Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Short cutting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

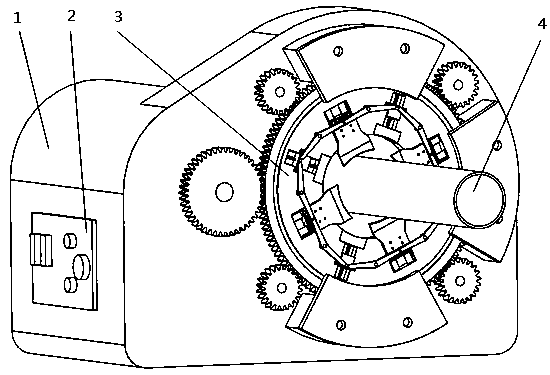

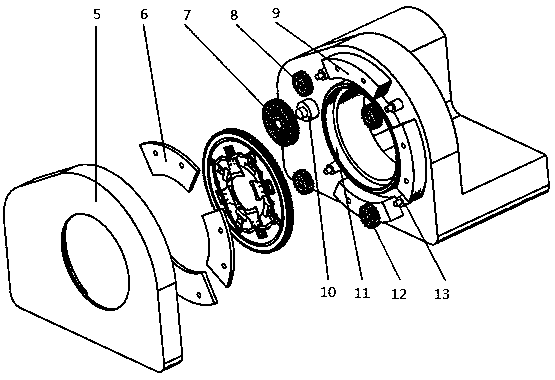

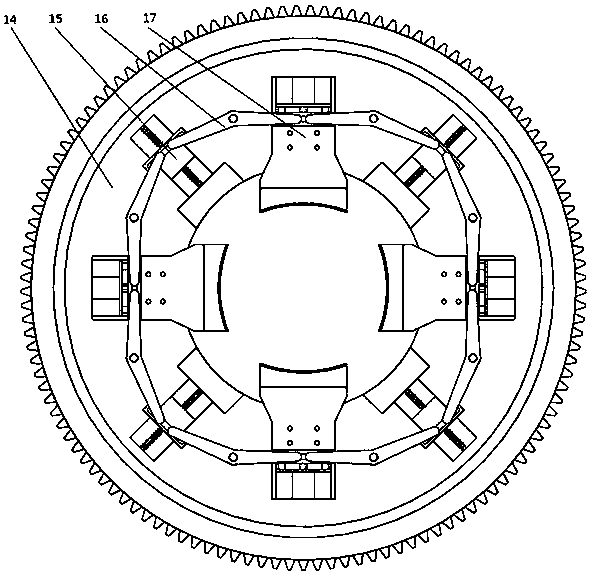

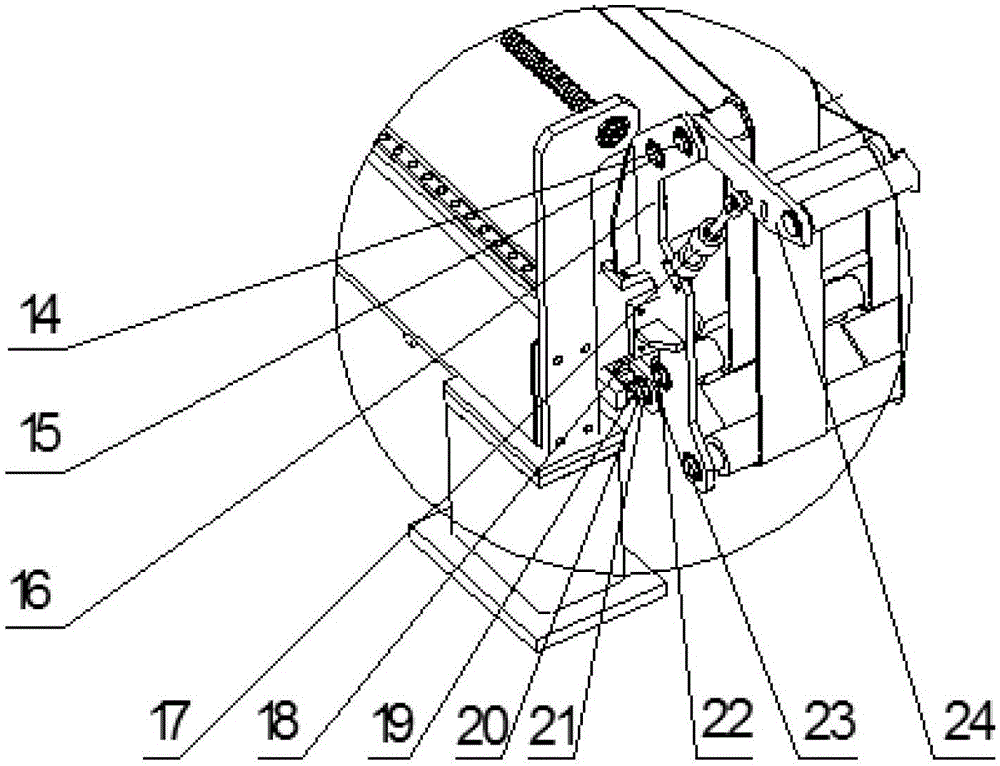

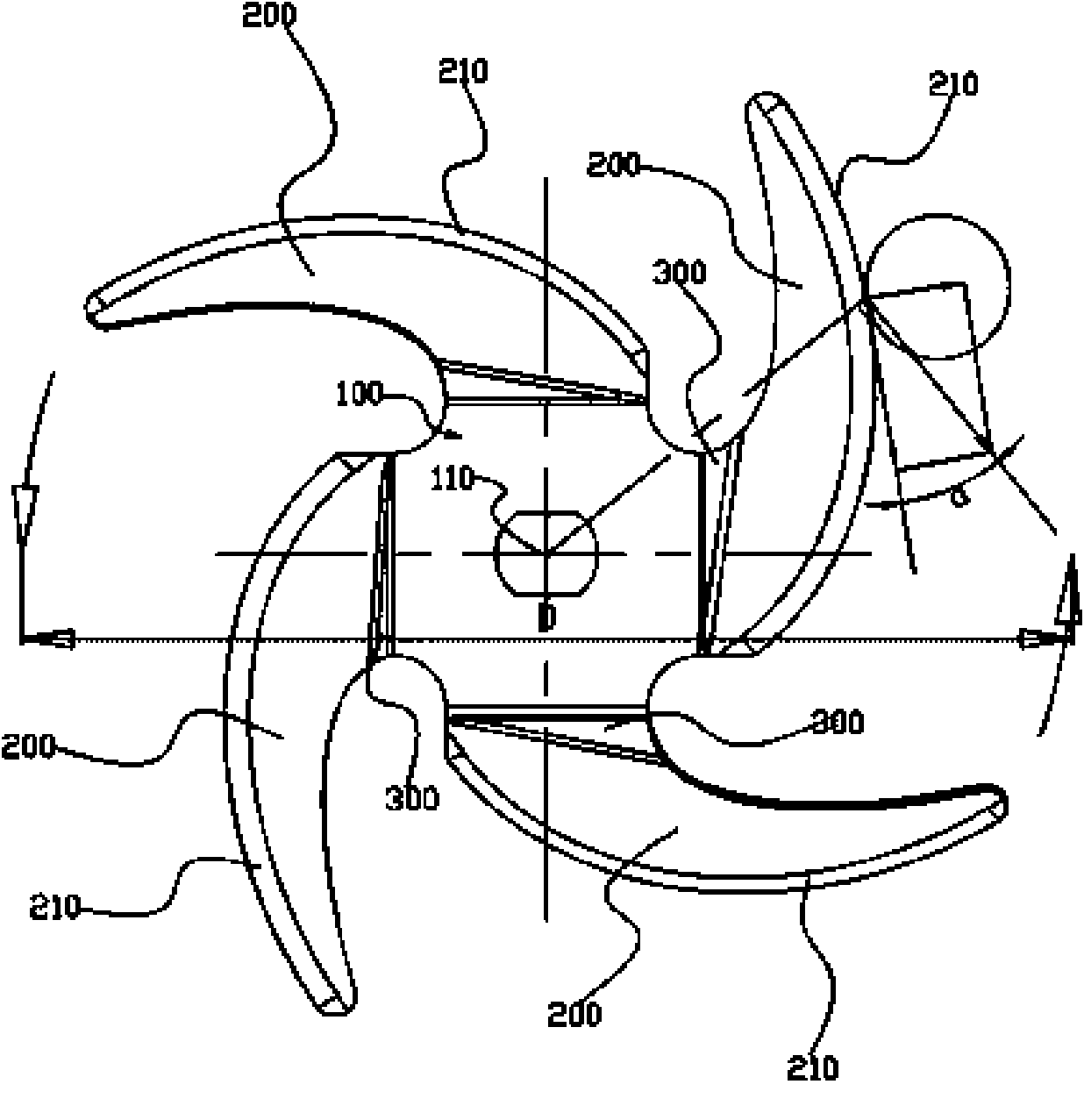

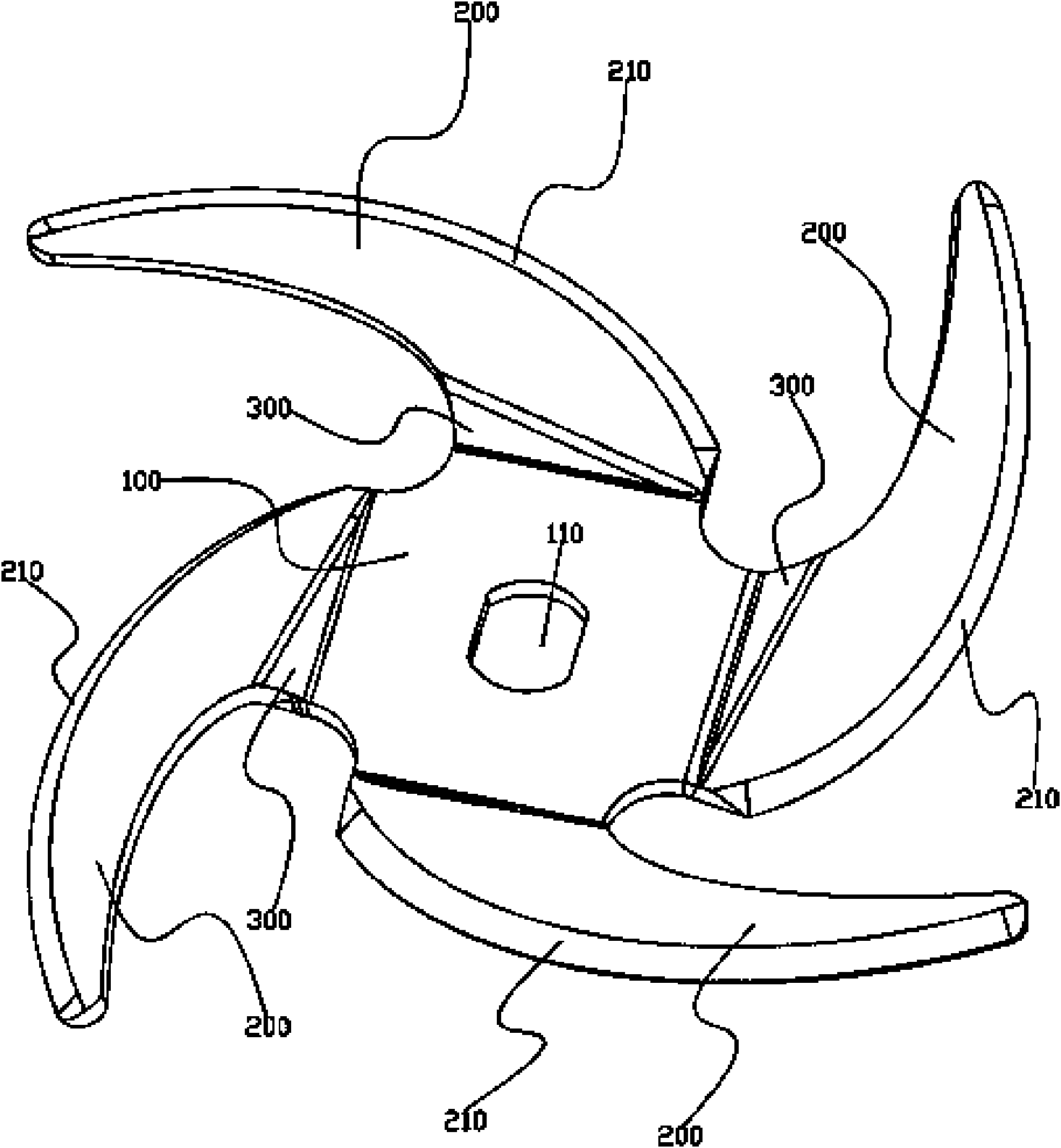

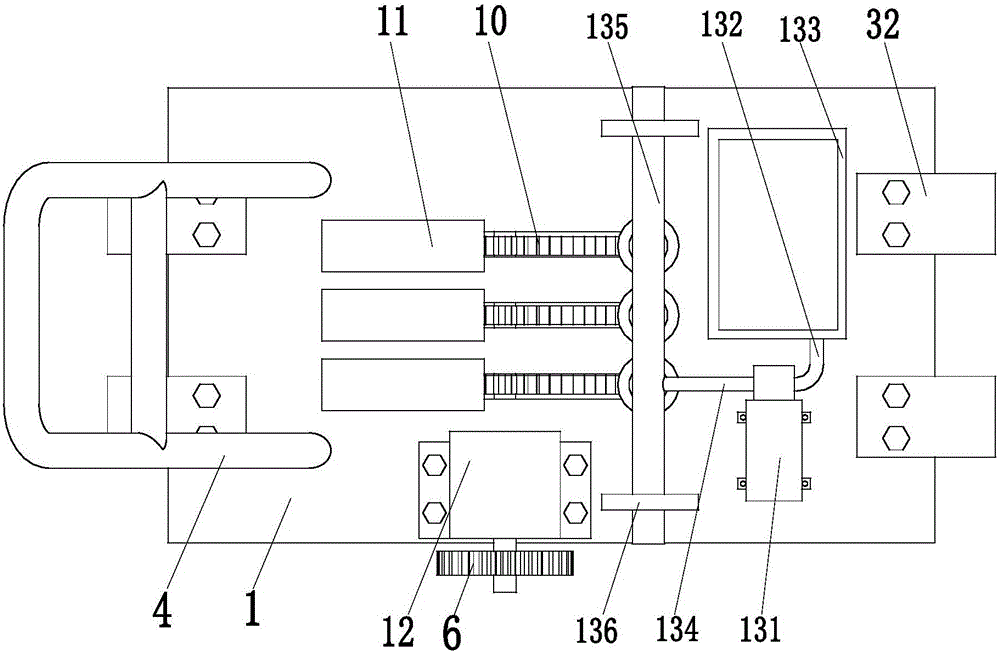

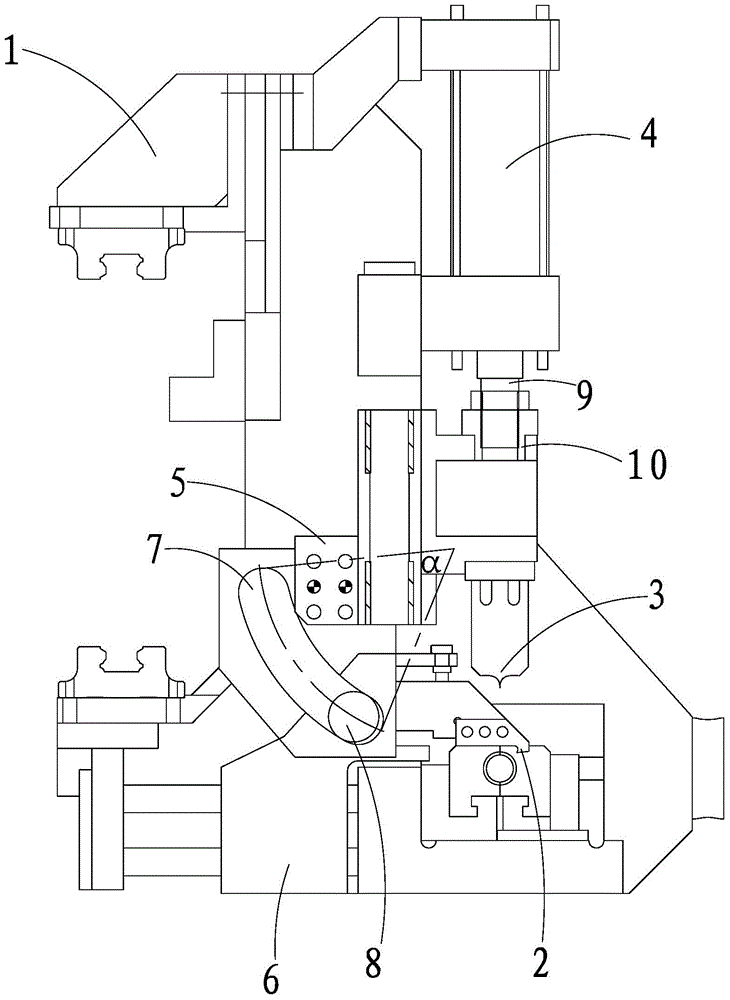

Rotary centrifugal multi-blade cutting machine

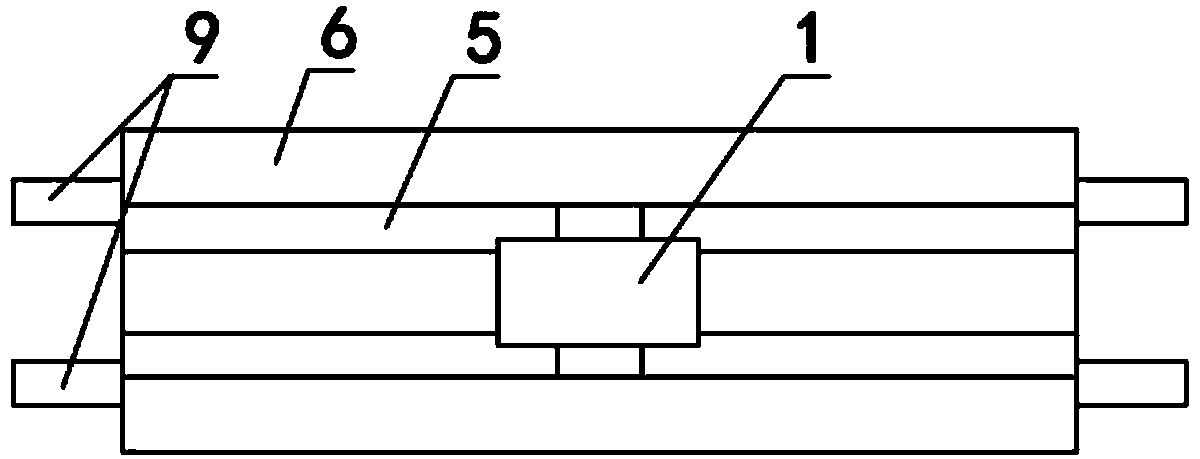

The invention relates to the field of pipe material feeding, in particular to a rotary centrifugal multi-blade cutting machine. The machine comprises a machine base and a cutting unit; the machine base comprises a motor, a control panel, a driving gear, an auxiliary gear, a supporting gear and a supporting bearing; the cutting unit comprises a gear cutter head, a knife seat mechanism, a centrifugal mechanism and a connecting rod, various sliding grooves are formed in the surface of the gear cutter head for respectively mounting the knife seat mechanism and the centrifugal mechanism, the knifeseat mechanism includes a base, a cutter head sliding block, a blade, a return spring, a limit block and the like, the cutter head sliding block is connected to the base through a sliding through, a circular groove formed in the middle after connection is used for mounting the spring, and the connecting rod is connected to the cutter head sliding block and the centrifugal mechanism. The structureof the machine is simple, only a single motor is required to drive the cutter head to rotate, the centrifugal force of the centrifugal mechanism is converted into the axial cutting force of the bladeduring the rotary cutting process, no other power is provided, the blade replacement is convenient, the contact area of the annular blade and a pipe material is large, and the quality of the incisionis ensured.

Owner:CHINA UNIV OF MINING & TECH

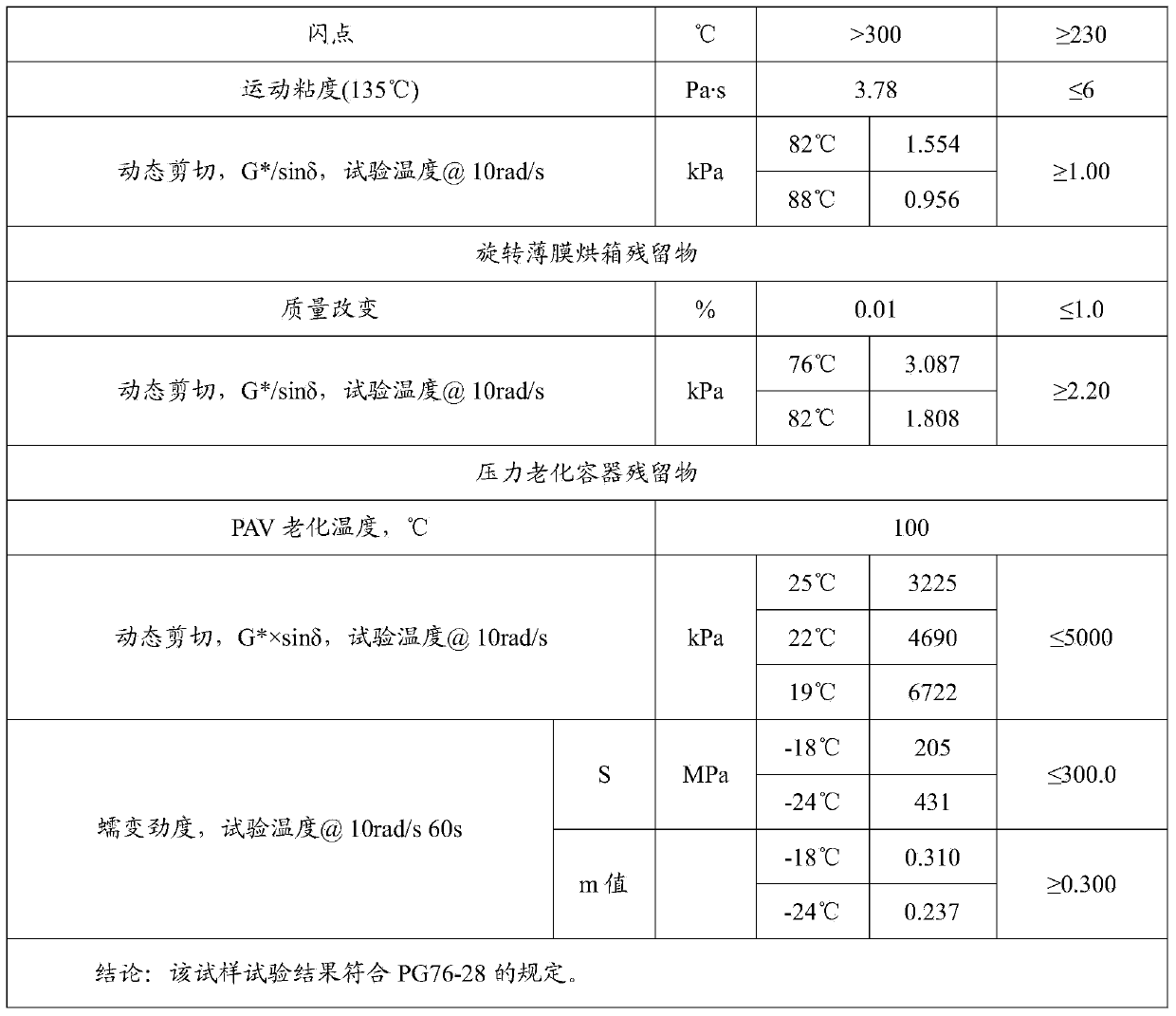

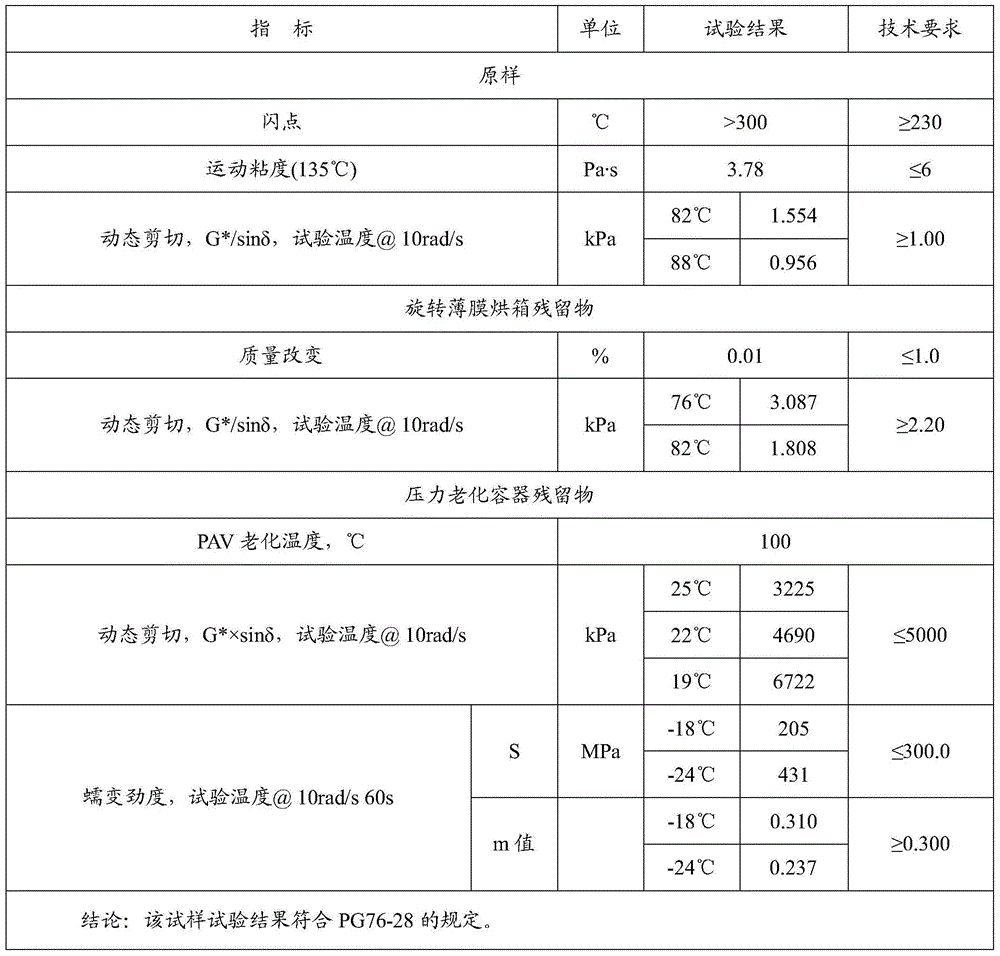

Rubber and plastic alloy modified asphalt and asphalt mixture

InactiveCN103436039AHigh temperature strengthGood modification effectPlastic recyclingBuilding insulationsPolymer scienceAlloy

The invention relates to the field of asphalt. A rubber alloy modifier is obtained with untreated waste plastics and waste tire rubber powder as main raw materials. Modified asphalt which does not affect the rubber / plastic independent modification effects and has good asphalt storage stability and simple production process is finally obtained by utilizing the modifier to modify asphalt. The modified asphalt can be applied to continuous dense gradation of an asphalt mixture. On the premise that the high-and-low temperature performance of the mixture meets the requirement, the water stability is obviously improved, thus achieving effective treatment of two types of polymer waste pollutants such as waste tire rubber powder and waste plastics and change of asphalt properties.

Owner:山东高速交通建设集团有限公司

Rubber and plastic alloy asphalt modifier

ActiveCN103421222AShort cutting timeGood high temperature performance and low temperature performancePlastic recyclingBuilding insulationsWaste tiresAsphalt

The invention relates to the field of asphalt additives and provides a rubber and plastic alloy asphalt modifier. The rubber and plastic alloy asphalt modifier is mainly made of untreated wasted plastic particles and wasted tire rubber powder and does not damage the individual modification effect of rubber and plastic. The rubber and plastic alloy asphalt modifier is good in asphalt storage stability performance and simple in the production technology. Rubber and plastic alloy modified asphalt manufactured with the rubber and plastic alloy asphalt modifier is applicable to continuously densely prepared asphalt blended materials. Under the condition that the high-temperature and the low-temperature performance of the blended materials can meet the requirements, water stability is obviously improved and two kinds of macromolecule wasted pollutants including wasted tire rubber powder and wasted plastic are effectively processed.

Owner:JIANGSU ZHONGHONG ENVIRONMENT TECH CO LTD

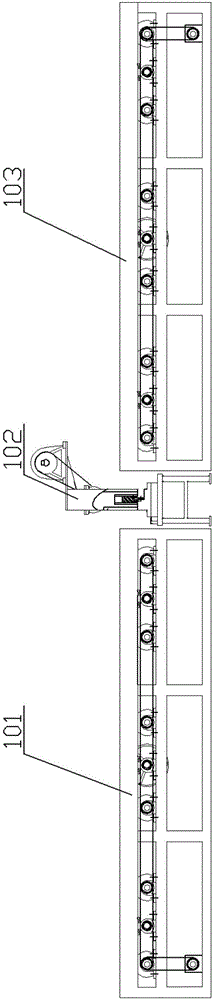

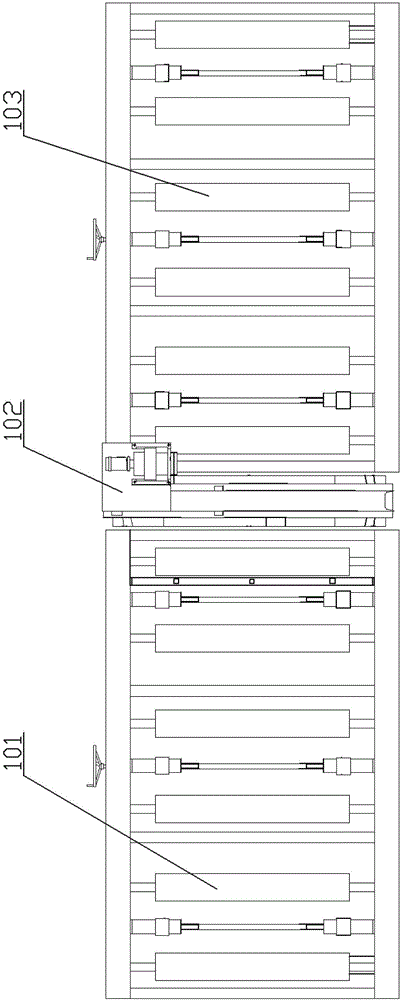

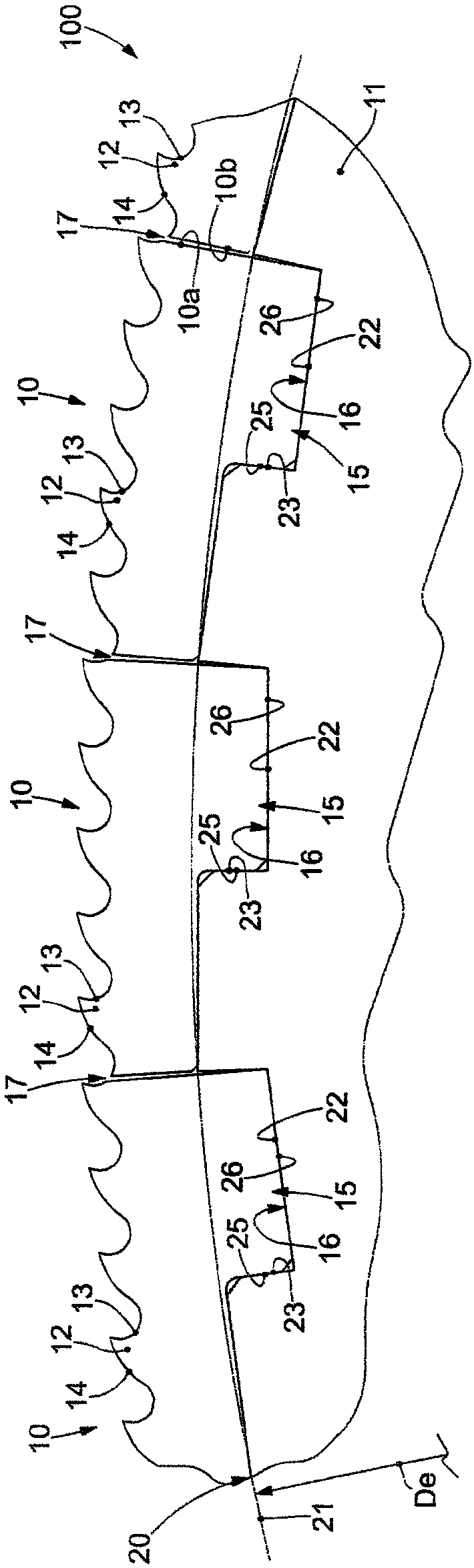

Rapid pineapple harvester

InactiveCN108207318AGood accuracy retentionGood synchronizationPicking devicesAgricultural engineering

The invention discloses a rapid pineapple harvester. The rapid pineapple harvester mainly comprises a first collection module, a second collection module, a connection module, a cutting module, a leafpressing block and a lifting mechanism. The first collection module is connected with the second collection module through the connection module. The cutting module is used for cutting off stems of pineapples. The leaf pressing block is used for pressing down leaves of the pineapples. The lifting mechanism is used for adjusting the height of the cutting module. The rapid pineapple harvester has the advantages of capability of accurately harvesting the complete pineapples at a high speed, simple and reliable structure, simplicity and convenience in operation, low cost, high practicability andwide application range.

Owner:CHONGQING UNIV

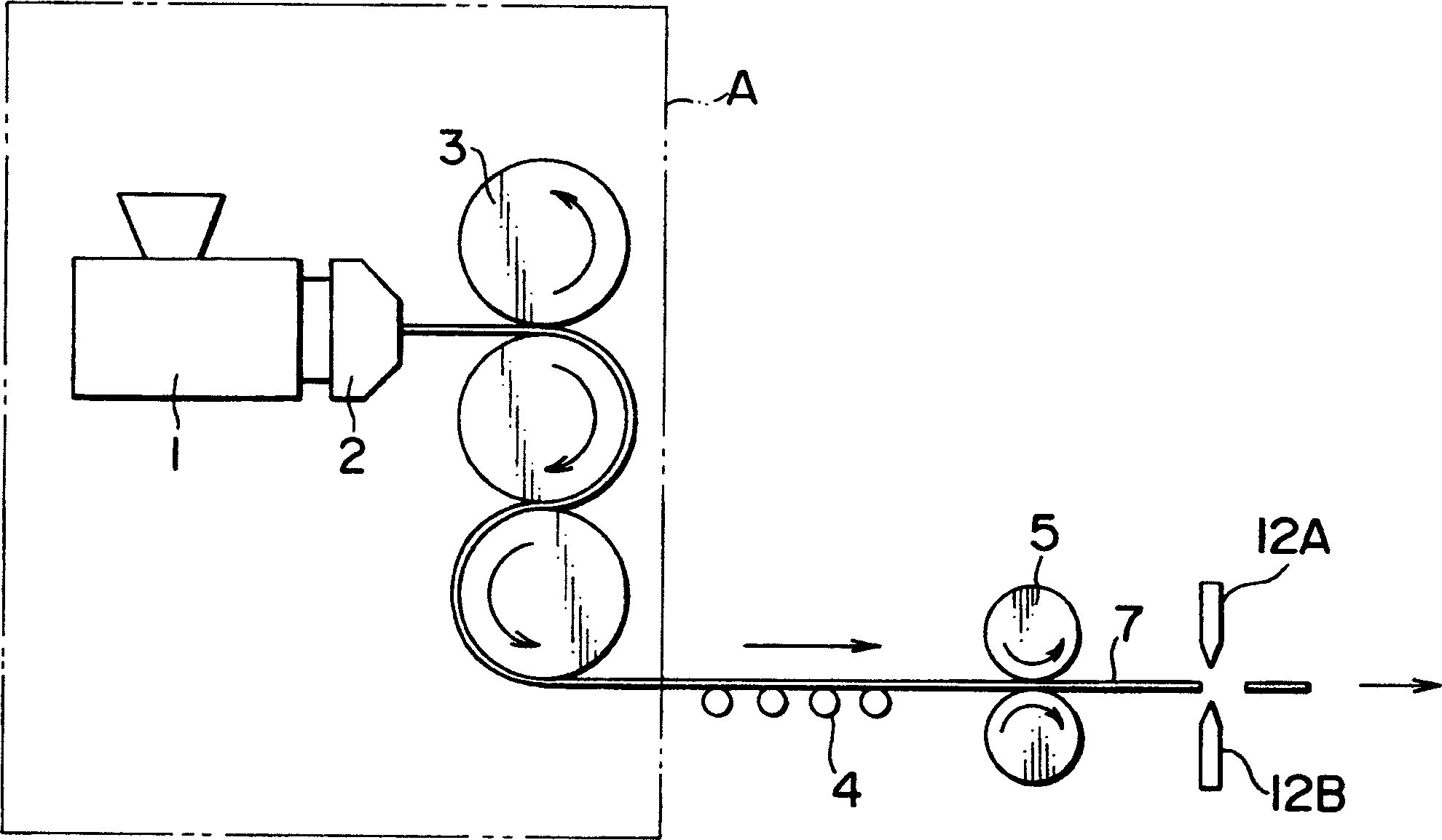

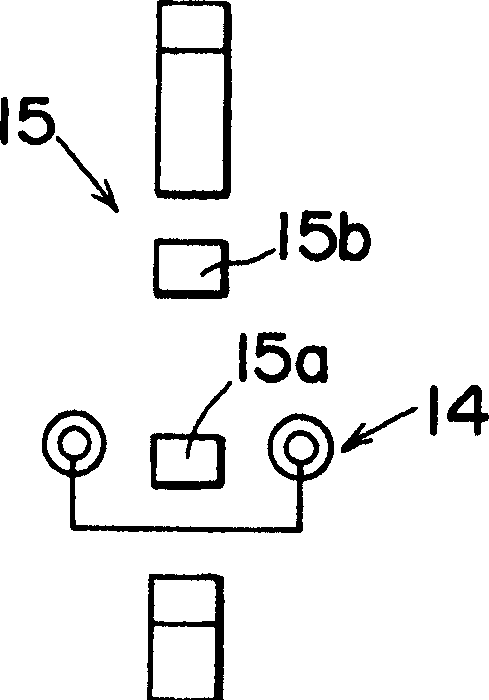

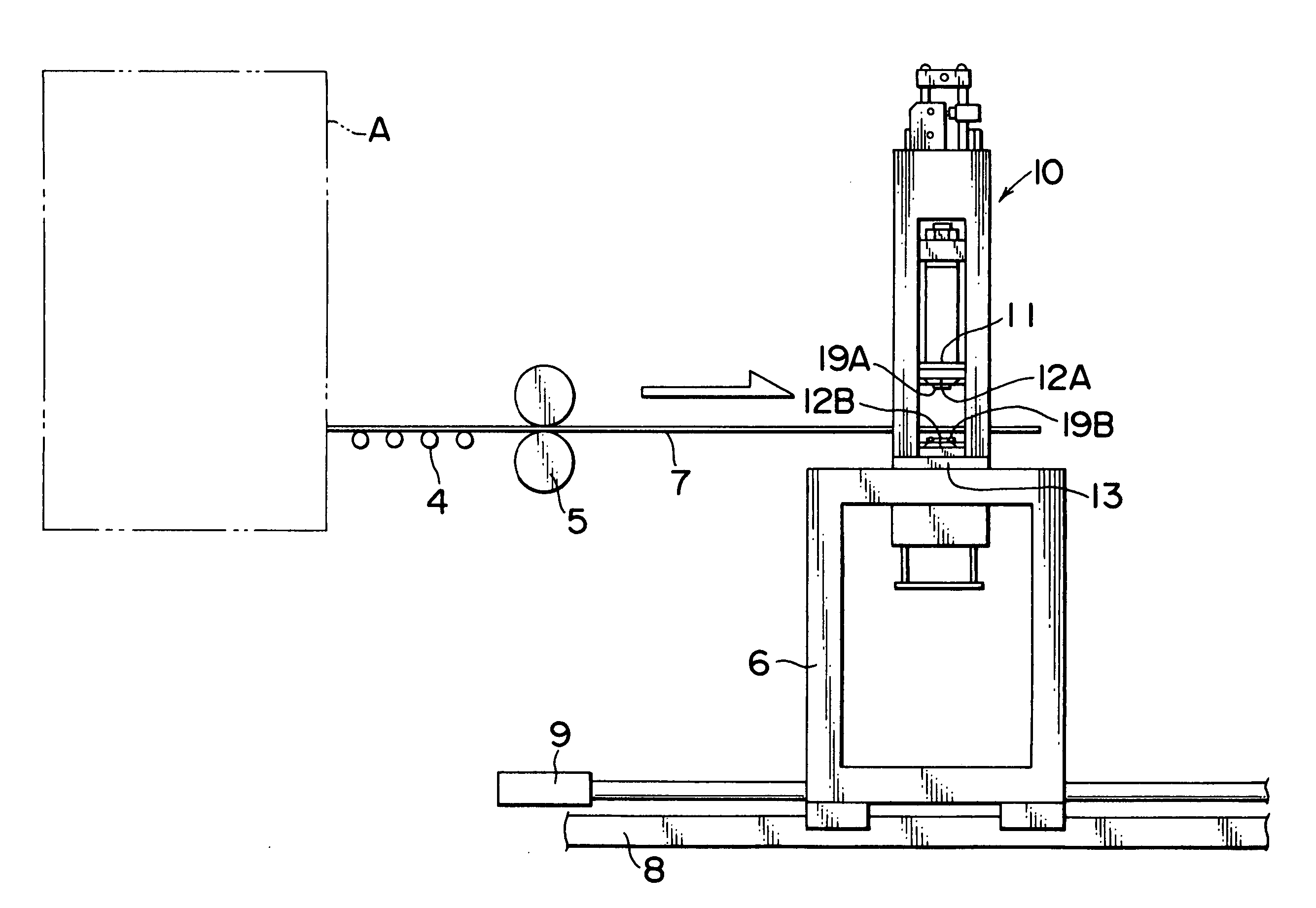

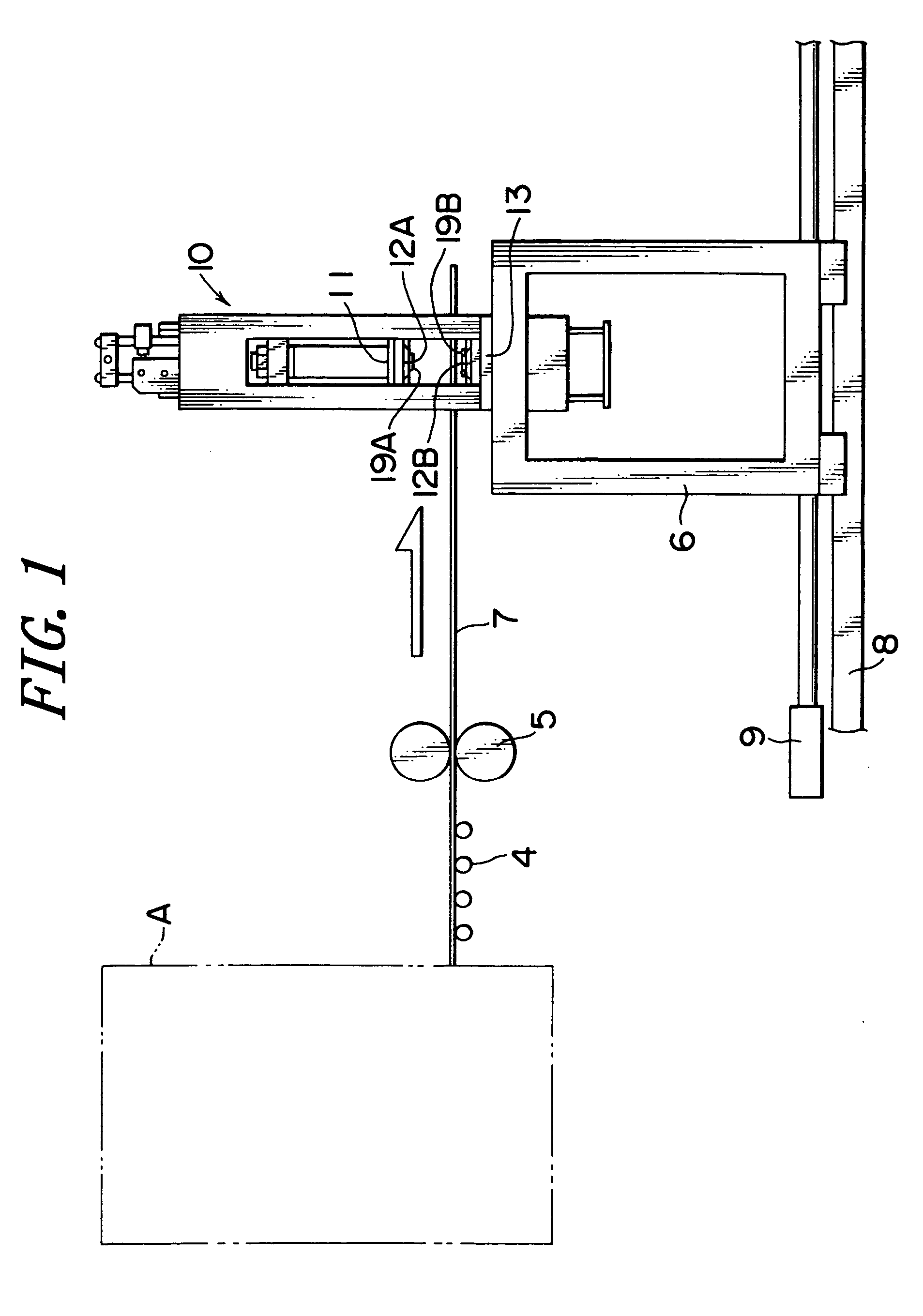

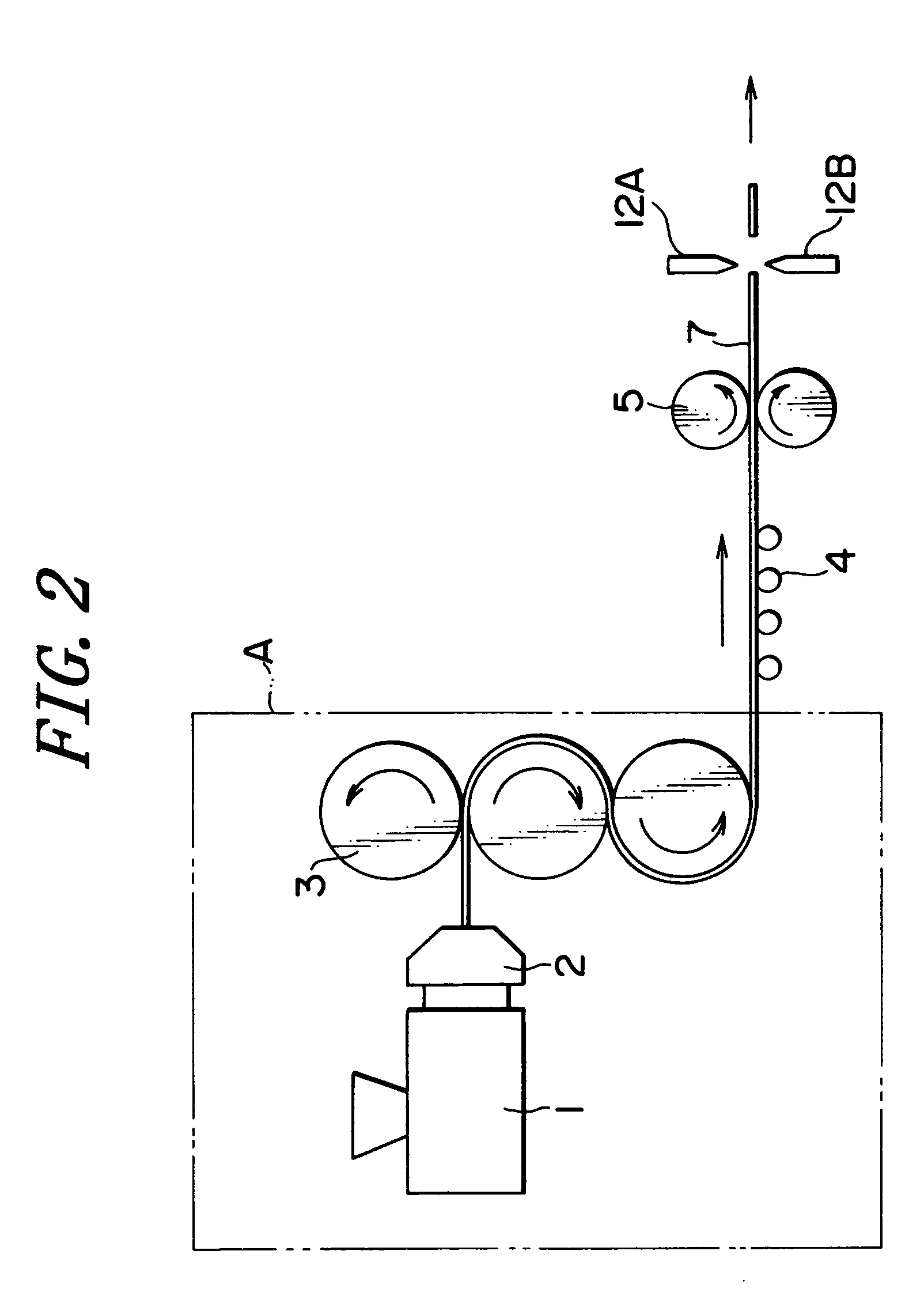

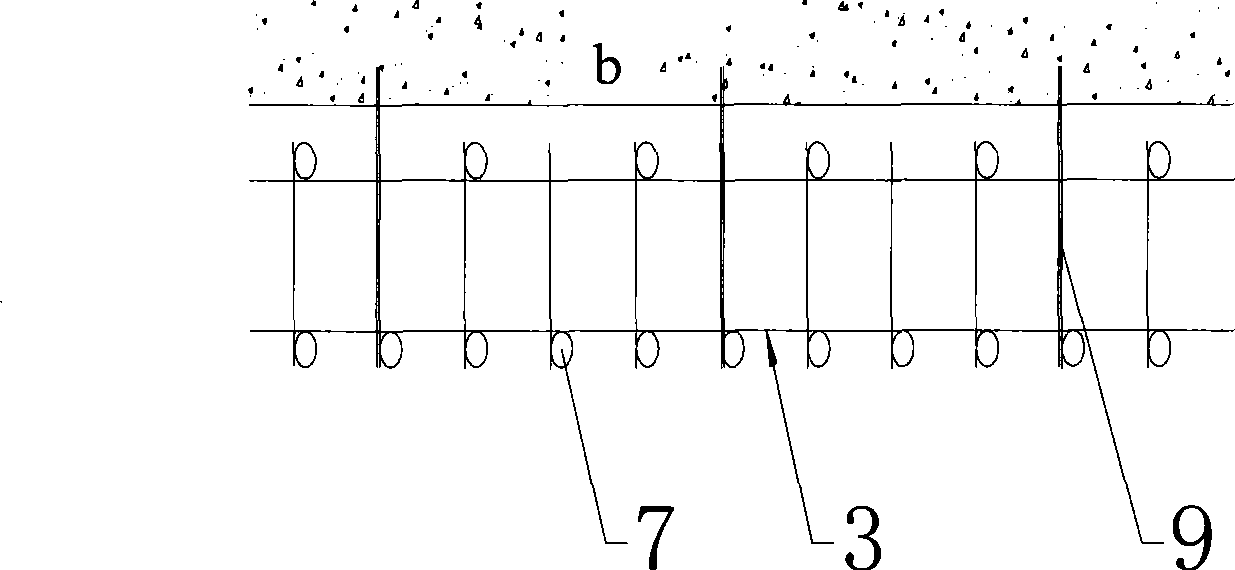

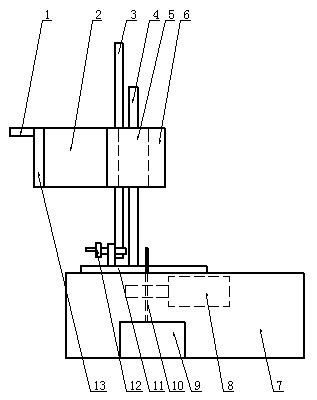

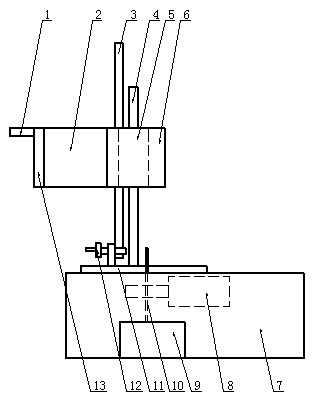

Cutting machine and manufacturing system for fixed size sheet

InactiveCN1757493AShort cutting timeImprove cutting accuracyMetal working apparatusElastic componentAcrylic resin

The invention provides a cutting machine capable of cutting rigid synthetic resin plate at high quality, in particular to the wide and thin rigid synthetic resin plate made from rubber and added with little acrylic resin or the like and provides a cutting machine capable of cutting out standard plate without chip from continuously flowing rigid synthetic resin plate. The cutting machine (10) comprises opposite an upper blade (12A) and a lower blade (12B), wherein two side faces of each blade are with elastic components (19A, 19B) protruded than the blades, while the elastic components can clamp rigid synthetic resin plate (7) when in cutting, the elastic components arranged on two side faces of the upper or lower blade are composed of an elastic portion near the blade and an elastic portion far from the blade, while the rigidity of the elastic portion near the blade is higher than the elastic portion far from the blade.

Owner:SUMITOMO CHEM CO LTD

Method for cutting wafer of high-power power electronic device by invisible laser

ActiveCN104625425AGuaranteed reliabilityNo or very little laser scratchesMetal working apparatusLaser beam welding apparatusSemiconductor materialsWood splinter

The invention discloses a method for cutting a high-power power electronic device by an invisible laser. The high-power power electronic device comprises an epitaxial layer with a substrate of semiconductor materials and is formed in the surface of the substrate. The method for cutting a chip of the high-power power electronic device comprises the steps that an invisible laser scribing is conducted on the back side of the substrate of the high-power power electronic device, and then a front splinter is conducted by a splinter machine according to scratches in the inner portion. The depth of the scratches in the inner portion is about one tenths to a half of the thickness of the chip. The method for cutting a wafer of the high-power power electronic device by the invisible laser uses a method of cutting the to-be-cut inner portion of the chip by laser beam focusing, the laser beam is adopted to cut the inner portion of the high-power power electronic device, and a laser energy region is located on the lower half portion of the chip and namely is close to a substrate region. The laser invisible cutting is adopted, so that an active region of the front side of the chip is furthest guaranteed, the front side of a region is not broken, the device with a neat edge is obtained, and the productivity and the reliability of the chip with a large region are highly improved.

Owner:STATE GRID CORP OF CHINA +1

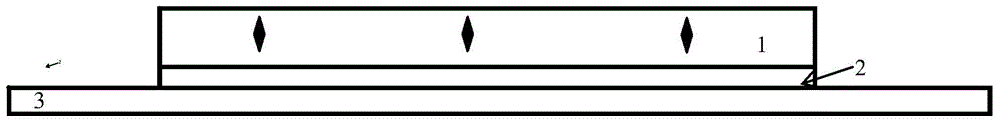

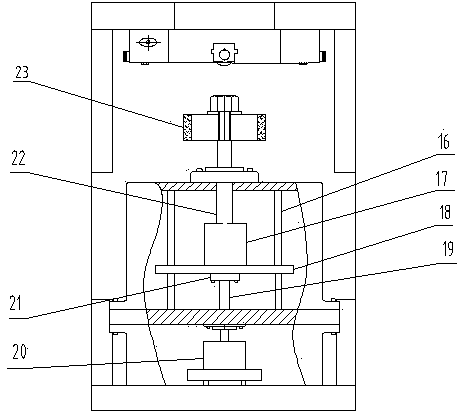

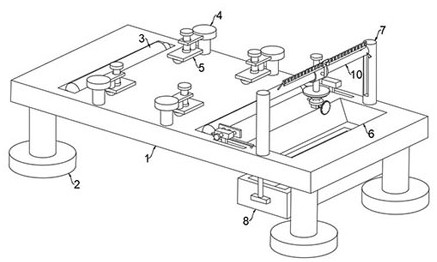

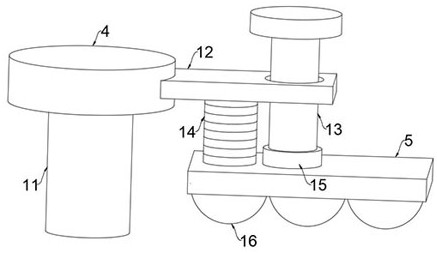

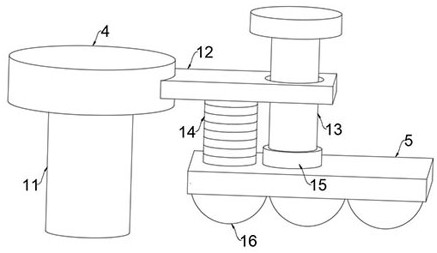

Automatic diamond grinding wheel trimming device

ActiveCN103962960AShorten dressing timeImprove processing efficiencyAbrasive surface conditioning devicesPhysicsDiamond grinding

The invention discloses an automatic diamond grinding wheel trimming device which is mainly composed of a working table, a chuck and a cylinder body. The chuck is fixed below an upper top plate of the working table and comprises a small bevel gear (11) and a big bevel gear (12) which are meshed with each other. The big bevel gear is connected with a sliding block (15). An energy converter (9), an amplitude-change pole (13) and a diamond stylus (14) are arranged on the sliding block. The energy converter is connected with an ultrasonic generator. A ball screw penetrates through a fixed supporting plate to be connected with a servo motor. A guide shaft penetrates through a movable supporting plate to be connected with an upper cylinder body and the fixed supporting plate. A three-phase asynchronous motor is connected with a grinding wheel (23) through a main shaft. One end of a circuit board is connected with a proximity switch, and the other end of the circuit board is respectively connected with the servo motor and the three-phase asynchronous motor. By means of the automatic diamond grinding wheel trimming device, ultrasonic elliptic vibration of the diamond stylus can be achieved, machining efficiency and machining accuracy of the grinding wheel are improved, rigidity and stability of a cutting system are enhanced, the service life of the diamond stylus can be prolonged, and the automatic diamond grinding wheel trimming device is relatively suitable for trimming grinding wheels made of hard materials.

Owner:CONPROFE TECH GRP CO LTD +1

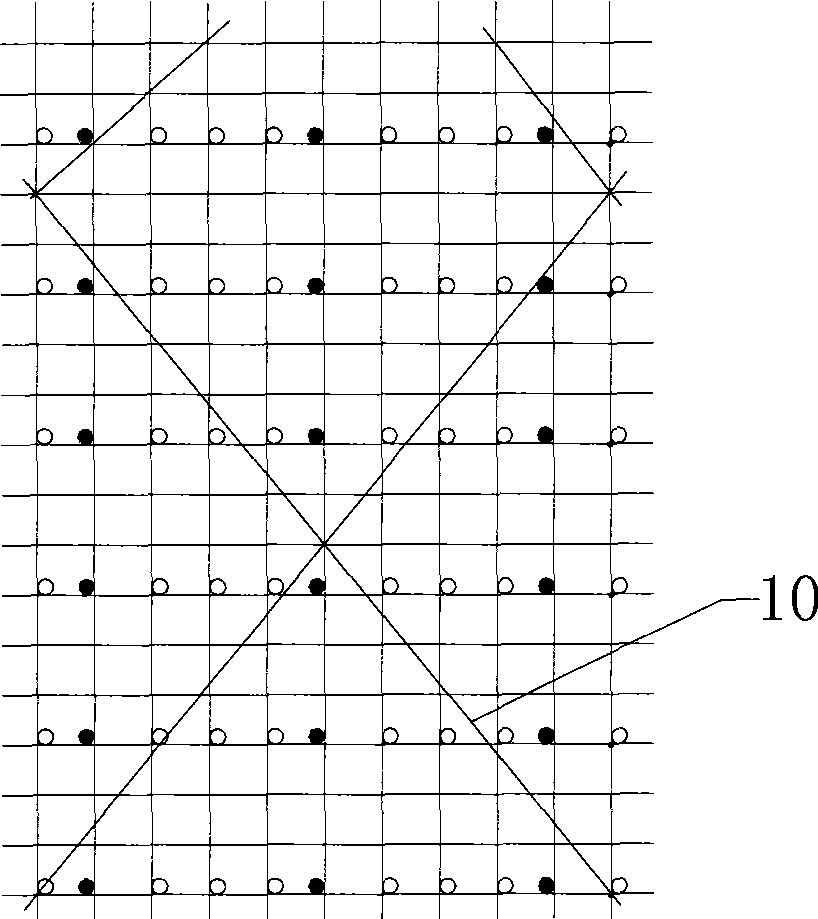

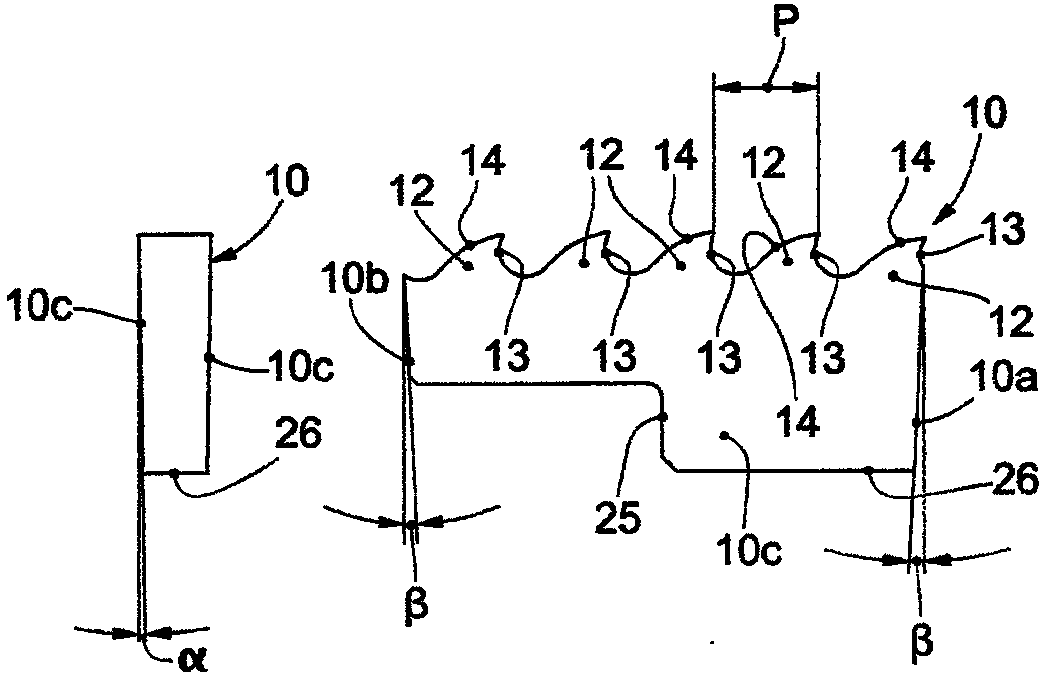

Cutting machine and manufacturing system for fixed size sheet

InactiveUS20060075863A1High precision cuttingShort cutting timeMetal working apparatusEngineeringHardness

A cutting machine 10 includes an upper blade 12A and a lower blade 12B installed at upper and lower positions, and resilient members 19A, 19B installed on both sides of the blades and protruding more than the blades for supporting a hard plastic sheet 7 during cutting. The resilient members installed on both sides of either of the upper and lower blades include a resilient member at a section near the blade and a resilient member at a section far from the blade, and the hardness of the resilient member at a section near the blade is different from the hardness of the resilient member at a section far from the blade.

Owner:TEIPI THERMAL ENG +2

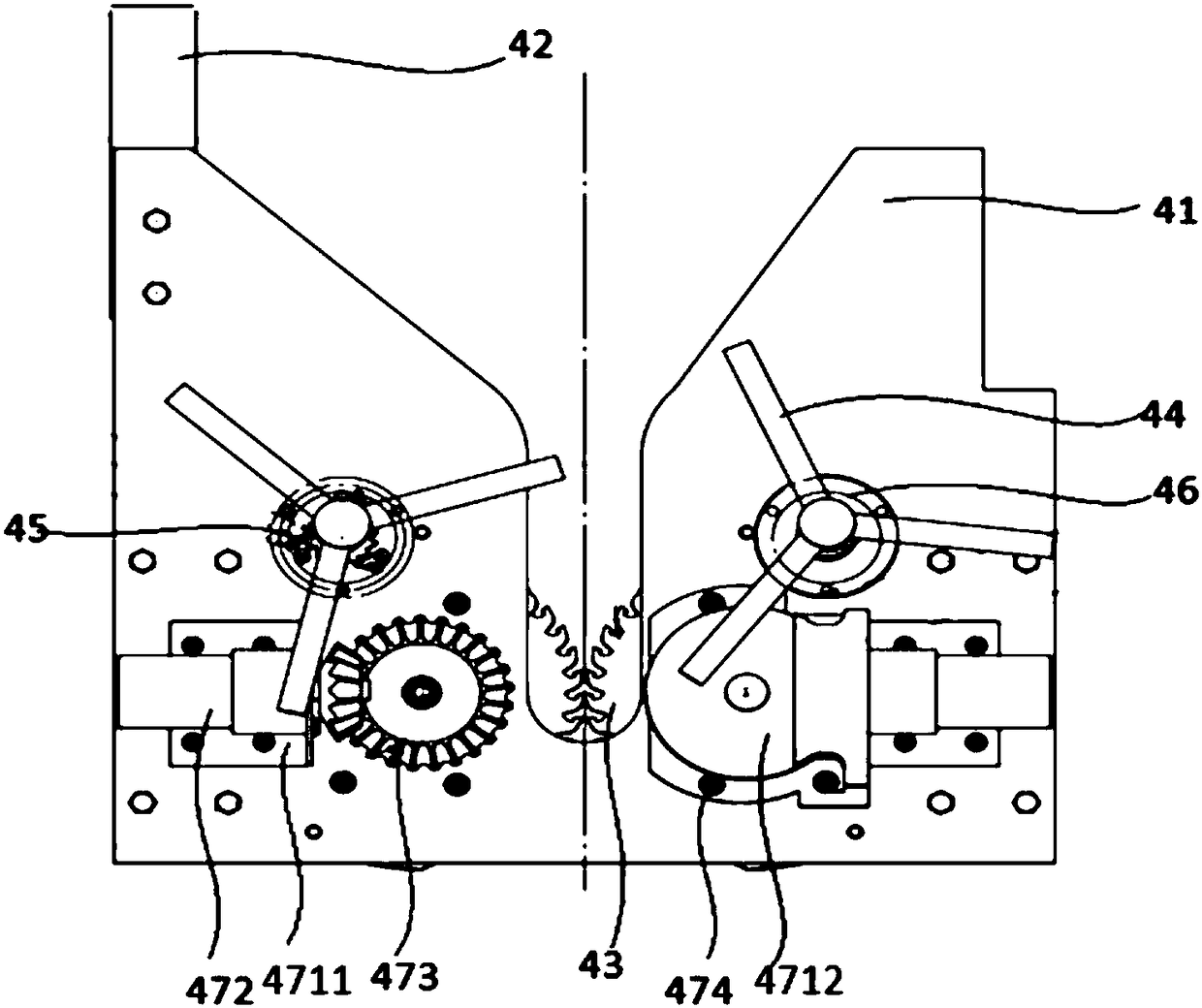

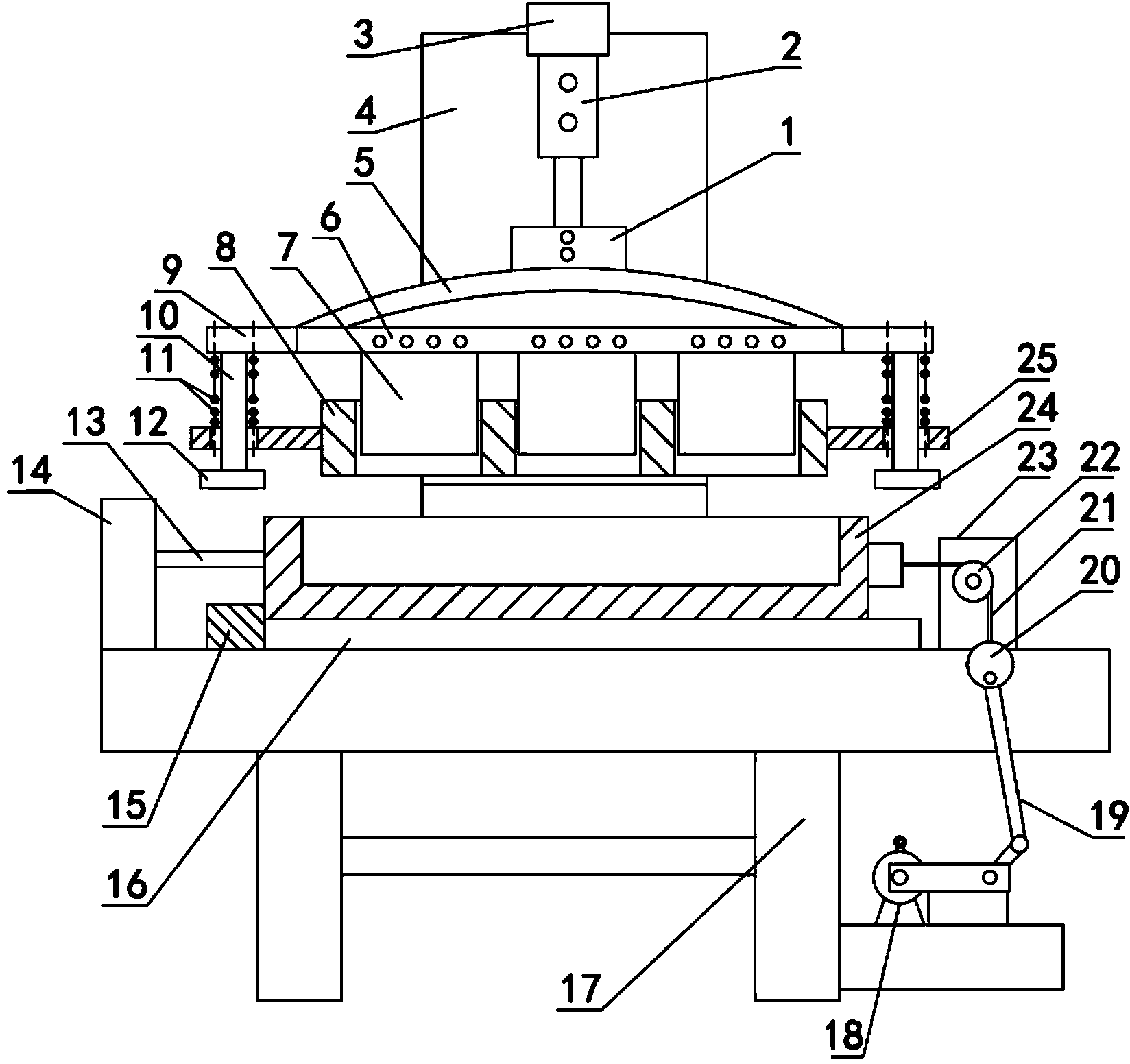

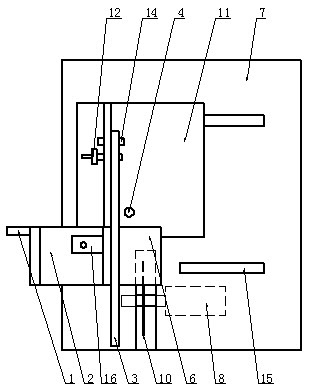

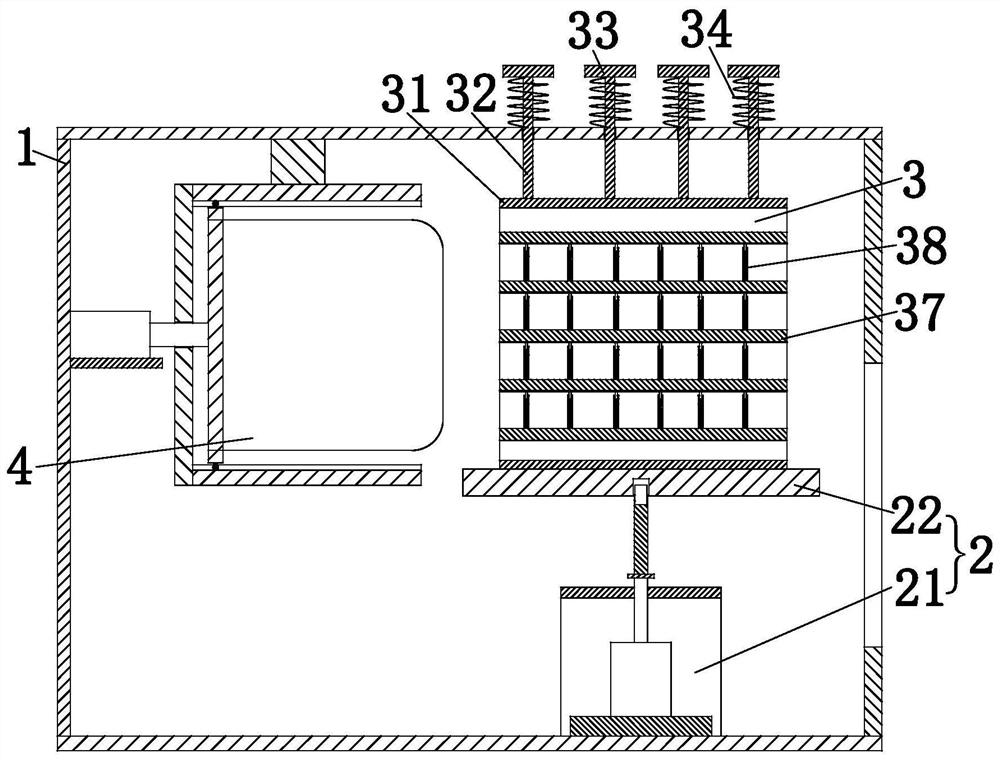

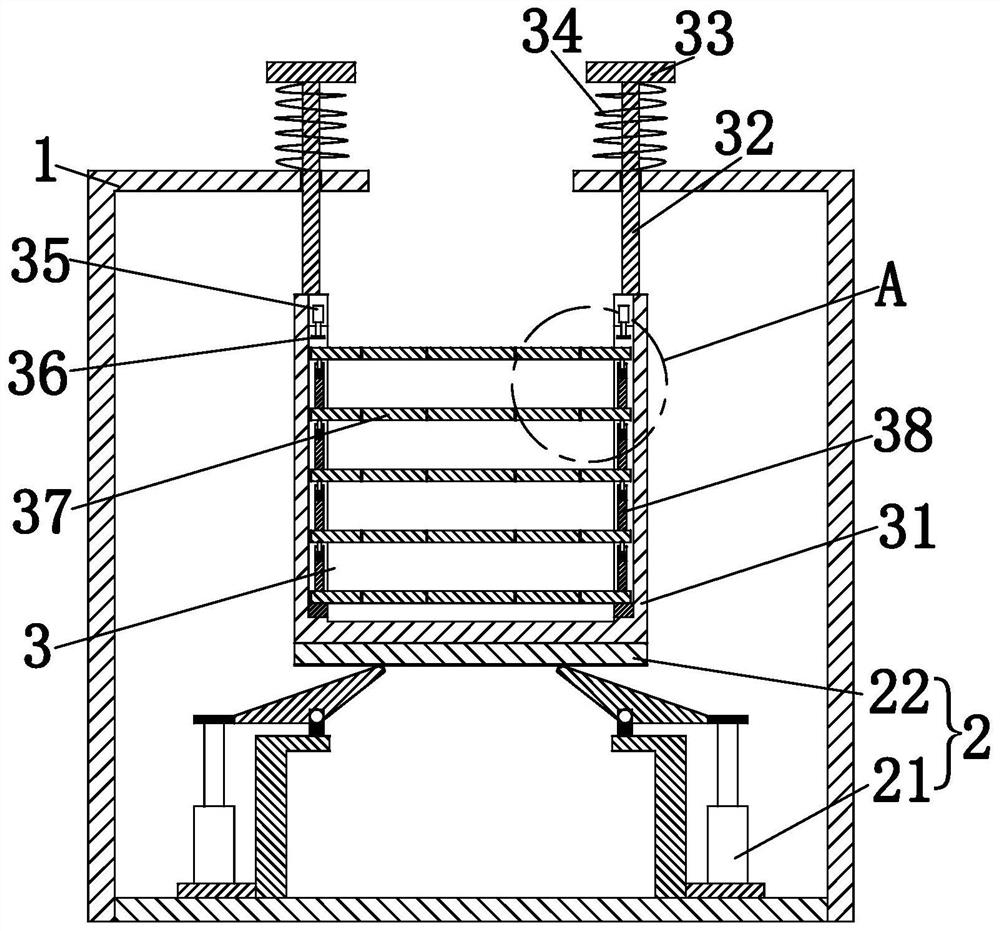

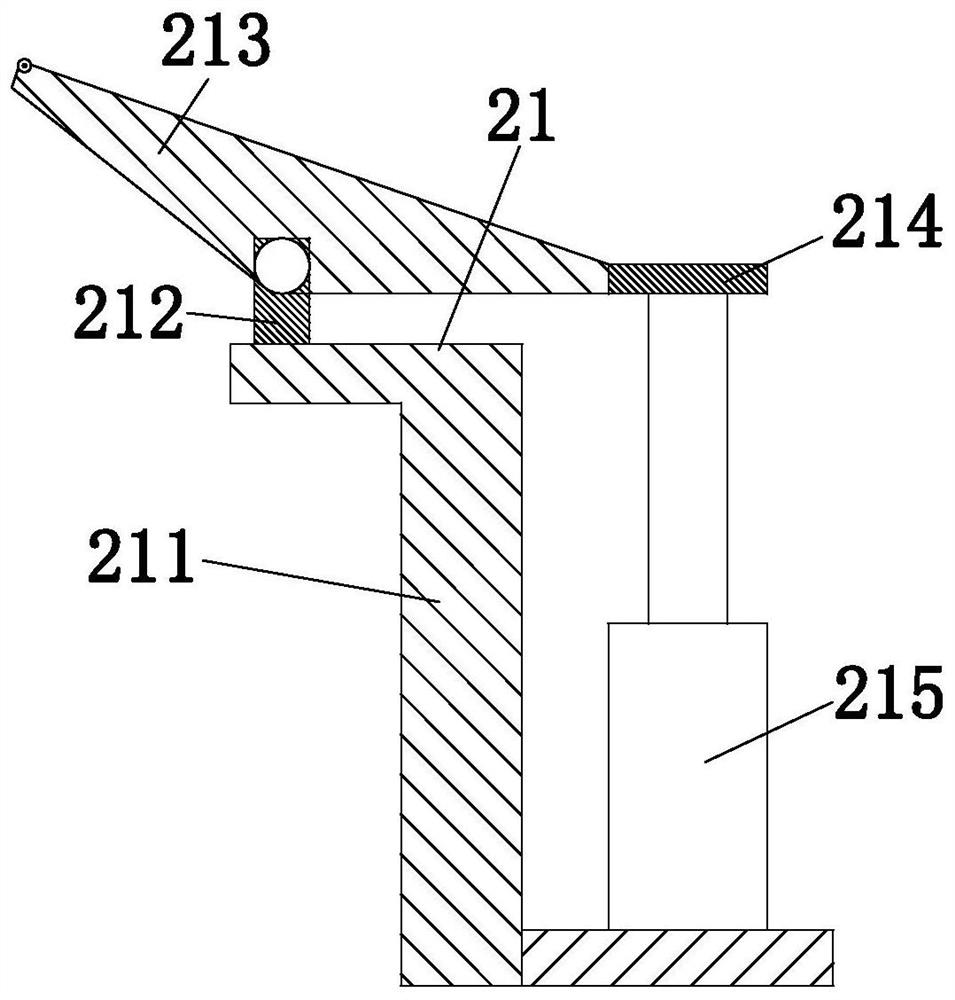

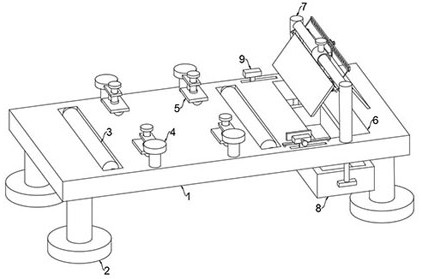

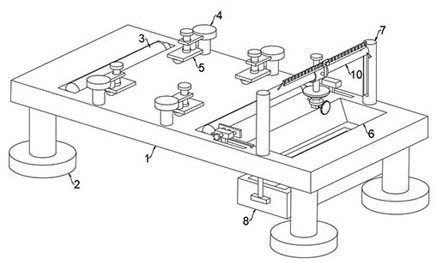

Pressing-cutting integrated type roam raw material cutting device capable of mixing materials through crankshaft and connection rod

ActiveCN103962203AAchieve the purpose of mixingSimple structureGrain treatmentsHydraulic cylinderPulp and paper industry

The invention relates to a pressing-cutting integrated type foam raw material cutting device capable of mixing materials through a crankshaft and a connection rod and belongs to the technical field of the foam raw material cutting. The pressing-cutting integrated type foam raw material cutting device comprises a working table, wherein a supporting leg is vertically fixed on the working table; a mounting bracket is mounted at the top of the supporting leg; 2-4 guide rails are transversely arranged on the working table in parallel; cutting grooves capable of sliding are formed in the guide rails; driving mechanisms are arranged on the right sides of the cutting grooves and used for pulling the cutting grooves rightwards; a cutting mechanism and a pressing mechanism are arranged above the cutting grooves and mutually matched; the cutting mechanism comprises a vertical hydraulic cylinder and a horizontal cutter base; cutter groups in equidistant arrays are mounted at the bottom of the cutter base; a cylinder body of the hydraulic cylinder is fixed at the bottom of the mounting bracket; a piston rod of the hydraulic cylinder is connected with the cutter base through a pushing bracket; return mechanisms are arranged on the left sides of the cutting grooves. The pressing-cutting integrated type foam raw material cutting device is simple in structure, simple to operate, short in cutting time, low in use cost and maintenance cost, time-saving and labor-saving.

Owner:CHONGQING GUOHUA PACKAGING PROD

Tracking plate shearing machine for transverse plate shearing

The invention discloses a tracking plate shearing machine for transverse plate shearing and belongs to the field of metal plate shearing machinery. The tracking plate shearing machine comprises a shearing and walking device, an extensible belt device and a turnover belt device, wherein a driving system of a walking device of a shearing mechanism adopts a structure that a servo motor is matched with an accelerating air cylinder, a load is reduced during starting, starting is quick, the air cylinder absorbs inertia during returning, and positioning of a parking position is accurate. Extensible belts move with a shearing mechanism, receive sheared plates and ensure plate surface quality. The multiple extensible belts are driven simultaneously and can be independently tensioned. When a turnover belt normally works, the turnover belt is horizontal and immovable and downwards turns over during air cylinder action when a sample is needed to be taken, offline material taking is achieved, a unit is not needed to shut down, and the working efficiency is improved.

Owner:沈阳智勤机器人系统工程有限公司

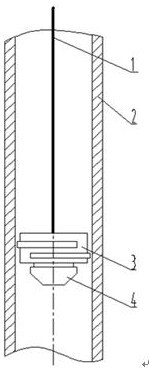

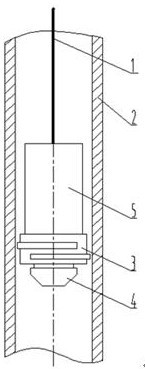

Plasma cutting device and method for underground oil casing

PendingCN112443286AReal-timeRealize regulationDrilling rodsDrilling casingsEngineeringElectric cables

The invention discloses a plasma cutting device and method for an underground oil casing. The plasma cutting device comprises an electrode, an electrode feeding mechanism and a guide shoe, the electrode is fixed to the electrode feeding mechanism, the electrode is arranged outwards in the radial direction, the guide shoe is connected to the axial lower end of the electrode feeding mechanism, and the electrode and the electrode feeding mechanism are both connected with a cable; the upper end of the electrode feeding mechanism is connected with a rotating mechanism; the upper end of the rotatingmechanism is connected with an upper centering mechanism; and a lower centering mechanism is further connected between the guide shoe and the electrode feeding mechanism. Strings are cut, the cuttingefficiency is high, and the success rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

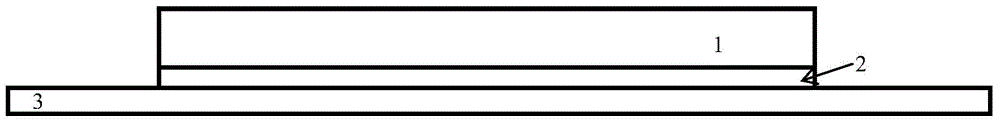

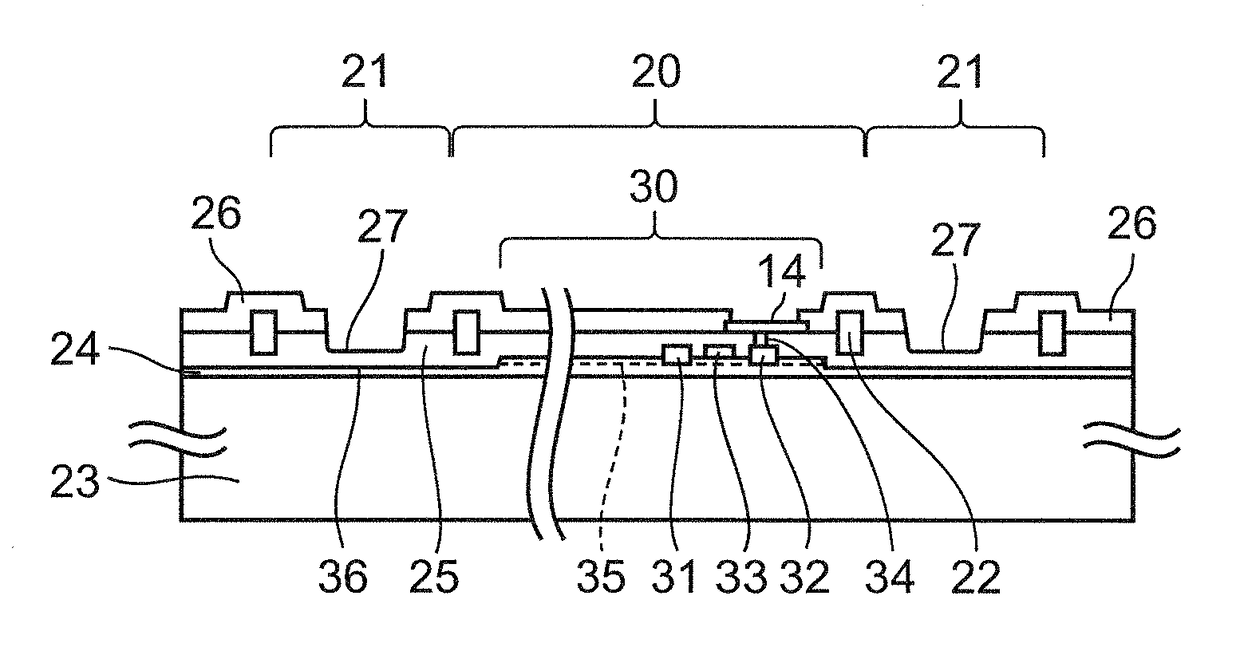

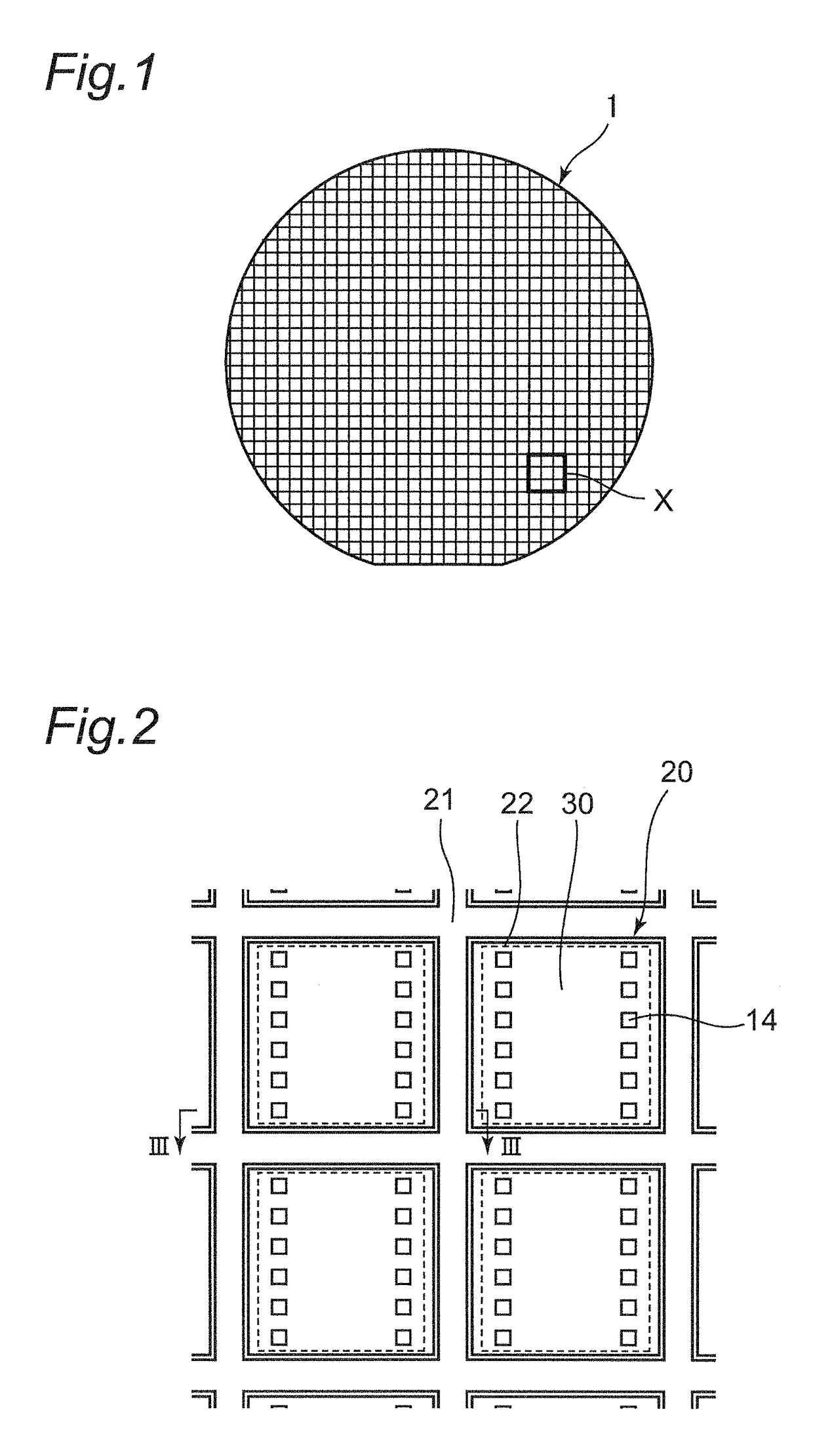

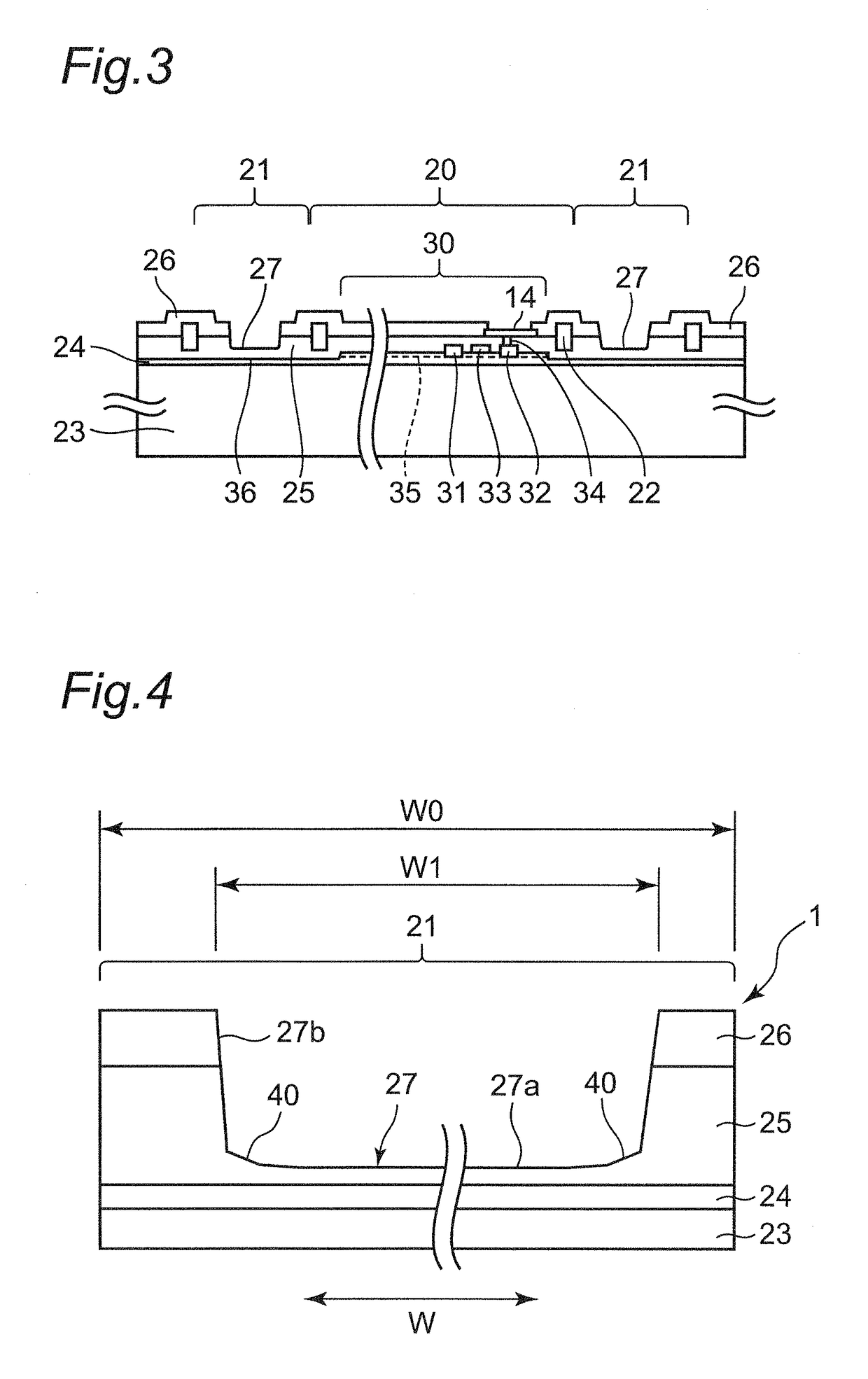

Semiconductor wafer, semiconductor device diced from semiconductor wafer, and method for manufacturing semiconductor device

ActiveUS9917011B2Avoid expansionIncrease productionSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor wafer is provided with a substrate, a GaN type semiconductor film which is laminated on the substrate, a plurality of element regions which are provided on the GaN type semiconductor film, a dielectric film which is laminated on the GaN type semiconductor film, and a dicing region which has a dicing groove which is provided in a lattice form without passing through the dielectric film described above so as to partition the element regions described above. Then, an end on the element region side of the dicing groove is higher or lower than a central portion of the dicing groove in a width direction in a bottom surface of the dicing groove.

Owner:ROHM CO LTD

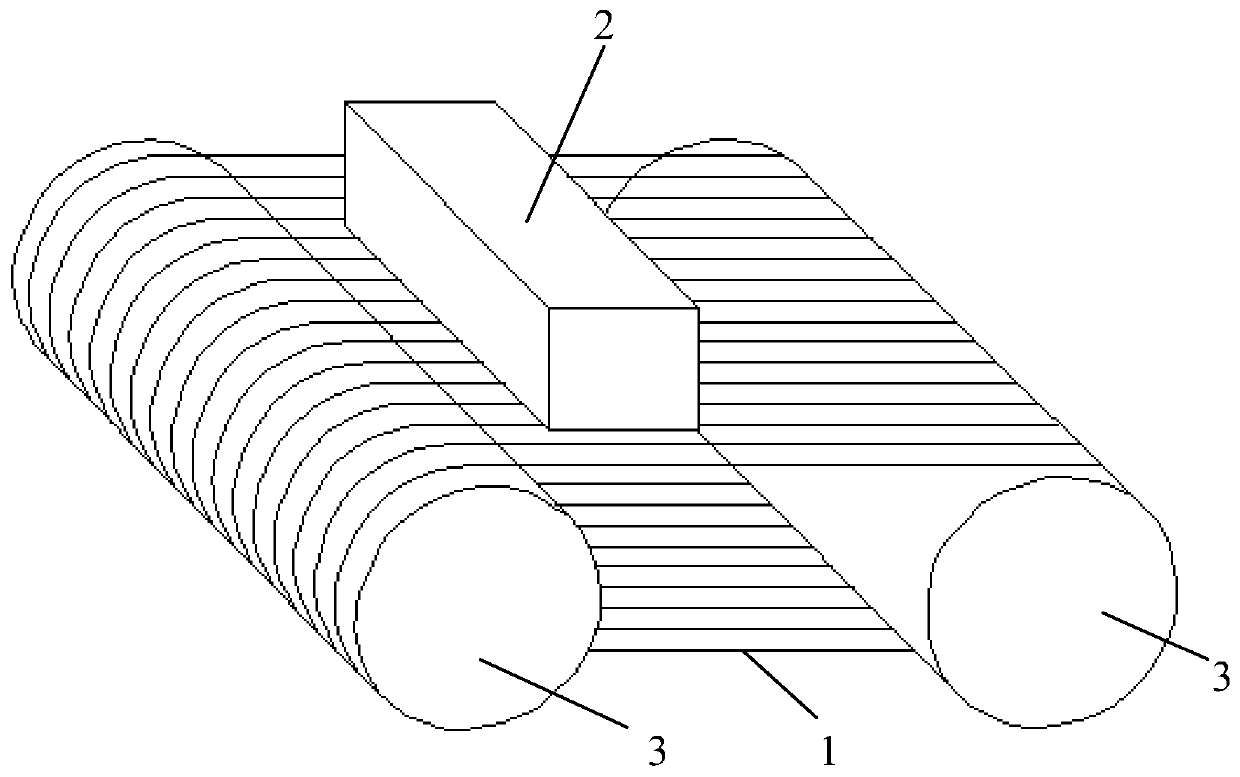

Scaffold

InactiveCN101377093AEasy to truncateEasy to operateBuilding support scaffoldsBiomedical engineeringMain bearing

The present invention discloses a scaffold (1), which comprises an inner scaffold body (2) and an outer scaffold body (3); wherein, the inner scaffold body (2) is arranged close to a building; the outer scaffold body (3) is arranged away from the building; small cross rods (4), which are arranged between the outer scaffold body (3) and the inner scaffold body (2), connect the outer scaffold body (3) and the inner scaffold body (2) together; the material of at least part of the inner scaffold body (2) is different from the material of the outer scaffold body (3); and moreover, the rigidity of the material of the outer scaffold body (3) is not less than the rigidity of the material of the inner scaffold body (2). Given that the outer scaffold body of the scaffold plays a main role in bearing and that the inner scaffold body is not a main bearing part, the outer scaffold body needs to be constructed with highly rigid material, while at least part of the inner scaffold body can adopt material with relatively low rigidity and strength, and thereby, the construction cost of the scaffold can be reduced. In the preferred embodiment of the scaffold, the inner scaffold body is made of material which can be easily cut, so a manual tool can easily cut the inner cross rods and / or inner upright rods of the inner scaffold body, and therefore construction is convenient.

Owner:SINOSCAFF GROUP

Rotating knife of food cooking machine

InactiveCN101675865AGood chance of being cutIncrease the chance of being cutGrain treatmentsStrainersEngineeringKnife blades

The invention discloses a rotating knife of a food cooking machine and comprises a rotatable knife seat driven by a power mechanism and a plurality of knife blades fixedly mounted on the knife seat, each knife blade is provided with a curve knife edge, the cutting angle alpha of each point on the knife edge has a range of 10-60 degrees and is referred to the included angle between the tangential direction and the motion direction. When cutting, the action of the knife edge on food can be divided into two parts, one is cutting (the knife is vertically applied on food and cut into food), and theother is mowing (the knife is parallel applied on food and the knife and food slide relatively).

Owner:ZHANGZHOU WANLIDA ELECTRICAL APPLIANCE

Method for cutting silicon wafer in thinning manner

InactiveCN111015985AImprove production rateShort cutting timeWorking accessoriesGrinding machinesSurface roughnessSilicon chip

The invention provides a method for cutting a silicon wafer in a thinning manner. The method adopts a diamond line with the diameter of 45 [mu]m for cutting, and in the cutting process, the acceleration of the diamond line is 5m / s<2>-9m / s<2>, the running speed is 800m / min-2000m / min, and the tension of the diamond line is 6N-13N; and the downward moving speed of a silicon material is set as follows: the cutting speed of a cutter entering area is 0.5mm / min-1.5mm / min, the cutting speed of a main cutting area is 1.6mm / min-2.8mm / min, and the cutting speed of a cutter retracting area is 0.2mm / min-1.0 mm / min. When the method is adopted for cutting the silicon wafer, the surface roughness and the thickness of a damaged layer of the obtained silicon wafer are low, the TTV mean value of the siliconwafer is low, and the performance of the silicon wafer is good; and in the cutting process, the loss of the silicon material is less, the wafer yield is high, and the cutting time of the silicon material with the same size is shorter, so that the cost is effectively reduced.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

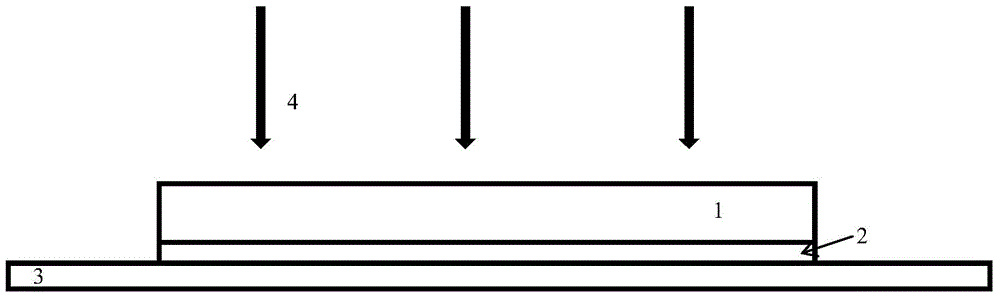

Magnesium oxide board cutting and separating device and cutting method thereof

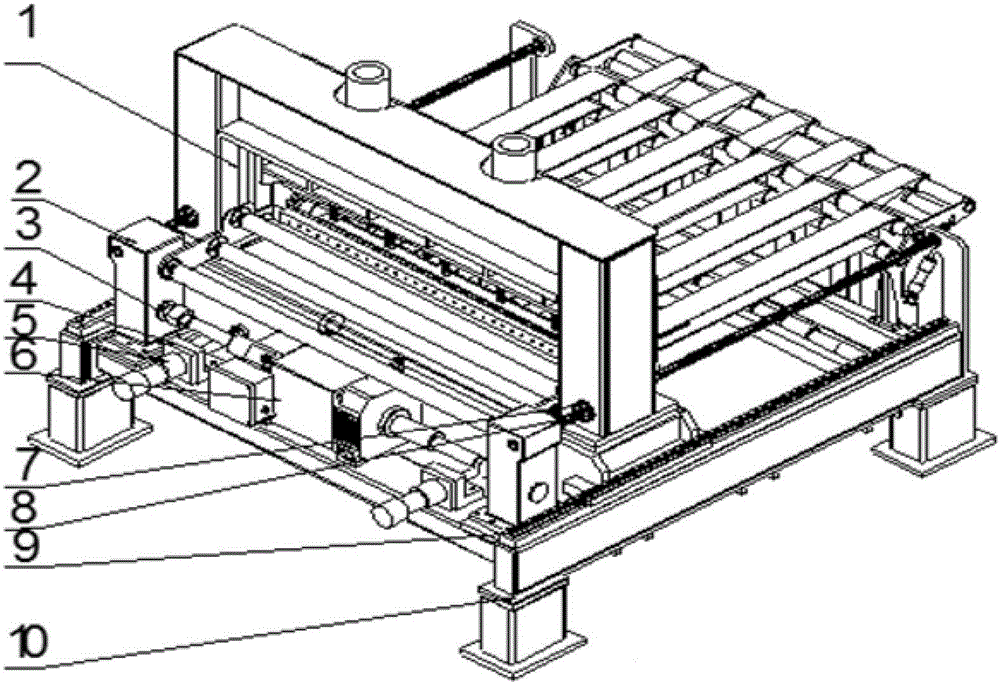

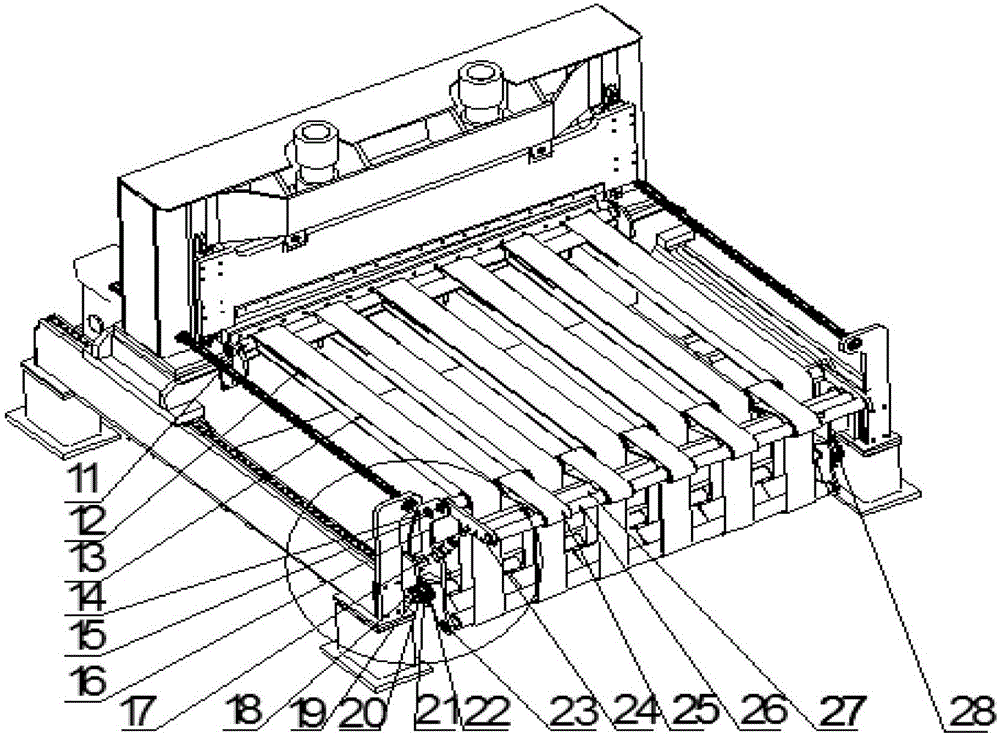

ActiveCN106626093AAvoid damageShort cutting timeWorking accessoriesStone-like material working toolsMoving speedMagnesium

The invention provides a magnesium oxide board cutting and separating device which comprises a conveying assembly, a cutting assembly and a separating assembly. The conveying assembly is used for conveying magnesium oxide boards of different width specifications, and meanwhile, a photoelectric sensor is used for detecting the moving speed and inclination degree of the magnesium oxide boards. The position of the cutting assembly is adjusted in real time according to the inclination degree of the magnesium oxide boards so that the magnesium oxide boards can be cut. The separating assembly is used for separating cut magnesium oxide boards. The magnesium oxide board cutting and separating device is simple in structure, high in automation degree, high in magnesium oxide board cutting efficiency, and suitable for cutting and separating the magnesium oxide boards of different width specifications and different length specifications.

Owner:JIANGSU UNIV OF SCI & TECH

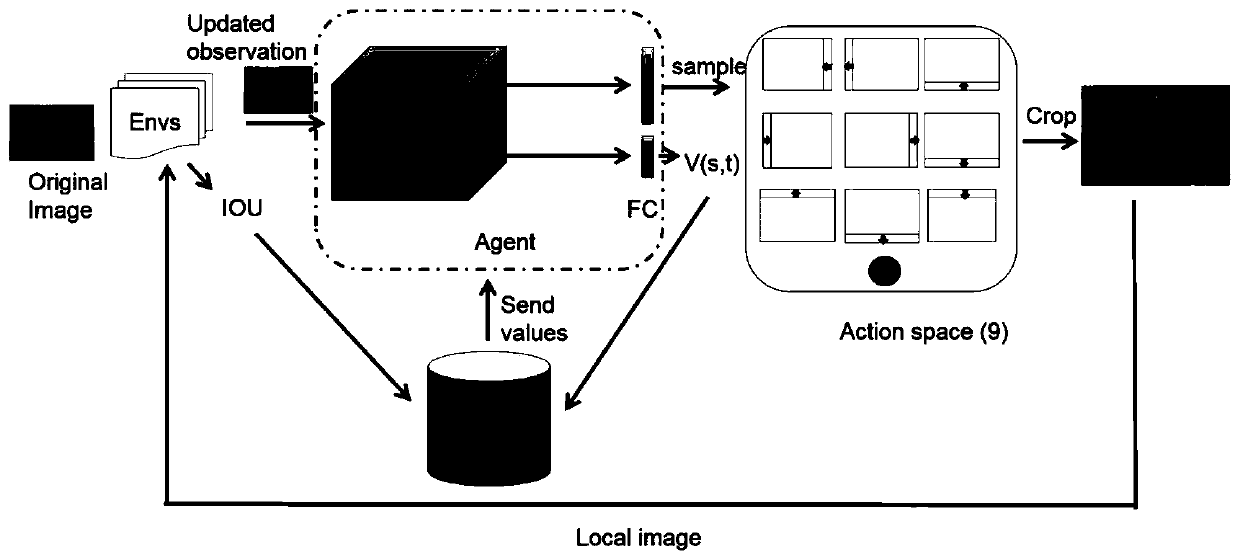

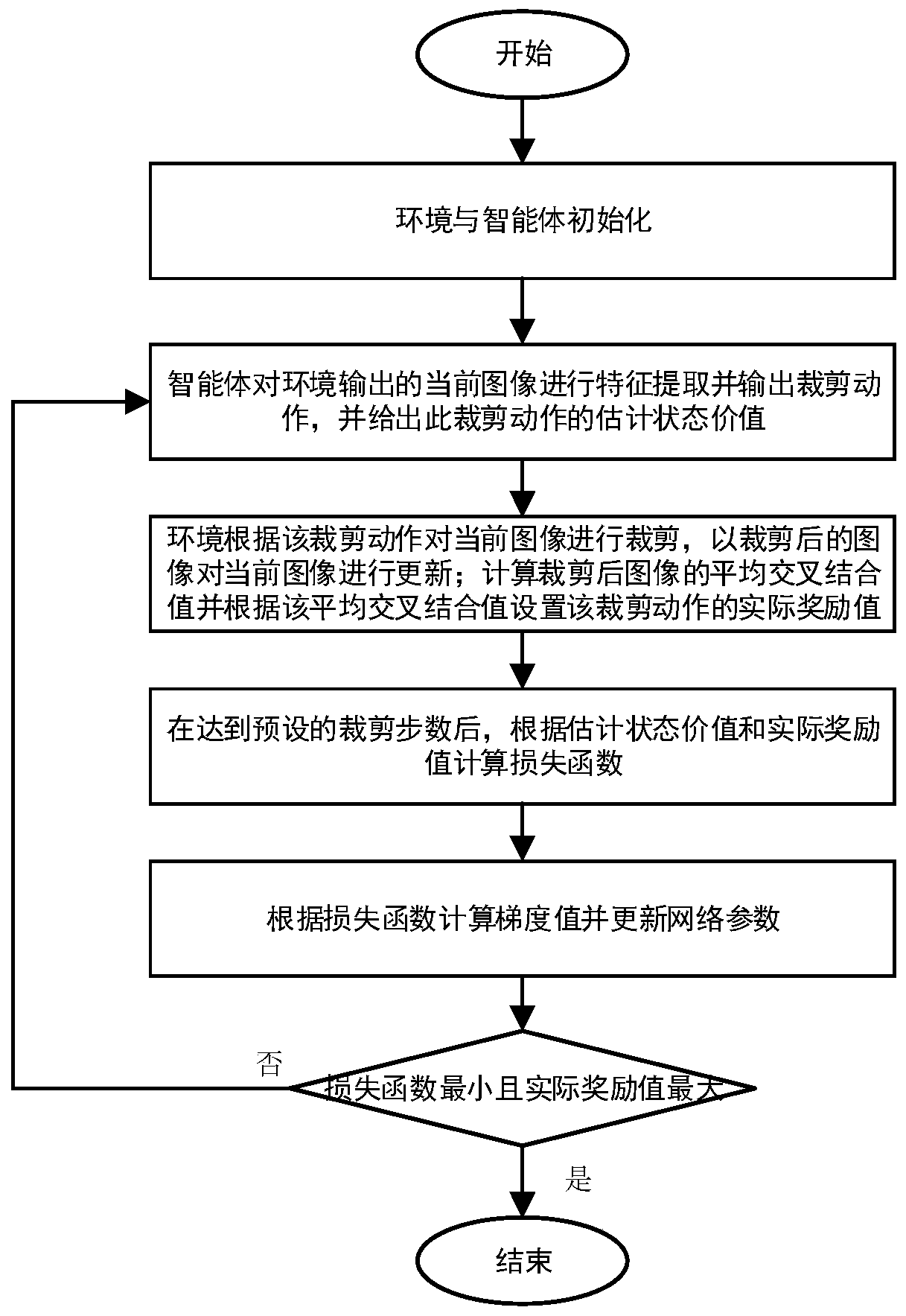

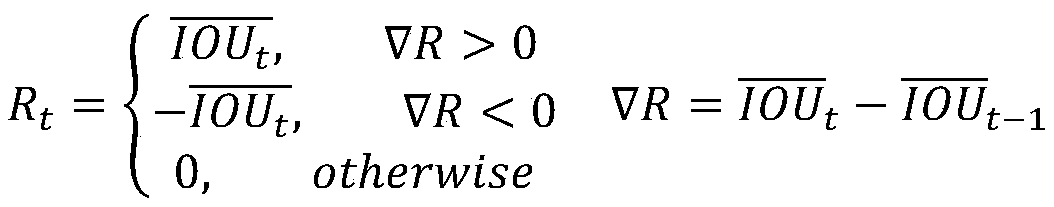

Lightweight image automatic clipping system and method based on deep reinforcement learning

ActiveCN110096202AAuto crop fastAvoid wastingImage analysisInput/output processes for data processingFeature extractionClipping - action

The invention discloses a lightweight image automatic clipping system and method based on deep reinforcement learning. The system comprises an environment, an action space and an agent embedded in theenvironment, wherein the environment provides current observation for the intelligent agent, calculates an actual reward value of a cutting action, executes the cutting action on a current observation image, and updates the current observation; the intelligent agent comprises a pre-trained convolutional neural network MobileNetV2 model and two full connection layers and is used for extracting image features and outputting a clipping action value and an estimated state value. The action space provides an actual cutting action for the environment according to the cutting action value output bythe intelligent body; the intelligent agent can automatically learn how to make a sequence clipping action, an IOU value calculated through the environment is used as a reward function, and SOTA performance can be achieved with fewer clipping steps and shorter clipping time.

Owner:HUAZHONG NORMAL UNIV

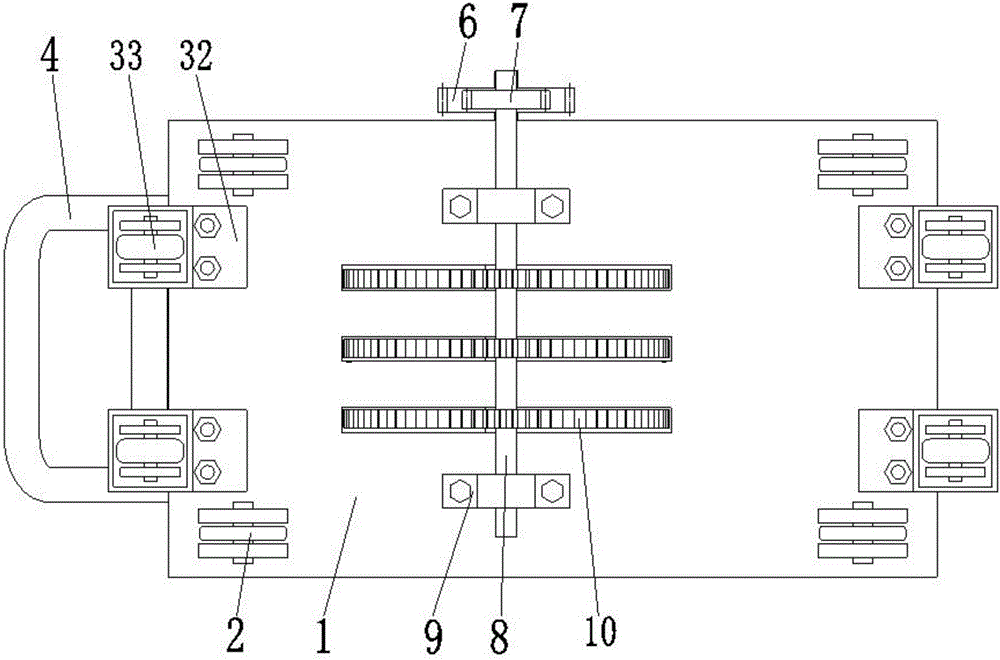

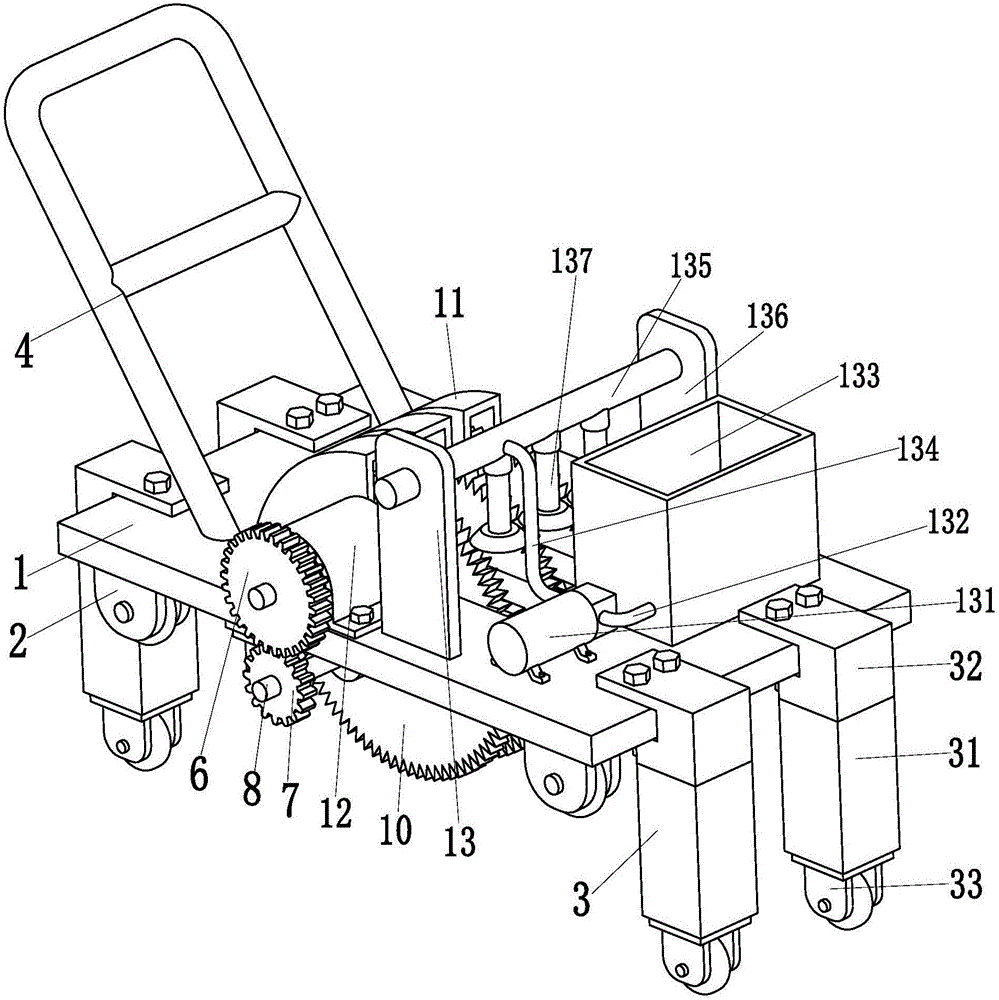

Bituminous concrete cutting device

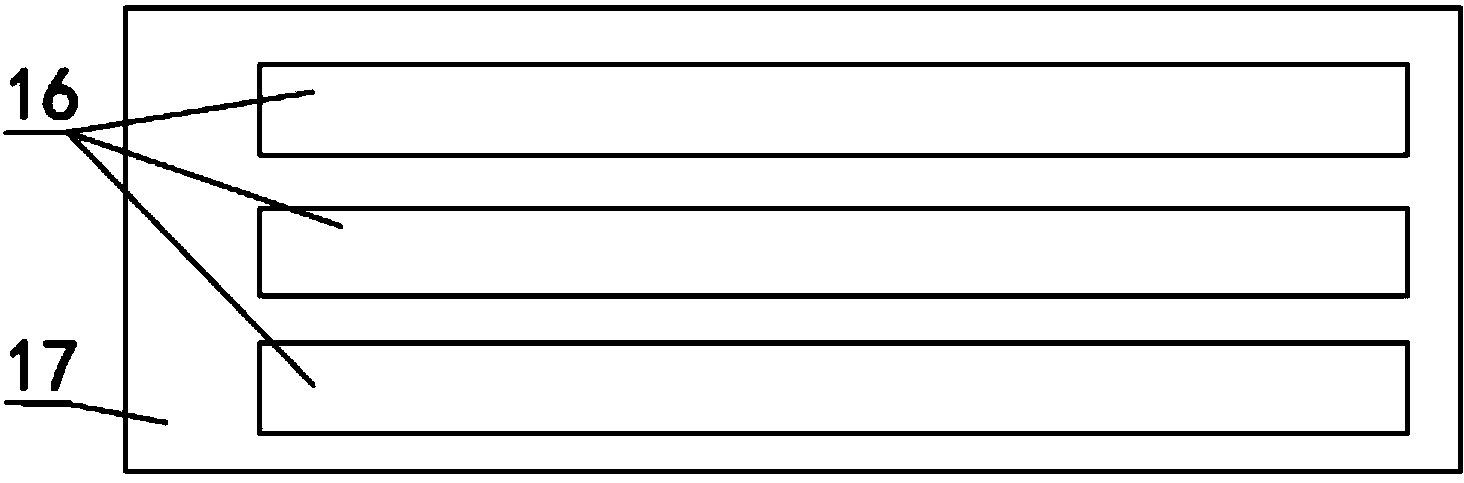

InactiveCN106087686ALower working temperatureFast cutting speedRoads maintainenceDrive shaftDrive motor

The invention relates to a bituminous concrete cutting device which comprises a bottom plate. Four first universal wheels are symmetrically installed on the lower end face of the bottom plate. A handrail is mounted at the left end of the bottom plate obliquely. A drive motor is mounted on the front side of the bottom plate through a motor base. A drive gear is mounted on a drive shaft of the drive motor through a key. The drive gear is engaged with a driven gear which is mounted on a rotary shaft through a key. The two ends of the rotary shaft are symmetrically mounted on two support seats through bearings. The two support seats are mounted on the lower end face of the bottom plate through screws. Three cutting blades are evenly mounted on the rotary shaft. Three mud stop frames are arranged at the edges of three cutting ports in the bottom plate correspondingly. A motor waterproof jacket is mounted on the front side of the bottom plate through screws. Branched cooling chains are mounted on the right side of the upper end face of the bottom plate. According to the bituminous concrete cutting device, the function that a plurality of cutting blades can be used for cutting simultaneously is achieved; the cutting device has the advantages of being short in cutting time, high in cutting speed and working efficiency and the like; and the reciprocating cutting frequency is remarkably decreased, and the labor intensity is relieved.

Owner:廉高峰

Cutting device for metal can body

InactiveCN102019463AReduce cutting timeImprove cutting efficiencyMetal sawing devicesMetal sawing accessoriesMotor driveEngineering

The invention relates to a cutting device for a metal can body. The cutting device comprises an operating platform, an operating rod and a sample protective sleeve, wherein, the operating platform is internally equipped with a motor-driven rotating saw blade; the operating rod is hinged on the operating platform through a mounting base; the sample protective sleeve is fixedly arranged on the operating rod; and one end of the sample protective sleeve corresponds to the part of the rotating saw blade exposed out of the operating platform. The cutting device for the metal can body has the advantages of simple structure, scientific and reasonable design, long service life, short cutting time, high efficiency, good quality and high safety and reliability, and is simple to manufacture.

Owner:CHINA PACKAGING RES & TEST CENT

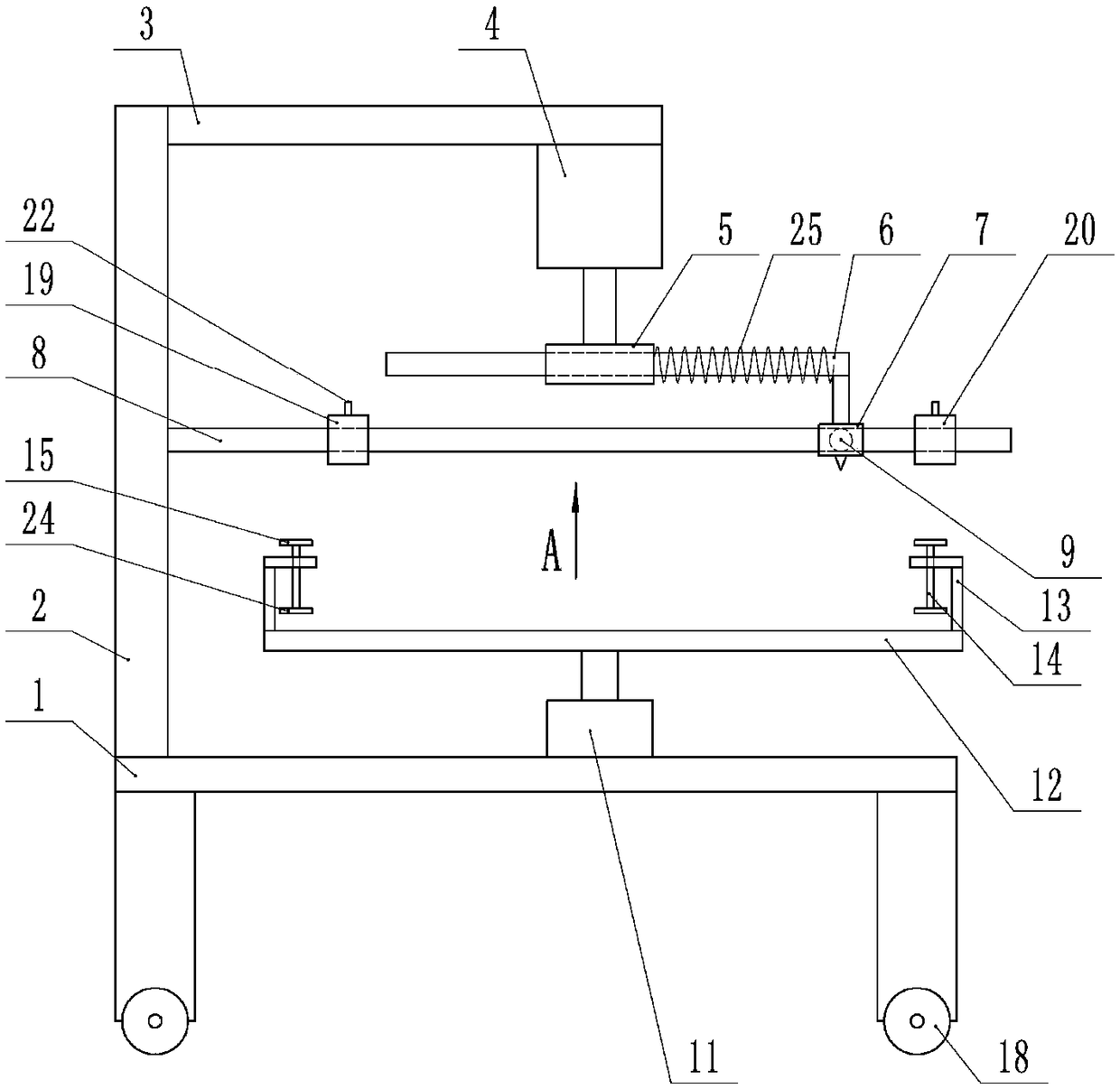

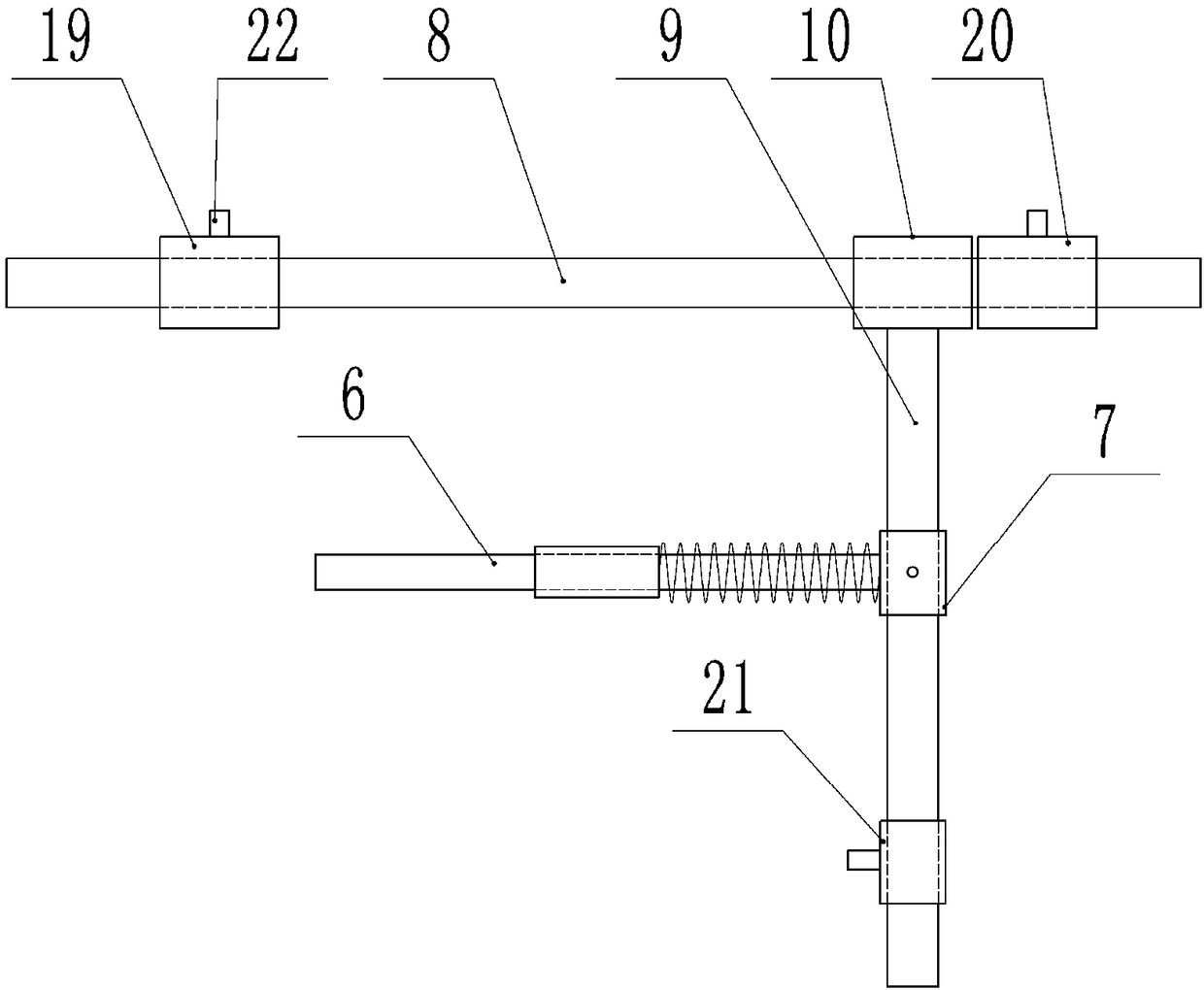

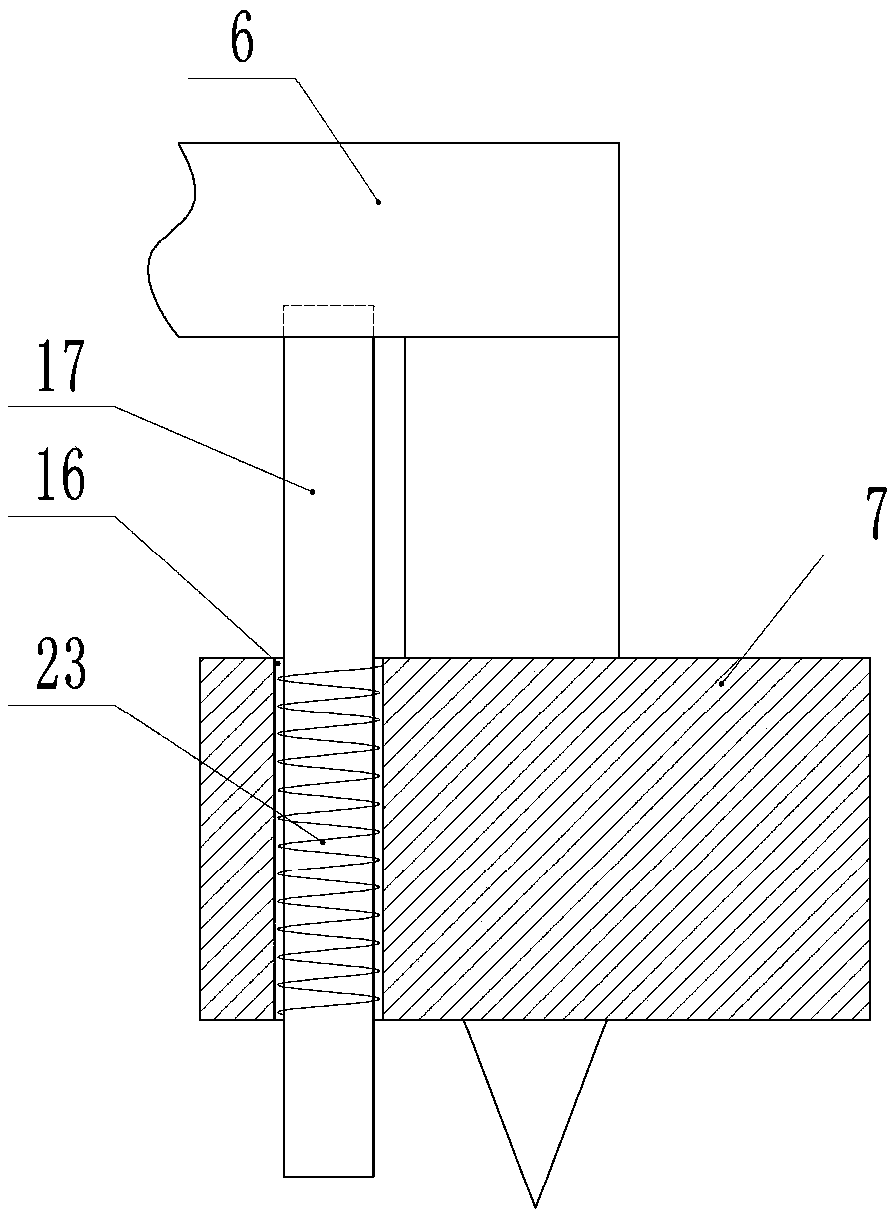

Wood board cutting device

PendingCN108608502AReduce stepsShort timeGripping devicesClamping devicesAgricultural engineeringWood panel

The invention belongs to the technical field of wood board processing devices, and particularly discloses a wood board cutting device. The device comprises a machine frame, wherein a vertical supporting plate is arranged on the machine frame; a cross beam is arranged on the upper part of the supporting plate, a motor is arranged on the cross beam, a sleeve pipe is arranged on an output shaft of the motor, and a sliding rod is arranged on the sleeve pipe; a cutting tool bit is arranged on the sliding rod, a first spring is connected between the cutting tool bit and the sleeve pipe, a cross rodis arranged on the supporting plate, and a first positioning block and a second positioning block are arranged on the cross rod; and a guide rod is arranged on the cross rod, the cutting tool bit is in sliding connection with the guide rod, a third positioning block for preventing the cutting tool bit from falling off is arranged on the guide rod, and a clamping part used for fixing the wood boardis arranged on the machine frame. According to the wood board cutting device, the device is mainly used for cutting wood boards, and the problem that when the wood boards are cut in different directions, the cutting positions need to be adjusted multiple times, so that operation steps of the cutting process are increased, and the cutting efficiency is reduced are solved.

Owner:重庆草衣木食文化传播有限公司

Rod and wire rod continuous casting and direct rolling process without heating furnace

InactiveCN110421002AReduce temperature lossReduce the impactMetal rolling arrangementsWire rodHeating furnace

The invention discloses a rod and wire rod continuous casting and direct rolling process without a heating furnace, and belongs to the technical field of rod and wire rod production processes. According to the rod and wire rod continuous casting and direct rolling process without the heating furnace, heating-free direct rolling without the heating furnace is adopted, so that fuel is saved and energy consumption is reduced; secondary heating of a steel billet is avoided by adopting the direct rolling, and oxidation burning loss is reduced by 0.6% or more; a hydraulic shear is adopted in the process of continuous casting blank cutting, the shearing time is short, the temperature loss of a casting blank is reduced, the gas consumption is reduced, and the cost is saved; a heat preservation roller table is adopted, so that the temperature loss is reduced, the surface temperature of the continuous casting blank before entering a continuous casting cooling bed is guaranteed to be 1,000 DEG Cor above so as to facilitate the direct rolling process; and by adopting the design without the heating furnace, the influence on steel rolling production when the heating furnace is stopped for maintenance is reduced.

Owner:JIANGSU HUANGMING ENERGY TECH

Rubber and plastic alloy asphalt modifier

ActiveCN103421222BImprove road performanceGood compatibilityPlastic recyclingBuilding insulationsAlloyAsphalt

Owner:JIANGSU ZHONGHONG ENVIRONMENT TECH CO LTD

EVA lining foam packaging material slitting processing machine and processing technology

InactiveCN112060142ALabor intensiveShort cutting timeMetal working apparatusEngineeringMachining process

The invention relates to an EVA lining foam packaging material slitting processing machine and a processing technology. The EVA lining foam packaging material slitting processing machine comprises a frame body, a jacking device, a discharging device and a slitting device, wherein the discharging device is installed at the upper end of the right side of the interior of the frame body; the slittingdevice is arranged at the left side of the discharging device; the lower part of the discharging device is connected with the jacking device; and the jacking device is placed at the bottom of the frame body. The EVA lining foam packaging material slitting processing machine can solve the problems that in a traditional foam packaging material slitting mode, a mechanical cutter is manually controlled to slit foam packaging material plates, and only one foam packaging material plate can be cut at a time, so that the labor intensity of slitting personnel is increased by the slitting mode, the slitting time is relatively long and the slitting efficiency is low.

Owner:广州粤科塑胶科技有限公司

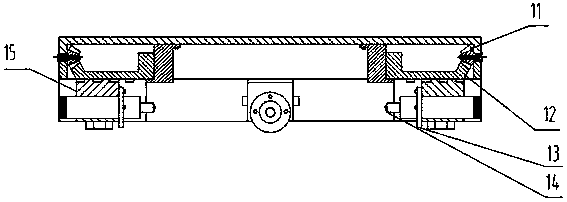

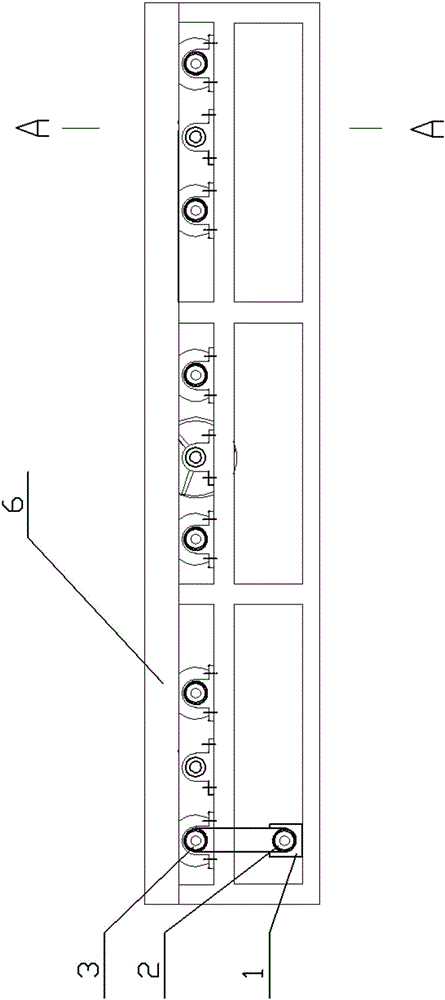

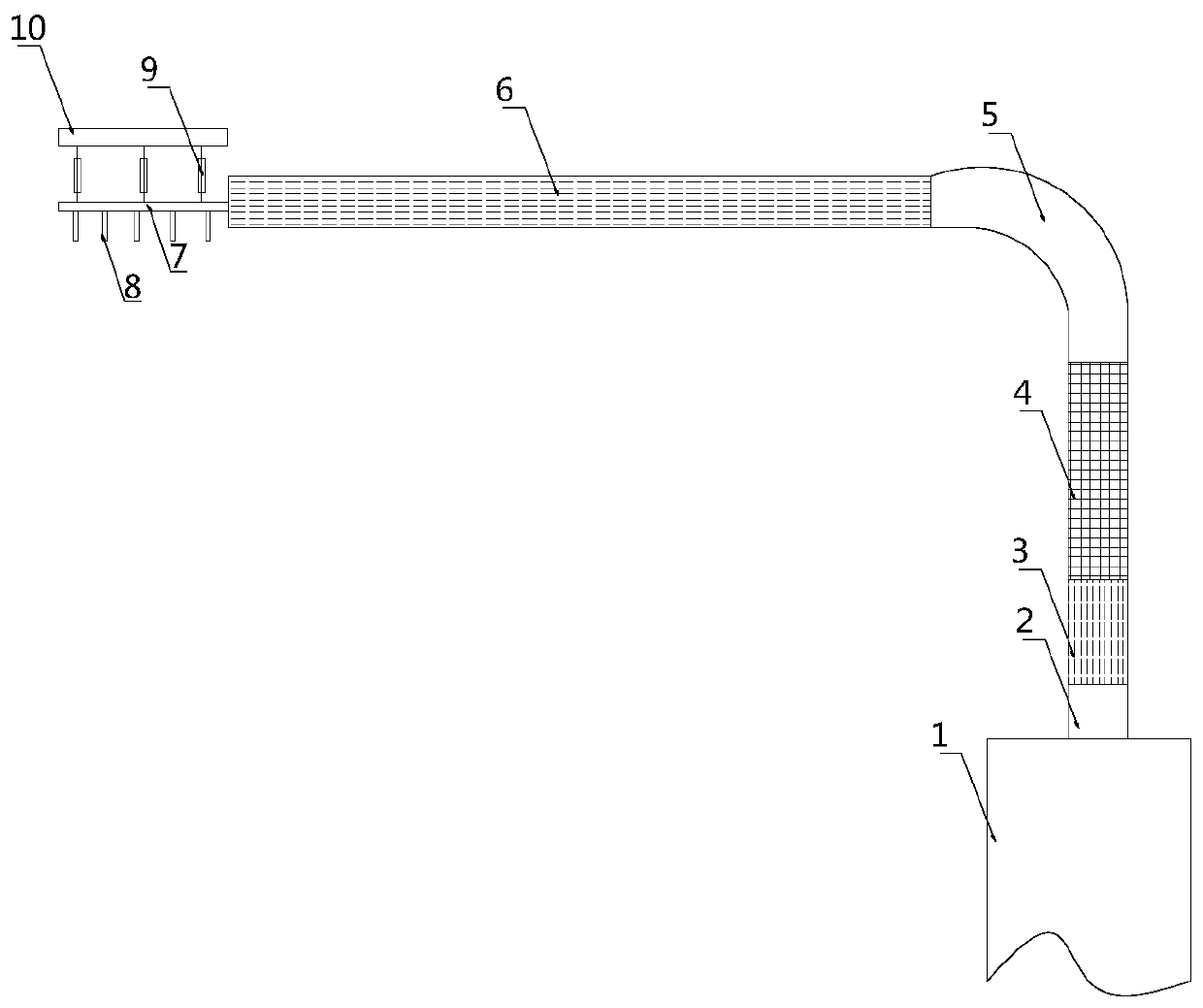

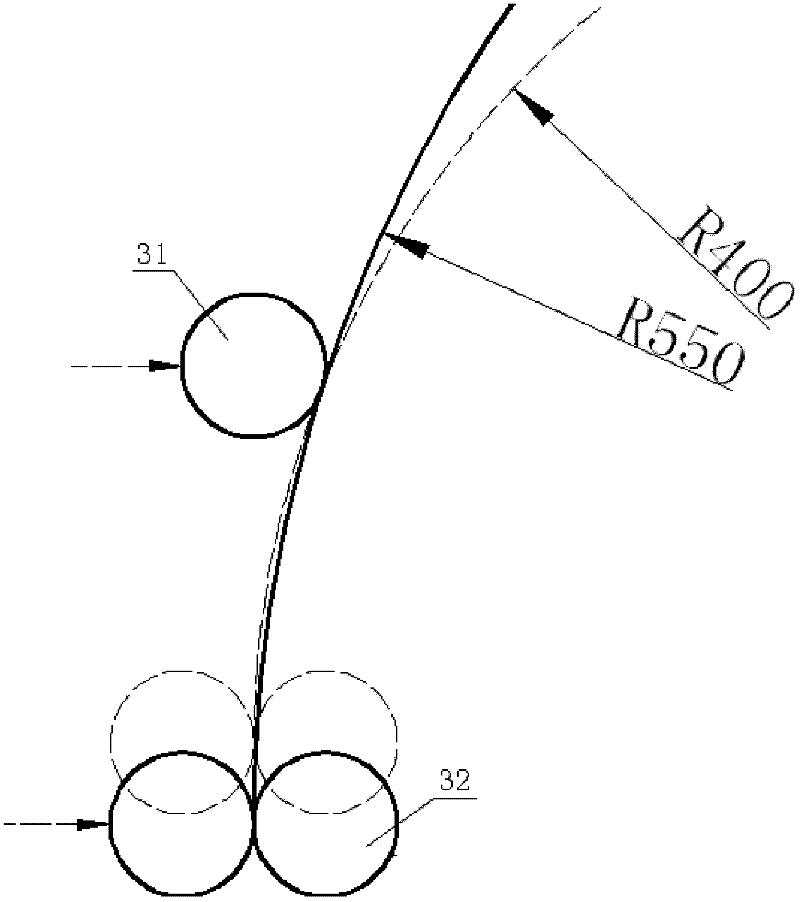

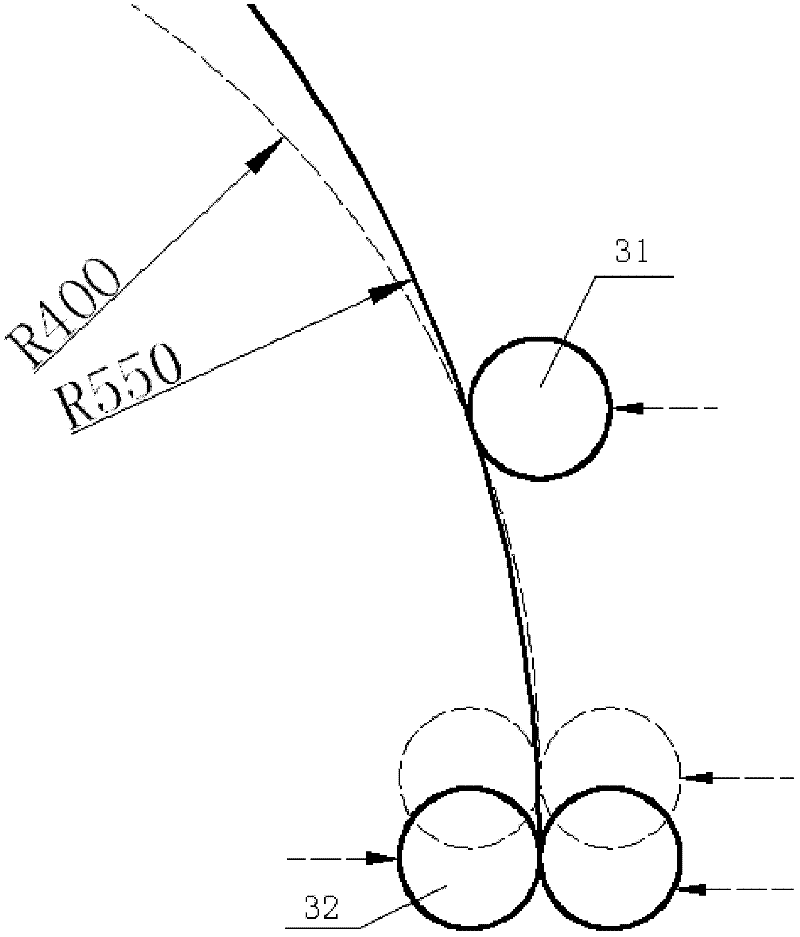

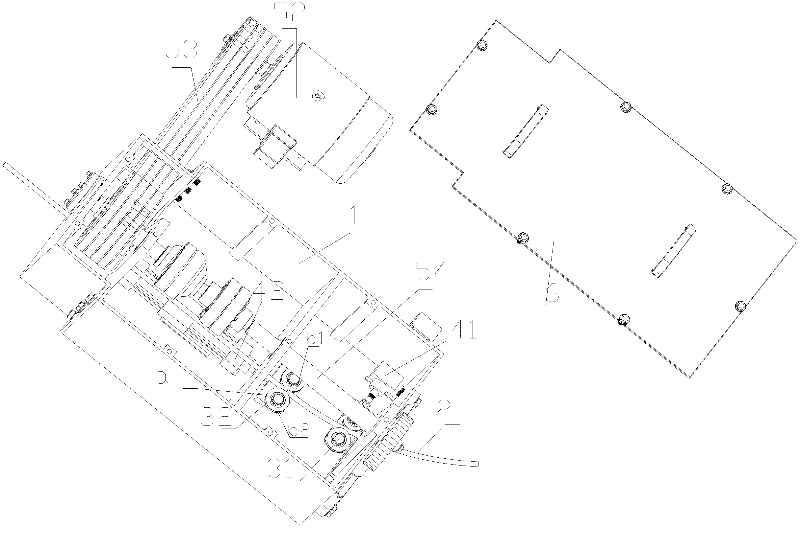

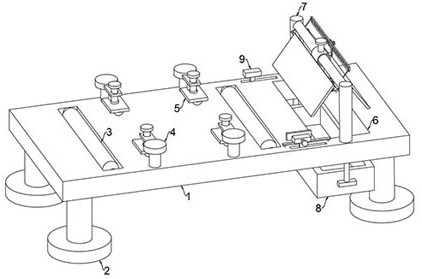

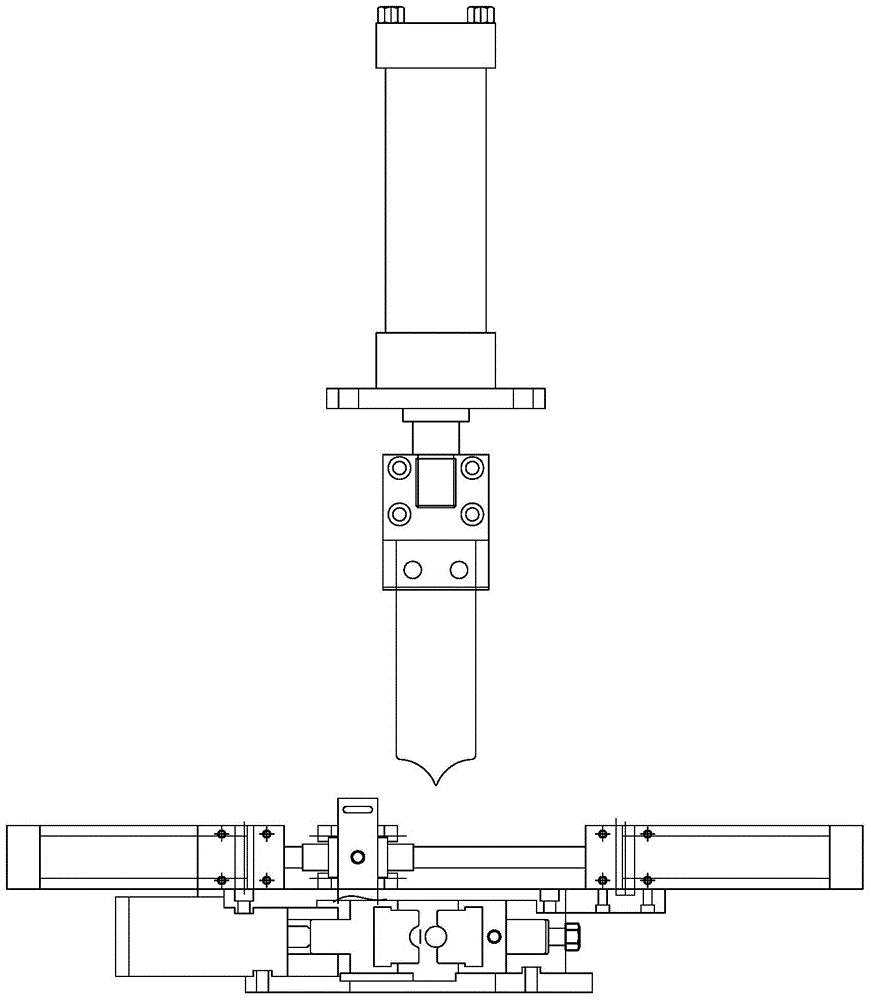

Automatic coiler feeding machine

InactiveCN102335779AIncrease productivityRealize mechanical automationTube shearing machinesShearing machine accessoriesEddy currentAutomation

The invention discloses an automatic coiler feeding machine, comprising a rack, wherein one end of the rack is a piping feeding end, and the other end of the rack is a discharging end; a first guide wheel group and a second guide wheel group are successively arranged between the feeding end and the discharging end; the second guide wheel group is connected with a longitudinal cylinder; the first guide wheel group is connected with a lateral cylinder which pushes the first guide wheel group along the piping forwarding direction; each guide wheel group comprises a bottom support and one pair ofguide wheels symmetrically installed on the bottom support; a base is provided with guide wheel mounting columns corresponding to the guide wheels; bearings are arranged between the guide wheels and the guide wheel mounting columns; the piping passes between the two guide wheels; the guide wheels mutually press the piping; the discharging end is provided with a cutter mechanism for cutting off the piping; the feeding end is provided with an eddy current flaw detector for detecting the welding line of the piping; the eddy current flaw detector is connected with the controller; and the controller controls the cutter mechanism to cut the piping in the welding line of the piping. According to automatic coiler feeding machine, coiler quality is improved, mechanical automation can be realized, labor force is saved, and the automatic coiler feeding machine has the advantages of high production efficiency and the like.

Owner:ZHEJIANG UNIV

High-precision furniture plate fixed-length cutting device

ActiveCN113681651AShort cutting timePrecise controlProfiling/shaping machinesBark-zones/chip/dust/waste removalMagnetic disksStructural engineering

The invention discloses a high-precision furniture plate fixed-length cutting device comprising a platform. An auxiliary mechanism and a storage mechanism are installed on the platform, two vertical rods are fixedly installed on the platform, a lifting rod is installed between the two vertical rods through a sliding mechanism, and a sleeve is slidably arranged on the lifting rod in a sleeving mode. A scale cross rod is installed between the sleeve and the lifting rod through a positioning mechanism, a telescopic rod is fixedly installed on the sleeve through a fixing disc, a cutting disc is rotatably installed on the telescopic rod through cooperation of a magnetic disc and a servo motor, and a magnetic ring matched with the magnetic disc is fixedly installed on the fixing disc. The high-precision furniture plate fixed-length cutting device has the advantages that accurate longitudinal and transverse cutting can be conducted on furniture boards on the premise that the furniture boards are not moved or turned over, multi-angle inclined cutting can also be conducted on the furniture boards, the overall cutting efficiency is high, and the cutting range is wide.

Owner:南通弈驰新型建材科技有限公司

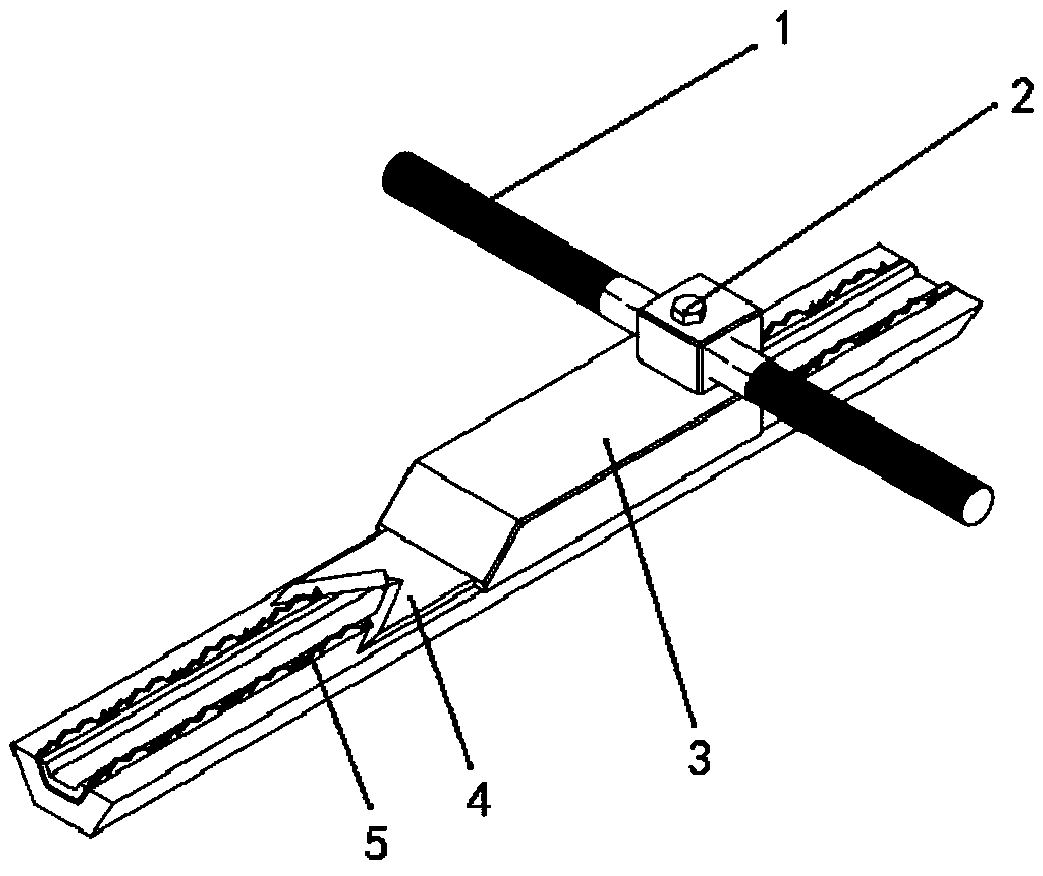

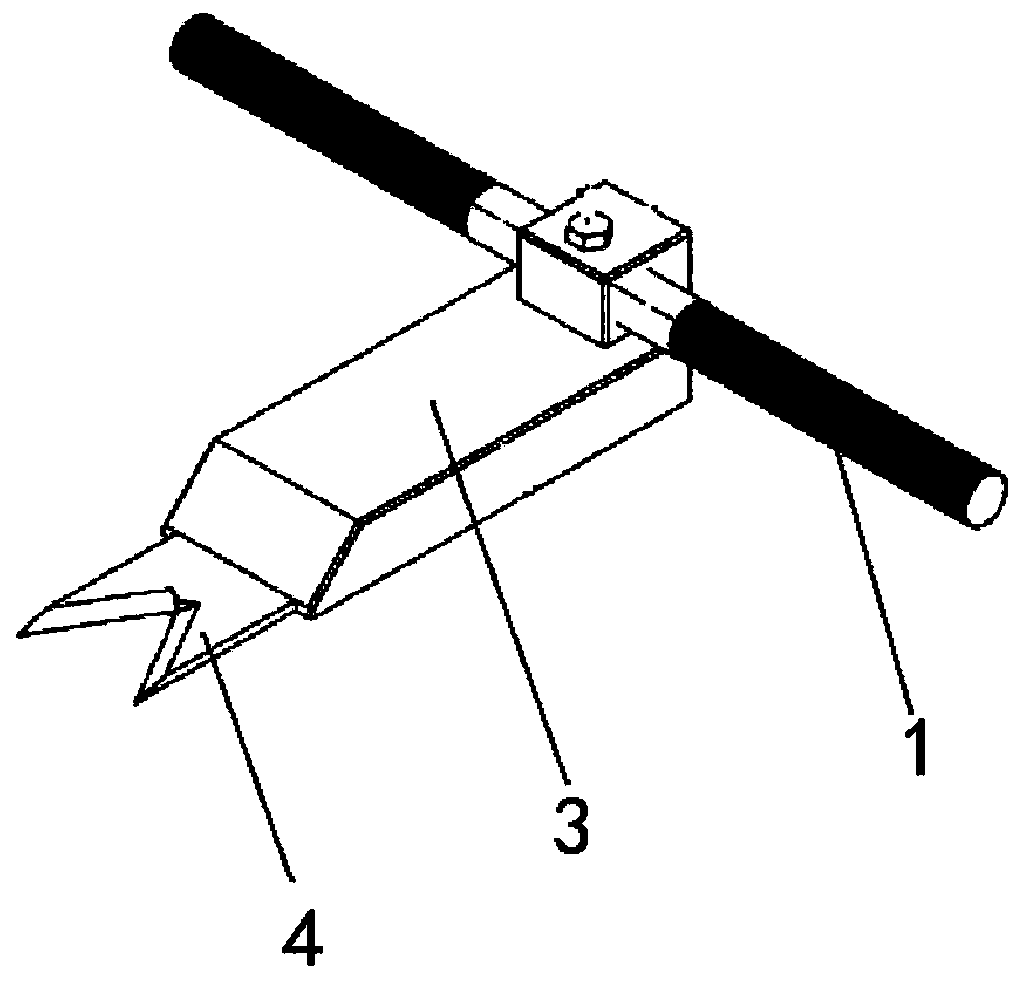

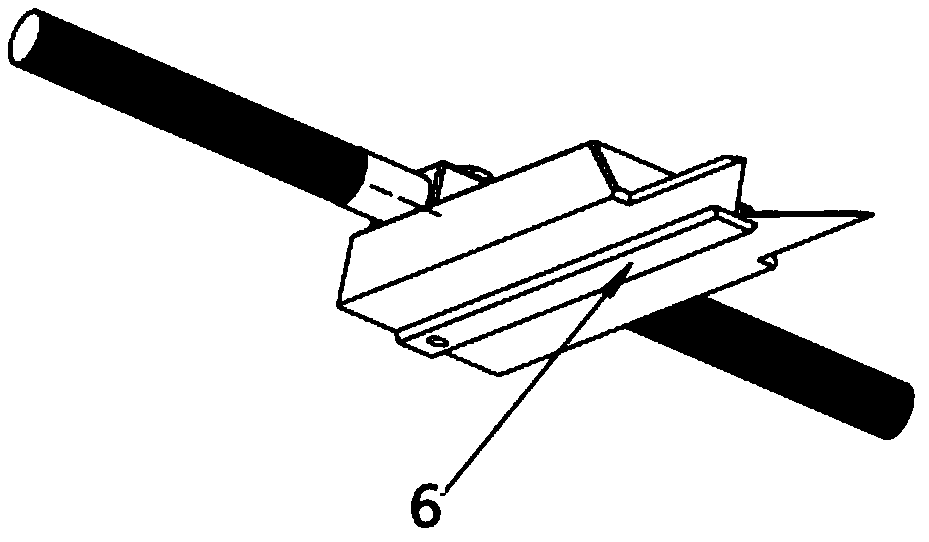

Planer device for clearing part surfaces and using method of planer device

InactiveCN109604699AGood removal effectTo achieve the purpose of cutting residuePortable planing/slotting machinesEngineering

The invention provides a planer device for clearing the part surfaces and a using method of the planer device. The planer device comprises a grip handle, a connecting block, a base and a planer tool;the grip handle is installed on the connecting block; the connecting block is installed on the base through a fixing piece; the planer tool is installed at the top end of the lower part of the base; aconvex strip is arranged on the lower part of the base; the connecting block is provided with a convex block and a concave hole A, and a gap is formed between the convex block and the concave hole A;the base is provided with a square groove and a concave hole B, and a gap is formed between the square groove and the concave hole B; the convex block is connected with the square groove; and the concave hole A and the concave hole B are the same correspondingly. The operation accuracy of the planer device is easy to control, parts can be protected against scratches, the part scrapping probability is decreased, the cutting time is short, and the production efficiency is high.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

A high-precision furniture board fixed-length cutting device

ActiveCN113681651BShort cutting timeEasy to controlProfiling/shaping machinesBark-zones/chip/dust/waste removalOblique cuttingElectrical and Electronics engineering

The invention discloses a high-precision fixed-length cutting device for furniture boards, which includes a platform, on which an auxiliary mechanism and a storage mechanism are installed, on which two upright poles are fixedly installed, and between the two upright poles The lifting rod is installed through the sliding mechanism, the sliding sleeve on the lifting rod is provided with a sleeve, and a scale cross bar is installed between the sleeve and the lifting rod through a positioning mechanism, and a telescopic rod is fixedly installed on the sleeve through a fixed plate A cutting disk is installed on the telescopic rod through the cooperation of the magnetic disk and the servo motor, and a magnetic ring matching the magnetic disk is fixedly installed on the fixed disk. The advantages are: the furniture board can be precisely cut vertically and horizontally without moving or flipping it over, and it can also be cut at multi-angle obliquely. The overall cutting efficiency is high and the cutting range is wide.

Owner:南通弈驰新型建材科技有限公司

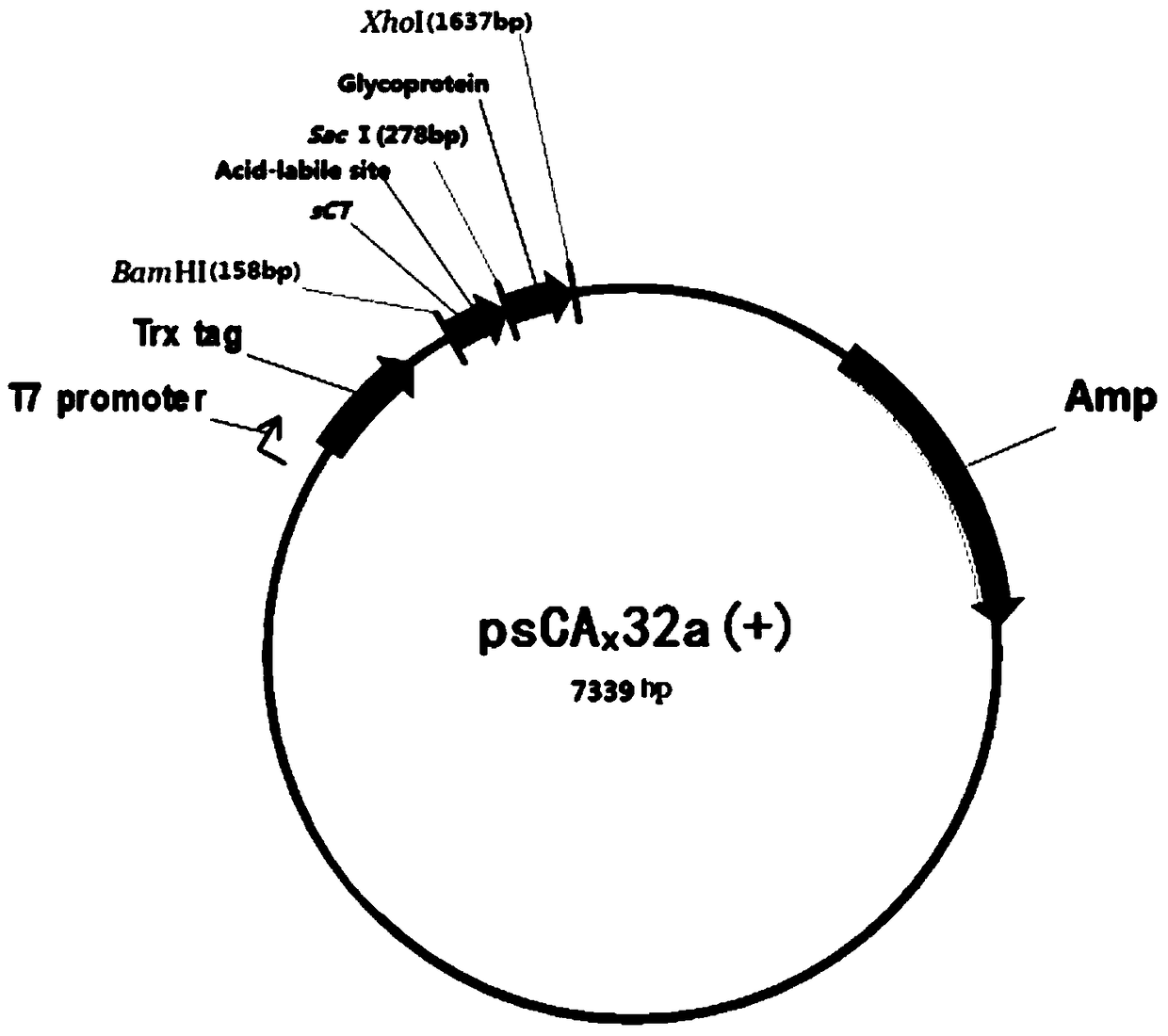

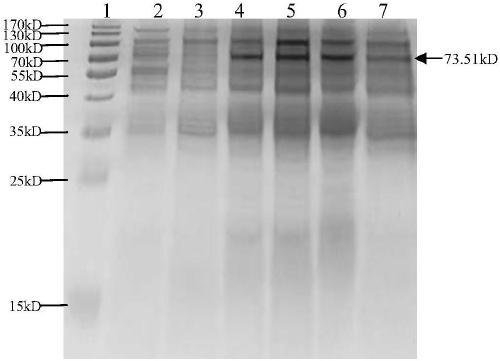

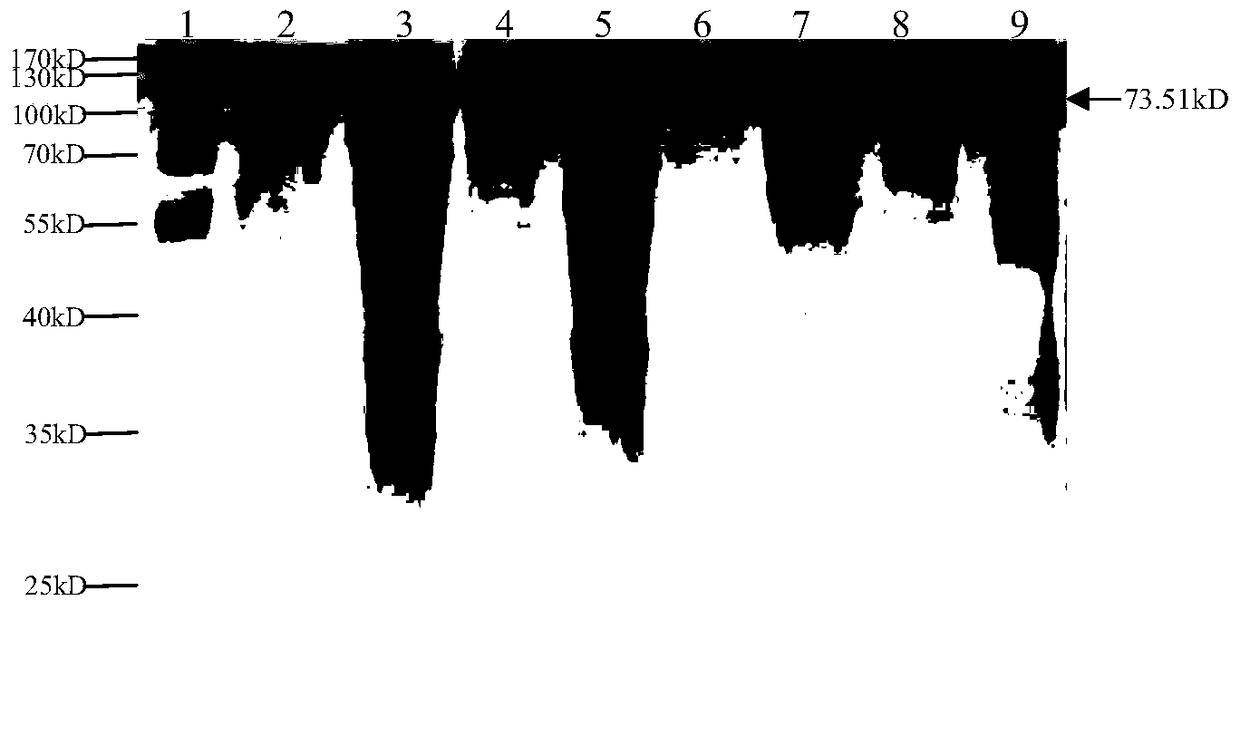

Formic acid cleavage site peptides and their related biomaterials and their application in the production of calcitonin

ActiveCN105218633BReduce purification costsShort cutting timeCalcitoninsPeptide preparation methodsCalcitoninVolume percent

The invention discloses a formic acid cleavage site peptide, a correlative biomaterial and applications of the formic acid cleavage site peptide and the correlative biomaterial in production of calcitonin. The provided formic acid cleavage site peptide is named after CA3, and is a peptide with an amino acid sequence shown in SEQ ID No.2. The formic acid cleavage site peptide CA3 is employed as a fusion protein for formic acid cleavage site construction, the cleavage rate is 85.3% in the following formic acid cleavage conditions: the formic acid (a cleavage agent) concentration is 40% (volume percent), the cleavage temperature is 43 DEG C and the cleavage time is 2.5h. The fusion protein containing the formic acid cleavage site peptide CA3 carries out formic acid cleavage to generate aim protein, the formic acid cleavage time is short, the cleavage efficiency is high, the cleavage efficiency of the fusion protein is raised effectively, the purification cost of the aim protein is saved, a new idea is provided for industrial production of protein recombination, and technical support is provided for production of protein products.

Owner:THE INST OF BIOTECHNOLOGY OF THE CHINESE ACAD OF AGRI SCI

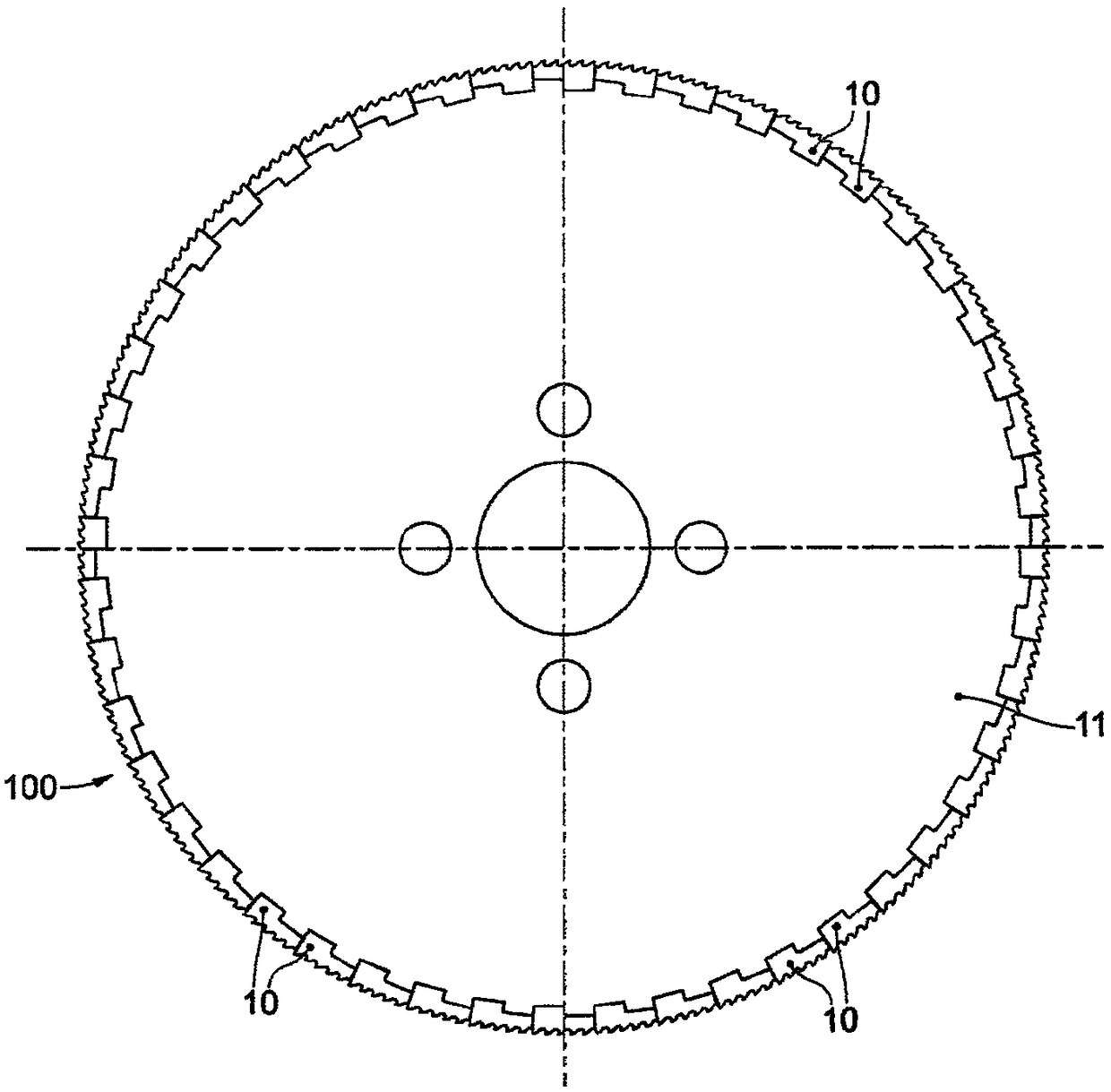

Circular tool for cutting material

InactiveCN108472753AImprove performanceImprove cut qualityMetal sawing tool makingMetal sawing toolsEngineeringMechanical engineering

Owner:JULIA UTENSILI

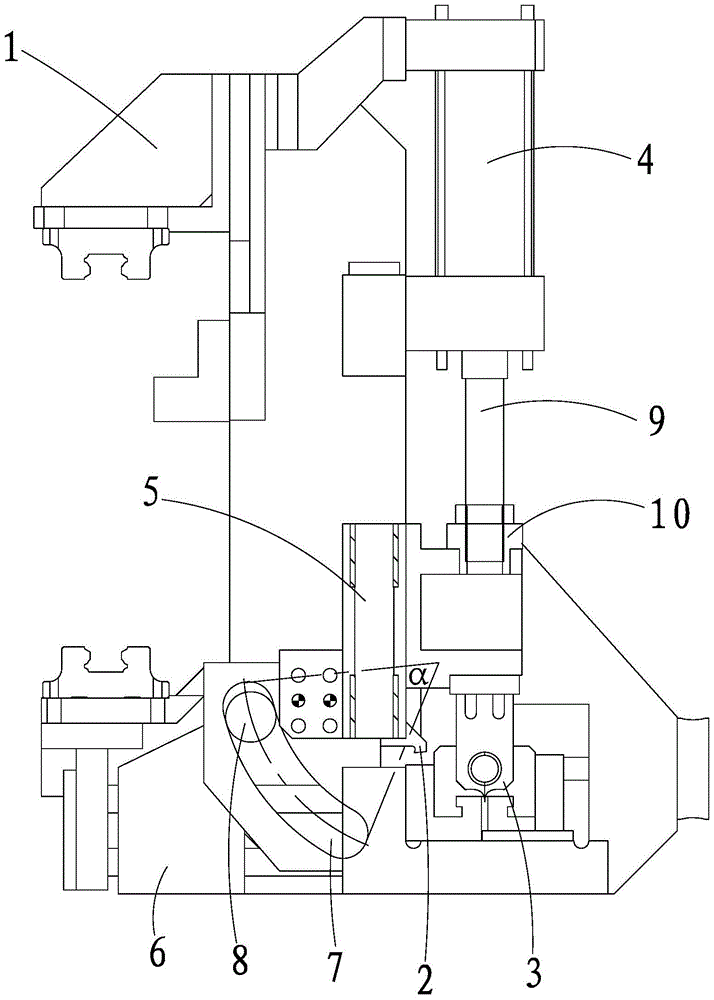

A pipe cutting device

Owner:SUZHOU AOZHI INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com