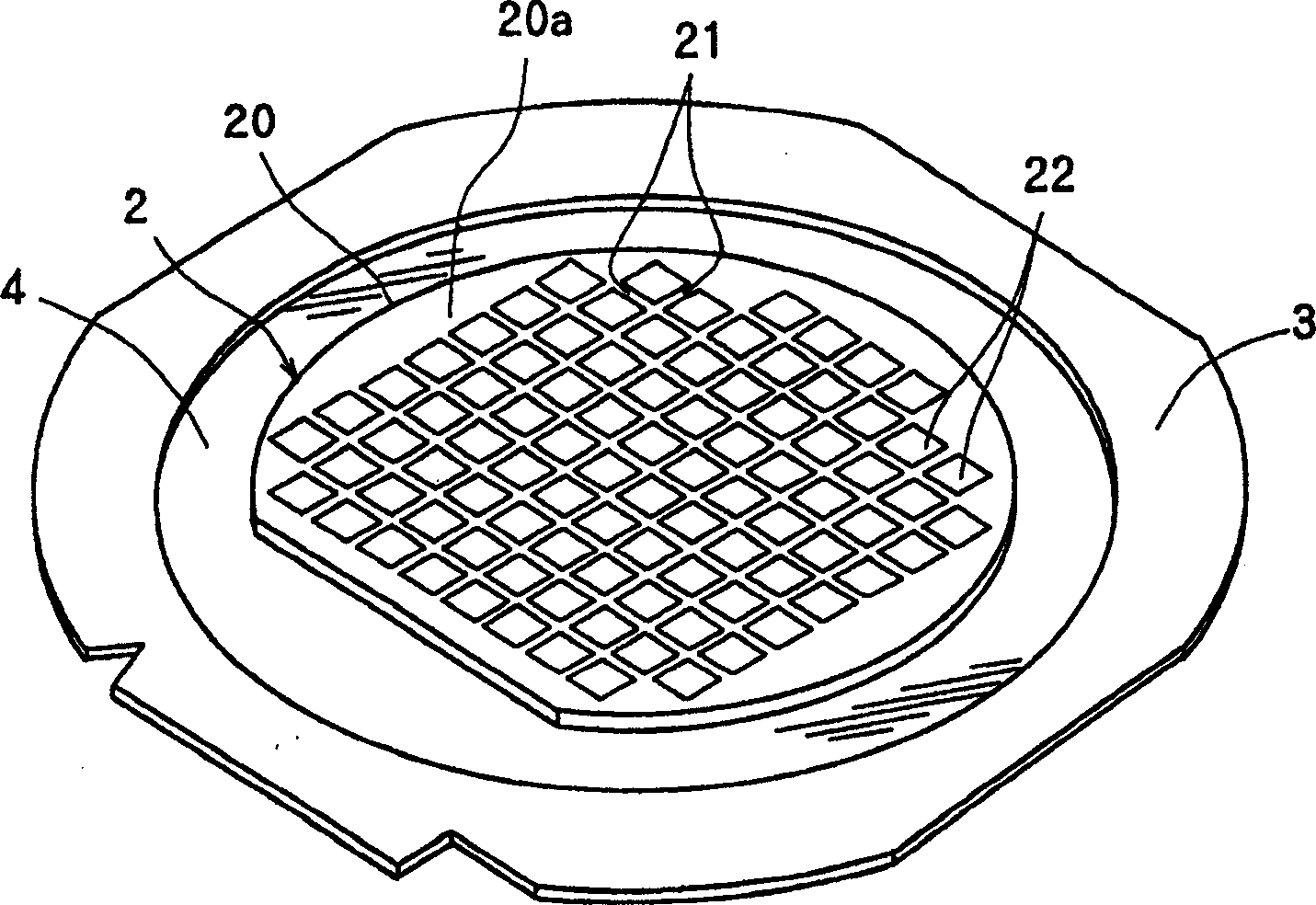

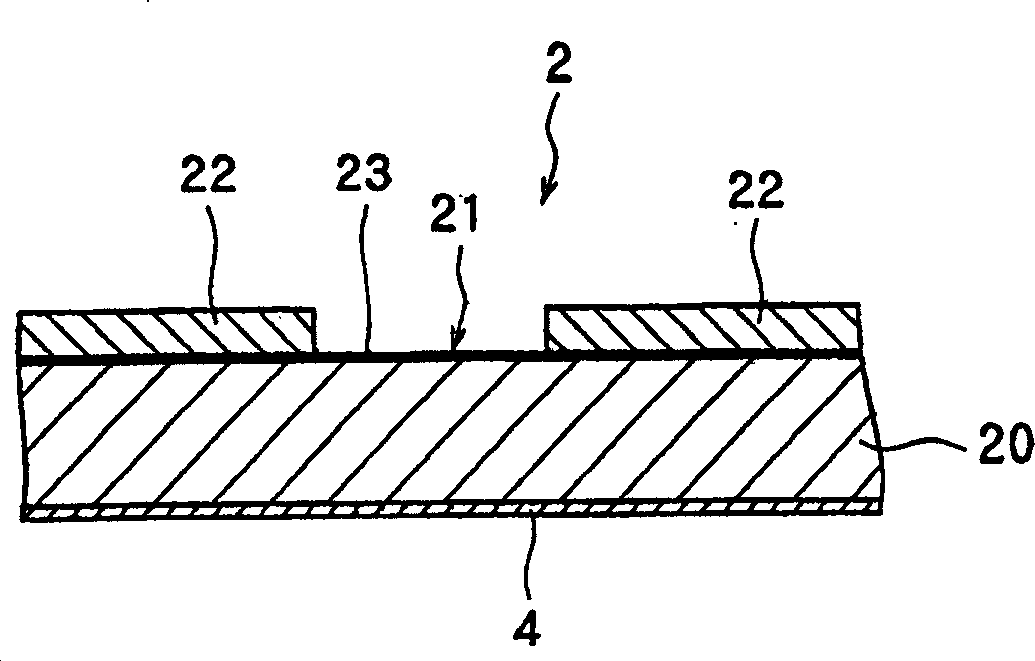

Adhesive tape cutting method and adhesive tape cutting apparatus

InactiveCN104022012AHigh precision cuttingSemiconductor/solid-state device manufacturingMetal working apparatusEngineeringMechanical engineering

A strip adhesive tape except for a portion on a notch of a wafer W is cut by contacting a cutter of a first cutting mechanism along an outer periphery of the wafer. The adhesive tape cut out into a wafer shape is reeled and collected while being separated. Thereafter, the wafer with the adhesive tape is transported to a second cutting mechanism. The second cutting mechanism cuts out the portion of the adhesive tape on the notch with a cutter having the same shape as that of the notch.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com